Large 3d printers prices

BIG volumes starting at $310

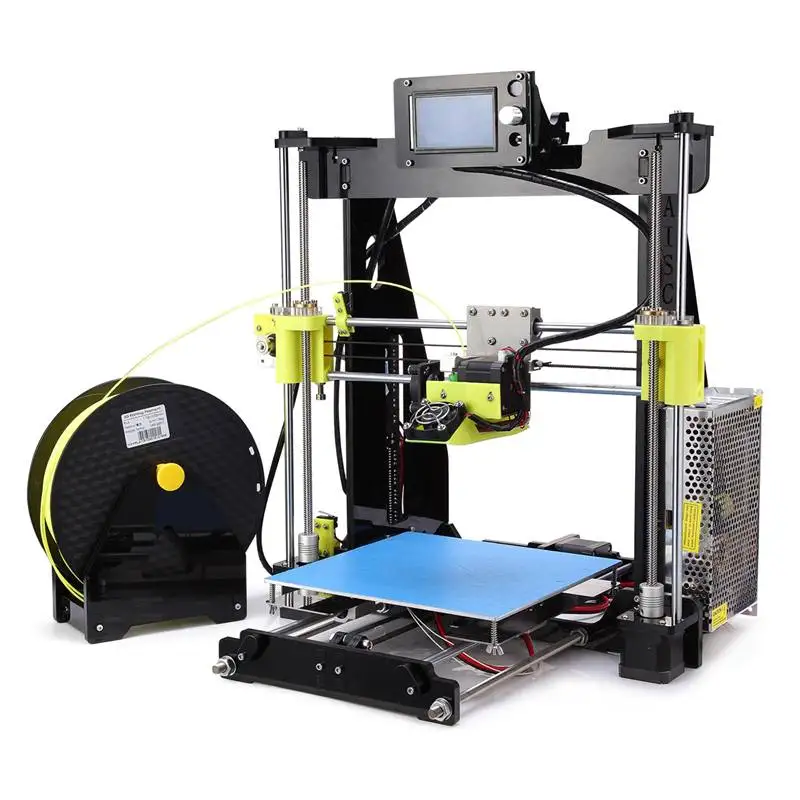

Large 3D printers for consumers used to be hard to find. Today, there are many different low-cost brands that offer affordable large volume 3D printing. Check out our selection and large volume 3D printer buying guide below!

Table of contents

What’s the best large 3D printer when you’re on a low budget?

Big, affordable 3D printers under $1,000

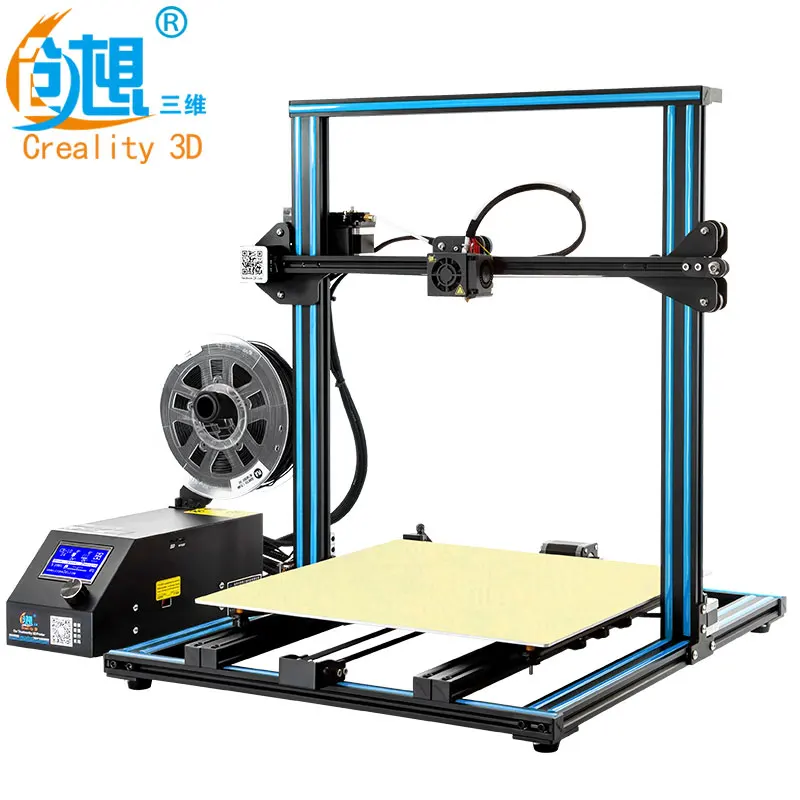

CR-10 S5

Duplicator 9

CR-10 Max

Chiron (Kit)

