3D printer terminology

3D Printing Glossary of Terms

Glossary of 3D Printing TermsHere is the glossary from the back of our user manual. We use this vocabulary in our videoconference trainings and tech support.

3D

Three-dimensional

3D Printing

The process of creating a three-dimensional object from a digital file. Usually, it is achieved by stacking two-dimensional layers of material to form a physical 3D object. There are many different 3D printing processes that use many different materials, but the most common process is material extrusion—also known as Fused Deposition Modeling and Fused Filament Fabrication—which uses thermoplastic filament. Also known as additive manufacturing.

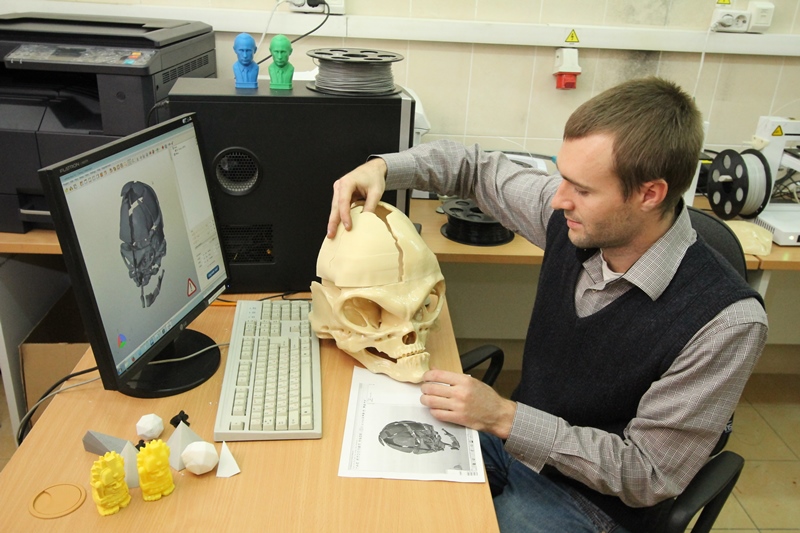

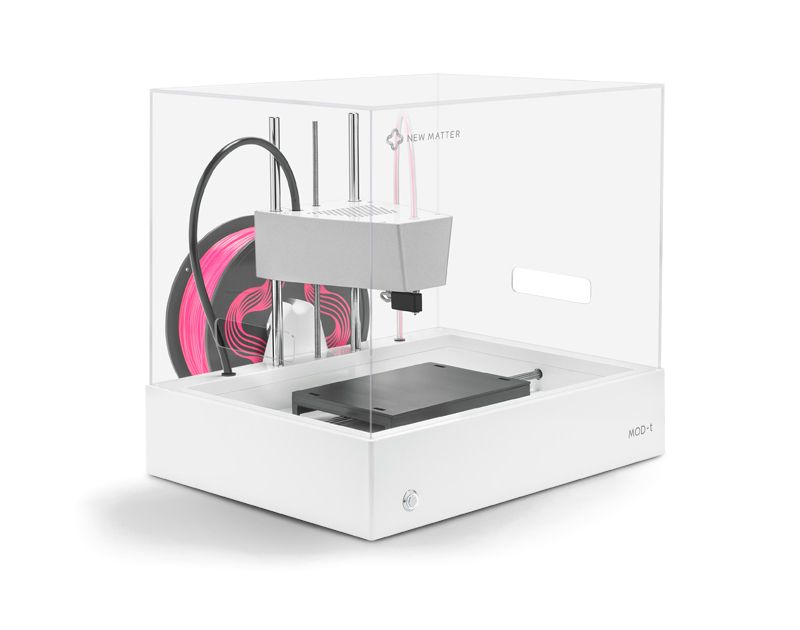

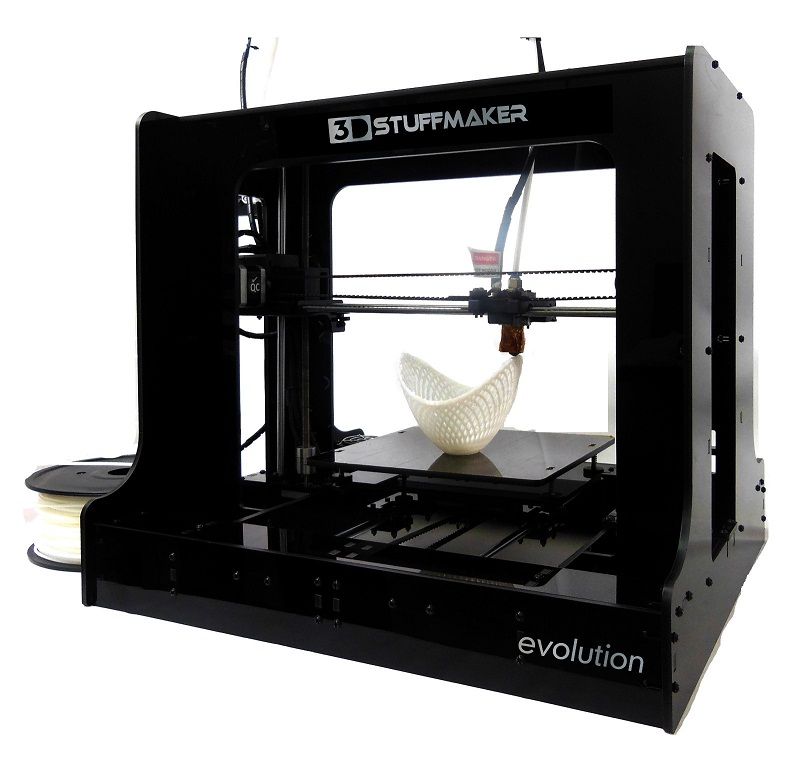

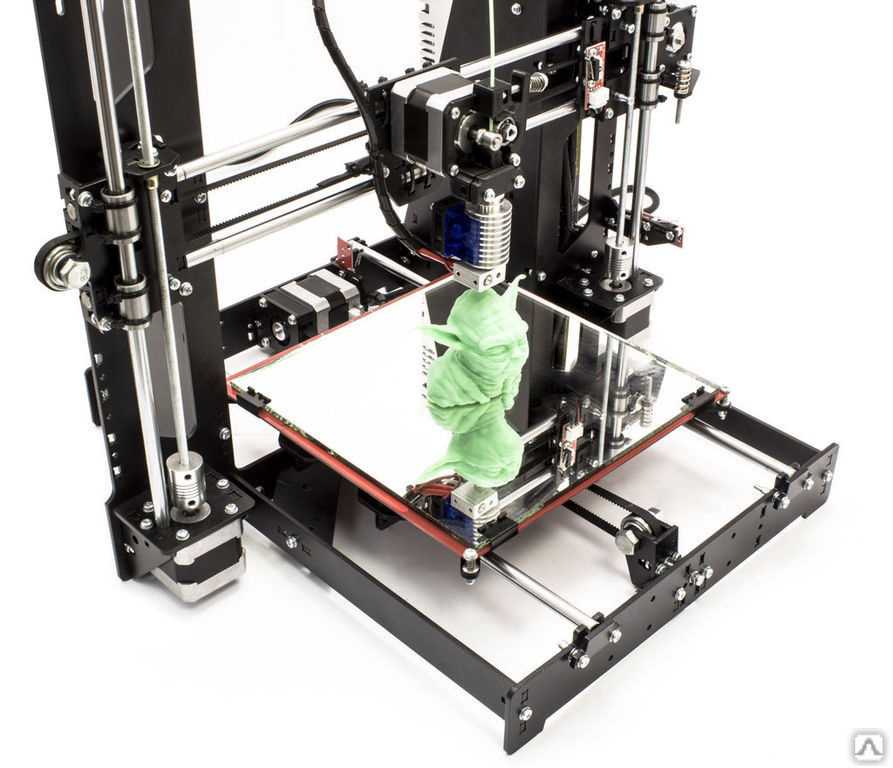

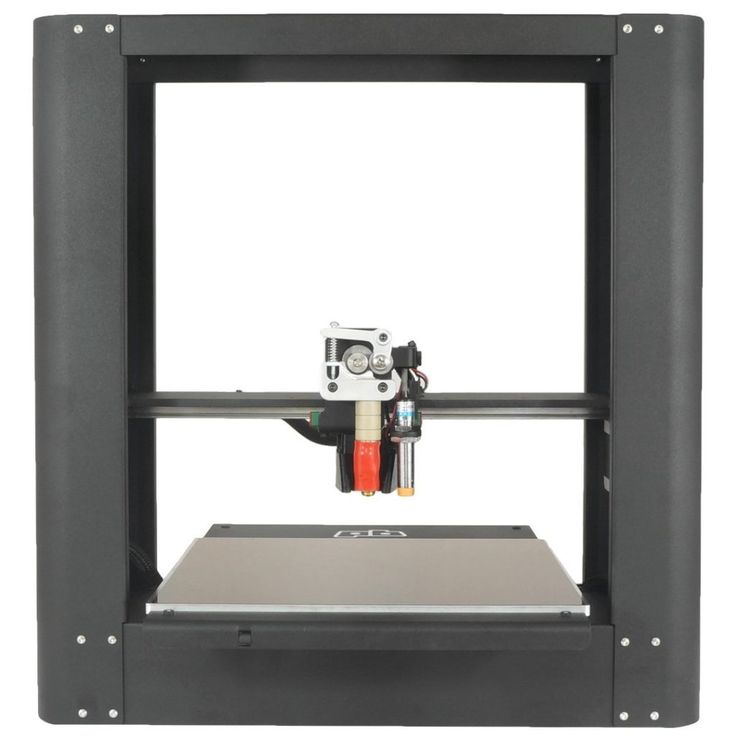

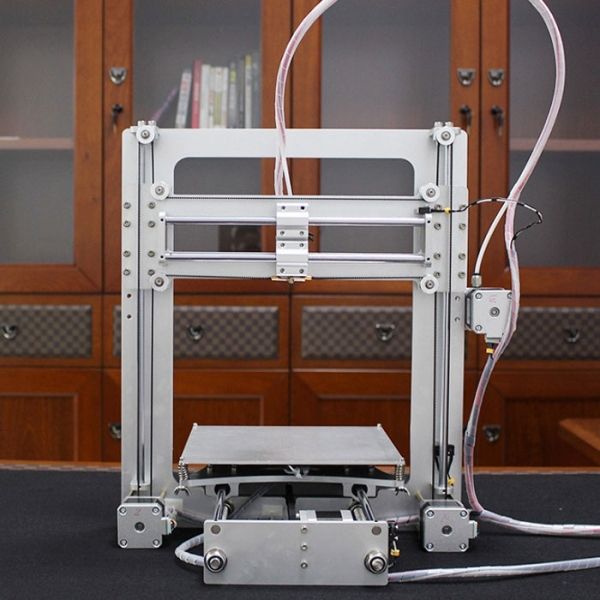

