3D printer health hazards

3D Printing Health Hazards and PPE for Proper Protection

Also known as additive manufacturing, 3D printing has rapidly gained traction in the manufacturing industry. This innovative technology allows producers to create products using a combination of inexpensive materials and highly accessible equipment.

While the popularity of 3D printing has grown, many 3D printing health hazards are just starting to gain recognition. For the protection of all workers involved in 3D printing, it is critical that organizations get familiar with the unique health hazards involved and how to properly combat those risks with the use of proper practices and personal protective equipment (PPE).

The 3D Printing Processes

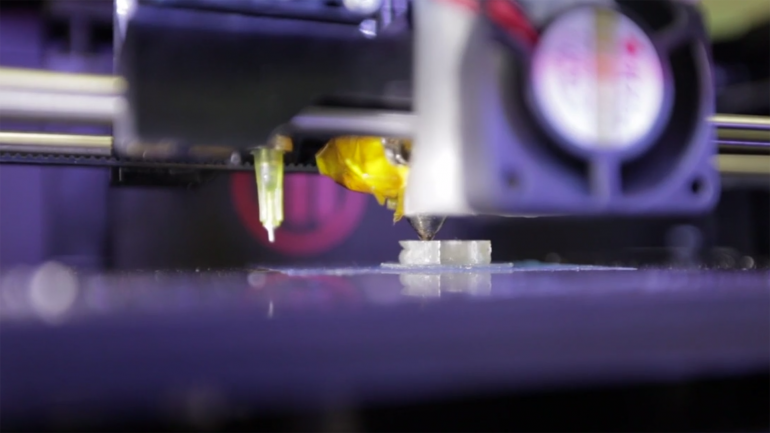

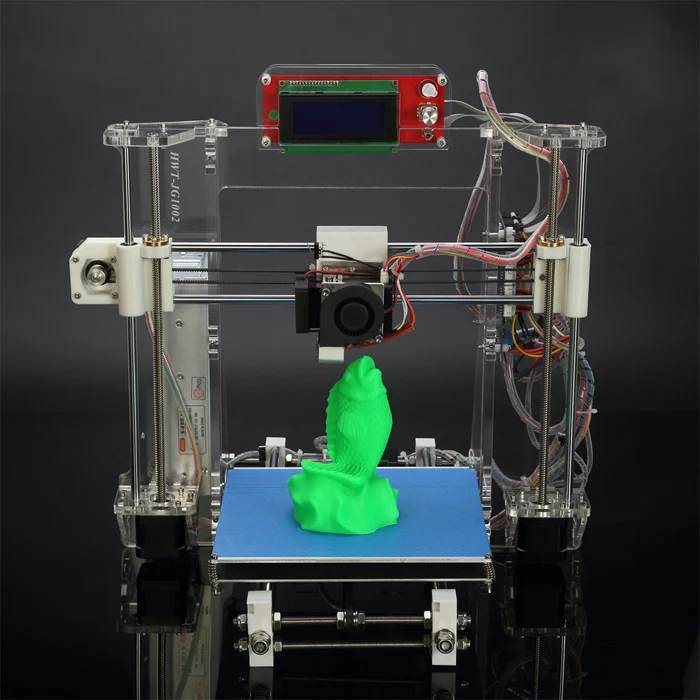

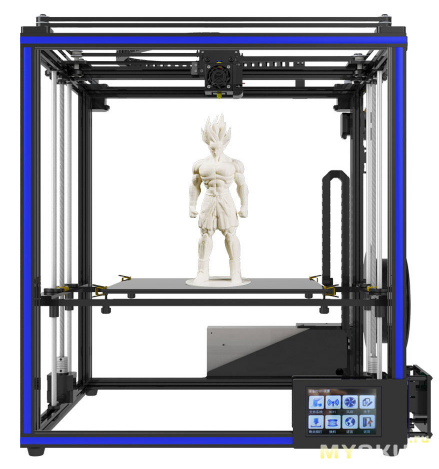

The 3D printer is an advanced piece of equipment that can utilize user inputs on a computer and filaments or printing materials to create dimensional objects layer by layer. Essentially, the printer stacks multiple layers of a raw material until the three-dimensional shape has been created.

The majority of 3D printers use what is referred to as feedstock, which is a plasticized filament. The threaded filament gets fed through a heating element where it is liquefied, and then the fluid plastic is released through a controlled nozzle to create an object.

