3D print hinged box

Free STL file Box with hinge・3D printer design to download・Cults

Mini Fig

Free

Screw nr3

Free

Screw nr2

Free

Two Rings

Free

Little Pot

Free

Letter M as keyholder

Free

Mason Jar Dispenser

Free

Bearded Man

Free

Best 3D printer files of the Fashion category

Fancy Bow Tie Version 2.0

Free

JUJUTSU KAISEN | Kento Nanami's Glasses

€1.42

clock

Free

Cellular Soccer Boot (Inspired by Second Skin)

Free

1989 Batman Gasmask - Vicki Vale

€4. 72

Vader Style Mask

Free

Neo Monkey - cosplay mask - digital stl file for 3D-printing

€20 -25% €15

SpecStand (Short) Eyeglasses/Sunglasses Stand

Free

Best sellers of the category Fashion

NIKE SHOES

€3.50

Skull Keychain

€1.23

CARD AND CASH HOLDER

€0.75

NEVERMORE LOGO

€0.91

FLORK WORLD CUP ARGENTINA KEY RINGS

€2.11

Print-in-Place Cuban Link Chain

€3. 50

50

Messi what are you looking at you fool

€2.03

Nike Dunk Low

€3.50

Croc Nuts

€0.95

MAGIC SNAKE, ARTICULATED, PRINT-IN-PLACE, POSABLE, ANIMATED, FIXABLE

€3.75

WOTP Mask from MUSE - Will of the People mask

€5 -25% €3.75

3D Sock Knitting Machine

€28.39 -25% €21.30

BATCAT HELMET

€3.62

12 in 1 Storage cube for Nintendo Switch game cartridges and MicroSD cards

€1. 99

99

Ghost CoD Mask

€13.82 -50% €6.91

NIKE Sneaker Pack 1

€12

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ hinged lid box 3d models 【 STLFinder 】

Hinged Lid Box

thingiverse

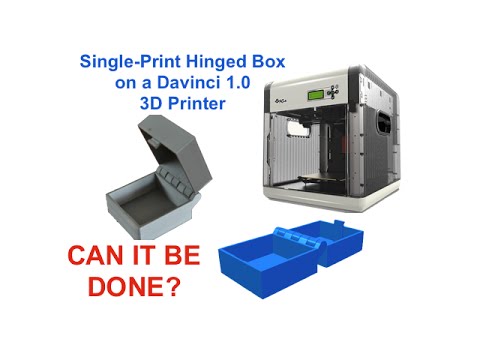

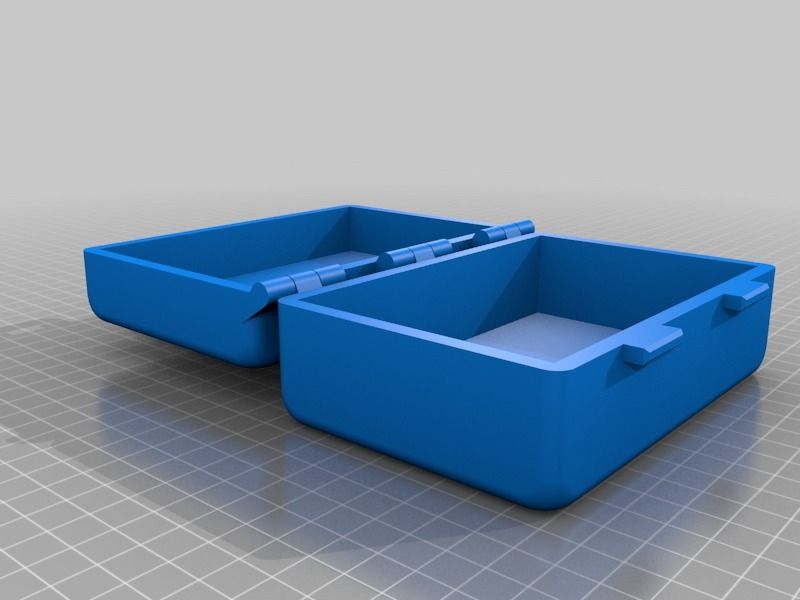

A print in place hinge lidded box.

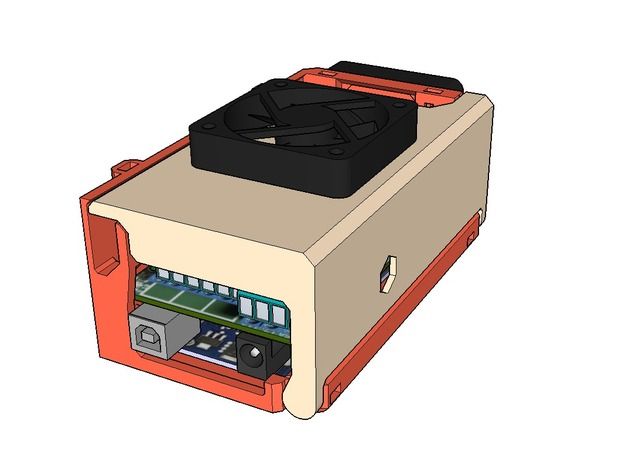

Misc... Remote Docker, Earphone/Cable Containers and Hinged Lid Box

thingiverse

Let's see, how about a box with a hinged lid. It's roughly 150x100x80 and the front latch needs to be rotated 180 so that a press in on the face releases it (whatever, it's printed, not worth the effort). I made the hinge holes 2mm, more than enough...