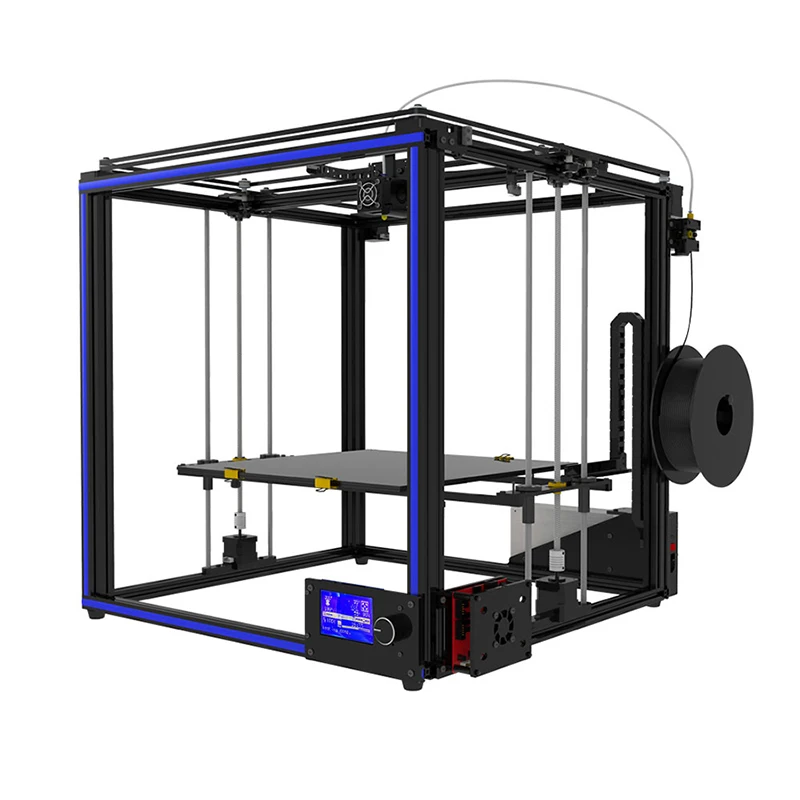

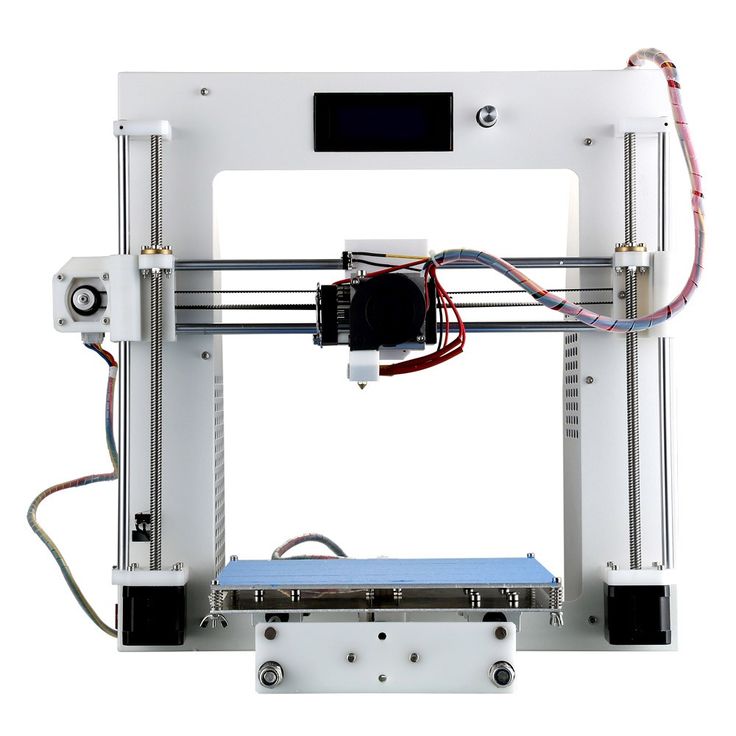

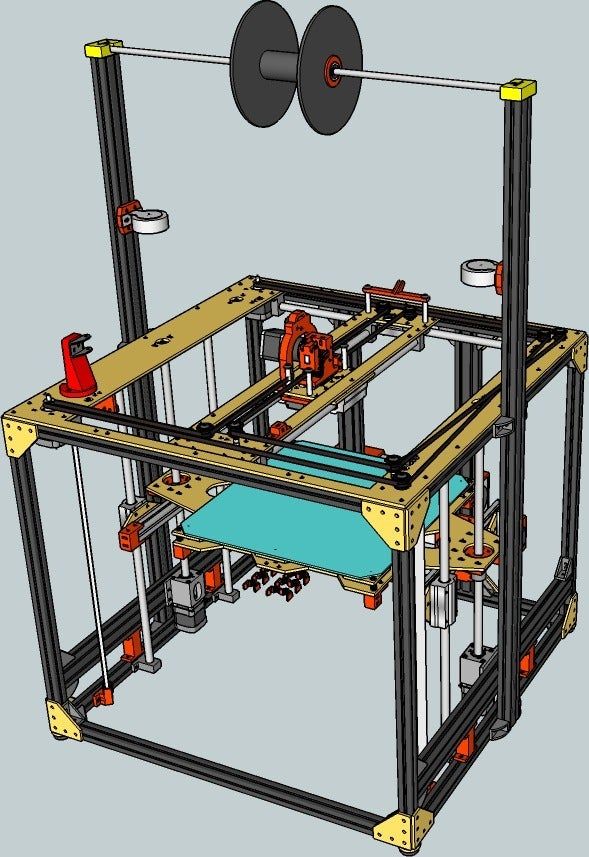

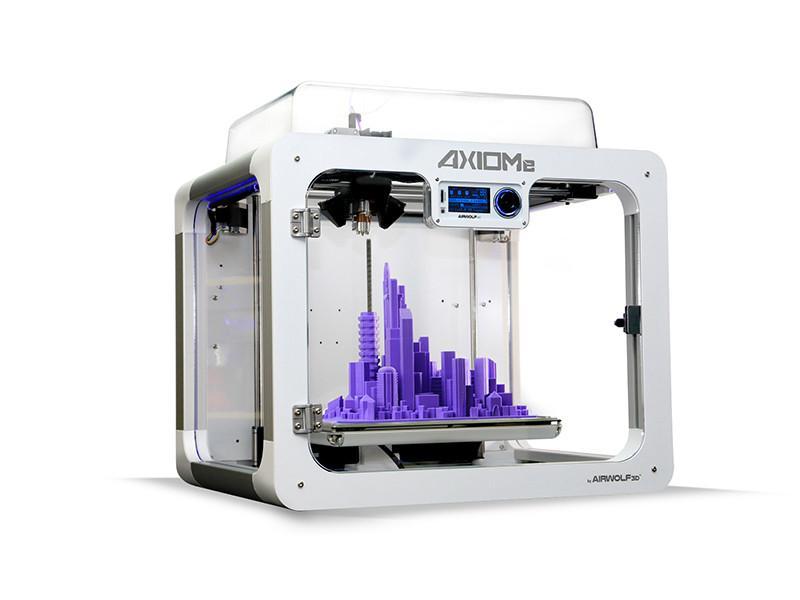

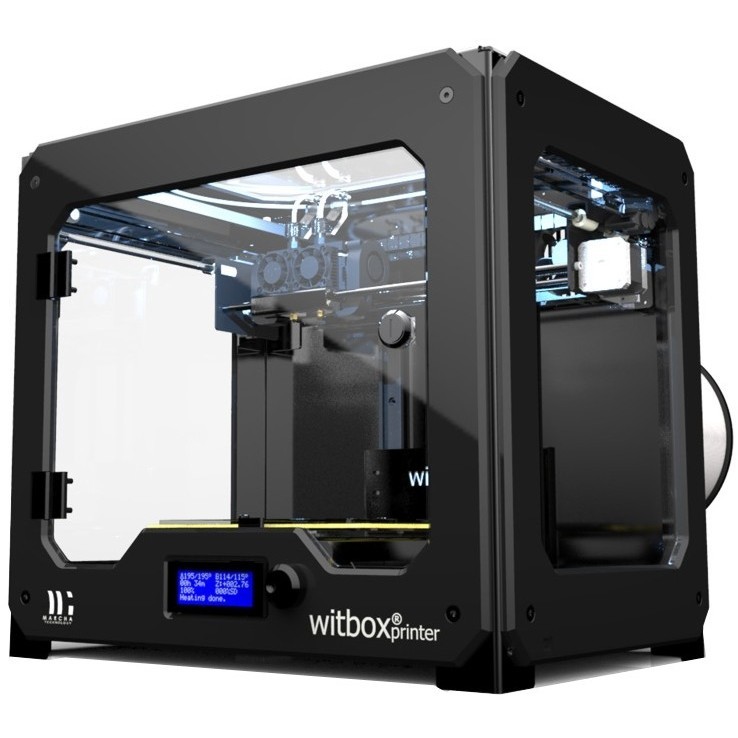

3D Printer

A machine tool that creates a three-dimensional object from a digital file by stacking thin, two-dimensional layers of material. This machine usually reads g-code files that give it specific instructions on how to print an object. The most common type of 3D printer uses the process of material extrusion, or fused deposition modeling (FDM), to form parts.

3D Design Program

A type of software used to visualize, design, and manipulate 3D products while providing a test environment for strength and dynamic analysis. Also known as a Computer Aided Design (CAD) program or 3D Modeling Software. Free examples for educators include Autodesk Inventor, Fusion360, SketchUp, Onshape, and Tinkercad.

3D Modeler