Numerous types of thermoplastics may be used as feedstock, including Acrylonitrile Butadiene Styrene (ABS), nylon, and Polylactic Acid (PLA). However, some 3D printers also rely on ultraviolet light to cure a piece, lasers for shaping a piece, and even metal powders to create a piece.

Industries That Use 3D Printing

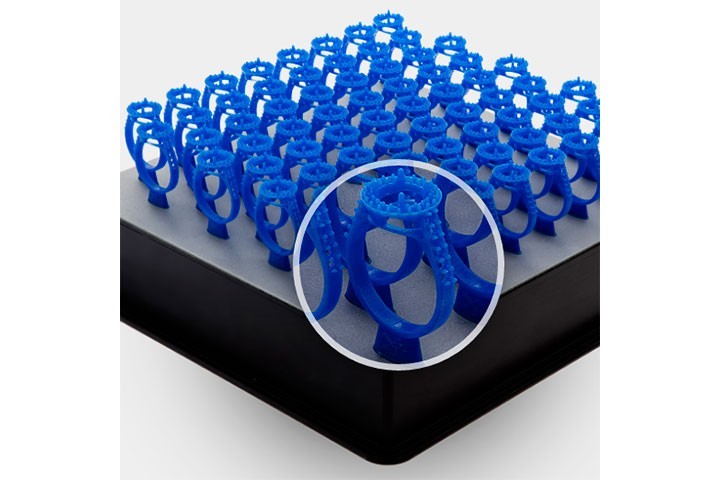

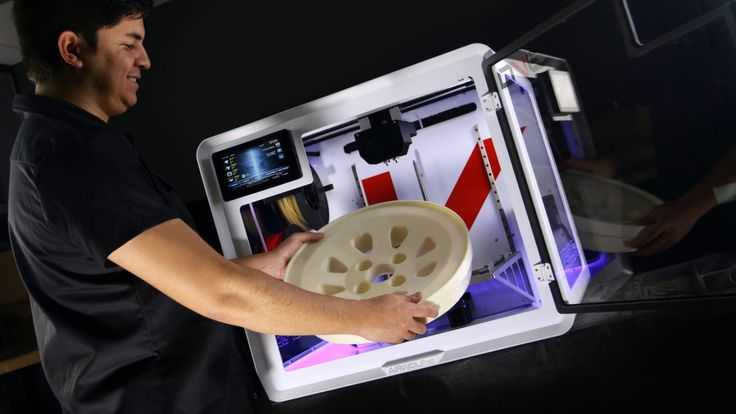

One of the biggest benefits of 3D printing is that the process offers the ability for product engineers to quickly and inexpensively create parts and products in-house. Therefore, initially, 3D printers were primarily put to use in engineering processes.

Engineers could use a 3D printer to build a prototype from the ground up with little cost involved. However, now this tech-based form of printing has grown to be a common process in everyday manufacturing and production processes. Some companies now use numerous 3D printers in their operations on a daily basis.

Some companies now use numerous 3D printers in their operations on a daily basis.