Predator

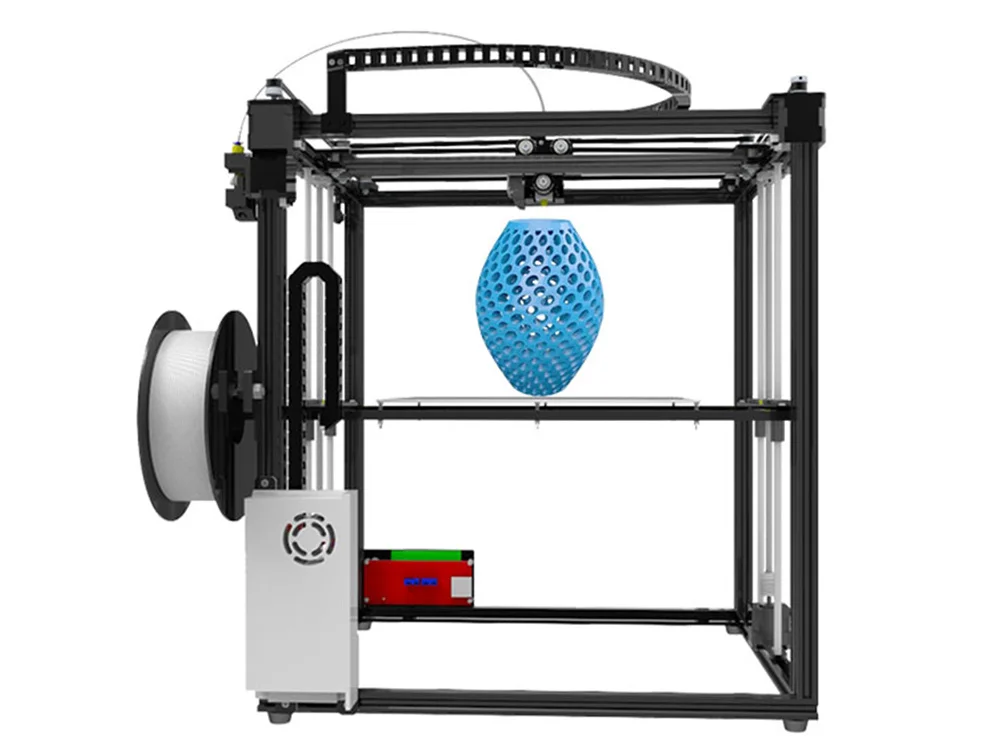

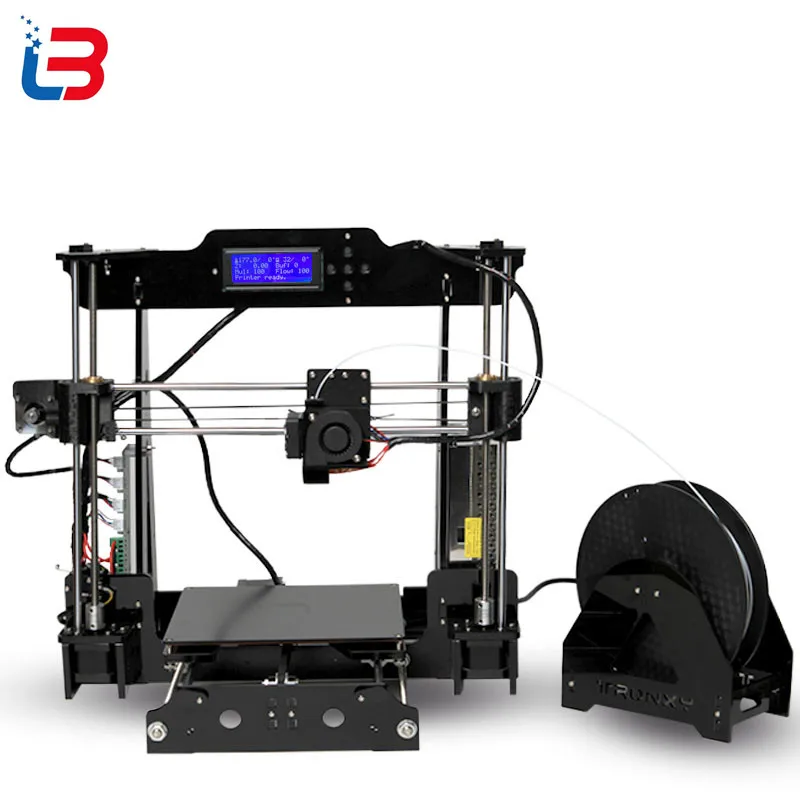

X5S (Kit)

A30

U20 (Kit)

Sidewinder X1

CR-10 V2

A5S

Construction

Structure: cartesian, delta, or CoreXY

Material support

Features

Customer support

FAQ

What’s the best large 3D printer when you’re on a low budget?

Build volume is generally an area where “bigger is better” if it’s within your budget. A large 3D printer will allow you to print anything from a TPU smartphone case to a full-sized stormtrooper helmet made from ABS.

As you can imagine, large build sizes are especially useful if you need to 3D print big objects. With a smaller desktop 3D printer, you’d have to break down your big 3D model into multiple parts and print them separately, to assemble or glue them together afterward. Big 3D printers are also great for printing a series of objects in one go.

Our guide focuses on 3D printers with a large build area that is available for under $1000. While some consider any printer beyond 250 x 250 x 250 mm to be in the oversized class for home use, our picks all exceed 300 x 300 x 300 mm.

Big, affordable 3D printers under $1,000

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Alfawise | U20 (Kit) | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | – | $ 310318 €279 £45,063 ¥ | Contact |

| Geeetech | A30 | 320 × 320 × 420 mm12.6 × 12.6 × 16.54 in | – | $ 330339 €297 £47,970 ¥ | Contact |

| Tronxy | X5S (Kit) | 330 × 330 × 400 mm12.99 × 12.99 × 15.75 in | – | $ 360369 €324 £52,331 ¥ | Contact |

| Artillery 3D | Sidewinder X1 | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | – | $ 399499 €360 £58,001 ¥ | Contact |

| JGAURORA | A5S | 305 × 305 × 320 mm12.01 × 12.01 × 12.6 in | – | $ 399409 €360 £58,001 ¥ | Contact |

| ANYCUBIC | Chiron (Kit) | 400 × 400 × 450 mm15.75 × 15.75 × 17.72 in | – | $ 499512 €450 £72,537 ¥ | Contact |

| Creality | CR-10 V2 | 300 × 300 × 400 mm11.81 × 11. 81 × 15.75 in 81 × 15.75 in | – | $ 519533 €468 £75,444 ¥ | Contact |

| ANYCUBIC | Predator | 370 × 370 × 455 mm14.57 × 14.57 × 17.91 in | – | $ 588603 €530 £85,475 ¥ | Contact |

| Wanhao | Duplicator 9 | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | – | $ 649666 €585 £94,342 ¥ | Contact |

| Creality | CR-10 S5 | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | – | $ 759779 €684 £110,332 ¥ | Contact |

| Creality | CR-10 Max | 450 × 450 × 470 mm17.72 × 17.72 × 18.5 in | – | $ 1,1001 129 €992 £159,902 ¥ | Contact |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Product | Brand | Build volume | Build size | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| U20 (Kit) | Alfawise | 36 L | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | $ 310318 €279 £45,063 ¥ | Contact manufacturer |

| A30 | Geeetech | 43.01 L | 320 × 320 × 420 mm12.6 × 12.6 × 16.54 in | $ 330339 €297 £47,970 ¥ | Contact manufacturer |

| X5S (Kit) | Tronxy | 43.56 L | 330 × 330 × 400 mm12.99 × 12.99 × 15.75 in | $ 360369 €324 £52,331 ¥ | Contact manufacturer |

| Sidewinder X1 | Artillery 3D | 36 L | 300 × 300 × 400 mm11.81 × 11.81 × 15.75 in | $ 399499 €360 £58,001 ¥ | Contact manufacturer |

| A5S | JGAURORA | 29.77 L | 305 × 305 × 320 mm12.01 × 12.01 × 12.6 in | $ 399409 €360 £58,001 ¥ | Contact manufacturer |

| Chiron (Kit) | ANYCUBIC | 72 L | 400 × 400 × 450 mm15.75 × 15.75 × 17.72 in | $ 499512 €450 £72,537 ¥ | Contact manufacturer |

| CR-10 V2 | Creality | 36 L | 300 × 300 × 400 mm11. 81 × 11.81 × 15.75 in 81 × 11.81 × 15.75 in | $ 519533 €468 £75,444 ¥ | Contact manufacturer |

| Predator | ANYCUBIC | 62.29 L | 370 × 370 × 455 mm14.57 × 14.57 × 17.91 in | $ 588603 €530 £85,475 ¥ | Contact manufacturer |

| Duplicator 9 | Wanhao | 125 L | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | $ 649666 €585 £94,342 ¥ | Contact manufacturer |

| CR-10 S5 | Creality | 125 L | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | $ 759779 €684 £110,332 ¥ | Contact manufacturer |

| CR-10 Max | Creality | 95.18 L | 450 × 450 × 470 mm17.72 × 17.72 × 18.5 in | $ 1,1001 129 €992 £159,902 ¥ | Contact manufacturer |

Overview of the best large desktop 3D printers

Below you’ll find more details about each large 3D printer.

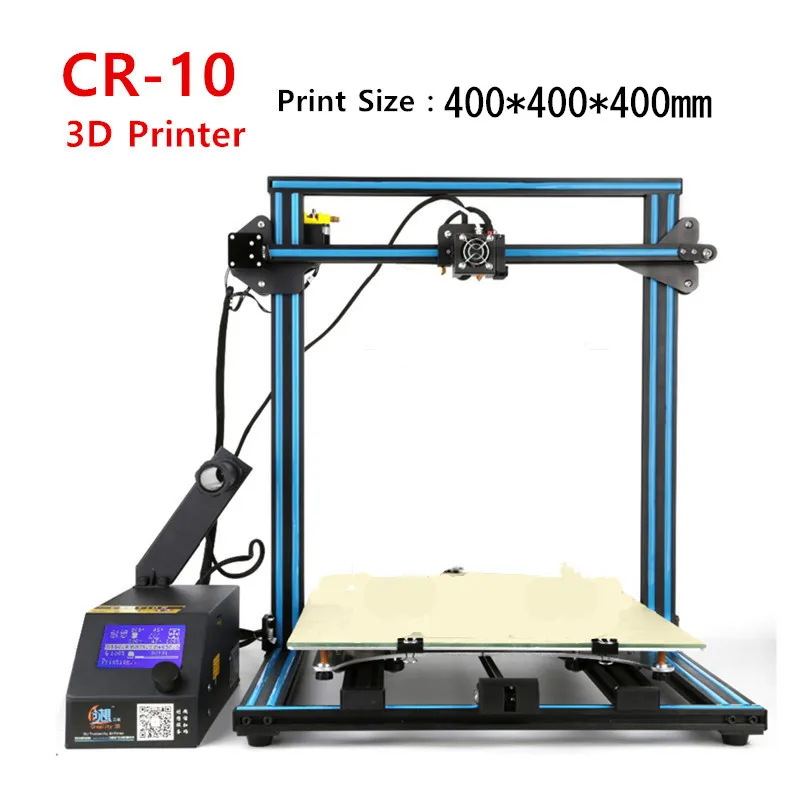

The Creality CR-10 S5 is one of the best large scale 3D printer options in this class with a build volume of 500 x 500 x 500mm. With only a few sections, it’s also one of the easier machines to assemble, and the build quality is a nice upgrade over the base model CR-10.

With only a few sections, it’s also one of the easier machines to assemble, and the build quality is a nice upgrade over the base model CR-10.

Dual Z rod screws ensure excellent accuracy along on this open-source machine, and the hot end can handle PLA, ABS, and TPE. As it’s essentially a larger version of the CR-10S, you can expect features like a heated bed, auto-resume, and filament runout detection as well.

Contact manufacturer Add to comparison

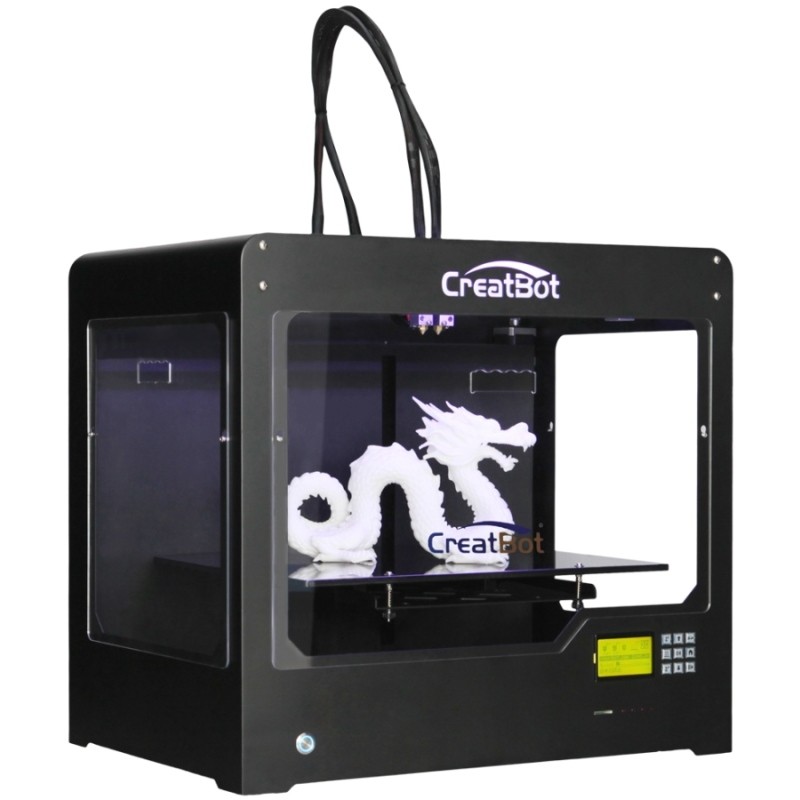

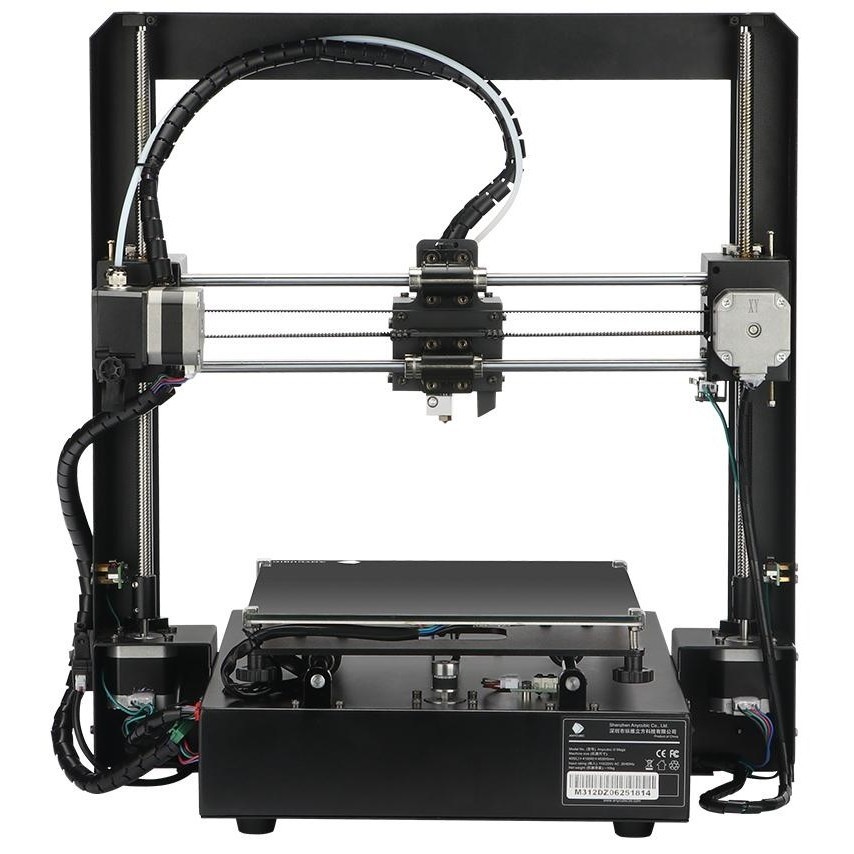

Wanhao is one of the more popular brands with makers looking for an affordable machine, and the Duplicator 9 500 (D9 500) is a large 3D printer with an array of excellent features. It’s well-built with an extruded aluminum frame and easy to use thanks to an integrated touchscreen display and auto-resume.

The MK10 full metal hotend is another highlight of this printer. It can reach 300°C, which allows you to print with a broader range of materials. Automatic bed leveling and a heated bed with an anti-backlash rolling system are also great features.

Contact manufacturer Add to comparison

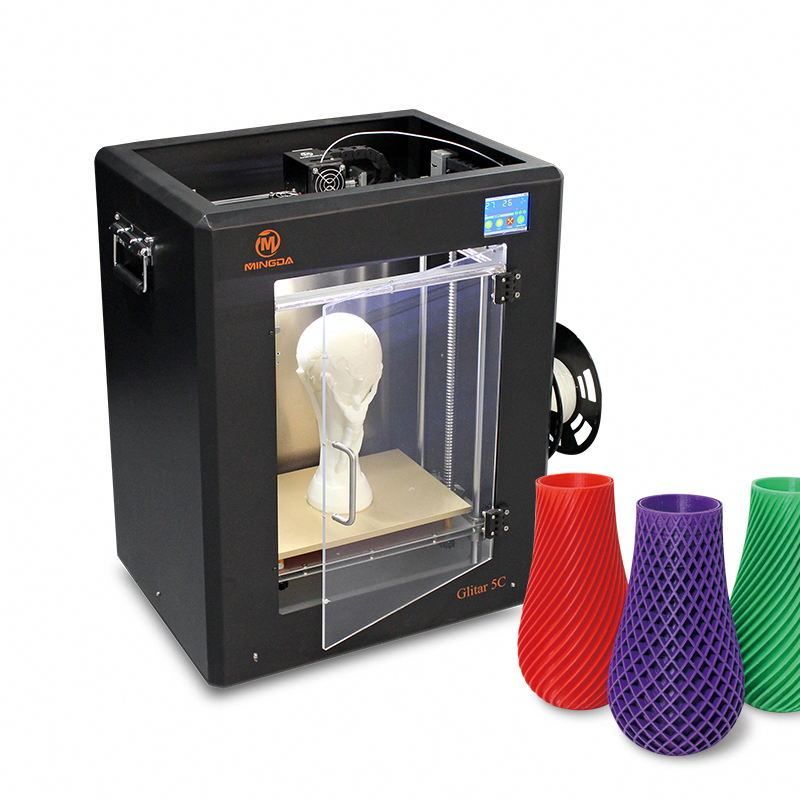

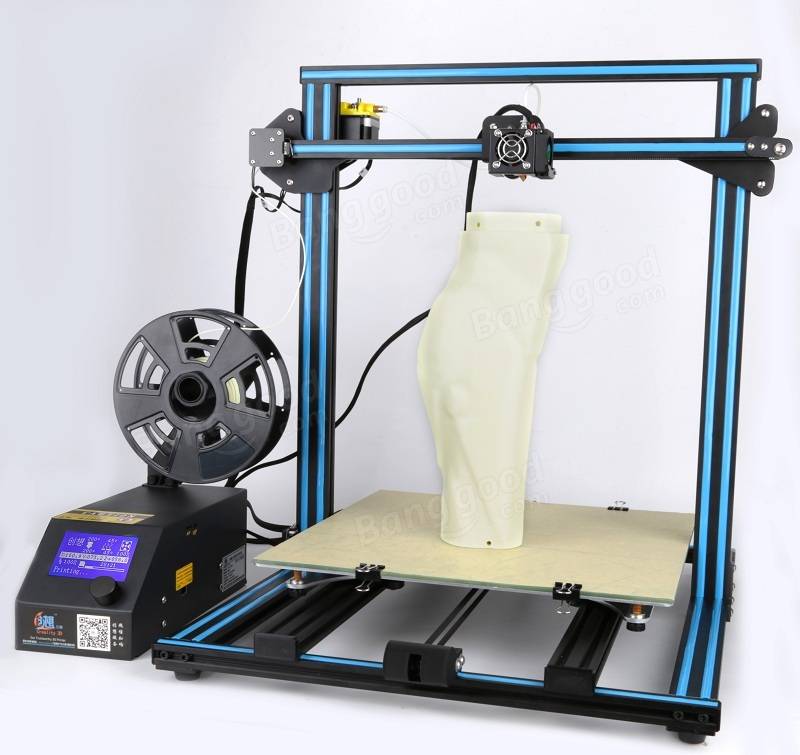

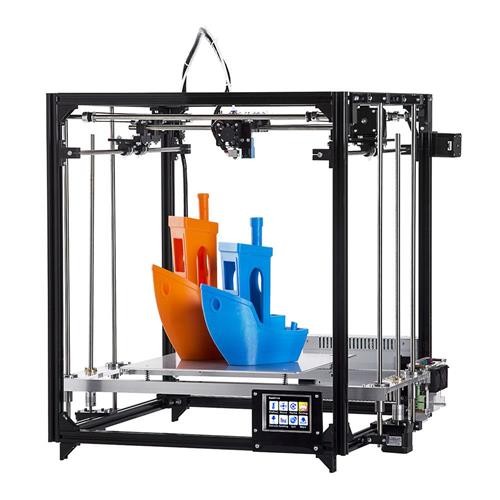

The CR-10 Max is another new addition to Creality’s arsenal and a printer worthy of being in the large format class for average consumers. The spacious 450 x 450 x 470mm build volume gives you plenty of room to work, and several areas of this machine have seen a substantial upgrade over standard models in the CR-10 lineup.

Smooth prints on a large scale are possible with the CR-10 Max thanks to its unique Z-axis bracing system that Creality calls “the Golden Triangle”. Automatic bed leveling and the touchscreen-based UI are also great features to have on hand as well as the split-flow power supply, which heats up the bed in an instant.

Contact manufacturer Add to comparison

ANYCUBIC has several impressive 3D printers in their lineup, and they recently jumped into the large scale range with the Chiron. Given its price point and the build area compared to some of the printers on our list, it’s certainly an option for one of the best large 3D printer under $1000.

The ANYCUBIC Chiron keeps things simple with a classic design featuring a top-notch heated print bed and a 25-point leveling system. The single extruder and hot end are rated to work with ABS, HIPS, and TPU as well as PLA on this affordable big 3D printer.

Contact manufacturer Add to comparison

While a little smaller than the Chiron, the ANYCUBIC Predator is still one of the best big 3D printers under $1000. It’s just as capable as its larger sibling and is the perfect choice if you prefer Delta 3D printers to Cartesian-style machines.

The Predator offers up one of the largest build areas of any Delta printer in this range. It sports a quick heating Ultrabase Pro platform that can reach 100°C and has a 37-point auto-leveling system. An integrated touchscreen and filament sensors are also features to appreciate with the ANYCUBIC Predator 3D printer.

Contact manufacturer Add to comparison

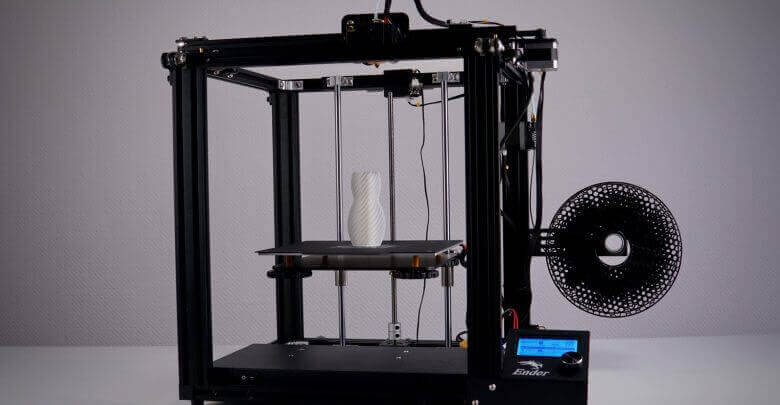

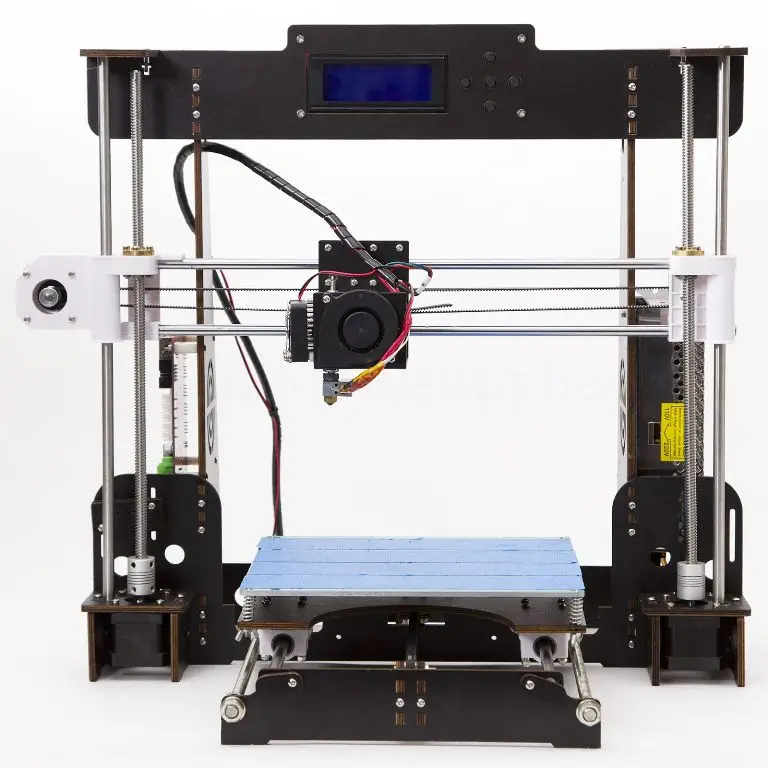

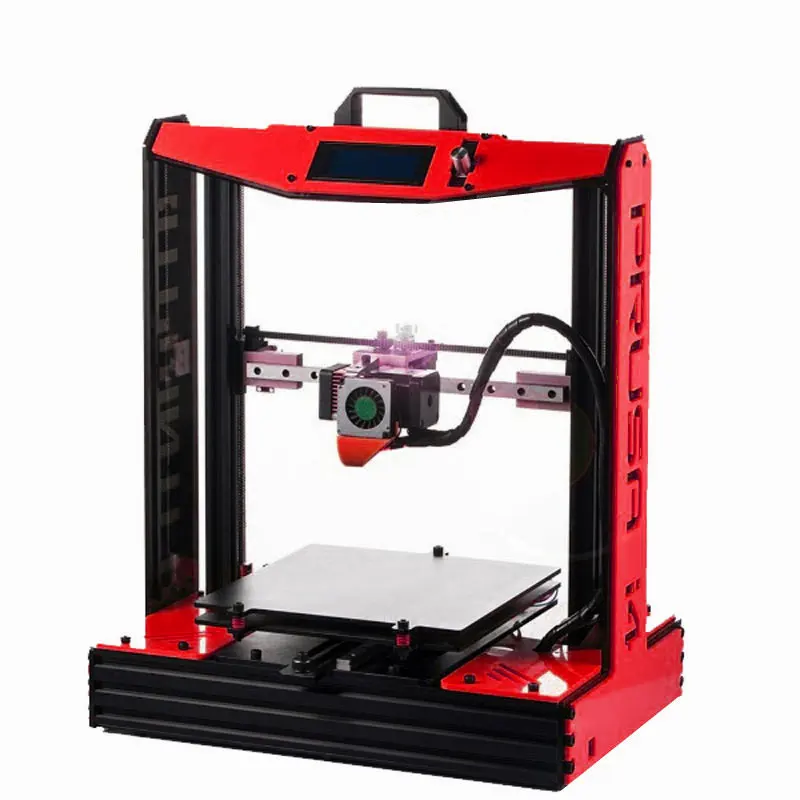

TronXY is a company out of China that specializes in producing affordable machines. Their entry onto our list of the best large 3D printers under $1000 is the TronXY X5S. It’s a DIY kit with excellent reviews and a very stable structure.