I made the hinge holes 2mm, more than enough...

Box with hinged lid

prusaprinters

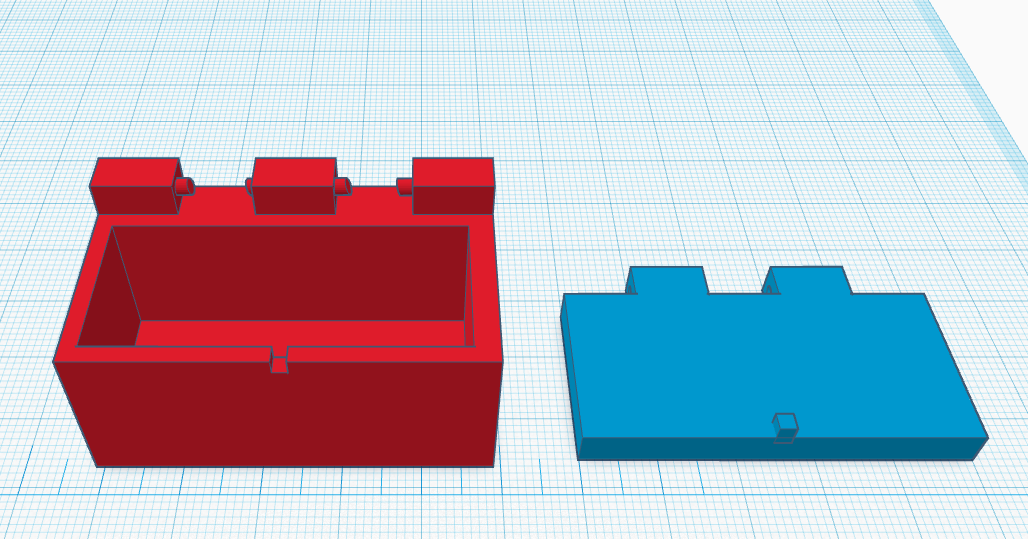

<p>Just practicing with Fusion 360 parametric design. ...- this box can be sized up or down as needed

Box with Hinged Lid

thingiverse

This is a box for transporting anything. I designed it for a portable Water Chlorine Test Kit for work. Bolts work for the hinge or 3D printed pins can be glued into place. The inside of the box can be redesigned to fit anything. I used Tinkercad...

Box with hinged lid

thingiverse

Here is a box that I made with my reprstrap. It has an inside size of 50 mm by 50 mm by 25 mm (approx). Instructions The hinge pin is made from 1/16 inch brass rod. ... The hinge pin holes were chased...

It has an inside size of 50 mm by 50 mm by 25 mm (approx). Instructions The hinge pin is made from 1/16 inch brass rod. ... The hinge pin holes were chased...

