Flashforge 3d printer creator pro vs makerbot

Which 3D Printer Should You Choose?

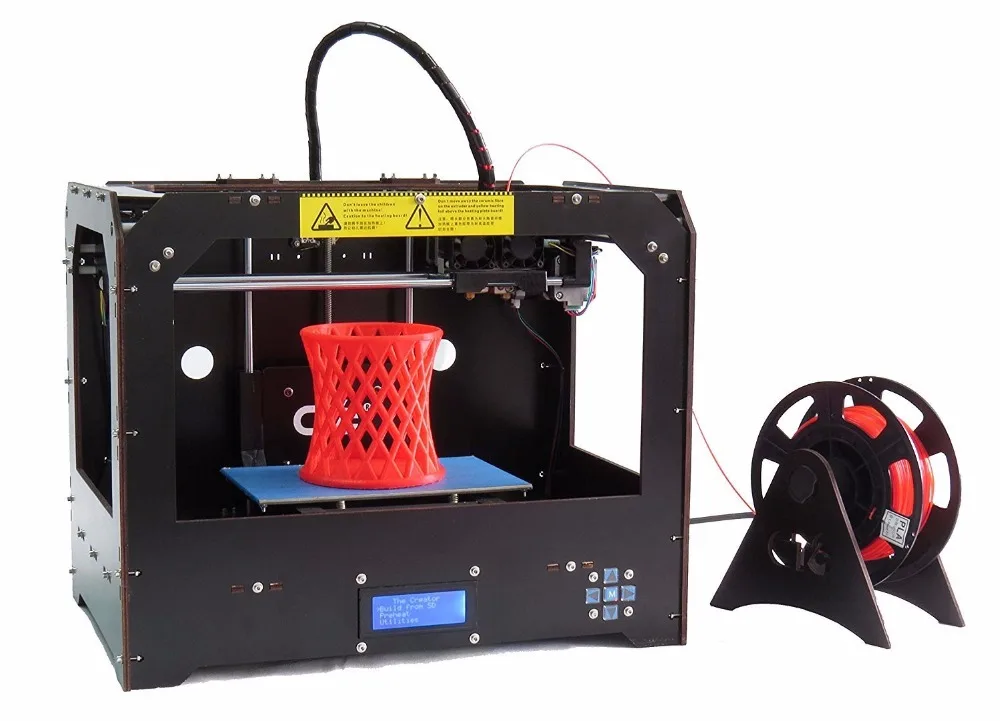

There’s no doubt that choosing between a Makerbot vs. Flashforge 3D printer can be a difficult decision, especially given the similarities between the two.