A type of multimedia artist or animator who creates three-dimensional models or visuals of items using a variety of different computer software programs and tools. Also, a program used to manipulate 3D shapes to create objects for animation or production.

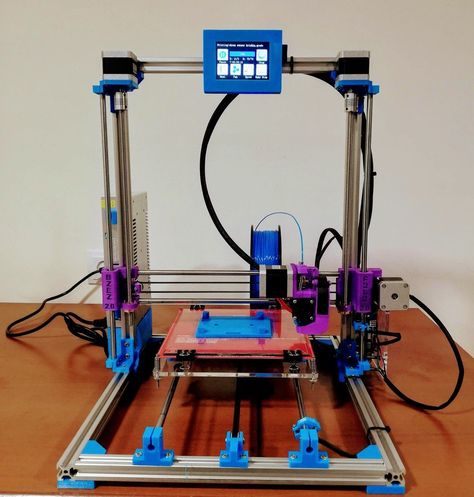

A5

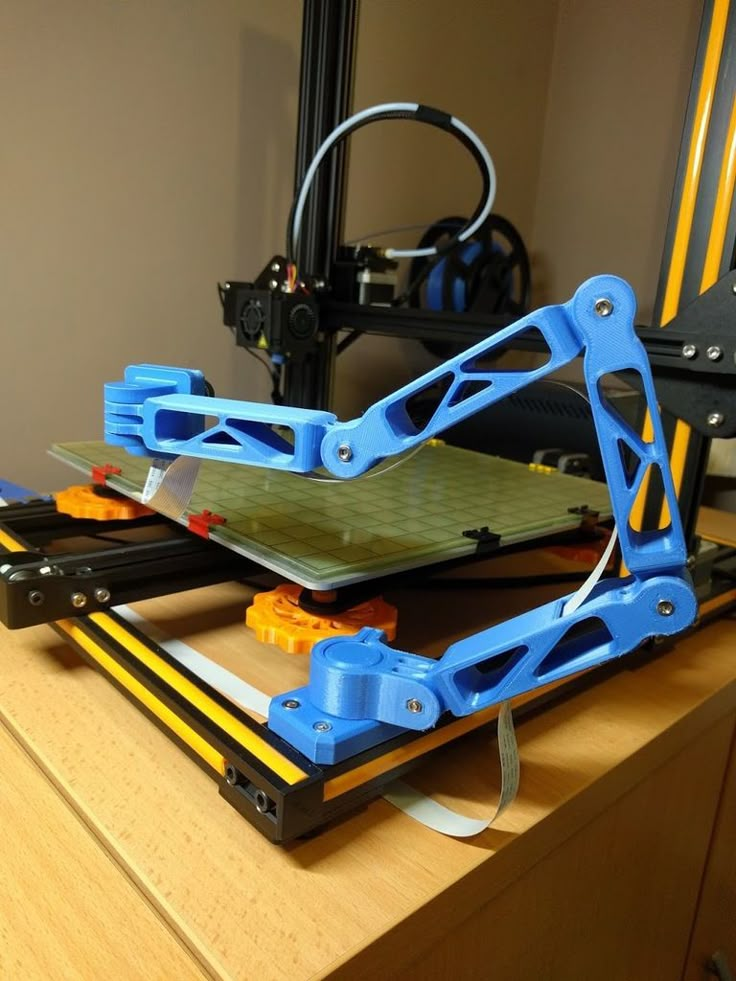

The A5 is an open source material extrusion 3D printer design that prints 125 x 150 x 100mm. NWA3D heavily modifies this original design to meet the rigorous classroom environment and calls the version an NWA3D A5. We build, modify, and test every printer. We are the sole-source provider of the NWA3D A5. Changes include hardware upgrades, custom operating system, and our unmatched warranty, lifetime training, and support for educators.

We build, modify, and test every printer. We are the sole-source provider of the NWA3D A5. Changes include hardware upgrades, custom operating system, and our unmatched warranty, lifetime training, and support for educators.