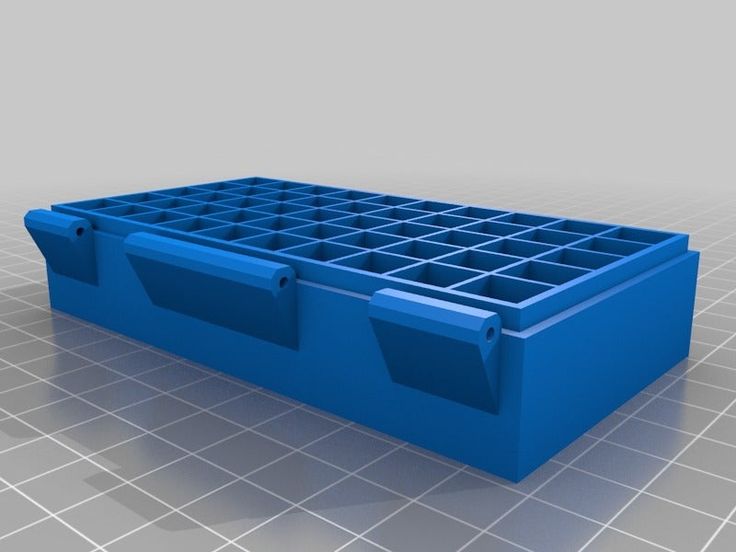

Storage Box with Hinged Lid

thingiverse

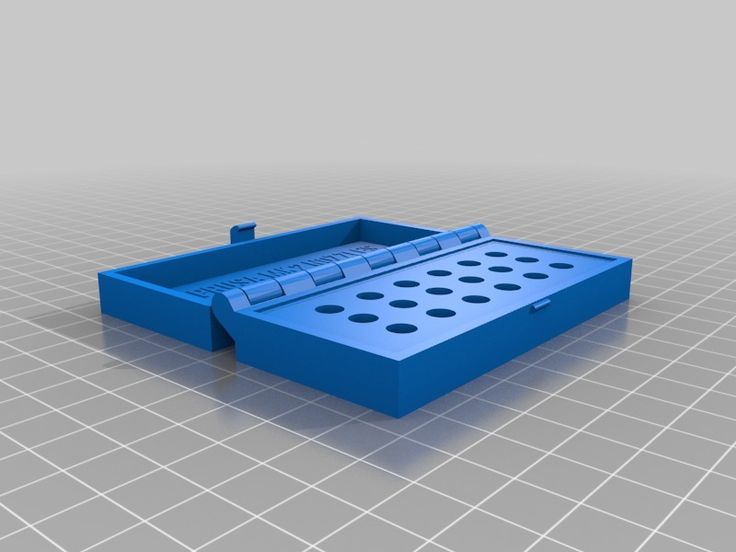

Here is a simple storage box with hinged lid for screws, nuts, washers or any small objects. The dimensions are 100 mm x 80 mm with a height of 47 mm with the lid. You can split the box in 2 compartments by using the separator. ... This box can me...

Storage Box with Hinged Lid

myminifactory

Here is a simple storage box with hinged lid for screws, nuts, washers or any small objects. The dimensions are 100 mm x 80 mm with a height of 47 mm with the lid. You can split the box in 2 compartments by using the separator. ... This box can me...

The dimensions are 100 mm x 80 mm with a height of 47 mm with the lid. You can split the box in 2 compartments by using the separator. ... This box can me...

Storage Box with Hinged Lid

cults3d

Here is a simple storage box with hinged lid for screws, nuts, washers or any small objects. The dimensions are 100 mm x 80 mm with a height of 47 mm with the lid. You can split the box in 2 compartments by using the separator. This box can me...

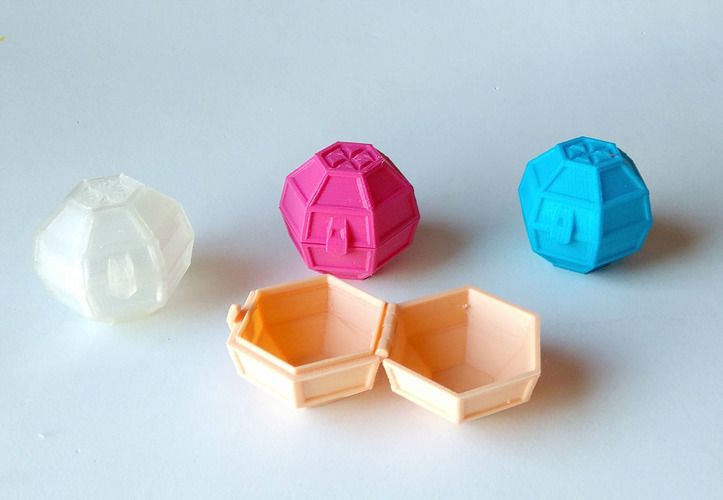

Heart Box with Hinged Lid

thingiverse

Here is a simple heart shaped box with a hinged lid. OpenSCAD code is included. Instructions The box and lid can be printed directly on the build platform. The hinge uses a short piece of 1.8 mm printing plastic. ... Ample clearences make assembly...

The hinge uses a short piece of 1.8 mm printing plastic. ... Ample clearences make assembly...

Small Box with Hinged Lid

thingiverse

... in a bag. Much easier to organize and identify. The lid snaps onto the box and stays where you put it. You can print it with fairly low infill, but don't go too hollow on the lid so it doesn't break when snapping it on or off the box.

Hinged box with magnetic lid

thingiverse

... as the hinge pin. simply thread the filament through the holes and affix using glue or heat to the two end bits of the lid the box has inner dimensions of 35mm x 35mm x 18. 6mm (length x breadth x height) and the walls are 1.8mm almost everywhere

6mm (length x breadth x height) and the walls are 1.8mm almost everywhere

box with hinged lid 100x70x25

thingiverse

storage box with hinged lid. requires a metal rod for pin. open holes with a drill bit if required. supports will be needed for hinge on lid. I used some 1.5mm mains cable, The earth wire works well bend over end as in last pic, push in use...

box with hinged lid - printable

thingiverse

A box with 3 compartments for coins or small stuff Inside is rounded to make things easy to catch Hinge hole is 1.75mm Angles are set to make the box and the cover printable without support v4 update: recenter hinges, increase hole size, add material. ..

..

Heart Shaped Box with hinged lid

thingiverse

A heart-shaped box for kids. ...Hinged lid.

3x3 Rubik's Cube Box (Hinged Lid)

thingiverse

3x3 Rubik's cube box with a print in place hinged lid design.