Their entry onto our list of the best large 3D printers under $1000 is the TronXY X5S. It’s a DIY kit with excellent reviews and a very stable structure.

The TronXY X5S is a CoreXY printer with a sturdy metal frame. That adds stability while you print and the auto-leveling system ensures accuracy. Filament runout detection, a heated bed, and a touchscreen are included, but their customer support isn’t quite up to the standards of other manufacturers in this class.

Contact manufacturer Add to comparison

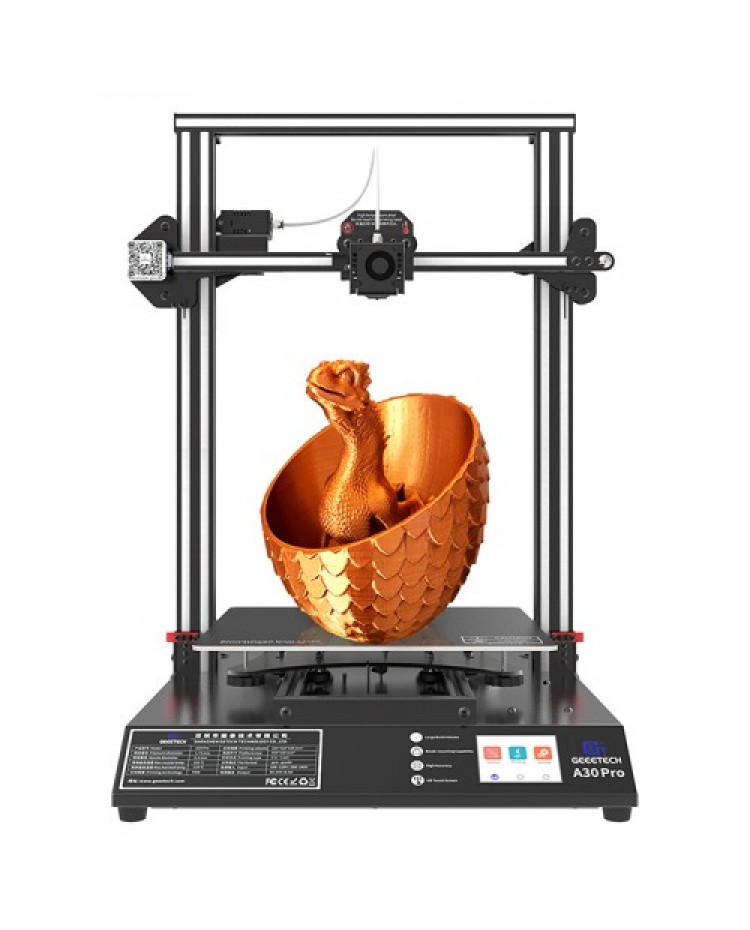

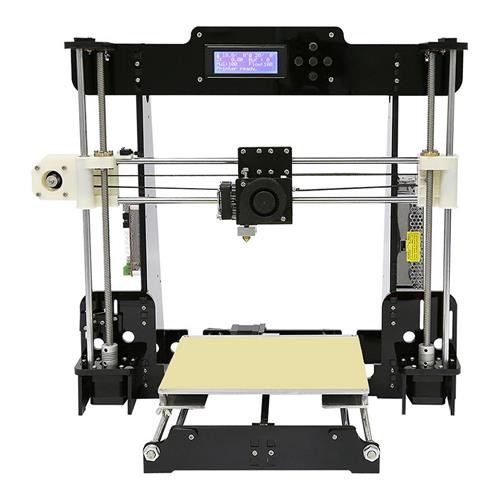

Fans of the popular CR-10 will recognize this printer and appreciate the price. The Geeetech A30 is a big desktop 3D printer with a frame built from extruded aluminum parts. It prints materials like ABS, Nylon, and Woodfill with ease, which is ideal when you’re looking for a large 3D printer.

This large FDM 3D printer is a capable machine with an ample build volume and heated bed sporting a silicone carbine glass plate. Makers found the colorful 3.2-inch touchscreen a pleasure to use, although some had issues with software and offsets. Customer service and community support are both solid with this brand of 3D printer.

Customer service and community support are both solid with this brand of 3D printer.

Contact manufacturer Add to comparison

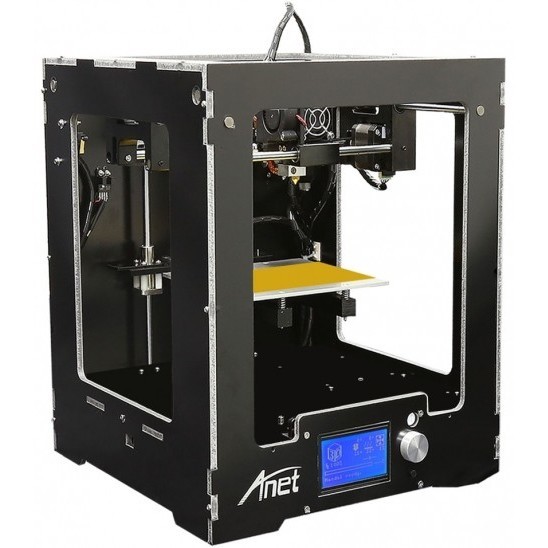

The Alfawise U20 is a Gearbest 3D printer and a substantial upgrade over the previous model. It’s accurate and also one of the cheapest large 3D printers on our list, although missing a few features found on more expensive big 3D printers.

With a large build volume of 300 x 300 x 400mm, the Alfawise U20 can bring large creations to life whether you prefer PLA or TPU. It has all the standard bells & whistles, including a color touchscreen, but bed leveling is handled manually. Aside from a few awkward design decisions and a noisy fan, the U20 provides a lot of bang for your buck.

Contact manufacturer Add to comparison

Artillery has produced several popular printers over the past few years, including the Sidewinder X1. This sleek printer is quieter than other 3D printers with a large build area and has a heated bed capable of hitting its maximum temperature in around 2 minutes..jpg)

The Artillery Sidewinder X1 can print a wide range of materials with a direct drive extruder and Titan-style hot end. An extruded aluminum frame keeps the X1 stable regardless of your print speed, while the color touchscreen makes the machine a joy to use. Cable management and the synchronized Dual Z system are two additional perks of the X1.

Contact manufacturer Add to comparison

The Creality CR-10 V2 is one of the newest variants of the company’s extremely popular CR-10 3D printer. The new model shares plenty of similarities with the original but is a better option if you don’t need a printer quite as large as the CR-10 Max.

One advantage of the CR-10 V2 is the separate control box, which is ideal if you want to add an enclosure. The “Golden Triangle” design and aluminum frame ensure stability while 3D printing, and the dual-port hot end cooling fans help dissipate heat. Other noteworthy features include filament runout detection and auto-resume.

