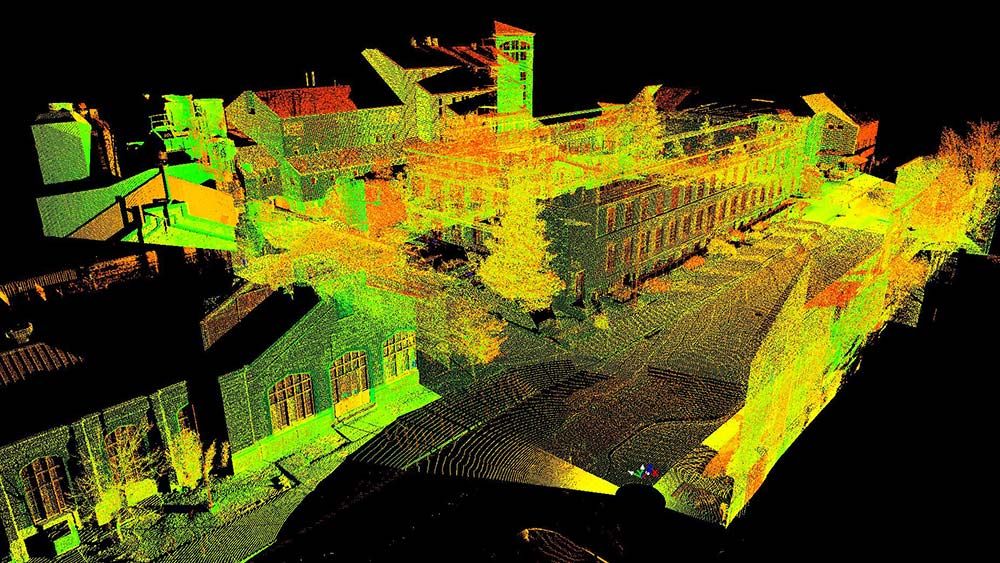

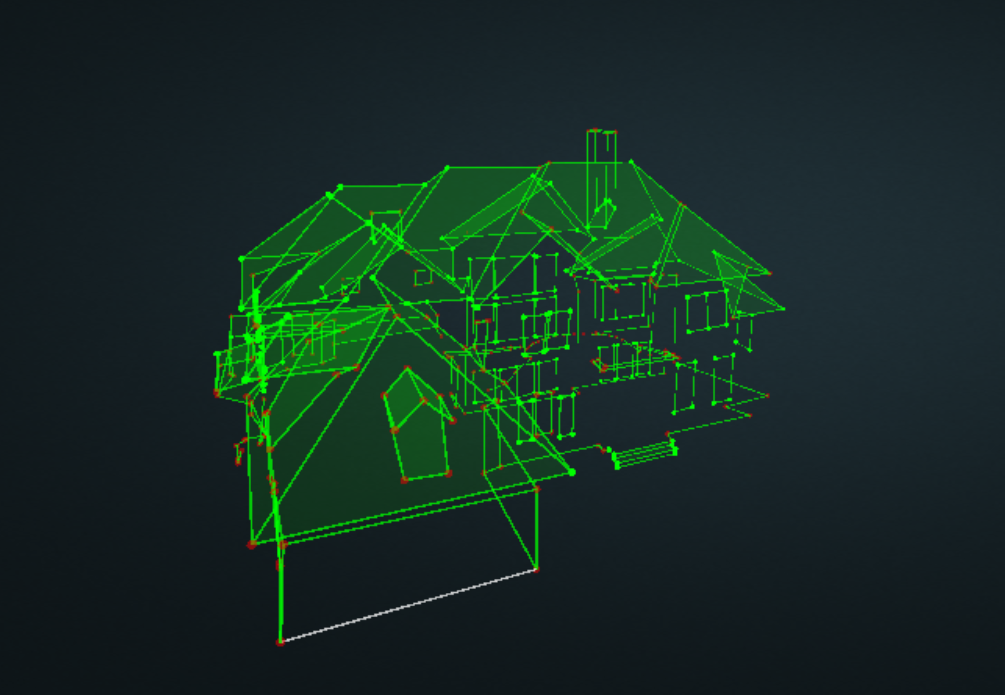

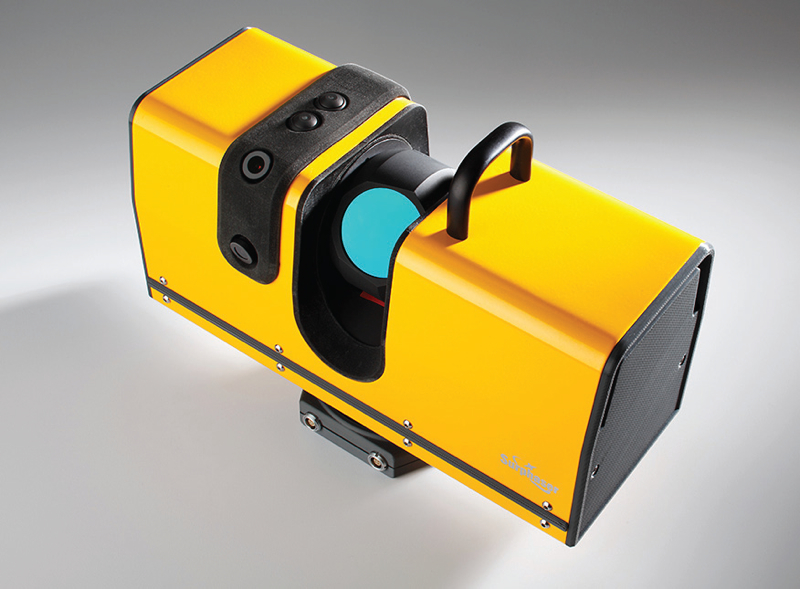

Lidar scanner 3d model

LiDAR & 3D Scanner for iPhone & Android

Polycam - LiDAR & 3D Scanner for iPhone & Android3D Capture, for Everyone

LiDAR scanning and photogrammetry made easy.

Welcome

Polycam is the world’s most popular 3D scanning app for iOS, web and Android. We believe that 3D capture is for everyone, so we made it easy. Now you can scan the world around you with your mobile device, DSLR camera, or drone to get beautiful, accurate 3D models.

Captures are helpful in every single professional 3D workflow. You can use them in floor plans, architectural renderings, VFX and filmmaking, 3D art, scene building and more. Join the growing worldwide community today and try Polycam for free.

