3D scanner spray

About 3D Scan Spray : 3DScanSpray.com

To achieve optimal accuracy and results with 3D laser scanning it is often necessary to apply an anti-reflection coating. Helling 3D Scan Spray is especially designed for this purpose, providing a great solution for coverage.

Check out our most frequently asked questions below- if you have another question not answered, feel free to contact us.

Why choose Helling 3D Scan Spray from Laser Design?

Is 3D Scan Spray Removable?

Is 3D Scan Spray Good for Use in the Dental Market?

Does this 3D scan spray work with white light 3D scans?

How can I purchase 3D Scan Spray outside of the USA & Canada?

What are the technical specs of the 3D Scan Spray?

What is the Tariff Schedule B or HTS (Harmonized Tariff Schedule) number?

How does the spray work with scan targets?

Can 3DScanSpray be used on polished/coated or transparent optical surfaces? Whats is the cleaning process for such surfaces?

Can all particles from the 3DScanSpray be removed from a part?

How well does the spray work on clear glass?

How does Helling 3D Scan Spray compare to dulling spray?

What is the Export Classification?

What is the drying time of the spray?

What types of parts and colors can be sprayed?

Can we prep a part using alcohol wipe? or clean the part to remove the spray coating with alcohol wipe (or perhaps soap and water)?

What is the thickness of the spray?

What kind of environment should the spray be used in?

What is the spray made of?

Can the Helling spray be used on electronics such as tablets and smartphones?

How long does a can of spray last?

Can the Helling 3D spray be used on hot surfaces?

What are the hazardous ingredients (including the propellant) in the Helling 3D scan spray?

Why don’t Sections 3 and 8 align on the English MSDS and why are they different from the Spanish and other MSDS?

Additional information on differences between the English and Spanish MSDS.

Why choose Helling 3D Scan Spray from Laser Design?

- Provides more uniform coverage using less spray material due to proprietary reflective qualities

- Using less spray means this 3D scan spray is more cost effective than other commonly used reflective sprays!

- Because of the fine grained structure of our spray it is possible to apply evenly layers of spray with minimal thickness (average particle size of 2,8 µm).

- The Helling 3D Scan Spray is anti-glare and easily removable

- 3D Scan spray is imported from Germany, and specifically designed for 3D scanning. As the leading spray used in Europe we are excited to be the exclusive North American distributor.

Is 3D Scan Spray Removable?

Yes, this spray is not only the least harmful of all sprays to your parts, it also gives the best coating too.

Small white particles coat the surface, and if the surface is porous like wood then the particles can get embedded. They don’t fuse or melt to the surface, so elbow grease and a brush can remove the particles.On non-porous surfaces like machined surface metals, the spray wipes cleanly off. Craggy surfaces like cast metal surfaces require more than just a rag to wipe over it, but a couple scrubs back and forth to make sure the cloth brushes through all the crags.

They don’t fuse or melt to the surface, so elbow grease and a brush can remove the particles.On non-porous surfaces like machined surface metals, the spray wipes cleanly off. Craggy surfaces like cast metal surfaces require more than just a rag to wipe over it, but a couple scrubs back and forth to make sure the cloth brushes through all the crags.

The Helling 3D Scan Spray is the optimal product for accurate laser technology and is available in a 400ml spray can. Order Your 3D Scan Spray today.

Is 3D Scan Spray Good for Use in the Dental Market?

This spray is ideal for dental applications especially for single tooth scanning/measuring for re-building (synthetics, synthetic coated models) and mold/wax figure models. Note: this spray is not safe for use inside a person’s mouth. It is intended to be used only on inanimate objects.

