3D printer diy best

The 10 Best DIY 3D Printer Kits 2022 (Starting at $150!)

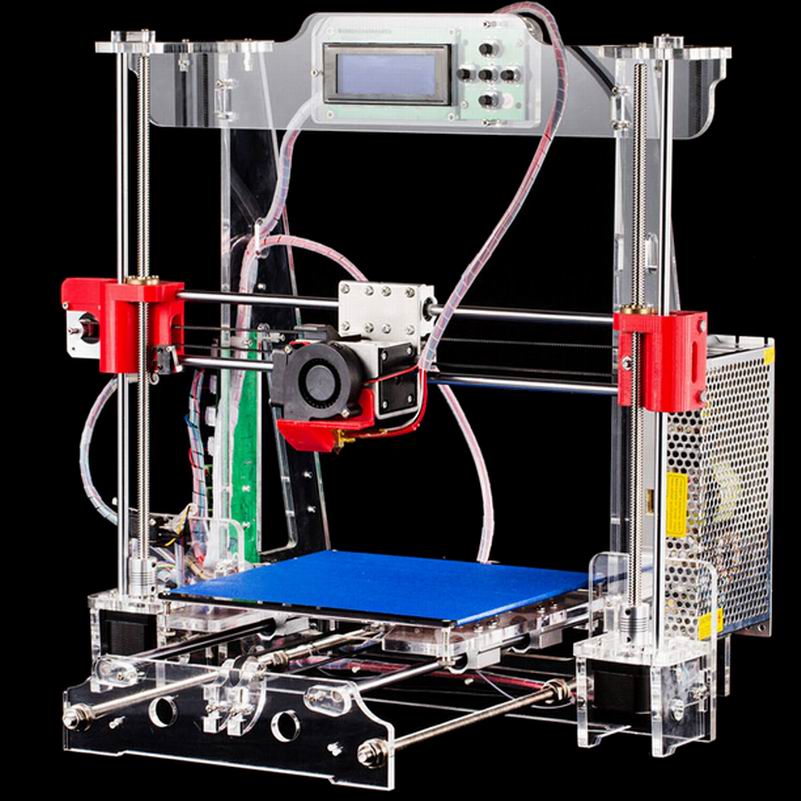

Increasingly, makers are turning away from desktop FDM 3D printers, preferring to buy a cheap 3D printer kit and build their own DIY 3D printer from scratch. Some of these are RepRap 3D printer kits, and some are specially designed kits.

The 3D printer kit revolution has reduced prices, led to a number of key breakthroughs, and has made 3D printing more accessible than ever before.

These 3D printer kits can take just a few minutes to assemble, or take hours or even days. They can also vary greatly in price, print accuracy, maximum build and print speed. Some even use technologies other than fused deposition modeling — you can now buy DIY SLS 3D printers and SLA 3D printers.

| 3D printer kit name and brand | Build Volume (mm) | Price | Where to purchase for best price | Alternative Purchase Option |

|---|---|---|---|---|

| Creality Ender 3 | 220 x 220 x 250 | $189 | Creality Store here | Amazon here |

| Prusa Mini | 180 x 180 x 180 | $399 | Prusa Store here | |

| Creality Ender 3 V2 | 220 x 220 x 250 | $279 | Creality Store here | Amazon here |

| Creality Ender 5 | 220 x 220 x 300 | $349 | Amazon here | 3DJake UK & Europe |

| Flsun QQ-S | 255 x 255 x 360 | $369 | Amazon here | |

| Tronxy X5SA Pro | 330 x 330 x 400 | $399 | Amazon here | |

| Anycubic Vyper | 245 x 245 x 260 | $429 | Anycubic Store here | Amazon here |

| Creality CR-10 / V3 | 300 x 300 x 400 | $369 / $459 | Creality Store here | Amazon here |

| Prusa i3 MK3S | 250 x 210 x 210 | $749 / $999 | Kit available on Prusa store here | Fully assembled on Prusa store here |

| Peopoly Moai | 130 x 130 x 180 | $1,295 | Matterhackers here |

Advantages of DIY 3D printers

- Open source: Most homemade 3D printers are also open source 3D printers, meaning they can be tinkered with, upgraded, and modded freely with the creators’ permission.

Many Creality, Prusa and Anet printers are open source, as well as desktop 3D printers like BCN3D and Ultimaker printers.

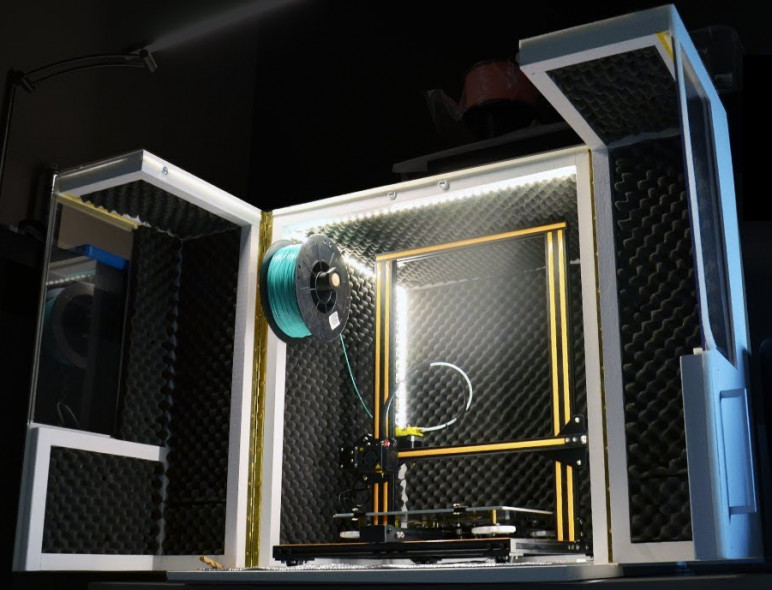

- Open build areas: 3D printer kits rarely feature closed chambers or enclosures as standard. This would affect the printing of filaments like Nylon or PEEK, but is less of an issue for standard filaments like PLA or PETG.

- Easily upgradable parts: DIY 3D printer owners are frequently switching out parts, such as nozzles, hot ends and extruders for better quality parts.

- Lower price: For the quality and size, you get a better deal if you build your own 3D printer.

- Larger build volume: The open build area means that you can have a larger 3D printer build area for the same size, neglecting the need for an enclosing frame. Therefore, low cost kits like the Creality CR-10 can have huge build volumes.

Build your own 3D printer: what makes a good DIY 3D printer?

We used several criteria to determine which 3D printer kit made it into our ranking:

- Cheap DIY 3D printer kits: We only included FDM 3D printer kits under $1,500.

The printers are listed in price order, cheapest first.

The printers are listed in price order, cheapest first. - Print quality

- It it easy to build your own 3D printer: Not everyone is a technology wizard. Therefore, any kit that can be assembled quickly, easily, and is simple to operate, is at an advantage.

The best 3D printer kits

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

1. Creality Ender 3

- Price: $189 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

The original Ender 3 is still one of the most popular 3D printer kits in the world, more than three years after it was originally released. The low price, great build area, and reliability have cemented the Ender 3 as one of the best 3D printer kits around.

The reliability is a major selling point in such a cheap 3D printer kit. Whereas most DIY printers in this price range are plagued by issues caused by low-quality parts, the Ender 3 is dependable and consistent, partly due to its upgraded extruder to prevent clogging or poor extrusion.

The resume printing function is useful if you’re prone to power cuts or want to print for several days straight and don’t want to risk a huge ruined print, and the Ender 3 is fairly quick to assemble, and shouldn’t take more than an hour or so.

However, it doesn’t feature auto-leveling — you’ll need to install a BLTouch or similar kit for that.

2. Prusa Mini — Great Prusa 3D printer kit

- Price: $399 — Available on Prusa Store here

- Print volume: 180 x 180 x 180 mm

- Print speed: up to 200mm/s

The Mini 3D printer version of the wildly successful Prusa MK3S, the Mini retains the 0.05mm layer precision and can still calibrate itself, but costs less than half of the i3 MK3S. With the Mini, you can build your own 3D printer — and one with Prusa-level reliability! — for just $349.

It’s more compact, with a smaller build volume, and features removable spring steel sheets that make removing finished prints extremely easy — just flex the build plate and prints will come off with ease.

The extruder cannot reach the same temperatures during printing as the MK3S, though you can still print a number of tougher filaments like ABS, PETG, ASA and flexible filaments. The Mini retains the fast 200mm/s max printing speed, and can be upgraded to feature a filament sensor.

Overall, it’s another reliable 3D printer by the trusted Prusa brand who have proven over the years that their printers are some of the best 3D printer kits around. If you have the money, go for the MK3S, but for those on a budget, the Mini does a great job.

3. Creality Ender 3 V2 — Best DIY 3D Printer Under $300

- Price: $279 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

Building on the success of the Ender 3 and improving and fixing its few flaws, the Ender 3 V2, while the same size build volume, is a much enhanced DIY 3D printer.

The upgraded motherboard makes the printer quieter than ever, and the extra power makes for a much more stable and precise printing experience.

Read more: the quiet 3D printer buyer’s guide

The upgraded extruder is also a great touch. It’s easier to load and feed filament into via the rotary knob, ideal for PLA and flexible filaments. The large 4.3-inch screen makes the interface more intuitive, and the Ender 3 V2 is really easy to use overall.

Another extra is the carborundum glass platform, which can heat up faster than ever and improves adhesion so you can be sure of a great first layer. Overall, if you have the extra $100 to spare, consider going for the Ender 3 V2 over the original.

4. Creality Ender 5 — The Best DIY 3D printer under $500

- Price: $349 — Available on Amazon here / 3DJake UK & Europe here

- Print volume: 220 x 220 x 300 mm

Another Creality kit, the Ender 5 is another great 3D printer you can build at home. The Ender 5 is $100 more expensive, but boasts a number of improvements that make the extra money seem worth it.

Firstly, it can print taller prints than the Ender 3 — 300 mm high rather than 250 — important if you print tall structures like tall vases or monument 3D models. The structure is also stronger, having adopted a cube shape like the Tronxy X5SA which helps with stability, reducing vibrations or movements from external events, and improving part surface finish and quality.

The structure is also stronger, having adopted a cube shape like the Tronxy X5SA which helps with stability, reducing vibrations or movements from external events, and improving part surface finish and quality.

Moreover, the minimum layer height of 50 microns is extraordinary for such a cheap machine. Review after review repeats how crisp the surface finish of their prints look with the Ender 5, so it’s fair to say the Ender 5 is a smash hit.

- For an extra $50 you can upgrade to the Ender 5 Pro printer kit, at $399. It’s available to buy here.

Note: while the Ender 5 can be tweaked to increase print speed without a noticeable loss in print quality, we recommend you don’t get too extravagant with this. Stick with 60 mm/s or below for models with intricate parts — it’s worth a bit of extra printing time to guarantee crisp prints.

5. FLSUN QQ-S — Great Delta DIY 3D printer

- Price: $369 — Available on Amazon worldwide here

- Print volume: 255 x 255 x 360 mm

- Print speed: up to 300mm/s

One of the best DIY delta 3D printer machines out there, the Flsun QQ-S features notable improvements on the original Flsun QQ. It comes 90% assembled, so though technically still a 3D printer kit it will take under an hour to get up and running.

It comes 90% assembled, so though technically still a 3D printer kit it will take under an hour to get up and running.

- We were lucky enough to test the FLSUN QQ-S, make sure to also check out our FLSUN QQ-S review.

Not only does it have a fantastic build volume for the price — especially the ability to print tall parts! — but it also comes with an upgraded lattice glass print bed, allowing for faster heating up to 100C in under 5 minutes, less warping and better adhesion during 3D printing. This is perfect for materials such as ABS filament, which are known to warp significantly under the wrong conditions.