Download on theApp Store

Get it onGoogle Play

Try for freeon the web

t-rex skull@e

Provo, UTAug 4, 11AM

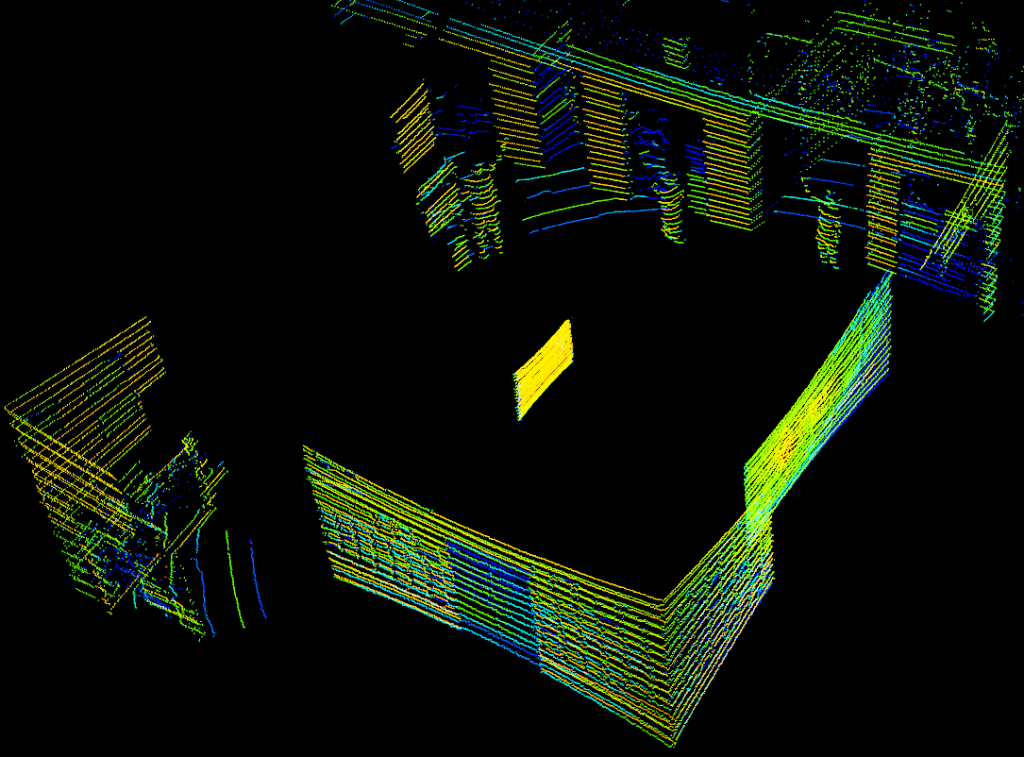

LiDAR Scanning

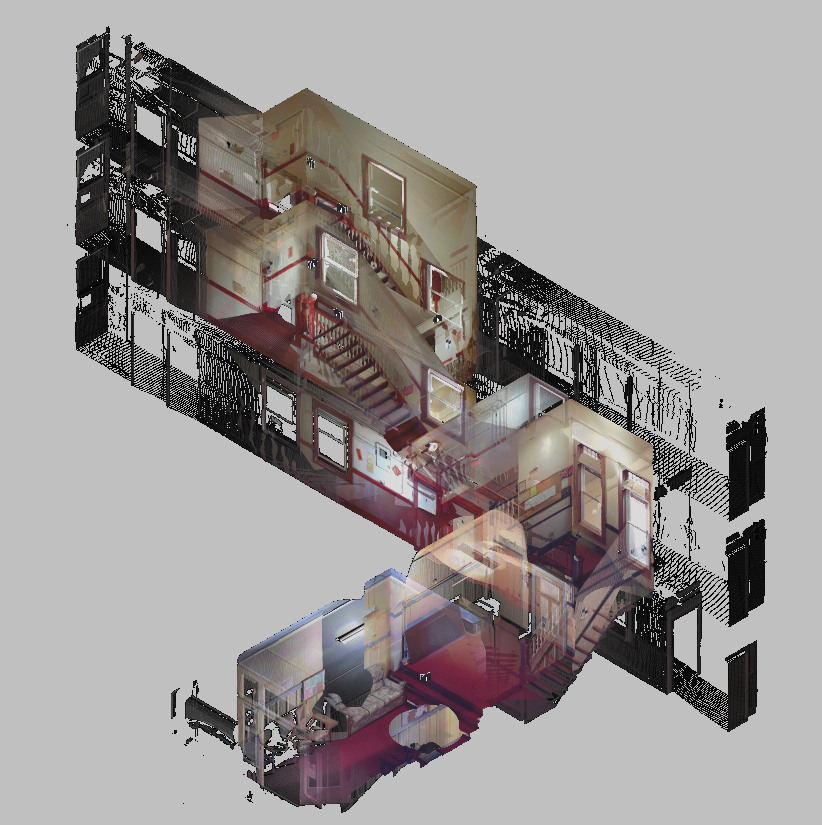

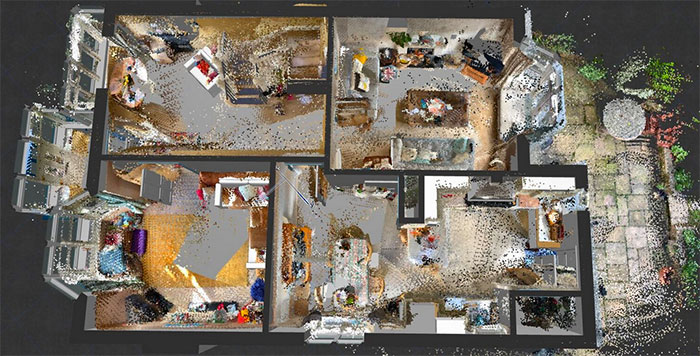

With the LiDAR sensor on Pro iOS devices you can scan the world around you in stunning 3D.

LiDAR Scanning

LiDAR scanning is the most fun and helpful feature of newer, pro-model iOS devices. Never before has 3D scanning been possible on a mobile device.

Polycam’s free LiDAR scanning pipeline lets you capture an entire home in 3D in minutes. It’s the best LiDAR scanning app for contractors, interior designers, and architects.

Download on theApp Store

SM Tides Residence@ZARHA_DESIGN

LiScanned

w/ LiDAR

Photogrammetry

Use Photo Mode on your device or on the web to get instant, accurate 3D models of absolutely anything.

Photogrammetry

Photo Mode turns every iPhone and Android device into the start of a powerful photogrammetry pipeline. You can use it to capture your world in incredible detail.

Choose Photo Mode if you want to get high quality 3D models in minutes, and publish them to our Explore feed to share with our community across the globe. Use models for scene building, game development, VFX and more.

From the Polycam web app, you can upload images captured on any device, including your professional camera or drone.

Download on theApp Store

Get it onGoogle Play

Try for freeon the web

Yoda One For Me@MakeItMoveMedia

PhScanned

w/ photo

Free 3D Models

Discover free 3D models in the explore feed. Join the largest community of 3D capture enthusiasts and share your 3D content directly on Polycam.

Free 3D Models

You’ve never seen a 3D model collection like this before. Browse millions of 3D models and download them for free in Polycam Explore.

All captures are stylistically consistent, and can instantly be used in 3D art and VFX projects. If you can’t scan an object yourself, it probably exists in Polyworld. Create albums and collect 3D models for fun or curate models for specific projects. Whatever your use case, the Polycam Explore feed is full of the largest variety of high quality captures generated by our very own users.

get free 3D models

Explore in Augmented Reality

View your 3D models in AR. Create and save videos to wow and share.

Augmented Reality

We believe some very cool things are around the corner in AR/VR. With Polycam, you can create AR videos by blending captures into the environment around you.

It’s the easiest way to wow friends, clients, and potential buyers. AR is great as a tool for e-commerce. You can scan your products and visualize them in 3D, with real-world dimensions.

discover AR

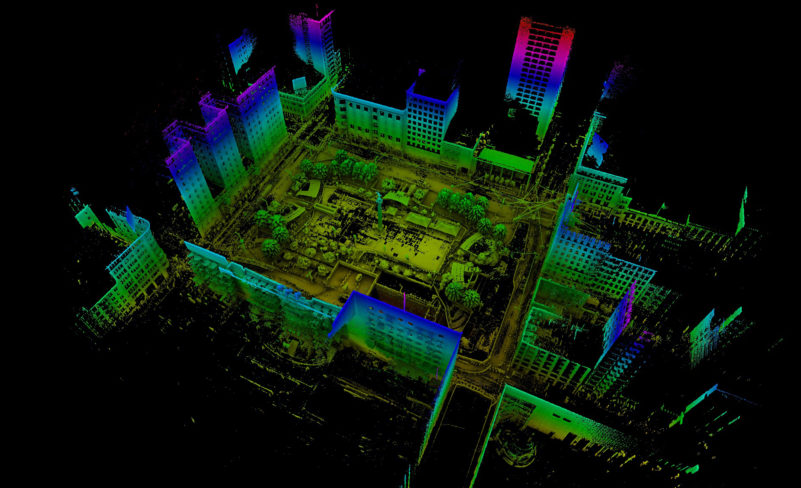

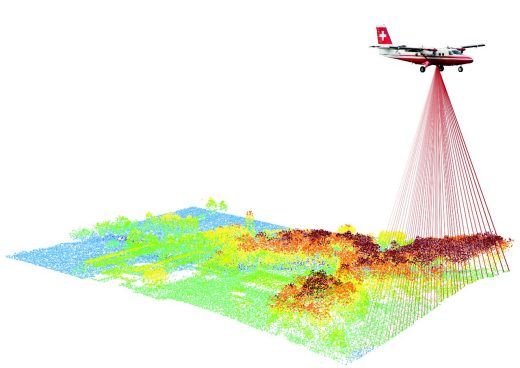

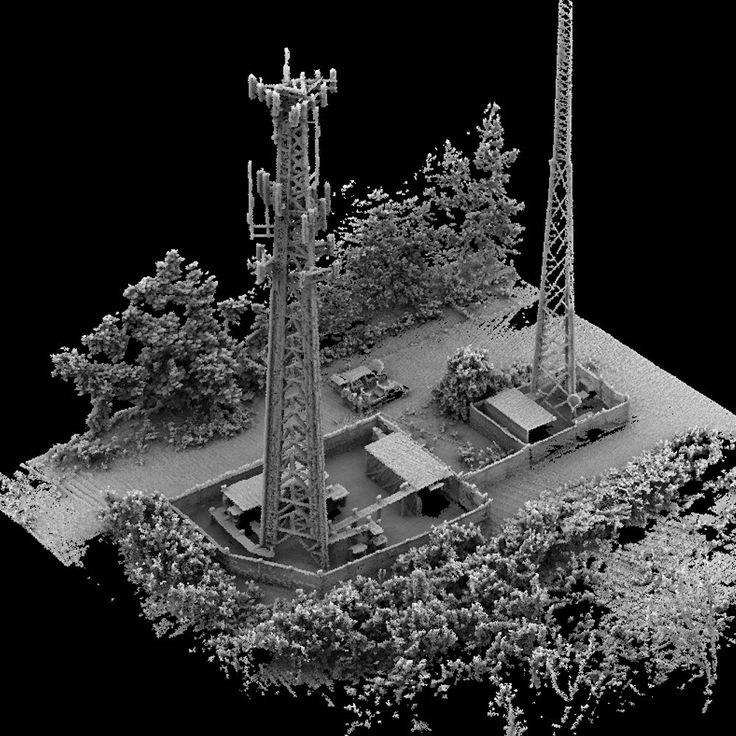

Drone Mapping

Upload drone imagery to Polycam Web to generate 3D scans of entire buildings, structures or city blocks.

Drone Mapping

Polycam makes it easy to turn drone footage into expansive 3D models. Upload your keyframed drone images on Polycam Web and get a capture back in minutes.

Other drone-mapping services can cost $100/month. Polycam is over ten times cheaper, and much easier to use. It’s perfect for drone pilots who want to create 3D captures from in-flight footage, but don’t want to break the bank or spend hours learning new software.

Polycam is over ten times cheaper, and much easier to use. It’s perfect for drone pilots who want to create 3D captures from in-flight footage, but don’t want to break the bank or spend hours learning new software.

create 3D models with drones

Join the Community

Follow us everywhere and become a part of the growing Polycam world, and reach out for collaboration opportunities!

Community

Love Polycam? Want to learn more or collaborate? We love talking with our users and have a very active presence on Discord, Twitter, Instagram and TikTok. Feel free to reach out with any questions, feedback or ideas. We look forward to hearing from you.