3x3 Rubik's Cube Box (Hinged Lid)

prusaprinters

3x3 Rubik's cube box with a print in place hinged lid design. Category: Puzzles

Multi-partition storage box with hinged lid.

thingiverse

Multi-partition storage box with hinged lid. Instructions Designed in Sketchup, printed in PLA, 2 borders with 25% infill. ...Added hingeshaft2 as it is stronger than the original one.

18640 & 21700 Box, 4 Cells, Hinged Lid

thingiverse

... for 4 cells. ...The hinged lid will snap in closed position. The hinge needs two M3 x 20 screws with lock-nuts. 05.07.2019, 21:00: Sorry to all! I had a design flaw in the 21700 box. ...It's updated now, but make sure you use the actual model!

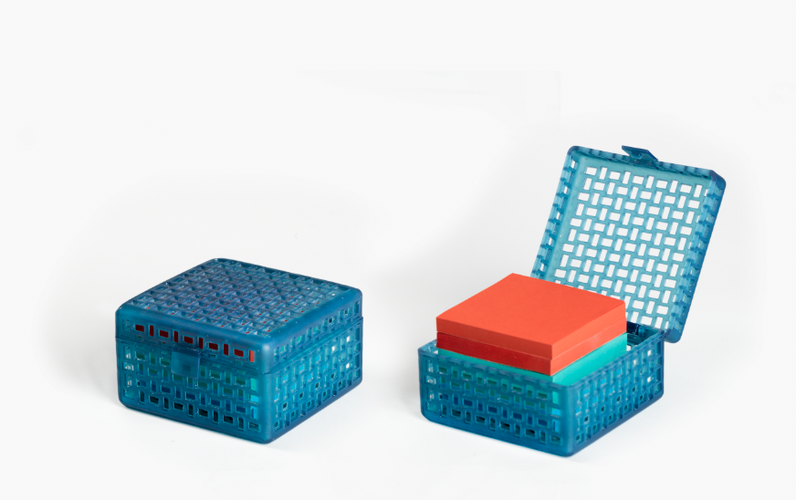

Square Textured Box with Hinged Lid

thingiverse

Came across the box with a lid and the box with texture and decided to merge the two. Scaled the textured box down to have a 40x40x40mm interior volume. Then merged the top and bottom and use the box with lid to build a new lid and for the hinges. ...

Scaled the textured box down to have a 40x40x40mm interior volume. Then merged the top and bottom and use the box with lid to build a new lid and for the hinges. ...

box with 4-link hinged lid

myminifactory

...You'll notice at the end of each arm is an extra rounded piece sticking out. At the box mounting end these must point down and at the lid they'll obviously point upwards. ... The pics will hopefully give enough indication of how it all fits together.

Singularity Box - Support-free hinged lid!

myminifactory

How can it be?! A box with a hinged lid, support-free and printing assembled! Prepare to be slightly amazed! This box prints on an edge, rather than a face, and all the angles are designed to be safely printable. Just make sure the whole thing...

Just make sure the whole thing...

box with 4-link hinged lid

thingiverse

... You'll notice at the end of each arm is an extra rounded piece sticking out. At the box mounting end these must point down and at the lid they'll obviously point upwards. ...The pics will hopefully give enough indication of how it all fits together.

Parametric box with hinged lid - rzigzagto

thingiverse

Parametric box with lid written in Postscript Set your size, materialthickness, offground height, lid lip, zigzagwidth and tabwidth. The postscript is written so for minimal cut length and assembly without glue. The program is not yet perfect...

The program is not yet perfect...

Box with Hinged Lid (Ver. 02)

thingiverse

This is an updated version of the hinged box (http://www.thingiverse.com/thing:2312532) This version has a different design of catch

Box with Hinged Lid

thingiverse

Printed on FDM 3D printer with abs plastic for best results

Commander Deck Box with hinged lid and magnets

thingiverse

Commander Deck Box with hinged lid and magnets to hold the lid closed. ...

...

Rosin Box with Print in place hinged lid

thingiverse

... attach to the box using M4 screws. They fit over the numbs on the back of the box and should secure tightly to a raised spring dance floor edge. This box can be used elsewhere and for a variety of purposes... ...just designed with a dancer in mind

small box with hinged lid made from thing 506288

thingiverse

Have them combined, provided with my modular box system:http://www.thingiverse.com/thing:506288 It uses my latest creation a hinged windowed topframe with lid. The hinges splints are made from toothpicks 2mm diameter. . Have fun. I will make another...

. Have fun. I will make another...

Polarity Box - hinged lid prints in place, zero support!

myminifactory

Hot on the heels of the Singularity Box, here's another print-in-place hinged-lid box that requires no support! This time, it doesn't print on an angle, either. That does make it less fun, but it also makes it a vastly more reliable print :P You...