Another advantage that beginners will enjoy is that as delta 3D printers don’t move the print bed — the print head does all the moving — the printer only needs to be auto-leveled once. It comes with a titan extruder, and can print with common printing materials like PLA and ABS, PVA, and HIPS for supports, as well as wood-filled filaments and flexible filaments.

It’s accurate, too, able to print at up to 50 microns. Overall, it’s a fantastic delta 3D printer kit that prints accurately, and super fast — it even made it into our fastest 3D printer ranking. It’s also one of the easiest DIY 3D printers to build, coming almost fully assembled — you just need to attach the gears and rods to hold the structure up, and then attach the extruder and filament holder.

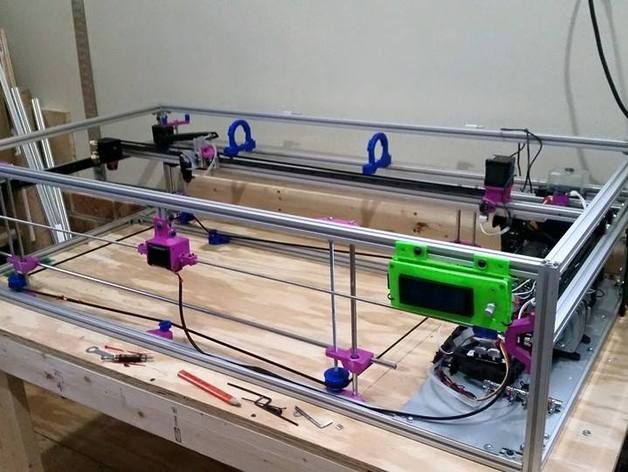

6. Tronxy X5SA Pro — Huge Self-Assemble 3D printer

- Company based: China

- Price: $399 — Available on Amazon here

- Build volume: 330 x 330 x 400 mm

Kit 3D printer kings Tronxy showed humility and dedication to improve the X5SA Pro, fixing a number of small issues that affected the original. The X5SA Pro addresses the X-axis issues and has made it more stable, and upgraded the materials forming the printer kit’s structure. Now on the X5SA Pro, most of the printer is made from aluminum and is heavier and more stable, reducing vibrations and generally improving print performance.

As for the X5SA’s specs, it’s a large 3D printer DIY kit with similar printing sizes to the Creality CR-10, and boasts a 330 x 330 x 400 build volume. It claims increased precision vs the original Tronxy X5SA, and has a maximum accuracy of 125 microns. It’s impressive, reliable and one of the best cheap 3D printers you can get with such a large size — so those with big 3D printing ideas will enjoy both this and the Creality CR-10.

It’ll probably take you around four hours to build this printer kit, but it’ll be worth it once you start printing!The Tronxy X5SA Pro’s cube shape offers stability benefits resulting in good surface finish.

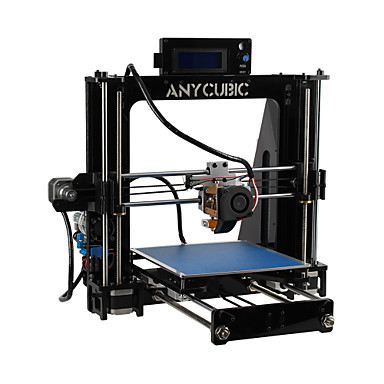

7. Anycubic Vyper

- Price: $429 — Available on Anycubic store here / Available on Amazon here

- Build volume: 245 x 245 x 245 mm

A key feature on the Anycubic Vyper missing from many printers in this price range is that the Vyper self-levels. This is a huge relief for busy makers who would rather not re-level their printer every few prints, and who just want to get to the fun part — printing! The 16-point bed leveling process accounts for differences between the nozzle and bed and can be done in just one click.

The 32-bit motherboard is beefed up compared to previous Anycubic 3D printer kits, offering silent printing and improved stability. We tested the Anycubic Vyper and found it to be consistent in printing, easy to operate with the 4.3-inch touchscreen, and it was incredibly easy to assemble — we built it in 10-15 minutes.

The new PEI spring steel magnetic print bed can be lifted off the platform easily for easy removal of your finished parts, and is designed to be scratch and heat resistant and to work well with standard filaments such as PLA, ABS, PETG, and TPU.

The Vyper also features an innovative new two-fan dual cooling system, cooling down parts quicker and enabling faster printing without causing errors — the Vyper can comfortably print at 100mm/s.

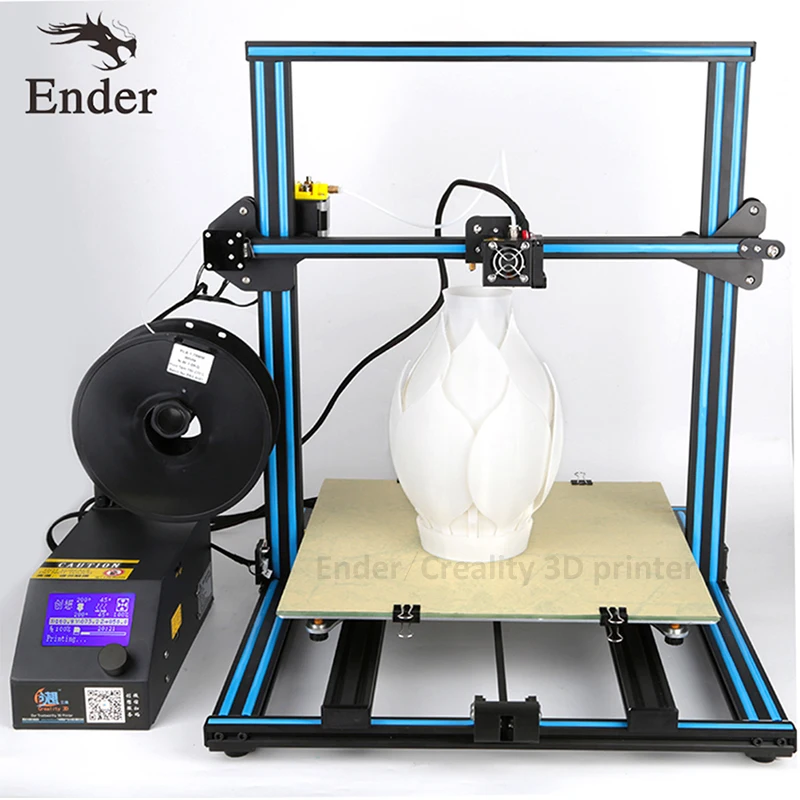

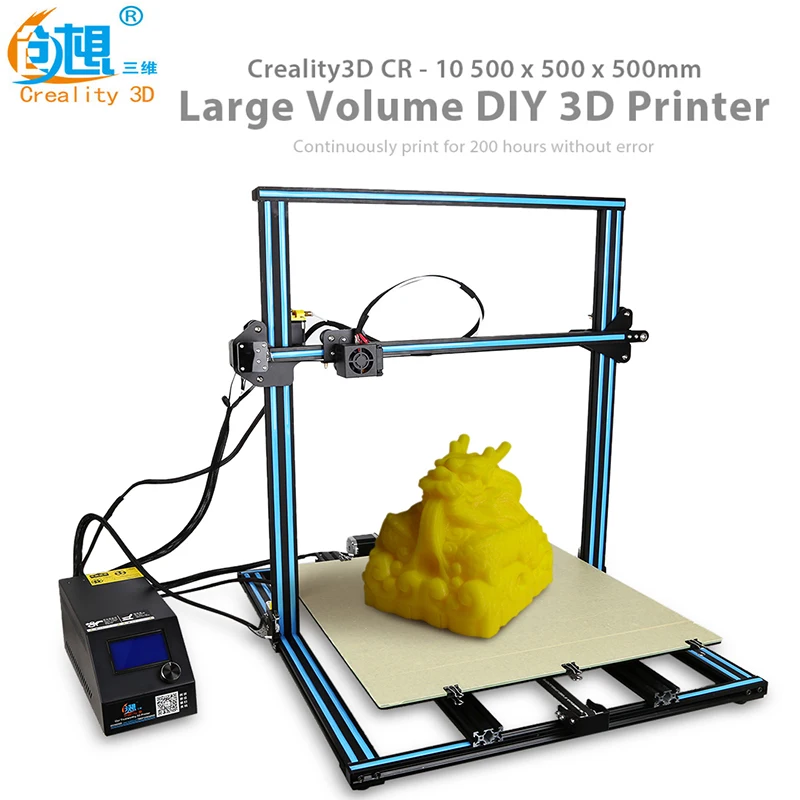

8. Creality CR-10 / V3

- Price: $369 / $459 — Available on Amazon here / Available on Creality Store here

- Print volume: 300 x 300 x 400 mm

The Creality CR-10 has a passionate group of supporters who hail it as the best DIY 3D printer kit in its price range. Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

- For a larger version, the Creality CR10 MAX has 450 x 450 x 470 mm maximum build volume, and costs $999. You can buy it here / or on 3DJake UK & Europe here

- For a smaller version, the CR10 Mini is available — you can buy it here / or on 3DJake UK & Europe here

The Creality CR-10 has an accuracy and print volume which is competitive with printers 5 times more expensive. With it’s minimum layer thickness of 0.05mm and fantastic 300 x 300 x 400 mm build volume, the Creality CR-10 is a great printer for just $370. It’s easy to use, making it the perfect 3D printer for beginners.

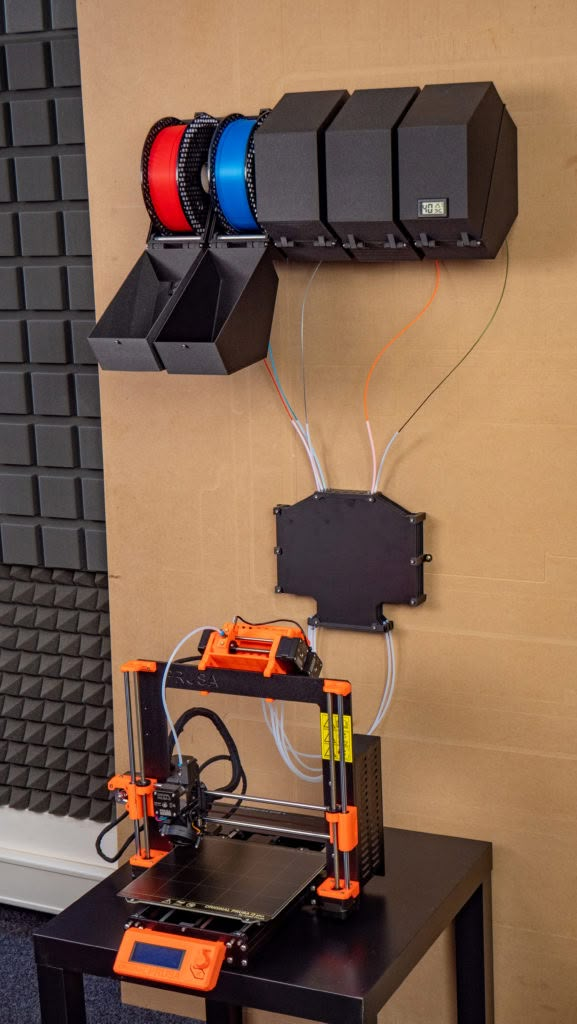

9. Prusa i3 MK3S — best 3D printer kit

- Company based: Czechia

- Price: $749 as a kit — Available on the Prusa store here / $999 fully assembled — Available on the Prusa store here

- Build volume: 250 x 210 x 210 mm

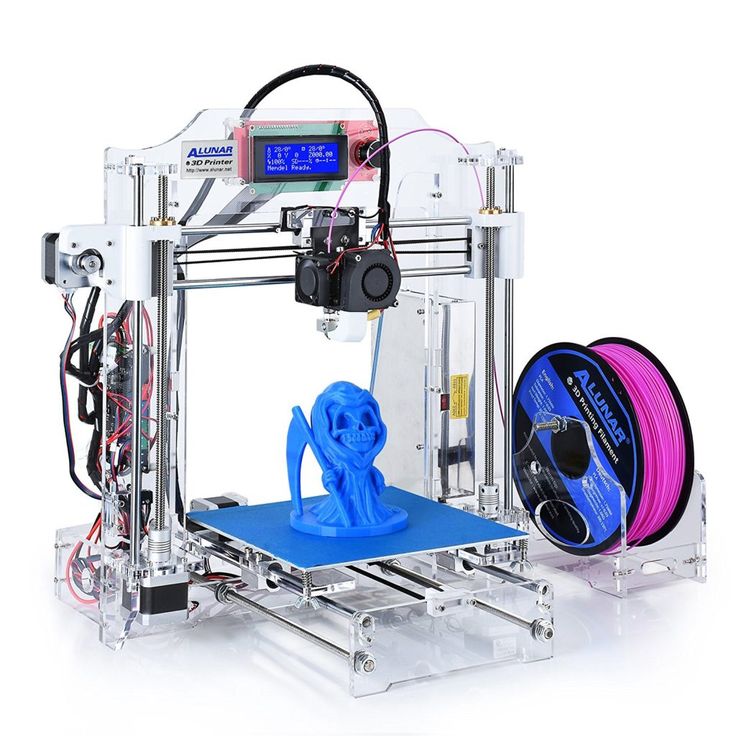

The Prusa i3 is known as the undeniable king of DIY 3D printer kits. These RepRap kits are fantastic, sporting an impressive print volume of 250 x 210 x 210 mm, and being able to print at speeds up to 200mm/s! It’s also accurate, durable and a complete workhorse, with layer heights from 0.05 mm and a bendable print surface to make removing finished prints as easy as possible.

