Kapton 3d printing

Bed Surfaces: Applying Kapton Tape

Certain filaments call for certain bed surfaces. Kapton Tape is a key choice for ABS, but it can get tricky when it comes to application. Learn how to apply this sticky tape flawlessly with our helpful tutorial.

MatterHackers

April 28, 2016

Kapton tape is the recommended bed surface for 3D printing ABS filament. The tape protects the bed surface and acts a base layer, while the hair spray or juice provides the adhesion.

Kapton tape (a registered trademark of DuPont) is a polyimide film. Created for the aerospace industry in the 1960s, Kapton tape as a flexible adhesive tape that is stable over a wide range of temperature, from -269C to +400C. The film was used for many awesome projects like the Apollo Lunar Module.

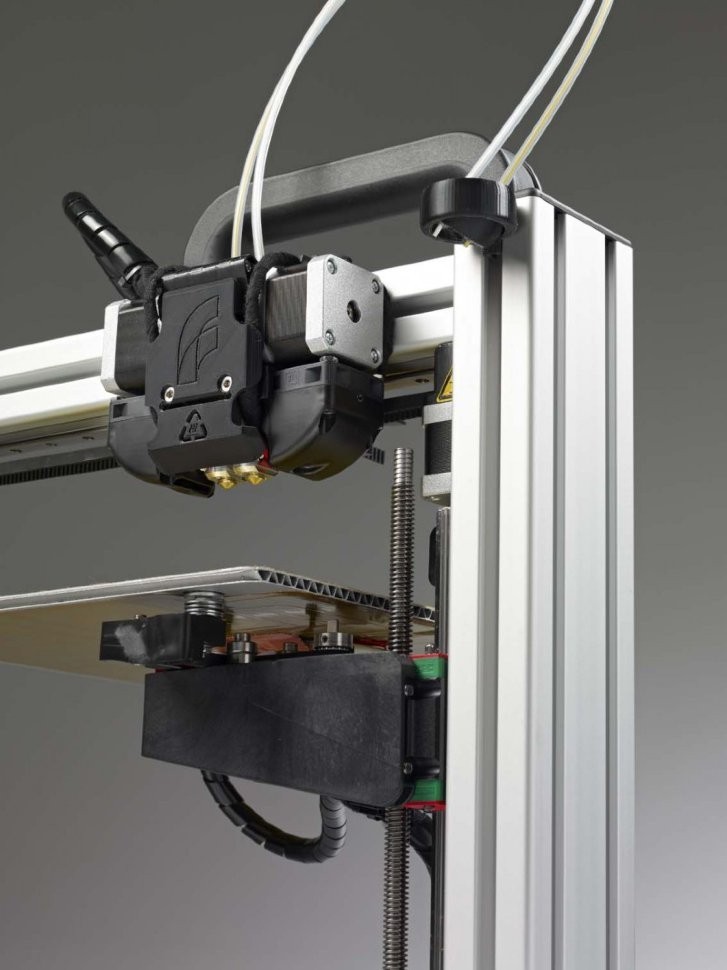

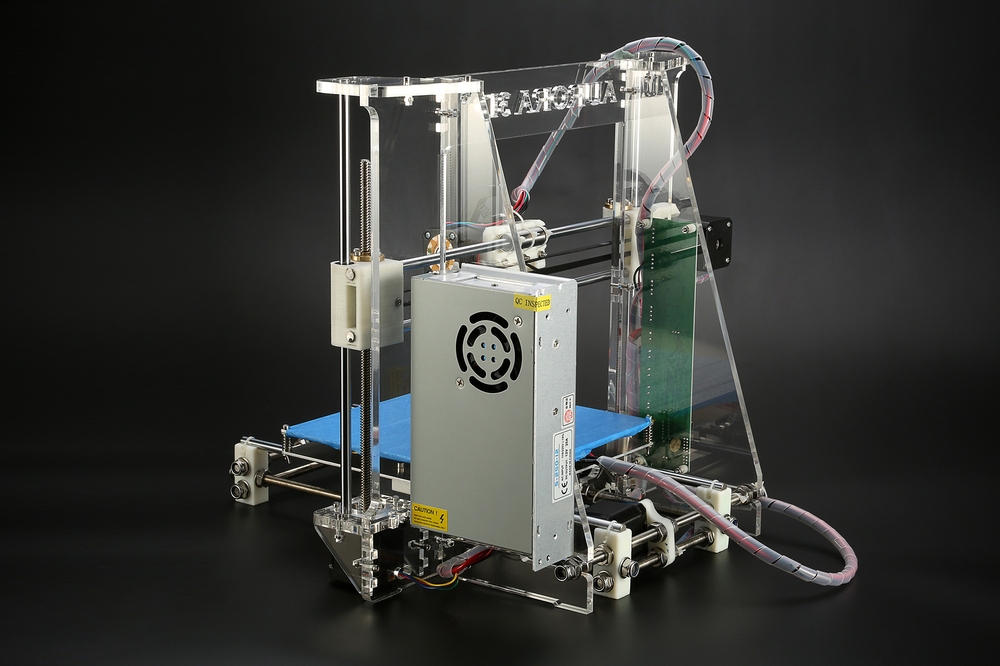

The tape was then discovered and utilized widely in the Electronics manufacturing industry for its electrical isolation properties in addition to the thermal stability. 3D printing, in particular the RepRap Community, discovered a new use for the robust material as a bed surface.

Kapton tape comes in large rolls which allow you to cover the entire bed with a single sheet. Unfortunately, applying the tape is tricky since it is easy to trap air bubbles underneath or make creases. In this guide we will show you an easy way to apply Kapton without trouble.

Step 1- Create Soapy Water Mixture

- First, you will need an empty spray bottle and some dish soap.

- Fill the spray bottle with water, then add a few squirts of dish soap. The exact mixture is not important.

- Shake vigorously.

Step 2- Remove Glass Bed

- Remove the glass build plate from your printer.

- If necessary, scrape off any residual plastic and clean the surface using Windex.

Step 3- Spray Bed With Soapy Water

-

Things are going to get messy at this point. Either lay down some towels or do this some place where you don't mind getting water everywhere.

-

Spray the entire surface of your glass plate with the soapy water. Do not be afraid to use too much.

-

Spread the soap around and make sure that the entire plate is covered. If you miss a spot, the tape will get stuck there and you will have a problem.

Step 4- Lay Down Tape

- Pull enough tape off the roll to cover the entire bed, plus plenty of extra.

- Be careful not to let the tape get stuck to itself. You may need someone to help you at this point to hold the sheet as you cut it from the roll.

- Lay the tape down on the glass. The soap will prevent it from sticking and allow you to slide it around to get it in the right position.

- When you have the tape aligned correctly, stick the overhanging edges to the workbench below. This will hold the tape in place during the following steps.

Step 5- Squeegee Water Out

- Use a credit card or some other object with a hard edge to start pushing the soapy water out from under the tape.

- Begin at the center of the bed and work outwards.

- You will probably want to use a paper towel to soak up the water around the edges.

- Do your best to get out as much of the water as you can, especially around the edges. If you don't, they will be likely to peel up.

Step 6- Cut Tape to Size

- At this point you can cut off the excess tape with an art knife or sharp blade and then throw it away. The sheet will be stuck to the glass.

Step 7- Bake Moisture Out

- Now you have a perfectly applied sheet of Kapton with no bubbles underneath, however it is not ready for use yet.

- When the bed is heated, any residual moisture under the tape will boil, creating bubbles of water vapor. To prevent this, we need to thoroughly dry your build plate before use.

- Install it back on the printer, and turn on the bed heater to low heat (60-70 °C).

- Let the build plate bake for an hour.

Step 8- Apply Hair Spray or ABS Juice

- You are now almost ready for printing.

- Apply your favorite bed adhesion solution. Hair spray works well and is convenient, but for the toughest prints you will want to use ABS juice.

Step 9- Print

- Heat your bed to at least 90 °C. If your printer is capable of getting up to 100 or 110 °C, then do so.

- Enjoy printing with ABS.

- If you are still having problems with peeling or layer separation, consider building an enclosure for your printer.

And that's it! It is really that easy. Now, get that Kapton tape on your printer and enjoy!

Happy Printing!

Kapton Tape for 3D Printers

Gizmo Dorks

$13.99

Current stock: 0

Kapton Tape for 3D Printing Beds

Get this superior quality Kapton tape for 3D printers! This tape works with many different 3D printing bed platforms. The beauty of Kapton tape is the ability of the polyimide film to withstand temperature. Therefore, many 3D printer users love applying this polyimide Kapton tape on 3D printers with heated build platforms. The plastic filament will have full adhesion to the polyimide film at the designated temperature, but it also has self releasing characteristics as the bed cools. Your print will be easy to pop off. Kapton tape is the practical choice for your 3D printer bed.

The beauty of Kapton tape is the ability of the polyimide film to withstand temperature. Therefore, many 3D printer users love applying this polyimide Kapton tape on 3D printers with heated build platforms. The plastic filament will have full adhesion to the polyimide film at the designated temperature, but it also has self releasing characteristics as the bed cools. Your print will be easy to pop off. Kapton tape is the practical choice for your 3D printer bed.

Kapton Tape Info

- Kapton layer thickness - 1 mil

- Adhesive (silicone) layer thickness - 1 mil

- Prints adheres well but come off cleanly

- Able to withstand high temperature from heated beds

- Durability to last several print cycles

- Works on many print surfaces

- Color - Amber Yellow

Available Sizes

Rolls

6.25 inches by 100 feet

9 inches by 100 feet

Sheets of 10

6.25 inches by 6.25 inches

8 inches by 8 inches

9 inches by 12 inches

10 inches by 10 inches

12 inches by 12 inches

Application of Kapton Tape

Kapton tape can be applied via either the dry or wet method

Dry method

Apply the tape by rolling the tape on the build plate. Start with one edge first, and application is made easier if using a straight edge such as a ruler to adhere towards the other edge.

Start with one edge first, and application is made easier if using a straight edge such as a ruler to adhere towards the other edge.

Wet method

Unroll and cut the desired size Kapton tape. If you are using the precut sheets, then simply peel away the protective backing. Spray down a thing layer of soapy water on to the build plate. Place the Kapton tape directly on to the soapy water mixture. The tape can be easily repositioned to the desired location because of the soapy water. Flatten and remove air bubbles along with excess soapy water with a squeegee. Allow the build plate to dry completely before use which will probably take a few hours.

Your shopping cart

Account

Log in

Email Address *

Password *

Forgot password?

New Customer

Create an account with us and you'll be able to:

- Check out faster

- Save multiple shipping addresses

- Access your order history

- Track new orders

- Save items to your wish list

Create Account

Forgot Password

Fill in your email below to request a new password. An email will be sent to the address below containing a link to verify your email address.

An email will be sent to the address below containing a link to verify your email address.

Email Address *

Kapton material to be used as 3D printing resin

Sep42017

Heat resistant Kapton material

Many of those who deal with 3D printing have probably used Kapton material at least once in their lives. Without it, printing with materials like ABS can be a real nightmare, because sometimes they don't want to stick to the 3D printer platform at all. However, Kapton material is not only a high-quality substrate for a 3D printer platform. It is a high-performance, heat-resistant material with excellent insulating properties, which is widely used in various industries.

For example, in the aerospace industry, Kapton is used to insulate spacecraft and satellites. Also, its insulating properties are highly valued in the electronics industry. And if earlier in the 3D sphere the Kapton material was used exclusively as a substrate, then soon it will also be possible to print it. Thanks for such a breakthrough is the researchers at Virginia Tech, who managed to synthesize the molecules needed to use Kapton as a consumable.

Thanks for such a breakthrough is the researchers at Virginia Tech, who managed to synthesize the molecules needed to use Kapton as a consumable.

How Kapton was developed for 3D printing

It was extremely important to create stable macromolecules that retain their thermal and insulating properties, because without this the very essence of the experiment is lost. The main difficulty lies in the complex molecular structure of the material, which is almost impossible to reproduce in laboratory conditions. The Kapton material is an aromatic polymer that consists of carbon and hydrogen atoms in benzene rings. It is this combination that provides it with exceptional temperature and chemical resistance.

It took the researchers about a year to get a successful result, and it was certainly worth the effort. Just imagine, if before the Kapton material was produced exclusively in the form of thin sheets, then using it as a raw material for 3D printers opens up access to the creation of Kapton products of any architecture. With this technology, the possibilities of using Kapton are almost limitless. However, it is not only the mass industry that benefits, but also the 3D printing technique itself.

With this technology, the possibilities of using Kapton are almost limitless. However, it is not only the mass industry that benefits, but also the 3D printing technique itself.

Kapton material for 3D printers

Even the strongest and most heat-resistant 3D printing materials available on the market today can withstand about 150˚ At this temperature, they begin to lose their mechanical strength. As for the development discussed in this article, it is almost three times more heat resistant than even the strongest polymers. Thus, Kapton material is able to withstand temperatures up to 550 ˚С without losing its properties. And this means that the functionality of 3D printers can increase significantly.

Over the course of a year, the researchers tested the development in various conditions and with various settings before reaching the optimal result. After the successful completion of the project, the team of scientists applied for a patent, and within a short time, several large companies have already expressed their interest in the development. Given the prospects of the developed material, its application in large industrial projects is unlikely to take long. But the appearance of Kapton in the list of materials available for household 3D printing is unlikely to be soon.

Given the prospects of the developed material, its application in large industrial projects is unlikely to take long. But the appearance of Kapton in the list of materials available for household 3D printing is unlikely to be soon.

Back to main page

Kapton - the most heat resistant polymer produced by 3D technology

Kapton - the most heat resistant polymer produced by 3D technology

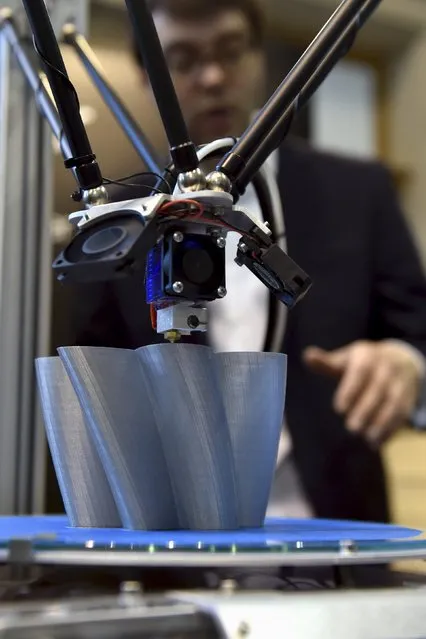

produced by 3D printing. This is a significant breakthrough that allows to increase the number of potential applications for technology 3D printing in space research projects, as well as in electronics and aerospace industries, where the material is also often used. Researchers at Virginia Tech have been able to synthesize the molecules needed to 3D print a polyimide material that is formally known as Kapton.

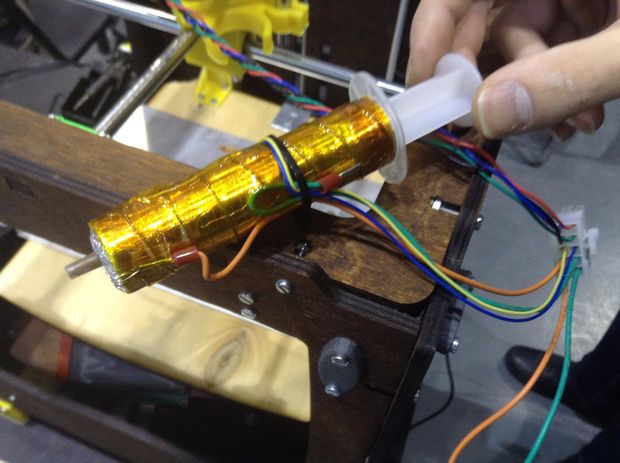

The process of creating the necessary macromolecules for 3D printing Kapton were invented in such a way that they remain stable and retain their thermal properties, it took researchers from the Virginia College of Engineering and the College of Science about a year of study and experience to achieve these properties. The success of the project lies in the fact that a theoretically limitless variety of shaped parts and components can now be made from Kapton yarn, which was previously possible in the form of large thin sheets. These gold foil sheets are present in the layered insulation found on many satellites and spacecraft to protect them from the extreme temperatures and cold conditions they are exposed to.

The success of the project lies in the fact that a theoretically limitless variety of shaped parts and components can now be made from Kapton yarn, which was previously possible in the form of large thin sheets. These gold foil sheets are present in the layered insulation found on many satellites and spacecraft to protect them from the extreme temperatures and cold conditions they are exposed to.

The difficulty in manufacturing parts from Kapton is due to its molecular structure. It is an aromatic polymer composed of carbon and hydrogen atoms in benzene rings, which gives it exceptional thermal and chemical stability, but also means complex structures are almost impossible to manufacture.

3D printing parts with Kapton not only expands the possibilities for industries that already use it, but also for 3D printing technology . Typically, 3D printed polymers begin to lose their mechanical strength at around 300 degrees Fahrenheit. According to the research team, Kapton can maintain its properties up to 1020 degrees Fahrenheit. This means that 3D printing can now be used for all new high-end applications.

This means that 3D printing can now be used for all new high-end applications.

“Now we can print the highest temperature resin ever, when the temperature reaches about 285 degrees Fahrenheit, the melting point of this resin is higher than any other printable resin in existence. In addition, our 3D printed material has the equivalent strength of traditionally machined Kapton thin film material,” said Christopher Williams, Associate Professor of Mechanical Engineering at the College of Engineering, and Head of Design, Research, and the Education Lab for Additive Manufacturing (DREAMS).

The project was a large collaborative effort: Williams worked with Timothy Long, professor of chemistry and director of the Macromolecule Innovation Institute (MII), and then post-professional researcher Maruti Hedde, associate of the University of North Carolina at Chapel Hill. Specialists from Vishwanath Meenakshi Sundar College of Engineering Doctoral Students, India and scientist Nicholas Chartrain from Westfield, New Jersey were also involved.