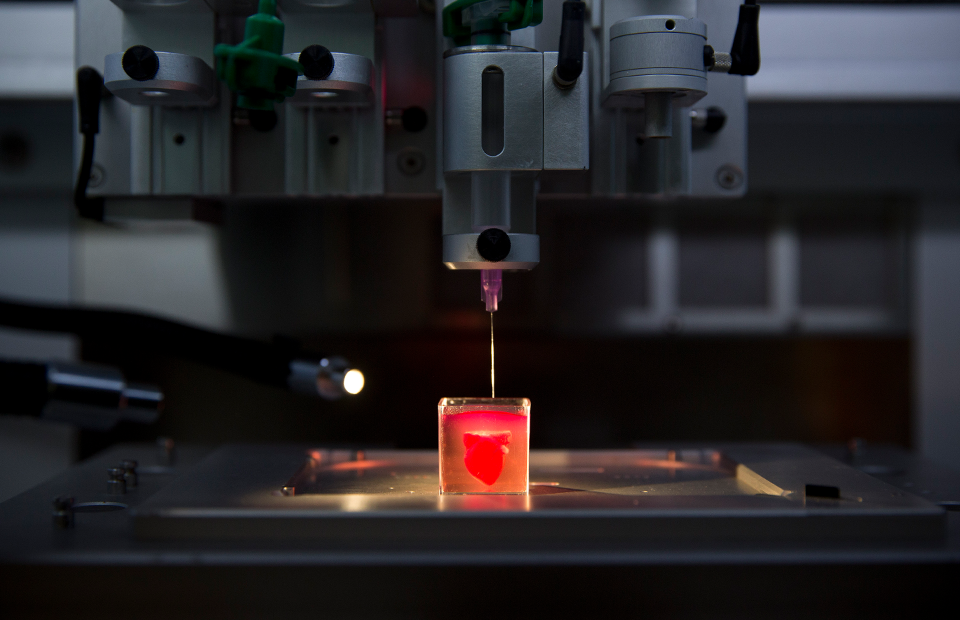

You don't have to look far to find 3D printing technology in action. To date, 3D printers have made their way into numerous settings, including medical laboratories, automotive parts manufacturers, electronics manufacturers, and even the aerospace industry.

The ways in which these industries rely on 3D printing can vary drastically from one to the next. For example, some medical practices are using 3D printers to create custom, built-to-fit prosthetics for patients. Likewise, some automotive parts manufacturers use 3D printers to create plastic parts for automobiles.

Potential Hazards of 3D Printing

3D printing hazards can include breathing in harmful chemicals or compounds, skin exposure to harmful chemicals or solvents, and the risk of fire and explosion. Some printers operate at extremely high temperatures, which could also mean the user is at risk of getting burned.

3D printing hazards vary depending on what type of equipment, materials, and setup are used. For instance, some printers use fine powders that can cause skin or respiratory hazards, while others may use ABS filaments that produce hazardous emissions upon heating. Two primary threats come along with exposure to ultrafine particles (UFPs) and volatile organic compounds (VOCs).

For instance, some printers use fine powders that can cause skin or respiratory hazards, while others may use ABS filaments that produce hazardous emissions upon heating. Two primary threats come along with exposure to ultrafine particles (UFPs) and volatile organic compounds (VOCs).

UFPs are referred to as nanoparticles because they are anywhere from 1 and 100 nanometers in size. These particles are so small, they can be inhaled, travel through the bloodstream, and even make their way into bodily organs. UFP exposure has been linked to:

- Cardiovascular disease

- Respiratory infection

- Lung cancer

- Chronic obstructive pulmonary disease (COPD)

VOCs can vaporize even at room temperature. These organic chemicals can then saturate the surrounding environment's air and pose health hazards. Some materials commonly used in 3D printing processes, such as nylon, PLA, and ABS produce particularly concerning VOCs like butanol and styrene.

Some VOCs are thought to be active carcinogens (cancer-causing agents). However, VOCs can have a variety of other

However, VOCs can have a variety of other

damaging health effects, including:

- Central nervous system damage

- Irritation of the throat, nasal passages, and eyes

- Loss of general coordination

- Headaches

- Nausea

- Skin irritation

Some 3D printers also use chemical solutions to dissolve unnecessary support pieces that are printed during the creation of a 3D piece. These solutions are corrosive, so they pose risks to the eyes and skin such as blindness or chemical burns.

How Organizations Can Protect Workers from 3D Printing Hazards

The National Institute for Occupational Safety and Health (NIOSH) has rapidly taken initiatives to help organizations protect their workers while using 3D-printing equipment.

Only trained professionals should operate 3D printing equipment.3D printing may not be the most complicated task, but only trained employees or authorized individuals should have access to the equipment. Untrained or inexperienced workers using the equipment can experience unnecessary exposure to hazards.

Untrained or inexperienced workers using the equipment can experience unnecessary exposure to hazards.

3D printers should be in isolated enclosures equipped with ventilation to control emissions. If you do not have an isolated enclosure for printing equipment, select a room or location that has high airflow, operable windows, and exhaust to the outdoors.

Opt for 3D-printing materials and equipment with lower emissions.Printing equipment should be purchased from reputable manufacturers who have created the unit with emissions and safety in mind. A standard has been developed that shows a printer has been designed to reduce emissions.

Look for those that meet the ANSI/CAN/UL 2904 Compliance Standard. Likewise, the filaments used should be carefully chosen. As noted above, some filaments create higher emissions, and some create more toxic emissions.

Reduce time workers are in proximity to printing equipment.

Although watching a 3D printer in action is interesting, employees should not spend any more time near the operational 3D printer than necessary. Some organizations set up alternative cameras or other mechanisms to oversee the printer without an employee having to be nearby.