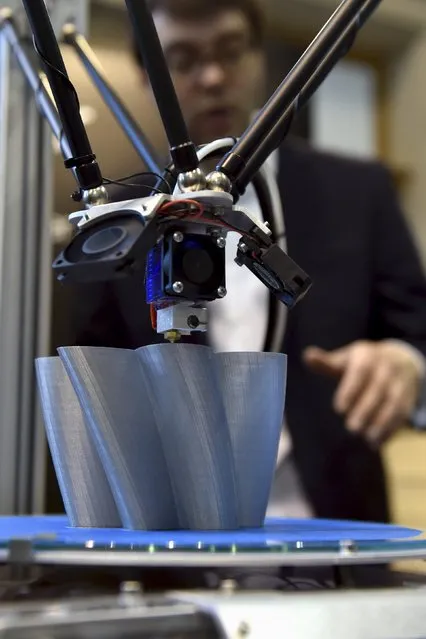

Does this 3D scan spray work with white light 3D scans?

Yes, the 3D spray is suitable for use with all types of 3D scanners including white light systems. It dulls the surface of any shiny or reflective part.

It dulls the surface of any shiny or reflective part.

How can I purchase 3D Scan Spray outside of the USA & Canada?

To order 3D scan spray in other areas outside of the Continental U.S & Canada:

In Mexico, Venezuela, Colombia and Peru contact:

ALVARO G VASQUEZ

Tel: 305-599-7694

www.intexportrade.us

[email protected]

For all other areas outside of the US & Canada contact Helling GmbH directly.

HELLING GMBH

Spökerdamm 2 • 25436 Heidgraben

Telefon: 04122 – 922 – 0

Fax: 04122 – 922 – 201

E-Mail: Helling GmbH

Technical specs:

Safety Data Sheet – SDS

LDI’s Exclusive Selling Certificate for North America

Shelf Life of Helling 3D Scan Spray

ISO Certification

Anti-Glare Certificate

Anti-Glare Data Sheet

Video of Spray in Action

What is the Tariff Schedule B or HTS (Harmonized Tariff Schedule) number?

Anti-Glare Spray Cases: 3206. 49.6050

49.6050

Anti-Glare Spray in 1L Containers: 3824.99.9297

How does the spray work with scan targets?

Best practice in using 3D Scan Spray with scan targets is to:

– Apply before or after a light coat of spray

– Wipe scan spray off the targets using a cotton swap, tissues, or your fingertip

– For parts that require a heavier coat of spray (like glass), apply the stickers first, then spray, and then wipe off the spray from the stickers.

Can 3DScanSpray be used on polished/coated optical surfaces? Whats is the cleaning process for such surfaces?

Yes, it can be used on polished/coated surfaces. You will need to be careful while cleaning due to low but existent abrasive properties of the product. We’d recommend washing the spray off under water and then using some kind of washing up liquid (if necessary).

Can all particles from the 3DScanSpray be removed from a part?

We are unable to guarantee a complete removal of all particles because it depends on the surface of the part. However, we have found that the spray is very low in detrimental material and a recent customer performed this Chemical Analysis PDF on a fine surface finish.

However, we have found that the spray is very low in detrimental material and a recent customer performed this Chemical Analysis PDF on a fine surface finish.

How well does this spray work on clear glass?

Our engineers advise that the spray works very well for clear glass. You just need to spray on a thick enough coating.

How does Helling 3D Scan Spray compare to dulling spray?

Dulling spray is designed for photography not for 3D scanning. Our experience is that a large quantity of dulling spray needs to be applied to achieve the desired effect for 3D scanning of shiny objects. The result is a coating that is way too thick / uneven and a process that is way too messy. Key differences are the uniformity of application and the particle size of the spray. The Helling spray is designed for demanding, high-accuracy applications where you want the minimum possible spray thickness applied as uniformly as possible. See below for our boilerplate explanation and thank you for your interest.

What is the Export Classification?

This product was developed for commercial purposes.

What is the drying time of the spray?

Our experience is that the spray dries in about 10 seconds and then you can start scanning. Translucent parts may require 2-3 applications of spray with 10 seconds of drying time in between applications.

What types of parts and colors can be sprayed?

Virtually all color parts and surfaces, including black and clear parts can be sprayed.

Can we prep a part using alcohol wipe? or clean the part to remove the spray coating with alcohol wipe (or perhaps soap and water)?

Yes, you can use for prep and cleaning/removal

What is the thickness of the spray?

the average thickness of the spray is about 2 microns.