Scaniverse Blog

Scaniverse BlogSummer Gu

·Sep 14

Scaniverse 2.0 adds support for non-LiDAR devices

No LiDAR? No problem. Scaniverse now supports all iPhones released since 2018 as well as most iPads. — Over time, we’ve heard from many people who have wanted to try Scaniverse, but were unable to without a LiDAR device. Since we believe that anyone can be a 3D content creator, we’ve been working hard to resolve this issue. We’re excited to announce that Scaniverse 2.0, …

— Over time, we’ve heard from many people who have wanted to try Scaniverse, but were unable to without a LiDAR device. Since we believe that anyone can be a 3D content creator, we’ve been working hard to resolve this issue. We’re excited to announce that Scaniverse 2.0, …

3 D Scanning

2 min read

Keith Ito

·May 27

Detail Mode Improvements and the Scanning Framework

This week at the Niantic Lightship Summit, we released improvements to the quality and speed of our reconstruction algorithms and showed a preview of our upcoming Scanning Framework. Read on to learn more. Detail Mode just got better We’re constantly improving our algorithms in an ongoing quest for realism. Scaniverse 1.9, which is now available…

2 min read

Scaniverse

·May 13

Reprocess scans with raw data

The new “Save raw data” option in Scaniverse lets you reprocess your scans with different settings in the future — We’re pleased to announce that the latest update to Scaniverse adds the ability to save raw data along with your processed scans. This makes it possible to reprocess your scans with different settings at any time. Saving raw data will also allow you to take advantage of future improvements to…

This makes it possible to reprocess your scans with different settings at any time. Saving raw data will also allow you to take advantage of future improvements to…

2 min read

Scaniverse

·Mar 25

Post to Scaniverse: a new way to share

Easily share your creations with our newest sharing option — Whether you’ve captured a building, a sculpture, or what you ate for lunch, it’s natural to want to share it with others. That’s why Scaniverse includes a variety of ways to share, such as sending your scan in a message or publishing it to Sketchfab. Over time, we’ve received many…

3 min read

Keith Ito

·Jan 25

Scaniverse Detail Mode

We’re excited to announce that Scaniverse 1.7 with Detail Mode is available on the App Store today. Detail Mode is a new processing mode for Scaniverse, in addition to the existing LiDAR options. It uses photogrammetry to produce high-quality scans of people, objects, and smaller scenes with lots of texture…

Scaniverse

2 min read

Keith Ito

·Nov 3, 2021

Share your scans with video

Scaniverse can now create dynamic videos from your 3D scans — We’ve consistently been impressed by videos people have created of their scans. The level of creativity and polish that go into these is truly amazing. For example, here are a few that Emmanuel de Maistre recently posted to Twitter: Hardly a day goes by without someone asking us how…

The level of creativity and polish that go into these is truly amazing. For example, here are a few that Emmanuel de Maistre recently posted to Twitter: Hardly a day goes by without someone asking us how…

2 min read

Keith Ito

·Aug 10, 2021

Scaniverse is joining Niantic

Scaniverse will remain a standalone app, with many exciting features planned for the future. Also, Scaniverse Pro is now free. — I’m excited to share that Scaniverse is joining Niantic! You can read the official announcement over at the Niantic blog. From the beginning, Scaniverse has aimed to be an app that anyone can use to capture and share the things they care about in 3D. After seeing some of the…

Niantic

2 min read

Keith Ito

·Jun 23, 2021

Mesh Simplification in Scaniverse

Scaniverse now supports simplification, allowing you to build more efficient models while maintaining a high level of fidelity — We’re excited to announce that Scaniverse now supports mesh simplification. With this update, scans process faster, take up less space, and render more efficiently — while remaining true to their original appearance. In addition, textures on simplified meshes generally have fewer seams and visual artifacts.

With this update, scans process faster, take up less space, and render more efficiently — while remaining true to their original appearance. In addition, textures on simplified meshes generally have fewer seams and visual artifacts.

Simplification

3 min read

Keith Ito

·Apr 11, 2021

Scaniverse now supports location

Save, share, and export location with Scaniverse, a lidar scanning app for the iPhone and iPad — 3D scanning apps such as Scaniverse allow you to capture and share your world in exciting new ways. The ability to manipulate an object or navigate through a scene adds a level of physical presence that doesn’t exist in other media. The physical nature of a 3D scan is closely…

3 min read

Keith Ito

·Mar 13, 2021

Attention to detail

The latest version of Scaniverse can resolve small objects and fine details better than ever before. Here’s how. — It’s a true feat of engineering that Apple managed to pack a LiDAR sensor into the latest generation of iPhones and iPads. As with any new technology, however, there are certain areas where the hardware still has room for improvement. One such area is resolution. Teardowns have shown that Apple’s…

As with any new technology, however, there are certain areas where the hardware still has room for improvement. One such area is resolution. Teardowns have shown that Apple’s…

4 min read

Scaniverse lets you capture, edit, and share 3D content directly from your phone.

Follow

Connect with Scaniverse Blog

Editors

Scaniverse

Scaniverse lets you capture, edit, and share 3D content directly from your phone. https://scaniverse.com

Follow

Status

Writers

Careers

Privacy

Knowable

iPhone LiDAR 3D Scan | arvr.media

As you probably know, the latest generation of iPhone (12 Pro and 12 Pro Max) is equipped with a lidar camera. 3D photography for me is a natural evolution of photography and I have been waiting for this day for almost 10 years.

Several 3D shooting applications have recently been released that take full advantage of this new capability. I have tested almost all of them available, and for the last 3 months I have been actively involved in 3D scanning. I am often asked what apps I recommend and how to get beautiful shots. Here is information about the apps that I love about each, as well as some general tips for using LiDAR on iPhone.

I have tested almost all of them available, and for the last 3 months I have been actively involved in 3D scanning. I am often asked what apps I recommend and how to get beautiful shots. Here is information about the apps that I love about each, as well as some general tips for using LiDAR on iPhone.

So here are my 6 scanning apps, all of which support exporting directly to Sketchfab:

Scaniverse

Scaniverse generally works well, is fast and easy to use, creates great textures, and does a good job of eliminating voids. Make sure you are working with your shots in ultra mode. This tool is very good for scanning things like cars. This frozen Mini is one of my best lidar shots. All my scanner shots are here, and the application is here.

Polycam

Polycam is fast and handles textures well. You can process the image in HD mode and get instant scan results. Very good for scanning things like rooms or murals and street art. You can see my Polycam shots here, and the app itself is here.

3D scanner app

The 3D scanner app offers a host of options that give you total control. For example, you can easily separate or trim excess space in an application. You can cut even with the help of a sphere. I think the app is especially good for small things like this dollar bill. Make sure you are using HD mode. Here you can see all my 3D scanner app images, and the application can be downloaded here.

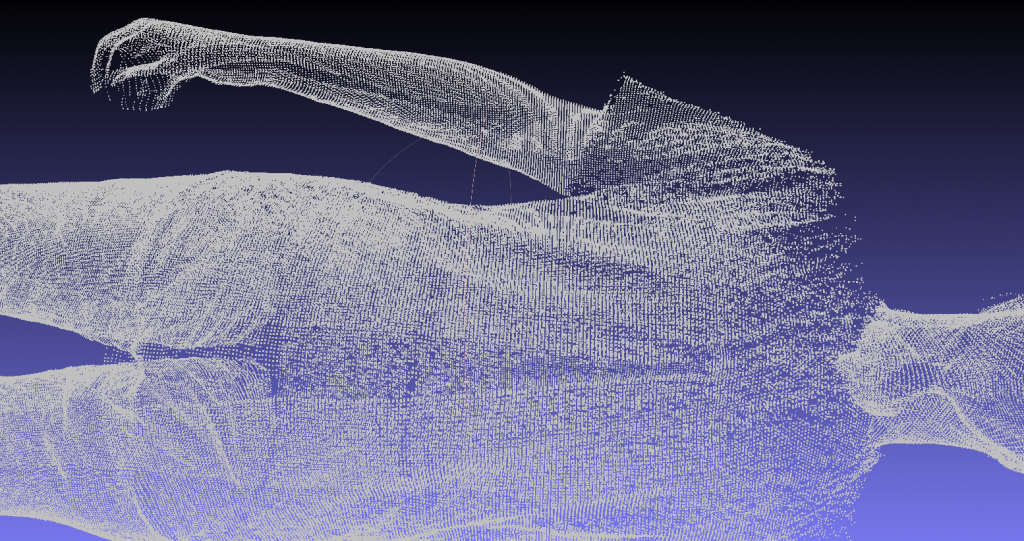

Record3D

Record3D allows you to shoot 3D video, also known as 4D content, i.e. 3D scanning per frame of video. Here are my daughter's first steps. Keep in mind that this format ends up with very heavy files, so you only need to shoot for a few seconds to be able to upload the video to Sketchfab. Here you can find all my recordings in Record3D format, and the application is here.

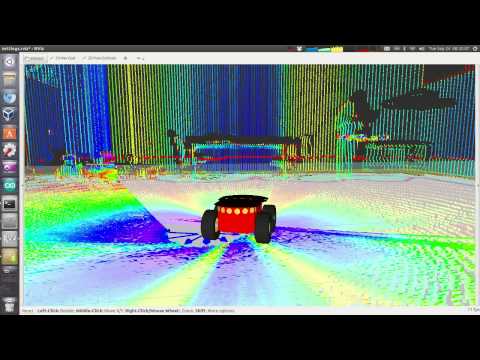

SiteScape

SiteScape is great for quickly creating accurate point clouds. You can adjust the density and size of dots. I like to use it for complex and intricate scenes or structures. Also can be great for cars. This is where all my SiteScape snapshots are located. The application can be found here.

Also can be great for cars. This is where all my SiteScape snapshots are located. The application can be found here.