Train employees on 3D printing hazards.Employees must know and understand the risks associated with 3D printers. There are many useful resources to help ensure proper training for employees. For example, the NIOSH offers informational posters on 3D printing with metal powders and 3D printing with filaments.

3D Printing PPE to Protect Workers

PPE for 3D printing can be the employee's first line of defense against the many hazards they can face when operating or working near 3D printing equipment.

Therefore, make sure every employee has the proper PPE , understands its importance, and knows how to properly don it.

Fit-Tested Respirators

General dust masks are not designed to block out the particulate matter that's often released during 3D printing processes. Instead, workers need commercial respirators that are NIOSH-approved for protection against both VOCs and UFPs. All respirators should be fit-tested to ensure proper functionality.

Instead, workers need commercial respirators that are NIOSH-approved for protection against both VOCs and UFPs. All respirators should be fit-tested to ensure proper functionality.

Neoprene or Nitrile Gloves

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

To protect the eyes from small particulate matter and potential chemical splashes, employees should always wear protective eyewear while using 3D printing equipment. Consider protective goggles over basic safety glasses because these PPE pieces can block out exposure to UFPs and VOCs by sealing off the eyes.

Consider protective goggles over basic safety glasses because these PPE pieces can block out exposure to UFPs and VOCs by sealing off the eyes.

Coveralls: Flame-Retardant, Chemical-Resistant, or Fine Particulate Protection

3D printing can involve working with hazardous chemicals, powders (particulates), and even pose the risk of flames or explosions. It’s important to identify which hazards are present throughout your 3D printing process to provide the proper PPE for workers.

When working with ultrafine particles and volatile organic compounds, particulate protection is needed. Body Filter 95+® disposable coveralls and garments are breathable and designed to filter out 95%-99% of 0.3-micron particles—similar to an N95 respirator.

Browse all Body Filter 95+® coveralls and disposable clothing

If corrosive chemical solutions are used in your 3D printing process, chemical-resistant coveralls are necessary to protect against chemical burns and chemical splash. ChemSplash® 1 coveralls, splash aprons, and sleeves protect against light chemical splash and less hazardous chemicals. This line includes styles with taped seams for added protection against liquid chemicals that can seep through exposed seams.

ChemSplash® 1 coveralls, splash aprons, and sleeves protect against light chemical splash and less hazardous chemicals. This line includes styles with taped seams for added protection against liquid chemicals that can seep through exposed seams.

For protection against more aggressive acids, chemicals, and caustics, ChemSplash® 2 coveralls offer the safety you need in more hazardous environments.

Browse all ChemSplash® chemical protective clothing

If your 3D printer uses volatile chemical compounds that can ignite and pose a fire or explosion hazard, consider fire-retardant coveralls. Better yet, chemical and fire-retardant coveralls provide protection against both flames and chemicals such as PyroGuard CRFRTM.

PyroGuard FR® coveralls are flame retardant and pass ASTM D6413 vertical flame testing as well as NFPA 2113 requirements for section 5.1.9. Our PyroGuard CRFMTM increases protection levels by safeguarding against a broad range of chemicals as well as being flame-retardant.

Browse all PyroGuard® coveralls

Safety and 3D Printing

By 2026, the 3D printing market is slated to reach 51.77 billion dollars. As more industries take advantage of this innovative form of production, more attention must be given to health hazards that can be involved.

While 3D printing seems relatively safe, a deeper look proves that compounds, chemicals, and materials used and emitted during printing are hazardous. From ensuring proper safety training to becoming more familiar with which equipment and materials pose the most risk, there are numerous paths to providing adequate protection.

Is 3D printing in an office space dangerous for your health?

3D printing news News Is 3D printing in an office space dangerous for your health?

Published on December 16, 2020 by Carlota V.

New studies have confirmed that particles emitted from 3D printers can negatively impact indoor air quality and have the potential to harm respiratory health. Invented 30 years ago, the unintended adverse impacts of 3D printing on human health are not that well documented. However, the increased use of 3D printers, especially in an office space, has warranted more research in recent years. If you remember, we had discussed at the start of the year the study from EPA (Environmental Protection Agency) that explained that many users were not aware of chemical emissions during the 3D printing process; especially the level of volatile organic compounds (VOCs) emitted, and the influence of filament additives on these levels.