These RepRap kits are fantastic, sporting an impressive print volume of 250 x 210 x 210 mm, and being able to print at speeds up to 200mm/s! It’s also accurate, durable and a complete workhorse, with layer heights from 0.05 mm and a bendable print surface to make removing finished prints as easy as possible.

Accessible via USB stick or by SD card, the Prusa i3 MK3 kits are designed to be simple to use as well as effective. With layer resolutions up to 50 microns, the Prusa i3 homemade 3D printer is so effective that it outperforms far more expensive 3D printers. It can print tougher filaments than more expensive printers too, with a Bondtech extruder that can reach temperatures of up to 300C, making printing Polycarbonate, ABS, Nylon, and other difficult filaments no problem.Colorful prints are possible with the Multi Material Upgrade Kit, which we discuss below.

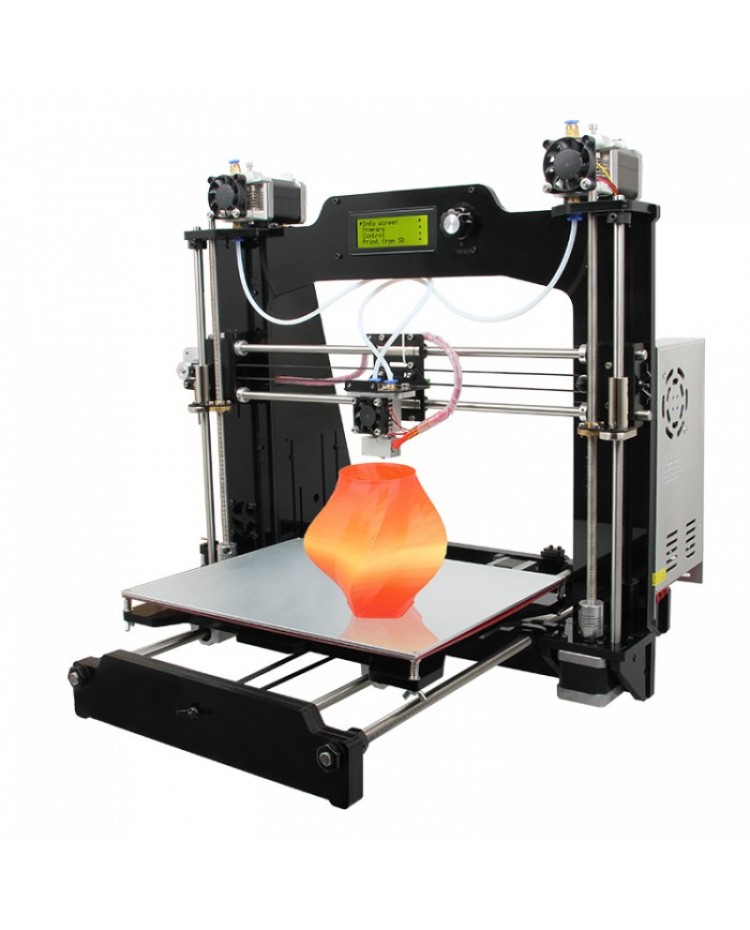

Additionally, you can print up to 5 colors simultaneously with your Prusa if you purchase their multi-material upgrade kit, costing $300. This makes colorful model printing a breeze, and opens up for far more extravagant printing projects.

This makes colorful model printing a breeze, and opens up for far more extravagant printing projects.

- With a Multi Material Upgrade kit, it can also print multiple colors. We explain more in our color 3D printer buyer’s guide.

- You can buy the Multi Material Upgrade Kit 2.0 here.

You can choose to either assemble the kit yourself or buy the printer pre-assembled, though this costs a few hundred dollars more. Overall, the Prusa remains the undisputed king of DIY 3D printer kits, with its competitors needing to do a lot of catching up to dethrone it.

The Prusa, with Multi Material Upgrade kit, allowing it to print multiple colors simultaneously. We explain this in our color 3D printer guide.10. Peopoly Moai SLA Kit — Homemade resin 3D printer kit

- Price: $1,295 — Available on Matterhackers here

- Build volume: 130 x 130 x 180 mm

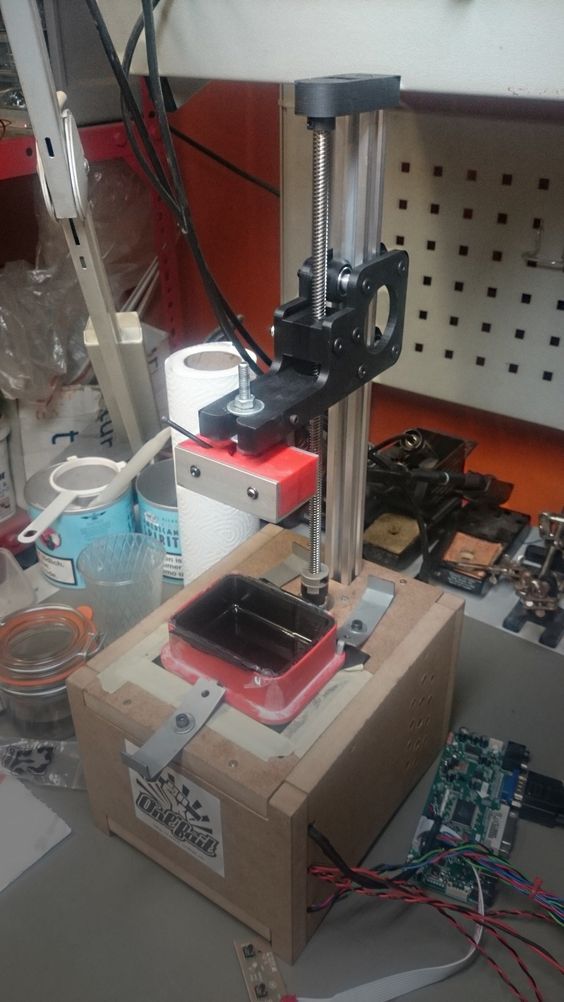

The only resin 3D printer featured in our 3D printer kit guide, the Peopoly Moai is an incredible feat of engineering. It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

For those looking for an effective SLA 3D printer, and who do not want to pay full price, the Moai kit could be the perfect printer for you. It is so accurate that it can mechanically print up to an astonishing 5-micron layer height, according to Peopoly, though you’ll likely never reach this accuracy because you won’t need to, nor would most resins or models accommodate this.

Featuring a 70-micron laser spot size, once you’ve built this homemade 3D printer you’ll be ready to create resin molds for 3D printed jewelry, dental models, engineering pieces, as well as prototypes for rapid prototyping or fun characters if you use the Moai as a 3D printer for miniatures.

The Peopoly Moai is open to use third-party resins, for those who want to save money on lower-cost resins and are fine with the slight quality drop-off. The printer itself however does not come with any resin, so you’ll need to purchase that with the kit. It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

9 Best DIY 3D Printer Kits (2022 Update)

- Last Updated: March 27, 2022

If you’re a hobbyist and a tinkerer who wants to get into 3D printing, the best way is to build your own 3D printer. You can purchase and assemble DIY 3D printer kits that combine your favorite childhood pastimes with your new obsession!

The big reason for building your own printer is the cost savings associated with it.

You might wind up saving hundreds of dollars if you opt for a DIY printer.

Creality Ender 3

Build Volume: 220 x 220 x 250 mm

Get Discount

Check Latest Price

Creality Ender 3 Pro

Build Volume: 220 x 220 x 250 mm

Get Discount (Official Store)

Check Latest Price

Prusa i3 MK3S

Build Volume: 250 x 210 x 210 mm

Check Latest Price

The hidden advantage is how much you’ll learn about your printer while putting it together.

An excellent way to think about it is you’re trading a few hours of your time in exchange for a deep understanding of 3D printing.

Table of Contents

- Best DIY 3D Printer Kits At A Glance

- 1. Creality Ender 3 Pro (Editor's Choice)

- 2. Prusa I3 MK3S (Best Overall - Top Pick)

- 3. Creality Ender 3 (Best Value)

- 4. Tronxy XY-2 PRO

- 5. Tronxy X5SA Pro

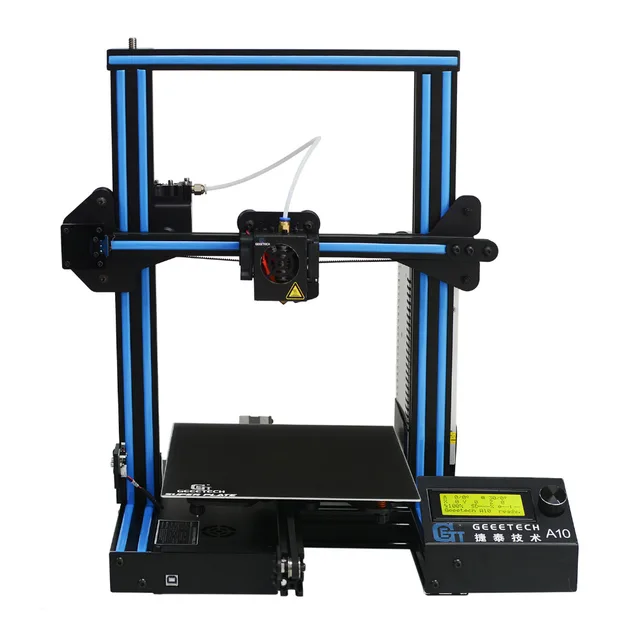

- 6. Geeetech A10

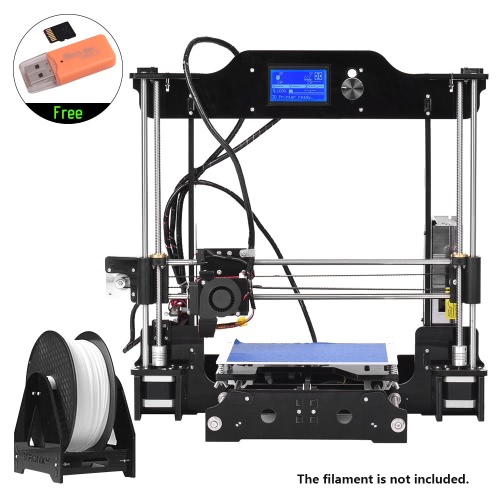

- 7. Anet A8 Plus

- 8. Creality CR-10 V2

- 9. Anycubic Kossel Plus

- Why DIY Printers?