Box for AA and AAA Batteries, Hinged Lid, OpenSCAD source

thingiverse

Hinged lid, staggered height rows, recessed label on top.

All new code, customizable. OpenSCAD source is included, and STL files for various sizes: AA: 96, 54, 24 batteries AAA: 104, 54, 24 batteries As with other hinged boxes, use a piece of...

OpenSCAD source is included, and STL files for various sizes: AA: 96, 54, 24 batteries AAA: 104, 54, 24 batteries As with other hinged boxes, use a piece of...

MakerBot Tough PLA

More and more companies are investing their money in desktop 3D printers as a prototyping tool and, in most cases, they are replacing more expensive industrial 3D printers. Using desktop 3D printers in the early stages of concept modeling allows engineers and designers to speed up the design process and produce more prototypes at a lower cost.

At MakerBot, one of the main goals is to simplify this process and offer solutions that expand the capabilities of the 3D printer. We've taken a big step in this direction with our newly created MakerBot Tough PLA plastic. It will allow designers and engineers to go beyond the concept of modeling and create more robust prototypes. It is a resilient and strong plastic that mimics or even surpasses many of the mechanical properties of ABS, offering the reliability and quality of PLA. nine0003

nine0003

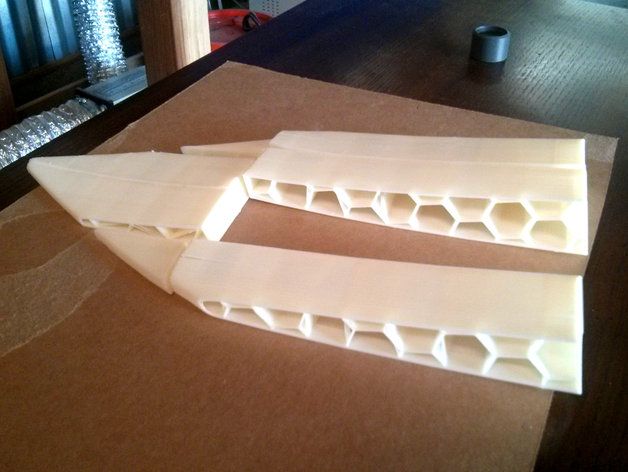

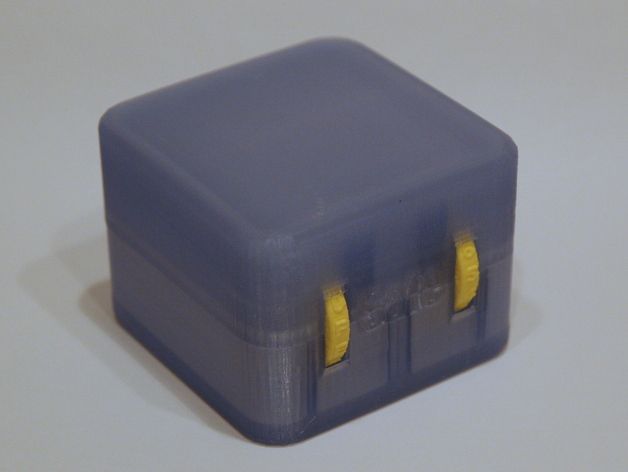

As the graph above shows, when subjected to tensile stress, MakerBot Tough PLA deforms and eventually returns to its original shape. In addition, Tough PLA exhibits a long strain-to-rupture range that is superior to ABS. In contrast, conventional PLA will simply break. These mechanical properties make MakerBot Tough PLA ideal for creating multi-functional prototypes such as hinges, latches, locks or threads. nine0003

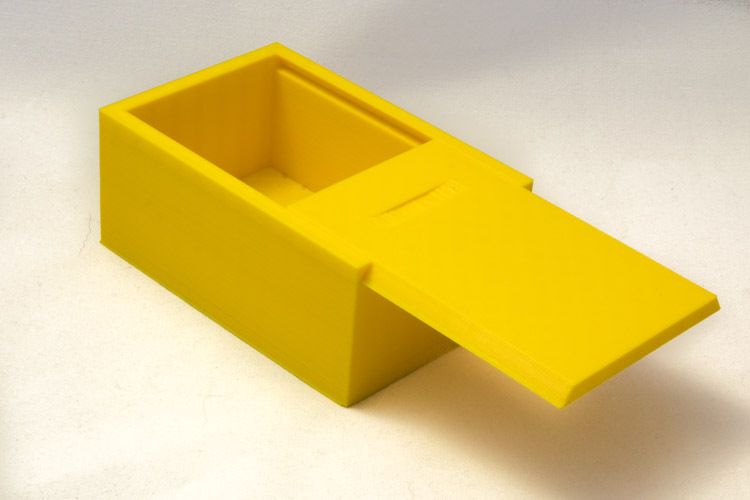

Hinges

The loop is a thin and flexible piece that is made from the same material as the two parts it connects. Since this hinge has a compact design and is easy to manufacture, it is an excellent alternative to mechanical hinges. Loops are popular in products such as disposable containers and food packaging. But creating loops in the prototyping process, however, is not so easy. Traditional methods require the use of a second material, such as industrial tape or polypropylene sheets, which are not only time consuming but also do not accurately represent the final product. nine0003

nine0003

Since Tough PLA is designed to deform before peak load, it is ideal for elastic mechanical properties such as those needed for hinges. The material has a significant plastic elongation, which allows it to bend into the working position. In addition, it is strong enough to withstand repeated use, while PLA plastic is brittle, which can lead to rapid wear.