Contact manufacturer Add to comparison

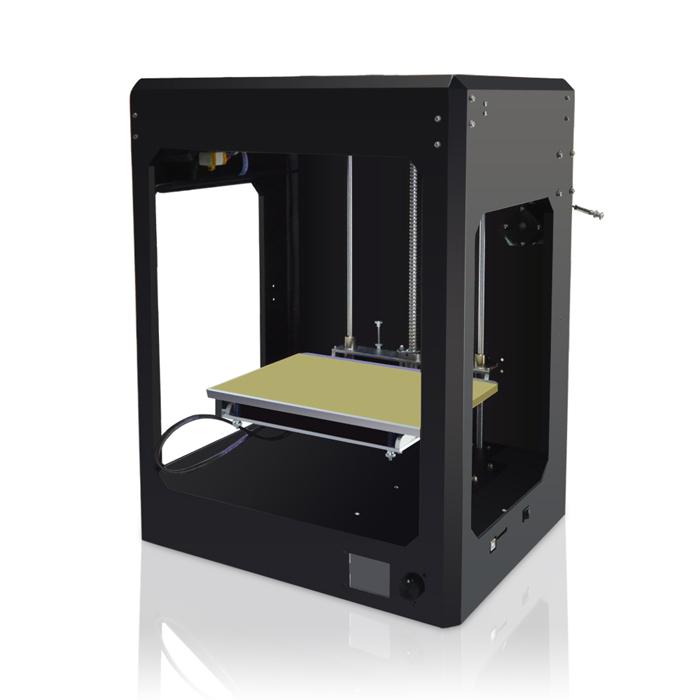

The JGAurora A5S is a 3D printer that proves good things come in small packages. This machine leaves a smaller footprint behind than many of its competitors, but still has a large build volume for your creations at 305 x 305 x 320mm.

This machine leaves a smaller footprint behind than many of its competitors, but still has a large build volume for your creations at 305 x 305 x 320mm.

This 3D printer has a black diamond glass plate and a heated bed with a maximum temperature of 110°C. A 32-bit motherboard keeps things running smoothly, and we’re fans of discreet cable management system as well. Calibration is semi-manual, but the overall setup is quick and straightforward with the A5S.

Contact manufacturer Add to comparison

How to find the best large 3D printer for under $1000

There are a lot of exciting machines available at this price point, which makes it difficult to narrow things down. Here are a few key areas you’ll want to take into consideration before you choose your large 3D printer.

Construction

Build quality is important with any type of 3D printer regardless of the price. Well, it’s even more crucial with a large 3D printer as you’ll need a stable machine that can handle massive prints, which can take hours or days.

All of the key components– especially the mainframe– should be made from metal (ie. aluminum). Plastic 3D printed parts on budget-friendly printers are common, but can easily be reprinted and replaced whereas frames and aluminum parts are far more expensive to upgrade. Buying a printer that’s built like a tank is never a bad idea.

You also need to keep the overall size of the printer in mind, as 3D printers with large build areas are going to have a larger footprint. Check the dimensions of each machine if you are short on space, and keep in mind that some of them have separate control boxes that take up extra room.

Structure: cartesian, delta, or CoreXY

If you’re looking for a 3D printer in the $200 to $300 range, you’re typically limited to one style of printer. When it comes to large 3D printers under $1000, there are three main styles to choose from: Cartesian, Delta, or CoreXY 3D printers.

- Cartesian (Prusa i3 type) – These machines are the most common, popular, and easy to alter.

In this price range, they also tend to be the ones that offer the biggest volumes. The print head moves up and down, and from right to left, while the build bed goes forwards and backward.

In this price range, they also tend to be the ones that offer the biggest volumes. The print head moves up and down, and from right to left, while the build bed goes forwards and backward. - Delta – This triangular type of 3D printer provides a cylindrical build volume, and is, therefore, taller than they are wide. The print head has more freedom to move as it is mounted at the center of three “arms”. The print bed stays in place, which eliminates wobbling issues that you can potentially find on an i3-type printer.

- CoreXY – It is a kind of cartesian 3D printer, but it looks like a cube. The printer itself takes up less room than a Prusa i3 type 3D printer since the fixed bed doesn’t require space to move back and forth. These printers can be tricky to assemble and tweak.

Material support

Material support comes down to two things – the hot end (nozzle) and the print bed. That means you need to consider the type of hot end that’s included with the printer as well as the temperatures it’s capable of reaching.

That means you need to consider the type of hot end that’s included with the printer as well as the temperatures it’s capable of reaching.

An all-metal hot end is the best choice for printing at higher temperatures or using exotic materials like LAYCeramic or Proto-Pasta’s conductive PLA. Nowadays, all-metal nozzles are a relatively standard feature on many large 3D printers.

However, if you do choose a printer with a brass nozzle, you won’t be able to print abrasive materials like carbon fiber without seriously damaging the hotend. Ordering a new nozzle and swapping the old one out isn’t too complicated though!

You will also find a heated bed find on the best big 3D printers, but how well they work and how quickly they will reach optimum temperatures can vary. A heated print bed will allow you to print with a wider range of materials too (TPU, Nylon, …) whereas without heating the platform you can pretty much only print PLA.

Features

With smaller machines, it’s not uncommon to find things like Wi-Fi connectivity or a dual extruder, but you won’t find either of those on large-sized 3D printers under $1000. These kinds of features generally don’t make the cut in order to help keep the price down.

These kinds of features generally don’t make the cut in order to help keep the price down.

That said, there are some other nice features that you can find on big 3D printers in this price range. Many of them are equipped with a touchscreen and SD card slot, and some also boast automatic or semi-automatic bed leveling.

Customer support

Excellent customer support is crucial when purchasing any technical device. Even the most highly rated machines can have issues, which is where a good customer support system comes in handy.

Given the fact that almost all of the largest 3D printers under $1000 come from China, it’s essential to know who will handle any issues if they arise with your new printer. Smaller brands may not have the best customer support but often make up for it with active users and forums or Facebook groups where you can find help quickly.

FAQ

How big can 3D printers print?

In the commercial range, there are printers with build volumes measured in meters, not millimeters. Printers with the big build size in the consumer class under $1000 typically come in under 500 x 500 x 500 mm.

Printers with the big build size in the consumer class under $1000 typically come in under 500 x 500 x 500 mm.

Can I print with Carbon Fiber filament and other composites using a large 3D printer?

As long as the hot end meets the manufacturer’s recommended requirements for the filament, it’s possible. How well that exotic material actually prints depends on your machine and how well it’s dialed in, however.

How heavy is a large format 3D printer?

Great question, but it depends on the model. On average, you can expect the big 3D printers on our list to weigh between 24 and 35 pounds fully assembled.