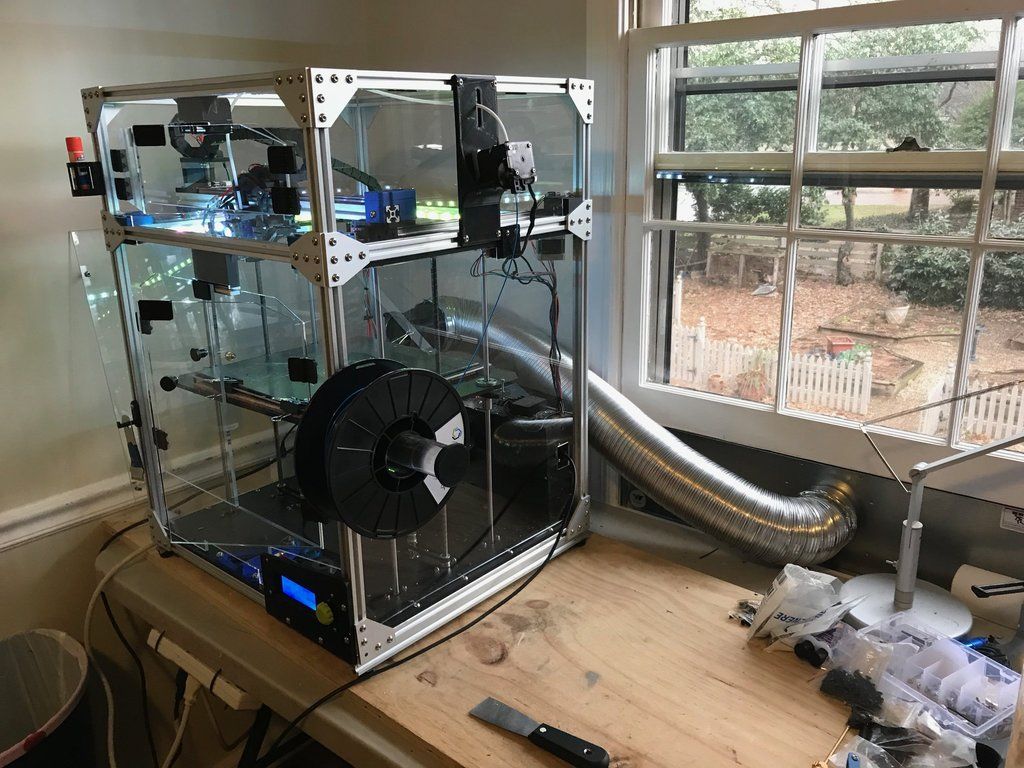

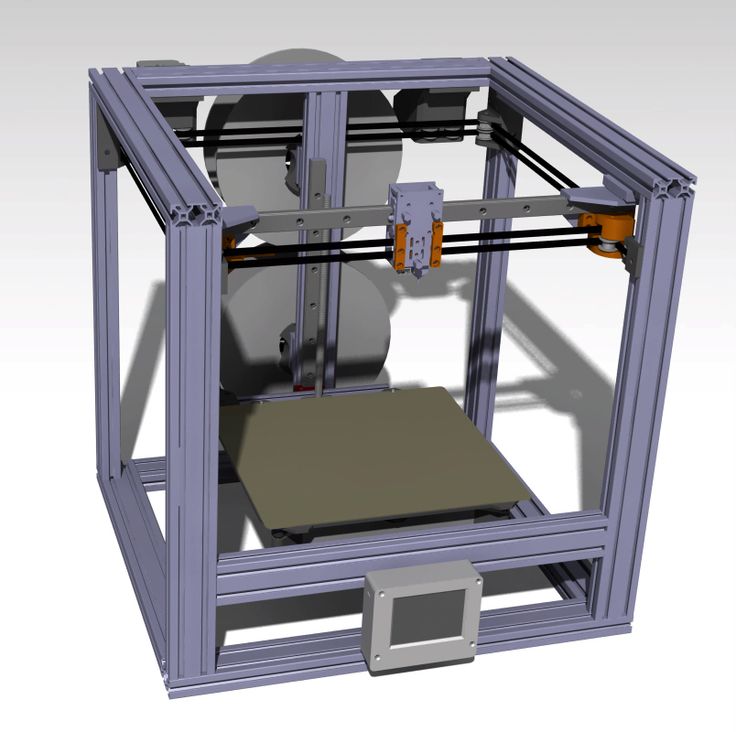

A31

The A31 is an open source material extrusion 3D printer design that prints 300 x 300 x 400mm. NWA3D modifies the original design to meet the rigorous classroom environment and calls the version an NWA3D A31. We build, modify, and test every printer. We are the sole-source provider of the NWA3D A31. Changes include hardware upgrades, custom operating system, and our unmatched warranty, lifetime training, and support for educators.

ABS

Stands for Acrylonitrile Butadiene Styrene, which is a thermoplastic used for 3D printing. ABS is a common form of plastic found in most household items that were injection molded.

Additive Manufacturing

The process of creating an object from a digital file by stacking 2D layers to form a 3D object. Also called 3D printing. see also 3D Printing

Also called 3D printing. see also 3D Printing

Axis Binding

A problem associated with the X-, Y-, or Z-axis on a printer, in which the axis is unable to move freely or perform a given movement.

Belt

Toothed gear belt that is used to transfer movement.

Bridging

Bridging occurs in a 3D print when filament is extended across an open area without supports. The distance a print can bridge is determined by the hardware capabilities of the printer and the slicer settings.

Brim

A platform adhesion option whose function is to reduce shrinkage of bottom print layers or better adhere a low surface area object by providing a larger base platform.

Build Plate

The surface where the printer deposits the materials used for printing. Also known as the Print Bed. see also Print Bed

Bowden Extruder

An extruder assembly used pushing filament that uses a tube to feed the filament from the motor to heated areas. This type of extruder assembly reduces heat transfer to filament pressure point, thereby reducing plastic buildup and clogs.

This type of extruder assembly reduces heat transfer to filament pressure point, thereby reducing plastic buildup and clogs.

CAD

Computer Aided Design or CAD is the process of digitally designing 3D models. see also CAM

Calibration

The act or process of adjusting a device or instrument to perform correctly or more efficiently.

CAM

Computer Aided Manufacturing or CAM is the process using digital programs and/or CAD to physically manufacture objects through additive or subtractive manufacturing.

Carriage

The moving assembly that holds the nozzle and hot end of the of the extruder.

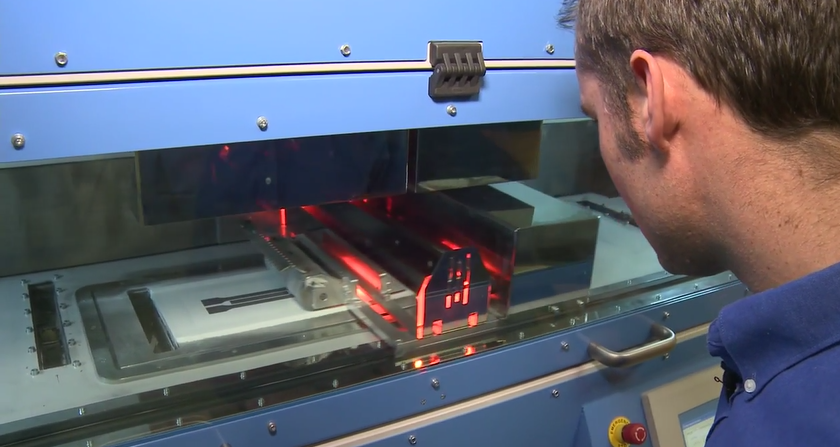

CNC

A Computer Numerical Control machine, or CNC, a a machine that uses subtractive manufacturing to create 3D objects. see also Subtractive Manufacturing

Control Screen

LCD screen that displays information and provides an interface to select settings and manipulate the printer.

Cooldown

The process of cooling down the hot end. Cooldown occurs automatically after a print is finished, or can be done manually after changing filament to to prevent filament baking and clogs. Can be controlled using the Control Screen or turning off the 3D printer.

Cura

A 3D printer slicing software. Utilized to transform 3D models into a X, Y, and Z coordinate language called g-code in “.gcode” format.

Endstop

Mechanical switches that indicate where the “home” or “zero” position is on each print axis. see also Limit Switch

Extrude

The act of dispensing build material onto the build platform through a small nozzle commonly referred to as a "hot end.”

Extruder

The assembly that handles feeding and extruding filament during a print. The extruder has two parts: the stepper motor and feeding system that pushes the material into the printer, and a hot end that heats and extrudes the material through a nozzle onto the build surface.

Extruder Fan

Fan that cools the heat sink of the extruder.

Extruder Motor

Stepper motor of the extruder assembly.

Extruder Nozzle

A brass or steel funnel-shaped die through which melted plastic is extruded.

Extruder Release Lever

The trigger lever that applies pressure to the extruder gear, which forces filament to flow into the Bowden tube of the extruder to the hot end.

Extrusion Multiplier

A percentage value associated with the flow rate of plastic extrusion. The flow rate can be manipulated by adjusting this multiplier.

Filament

Typically a thermoplastic formed into a continuous wire and wound onto a spool so it is compatible with a 3D printer’s extrusion system. see also ABS, PLA, TPU

Filament Diameter

The size designation of a roll of filament. Usually 1.75mm or 3mm/2.85mm (3mm and 2. 85mm are in the same size filament category are used interchangeably in 3mm and 2.85mm material extrusion 3D printers).

85mm are in the same size filament category are used interchangeably in 3mm and 2.85mm material extrusion 3D printers).

Fill

The area within a 3D-printed object that connects the top, bottom, and side layers. See also Infill

Fill Density

A percentage value that determines how much of the interior volume of a 3D-printed object is filled with material. This value can range from 0–100%, recommended is 5–25%.

Flow

The action of filament moving in a steady continuous stream. see also Extrusion Multiplier

Fused Deposition Modeling (FDM)

FDM is another name for material extrusion and FFF. It is a trade name created by Stratasys, the company that invented and first commercialized the material extrusion process. see also FFF, Material Extrusion

Fused Filament Fabrication (FFF)

FFF is another name for material extrusion and FDM. see also FDM, Material Extrusion

Gantry

The part of the extruder assembly and X-axis motor that moves up and down on the Z-axis of a 3D printer. see also Z-Axis Carriage

see also Z-Axis Carriage

G-code

Coding language that the 3D printer understands. It is used to transmit instructions to a 3D printer’s control system to tell the printer how to print the 3D model. see also Cura, Slicer

Heated Build Plate / Heated Print Bed

The heated surface where the printer deposits the material used for printing. A heated bed can help reduce warping on large prints and help adhere parts better.

HIPS

High Impact Polystyrene (HIPS) is a thermoplastic used as a 3D printing material that can be dissolved using limonene and therefore used for dissolvable supports on delicate prints.

Hot End

The heated portion of the extruder assembly that includes the nozzle and heating block.

Infill

The area within a 3D-printed object that connects top, bottom, and side layers. This creates a rigid structure and determines print durability.

Kapton Tape

Heat-resistant polyimide adhesive tape typically used to secure wiring and insulate the hot end of the extruder.