What kind of environment should the spray be used in?

We recommending applying the spray with venting of fumes to the outside or with a downdraft table like this one.

If the product is being applied in a large amount over a long period of time, we’d also recommend some respiratory protection.

What is the spray made of?

The exact ingredients used in the Helling spray are a trade secret which cannot be revealed due to competitive reasons. The Helling 3D scan spray contains a harmless form of alcohol that is commonly used for disinfection along with a mineral compound of silicates and carbonates which are used in the cosmetics industry and as food additives. Notwithstanding that the solids used in the spray are generally regarded as harmless, we recommend using some kind of exhaust venting (downdraft table) and/or additional measures for respiratory system protection.

Can the Helling spray be used on electronics such as tablets and smartphones?

The Helling spray has been used successfully on many electronic devices. A little compressed air with an additional wipe of a rag normally off cleans most of the spray without any damage. Only a minimal amount of spray needs to be used so the risk of damage to the internal electronics is minimized.

Only a minimal amount of spray needs to be used so the risk of damage to the internal electronics is minimized.

How long does a can of spray last?

Assuming proper application of a very light coating, we estimate that a can of spray could last for spraying about 50 smartphones.

Can the Helling 3D spray be used on hot surfaces?

The spray seems to work well up until about 212°F. At increasingly hotter temperatures, the particles begin to coagulate and bounce off the substrate resulting in a speckled pattern of little white dots.

What are the hazardous ingredients (including the propellant) in the Helling 3D scan spray?

Hazardous components are the ones listed in section 3.2 of the MSDS.

Why don’t Sections 3 and 8 align on the English MSDS and why are they different from the Spanish and other MSDS?

The figures in section 8.1 may vary in different MSDS country versions. These are occupational exposure limits that are subject to national regulations. Country limits may vary, and there may be limits in some countries and not in others. An example is the general dust limit. For example, in Germany this does exist. In other countries, such as Great Britain, it doesn’t. There are dust limits only for specific powders/substances. Section 8.1 of the MSDS therefore generally refers to the national regulation from which the limit listed there comes from. In Germany, for example, this would be a standard called TRGS 900. In the UK it’s called regulation Eh50. And in Spain Royal Decree 374/2001 transposing Directive 98/24 / EC.

These are occupational exposure limits that are subject to national regulations. Country limits may vary, and there may be limits in some countries and not in others. An example is the general dust limit. For example, in Germany this does exist. In other countries, such as Great Britain, it doesn’t. There are dust limits only for specific powders/substances. Section 8.1 of the MSDS therefore generally refers to the national regulation from which the limit listed there comes from. In Germany, for example, this would be a standard called TRGS 900. In the UK it’s called regulation Eh50. And in Spain Royal Decree 374/2001 transposing Directive 98/24 / EC.

Additional information on differences between the English and Spanish MSDS.

The English and Spanish versions of the MSDS may contain different information due to the different national regulations that apply. There are content differences that may not have anything to do with per se, but rather national regulations.

For USA:

Legal basis for the information in the safety data sheet = 29 CFR Part 1910.1200

This is a regulation that applies within the USA, which also regulates the contents and mandatory information in a safety data sheet.

The US regulation does not provide for a Spanish version. The safety data sheet has to be issued in English.

For Spain:

The Spanish safety data sheet, on the other hand, is based on a European regulation = Regulation (EC) No. 1907/2006

This is the REACH regulation, which also regulates the contents of the safety data sheet within the EU.

The classification information is shown in Regulation (EC) No 1272/2008 (CLP Regulation). This is also a European regulation.

3DScanSpray.com is a part of LaserDesign, a CyberOptics Corporation Brand

5900 Golden Hills Drive, Minneapolis, MN 55416 – 952-884-9648

Aesub 3D Scanning Spray - GoMeasure3D

State-of-the-art coating developed and approved by 3D scanning experts

The AESUB brand of 3D scanning sprays provide optimal coating for challenging surfaces (i. e. dark, transparent, and shiny), as well as objects with deep cavities.

e. dark, transparent, and shiny), as well as objects with deep cavities.