- How To Build Your Own 3D Printer?

- How To Choose The Right DIY 3D Printer Kit

- Conclusion

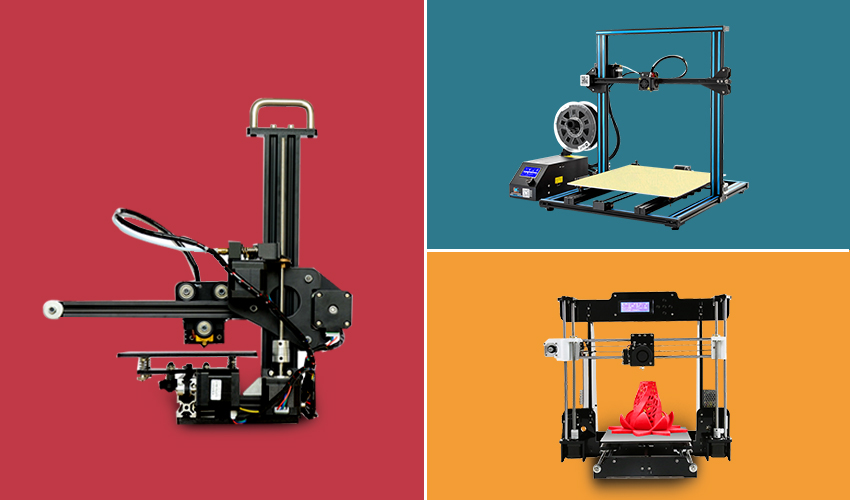

Best DIY 3D Printer Kits At A Glance

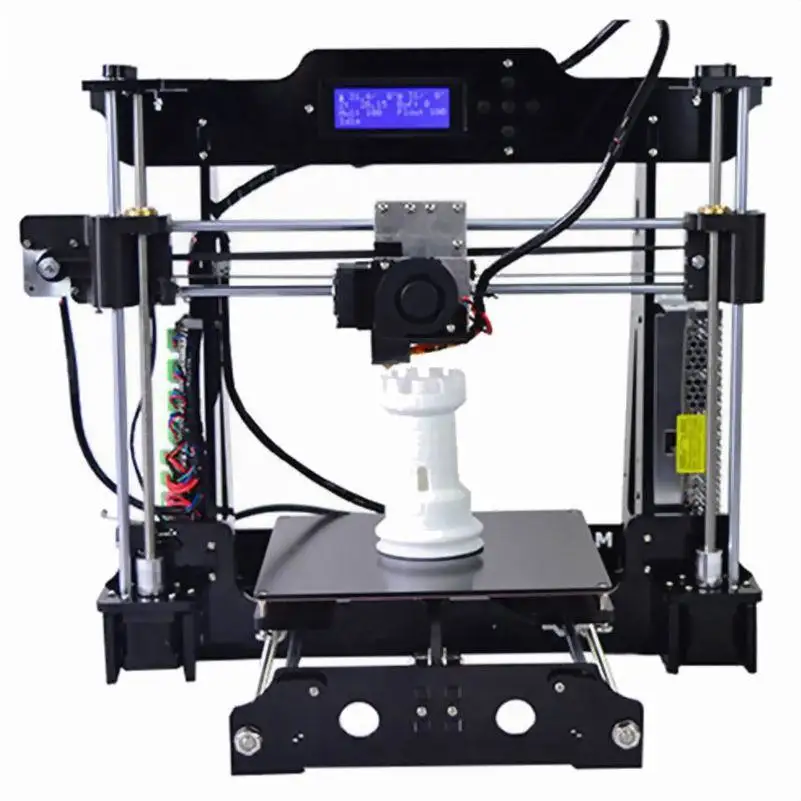

Now let’s look at some of the best DIY 3D printer kits on the market. All of these are FDM-style printers, so there’s no need to worry about resin or dangerous chemicals.

- Creality Ender 3 Pro (Editor’s Choice)

- Prusa I3 MK3S (Top Pick – Best Overall)

- Creality Ender 3 (Best Value)

- Tronxy XY-2 PRO

- Tronxy X5SA Pro

- Geeetech A10

- Anet A8 Plus

- Creality CR-10 V2

- Anycubic Kossel Plus

Quick Reference Table

| 3D Printer | Volume (mm) | Resolution (μm) | Assembly time (hrs) |

| #1 Creality Ender 3 Pro | 220 x 220 x 250 | 100 | 2 |

| #2 Prusa i3 MK3S | 250 x 210 x 210 | 50 | 7 |

| #3 Creality Ender 3 | 220 x 220 x 250 | 100 | 3-6 |

| Tronxy XY-2 Pro | 255 x 255 x 260 | 100 | 3 |

| Tronxy X5SA Pro | 330 x 330 x 400 | 125 | 4 |

| Geeetech A10 | 220 x 220 x 260 | 100 | 1 |

| Anet A8 Plus | 300 x 300 x 350 | 100 | 3 |

| Creality CR-10 V2 | 300 x 300 x 400 | 50 | 1 |

| Anycubic Kossel Plus | 180 x 180 x 320 | 100 | 4 |

1.

Creality Ender 3 Pro (Editor's Choice)

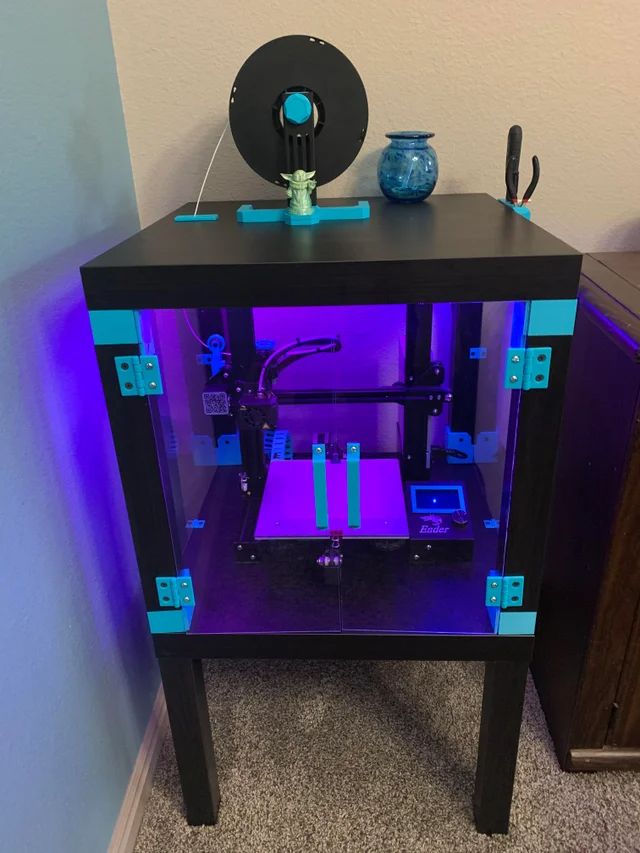

Creality Ender 3 Pro (Editor's Choice) The first 3D printer I’ve ever bought – the Ender 3 Pro is the big brother of the popular Ender 3.

It’s a great 3D printer if you like to tinker and modify, however, owning an Ender 3 Pro is a learning experience.

Because of it’s popularity you have the support of one of the largest communities of makers. If you need help with leveling your bed or calibrating your settings they’ve got you covered.

That said, a well-calibrated and upgraded Ender 3 Pro can go toe-to-toe with a Prusa’s print quality.

This kit is really easy to put together, and it quickly connects to your computer to make for easy printing. It took me about 2 hours to put together the semi-assembled kit following the 12-step pamphlet.

And that’s with leveling the bed too.

The big thing about this printer is how accurate and sturdy it is. It’s really hard to find another printer that can do what the Ender 3 Pro does at the same price point.

The Ender 3 Pro is the best 3D printer under $300.

The Ender 3 Pro is easy to use, has a lot of useful upgrades over the 3, and it has a decent build volume.

This printer is a great pick if you’re looking for an affordable, jack-of-all-trades type of printer, want a printer that’s easy to set up and use, and aren’t afraid to tinker around to achieve high-quality prints.

Get Discount (Official Store)

Check Latest Price

2. Prusa I3 MK3S (Best Overall - Top Pick)

If you can afford this beast, it is hands-down the best 3D printer in its class. Prusa is the company that blazed the trail for other DIY printer companies to follow. The proof is in the fact that their printer is called the “original” – it’s so good that other people use it as a skeleton to make their own.

The i3 MK3S is the most expensive kit on this list because it is fast, reliable, and super easy to use.

Compared to the Ender 3 Pro the Prusa i3 MK3S has automatic bed leveling so your prints can be beauties on the first try.

This printer also has a magnetic print bed, a new extruder, a ton of sensors, and a lot of features.

There are two versions of this printer:

- The fully assembled unit and the…

- DIY kit version

You can save over $200 if you get the DIY kit version.

It took me about 6 hours to assemble the kit. The kit comes with detailed setup instructions and you can also supplement this with more info on their site. Additionally, this printer has plenty of info available online from different forums and videos (YouTube is your friend!) that will detail exactly how to assemble it.

This 3D printer is super easy to use because of the iterations that the company has gone through to bring this printer to market. It’s worth mentioning that this printer is open source, so you can feel free to tinker and experiment with your setup.

It’s worth mentioning that this printer is open source, so you can feel free to tinker and experiment with your setup.

If you’re into exceptional print quality right out of the box then the Prusa i3 MK3S is for you. It is a reliable, well built machine that performs consistently with minimal maintenance. On the rare cases you need help or advice, Prusa also offers tech supports and a community of passionate fans.

- Check out more beginner-friendly 3D printers here

Check Latest Price

3. Creality Ender 3 (Best Value)

There’s a reason why this printer is was our #1 choice in the best 3D printer under $200 review.

No 3D printer seems to fuse quality and affordability quite like the Ender 3. With the right settings and patience, this printer can achieve quality as good as printers 4x the price.

The older generation of the Ender 3, it has all the quirks you’d expect from the old guard.

Like the Ender 3 Pro, it allows you to continue printing after losing power. Likewise, the heated built plate allows for easier printing and lets you print tougher filament materials.

You can read more about the Ender 3 vs. Ender Pro here.

This 3D printer is perfect for beginners and tinkerers who want to get their hands dirty. And who want the best bang for their buck.

Get Discount (Official Store)

Check Latest Price

4. Tronxy XY-2 PRO

Next up is the XY-2 PRO from Tronxy.

It has a reasonable price tag, a good print volume, and it looks pretty cool. It also has a sensor that detects when you’re out of filament, and it automatically stops the print.

It has auto-leveling, which makes the setup for printing more convenient. As a bonus, the folks at Tronxy put a touchscreen on this printer! These features are almost unheard of from a printer at this price point.

The XY-2 PRO is one of the easiest DIY 3D printer kits to assemble and start. If you have any problems, you can refer to their included instruction manual.

If you’re still stuck, you can use your lifetime technical support that comes with every purchase of a Tronxy kit. This means that their service technicians will help you with any questions or problems you have.