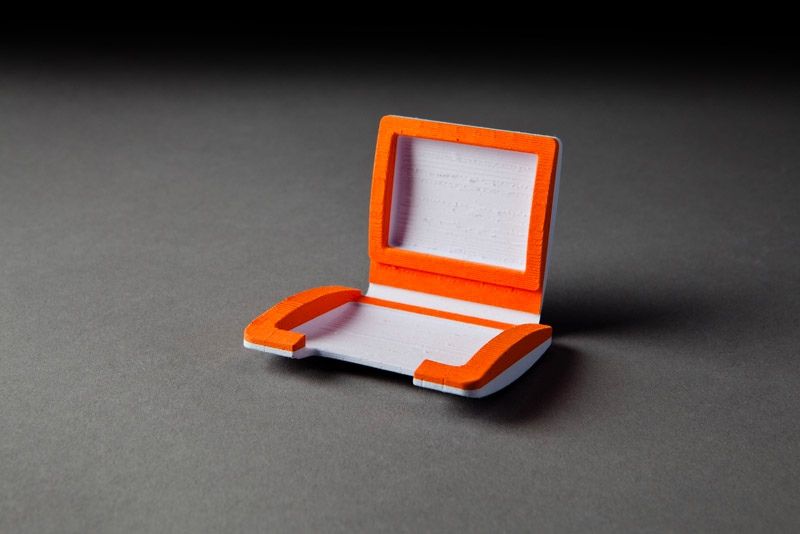

This Tough PLA box has a hinge that can be opened and closed hundreds of times over the lifetime of the prototype without breaking. The box can be printed in one piece, and thanks to technologies such as injection molding, the quality can be greatly improved. nine0003

Latches

Likewise, the same qualities that make Tough PLA ideal for mechanical functions such as hinges make it ideal for latches.

The Tough PLA box includes a latch that works in conjunction with a hinge to seal the lid tightly so that it can open and close for the life of the prototype. The ability to print dynamic, functional prototypes in the office allows engineers to test an extended range of design features at a low cost. nine0003

The ability to print dynamic, functional prototypes in the office allows engineers to test an extended range of design features at a low cost. nine0003