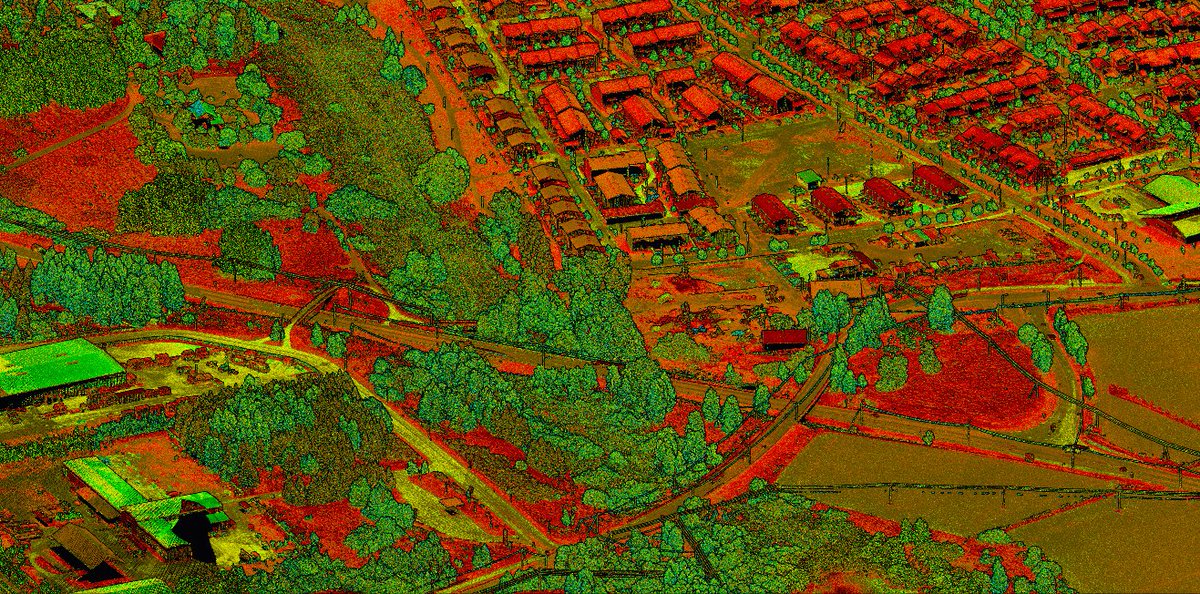

Everypoint

Everypoint is great for large point clouds, like this subway mosaic. The developers are teasing us about the upcoming app update combining lidar and photogrammetry, looking forward to trying it out. You can find all my Everypoint shots here, and the app is here.

General Tips

Here are some general tips for lidar scanning on iPhone:

- Remember that you can scan. People often get frustrated when scanning on the iPhone, usually scanning things that don't stand a good chance on their own. The most important thing to remember is that the scanner does not work with small things and objects. For example, a regular boot is often too small. Also, iPhone lidar does not work well with shiny/reflective elements

- Avoid rescanning an area already covered, this will most likely create misalignment issues and create artifacts in your image

- Scanning around something small/thin - like a statue, chair, or wall - generally doesn't work well

- Make sure that every part of the scanned area is well scanned to avoid gaps and voids.

To do this, I usually use something like a spray gesture, a bit like if I were painting with spray paint

To do this, I usually use something like a spray gesture, a bit like if I were painting with spray paint - Walk slowly and carefully. Don't flinch

- A beautiful and neat 3D image significantly affects the overall perception. 3Dscannerapp, Polycam and Scaniverse offer cropping directly in the app

- Sketchfab offers many options to help turn a bad scan into a normal one. I like to add shadows (2nd editor tab) and then post-process effects like sharpening, depth of field, saturation

- Adding 3D annotations to Sketchfab is a great way to turn a scan into a mini story

Sell 3D photos

Sketchfab store allows you to monetize your 3D creations. It seems to me that most of my iPhone lidar shots are still a little behind in quality in order to put them in the store. That being said, I put 2 of them up for sale (mini and doctor's office) because users actually asked me how they could buy them. The bottom line is that you never know how someone might use your scans, and it's often more about setting an appropriate price based on the quality and limitations of the content. Don't forget that the quality (and my skills) continues to improve, so I expect to be able to offer more 3D images for sale in the future. Remember that if you scan something with intellectual property (like Mini), you can only post it under a publishing license.

Don't forget that the quality (and my skills) continues to improve, so I expect to be able to offer more 3D images for sale in the future. Remember that if you scan something with intellectual property (like Mini), you can only post it under a publishing license.

Here is a post about my go-to apps, what I like about each of them, and some general tips for iPhone lidar scanning.

3D scanning with the iPhone lidar

About the author

Vladimir Voronov

Member since September 24, 2017

Discussion

Write a comment

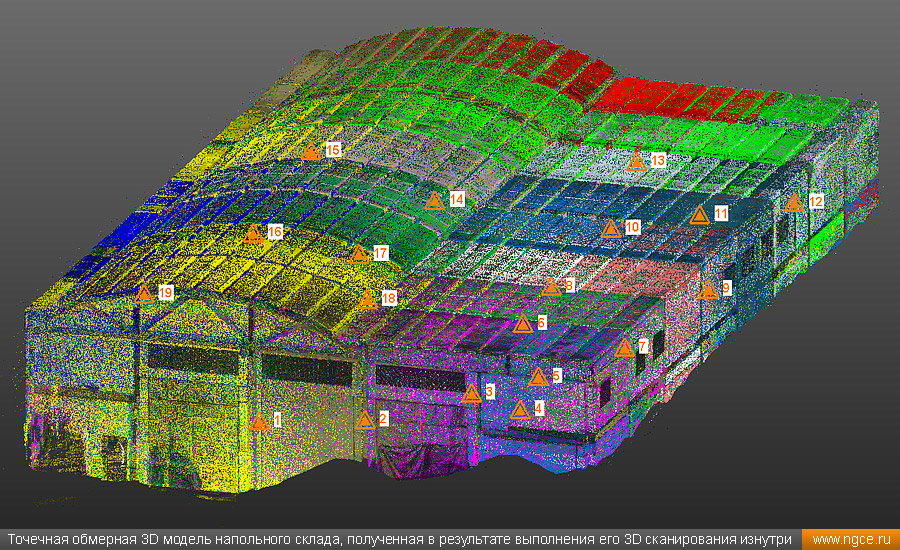

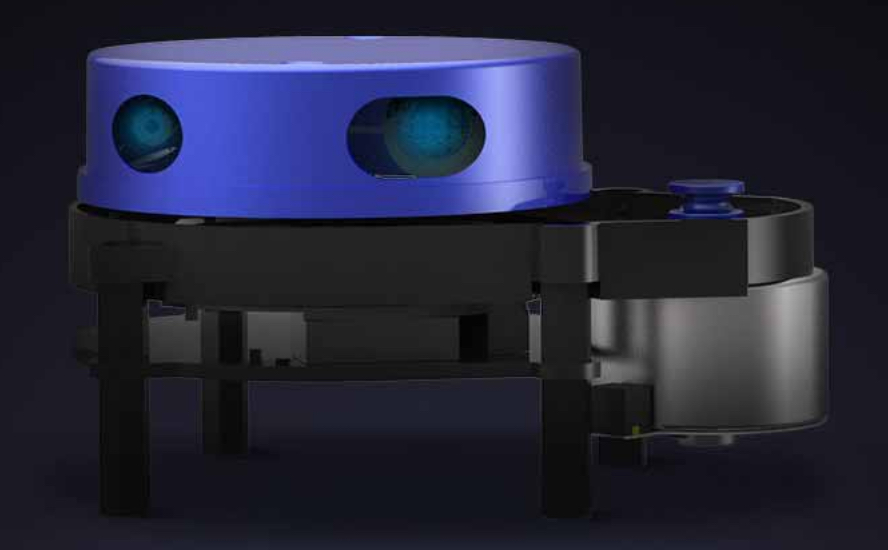

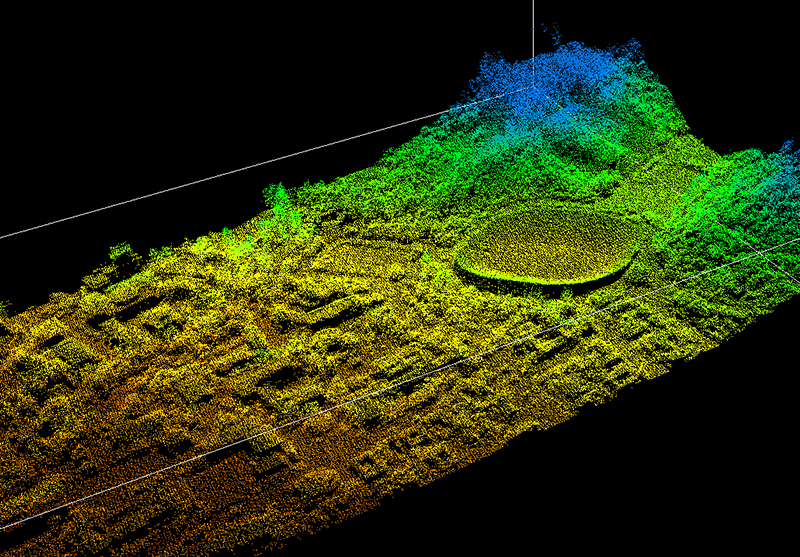

All about 3D scanners: from varieties to applications

The 3D scanner is a special device that analyzes a specific physical object or space in order to obtain data on the shape of an object and, if possible, its appearance (for example , about color). The collected data is then used to create a digital three-dimensional model of this object.

Create 3D-scanner allows several technologies at once, differing from each other in certain advantages, disadvantages, as well as cost. In addition, there are some restrictions on the objects that can be digitized. In particular, there are difficulties with objects that are shiny, transparent or have mirror surfaces.

Don't forget that 3D data collection is also important for other applications. So, they are needed in the entertainment industry to create films and video games. Also, this technology is in demand in industrial design, orthopedics and prosthetics, reverse engineering, prototyping, as well as for quality control, inspection and documentation of cultural artifacts.