Check Latest Price

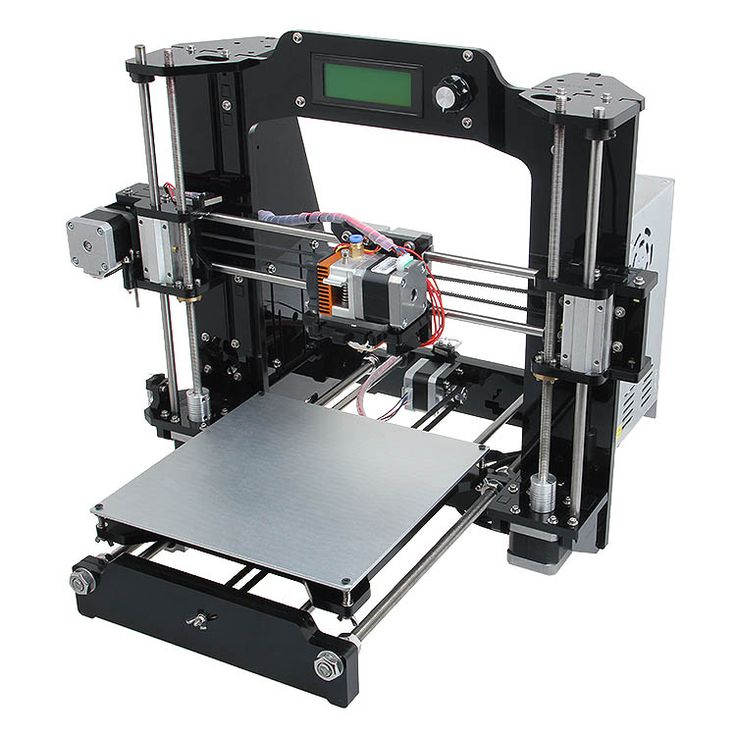

5. Tronxy X5SA Pro

Looking at another printer offered from Tronxy, the X5SA Pro is an upgraded version of their smaller printer.

The build volume is enormous on this guy (in fact, the largest on this list), and the price tag is still really fair for what you get – granted it’s pricier than others on this list.

When they released the X5SA, there were some concerns that were voiced by the 3D printing community. Tronxy was quick to fix them and released the X5SA Pro with all of the fixes.

Some of the fixes include a more robust x-axis, more stability overall, better materials used for the framework, fewer vibrations, and better precision.

The assembly time is around 4 hours, and it offers the same technical support that the XY-2 PRO offers. If the price tag is shocking, compare this printer to a premade model that might cost double the price.

What you get in this printer is a reliable workhorse. It has the same great features and touchscreen that the XY-2 PRO offers, this one is just a lot larger and sturdier.

Check Latest Price

6. Geeetech A10

The A10 from Geeetech is more of a middle-of-the-road type of printer. The price, build volume, and resolution is all in the middle of this list.

It also includes a sensor for when your filament runs out, and it will allow you to print remotely.

Building it is pretty easy, too. There’s a lot of resources online to help guide you through the process. This is a good pick if you aren’t crazy about either extreme of the printers available.

There’s a lot of resources online to help guide you through the process. This is a good pick if you aren’t crazy about either extreme of the printers available.

If you’re looking for a DIY 3D printing kit that has a little bit of everything, the A10 is a good pick.

Check Latest Price

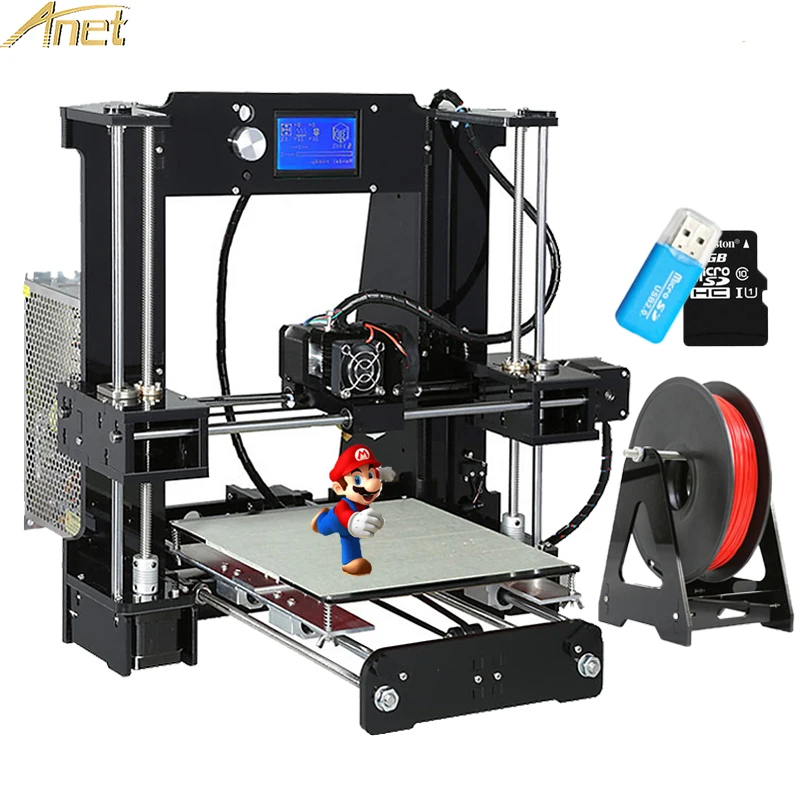

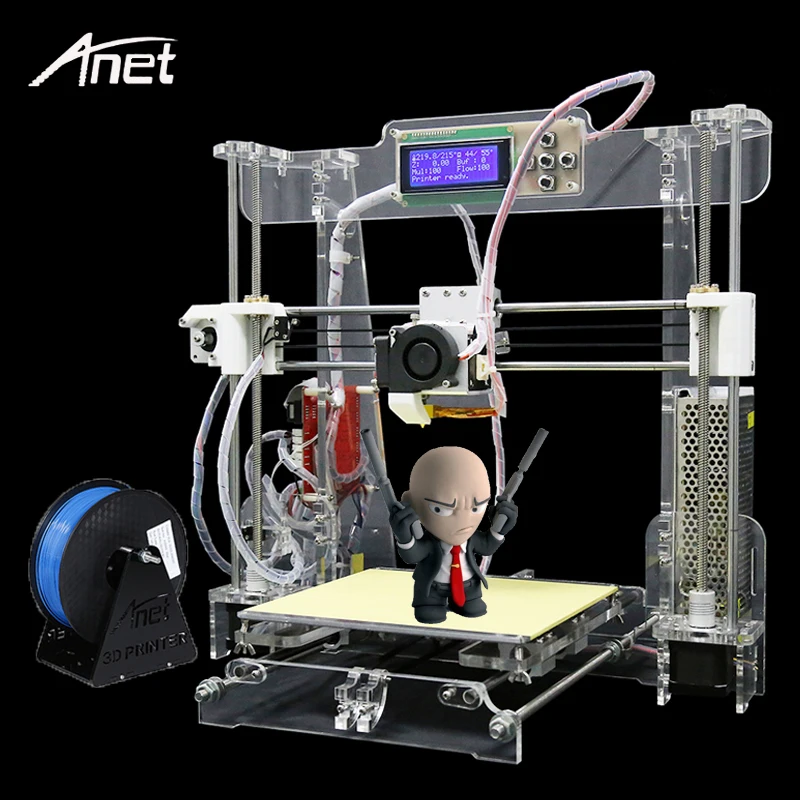

7. Anet A8 Plus

At first glance, you’ll notice the A8 Plus has a big build volume, a great display, and sturdy metal framework. These are the leading factors of why the price point is a little higher than others on this list.

You also get a heated build plate and a nozzle hot enough to print most commercially-available filaments. The machine is very robust and sturdy, which leads to better accuracy than the standard A8.

The wiring and assembly will take around 3 hours and isn’t that difficult based on our experience. If you get stuck, there are countless posts about how to assemble and troubleshoot your machine. This is largely due to how popular the brand and printer are.

This is largely due to how popular the brand and printer are.

Overall this is a good pick if you are looking for a bigger printer that’s sturdy and reliable.

Check Latest Price

8. Creality CR-10 V2

You were warned, there’s more Creality on this list! This slot is reserved for the CR-10 V2 from them, their biggest and baddest version.

The build volume is massive, and the printer is sturdy. Like other Creality DIY kits, the assembly time is around an hour and is really well-explained.

So easy, in fact, it’s easy to forget that it’s a DIY kit.

A lot of people will claim that this printer is the best kit option around the $450 price range, and it’s hard to disagree.

The printer also boasts pinpoint accuracy with its prints. Overall it’s hard to find fault with this printer, and the community is in love with it.

This printer is the perfect option for people who are a little more serious about their kit, people looking to print large items such as cosplay armor or props, and people who need an easy-to-use and assemble printer.

Get Discount

Check Latest Price

9. Anycubic Kossel Plus

The last printer on this list is the Kossel Plus from Anycubic. This printer might look a little funkier than the other printers, and that’s because it’s a delta printer.

These don’t work like traditional xy (or cartesian) style printers.

The benefit of a delta printer is you won’t have printing problems associated with slack in the belts.

There’s a lot to explore when it comes to delta printers. To simplify things, when it comes to DIY 3D printer kits, the Kossel Plus is the best delta option.

The framework is sturdy, and the assembly is really straightforward with a lot of videos and articles online about assembly.

The assembly is essentially 7 parts being put together. The extruder and heated build plate get hot enough to print almost any commercially sold filament. Kossel Plus is a very accurate unit and is a fun technology to watch print.

Overall this printer is great for anyone who wants to improve accuracy and precision in their prints. It’s also a good pick if you want a conversation piece since it’s an atypical 3D printer.

Get Discount

Check Latest Price

Why DIY Printers?The big reason for building your own printer is the cost savings associated with it. You might wind up saving hundreds of dollars if you opt for a DIY printer. The hidden advantage is how much you’ll learn about your printer while putting it together. An excellent way to think about it is you’re trading a few hours of your time in exchange for a deep understanding of 3D printing.

The actual process of building your own 3D printer is going to vary from kit to kit. The overall idea is you’re building it from scratch and doing everything except for the coding. The kits will include all of the pieces and detailed instructions for putting them together. It’s a lot like a Lego set.

For most of the kits, you just need to screw pieces together and connect some ribbon cable between pieces. For the most part, it’s no different than building a piece of furniture from IKEA, with some added steps after for troubleshooting.

No matter which kit you decide to go with, it will come with instructions, and there will be videos and blogs online to help you along the way.

How To Choose The Right DIY 3D Printer KitAs you’re going to see soon, there’s a lot of different options for DIY 3D printer kits. So how do you pick the perfect one? Ultimately it comes down to what you’re looking for in a 3D printer. The criteria for picking a DIY 3D printer kit is the exact same as if you were to buy a printer off-the-shelf, the only difference is that you have to build these printers yourself.

The criteria for picking a DIY 3D printer kit is the exact same as if you were to buy a printer off-the-shelf, the only difference is that you have to build these printers yourself.

You’ll see that these DIY kits have a wide range of prices, build volumes, precision, and features. Additionally, some printers have added features that lead to more convenient or reliable prints. Before you read some of the product reviews, you might want to think of some applications you’ll be using your printer for.

While you’re reading along, take a look at the highlighted features and consider if they are meaningful to you in your application. Now, there is something to keep in mind. Since these are all DIY kits, there are “assembly times” associated with each printer. This is how long it might take you from when you receive the package to when you make your first print.

Keep in mind that the printer only has to be assembled once, then it will be ready for continued use. In other words, along assembly time shouldn’t deter you from buying a printer that has great specs and features that you’re looking for. Refer to our product review table and take a look at the specific reviews below!

Refer to our product review table and take a look at the specific reviews below!

Our pick

Creality Ender 3 Pro

Best Overall

No 3D printer seems to fuse quality and affordability quite like the Ender 3 Pro. With the right settings and patience, this printer can achieve quality as good as printers 4x the price. Great for beginners and tinkerers.

Get Discount on Creality3D

and Amazon

ConclusionThere’s a lot to consider when it comes to picking the best DIY 3D printer kit. Hopefully, the information here will help you make the most informed decision to make sure you get exactly what you’re looking for! Keep in mind the different features and attributes that you’d prefer for your printing projects and take a look at the printers on this list to see which will best meet your needs.