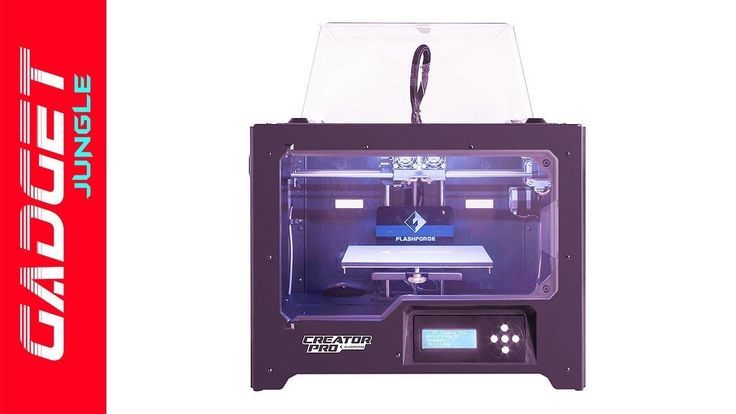

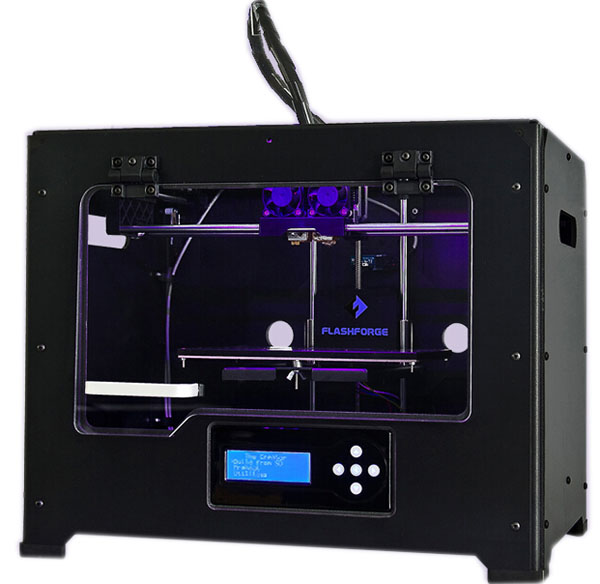

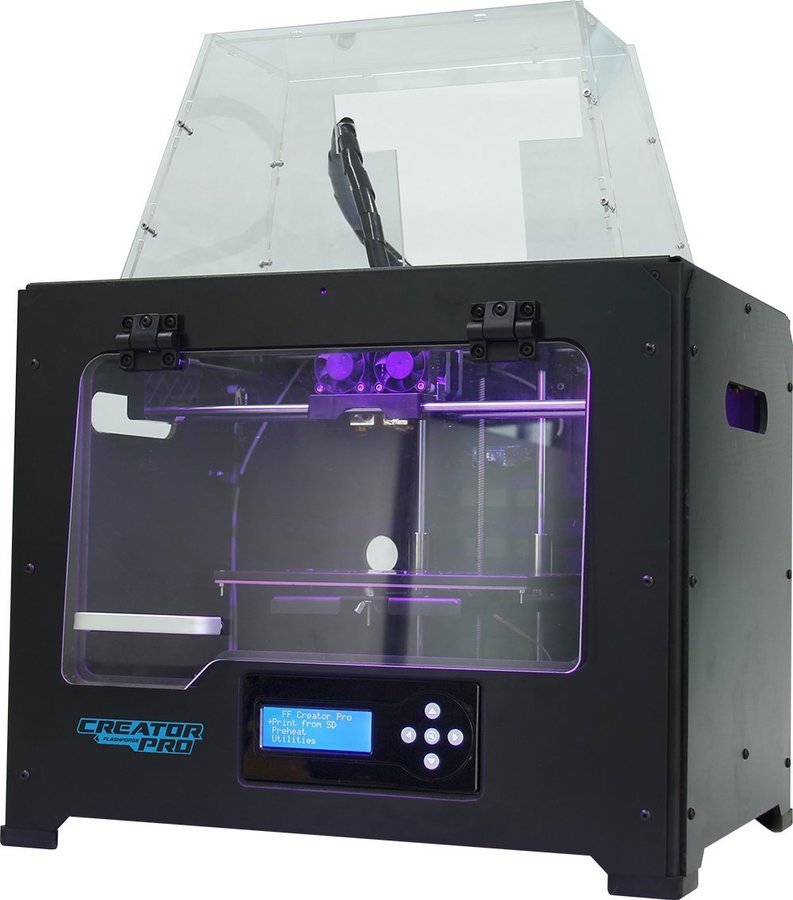

In fact, the two have so much in common that the Flashforge Creator Pro is often referred to in the maker community as a less-expensive clone of Makerbot’s signature model, the Makerbot Replicator.

Still, just because it’s cheaper, does that mean the Flashforge is always going to be the better deal or is it still worth splashing out for the genuine article in the form of the industry-leading Replicator?

In this guide, we’ll put the two models head-to-head to determine once and for all which is the better printer.

Makerbot Replicator vs. Flashforge Creator Pro: Technical Overview| Makerbot Replicator | Flashforge Creator Pro | |

| Print Technology | Fused Deposition Modelling (FDM) | Fused Deposition Modelling (FDM) |

| Build Volume | 11. | 8.9 x 5.7 x 5.9″ |

| Layer Resolution | XY Axis: 100 – 400 micron / 0.1 – 0.4mm | XY Axis: 100 – 300 micron / 0.1 – 0.3 mm |

| Filament Compatibility | PLA (1.75mm) | ABS/PLA |

| Extruder Nozzles | 1 x 0.4mm | 2 x 0.4mm |

| Build Area | Open | Enclosed |

| Filament Spool Storage | Internal | External |

| Monitoring Camera | HD Camera | None |

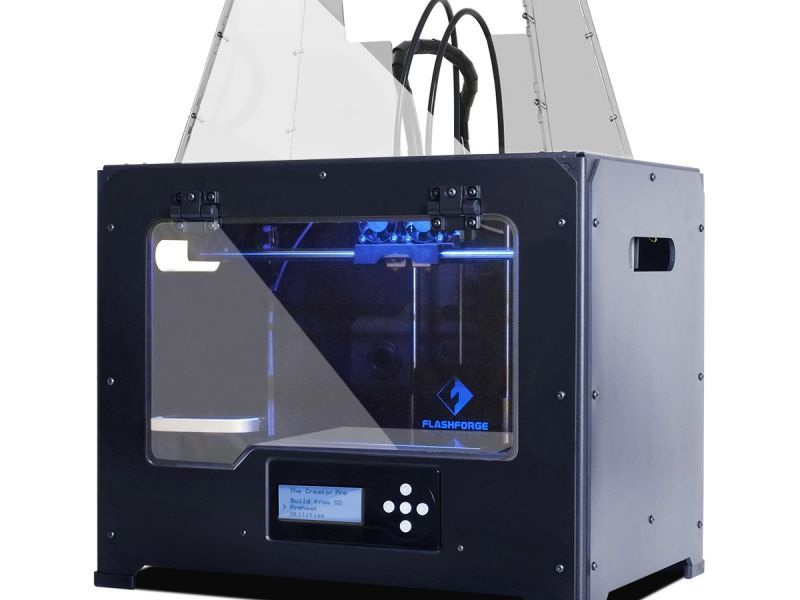

If you read our recent guide comparing the Makerbot Replicator to the Dremel Digilab 3D45, you’ll probably recall that the most immediately noticeable feature of the Replicator is its open design.