Functionality

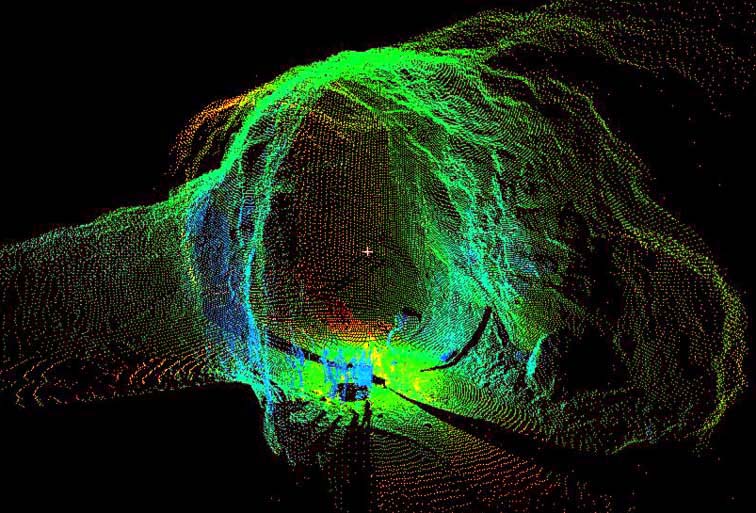

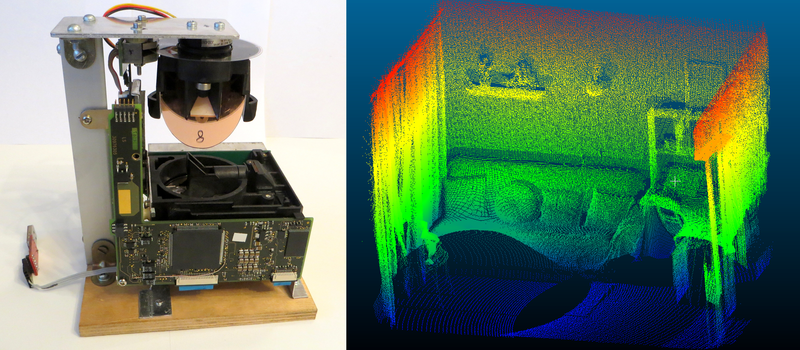

The purpose of the 3D Scanner is to create a point cloud of geometric patterns on the surface of an object. These points can then be extrapolated to recreate the shape of the object (a process called reconstruction). If color data were obtained, then the color of the reconstructed surface can also be determined.

If color data were obtained, then the color of the reconstructed surface can also be determined.

The 3D scanners are a bit like regular cameras. In particular, they have a cone-shaped field of view, and they can only receive information from surfaces that have not been darkened. The differences between these two devices is that the camera transmits only information about the color of the surface that fell into its field of view, but The 3D scanner collects information about distances on a surface that is also in its field of view. Thus, the "picture" obtained using the 3D scanner describes the distance to the surface at each point in the image. This allows you to determine the position of each point in the picture in 3 planes at once.

In most cases, one scan is not enough to create a complete model of the object. Several such operations are required. As a rule, a decent number of scans from different directions will be needed in order to obtain information about all sides of the object. All scan results must be normalized to a common coordinate system, a process called image referencing or alignment, before a complete model is created. This whole procedure from a simple map with distances to a full-fledged model is called a 3D scanning pipeline.

All scan results must be normalized to a common coordinate system, a process called image referencing or alignment, before a complete model is created. This whole procedure from a simple map with distances to a full-fledged model is called a 3D scanning pipeline.

Technology

There are several technologies for digitally scanning a mold and creating a 3D model of a object. However, a special classification has been developed that divides 3D scanners into 2 types: contact and non-contact. In turn, non-contact 3D scanners can be divided into 2 more groups - active and passive. Several technologies can fall under these categories of scanning devices.

Coordinated-measuring machine with two fixed mutually perpendicular measuring hands

Contact 3D scanners

Contact 3D-scanners 3D-scanners 3D 3D-scanners 3D 3D-scanners 3D 3D-scanners study (probe) the object is directly through the physical contact, while the subject itself is in the subject itself in the subject itself in the subject itself. on a precision surface plate, ground and polished to a certain degree of surface roughness. If the scanned object is uneven or cannot lie stably on a horizontal surface, then a special vise will hold it.

on a precision surface plate, ground and polished to a certain degree of surface roughness. If the scanned object is uneven or cannot lie stably on a horizontal surface, then a special vise will hold it.

The scanner mechanism comes in three different forms:

- Carriage with a fixed measuring arm positioned perpendicularly, and measurement along the axes occurs while the arm slides along the carriage. This system is optimal for flat or regular convex curved surfaces.

- Fixed component manipulator with high precision angle sensors. The location of the end of the measuring arm entails complex mathematical calculations regarding the angle of rotation of the wrist joint, as well as the angle of rotation of each of the joints of the arm. This mechanism is ideal for probing recesses or interior spaces with a small inlet.

- Simultaneous use of the previous two methods. For example, a manipulator can be combined with a carriage, which allows you to get 3D data from large objects that have internal cavities or overlapping surfaces.

The

The

CMM (coordinate measuring machine) is a prime example of the contact 3D scanner . They are used mainly in manufacturing and can be ultra-precise. The disadvantages of CMM include the need for direct contact with the surface of the object. Therefore, it is possible to change the object or even damage it. This is very important if thin or valuable items such as historical artifacts are being scanned. Another disadvantage of CMM over other scanning methods is slowness. Moving the measuring arm with the probe in place can be very slow. The fastest result of CMM operation does not exceed a few hundred hertz. At the same time, optical systems, for example, a laser scanner, can operate from 10 to 500 kHz.

Another example is hand-held measuring probes used to digitize clay models for computer animation.

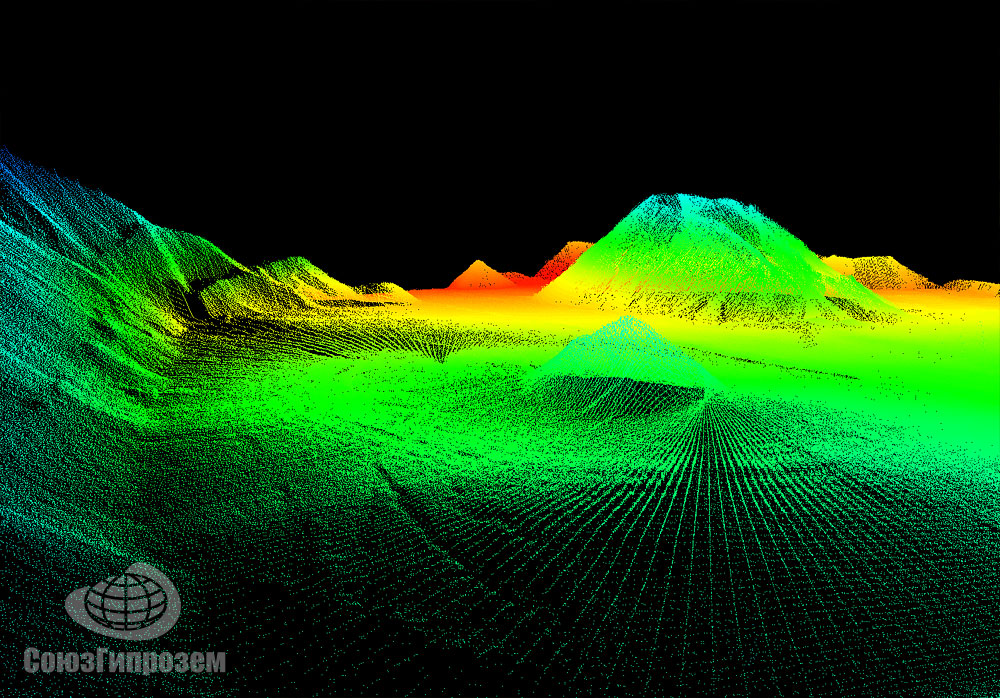

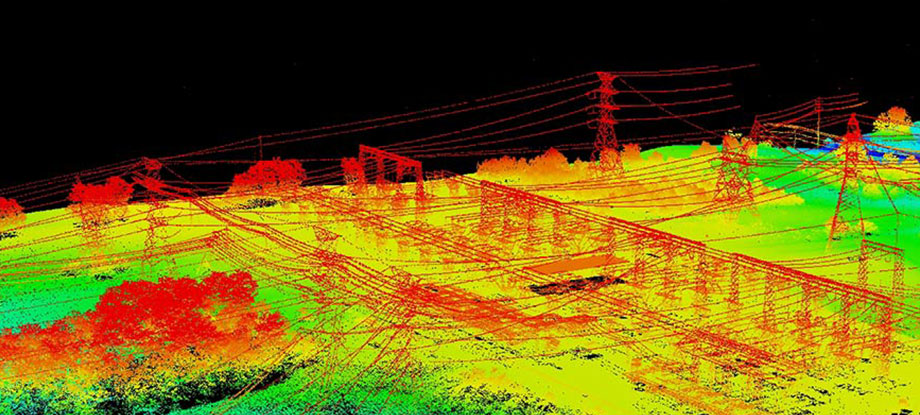

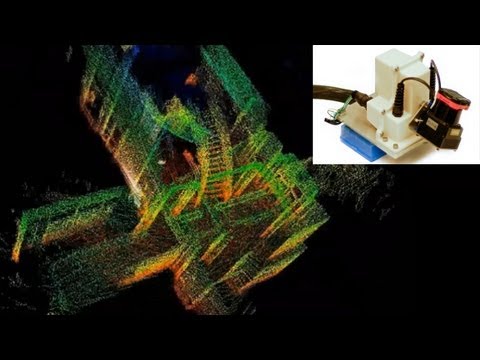

The Lidar device is used to scan buildings, rocks, etc., which makes it possible to create 3D models of them. The Lidar laser beam can be used in a wide range: its head rotates horizontally, and the mirror moves vertically. The laser beam itself is used to measure the distance to the first object in its path.

The laser beam itself is used to measure the distance to the first object in its path.

Non-contact active scanners

Active scanners use certain types of radiation or just light and scan an object through the reflection of light or the passage of radiation through an object or medium. These devices use light, ultrasound, or x-rays.

Time-of-Flight Scanners

Time-of-Flight Laser Scanner The 3D scanner is an active scanner that uses a laser beam to examine an object. This type of scanner is based on a time-of-flight laser range finder. In turn, the laser rangefinder determines the distance to the surface of the object, based on the time of flight of the laser back and forth. The laser itself is used to create a pulse of light, while the detector measures the time until the light is reflected. Given that the speed of light (c) is a constant value, knowing the time of flight of the beam back and forth, you can determine the distance over which the light has moved, it will be twice the distance between the scanner and the surface of the object. If (t) is the round-trip flight time of the laser beam, then the distance will be (c*t\2). Laser beam time-of-flight accuracy of the 3D scanner depends on how accurately we can measure time (t) itself: 3.3 picoseconds (approximately) is needed for the laser to travel 1 millimeter.

If (t) is the round-trip flight time of the laser beam, then the distance will be (c*t\2). Laser beam time-of-flight accuracy of the 3D scanner depends on how accurately we can measure time (t) itself: 3.3 picoseconds (approximately) is needed for the laser to travel 1 millimeter.

The laser distance meter determines the distance of only one point in a given direction. Therefore, the device scans its entire field of view in separate points at a time, while changing the direction of scanning. You can change the direction of the laser rangefinder either by rotating the device itself, or using a system of rotating mirrors. The latter method is often used, because it is much faster, more accurate, and also easier to handle. For example, time-of-flight 3D scanners can measure distance from 10,000 to 100,000 points in one second.

TOF devices are also available in 2D configuration. Basically, this applies to time-of-flight cameras. Triangulation scanners Two positions of the object are shown.

A point cloud is generated by triangulation and a laser stripe.

Triangulation laser scanners 3D scanners are also active scanners that use a laser beam to probe an object. Like the time-of-flight 3D scanners , triangulation devices send a laser to the scanned object, and a separate camera fixes the location of the point where the laser hit. Depending on how far the laser travels across the surface, the dot appears at different locations in the camera's field of view. This technology is called triangulation because the laser dot, the camera and the laser emitter itself form a kind of triangle. The length of one side of this triangle is known - the distance between the camera and the laser emitter. The angle of the laser emitter is also known. But the camera angle can be determined by the location of the laser dot in the field of view of the camera. These 3 indicators completely determine the shape and size of the triangle and indicate the location of the corner of the laser point. In most cases, to speed up the process of obtaining data, a laser strip is used instead of a laser dot. Thus, the National Research Council of Canada was among the first scientific organizations that developed the basics of triangulation laser scanning technology back in 1978 year.

In most cases, to speed up the process of obtaining data, a laser strip is used instead of a laser dot. Thus, the National Research Council of Canada was among the first scientific organizations that developed the basics of triangulation laser scanning technology back in 1978 year.

Advantages and disadvantages of

scanners Both time-of-flight and triangulation scanners have their own strengths and weaknesses, which determines their choice for each specific situation. The advantage of time-of-flight devices is that they are optimally suited for operation over very long distances up to several kilometers. They are ideal for scanning buildings or geographic features. At the same time, their disadvantages include measurement accuracy. After all, the speed of light is quite high, so when calculating the time it takes for the beam to overcome the distance to and from the object, some flaws (up to 1 mm) are possible. And this makes the scan results approximate.

As for triangulation rangefinders, the situation is exactly the opposite. Their range is only a few meters, but the accuracy is relatively high. Such devices can measure distance with an accuracy of tens of micrometers.

The study of the edge of an object negatively affects the accuracy of the TOF scanners. The laser pulse is sent one, and is reflected from two places at once. The coordinates are calculated based on the position of the scanner itself, and the average value of the two reflections of the laser beam is taken. This causes the point to be defined in the wrong place. When using scanners with high resolution, the chances that the laser beam hits the exact edge of the object increase, but noise will appear behind the edge, which will negatively affect the scan results. Scanners with a small beam can solve the edge scanning problem, but they have limited range, so the beam width will exceed the distance. There is also special software that allows the scanner to perceive only the first reflection of the beam, while ignoring the second.

At 10,000 dots per second, low resolution scanners can do the job within seconds. But for scanners with high resolution, you need to do several million operations, which will take minutes. It should be borne in mind that the data may be distorted if the object or the scanner moves. So, each point is fixed at a certain point in time in a certain place. If the object or scanner moves in space, then the scan results will be false. That's why it's so important to mount both the object and the scanner on a fixed platform and keep the possibility of vibration to a minimum. Therefore, scanning objects in motion is practically impossible. Recently, however, there has been active research on how to compensate for the effect of vibration on data corruption.

It is also worth considering that when scanning in one position for a long time, a slight movement of the scanner may occur due to temperature changes. If the scanner is mounted on a tripod and one side of the scanner is exposed to strong sunlight, then the tripod will expand and the scan data will gradually distort from one side to the other. However, some laser scanners have built-in compensators that counteract any movement of the scanner during operation.

However, some laser scanners have built-in compensators that counteract any movement of the scanner during operation.

Conoscopic holography

In the conoscopic system, a laser beam is projected onto the surface of an object, after which the beam is reflected along the same path, but through a conoscopic crystal, and is projected onto a CCD (charge-coupled device). The result is a diffraction pattern from which frequency analysis can be used to determine the distance to the surface of an object. The main advantage of conoscopic holography is that only one beam path is needed to measure the distance, which makes it possible to determine, for example, the depth of a small hole.

Handheld laser scanners

Handheld laser scanners create a 3D image using the triangulation principle described above. A laser beam or stripe is projected onto an object from a hand-held emitter, and a sensor (often a CCD or position-sensitive detector) measures the distance to the surface of the object. The data is collected relative to the internal coordinate system and therefore, to obtain results, if the scanner is in motion, the position of the device must be accurately determined. This can be done using basic features on the scanned surface (adhesive reflective elements or natural features) or using the external tracking method. The latter method often takes the form of a laser tracker (providing a position sensor) with a built-in camera (to determine the orientation of the scanner). You can also use photogrammetry, provided by 3 cameras, which gives the scanner six degrees of freedom (the ability to make geometric movements in three-dimensional space). Both techniques typically use infrared LEDs connected to the scanner. They are observed by cameras through filters that ensure the stability of ambient lighting (reflecting light from different surfaces).

The data is collected relative to the internal coordinate system and therefore, to obtain results, if the scanner is in motion, the position of the device must be accurately determined. This can be done using basic features on the scanned surface (adhesive reflective elements or natural features) or using the external tracking method. The latter method often takes the form of a laser tracker (providing a position sensor) with a built-in camera (to determine the orientation of the scanner). You can also use photogrammetry, provided by 3 cameras, which gives the scanner six degrees of freedom (the ability to make geometric movements in three-dimensional space). Both techniques typically use infrared LEDs connected to the scanner. They are observed by cameras through filters that ensure the stability of ambient lighting (reflecting light from different surfaces).

Scan data is collected by a computer and recorded as points in 3D space, which after processing are converted into a triangulated grid. The computer-aided design system then creates a model using a non-uniform rational B-spline, NURBS (a special mathematical form for creating curves and surfaces). Handheld laser scanners can combine this data with passive visible light sensors that capture surface texture and color to create or reverse engineer a complete 3D Models .

The computer-aided design system then creates a model using a non-uniform rational B-spline, NURBS (a special mathematical form for creating curves and surfaces). Handheld laser scanners can combine this data with passive visible light sensors that capture surface texture and color to create or reverse engineer a complete 3D Models .

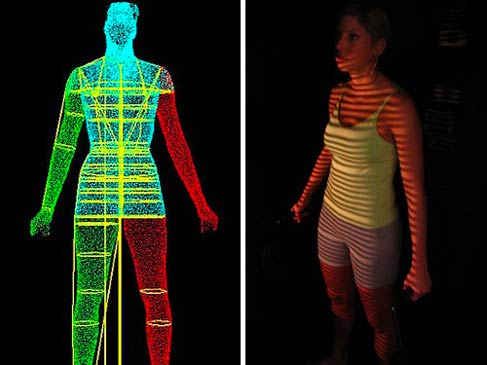

Structured light

Structured light 3D scanners are a projection of a light grid directly onto an object, the deformation of this pattern is a model of the scanned object. The grid is projected onto the object using a liquid crystal projector or other constant light source. A camera positioned just to the side of the projector captures the shape of the network and calculates the distance to each point in the field of view.

Structured light scanning is still an active area of research, with quite a few research papers devoted to it each year. Ideal maps are also recognized as useful as structured light patterns that can solve matching problems and allow errors to be corrected as well as detected.

The advantage of the structured light 3D scanners is their speed and accuracy. Instead of scanning one point at a time, structured scanners scan several points at the same time or the entire field of view at once. Scanning the entire field of view takes a fraction of a second, and the generated profiles are more accurate than laser triangulations. This completely solves the problem of data corruption caused by motion. In addition, some existing systems are capable of scanning even moving objects in real time. For example, the VisionMaster, a 3D scanning system, has a 5-megapixel camera, so each frame contains 5 million dots.

Real-time scanners use digital edge projection and a phase-shifting technique (one of the techniques for applying structured light) to capture, reconstruct, and create a high-density computer model of dynamically changing objects (such as facial expressions) at 40 frames per second. A new type of scanner has recently been created. Various models can be used in this system. The frame rate for capturing and processing data reaches 120 frames per second. This scanner can also process individual surfaces. For example, 2 moving hands. Using the binary defocusing method, the shooting speed can reach hundreds or even thousands of frames per second.

The frame rate for capturing and processing data reaches 120 frames per second. This scanner can also process individual surfaces. For example, 2 moving hands. Using the binary defocusing method, the shooting speed can reach hundreds or even thousands of frames per second.

Modulated light

When using the 3D scanners based on modulated light, the light beam directed at the object is constantly changing. Often the change of light passes along a sinusoid. The camera captures the reflected light and determines the distance to the object, taking into account the path that the light beam has traveled. Modulated light allows the scanner to ignore light from sources other than the laser, thus avoiding interference.

Volumetric techniques

Medicine

Computed tomography (CT) is a special medical imaging technique that creates a series of three-dimensional x-ray images of an object, a large three-dimensional image of the internal space. Magnetic resonance imaging works on a similar principle - another imaging technique in medicine, which is distinguished by a more contrast image of the soft tissues of the body than CT. Therefore, MRI is used to scan the brain, the musculoskeletal system, the cardiovascular system, and to search for oncology. These techniques produce volumetric voxel models that can be rendered, modified, and transformed into a traditional 3D surface using isosurface extraction algorithms.

Magnetic resonance imaging works on a similar principle - another imaging technique in medicine, which is distinguished by a more contrast image of the soft tissues of the body than CT. Therefore, MRI is used to scan the brain, the musculoskeletal system, the cardiovascular system, and to search for oncology. These techniques produce volumetric voxel models that can be rendered, modified, and transformed into a traditional 3D surface using isosurface extraction algorithms.

Production

Although MRI, CT or microtomography are more widely used in medicine, they are also actively used in other areas to obtain a digital model of an object and its environment. This is important, for example, for non-destructive testing of materials, reverse engineering or the study of biological and paleontological samples.

Non-contact passive scanners

Passive scanners do not emit light, instead they use reflected light from the surroundings. Most scanners of this type are designed to detect visible light, which is the most accessible form of ambient radiation. Other types of radiation, such as infrared, may also be involved. Passive scanning methods are relatively cheap, because in most cases they do not need special equipment, a conventional digital camera is enough.

Most scanners of this type are designed to detect visible light, which is the most accessible form of ambient radiation. Other types of radiation, such as infrared, may also be involved. Passive scanning methods are relatively cheap, because in most cases they do not need special equipment, a conventional digital camera is enough.

Stereoscopic systems involve the use of 2 video cameras located in different places, but in the same direction. By analyzing the differences in the images of each camera, you can determine the distance to each point in the image. This method is similar in principle to human stereoscopic vision.

Photometric systems typically use a single camera that captures multiple frames in all lighting conditions. These methods attempt to transform the object model in order to reconstruct the surface for each pixel.

Silhouette techniques use contours from successive photographs of a three-dimensional object against a contrasting background. These silhouettes are extruded and transformed to get the visible skin of the object. However, this method does not allow you to scan the recesses in the object (for example, the inner cavity of the bowl).

However, this method does not allow you to scan the recesses in the object (for example, the inner cavity of the bowl).

There are other methods that are based on the fact that the user himself discovers and identifies some features and shapes of the object, based on many different images of the object, which allow you to create an approximate model of this object. Such methods can be used to quickly create a three-dimensional model of objects of simple shapes, for example, a building. You can do this using one of the software applications: D-Sculptor, iModeller, Autodesk ImageModeler or PhotoModeler.

This 3D scan is based on the principles of photogrammetry. In addition, this technique is in some ways similar to panoramic photography, except that the photographs of the object are taken in three-dimensional space. Thus, it is possible to copy the object itself, rather than taking a series of photos from one point in three-dimensional space, which would lead to the reconstruction of the object's environment.

Reconstruction

From point clouds

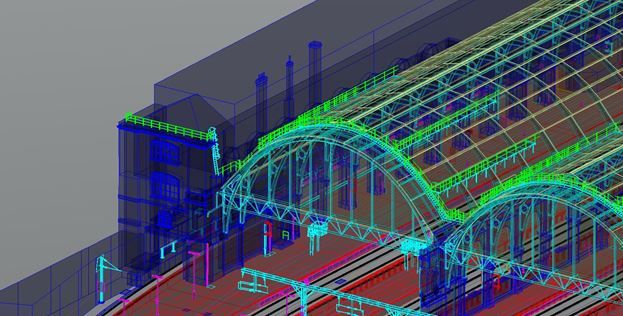

The point clouds generated by the 3D Scanners can be directly used for measurements or visualizations in architecture and engineering.

However, most applications use non-homogeneous rational B-spline, NURBS, or editable CAD models (also known as solid models) instead of polygonal 3D models.

- Polygon mesh models: In polygon representation shapes curved surfaces consist of many small flat surfaces with edges (a striking example is a ball in discotheques). Polygonal models are very in demand for visualization in the field of CAM - an automated system for technological preparation of production (for example, mechanical processing). At the same time, such models are quite « heavy" (accommodate a large amount of data) and are quite difficult to edit in this format. Reconstruction into a polygonal model involves searching and combining neighboring points with straight lines until a continuous surface is formed.

For this, you can use a number of paid and free programs (MeshLab, Kubit PointCloud for Au toCAD, 3D JRC Reconstructor, ImageModel, PolyWorks, Rapidform, Geomagic, Imageware, Rhino 3D, etc.).

For this, you can use a number of paid and free programs (MeshLab, Kubit PointCloud for Au toCAD, 3D JRC Reconstructor, ImageModel, PolyWorks, Rapidform, Geomagic, Imageware, Rhino 3D, etc.). - Surface models: This method represents the next level of sophistication in the field of modeling. It applies a set of curved surfaces that give your object its shape. It can be NURBS, T-Spline or other curved objects from the topology. Using NURBS converts, for example, a sphere to its mathematical equivalent. Some applications require manual processing of the model, but more advanced programs also offer automatic mode. This option is not only easier to use, but also provides the ability to modify the model when exporting to a computer-aided design system (CAD). Surface models are editable, but only in a sculptural way. Organic and artistic forms lend themselves well to modeling. Surface modeling is available in Rapidform, Geomagic, Rhino 3D, Maya, T Splines.

- 3D CAD Models: From an engineering and manufacturing perspective, this type of simulation is a full digitized form of a parametric CAD model.

After all, CAD is the industry's common "language" for describing, editing, and preserving the shape of an enterprise's assets. For example, in CAD, a sphere can be described by parametric functions that are easy to edit by changing their value (say, radius or center point).

After all, CAD is the industry's common "language" for describing, editing, and preserving the shape of an enterprise's assets. For example, in CAD, a sphere can be described by parametric functions that are easy to edit by changing their value (say, radius or center point).

These CAD models don't just describe the shell or shape of an object, but they also enable design intent (ie, critical features and their relationship to other features). An example of design intent that is not expressed in form would be the ribbed bolts of a brake drum, which should be concentric with the hole in the center of the drum. This nuance determines the sequence and method of creating a CAD model, so the engineer, taking into account these features, will develop bolts tied not to the outer diameter, but, on the contrary, to the center. Thus, to create such a CAD model, you need to correlate the shape of the object with the design intent.

There are several approaches to get a parametric CAD model. Some involve only exporting a NURBS surface, leaving the CAD engineer to complete the modeling (Geomagic, Imageware, Rhino 3D). Others use the scan data to create an editable and verifiable function model that can be fully imported into CAD with an intact fully functional tree, providing a complete fusion of shape and design intent of the CAD model (Geomagic, Rapidform). However, other CAD applications are powerful enough to manipulate a limited number of points or polygonal models in a CAD environment (CATIA, AutoCAD, Revit).

Some involve only exporting a NURBS surface, leaving the CAD engineer to complete the modeling (Geomagic, Imageware, Rhino 3D). Others use the scan data to create an editable and verifiable function model that can be fully imported into CAD with an intact fully functional tree, providing a complete fusion of shape and design intent of the CAD model (Geomagic, Rapidform). However, other CAD applications are powerful enough to manipulate a limited number of points or polygonal models in a CAD environment (CATIA, AutoCAD, Revit).

From a set of 2D slices

3D reconstruction of the brain or eyeballs based on CT results is performed using DICOM images. Their peculiarity is that the areas on which air is displayed, or bones with a high density are made transparent, and the sections are superimposed in a free alignment interval. The outer ring of biomaterial surrounding the brain is made up of the soft tissues of the skin and muscles on the outside of the skull. All sections are made on a black background. Since they are simple 2D images, when added one-to-one when viewed, the borders of each slice disappear due to their zero thickness. Each DICOM image is a slice about 5 mm thick.

All sections are made on a black background. Since they are simple 2D images, when added one-to-one when viewed, the borders of each slice disappear due to their zero thickness. Each DICOM image is a slice about 5 mm thick.

CT, industrial CT, MRI or microCT scanners do not create a cloud of points, but 2D slices (referred to as a “tomogram”) that are superimposed on each other, resulting in a kind of 3D model. There are several ways to do this scan, depending on the desired result:

- Volume rendering: Different parts of an object usually have different thresholds and grayscale densities. Based on this, a three-dimensional model can be freely designed and displayed on the screen. Several models can be made from different thresholds, allowing different colors to represent a specific part of an object. Volumetric rendering is most often used to render a scanned object.

- Image segmentation: When different structures have similar threshold or midtone values, it may not be possible to separate them simply by changing volume rendering parameters.

The solution to the problem will be segmentation - a manual or automatic procedure that will remove unnecessary structures from the image. Special programs that support image segmentation allow you to export segmented structures to CAD or STL format, which will allow you to continue working with them.

The solution to the problem will be segmentation - a manual or automatic procedure that will remove unnecessary structures from the image. Special programs that support image segmentation allow you to export segmented structures to CAD or STL format, which will allow you to continue working with them. - Meshing based on image analysis: When 3D image data (CFD and FEA) is used for computer analysis, simple data segmentation and meshing from a CAD file can be quite time consuming. In addition, some typical image data may not be inherently suitable for a complex topology. The solution lies in image analysis meshing, which is an automated process for generating an accurate and realistic geometric description of the scanned data.

Applications

Material Handling and Manufacturing

3D Laser Scanning describes a general way to measure or scan a surface using laser technology. It is used in several areas at once, differing mainly in the power of the lasers that are used and the results of the scan itself. Low laser power is needed when the scanned surface should not be influenced, for example, if it only needs to be digitized. Confocal or 3D laser scanning are methods that provide information about the scanned surface. Another low power application involves a projection system that uses structured light. It is applied to solar panel plane metrology involving voltage calculation with a throughput of more than 2,000 plates per hour.

Low laser power is needed when the scanned surface should not be influenced, for example, if it only needs to be digitized. Confocal or 3D laser scanning are methods that provide information about the scanned surface. Another low power application involves a projection system that uses structured light. It is applied to solar panel plane metrology involving voltage calculation with a throughput of more than 2,000 plates per hour.

The laser power used for laser scanning of industrial equipment is 1W. The power level is typically 200mW or less.

Construction industry

- Robot control: Laser scanner acts as the eye of the robot

- Executive drawings of bridges, industrial plants, monuments

- Documentation of Historic Sites

- Site modeling and layout

- Quality control

- Measurement of works

- Reconstruction of highways

- Marking an already existing shape/state to identify structural changes after extreme events - earthquake, ship or truck impact, fire.