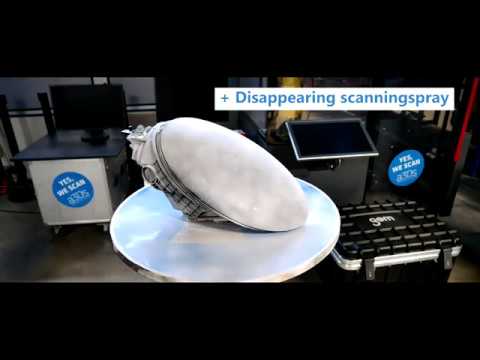

3D Scanning Spray Like No Other

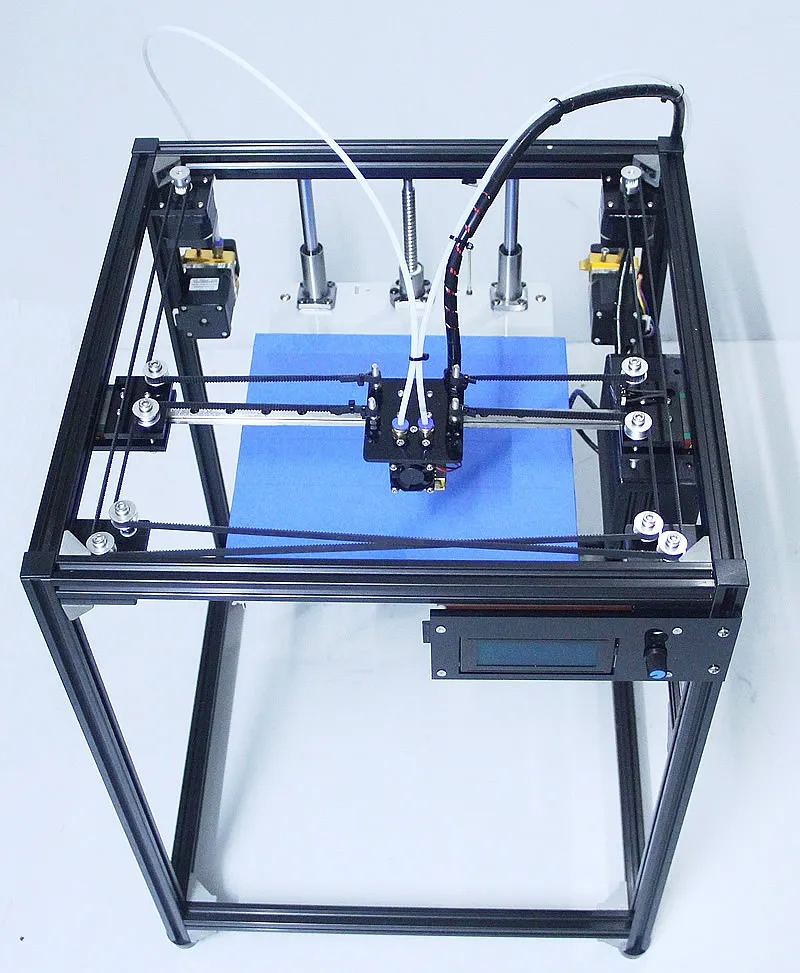

AESUB 3D scanning sprays are developed for scanning challenging surfaces that would normally be difficult to do with an optical 3D scanner. Difficult surfaces that would benefit from spraying the object:

- Transparent / Clear

- Reflective / Metallic / High Gloss

- Dark materials

- Sophisticated components with complex geometries

- Areas with deep grooves, holes, or cavities

Whether your project is big or small, AESUB brand of 3D scanning sprays provide you with the optimal thin and homogenous coating for 3D scanning objects—with no clumps left behind. Their sublimation spray disappears into the air with no messy cleanup!

🚚 FREE GROUND SHIPPING on physical orders $100 AND MORE • ORDERS Flat Shipping Rate $12. 50 🚚

50 🚚

AESUB white

Permanent

3D scanning spray

(Requires cleaning)

Stays on until you clean it

- Free of titanium dioxide (TiO2)

- Thin and homogeneous coating

- Excellent scannability

* Currently available for shipping to the US only

AESUB blue

Vanishing

3D scanning spray

(No cleaning required)

No mess, disappears without a trace within a few hours

- Thin and homogeneous coating

- Free of pigments

- Residue-free sublimation

* Currently available for shipping to the US only

AESUB Orange

Long-Lasting, Vanishing

3D scanning spray

(No cleaning required)

No mess, disappears without a trace within 24 hours

- Thin and homogeneous coating

- Free of pigments

- Residue-free sublimation

* Currently available for shipping to the US only

AESUB Green

Large Application, Vanishing

3D scanning spray

(No cleaning required)

No mess, disappears without a trace in about 6 hours

- Thin and homogeneous coating

- Free of pigments

- Residue-free sublimation

* Currently available for shipping to the US only

Why Choose Aesub 3D Scanning Spray?

The AESUB brand is well-known for its vanishing type of 3D scanning sprays:

- AESUB Blue

- AESUB Orange

- AESUB Green

They have an advantage when compared with traditional sprays. The coating evaporates after time lapses without leaving any residue. This eliminates the otherwise time-consuming and tedious task of cleaning after scanning.

In addition, the AESUB vanishing sprays are free of any pigments. They don’t contaminate the measurement environment nor pigment deposits, for example in air filters. This means that the spray can be used directly on the scanner with no cross-contamination–which was previously not possible.

Traditional powder spays cover but do not really adhere to the object’s surface to be scanned very well. As a result, it’s extremely difficult to move or rearrange the object after it has been sprayed. The AESUB vanishing scanning spray adheres to the surface. This enables you to handle the object if needed without damaging the coating to produce high quality 3D scans.

Reference points (i.e. photogrammetry dots) ensure you get high accuracy 3D scanning results when aligning scans together. Typically, these points do not adhere well to the surface with traditional powder sprays. You would have to place them before spraying. Once placed directly on the object to be scanned, it can be tedious to remove them and they often leave adhesive residues.

In contrast to powder sprays, reference points can be placed after spraying when using the AESUB vanishing 3D scanning spray. This eliminates the need for cleaning the points before scanning and allows for easy removal after scanning without such adhesive residues.

Your health is very important. That’s why AESUB products are less toxic compared to similar sprays in the market. All our AESUB products are free of harmful titanium dioxide. AESUB Blue, Orange, and Green are free of pigments, while AESUB White is pigment-based but is FREE of titanium dioxide nano particles (TiO2). Titanium dioxide has received its carcinogenicity classification from the EU CLP.

-

AESUB Blue

- Safety Data Sheets (SDS)

- Technical Data Sheet

- Report for the residue analysis

-

AESUB White

- Safety Data Sheets (SDS)

- Technical Data Sheet

-

AESUB Orange

- Safety Data Sheets (SDS)

-

AESUB Green

- Safety Data Sheets (SDS)

“The AESUB’s response is a spray that gives your target a consistent, non-reflective white coating, enabling the scanner to grab all the details you need.

– Excerpt from Develop3D.comCoating disappears overnight, leaving no sticky mess to clean up – it’s like magic in a can.”

What’s New?

AESUB has expanded its lineup with two new products:

-

AESUB Orange

Long-Lasting, Vanishing Spray

Aerosol Solution

Disappears Within 24 Hours

Backed by customer demands, AESUB Orange is a new long-lasting, vanishing scanning spray. It’s similar to AESUB Blue except it evaporating within 24 hours instead of a few hours.

- free of pigments

- no cleaning after scanning

* Currently available for shipping to the US only

-

AESUB Green

For Large-Scale Automated 3D Scanning

Spray Gun Solution

Vanishing Spray for Spray Gun

AESUB green was developed for large-scale and automated scanning. AESUB green has a layer thickness of ~4 microns (μm) and evaporates within approximately 6 hours.

- free of pigments

- no cleaning after scanning

* Currently available for shipping to the US only

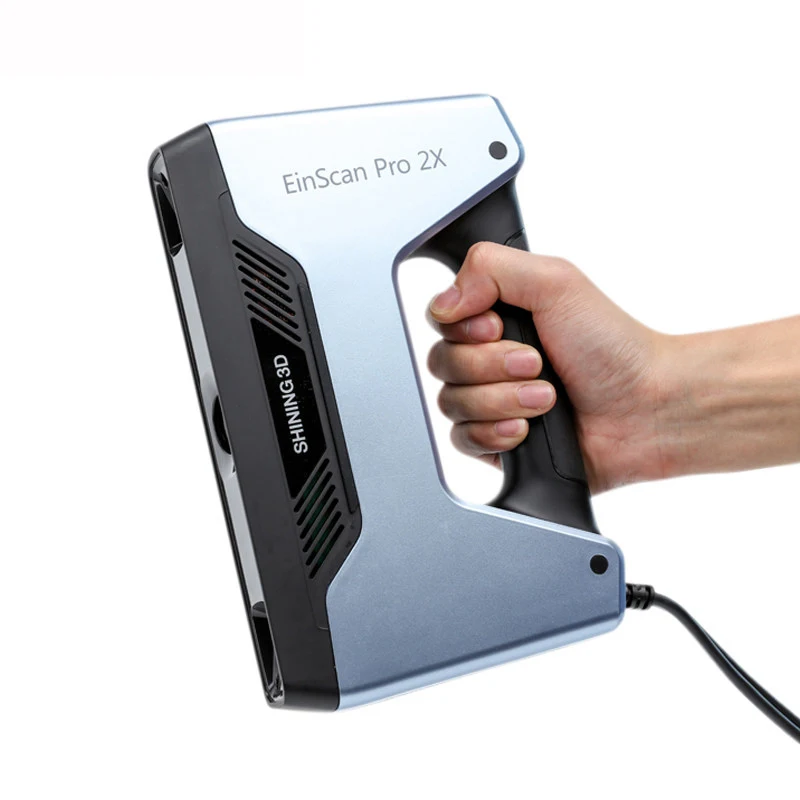

How it Works:

3D Scanning a Reflective Part

Step 1: Use the AESUB 3D scanning spray to apply an even coating onto the scanning part’s surface.

Step 2: Once sprayed, continue as you normally would with your 3D scanning process.

Final 3D scanning results: AESUB spray allows you to capture areas that you normally can’t capture with a 3D scanner without preparation.

When using the AESUB Blue, Orange, or Green vanishing spray, the coating will disappear within a few hours depending on temperature and environment. If you use the AESUB White permanent spray, you will have to clean up the coating once your 3D scanning job is completed.

If you use the AESUB White permanent spray, you will have to clean up the coating once your 3D scanning job is completed.

AESUB Blue Vanishing Spray

Video Demo and Analysis

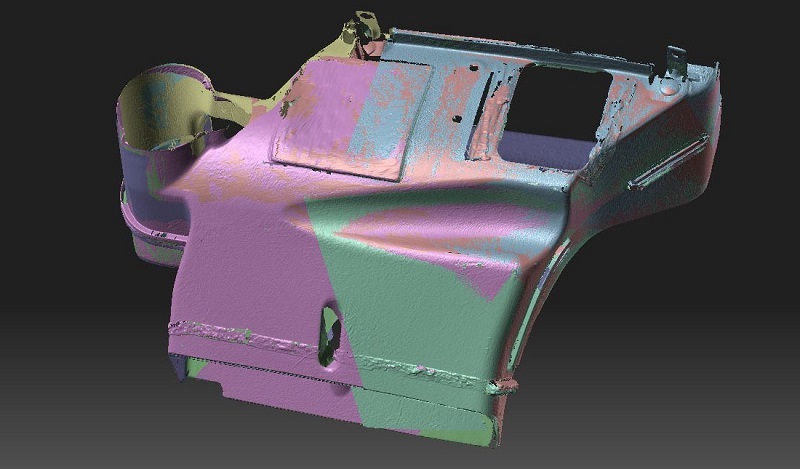

Our team wanted to better understand how adding a 3D scanning spray can impact scanning results which is outlined in the following video. While AESUB Blue vanishing spray adds ~8-15 microns of thickness to the part’s surface, it provides a consistent layer that aids the 3D scanner in capturing the true nature of the part, without the distortion caused by the challenging surface that would cause bad scanning results.

Compare Results Without Coating

versus Coating With AESUB

🚚 FREE GROUND SHIPPING on physical orders $100 AND MORE • ORDERS Flat Shipping Rate $12.50 🚚

Which 3D Scanning Spray is Right for Me?

* Currently available for shipping to the US only.

Ideal for:

- Long Projects: Scanning projects that take more than a few hours to days.

- The Budget Conscious: If budget is important, the white permanent spray is more economical compared to the vanishing sprays.

Ideal for:

- Delicate Parts: Working with scan parts that cannot be sprayed or cleaned of white coating. AESUB Blue uses a special, evaporating formula that requires no cleaning, won’t stain your surfaces, or affect your product.

- Efficiency: Great for doing quick jobs where you only need to scan the part for a short period of time as the spray will vanish with time (within a few hours). No need for cleanup!

Ideal for:

- Delicate Parts: Working with scan parts that cannot be sprayed or cleaned of white coating. AESUB Orange uses a special, evaporating formula that requires no cleaning, won’t stain your surfaces, or affect your product.

- Longer Projects: Great for doing jobs where you need a longer lasting vanishing spray and you don’t want to clean the part after your project is done. The coating disappears within 24 hours.

Ideal for:

- Large Parts: Great for scanning boats, cars, or parts that require large coating application with a spray gun.

- No Messy Cleanup: It’s difficult to clean large parts so AESUB Green is ideal when you just want to focus on your scanning project and then you’re done. Scan. Spray. Done.

Buy Now

Self Disappearing Scanning Matte Spray

Self Disappearing Scanning Spray

GHOST

Our company is proud to present you with a self-disappearing 3D Scanning Matting Spray.

GHOST ATECO

will disappear without a trace

Self-disappearing matte 3D scanning spray will make the scanning process easier and eliminate unnecessary manipulations with the object. The absence of pigment and a consistently repeatable result with a minimum thickness of the applied layer will make the scanning process less time consuming.

The absence of pigment and a consistently repeatable result with a minimum thickness of the applied layer will make the scanning process less time consuming.

Without pigments. keep your work clean

GHOST Spray contains no pigments and will not harm your 3D scanner or accessories. You do not need a special room for spraying, if something gets on third-party objects, the spray will simply disappear soon and you will not have to clean the workplace.

Saves time and money

With our spray you no longer have to clean up objects after scanning, which saves you time and therefore money. Save with us.

thin matt layer

The low thickness of the matt layer and its uniformity will allow you to scan objects with maximum accuracy.

Installing markers

Stick the markers directly on top of the matting layer, our spray allows this.

approved by scanning experts

Our spray has been tested and recommended by leading 3D scanning experts and 3D scanner manufacturers.

Ideal Volume

The 400 ml volume will last you for a long time, because the excellent coverage of the surface will help save spray when matting small objects that take 20-30 minutes to scan. If this is a three-dimensional model, then you can be sure that you can cover up to 4 sq.m with one balloon.

* coverage and fade time depends on the amount of spray applied

400 ml m

compact size

Homemade Ghost Mattifying Spray is also available in 200 ml. You can easily hold it in your hand and it will not take up much space when scanning on the spot. And of course, this is what you need if you have not tried working with Ghost spray yet and just want to start and try. Start small and always use when needed.

* Coverage volume and fade time depend on the amount of spray applied

200 ml m

ATECO GHOST

applications

Ghost self-vanishing spray facilitates and enables optical digitizing in a wide range of industrial sectors and applications:

- Reverse engineering

- Metrology

- R&D

expert community

Prior to launching our product on the market, we conducted extensive testing and validation of Ghost spray by experts in 3D scanning and metrology.

The result is an amazing product that we are proud to present to you.