Pat Nathaniel

Pat is the editor-in-chief at Printing Atoms. He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

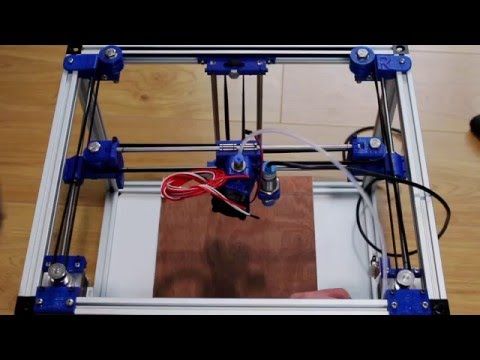

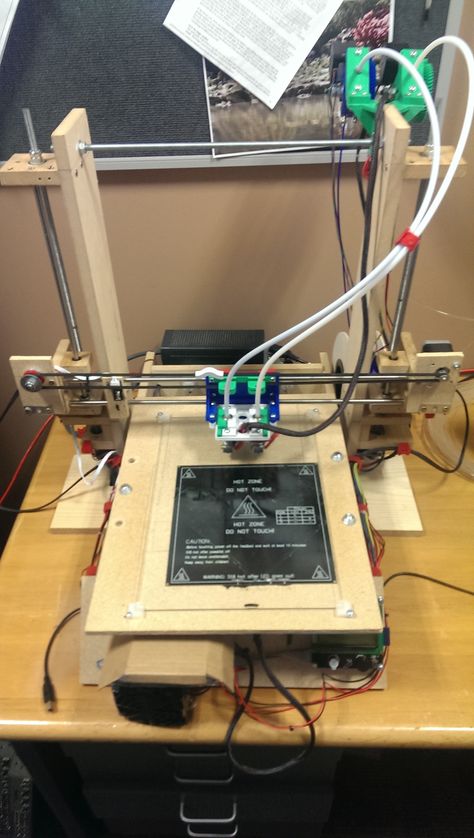

Building a home 3D printer with your own hands: recommendations from personal experience

3D printing and assembly of 3D printers is my hobby and passion. Here I will not share detailed diagrams and drawings, there are more than enough of them on specialized resources. The main goal of this material is to tell you where to start, where to dig and how to avoid mistakes in the process of assembling a home 3D printer. Perhaps one of the readers will be inspired by applied engineering achievements.

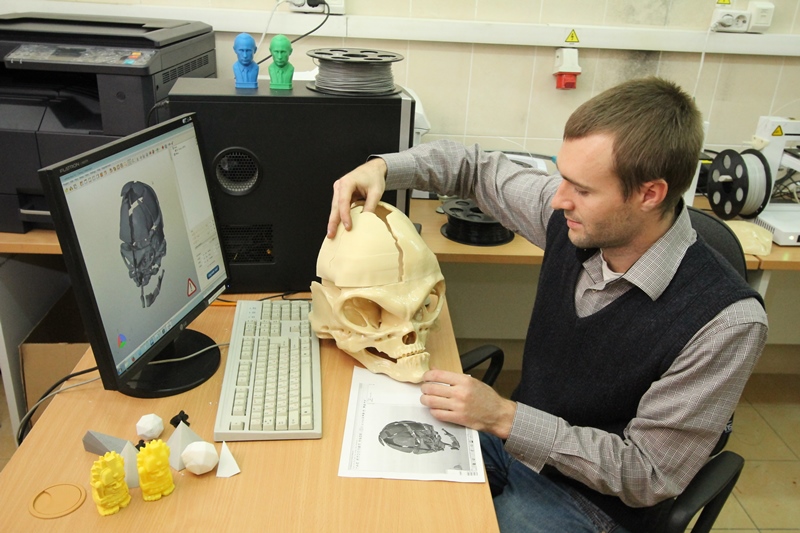

Why do you need a 3D printer? Use cases

I first came across the idea of 3D printing back in the 90s when I was watching the Star Trek series. I remember how impressed I was by the moment when the heroes of the cult series printed the things they needed during their journey right on board their starship. They printed anything: from shoes to tools. I thought it would be great someday to have such a thing too. Then it all seemed something incredible. Outside the window are the gloomy 90s, and the Nokia with a monochrome screen was the pinnacle of progress, accessible only to a select few.

Then it all seemed something incredible. Outside the window are the gloomy 90s, and the Nokia with a monochrome screen was the pinnacle of progress, accessible only to a select few.

Years passed, everything changed. Around 2010, the first working models of 3D printers began to appear on sale. Yesterday's fantasy has become a reality. However, the cost of such solutions, to put it mildly, discouraged. But the IT industry would not be itself without an inquisitive community, where there is an active exchange of knowledge and experience and who just let them dig into the brains and giblets of new hardware and software. So, drawings and diagrams of printers began to surface more and more often on the Web. Today, the most informative and voluminous resource on the topic of assembling 3D printers is RepRap - this is a huge knowledge base that contains detailed guides for creating a wide variety of models of these machines.

I assembled the first printer about five years ago. My personal motivation to build my own device is quite prosaic and based on several factors. Firstly, there was an opportunity to try to realize the old dream of having your own device, inspired by a fantasy series. The second factor is that sometimes it was necessary to repair some household items (for example, a baby stroller, car elements, household appliances and other small things), but the necessary parts could not be found. Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

My personal motivation to build my own device is quite prosaic and based on several factors. Firstly, there was an opportunity to try to realize the old dream of having your own device, inspired by a fantasy series. The second factor is that sometimes it was necessary to repair some household items (for example, a baby stroller, car elements, household appliances and other small things), but the necessary parts could not be found. Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

Agree, it is better to place your device based on Raspberry Pi or Arduino in an aesthetically pleasing "body", which is not a shame to put in an apartment or take to the office, than to organize components, for example, in a plastic bowl for food. And yes, you can print parts to build other printers :)

There are a lot of scenarios for using 3D printers. I think everyone can find something of their own.

A complex part in terms of drawing that I printed on my printer. Yes, it's just a figurine, but it has many small elements

Ready solution vs custom assembly

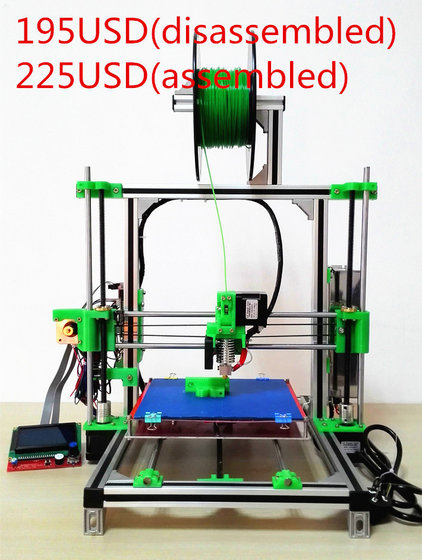

When a technology has been tested, its value in the market decreases markedly. The same thing happened in the world of 3D printers. If earlier a ready-made solution cost simply sky-high money, then today acquiring such a machine is more humane for the wallet, but nevertheless not the most affordable for an enthusiast. There are a number of solutions already assembled and ready for home use on the market, their price range ranges from $500-700 (not the best options) to infinity (adequate solutions start from a price tag of about $1000). Yes, there are options for $150, but we, for understandable, I hope, reasons, will not dwell on them.

In short, there are three cases to consider a finished assembly:

- when you plan to print not much and rarely;

- when print accuracy is critical;

- you need to print molds for mass production of parts.

There are several obvious advantages to self-assembly. The first and most important is cost. Buying all the necessary components will cost you a maximum of a couple of hundred dollars. In return, you will receive a complete 3D printing solution with the quality of manufactured products acceptable for domestic needs. The second advantage is that by assembling the printer yourself, you will understand the principles of its design and operation. Believe me, this knowledge will be useful to you during the operation of even an expensive ready-made solution - any 3D printer needs to be serviced regularly, and it can be difficult to do this without understanding the basics.

The main disadvantage of assembly is the need for a large amount of time. I spent about 150 hours on my first build.

What you need to assemble the printer yourself

The most important thing here is the presence of desire. As for any special skills, then, by and large, in order to assemble your first printer, the ability to solder or write code is not critical. Of course, understanding the basics of radio electronics and basic skills in the field of mechanics (that is, "straight hands") will greatly simplify the task and reduce the amount of time that needs to be spent on assembly.

Of course, understanding the basics of radio electronics and basic skills in the field of mechanics (that is, "straight hands") will greatly simplify the task and reduce the amount of time that needs to be spent on assembly.

Also, to start we need a mandatory set of parts:

- Extruder is the element that is directly responsible for printing, the print head. There are many options on the market, but for a budget build, I recommend the MK8. Of the minuses: it will not be possible to print with plastics that require high temperatures, there is noticeable overheating during intensive work, which can damage the element. If the budget allows, then you can look at MK10 - all the minuses are taken into account there.

- Processor board. The familiar Arduino Mega is well suited. I didn't notice any downsides to this solution, but you can spend a couple of dollars more and get something more powerful, with a reserve for the future.

- Control board. I'm using RAMPS 1.4 which works great with the Arduino Mega. A more expensive but more reliable board is Shield, which already combines a processor board and a control board. In modern realities, I recommend paying attention to it. In addition to it, you need to purchase at least 5 microstep stepper motor controllers, for example - A4988. And it's better to have a couple of these in stock for replacement.

- Heated table. This is the part where the printed element will be located. Heating is necessary due to the fact that most plastics will not adhere to a cold surface. For example, for printing with PLA plastic, the required surface temperature of the table is 60-80°C, for ABS - 110-130°C, and for polycarbonate it will be even higher

There are also two options for choosing a table - cheaper and more expensive. Cheaper options are essentially printed circuit boards with preheated wiring. To operate on this type of table, you will need to put borosilicate glass, which will scratch and crack during operation. Therefore, the best solution is an aluminum table.

Therefore, the best solution is an aluminum table. - Stepper motors. Most models, including the i2 and i3, use NEMA 17 size motors, two for the Z axis and one each for the X and Y axes. Finished extruders usually come with their own stepper motor. It is better to take powerful motors with a current in the motor winding of 1A or more, so that there is enough power to lift the extruder and print without skipping steps at high speed.

- Basic set of plastic fasteners.

- Belt and gears to drive it.