- Creation of GIS (Geographic Information System), maps and geomatics

- Scanning of subsurface in mines and karst voids

- Court records

Benefits of 3D scanning

Creating a 3D model through scanning has the following benefits:

- Increases efficiency in working with complex parts and shapes

- Encourages product design when needed to add a part created by someone else.

- If CAD models become outdated, 3D scanning will provide an updated version

- Replaces missing or missing parts of

Entertainment

3D scanners are widely used in the entertainment industry to create 3D digital models in film and video games. If the model being created has a counterpart in the real world, then scanning will allow you to create a three-dimensional model much faster than developing the same model through 3D modeling. Quite often, artists first sculpt a physical model, which is then scanned to get a digital equivalent, instead of creating such a model on a computer.

Reverse engineering

Reverse engineering of mechanical components requires a very precise digital model of the objects to be recreated. This is a good alternative to converting many points of a digital model to a polygon mesh, using a set of NURBS flat and curved surfaces, or, ideally for mechanical components, creating a 3D CAD model. A 3D scanner can be used to digitize objects that freely change shape. As well as the prismatic configuration, for which a coordinate measuring machine is usually used. This will allow you to determine the simple dimensions of the prismatic model. This data is further processed by special programs for reverse engineering.

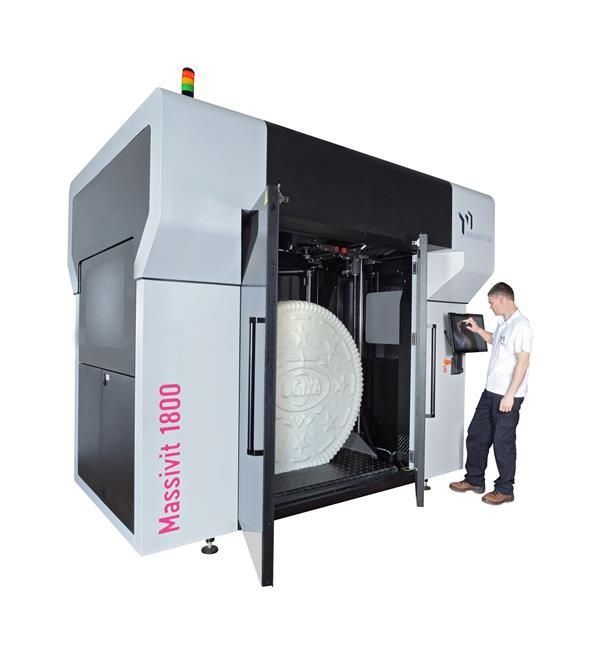

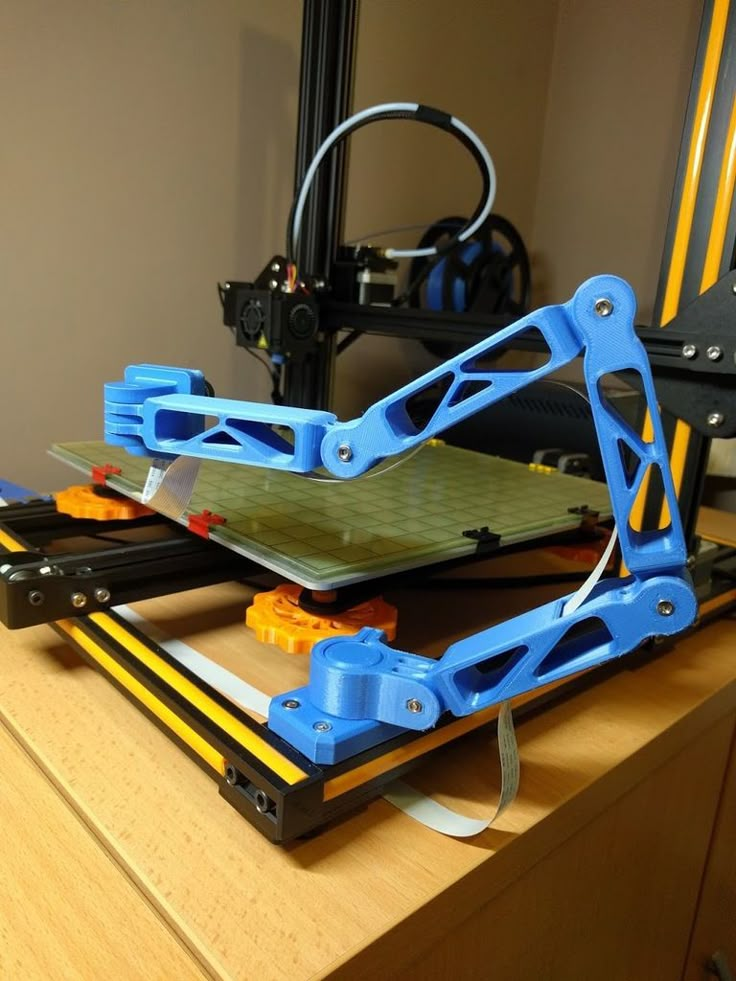

3D printing

3D scanners are also actively used in the field of 3D printing, as they allow you to create fairly accurate 3D models of various objects and surfaces in a short time, suitable for further refinement and printing. In this area, both contact and non-contact scanning methods are used, both methods have certain advantages.

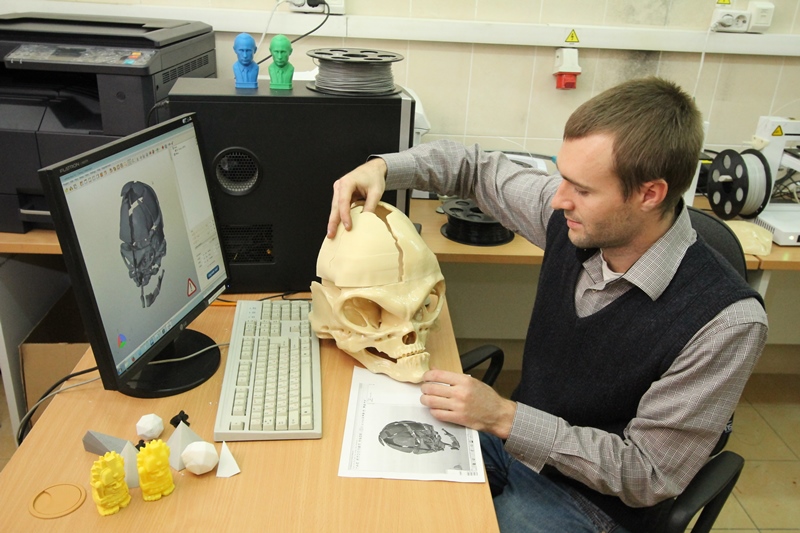

Cultural heritage

An example of copying a real object through 3D scanning and 3D printing. There are many research projects that have been carried out using the scanning of historical sites and artifacts to document and analyze them. The combined use of 3D scanning and 3D printing makes it possible to replicate real objects without the use of a traditional plaster cast, which in many cases can damage a valuable or delicate cultural heritage artifact. The sculpture of the figure on the left was digitized using a 3D scanner, and the resulting data was converted in the MeshLab program. The resulting digital 3D model was printed using a rapid prototyping machine that allows you to create a real copy of the original object.

Michelangelo

There are many research projects that have been carried out using scanning of historical sites and artifacts to document and analyze them.

In 1999, 2 different research groups started scanning Michelangelo's statues. Stanford University, along with a team led by Mark Levoy, used a conventional laser triangulation scanner built by Cyberware specifically to scan Michelangelo's statues in Florence. In particular, the famous David, "Slaves" and 4 more statues from the Medici chapel. Scanning is performed with a dot density of 0.25 mm, sufficient to see the traces of Michelangelo's chisel. Such a detailed scan involves obtaining a huge amount of data (about 32 gigabytes). It took about 5 months to process them.

Around the same time, a research group from IBM was working, led by H. Raschmeyer and F. Bernardini. They were tasked with scanning the Florentine Pieta sculpture to obtain both geometric data and color information. The digital model obtained from a Stanford University scan was fully used in 2004 to further restore the statue.

Medical applications CAD/CAM

3D scanners are widely used in orthopedics and dentistry to create a 3D patient shape. Gradually, they replace the outdated gypsum technology. CAD/CAM software is used to create prostheses and implants.

Gradually, they replace the outdated gypsum technology. CAD/CAM software is used to create prostheses and implants.

Many dentistry uses CAD/CAM as well as 3D scanners to capture the 3D surface of a dentifrice (in vivo or in vitro) in order to create a digital model using CAD or CAM techniques (e.g. , for a CNC milling machine (computer numerical control), as well as a 3D printer). Such systems are designed to facilitate the process of 3D scanning of the drug in vivo with its further modeling (for example, for a crown, filling or inlay).

Quality assurance and industrial metrology

The digitization of real world objects is of great importance in various fields of application. 3D scanning is very actively used in industry to ensure product quality, for example, to measure geometric accuracy. Predominantly all industrial processes such as assembly are quite complex, they are also highly automated and are usually based on CAD (computer-aided design data). The problem is that the same degree of automation is required for quality assurance. A striking example is the automated assembly of modern cars, because they consist of many parts that must match exactly with each other.

The problem is that the same degree of automation is required for quality assurance. A striking example is the automated assembly of modern cars, because they consist of many parts that must match exactly with each other.

Optimum performance levels are guaranteed by quality assurance systems. Geometrical metal parts need special checking, because they must be of the correct size, fit together to ensure reliable operation.

In highly automated processes, the results of geometric measurements are transferred to machines that produce the corresponding objects. Due to friction and other mechanical processes, the digital model may differ slightly from the real object. In order to automatically capture and evaluate these deviations, the manufactured parts must be rescanned. For this, 3D scanners are used, which create a reference model with which the received data are compared.

The process of comparing 3D data and CAD model is called CAD comparison, and can be a useful method for determining mold and machine wear, final assembly accuracy, tear analysis, and the volumetric surface of a disassembled part.