Layer

Extruded plastic of a closed loop, represented as a two-dimensional drawing on the X-Y plane. When replicated over again in the Z direction, it produces a 3D object or multi-layered X-Y drawing. see also Layer Height

Layer Height

Utmost determinant of quality for 3D printing, it defines the distance between lines of extruded plastic in the Z-direction. Material extrusion 3D printers typically print layers between 0.1mm and 0.3mm high. A lower layer height translates to a smoother, higher quality print. A higher layer height translates into a faster, low quality print.

Limit Switch

Mechanical switch that indicates where the “home” or “zero” position is on each print axis. see also Endstop

Material Extrusion

A 3D printing process that dispenses material through a nozzle or orifice. Also known as FFF or FDM. see also FDM, FFF

Also known as FFF or FDM. see also FDM, FFF

Minimal Layer Time

The least amount of time required of the printer to maintain action on any layer of a printed object for the filament to sufficiently cool before fusing a layer on top if it.

Mesh

A collection of polygons attached by edges and vertices that makes up a net-like surface area in CAD.

Motor

In 3D printing, the stepper motor that produces precise movement of the extruder, X-, Y-, or Z-axis. see also Stepper

Nozzle

A brass or steel funnel-shaped die through which melted plastic is extruded. see also Extruder Nozzle, Hot End

OBJ

OBJ stands for Object File, an alternative to the STL file format. OBJ (.obj) files store object exterior pattern and color.

PLA

Polylactic Acid (PLA) is a biodegradable thermoplastic polymer derived from the starch in plants (normally corn) that is used for 3D printing.

Perimeter

A continuous line forming the boundary of a closed geometric figure. In 3D printing, the perimeter is created by the edges of every layer. see also Shell

Preheat

Heating prior to using the device or tool. In 3D printing, the nozzle needs to be preheated before printing or for loading and unloading filament.

Print Bed

The surface where the printer deposits the materials used for printing. Also known as the build plate. see also Build Plate

Print Speed

The rate at which a 3D printer is capable of moving while extruding plastic. A print speed of 50mm/s will be successful on most FDM printers. A print speed of 20–30mm/s will produce higher quality prints.

Print Quality

Refers to the quality of the print and is determined by many factors including mechanical capabilities of the printer, slicer used, layer height, print speed, support, and print orientation.

Printing Temperature

The temperature of the hot end at which the filament is melted and extruded.

PVA

Polyvinyl Alcohol (PVA) is a water soluble plastic that is a common ingredient in standard wood glue. It can be used in 3D printing to print dissolvable supports.

Raft

A platform adhesion option in which several layers of printed material are deposited on the build surface to smooth out any irregularities in the build surface and help prevent warping in the model being printed on top of the raft. A raft also helps with bed adhesion of delicate models.

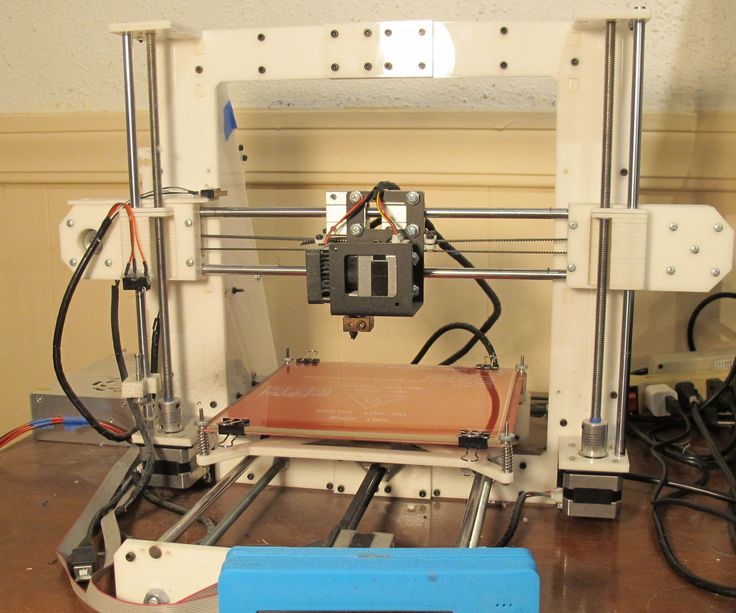

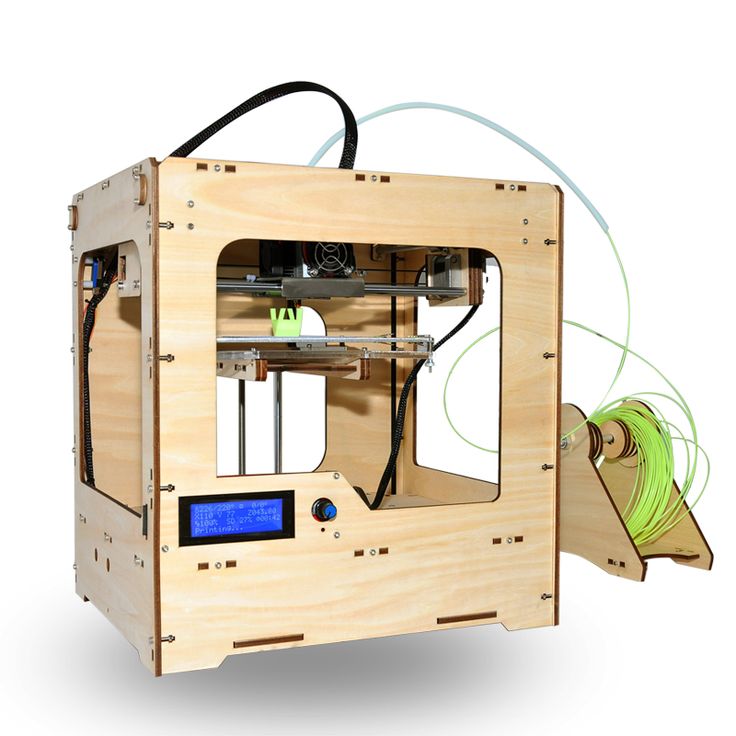

RepRap

An open source 3D printing project, started in 2005, to create the best desktop printers and to make them capable of duplicating themselves.

Repetier Host

An open source slicer program, used for the preparation of STL files prior to 3D printing. Allows manipulation of files prior to printing; rotating, scaling, and duplication.

Resolution

The smallest movement a printer’s extruder can make within a single X-Y layer. Often indicates the produced quality of a printed model.

Retraction

Backwards movement of an extruder motor to reduce the amount of material stringing or oozing.

SD Card

A non-volatile memory card for use in portable devices to transfer information, such as .gcode to 3D printers.

Seam

The point at which two layers of 3D-printed material connect.

Shell

The sidewalls of a 3D printed model, created by the exterior edges of every layer. see also Perimeter

Shell Thickness

The total width of an outside wall of a 3D-printed part. Shell thickness should be a multiple of nozzle size. Two shells is typically best. An increased number of shells will lead to a stronger model. see also Shell

Skirt

A platform adhesion option that extrudes an offset outline of the model on the first layer of the print. The skirt helps to remove unwanted colors and build pressure for material extrusion. It also checks the accuracy of bed leveling.

The skirt helps to remove unwanted colors and build pressure for material extrusion. It also checks the accuracy of bed leveling.

Slice

The action of changing a model file (STL, OBJ, etc.) into a a G-code file. The coordinate type can vary depending upon setting selection. The most common type uses cartesian coordinates on an XYZ plane. see also Slicer

Slicer

A type of program, such as Cura or Repetier Host, that allows manipulation of a 3D model and converts the file type into a coordinate system (usually .gcode) the printer follows to create a model. see also Cura, Repetier Host

Soft Pull/Soft Removal

The process of heating filament to the phase transition temperature (solid to liquid) and removing it from the extruder assembly. The process helps to remove unwanted material and can assist in the removal of nozzle blockage. NWA3D recommends to always remove filament using the soft pull method as preventive maintenance for your 3D printer.

Stepper/Stepper Motor

An electric motor that moves in discrete movements, or steps, to allow more precise regulation of its movement. see also Motor

STL

The STL file format (STL stands for stereolithography) is the recommended file format for 3D models for 3D printing. The filetype contains the best mesh for solid 3D-printed objects. see also Mesh

Support

Additional removable structures that are printed to support overhangs or other parts of a model that do not make contact with the build plate during printing.

Subtractive Manufacturing

Manufacturing techniques that remove material to create an object. Common types are CNC routing and laser cutting.

Tension Arm

Arm that presses the filament into the gear of the extruder motor. see also Extruder Lever

TPU

Thermoplastic urethane (TPU) is a semi-flexible plastic that is used in 3D printing.

Travel Speed

The rate at which the nozzle assembly will move to a new position when not extruding.

USB Connection

USB, short for Universal Serial Bus, is a connection type to send files from a slicer on a computer to a 3D printer via a USB cable.

Viscosity

A measure of a fluid’s resistance to flow. The higher the viscosity, the more resistant the fluid is to flowing.

Vitamin

A part for a 3D printer or 3D printing project that isn’t 3D printable.