Invented 30 years ago, the unintended adverse impacts of 3D printing on human health are not that well documented. However, the increased use of 3D printers, especially in an office space, has warranted more research in recent years. If you remember, we had discussed at the start of the year the study from EPA (Environmental Protection Agency) that explained that many users were not aware of chemical emissions during the 3D printing process; especially the level of volatile organic compounds (VOCs) emitted, and the influence of filament additives on these levels.

More recently, a new study has emerged to capture the effects of 3D printer emissions and some best practises to protect users in a closed environment, such as an office or school. Of course, the 3D printing process can use different technologies to build objects from plastics, metals, ceramics, etc. Today, many consumer-grade 3D printers use plastic filaments during material extrusion. Published on September 12th, researchers from Georgia Institute of Technology’s new study looked at particles emitted from various types of filament printing, and conducted several tests to gauge their impact on respiratory cell cultures. The study was part of a multi-year research project aimed at characterizing particle emissions, and evaluating their potential for toxicity.

The study was part of a multi-year research project aimed at characterizing particle emissions, and evaluating their potential for toxicity.

Many consumer-grade 3D printers use plastic filaments during material extrusion.

What is the potential for toxicity of particles emitted?

The team found that the hotter the temperature required to melt the filament, the more emissions were produced. Therefore, ABS filament, which requires a higher temperature to melt than PLA filament, produced more emissions. However, when testing the impact on live cells, the researchers noticed that PLA prompted a more toxic response. “The toxicity tests showed that PLA particles were more toxic than the ABS particles on a per-particle comparison; but because the printers emitted so much more of the ABS, it’s the ABS emissions that end up being more of the concern,” explained Rodney Weber, who led the research. He added: “Taken together, these tests indicate that exposure to these filament particles could over time be as toxic as the air in an urban environment polluted with vehicular or other emissions. ”

”

Additionally, the team found that the particles emitted had different chemical characteristics than the filament itself. To achieve certain characteristics, it is quite common for manufacturing companies to add small mass percentages of other compounds. These additives were shown to affect the amount of emissions, particularly for ABS: “Because there can be great variability in the type and amount of additives added to ABS, a consumer may buy a certain ABS filament, and it could produce far more emissions than one from a different vendor.” Finally, the study looked at which types of environmental scenarios were more dangerous. In an office or commercial building, they estimated that better ventilation could limit exposure. However, in a typical residential setting, the exposure could be much higher.

Some Measures

• Operating 3D printers only in well-ventilated areas

• Setting the nozzle temperature at the lower end of the suggested temperature range for filament materials

• Standing away from operating machines

• Using machines and filaments that have been tested and verified to have low emissions.

To achieve certain characteristics, it is quite common for manufacturing companies to add small mass percentages of other compounds.

Even more recently, multiple studies that aim to characterize and quantify the release and composition, particle size, and more from 3D printer emissions, were presented during the 2020 Society for Risk Analysis in a symposium entitled: Exposure and Risk Assessment of 3D Printing and Emerging Materials on December 15th. The symposium found similar findings, which you can read about HERE.

You can find more information about the study from Georgia University of Technology HERE. Were you aware of the toxicity of 3D printer emissions? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Are 3D printers dangerous to health? Expert opinion

3D printers, which have appeared relatively recently, but are already actively penetrating into the daily life of a person and business, can be dangerous to human health. This assumption was made by a group of scientists from the University of California at Riverside, according to the results of the research. These results have already raised many questions regarding the safe use and further development of additive technologies.

This assumption was made by a group of scientists from the University of California at Riverside, according to the results of the research. These results have already raised many questions regarding the safe use and further development of additive technologies.

We studied the arguments of this group of researchers, as well as received an expert opinion from industry experts, and tried to answer the question of whether 3D printing is harmful to humans, what precautions can be taken, and what the future holds for the additive technologies industry.