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

- Request XL service quote

When To Consider Large Scale 3D Printing

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics. Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects.

Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts. - Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means. With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

- Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter. Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

- Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures.

Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight. 3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix, BLB Industries, Tractus3D or Cosine Additive.

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$11,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

Tractus3D T2000

The T2000 is measuring 2 meters (78.7″) in height and is capable of printing parts measuring 1 meter (39.4”) in height and a diameter of 68 cm (26.7″). Besides its massive build volume, this machine is packed with the latest innovations from Tractus3D. Including a fast extrusion system, the F033L, which ensures print speeds of up to 300 mm/s.

T2000

- Benefits

- Applications

- - Large scale delta filament 3D printer

- - Extremely fast printing with the F033L print head

- - Huge print area: 680 mm (D) 1000 mm (H)

- - Can print a wide range of specialty materials

- - Complementary Simplify3D software licence

- - XL 3D printer that is designed to be used in the office space

Mold Making, Prototyping, Research and Development, Restoration

Cosine Additive AM1

The Cosine Additive AM1 is a large scale, material extrusion 3D printer. Cosine lets you choose between multiple extrusion options. The pellet extrusion system offers flexibility and cost savings. Instead of being limited to only 10 – 20 different kinds of plastic in filament, powder or resin form – with pellet extrusion you have the entire market at your disposal. So tens of thousands of different types of plastic from the injection molding and extrusion worlds are all available for you to print.

Cosine lets you choose between multiple extrusion options. The pellet extrusion system offers flexibility and cost savings. Instead of being limited to only 10 – 20 different kinds of plastic in filament, powder or resin form – with pellet extrusion you have the entire market at your disposal. So tens of thousands of different types of plastic from the injection molding and extrusion worlds are all available for you to print.

Starting at $125,000Cosine Additive

Request a Quote

cosine am 1

- Benefits

- Applications

- - Large scale material extrusion 3D printer

- - Print size: 1100 x 850 x 850 mm

- - High speed printing: up to 1000 mm/s

- - Improved humidity controlled filament spool chamber

- - Closed and temperature controlled print chamber

- - ACS High Performance Multi-Axis EtherCAT motion control system

Mold Making, Production, Prototyping, Research and Development, Tooling

BLB Industries The BOX SMALL

Hailing from Sweden, BLB Industries is a company that has made major waves in the 3D printing industry. The BOX SMALL enables you to print parts measuring 1500 x 1000 x 1000 mm.

The BOX SMALL enables you to print parts measuring 1500 x 1000 x 1000 mm.

$205,000 - $245,000BLB Industries

Request a Quote

€167.500 - €200.000BLB Industries

Request a Quote

BLB Industries The BOX SMALL

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1000 x 1000 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 14 kg per hour

- - 15" touch screen

- - High quality linear motion modules from Rexroth

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$13,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,900Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$6,900Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Get a Quote

XL 3D Print Service

3D printing is a viable option for display advertising, large scale concept models, car parts, furniture, molds & tooling. We offer both cost effective solutions with thick layers and rough surfaces for rapid prototyping as well as highly detailed & post-processed end-use objects. Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

- Technologies: FDM, SLA, GDP

- Materials: From PLA to CF composites & more

- Maximum print size: 1450 x 1100 x 1800 mm

- Post-processing: Spray paints, metal coatings, assembly & many more

Large camera 3D printers

Large camera 3D printers3D equipment supplier since 2010

[email protected] a call+7 495 646-15-338 800 333-12-82

3D-scanners printersSoftwareServices

About the companyClients and projectsDemo hallGovernment procurementDeliveryService3D Encyclopedia

BlogContacts

3D printing systems equipped with large build chambers: models, characteristics, materials, cost

How to choose a 3D printer 9Olo powder0

Sand

0

Manufacturer

-

3DLAM

0

028

-

Total Z

1

-

UnionTech

4

-

Intamsys

1

-

Farsoon

1

-

Stratasys

4

-

3D Systems

0

-

BIGREP

3

-

SLM Solutions

5

-

Flashforge

0

-

SteereTech

Price on request

to 3 months

Relatives morePrice on request

more0002 Price on requestto 3 months

morePrice upon request

Up to 6 months

MoreTotal-Z AnyForm 650 PRO

- Production: Russia

- Chamber: 650×500×650 mm

- Technology:9 FDM up to 9005 extruder: up to 50 Extruder

- Technology: SLA

- Chamber: 2100×700×800 mm

- Layer thickness: 0.

1–0.23 mm China 90 28

1–0.23 mm China 90 28 - Technology: SLA

- Camera: 1400×700×500 mm

- Layer thickness China: 0.28–9022 mm

- Technology: FDM

- Camera: 406 × 355 × 406 mm

- layer thickness: 0.127–0.330 mm

- Technology: FDM

- Camera: 914 × 610 × 914 mm

- layer thickness: 0.127–0.508 mm

- Material: thermal plastics

- Technology: FDM

- Material: Plastic

- Camera: 1005x1005x1005 mm

- layer thickness: 0.3-1 mm

- Technology: FDM

- Material: Plastic

- Camera: 1020 x 970 x 980 mm

- layer thickness: 0.

3-0.6 mm

3-0.6 mm -

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one particular model?

-

Are there any tools or devices available to automate some of these tasks?

Price on request

Up to 6 months

More detailsUnionTech RSPro 2100

Price upon request

Up to 3 months

Learn moreUnionTech RSPro 1400

Price on request

to 3 months

more Read moreStratasys Fortus 450MC

002 Up to 3 months

Read moreStratasys Fortus F900

9000 9000 9000 to 3 months

Read moreBigrep One

Price on request

to 3 months 9 months 9 months 9 months0003 Read more

Bigep Pro

Price for

to 3 months to 3 months

Read more- +7 495 646-15-338 800 333-12-82

2010–2022, Globatek JSC. All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate your costs

Three of the most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail, and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Metal Direct 461LS2 461LS2 | ||||

|---|---|---|---|---|---|---|---|---|

| Permission | ★ Look | ★ opa | ★cle | ★cle | ★☆★ opa ★ ution | ★cle ★ Look | ★ opa | ★ opa ventary |

| Surgery | ★ op ★ opa ☆ | ★ any ☆ | ★cle | |||||

| Ease of use | ★ opa | ★ Look | ★cle | ★cle | ★ | |||

| PROMISE | to OL x 300 x 600 mm (Desktop and Workshop 3D printers)Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm | ||||

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750, while high-volume large format desktop printers are available from $11,000. | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. | |||

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. | |||

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). Machining and other types of surface treatment can be used. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. | |||

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. | |||

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring tight tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial runs. | Robust and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take much time to achieve high quality models, while models printed using FDM technology require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

Outsource production orders to third-party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, a bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could bring products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes.

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.