X-Axis

The principal or horizontal axis of a system of coordinates.

Y-Axis

The secondary or vertical axis of a system of coordinates.

Z-Axis

The axis in three-dimensional Cartesian coordinates which is usually oriented vertically.

Z-Lift

The process that a printer uses to lift the hot end upward prior to retraction and moving.

Z-Axis Carriage

The part of the extruder assembly and X-Axis motor that moves up and down on the Z-Axis of a 3D printer. see also Gantry

see also Gantry

3D printing glossary for beginners

Brim: a series of attached/concentric layers all in contact with the bed and your piece to maximize the grip of your piece to the bed. Especially useful for pieces with "islands" (the end points of contact with the bed. For example, if you print the model a chair on your printer). In the image on the opposite side, the Brim is shown in green.

Extruder gauge: also called an extruder nozzle gauge, it is the print head diameter (extruder). It is usually 0.35 mm or 0.4 mm by default. Some 3D printers offer packs of nozzles with different diameters, such as the Olsson Pack for Ultimaker, with nozzles from 0.15 mm (precise printing) to 1 mm (fast printing).

CAD:Computer Aided Design refers to all graphical modelling techniques and software making it possible to virtually test and make manufactured goods.

SD card: SD cards are memory cards for storing and transferring all kinds of computer files.

External dimensions: the external dimensions of your device (3D printer, scanner, etc.).

Extruder: A special term used in FDM 3D printing (fused deposition). It's the print head that the melted plastic flows out of (just like ink in a conventional printer).

STL file: 3D modelling file format commonly used for 3D printing. All the data from your 3D model enabling your printer to understand where and how to lay down the layers of material are recorded in the STL file.

3D filament: this is the consumable of 3D printing called FDM, just like the ink cartridge for a conventional/2D printer. It is usually a coil of filament material (generally plastic based) that is progressively melted through the extruder to model, layer by layer, the desired object.

Gcode: file format containing the 3D model (usually an STL file) as well as the instructions so the 3D printer can print it (travel, speed, layer height, etc. ). This is the final format to launch a 3D print.

). This is the final format to launch a 3D print.

Firmware: Micro software integrated into the machine. Manages the 3D printer's various native functions.

Fused Deposition Modelling (FDM): this is an additive manufacturing technology. That is to say, the process is the deposition of material layer by layer (additive). This is the technology used by most desktop 3D printers as it was the first to become more accessible.

Layer thickness / Layer height: Certainly one of the most watched criteria by makers. This is the fineness of your 3D printer's printed object. The 3D printing is done by successively depositing superimposed layers of material, and the layer thickness (or layer height) refers to the thickness of each layer of deposited material. A succession of very thin layers (0.02 mm, or 20 microns, for example) provides a perfectly smooth rendering your final piece. On the other hand, your print will last longer than if you print with layers of 200 microns, with a final result that's more 'rough'.

Hollow : means a piece whose degree of filling (Infill) is 0%. The printed piece is, therefore, only made of the walls, and the interior is empty.

Islands: small points of contact of a piece with the bed. For example, if you print a chair standing on your bed, the legs of the chairs are islands. These islands are likely to come unstuck from the bed more easily. You can counteract this effect by printing a Brim.

3D printer: The 3D printer is the machine intended to make three dimensional pieces by depositing successive layers of melted material (plastic, metal, food, etc.). 3D (or "three-dimensional") printers, therefore, make it possible to produce real objects.

Infill: Expressed in percentage or decimals (0 to 1) depending on the software, the "Infill" option is the fill rate of the inside of your 3D creation. 10% Infill means the inside your piece will be 10% material and 90% empty. 100% Infill refers to a completely solid piece.

Maker (a): An English term meaning "one who makes", it is commonly used abroad for a person who designs 3D objects using a 3D printer.

Micron: reference unit of length when talking about printing accuracy for a 3D printer. 1 micron (1µ) = 0.001 millimetre. For example, an accuracy of 100 microns is equal to 0.1 mm (one tenth of a millimetre).

3D Model: the 3D model is the three dimensional "drawing" of your object to be printed. Generally, it's sent to the 3D printer as an STL file. The 3D model, when imported and then processed through print software comes out in Gcode format. Therefore, in its memory, it contains all the necessary characteristics for an object so that it is understood and printed by the 3D printer.

Offset: voluntary forced displacement of a measurement. Applying a 1 mm offset to Z axis, for example, through the printer software, means that when printing starts, the bed will be shifted 1 mm from the nozzle throughout printing.

Open Source: The open source, or "open source code", designation applies to software and products whose licence meets specific criteria established by the Open Source Initiative, that is to say, free redistribution, access to the source code (the case of software) and the possibility of creating derivative works.

Printing bed: this is the bed on which the melted plastic will be deposited, layer by layer, in order to create the final object to be printed.

Bridge: area of a suspended 3D printed piece, cantilevered, for which no support is generated.

Pre-calibrated: a pre-calibrated device is a device already set according to pre-established reference data. In the case of a 3D printer, this means that the basic settings are already made, such as: the position of the extruder, axes settings, belt tension, horizontality of the bed, etc.).

Raft: These are the first layers deposited on the bed, on which your printed object will be deposited. They are thicker and provide better adhesion to the bed for your piece. Once printing is complete, the raft is removed from your final print.

They are thicker and provide better adhesion to the bed for your piece. Once printing is complete, the raft is removed from your final print.

RepRap: RepRap is the abbreviation for "replicating rapid prototyper". It's an initiative to develop an open source 3D printer that can print its own components and, consequently, can largely self-replicate. The advantage being building a low-cost 3D printer.

Retraction: the fact that the extruder "swallows" the filament, usually when going from point A to point B of your piece without extruding. That makes it possible to avoid "stringing" (the appearance of unwanted strings of material between point A and point B).

3D Scanner:3D scanners allow you to model an object by scanning it with lasers; that is to say, to record all its features, and make a 3D drawing/model of it. This is to transmit the scanned data (the 3D model) to a 3D printer, and reproduce the object at will.

Skirt: initial deposit of material around your piece to be printed. The skirt is deposited before printing your piece in order to ensure regular, clean flow when you 3D print starts.

The skirt is deposited before printing your piece in order to ensure regular, clean flow when you 3D print starts.

SLA: refers to stereolithography, a 3D printing technology operating on the principle of the photopolymerisation of liquid resins. Backed by the Manufacturer Formlabs, it's the second technology to become accessible after FDM. This technology makes highly precise 3D printing with an exceptional level of detail possible because it virtually eliminates the stair-stepping effect of FDM due to solidification by an ultra-precise laser.

Supports: supports are additions of soluble materials making it possible to print cantilevered sections on your pieces. In the case of a figurine with outstretched arms, the first layer deposited to form the arms rests on nothing if the supports are absent; therefore, your extruder will deposit the filament into empty space. From a 30° inclination, supports are usually required. Supports are made of PVA (water soluble and recommended for PLA) and HIPS (soluble in D-limonene and recommended with ABS). Find an example of a support on the HIPS 3D filament sheet.

Find an example of a support on the HIPS 3D filament sheet.

Shells: the "number of shells" refers to the thickness of the outer part of your piece. The minimum and standard for this measurement is 1. Each "shell" that you add adds an extra layer to the perimeter of your piece. So, if you specify "shells = 2" in your software, you will get a thickness of 3 concentric circles. These additional layers are added inside your piece so that the external dimensions do not vary.

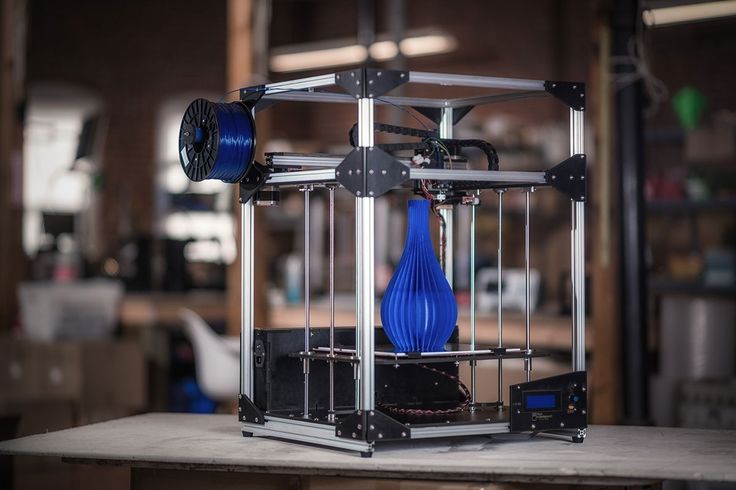

Vase mode: print mode in which the Z axis moves with snap action to the end of each layer. It moves progressively throughout printing; this is also called a dynamic "Z". Printing in vase mode is very restrictive as regards the characteristics of the model to be printed but generally produces cleaner prints.

Print speed: print speed is a highly regarded feature when buying a 3D printer. Indeed, designing a plastic part takes time, and the possibility of reducing its print time from 6 hours to 4 hours makes a difference. Current printers have print speeds from 20 mm/sec to 120 mm/sec as a standard speed. Some machines, like the Ultimaker 2+ can even print up to 300 mm/sec (however, high-quality results cannot be expected at this speed). Apart from the machine itself, print speed is particularly affected by the complexity of the piece or the desired accuracy.

Current printers have print speeds from 20 mm/sec to 120 mm/sec as a standard speed. Some machines, like the Ultimaker 2+ can even print up to 300 mm/sec (however, high-quality results cannot be expected at this speed). Apart from the machine itself, print speed is particularly affected by the complexity of the piece or the desired accuracy.

Print volume: often called "length x width x height" measurements (or LxWxH), the print volume is the maximum object volume/size that can be printed by the 3D printer. If a machine's maximum print volume is 25 x 20 x 18 cm, you can print objects with a maximum size of 25 cm in length, 20 cm in width and 18 cm in height. If the object is larger, nothing prevents you from printing it in several parts.

Back to the list of 3D guides

3D Printing Terms and Definitions – Volume

In this article I will explain the basic terms and concepts used in 3D printing. I will fill in the content as questions arise, if you want me to add some term - write it on the forum or in the Facebook group

ABS (ABS)

for FDM printing. Oil refinery product. There are manufacturers of ABS thread in Ukraine, so this plastic is the most affordable both in price (from 7 USD/kg) and in quantity. This plastic is considered strong enough and can carry a decent mechanical load. ABS plastic is characterized by heat shrinkage - when it cools down, the layers shrink and “contract the model”, which can lead to the model peeling off the surface or “delamination”. A heated platform is recommended for good adhesion. You can use kapton tape coated with ABS - juice. You can also use Blue tape on printers that do not have a heated bed. To reduce the effect of delamination, it is necessary to reduce the temperature difference between the print and the environment surrounding the model. Soluble with acetone, ethyl acetate.

Oil refinery product. There are manufacturers of ABS thread in Ukraine, so this plastic is the most affordable both in price (from 7 USD/kg) and in quantity. This plastic is considered strong enough and can carry a decent mechanical load. ABS plastic is characterized by heat shrinkage - when it cools down, the layers shrink and “contract the model”, which can lead to the model peeling off the surface or “delamination”. A heated platform is recommended for good adhesion. You can use kapton tape coated with ABS - juice. You can also use Blue tape on printers that do not have a heated bed. To reduce the effect of delamination, it is necessary to reduce the temperature difference between the print and the environment surrounding the model. Soluble with acetone, ethyl acetate.

The temperature of the platform: 108-1150s

The temperature of the nozzle: 230-2450s

Punis: is needed when printing bridges and small parts

ABS Juice (ABS Juice)

Pouric solution, pouring solution, which is applied to the surface for better adhesion of the part. It is obtained by mixing ABS plastic with ethyl acetate in proportions of approximately 1 to 1 (in fact, everyone mixes a solution that is more convenient for him to work with). Apply to the surface with a napkin or spatula.

It is obtained by mixing ABS plastic with ethyl acetate in proportions of approximately 1 to 1 (in fact, everyone mixes a solution that is more convenient for him to work with). Apply to the surface with a napkin or spatula.

G-Code (G-code)

The vast majority of 3D printers are controlled by a special command language called G-code. Initially, this language was developed and standardized for the control of CNC machines. And since a 3D printer is essentially a kind of CNC machine, it was quite logical to “fit” it to these standards. However, the G-code may differ in different 3D printers (some commands may be missing or even have a different meaning). I think the most convenient G-code reference for 3D printer owners is RepRap's Wiki.

Bridge (Bridge)

Over-the-air printing without support, when a horizontal line is printed between 2 dots without any support. The printing of "bridges" depends on a large number of parameters, including: material, nozzle temperature, speed, medium temperature, forced cooling. A good indicator is the ability to print bridges up to 20mm without sagging. But there are cases that significantly exceed this figure, for example, here

A good indicator is the ability to print bridges up to 20mm without sagging. But there are cases that significantly exceed this figure, for example, here

PLA (PLA)

PLA (polylactide) is the second most popular plastic for FDM printing. It is made from corn or sugar cane and is therefore biodegradable. It becomes softer at a temperature of 60C, which makes it unsuitable for the manufacture of rubbing and heated parts. Nevertheless, it has a very big advantage over ABS plastics - there is practically no heat shrinkage, which allows you to print complex, large models without delamination. Soluble with dichloroethane. Hardens longer than ABS, so forced cooling is desirable.

The temperature of the platform: 60-700C

The temperature of the nozzle: 200-2100C

PUDIV: Preferably constant

Plant / Heated platform (Printing Bed / Heatbed)

000 the heated bed is the part of the printer where the “growing” of the model begins. Platforms are heated and non-heated. As a rule, the platform is heated to the glass transition temperature of the plastic: for ABS - 110 degrees, for PLA - 65-70 degrees. The advantage of a heated platform is that when printing with plastic with a high degree of heat shrinkage, heating the platform can reduce the temperature difference, thereby reducing the degree of shrinkage of the plastic, and also increase the adhesion force of the plastic to the platform. Therefore, it is highly desirable to use a heated bed when printing large nylon or ABS plastic models. The heated platform is usually covered with Kapton tape. Also, instead of Kapton, you can use frosted glass coated with ABS juice.

Platforms are heated and non-heated. As a rule, the platform is heated to the glass transition temperature of the plastic: for ABS - 110 degrees, for PLA - 65-70 degrees. The advantage of a heated platform is that when printing with plastic with a high degree of heat shrinkage, heating the platform can reduce the temperature difference, thereby reducing the degree of shrinkage of the plastic, and also increase the adhesion force of the plastic to the platform. Therefore, it is highly desirable to use a heated bed when printing large nylon or ABS plastic models. The heated platform is usually covered with Kapton tape. Also, instead of Kapton, you can use frosted glass coated with ABS juice.

Recently, alternative self-adhesive surfaces have appeared from FlashForge, Haftfolie, GeckoTek and others. However, reviews about them vary greatly, so it is still difficult to draw an unambiguous conclusion on them. The press without heating is possible on plexiglas, acryle. This method is well suited for printing PLA plastic, which has a low shrink ratio. In this case, the platform does not need to be heated. It is also possible to print on plexiglass with ABS plastic, but small details. It should be borne in mind that if the thickness of the plexiglass is too small - less than 3 mm - it can deform when heated.

In this case, the platform does not need to be heated. It is also possible to print on plexiglass with ABS plastic, but small details. It should be borne in mind that if the thickness of the plexiglass is too small - less than 3 mm - it can deform when heated.

Platform made of glass, plexiglass, acrylic coated with Kapton must be degreased with acetone (ethyl acetate) before printing.

Support

Support - Additional material that supports horizontal planes while printing and prevents them from falling off. Most 3D printers can print angles up to 45 degrees without any support.

All support is usually removed later (if this material is not inside the model). If your printer has more than one nozzle, you can print the support in a different color (to make it easier to spot), or with a special material.

There are 2 soluble support materials: PVA - dissolves in water, temperature properties are close to PLA, so it is usually used with it. HIPS is close to ABS in terms of temperature properties - it dissolves in limonene

Slicer (Slicer)

Slicer is a program that converts a 3D model into a G-code (set of commands) for a 3D printer. In fact, a slicer (from the English slice - cut) “cuts” the model into horizontal layers and draws a slice of the figure in each layer with G-code commands. Also, data on nozzle temperatures, heated surface, etc. are added to the G-code. All these parameters can be set in the slicer settings. There are many slicers with different interfaces, incl. including host controller. Our workshop uses free Slic3r and Cura. There are also free slicers for example: Kisslicer, Skeinforge.

In fact, a slicer (from the English slice - cut) “cuts” the model into horizontal layers and draws a slice of the figure in each layer with G-code commands. Also, data on nozzle temperatures, heated surface, etc. are added to the G-code. All these parameters can be set in the slicer settings. There are many slicers with different interfaces, incl. including host controller. Our workshop uses free Slic3r and Cura. There are also free slicers for example: Kisslicer, Skeinforge.

Dichloroethane

Dichloroethane is a clear, colorless liquid with an odor of chloroform.

Unlike ethyl acetate, dichloroethane can also dissolve PLA plastic, so it is used for surface smoothing and for bonding finished products made of both PLA and ABS plastic. To apply the solvent, you can use a non-synthetic brush (it can dissolve).

We want to note right away that dichloroethane is very toxic, with a pungent odor, when using it, you should use a respirator and thoroughly ventilate the room.

Ethyl acetate, acetone

Acetone was originally used as a solvent for ABS. But since in Ukraine this solvent is sold strictly by prescription, it can be replaced with ethyl acetate. It is a colorless volatile liquid with a pungent odor.