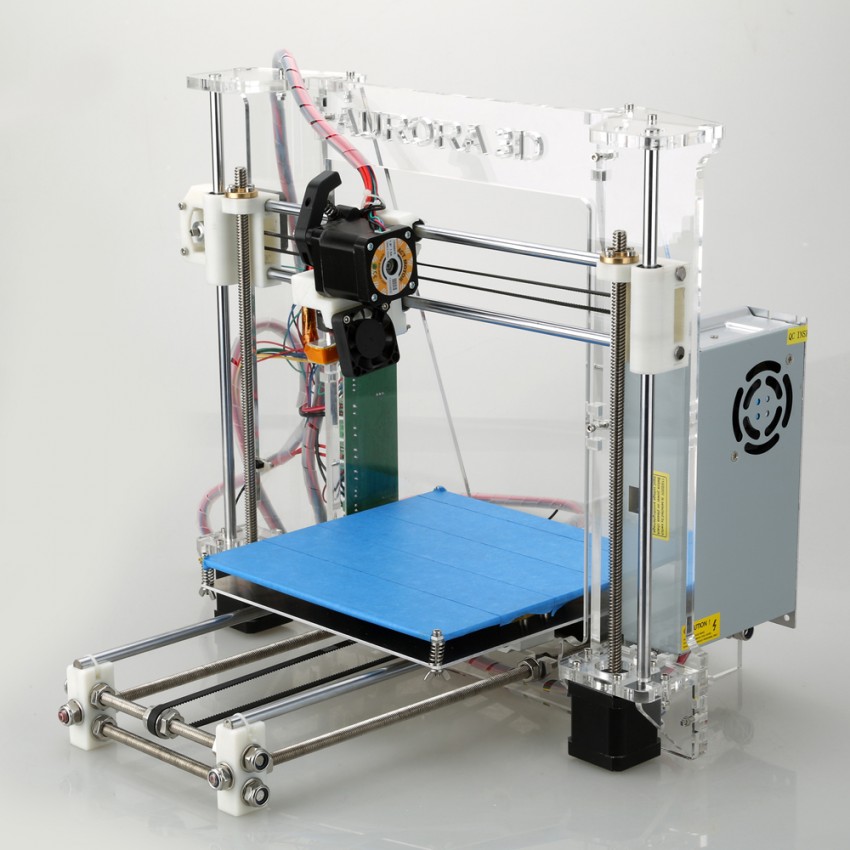

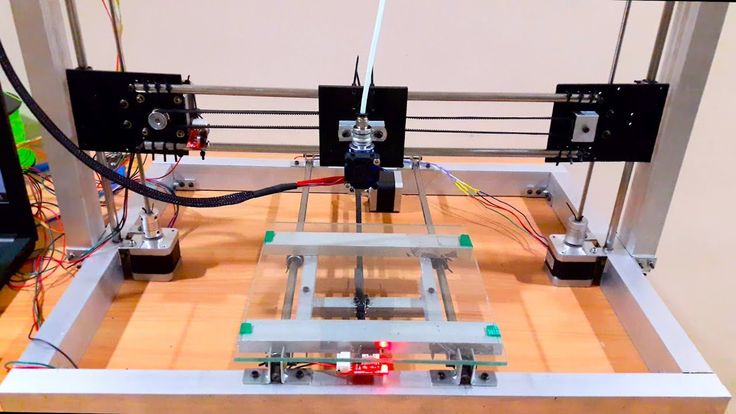

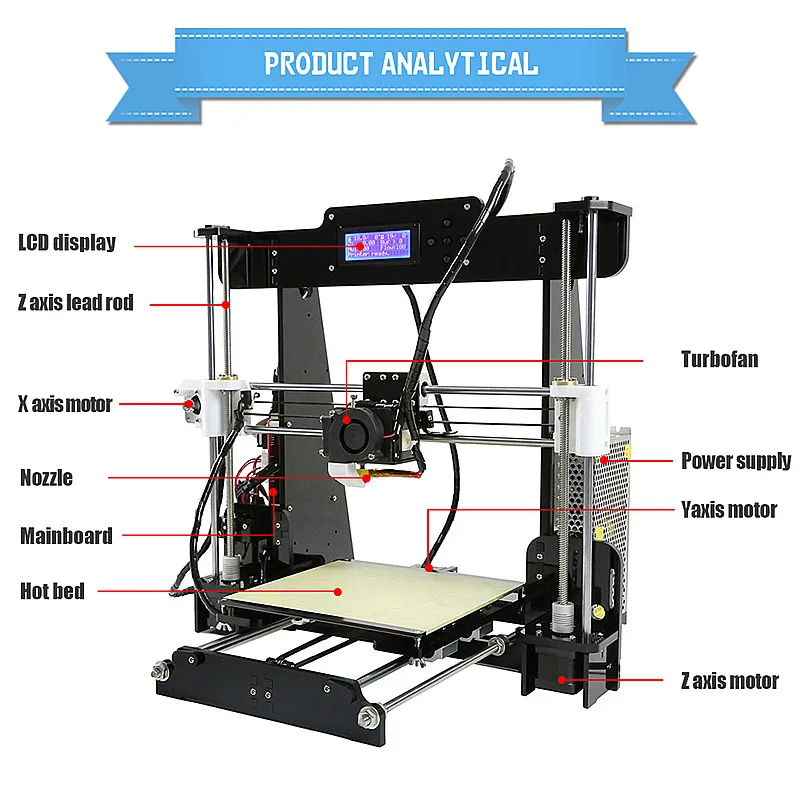

Examples of elements appearance: 1) MK8 extruder; 2) Arduino processor board; 3) RAMPS control board; 4) motor controllers; 5) aluminum heated table; 6) NEMA 17 stepper motor; 7) a set of plastic fasteners; 8) drive gears; 9) drive belt

This is a list of items to be purchased. Hardcore users can assemble some of them themselves, but for beginners, I strongly recommend purchasing ready-made solutions.

Yes, you will also need various small things (studs, bearings, nuts, bolts, washers ...) to assemble the case. In practice, it turned out that using a standard m8 stud leads to low printing accuracy on the Z axis. I would recommend immediately replacing it with a trapezoid of the same size.

M8 trapezoid stud for Z axis, which will save you a lot of time and nerves. Available for order on all major online platforms

You also need to purchase customized plastic parts for the X axis, such as these from the MendelMax retrofit kit.

Most parts available at your local hardware store. On RepRap you can find a complete list of necessary little things with all sizes and patterns. The kit you need will depend on the choice of platform (we'll talk about platforms later).

What's the price

Before delving into some aspects of the assembly, let's figure out how much such entertainment will cost for your wallet. Below is a list of parts required for purchase with an average price.

Platform selection

The community has already developed a number of different platforms for assembling printers - the most optimal case designs and the location of the main elements, so you do not have to reinvent the wheel.

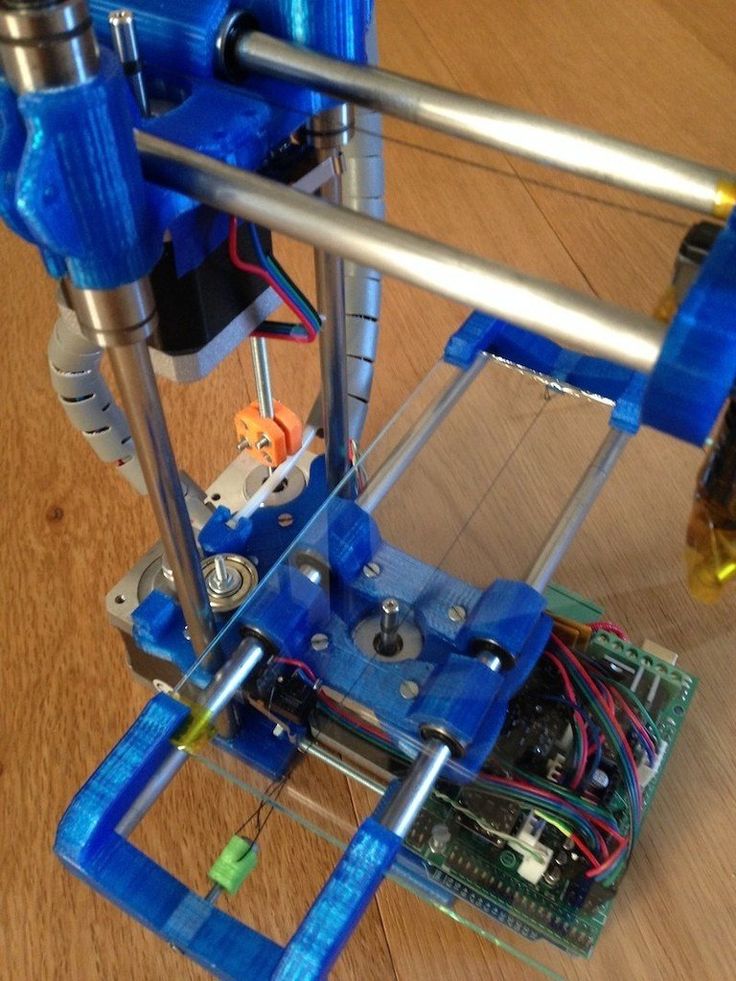

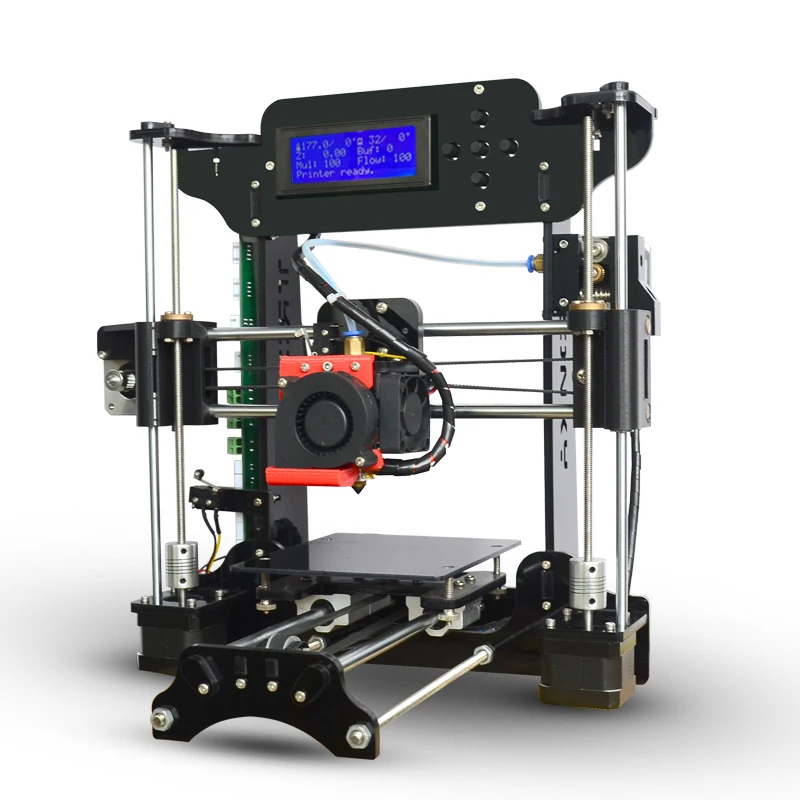

i2 and i3 are key platforms for self-assembly printer enclosures. There are also many modifications of them with various improvements, but for beginners, these two classic platforms should be considered, since they do not require special skills and fine-tuning.

Actually, illustration of platforms: 1) i2 platform; 2) i3 platform

On the plus side of i2: it has a more reliable and stable design, although it is a little more difficult to assemble; more opportunities for further customization.

The i3 variant requires more special plastic parts to be purchased separately and has a slow print speed. However, it is easier to assemble and maintain, and has a more aesthetically pleasing appearance. You will have to pay for simplicity with the quality of printed parts - the body has less stability than i2, which can affect print accuracy.

You will have to pay for simplicity with the quality of printed parts - the body has less stability than i2, which can affect print accuracy.

Personally, I started my experiments in assembling printers from the i2 platform. She will be discussed further.

Assembly steps, challenges and improvements

In this block, I will only touch on the key assembly steps using the i2 platform as an example. Full step by step instructions can be found here.

The general scheme of all the main components looks something like this. There is nothing particularly complicated here:

I also recommend adding a display to your design. Yes, you can easily do without this element when performing operations on a PC, but it will be much more convenient to work with the printer this way.

Understanding how all components will be connected, let's move on to the mechanical part, where we have two main elements - a frame and a coordinate machine.

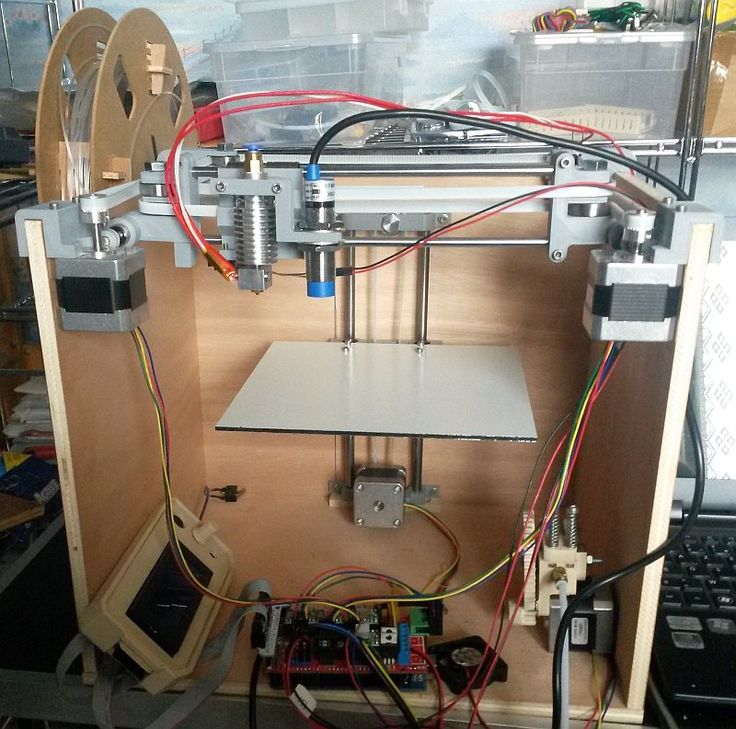

Assembling the frame

Detailed frame assembly instructions are available on RepRap. Of the important nuances - you will need a set of plastic parts (I already talked about this above, but I'd better repeat it), which you can either purchase separately or ask your comrades who already have a 3D printer to print.