The popular printer leaves the front and sides fully exposed, which makes it easier to not only watch your print-in-progress up-close and personal but, more importantly, makes the whole printer much more accessible if you need to get inside to troubleshoot.

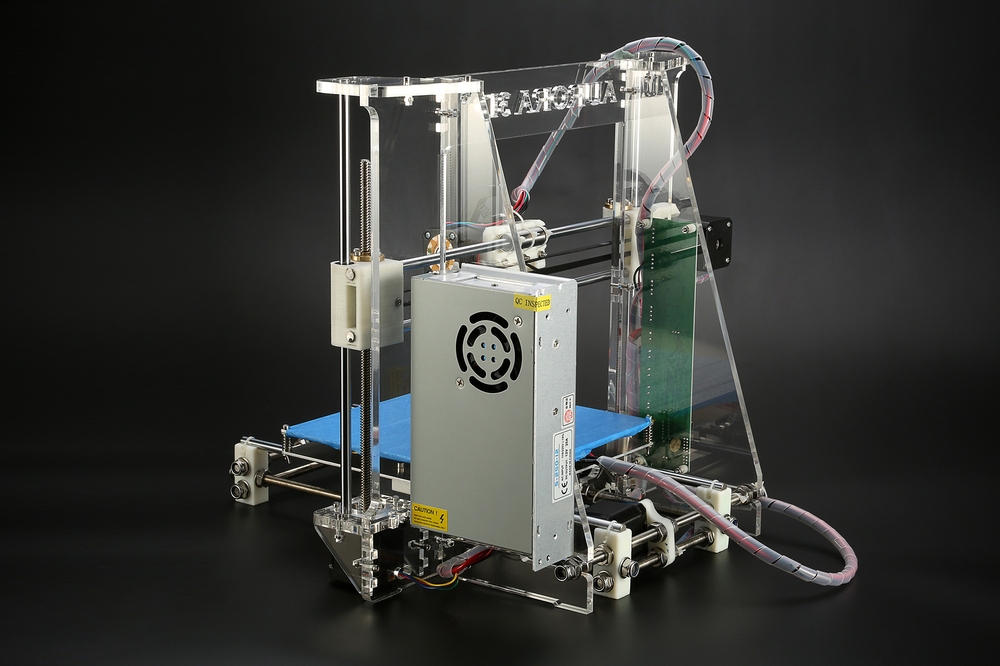

The Flashforge Creator Pro, on the other hand, features a fully closed design similar to the type you’d find in printers such as the Elegoo Mars and Anycubic Photon.

In this respect, at least, many makers would consider the Creator Pro to be superior to the Replicator as a closed design as they tend to be safer, less noisy, and more importantly, prevent warping so that you get a consistent finish with a wide range of materials.

Print CapacityThere’s no doubt that when it comes to building volume alone, the Makerbot Replicator is the better of the two.

The printer is at least several inches taller and the better part of an inch bigger in terms of width and depth than the Flashforge Creator Pro, meaning you have a much greater capacity for printing larger projects.

Printing MaterialsOne of the biggest drawbacks of the Makerbot Replicator is that it’s only designed to work with polylactic acid (PLA), a fast-melting thermoplastic that is cost-effective and durable while also relatively eco-friendly.

While that may be enough for some makers, you may prefer to work with other materials such as nylon, Acrylonitrile Butadiene Styrene (ABS), or Polyethylene terephthalate glycol (PETG).

Unfortunately, you won’t have much look with the Creator Pro either.

While it does do slightly better here in the sense that it can also be used with ABS, your choice of filaments is still going to be pretty limited.

Print BedHere’s another category where the Creator Pro starts to outdo the very model it’s accused of being a mere clone off.

Since it only works with PLA, the Replicator lacks a heated print bed, whereas the Flashforge model does.

Indeed, the Creator Pro features a 6.3mm aluminum build-plate that is temperature resistant up to about 130°C.

On the downside, the Creator Pro’s print bed doesn’t feature automatic leveling, which can be tricky for those new to 3D printing and time-consuming for any maker regardless of their experience level.

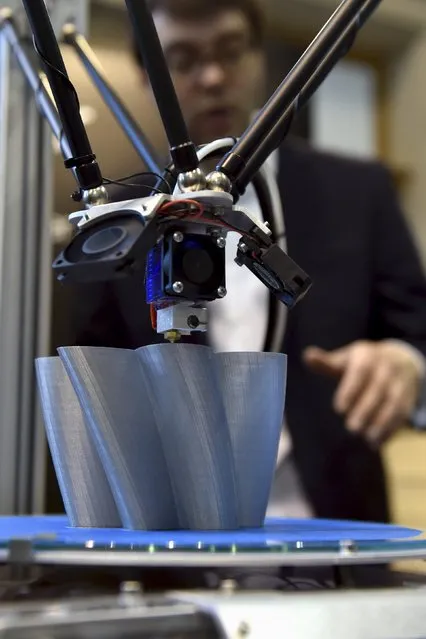

Again, the Creator Pro has a lot of appeal in the form of two separate extruders.

This means that you can print supporting structures at the exact same time as your main model or even use them to print in two different colors simultaneously.

To be fair to the Replicator, while it only features one extruder, it is the brand’s own patented Smart Extruder, which not only makes the printing process easier but ensures more reliable results.

We’re particularly big fans of the Smart Extruder’s filament detection features which pause the job when your PLA filament runs out and alert you via your app before picking up where it left off once replaced.

Software And Hardware CompatibilityIf you’re a Linux user, then Flashforge is going to be the one for you as it’s the only one of these two printers that come with Linux-compatible software.

It also runs on Windows (Versions 7+) and macOS (Versions 10.9+), just as the Replicator does.

Unfortunately, neither models are immediately compatible with both offer software itself is both smart, intuitive, and beginner-friendly.

In terms of supported file types, both will support the .stl file type, while the Replicator also works with MakerBot and .obj, and the Creator Pro supports .gcode and .x3g.

Camera And MonitoringWhere the Makerbot definitely triumphs over its more affordable adversary is in terms of remote monitoring.

The Replicator features a handy 640 x 480 resolution camera that can be streamed directly to your computer thanks to the onboard WiFi connectivity.

The Creator Pro, on the other hand, not only lacks a camera but also lacks in-built WiFi capabilities. As such, if you wanted to watch your print-in-progress, you’d have to invest in one of the best 3D printer cameras and a WiFi SD card to make that happen.

Print PerformanceOnce again, the Makerbot Replicator wins the round as it offers more reliability, consistency, and precision than the Flashforge Creator Pro.

Not only that, but the Replicator is also well regarded as one of the fastest printers on the market, meaning you’ll get great-quality results in a fraction of the time.

That’s not to say that the Creator Pro isn’t good. It still produces excellent quality results for the money, but in terms of performance, at least, you really do get what you pay for with both Flashforge and the more expensive Makerbot printer.

Frequently Asked Questions About Makerbot vs. Flashforge Is Flashforge A Makerbot?No, Flashforge and Makerbot are two separate brands making two separate printers, though the Makerbot Replicator and FlashForge Creator Pro are very similar.

Can I Use Cura With Flashforge Creator Pro?Yes. A third-party extension exists which connects your Creator Pro with Cura 4.5 BETA or above.

Is The Makerbot Replicator Worth It?If it’s within your budget, the Replicator is certainly an excellent purchase as it offers superior quality, fast printing, and consistent results.

The Makerbot Replicator and FlashForge Creator Pro may have a lot in common, but it’s the little things that set them apart that will ultimately make all of the difference when it comes to deciding which model to purchase.

If you have a large budget and you’re prepared to pay top dollar for top quality, the Replicator is the one for you and will ensure you get the fastest, most reliable printing of the two models.

However, if you are looking to keep costs down, you’ll find that the FlashForge Creator Pro still delivers great quality along with several incredibly useful features that its more costly competitor lacks, such as enclosed housing, double extruders, and the ability to print in ABS.

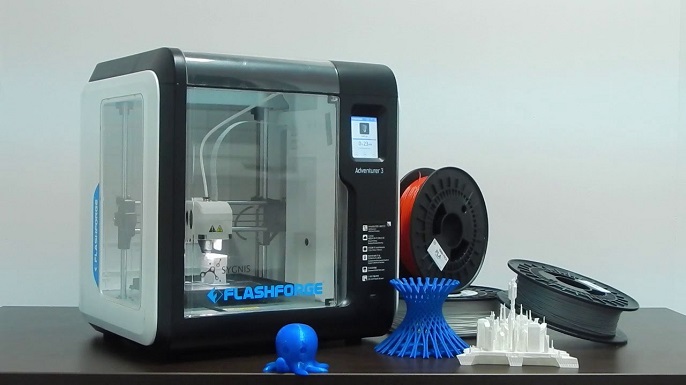

FlashForge Creator Pro Review 2022

Is the FlashForge Creator Pro a decent 3D printer or not? Should you buy it? Here's some interesting facts why you should NOT buy this 3D printer!

By Justin Evans

3. 9

9

See Price

3D printers aren’t usually the cheapest products around, which means that it’s important to find one that’s actually worth your hard-earned money. Today, we’ll be examining the FlashForge Creator Pro – a mid-budget printer that’s the successor to the fan-beloved FlashForge Creator. Is the Pro an improvement, or should you stick with the classic? Read on to find out.

| Filament Diameter | 1.75mm |

| Extruders | 2 |

| Supported Materials | PLA, ABS, PVA |

| Connectivity | USB, SD card |

| Printing Speed | 100mm/s |

| Build Volume | 225mm x 145mm x 150mm |

Table of ContentsShow

Design

The first thing to note is that the Creator Pro is a closed unit. As such, it lacks the raw building volume of more open models, but it does ensure that you can maintain a consistent temperature at all times. Further, this removes the need for constant ventilation during the printing process.

Further, this removes the need for constant ventilation during the printing process.

It’s also worth mentioning that this model comes fully assembled. Further, it boasts a universal power supply, so regardless of which country you’re in, you can count on it working as intended. Instead of being completely vertical, the controls are now at a 45° angle – a small touch, but a helpful one nonetheless.

Now, while the original Creator had a wooden case, this one is almost entirely made of heat-resistant metal. As a bonus, the front door opens to almost 180°, making it easy to remove all but the largest prints.

Printing

The FlashForge Creator Pro comes with two extruders, so you can print supporting structures, or even two different colored materials at once. Better yet, because this printer supports PVA filaments, you don’t even have to have snap-off supports. Just soak the finished model in water and you’re done.

That said, the Creator Pro doesn’t support a huge range of filaments. Other than PVA, you’re limited to PLA and ABS. Don’t get us wrong – this is fine for people new to printing or occasional printers, but if you’re serious about experimenting with this tech, you’ll want something with a wider range of supported materials.

Other than PVA, you’re limited to PLA and ABS. Don’t get us wrong – this is fine for people new to printing or occasional printers, but if you’re serious about experimenting with this tech, you’ll want something with a wider range of supported materials.

The layer resolution can be set between 100 and 500 microns. However, even at the highest setting, we found that small objects often had ragged edges or other imperfections. As such, the Creator Pro is better suited to creating medium or large items.

Features

This printer uses a 6.3mm aluminum build plate. It’s temperature-resistant and won’t warp even after prolonged exposure to heat. Of course, you can heat this to whatever temperature you like (up to 130°C), but we’d recommend about 90°C to prevent your materials from sticking.

Unfortunately, there’s no way to automatically level the print bed. This isn’t a huge problem, it just means a few minutes of extra prep work whenever you want to print. This can seem a little daunting to beginners but once you get the hang of it, it’s really not a big deal.

While this model doesn’t support WiFi connectivity as standard, this feature can be added using a WiFi SD card. It does, however, support printing from USB or SD cards, so you still have the most common options to choose from.

Cost

The FlashForge Creator Pro costs around $900 on its own, or you can throw in a copy of Simplify3D for an extra $30. Considering this software retails for about $150, that’s a pretty good deal. If you buy two printers at the same time, you can get this software for free, but without a further discount, this isn’t really worth it.

The price is about average for a mid-level printer like this one. Despite coming as a pre-assembled unit, all of the vital parts like the extruders can be removed and swapped out if you’d like. Really, the maintenance costs shouldn’t be too high as long as you take care of the components. Of course, this depends on how much filament you use!

Support

While the instructions that come with this model leave a lot to be desired, FlashForge provides detailed documentation, troubleshooting guides, and tips on their website. There are even tutorials for people who have never used a 3D printer before, which is great to see.

There are even tutorials for people who have never used a 3D printer before, which is great to see.

The company offers a 30-day money back guarantee, as well as a guaranteed response to another customer support issues within eight hours. That’s pretty good, but there is a rather significant drawback.

While this product comes with a one-year warranty, it has a couple of stipulations. Firstly, you have to register the printer within 30 days of purchase. No problem, right? However, the warranty states that you (i.e. not a shipping company) have to personally deliver the product to the company for any repairs. So what’s the issue?

Simply, the company is based in Hong Kong. Even if you live there, you’re potentially facing an hour’s drive. If you live overseas, the costs will be considerably higher and, in some cases, more than the cost of just buying a new printer. This is almost certainly intentional and can only be described as bad business. It’s a real shame considering that the printer itself is of such high quality.

Summary

The FlashForge Creator Pro is a great little entry-level 3D printer. It’s reasonably priced, capable of handling the most common filaments, and includes a wide selection of customization features. However, it’s marred by a warranty that is intentionally difficult to redeem and as such, it’s important to take very good care of it.

BCN3D Sigma Review

performance overview, design, print quality

There are many features that make it possible to distinguish professional 3D printers from consumer ones. Design, user-friendly interface, print quality, speed and compatibility with industrial-grade materials - all this is necessary for most users to successfully apply 3D printing in commercial projects.

One of the hurdles preventing small businesses and hobbyists from introducing professional 3D printers into their workshops is the sky-high price tag.

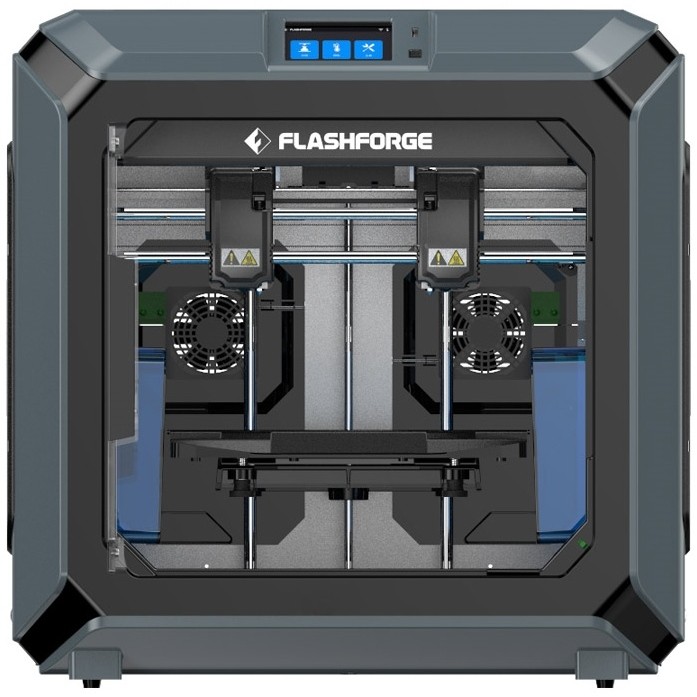

Flashforge Creator 3 Pro is a new and improved 3D printer that offers professional features at a reasonable price.

Let's take a closer look at the Creator 3 Pro and what makes it suitable for most professional tasks.

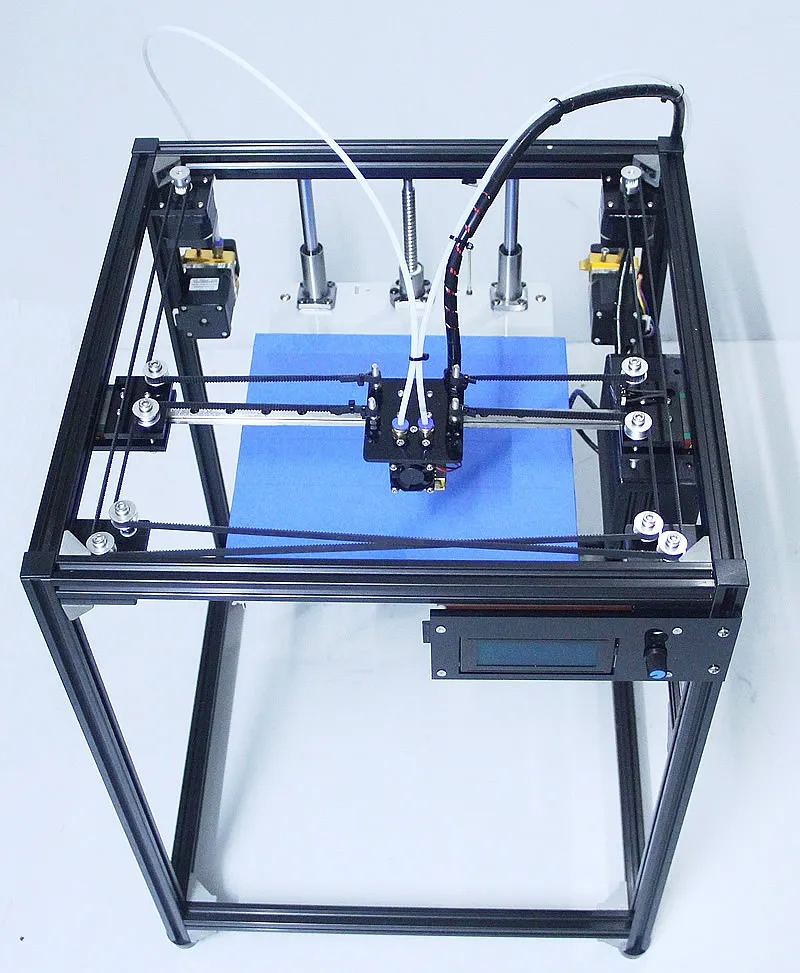

The Creator 3 Pro is the latest Flashforge in the professional 3D printing market. The new printer with a build area of 300x250x200mm is compatible with the latest materials required for educational and professional applications in various fields, including medicine, automotive, instrumentation and architecture.