Since ethyl acetate dissolves ABS plastic, it can be used to smooth or glue model surfaces. If you need to smooth out individual parts, use a brush (not synthetic - it can dissolve). There is also a method of smoothing with acetone / ethyl acetate pairs - called "Bath".

Ethyl acetate can be used to clean the build plate glass. It degreases, cleans and allows better adhesion of PLA and ABS plastics. To do this, soak a cotton pad (not cotton wool!!!) with a solvent and wipe the glass of the platform.

Ethyl acetate is available from almost any hardware store. We recommend using a respirator when working with it. Also keep in mind that ethyl acetate vapors, like the solvent itself, are highly flammable.

Host controller

Host (Host controller) - a program that allows you to control a 3D printer. There are many different programs that work on different operating systems, some are cross-platform. As a rule, the program has buttons for controlling the movement of the 3D printer head, platform and nozzle temperature controls, and a preview of the model, but the main task of the host is to send the model to the 3D printer in the form of a G-code. Some hosts include basic elements for converting/restoring 3D models. Usually, the host always goes in conjunction with the slicer, in some (for example, Cura) it is integrated, in others, you can configure communication with an external slicer module. Among the free hosts, Cura, Pronterface, Repetier host, Mattercontrol have proven themselves well. Also noteworthy is the paid all-in-one version of Simplify 3D and the basic host controller for android devices - gCodePrintr.

There are many different programs that work on different operating systems, some are cross-platform. As a rule, the program has buttons for controlling the movement of the 3D printer head, platform and nozzle temperature controls, and a preview of the model, but the main task of the host is to send the model to the 3D printer in the form of a G-code. Some hosts include basic elements for converting/restoring 3D models. Usually, the host always goes in conjunction with the slicer, in some (for example, Cura) it is integrated, in others, you can configure communication with an external slicer module. Among the free hosts, Cura, Pronterface, Repetier host, Mattercontrol have proven themselves well. Also noteworthy is the paid all-in-one version of Simplify 3D and the basic host controller for android devices - gCodePrintr.

Nozzle

The 3d printer nozzle is part of the print head. It is from it that the molten plastic comes out. There are various nozzle sizes from 0. 2 mm or more, depending on the media and desired print quality. The smaller the diameter of the nozzle opening, the better, but also slower printing. Nozzles with a diameter of 0.4 mm are widely used. A good nozzle should minimize the area of contact with the printed model, so they usually have a cone shape.

2 mm or more, depending on the media and desired print quality. The smaller the diameter of the nozzle opening, the better, but also slower printing. Nozzles with a diameter of 0.4 mm are widely used. A good nozzle should minimize the area of contact with the printed model, so they usually have a cone shape.

Terminology/slang in 3D printing in Russian

Hi all. I want to share my experience of my research in terms of 3D printed terminology. I myself am still a beginner in both 3D modeling and 3D printing, and at the beginning of studying the issue, I came across an abundance of terms unknown to me before. In order to ease the thorny path of the pioneers of 3D printing, I decided to create a list of terms / slang with a little interpretation (I took something from this site, something from WIKI, I interpreted something myself). I propose, within the framework of this entry, to limit ourselves to the FDM type of printing and not to interfere with the rest. I hope you throw those 9 in the comments0% of the article that I missed, well, correct me if I made a mistake somewhere.

I hope you throw those 9 in the comments0% of the article that I missed, well, correct me if I made a mistake somewhere.

The 3D Printer is a peripheral that uses a layer-by-layer method to create a physical object from a 3D digital model.

FDM (Fused deposition modeling)

Filament (plastic rod) (from English filament - thread) is a consumable used for printing on a 3D printer. It is a plastic thread with a cross section of 1.75 or 3 mm.

Extruder (from extrude - extrude) - a device that feeds a plastic rod into a heating block, in which a melt occurs under the influence of temperature and is squeezed out through a nozzle. A tube of toothpaste, a glue gun, a silicone sealant syringe work in a similar way. In a broad sense, this is a block consisting of a cold and a hot end.

Hot end (hot-end) — includes in the classical sense a nozzle, a heating block, a thermal barrier and an extruder heat sink. It is inside this block that the filament melts and is molded by welding.

It is inside this block that the filament melts and is molded by welding.

Cold end (cold-end) is a device responsible for feeding the filament to the hot end, in the classical sense it consists of a feed gear, a pressure roller and a stepper motor. Often an intermediate reduction gear is used between the feed gear and the stepper motor to improve the accuracy of material feeding when printing thin layers or when printing at low speed.

Nozzle (nozzle) — metal, ceramic or ruby hairpin with a longitudinal hole, this element is responsible for the shape and size of the extrusion melt at the outlet of the extruder.

Heating block - a block consisting of a heater (heater), thermistor (thermocouple, temperature sensor) and the block itself, which depletes these elements in itself.

Extruder heater (extruder heater) is an element that converts electric current into thermal energy and is responsible for heating the filament melt chamber inside the heating block.

Thermistor (thermocouple, temperature sensor) - takes temperature readings to control the voltage supply to the heating element to hold the temperature within the specified intervals. It is used both in an extruder and in a hot table.

Thermal barrier - a device whose task is to reduce the distance between the two phases of plastic - liquid and solid, in other words, does not allow the plastic to melt above what is needed, usually connects the heating block and the extruder radiator.

The extruder heatsink is a device designed to remove excess heat from the thermal barrier, usually through an air-cooled jacket, but liquid-cooled models are also available.

Work table (print bed, platform, bed) - a platform on which the material is directly melted from the extruder. The surface of the table can be either perfectly smooth or perforated / corrugated in both cases, it is required to improve adhesion with the print object.

Hot bed (hotbed) - the same as the work table, only with the heating function, which allows to reduce the warping of the deposited model, due to the gradual decrease in the temperature of the object. It also improves adhesion with the deposited object to the platform.

The stepper motor is a multi-winding brushless synchronous motor in which a current applied to one of the stator windings causes the rotor to lock. Sequential activation of windings of the motor causes discrete angular movements (steps) of the rotor.

Driver - microcircuit, the purpose of which is to convert the commands of the stepper motor controller into pulses applied to the windings of the Stepper motor and amplify them.

Direct Feed Extruder (direct) is a type of extruder where the cold end is located immediately before the hot end. Used for printing flexible plastics, rubber. The main disadvantage of this design is a lot of weight.

Bowden extruder ('Bowden extruder', Bowden extruder) is an extruder whose filament supply unit and nozzle are spaced apart: the cold end is rigidly fixed to the frame of the 3D printer, and the hot end is located on the movable print head. The filament, in this case, is fed into the nozzle through a long Teflon tube. Used for printing with rigid/elastic plastics.

The filament, in this case, is fed into the nozzle through a long Teflon tube. Used for printing with rigid/elastic plastics.

End switch - a sensor responsible for finding the carriage in the dimensions of the printer structure, in other words, limiters at the ends of the axles. They are created both on button sensors and on optical or based on the Hall sensor. When this sensor is triggered, the printer control board resets the position of the carriage, and then counts the position from this starting point.

Slicer - software that converts a 3d model (usually from STL format) into gcode with specific print settings and for a specific material and printer.

Gcode ( G-code) - conditional naming of the programming language (markup) of devices with numerical control (CNC).

Retract - reverse filament withdrawal from the hot end, used to prevent plastic melt from flowing out of the nozzle at the moments of idle movement of the extruder over the model to be welded.

Raft (raft, raft) - horizontal filament mesh located under the model. The rafts are designed to increase the level of adhesion, and level out the unevenness of the bed and poor calibration of the extruder relative to the table.

Brim (border) - a skirt around the object of printing associated with the object itself, used to improve adhesion and entrainment of the plane of contact with the bed.

Support - additional printing elements not part of the model, designed to support overhanging elements. The printer simply cannot print through the air, it needs a base where to fuse the material.

Adhesion (from Latin adhaesio - sticking) in physics - adhesion of surfaces of dissimilar solid and / or liquid bodies.

Delamination (stratification) - the term is borrowed from biology, simply splitting the cell into two layers, in 3D printing it means both peeling off the part from the bed and splitting the print object itself into layers due to warping of the object.

Juice (ABS Juice) - ABS solution in acetone with a consistency similar to baked milk, used to improve the adhesion of the printed object to the crib.

Post-processing - model processing after printing, sanding, heat treatment, chemical treatment, painting, gluing, etc.

Acetone (Dichloromethane, Dichloroethane) bath - a method of post-processing of the print object, in which the product is placed in an environment of saturated vapors of a particular chemical compound for a smooth effect on the model, after which the model changes its properties. Acetone bath for ABS makes the part smooth, glossy. The dichloromethane bath for PLA turns it into a kind of flex/rubber.

Hygroscopicity (from other Greek ὑγρός - wet and σκοπέω - observe) - the ability of some substances to absorb water vapor from the air, in our case, the ability of the filament to absorb moisture from the environment.

Drying - the process of drying 'raw' plastic, printing with raw plastic is difficult due to the water boiling inside the material and foaming as it exits the nozzle.