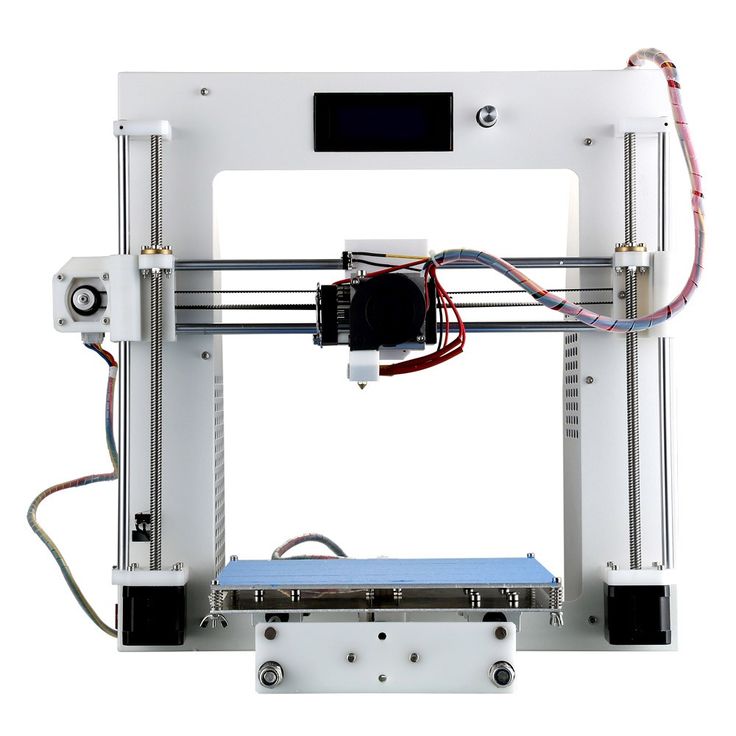

3 D-printer is a kind of mini factory in a small box.

We [society represented by specialized services] control the operation of factories (in this context, for compliance with environmental standards). And we would never put a factory in our house.

However, 3 D-printers are spreading and soon there will be as many of them in our homes as toasters.

– stated William Grover , Associate Professor of Bioengineering at Bourns College of Engineering (one of three colleges that form the structure of the University of California at Riverside).

In the course of their research work, scientists studied two types of 3D printers: Those that melt plastic to get the final object; and those that use light radiation, which turns a liquid substance into a solid body of the required shape. As a result, it turned out that consumables from both types of technologies are toxic to zebrafish embryos (the studies were conducted on them). Moreover, the results of printing (the resulting objects and waste materials) using the technology that uses light are the most toxic.

3 D-printers and health. Study description

The harmful effects of 3D printers on living organisms were discovered, as is often the case in science, quite by accident.

About a year ago, the mentioned Grover purchased a 3D printer for the needs of his laboratory.

In the course of the work of one of the graduate students ( Sherin Mesbaha Oskui ), who studied zebrafish embryos (as such) and used products printed on the same 3D printer in his research, it turned out that the embryos die (immediately or after a short time) after contact with printed objects. This circumstance (death of embryos) stopped Oskui's work on this project, but marked the beginning of a new study, which demonstrated the detrimental effects of 3D printers.

Oskuy and Grover have been joined by several other eminent scientists in their new research project. The objects for research were 2 models of 3D printers: melt-printing polymer material, Dimension Elite from Stratasys ; and, working by exposing the resin to light, Form 1+ from Formlabs .

Each of these 3D printers produced discs 1 inch (2. 54 cm) in diameter. Then, these discs, along with the embryos, were placed in Petri dishes in order to observe further developments.

54 cm) in diameter. Then, these discs, along with the embryos, were placed in Petri dishes in order to observe further developments.

As a result, it was found that the most detrimental effect (on experimental embryos) was exerted by those parts (and printing waste) that were obtained on devices working with light radiation and liquid printing materials (photopolymer resins).

Most of the embryos died on the third day after the "contact", almost all died by the seventh day. And those fish that did survive and eventually hatched had serious deviations and developmental defects.

The data obtained formed the basis of a separate research work (DOI: 10.1021/acs.estlett.5b00249), dedicated to the toxicity of 3D printers during their operation and the products obtained on them.

Of course, the researchers note, the detected toxicity has an incomparably smaller effect on humans than on tiny zebrafish embryos. However, the very fact of such an impact requires serious attention. 3D printing technologies are still at the very start of their rapid development, and many side (negative) effects may appear much later. They, along with the impact on humans of such fruits of scientific and technological progress as Wi-Fi, cellular communications and fluorescent lamps, need to be investigated now.

However, the very fact of such an impact requires serious attention. 3D printing technologies are still at the very start of their rapid development, and many side (negative) effects may appear much later. They, along with the impact on humans of such fruits of scientific and technological progress as Wi-Fi, cellular communications and fluorescent lamps, need to be investigated now.

3 Are D-printers dangerous to health? Yes or no? Expert opinion

As already mentioned, 3D printing technologies are very promising. The development of additive technologies promises great prospects for many sectors of the economy, and for society as a whole. And suspicions that these technologies and the resulting products can be harmful to humans can, if not stop, then certainly slow down the expected progress.

To find out how dangerous 3D printers are, if at all, we reached out to an industry expert for comment Sergey Ismulin , (development engineer, chief designer of research and production company TTF-Group (TTF-Group).

In the above example with Danio embryos, we are talking about printing technology with photopolymer resins - SLA . To fully understand the problem, it is necessary to say a few words about the technology itself. Prior to the growth of the final product, the raw material is a UV-active resin, presented in liquid form. During the printing process, the resin is activated by ultraviolet radiation, its physical properties change, and it hardens, similar to 9-based adhesive.0003 epoxy resin . This ideally, in practice, the process of activating the resin with UV radiation does not result in complete polymerization of and part of it retains a certain amount of volatility. As a result, the finished product may actively evaporate some of the "wet" resin. To be fair, not all resins used in the 3D printing process are toxic, and often the type of raw material used is determined by the manufacturer of the device.

However, SLA printing technology is not the market leader, the most interesting are printers using the most common FDM technology - melted plastic printing. In this case, the greatest danger is the evaporation of plastic heated to the melting point. Since incomplete polymerization of the initial monomers occurs during the production of raw materials, some of them are able to evaporate with increasing temperature. Among these monomers, styrene is the most dangerous. Extremely toxic substance, may evaporate in unacceptable quantities from raw materials from unverified manufacturers. There is a lot of research in the industry closest to FDM technology - extrusion injection molding. The results of these studies unequivocally answer the question of the dangers of heated polymer fumes - yes, it is harmful.

There is no unique and simple solution , a complex and multi-vector approach is needed. On the one hand, producers of raw materials must improve the quality of the latter and eliminate the presence of harmful substances as much as possible.

On the other hand, manufacturers of 3D printers should take care of ways to minimize harmful fumes during operation. This includes the maximum possible lowering of the extrusion temperature, the use of sealed chambers, and mandatory filtration or the use of absorbent materials in their devices. And if the device works non-stop, then the room in which the printer is located must be equipped with an active exhaust ventilation system. In turn, the state should develop and adopt a number of legislative measures and technical regulations regarding the certification of 3D printing technology. Only if all measures are followed, you can get a guarantee that there will be no harm to health in the 3D printing process.

As an example of a comprehensive approach , I can illustrate how our company operates under the strict standards we have set for ourselves. I’ll start with the last one, being an active participant in the cluster on additive technologies created by the Academy of Sciences of the Republic of Belarus, at regular meetings of the presidium we made a proposal to create regulations and standards in the field of 3D printing.

The proposal received the necessary support, and together with the regulatory authorities, we will deal with this issue closely as we advance our own developments. As for the materials used for 3D printing, we are actively collaborating with the laboratory of polymeric materials of the Institute of Chemistry of New Materials. Colleagues from the institute have developed a unique material optimized for 3D printing, and given their professional experience and adherence to strict chemical safety standards, we can say with full confidence that their raw materials are as harmless as possible. Meanwhile, in the devices we develop, we do not prohibit the use of materials from other manufacturers, which imposes certain requirements on the device. First, our 3 D printers are a hermetically sealed box that prevents the penetration of harmful fumes to the outside. Secondly, the air recirculation system using HEPA filters cleans the internal volume of the chamber during the printing process, which provides additional protection against emissions.

Thirdly, the raw material is preliminarily prepared and degassed in a special compartment of the printer. Thus, we carry out the whole range of measures in order to maximally secure the 3D printing process on our devices.

- the Belarusian developer of the study of American scientists commented.

In turn, Oskui , who conducted the studies described above, in the course of additional research found that the negative effect and toxicity of the products obtained can be reduced by the use of ultraviolet radiation. At least those parts (obtained on a 3D printer by light exposure to resins) that have been exposed to an hour of ultraviolet radiation, became significantly less toxic .

3 D-printers - growing popularity and prospects

Research conducted by Canalys says that the popularity of 3D printers is growing! And, most importantly, it will continue to grow at an accelerated pace. Thus, in particular, the report notes that the total market for 3D printing in 2012 amounted to $ 288 million, and already in 2013 - $ 2.5 billion. By 2018, according to Canalys, the global market for additive technologies will grow even more, reaching $16.2 billion marks

Thus, in particular, the report notes that the total market for 3D printing in 2012 amounted to $ 288 million, and already in 2013 - $ 2.5 billion. By 2018, according to Canalys, the global market for additive technologies will grow even more, reaching $16.2 billion marks

Growth in this market, as often happens, is progress in the development of technological solutions in this area, allowing: a) to increase the efficiency of printing ; b) increase the quality of the resulting products, and c) reduce the price of 3D printers.

Prices for 3D printers are really falling. You can buy a 3D printer that works on the principle of melting polymers (ABS plastics, PLA and other less popular plastics) for $ 200; You can buy a 3D printer that uses light radiation in its work for 3,000 US dollars. This dynamic allowed 3D printers to go beyond the walls of design bureaus and scientific laboratories and come into the homes of ordinary citizens who use 3D printers, for example, to print children's toys or collectible models, as well as for other useful and fun pastimes.

3D printers and people. Epilogue

Summing up the results of this material , it can be noted that “the devil is not as terrible as he is painted”. Simply put, new technologies are not as scary as it might seem at first. Such fears are certainly grounded, but for the most part, they are due to the very fact that there are certain gaps in the issue of studying additive technologies. This is quite natural, given the fact that the technology is new. Are 3D printers dangerous to health? Nothing more than (for example) a microwave oven, of course, subject to your reasonable handling of these fruits of progress.

At the same time, we in no way detract from the merits and discoveries of scientists from the University of California. Moreover, it is their (and their colleagues) working in close cooperation with the developers of the technologies and devices themselves and that will contribute to the further development of 3D printing technologies and the more active penetration of 3D printers into our daily lives .

Noticed an error? Select it and press Ctrl+Enter

Tweet

3D printers are harmful to health. Reedus

- Society

1 3 301

- July 26, 2013, 02:23

- Sokol85

3D printing may be the wave of the future, but a new study from the Illinois Institute of Technology has shown that 3D printers can be harmful to human health. They claim that printers release harmful particles that are bad for human health.

Professor Bren Stevens and his team at the Illinois Institute of Technology have measured the tiny particles that are deposited on office printers during normal operation. The results obtained allowed them to compare the operation of the printer with smoking. This study is published in the journal Atmospheric Environment. During the operation of a 3D printer, the plastic is heated and then extruded through a nozzle to create a layer. As the print head moves, a shape is formed.

The results obtained allowed them to compare the operation of the printer with smoking. This study is published in the journal Atmospheric Environment. During the operation of a 3D printer, the plastic is heated and then extruded through a nozzle to create a layer. As the print head moves, a shape is formed.

Scientists have measured two types of plastic PLA material and ABS material. PLA material melts at a lower temperature and releases a total of 20 billion particles per minute. ABS material (acrylonitrile butadiene styrene) melts at a higher temperature and releases as much as 200,000,000,000 particles per minute during normal operation. Stevens says these emissions are similar to those from cigarettes, gas or electric stoves.

Particles that are generated during printing end up in the lungs, where they accumulate, and then go to the brain. The results of the study showed that particles can cause asthma, stroke, and heart problems.

Picture of the day

- Ben Wallace made public the fact that a missile was launched from a Su-27 near an RAF aircraft

- British Prime Minister Liz Truss announces her resignation

- The Ministry of Digital Development will suspend the connection of schools to Wi-Fi

23 0 5712 read later read later

11 0 3355 read later read later

- Ben Wallace made public the fact that a missile was launched from a Su-27 near an RAF aircraft

- British Prime Minister Liz Truss announces her resignation0172

- The Ministry of Digital Development will suspend the connection of schools to Wi-Fi

Politics

Times: Boris Johnson intends to run for prime minister today

At the same time, supporters of Rishi Sunak are sure that he is the most suitable candidate.

-1 0 180 read later read later

Politics

Britain calls for immediate elections after Trusstoday's resignation

5 Liz Truss took over as prime minister on 6 September.

9 0 3601 read later read later

citizen journalism

Travel

History

As the city of the dead has been waiting for revival for 75 years today

Who are the Palestinian refugees?

16 0 6326 read laterread later Most British Conservatives want the prime minister's immediate resignation.

-28 0 4586 read later read later

Technology

In the realm of electric scooters: history in detail today 9002 9002 I met interesting people and went where the average scooter user would never go.