Yakov Bondarev

Commercial Director "ScanForm"

The best combination of price/quality on the market of scanning sprays. Small particle size and consumption, excellent hiding power. Various options for Ateco sprays from simple to vanishing and two-component. After Ateco tests, if I use a spray, then only this one. Scanform - recommends.

Yuliya Popova

LEADING SPECIALIST "3D COMPLECT"

Self-disappearing matting spray of excellent quality for use in 3D scanning of cultural heritage objects, or objects of complex geometric shapes, in the cavities of which powder particles can clog, which are then difficult to clean up. And this spray itself will disappear after a while, depending on the thickness of the applied layer.

Mikhail Chizhikov

Top3DSHOP service department engineer

According to the Ghost spray "Very easy to use, easy to apply and evaporates without a trace.

Hiding power is very good, consumption is low. It adheres well to details. It is applied in a very thin layer and almost does not hide the geometry of the scanned objects" What else do you need from a spray? Excellent spray

Hiding power is very good, consumption is low. It adheres well to details. It is applied in a very thin layer and almost does not hide the geometry of the scanned objects" What else do you need from a spray? Excellent spray

Nabakem MegaCheck 3d Scan Matting Spray

- Description

- Reviews (0)

Nabakem Matting Spray is used as a 3D scanning consumable for glossy and transparent materials. The fine coating guarantees an optimal anti-reflection coating with precise observance of the geometry of the object to be scanned. Nabakem sprays give a guaranteed particle size of no more than 5 microns, which allows you to apply an anti-reflective coating that is optimal in thickness with precise observance of the geometry of the object to be scanned. To obtain reliable and reproducible results, careful preparation of the entire surface of the scanned object is necessary, without dividing into convenient and difficult areas.

The cost of our matting sprays will allow you not to think about the choice of "hot" zones, but simply treat all 100% of the object, regardless of its size.

The cost of our matting sprays will allow you not to think about the choice of "hot" zones, but simply treat all 100% of the object, regardless of its size. Optimum 450 ml can can treat up to 5 square meters of surface.

The quality of Nabakem spray allows it to be used in various industries:

- 3D model making in museums and restoration workshops;

- Reengineering;

- Car tuning;

- In dental CAD/CAM systems;

- In industrial x-ray control - to suppress glare on x-rays;

- In thermal control - as an alternative to self-adhesive film used to measure the temperature of a polished surface with pyrometers and thermal imagers.

How to use Nabakem matting spray

- The recommended surface temperature to be controlled is 10℃~40℃.

- Shake the can before use for 2-3 minutes to re-suspend the white particles. With sufficient agitation, the sound of the agitating balls will be clearly audible.

- Apply the developer evenly on the surface to be inspected from a distance of 20 ~ 30 cm from it.

- After drying, a white matte film forms on the surface.

- The object must be cleaned after scanning. The Mega Check Cleaner is recommended for this.

Tips for using spray cans

- To make the sprayed layer even and smooth, start spraying on the area adjacent to the test.

- Spray across the surface to be examined at a constant slow speed, remembering that 2 or 3 thin coats are better than one thick coat.

- Use between 5°C and 50°C.

Cold weather complicates the application process, slows down the drying rate and reduces pressure in the spray bottle. To eliminate these difficulties, we advise you to take the following steps:

-

If there is condensation, wipe the surface to be treated dry and, if possible, heat the surface with some kind of heating device.

Heating by hot air with a temperature not higher than 50 °C is allowed.

Heating by hot air with a temperature not higher than 50 °C is allowed. -

Spray the spray from a greater distance than usual so that it hits the surface dry rather than wet.

- Keep aerosol cans warm if possible.

- Extend the holding time of the processed object before further work by 2-5 minutes.

Your name:

Your review

Warning: HTML is not supported! Use plain text!

Rating Badly Good

CaptchaEnter code

Tags: 3D scanning, matte spray, anti glare spray Nabakem

Best offer

Metolab 101

METOLAB 101 – analog stationary rockwell hardness tester, modified hardness tester.

Learn more