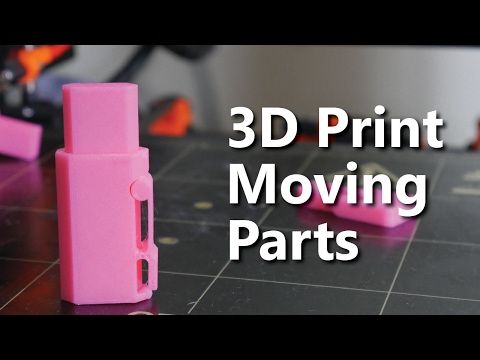

Clip-on parts

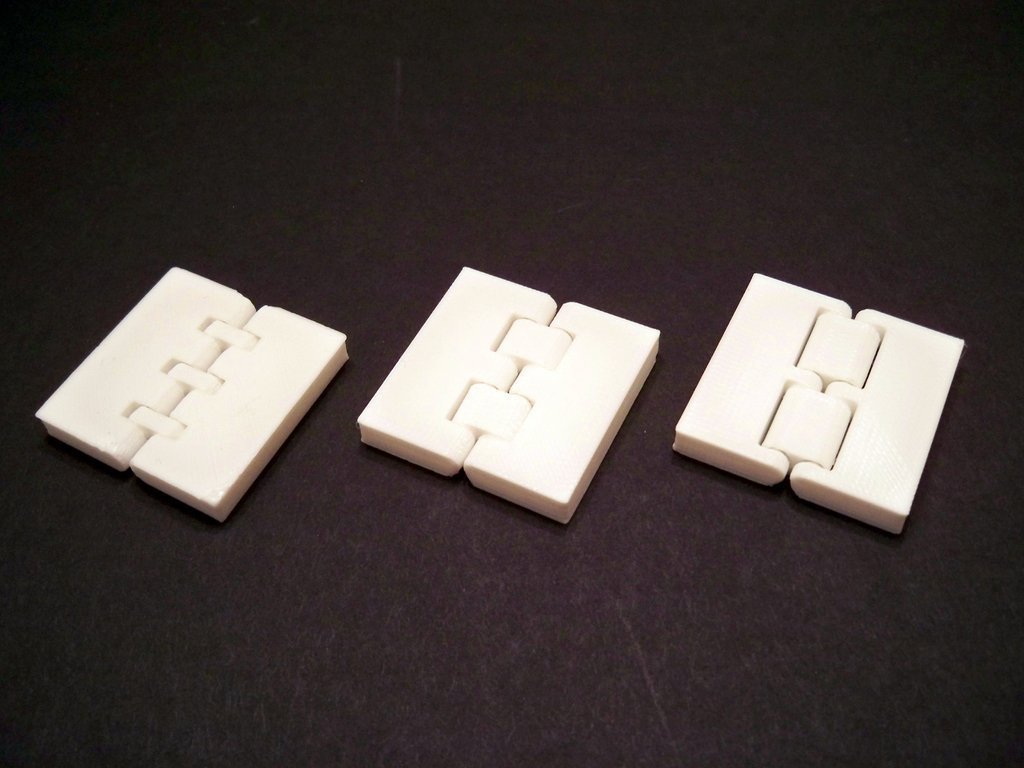

The snap-in feature is popular with products that need to be assembled and disassembled regularly. And in order for this functionality to work, the printed material must withstand friction and tension. Conventional PLA is prone to breakage under force and is therefore not suitable for printing lock parts. But MakerBot Tough PLA is great for printing interlocks like hinges and ball joints. The material is resilient enough to slide in and out of place, and also smooth enough to withstand long-term use. nine0003

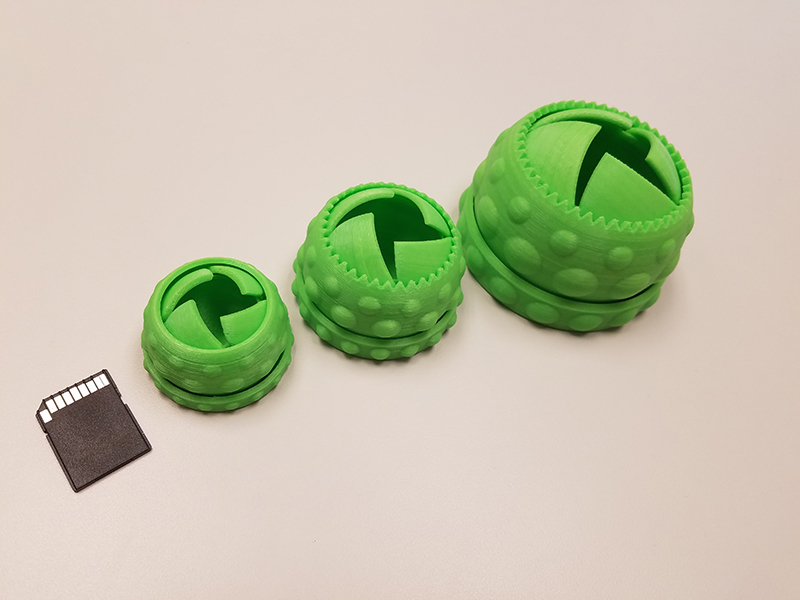

The picture above shows two hinges. The right one is printed with regular PLA plastic, and the left one is printed with Tough PLA plastic. Regular PLA breaks, while Tough PLA is flexible enough to hold its shape. This smoothness also helps resist wear from friction within the hinge.

Precise and durable threading features

In addition to latches, the properties of Makerbot Tough PLA allow you to create precise and durable carvings on printed items. Tough PLA can be carefully drilled to create an accurate hole size, as well as threaded using standard tools for this. This way you can create strong fasteners that can be assembled with each other or included in other functional prototypes or assemblies. nine0003

For example, as you can see in the picture above, holes are drilled into the part that can accommodate fasteners of various sizes. While normal PLA will crack under stress from drilling and threading, Tough PLA will hold its shape.

Whether you're going to be printing a hinge, a latch, an interlocking part, or a part that will need to be threaded, the new MakerBot Tough PLA takes you beyond the concept of modeling to create strong, impact-resistant fasteners. By adding new materials such as Tough PLA, MakerBot aims to give professional designers and engineers more ways to create functional prototypes and expand their ability to get the most out of their MakerBot printers. nine0017

nine0017

Share on social networks:

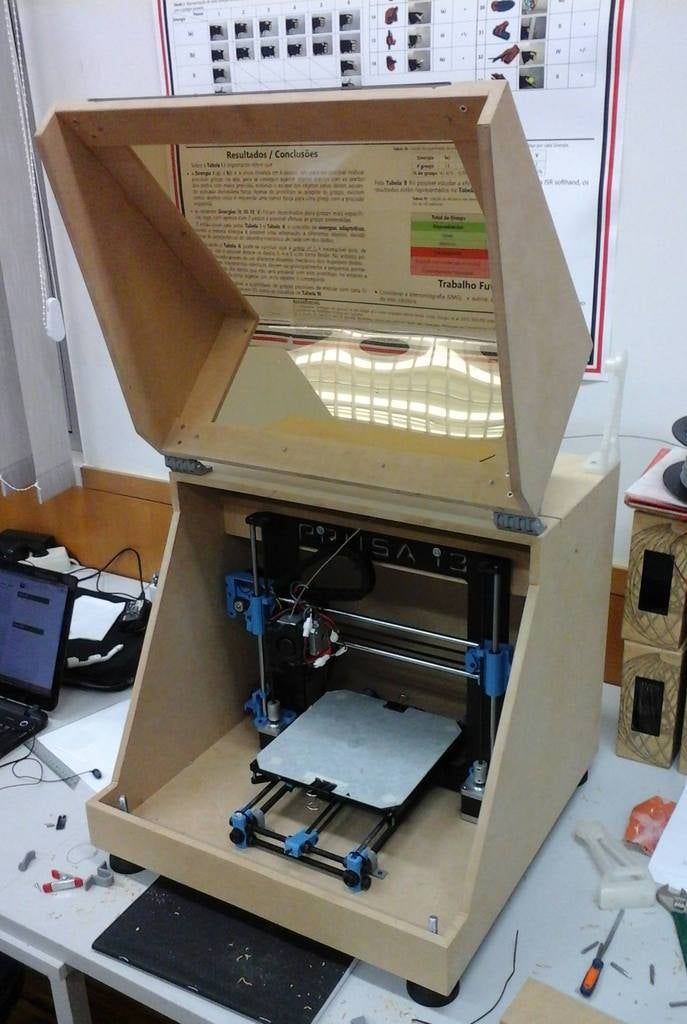

As a beginner I bought a 3D printer. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer. nine0017

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here on Habré), the important points were:

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer". It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work.

In short, I needed a printer that didn't need to be assembled and that could work right out of the box. nine0077

In short, I needed a printer that didn't need to be assembled and that could work right out of the box. nine0077 - It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy. So I was willing to spend a couple of hundred, no more.

- It should not be too big. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option. nine0077

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

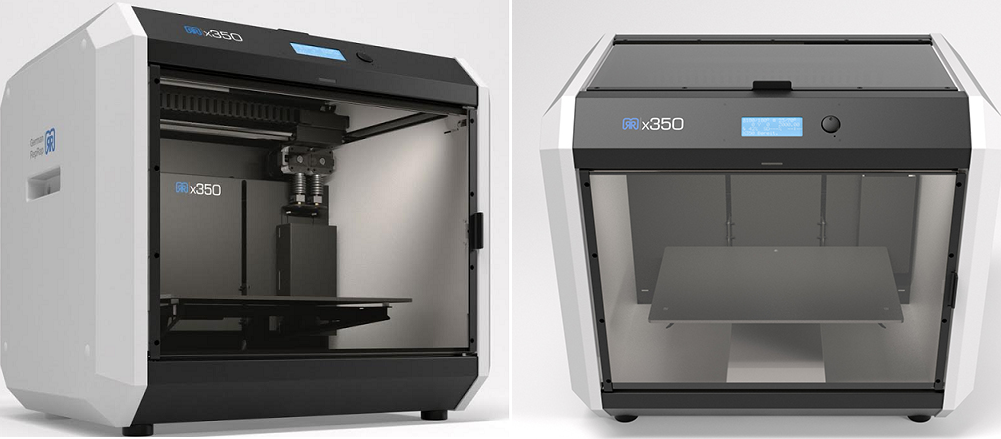

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store. nine0003

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Supported material: manufacturer claims PLA, but may work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .

STL, G-code

STL, G-code - Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touch screen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner. nine0003

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head. nine0003

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case. nine0003

The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case. nine0003

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the printhead was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects; nine0077

- Impossibility of direct printing of models downloaded from the Internet.

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré; - Slicers are not compatible with the printer model. Slicer needs to set printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker; nine0077

- No WiFi. As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed;

- Long print time.

I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews. nine0077

I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews. nine0077

Practical use

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive). nine0003

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands. nine0003

Soldering iron stand. You just need a comfortable stand, from which the soldering iron will not fall, like from a Chinese stand that I once bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out? nine0003

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

Extractor for printed parts stuck to the table. Nearly all parts stick to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great. nine0003

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know that this can be achieved by buying a professional 3D printer). nine0003

In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know that this can be achieved by buying a professional 3D printer). nine0003

Sometimes parts are printed, but for some reason the actual and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready. nine0003

nine0003

It takes a long time to print a part. Some printouts take hours to complete, so making a simple car phone stand can take half a day.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD. nine0003

My printer desktop is small . Not all objects that I would like to print can be implemented. In particular, I wanted to get a different microscope stand model. But it did not work out, because it is larger than the printer table. The same problem with the handle of a robot vacuum cleaner (not the one in the photo, another one).

Fin

Am I satisfied, as a beginner, with the printer? Yes very. It met my expectations almost completely.