Building on the advanced features of its predecessor, Flashforge Creator 3 Pro offers more options for professional use. Compared to the Creator 3, the new model features upgraded components and greater efficiency.

FLASHFORGE CREATOR 3 PRO VS CREATOR 3

Compared to its predecessor, Flashforge Creator 3 Pro has notable improvements that make it more efficient in the field of industrial production. First, Flashforge doubled the number of extruder cooling fans from one to two, resulting in better quality. Secondly, a second generation logic control chip has been added to ensure smoother 3-axis operation.

Secondly, a second generation logic control chip has been added to ensure smoother 3-axis operation.

The Creator 3 Pro can also reach higher nozzle temperatures much faster than the previous model. It features an extruder that heats up to 200°C in one minute, which is twice as fast as the Creator 3. The professional model heating table has a short heat-up time of 3 to 5 minutes, which is much better than the Creator 3. The heating time of the previous model is 15 to 20 minutes.

The successful combination of these improvements with a smoother bezel and an optimized touch screen interface is backed by Flashforge's continuous research and development.

INDEPENDENT DUAL EXTRUDER SYSTEM

Flashforge has completely updated its famous independent dual extruder system for the Creator 3 Pro. It has been re-engineered and optimized for engineering grade materials, ensuring smooth feeding of refractory materials.

With two extruders, users can use duplication mode, two-color printing mode and mirror printing mode. New and improved sensors have been integrated into the extruder system to improve the accuracy of automatic alignment and positioning.

New and improved sensors have been integrated into the extruder system to improve the accuracy of automatic alignment and positioning.

Creator 3 Pro is compatible with a set of six nozzles: steel and carbon steel. With a maximum printing temperature of up to 320°C, these nozzles are highly durable, high temperature resistant, corrosion resistant, and can withstand the abrasive properties of carbon fiber composite materials. That's why Flashforge has made it easy to replace nozzles with a focus on speed and efficiency.

The range of nozzles and high print temperatures make the Creator 3 Pro compatible with a wide range of filaments including PLA, ABS, PA, PC, PVA, HIPS, PETG, Wood, ASA and PA-CF.

STRONG AND SMART DESIGN

For a 3D printer to meet the strict requirements of commercial projects, it is necessary that the equipment has a functional and intuitive design. Flashforge Creator 3 Pro is focused on solving professional tasks through numerous features and technical improvements.

In the printer's print chamber, users will find a flexible magnetic steel plate platform that provides excellent thermal conductivity and adhesion. To prevent harmful fumes from engineering plastics from entering the room, Flashforge has equipped the Creator 3 Pro with a HEPA h23 air filter and activated carbon filter, which is an important component when printing with certain materials.

Intuitiveness is also a key aspect of the Creator 3 Pro. The 4.3-inch touch screen interface allows users to quickly navigate menu tabs and customize the 3D printer for any application. Other important features of the printer include remote control of printing with a built-in HD camera, resuming printing after a power outage, and a low filament sensor.

Another interesting feature is the 3D printing cloud service that comes with the printer. With this service, users can store their projects and manage the Creator 3 Pro 3D printer from almost anywhere.

The Flashforge Creator 3 Pro was built to professional standards, yet remains an affordable 3D printer for small businesses and hobbyists. Whether you're prototyping in PLA or producing final parts in carbon fiber reinforced plastic, the Creator Pro 3 can handle commercial applications at an affordable price.

Features:

Print technology: FFF

Build area size: 300x250x200mm

Positioning Accuracy: Axis-X/Y: 0.011mm; Axis-Z: 0.0025mm

Layer thickness: 0.05 ~ 0.4mm

Print Resolution: ±0.2mm

Nozzle diameter: Steel: 0.4mm (included with the printer)

Hardened steel: 0.4/0.6mm and Steel: 0.8mm (sold separately)

Maximum extruder temperature: 320°C

Maximum table heating temperature: 120°C

Filament thread diameter: 1.75mm

Filament Compatibility: PLA, High Speed PLA, PLA Color Change, Ultra Strong PLA, Metal-Filled, Wood, ABS, ABS Pro, PETG, HIPS, *PA(Nylon), PC, PVA, ASA, PA-CF

Print speed: 10-150mm/s

Printer dimensions: 627x485x615mm

Weight: 40kg

Internal memory: 8G

Input power: 100-240VAC, 47-63Hz

Output power: 24V, 21A

Power: 500W

Connection Interface: USB Stick, Wi-Fi, Ethernet, and Could Printing

Software: FlashPrint

Format Compatibility: 3MF/STL/OBJ/FPP/BMP/PNG/JPEG File

Output Format: GX/G

Operating systems: Windows 7/8/10, Mac OS, and Linux

Source: https://all3dp. com/4/flashforge-creator-3-pro-desktop-3d-printer-that-easily-handles-engineering-gra...

com/4/flashforge-creator-3-pro-desktop-3d-printer-that-easily-handles-engineering-gra...

(Solution available) Using MakerBot Replicator 1 dual (or clone like FlashForge Creator) with Cura

ultimaker-cura g-code software makerbot replicator-dual

I have a Monoprice Architect which is a bare-bones clone of FlashForge Creator Pro, or Replicator 1 Dual. I upgraded the power supply and added a heated table, and after getting bored with the MakerBot software, I started using Cura for slicing and then post-processing with GPX.

I did a lot of searching and finally found someone who posted their start and end G-code for this particular printer. The only catch is that his code only works on version 15.04.

Don't get me wrong, 15.04 is a huge update over software. But I would really like to start using a newer version like 2.5 or something relatively new.

Here is the source code I found. I tried it in 2.5 with a bug in post processing. Any help would be greatly appreciated!!

; -- START GCODE -- M136; start build M73 P0 G90; absolute coordinates ; ; set temperatures and assert Vref M140 S{print_bed_temperature} M104 S{print_temperature} T0 G130 X118 Y118 A118 B118 ; set stepper motor Vref to defaults ; let the Z stepper vref stay at eeprom level (probably 40) ; ; home and recall eeprom home position T0 ; home on the right nozzle G28 X Y Z ; home all axes at homing speed G92 X0 Y0 Z0 A0 B0 ; set all coords to 0 for now G1 Z5 F500 ; move Z 5mm away so we can carefully hit the limit switch G161 Z F100 ; home Z slowly M132 X Y Z ; recall stored home offsets for XYZ axes ; ; wait for heat up G1 X110 Y-72 Z30 F3300 ; move to waiting position M116; wait for temps ; ; purge and wipe G92 E0 ; set current extruder position as 0 so that E15 below makes sense G1 X110 Y-70 Z0. 2 F2400.0 ; move to just on the bed G1 X110 Y70 E15 F1200.000 ; extrude a line of filament along the right edge of the bed G92 E0 ; set E to 0 again because the slicer's next extrusion is relative to this 0 ; ; Sliced at: {day} {date} {time} ; Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density} ; Print time: {print_time} ; Filament used: {filament_amount}m {filament_weight}g ; Filament cost: {filament_cost} ; -- end of START GCODE --

2 F2400.0 ; move to just on the bed G1 X110 Y70 E15 F1200.000 ; extrude a line of filament along the right edge of the bed G92 E0 ; set E to 0 again because the slicer's next extrusion is relative to this 0 ; ; Sliced at: {day} {date} {time} ; Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density} ; Print time: {print_time} ; Filament used: {filament_amount}m {filament_weight}g ; Filament cost: {filament_cost} ; -- end of START GCODE -- @Andrew Marzban, 👍4

Talk

4 answers

Best Answer:

▲ 1

Thank you all for your help. So after playing around with the G-code and trying to manually set the temperature, I came across a user post saying that Cura will automatically enable the temperature code regardless of your g-code. So I removed the m140 and m104 lines and now it works great!

I'm also going to take a second to rant about how hard it is to find information about this g-code business. It looks like the language that needs to be standardized differs depending on the slicer you are using. What's the matter?

It looks like the language that needs to be standardized differs depending on the slicer you are using. What's the matter?

, @ Andrew Marzban

▲ 1

Edit: After looking at the GPX more, I'm not sure what you're doing? Are you trying to slice something in Cura and use GPX to create an X3G file, or are you using the initial g-code from Cura in Makerware? The code you posted above is used in Cura to generate the gcode, and it looks like you should provide the GPX file of the gcode generated by Cura.

You didn't say what error you're getting or where, but if I had to guess, it's from the information in curly braces. Anything within curly braces "{}" is a variable in the slice used to generate the g-code.

All of the information below is useless to the printer and I would start by deleting it to see if you get an error.

; Sliced at: {day} {date} {time} ; Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density} ; Print time: {print_time} ; Filament used: {filament_amount}m {filament_weight}g ; Filament cost: {filament_cost} If you still have a problem after removing it, you can remove {print_bed_temperature} and {print_temperature} and hardcode those values to see if the process terminates.