Of the important nuances - you will need a set of plastic parts (I already talked about this above, but I'd better repeat it), which you can either purchase separately or ask your comrades who already have a 3D printer to print.

The frame of the i2 is quite stable thanks to its trapezoid shape.

This is how the frame looks like with parts already partially installed. For greater rigidity, I reinforced the structure with plywood sheets

Coordinate machine

An extruder is attached to this part. The stepper motors shown in the diagram above are responsible for its movement. After installation, calibration is required along all major axes.

Important - you will need to purchase (or make your own) a carriage for moving the extruder and a mount for the drive belt. Drive belt I recommend GT2.

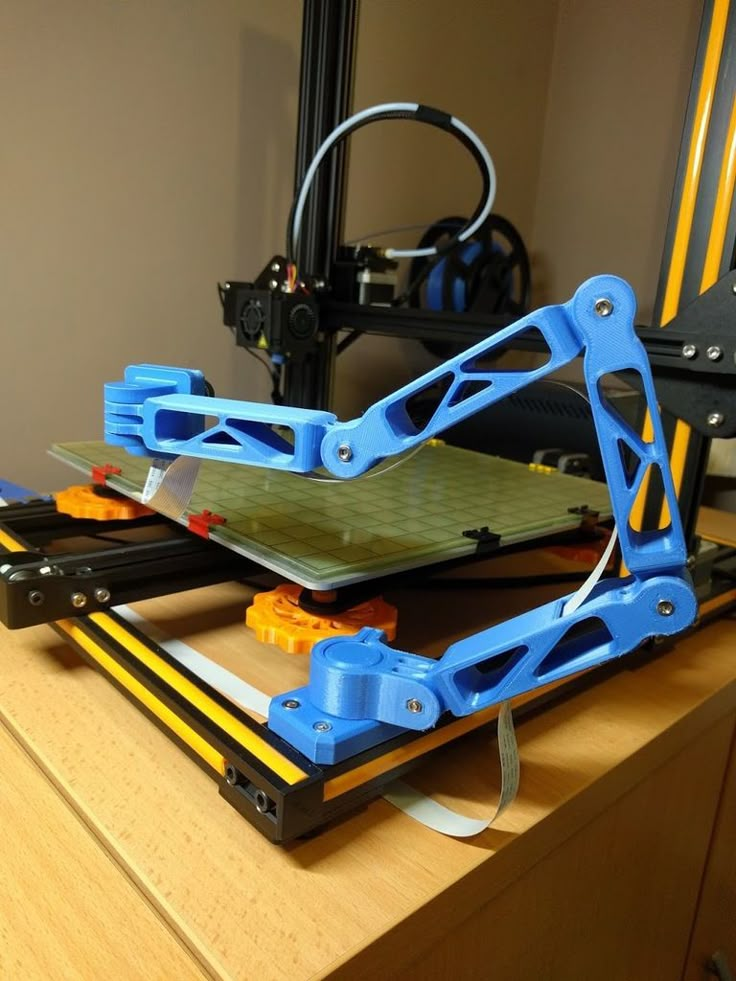

The carriage printed by the printer from the previous picture after it has been assembled. The part already has LM8UU bearings for guides and belt mount (top)

The part already has LM8UU bearings for guides and belt mount (top)

Calibration and adjustment

So, we completed the assembly process (as I said, it took me 150 hours) - the frame was assembled, the machine was installed. Now another important step is the calibration of this very machine and extruder. Here, too, there are small subtleties.

Setting up the machine

I recommend calibrating the machine with an electronic caliper. Do not be stingy with its purchase - you will save a lot of time and nerves in the process.

The screenshot below shows the correct constants for the Marlin firmware, which must be selected in order to set the correct number of steps per unit of measure. We calculate the coefficient, multiply it, substitute it into the firmware, and then upload it to the board.

Marlin 9 firmware constants0022

For high-quality calibration, I recommend relying on larger numbers in measurements - take not 1-1. 5 cm, but about 10. So the error will be more noticeable, and it will become easier to correct it.

5 cm, but about 10. So the error will be more noticeable, and it will become easier to correct it.

Calibrating the extruder

When the frame is assembled, the machine is calibrated, we start setting up the extruder. Here, too, everything is not so simple. The main task of this operation is to correctly adjust the supply of plastic.

If underfeeding, the printed test item will have noticeable gaps, like test die 1. Conversely, the result will look bloated if plastic is overfed (dice 2)

Getting Started Printing

It remains for us to run some CAD or download ready-made .stl, which describe the structure of the printed material. Next, this structure needs to be converted into a set of commands understandable to our printer. For this I use the Slicer program. It also needs to be set up correctly - specify the temperature, the size of the extruder nozzle. After that, the data can be sent to the printer.

Slicer interface

As a raw material for printing, I recommend starting with regular ABS plastic - it is quite strong, products made from it are durable, and it does not require high temperatures to work with. For comfortable printing with ABS plastic, the table must be heated to a temperature of 110-130 ° C, and the extruder nozzle - within 230-260 ° C.

For comfortable printing with ABS plastic, the table must be heated to a temperature of 110-130 ° C, and the extruder nozzle - within 230-260 ° C.

Some important details. Before printing, calibrate the machine along the Z axis. The extruder nozzle should be approximately half a millimeter from the table and ride along it without distortion. For this calibration, a regular sheet of A4 paper inserted between the nozzle and the surface of the heated table is best suited. If the sheet can be moved with little effort, the calibration is correct.

Another thing to keep in mind is the surface treatment of the heated table. Usually, before printing, the surface of the table is covered with something that hot plastic sticks to well. For ABS plastic, this can be, for example, Kapton tape. The disadvantage of adhesive tape is the need to re-glue it after several printing cycles. In addition, you will have to literally tear off the adhering part from it. All this, believe me, takes a lot of time. Therefore, if it is possible to avoid this fuss, it is better to avoid it.

Therefore, if it is possible to avoid this fuss, it is better to avoid it.

An alternative option that I use instead of scotch tape is to apply several layers of ordinary light beer, followed by heating the table to 80-100 ° C until the surface is completely dry and re-applying 7-12 layers. It is necessary to apply the liquid with a cloth moistened with a drink. Among the advantages of this solution: ABS plastic separates from the table on its own when it cools down to about 50 ° C and is removed without effort, the table does not have to be peeled off, and one bottle of beer will last you for several months (if you use the drink only for technical purposes :)).

After we have collected and configured everything, we can start printing. If you have an LCD screen, then the file can be transferred for printing using a regular SD card.

The first results may have bumps and other artifacts - do not worry, this is a normal process of "grinding" the printer elements, which will end after a few print cycles.

Tips to make life easier (and sometimes save money)

In addition to the small recommendations given in the text above, in this section I will also give a short list of tips that will greatly simplify the operation of a 3D printer and the life of its owner.

- Do not experiment with nozzles. If you plan to immediately print from materials that require high temperatures, then it is better to immediately take the MK10 extruder. On MK8, you can "hang" special nozzles that support high-temperature conditions. But such modifications often cause difficulties and require special experience. It is better to avoid this fuss on the shore by simply installing the right extruder for you.

- Add starter relay for heated table. Improving the power supply system for this important printing part with a starter relay will help solve the known problem of RAMP 1.4 - overheating of the transistors that control the power of the table, which can lead to failure of the board.

I made this upgrade after having to throw away a few RAMPS 1.4s.

I made this upgrade after having to throw away a few RAMPS 1.4s. - Select the correct filament diameter for printing. I recommend using 1.75mm plastic for MK8 and MK10. If we take plastic, for example, 3 mm, then the extruder simply does not have enough strength to push it at an acceptable speed - everything will be printed much longer, and the quality will drop. ABS plastic is ideal for MK8, MK10 will be able to produce products from polycarbonate.

- Use only new and precise X and Y guides. Print quality will be affected. It is difficult to count on good quality with bent or deformed guides along the axes.

- Take care of cooling. During my experiments with various extruders, the MK10 showed the best results - it prints quite accurately and quickly. The MK10 can also print plastics that require a higher print temperature than ABS, such as polycarbonate. Although it is not as prone to overheating as its younger brother MK8, I still recommend taking care of its cooling by adding a cooler to your design.

It must be permanently enabled, this option can be configured in Slicer. You can also add coolers to keep the stepper motors at an acceptable temperature, however, make sure that their air flows do not fall on the printed part, as this can lead to its deformation due to too rapid cooling.

It must be permanently enabled, this option can be configured in Slicer. You can also add coolers to keep the stepper motors at an acceptable temperature, however, make sure that their air flows do not fall on the printed part, as this can lead to its deformation due to too rapid cooling. - Consider heat retention. Yes, on the one hand, we are struggling with overheating of the elements. On the other hand, a uniform temperature around the printer will contribute to high-quality printing (the plastic will be more pliable). To achieve a uniform temperature, you can put our printer, for example, in a cardboard box. The main thing is to connect and configure the coolers before that, as described above.

- Consider insulating your desk. Heated table heats up to high temperatures. And if part of this heat leaves properly, heating the printed part, then the second part (from below) just goes down. To concentrate the heat from the table onto the part, you can perform an operation to insulate it.

To do this, I simply attach a cork mouse pad to its bottom using stationery clips.

To do this, I simply attach a cork mouse pad to its bottom using stationery clips.

Pins

I am sure that during the assembly process you will encounter a number of difficulties specific to your project. Neither this text nor even the most detailed guides will insure against this.

As I wrote in the introductory part, the above does not claim the status of a detailed assembly manual. It is almost impossible to describe all the stages and their subtleties within the framework of one such text. First of all, this is an overview material that will help you prepare for the assembly process (both mentally and financially), understand whether you personally need to bother with self-assembly - or give up on everything and buy a ready-made solution.

For me, assembling printers has become an exciting hobby that helps me solve some issues in home and work affairs, take my mind off programming and do something interesting with my own hands. For my children - entertainment and the opportunity to get unusual and unique toys. By the way, if you have children whose age allows them to mess around with such things, such an activity can be a good help for entering the world of mechanics and technology.

By the way, if you have children whose age allows them to mess around with such things, such an activity can be a good help for entering the world of mechanics and technology.

For everyone, the vectors of using 3D printers will be very different and very individual. But, if you decide to devote your personal time to such a hobby, believe me, you will definitely find something to print :)

I will be glad to answer comments, remarks and questions.

What to read/see

- what can be printed;

- 3D printer forum;

- RepRap community site with model descriptions and assembly instructions;

- printer that prints electronics.

Subscribe to the Telegram channel "DOU #tech" so you don't miss new technical articles.

Topics: DIY, embedded, tech

20 best and free software for 3D printing and 3D printer

Looking for 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

For beginners to prepare STL files for 3D printing 3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of the object from different angles - the more the better - after which they will be compiled into a 3D model.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D models for printing

online is another easy and intuitive tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the name fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb.de

Price: Free

Systems: PC, Mac, Linux

#10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community. Today the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and - the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i. e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will have everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and check STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools in existence. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

3

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically.