How to design 3d printed parts

What software to use for 3D printing: The complete guide

David Roberson13 May 2021

Guide

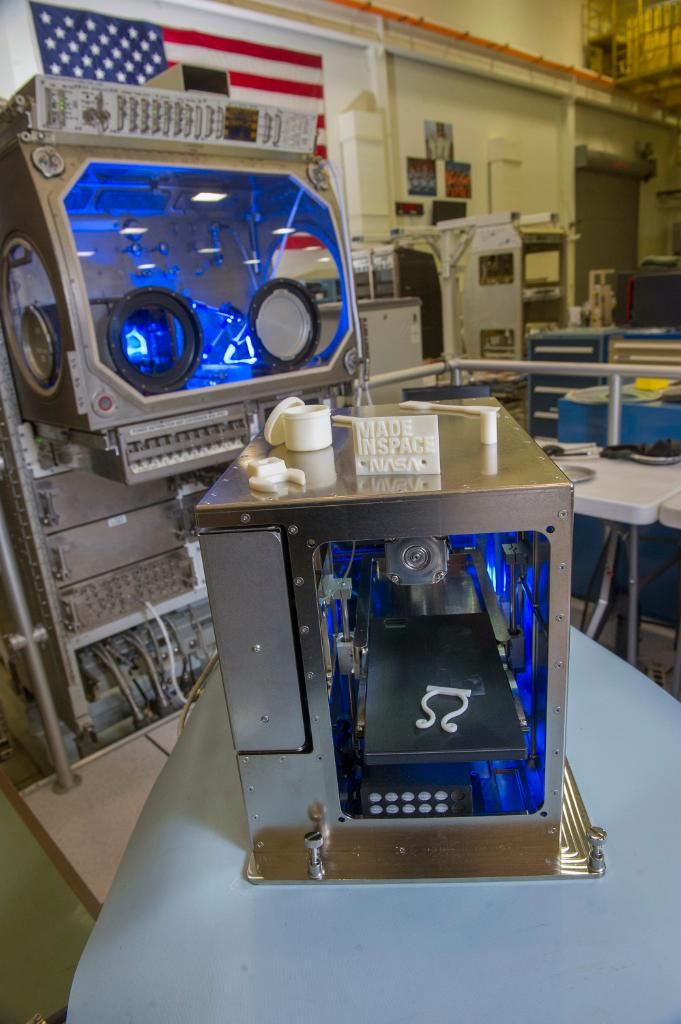

Before starting to 3D print, you will need to make sure you have gathered all the necessary software “ingredients” that will guide you through the printing process, from preparing your 3D model to managing printers themselves.

These include:

CAD software to create a 3D model (you can also use an existing 3D model, if you do not wish or need to design one)

Slicing software

Software to operate your printer remotely (this is optional, but can be convenient)

This article will go through each of these ingredients, and will also touch on how the Ultimaker platform creates a seamless end-to-end flow between hardware, software, and materials, empowering you to unlock the magic of 3D printing and make innovation happen.

What is a “slicer”?

A 3D printing slicer – also known as slicing or print preparation software – is a program that converts a 3D model into a language your 3D printer understands.

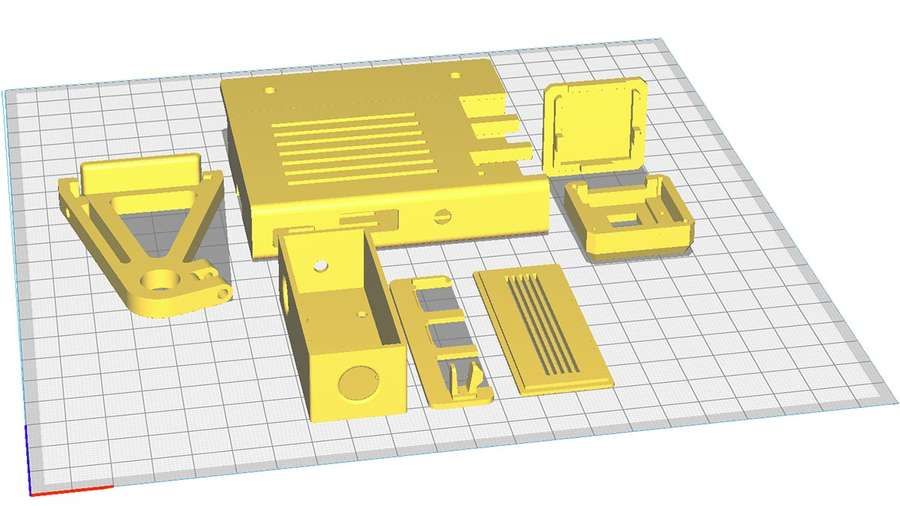

Slicing software, such as Ultimaker Cura, digitally cuts a model into flat layers, which your printer can then print one by one. With the Ultimaker platform, however, slicing software is not always needed, thanks to integrations that allow you to print directly from CAD or the Ultimaker Digital Library.

Preparing a 3D print using Ultimaker Cura software

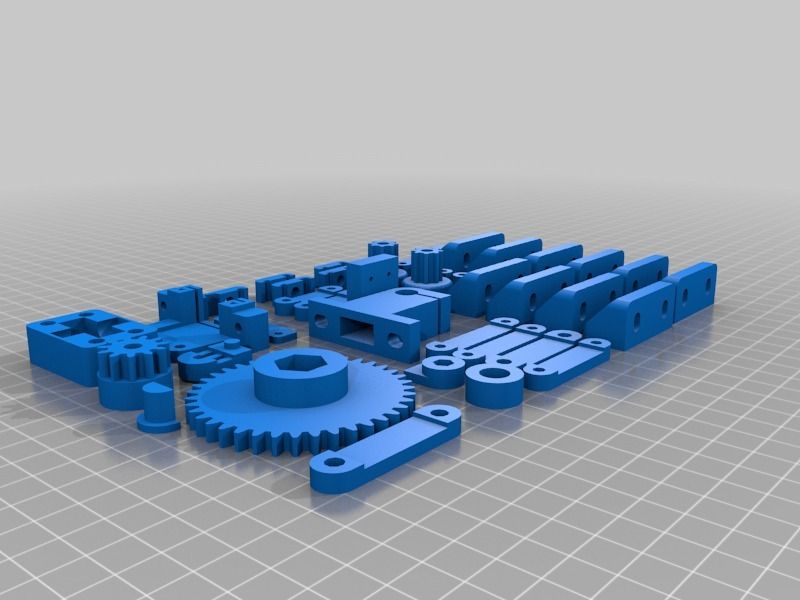

What is the best CAD software to design 3D prints?CAD, or computer-aided design, software enables you to design a 3D model from the ground, up. There are many types of CAD software, each with its own benefits. AutoCAD, created by Autodesk, is perhaps the best-known among them since it was one of the first CAD software programs available for personal computers when released in 1982. Other CAD platforms include:

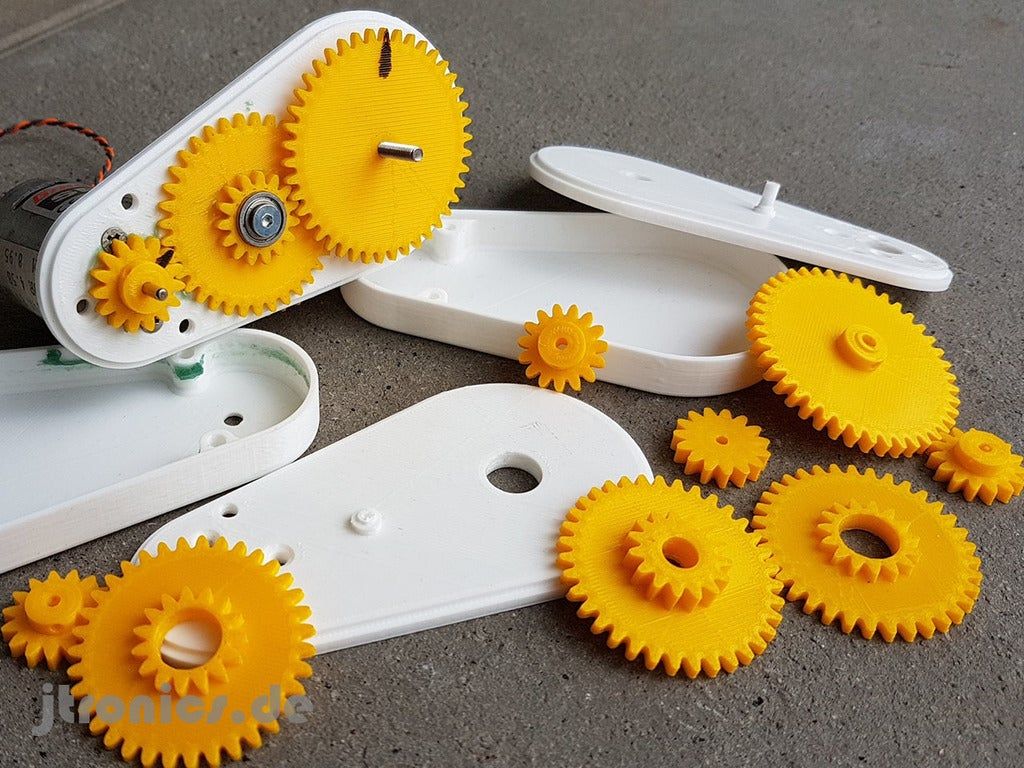

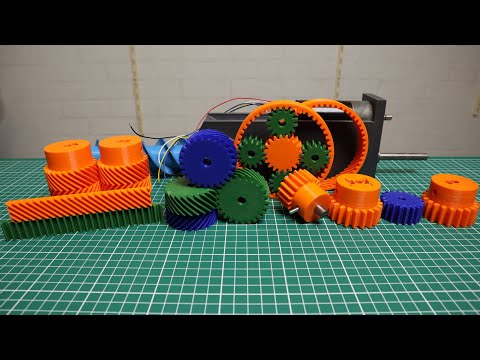

Fusion360 – great for designing and creating efficient mechanical parts

3ds Max – used in all types of 3D model creation, including video game design, architecture, and 3D printing

TinkerCAD – A free, browser-based CAD tool that allows users to build 3D models out of various shapes.

Popular with CAD novices and for STEAM education

Popular with CAD novices and for STEAM educationBlender – free, open-source 3D model creation software

Siemens NX – for designing and creating advanced 3D models

Solidworks – for designing and creating professional parts for industrial use

Catia – Advanced design software used for creating surfaces and engineering systems

Before you begin 3D printing, be sure to do your research and pick the CAD software that’s right for your use case. This way, you’ll get the most out of the model you choose to design and print.

Also check which file types your slicing software is compatible with, so you can make your 3D designs into 3D prints.

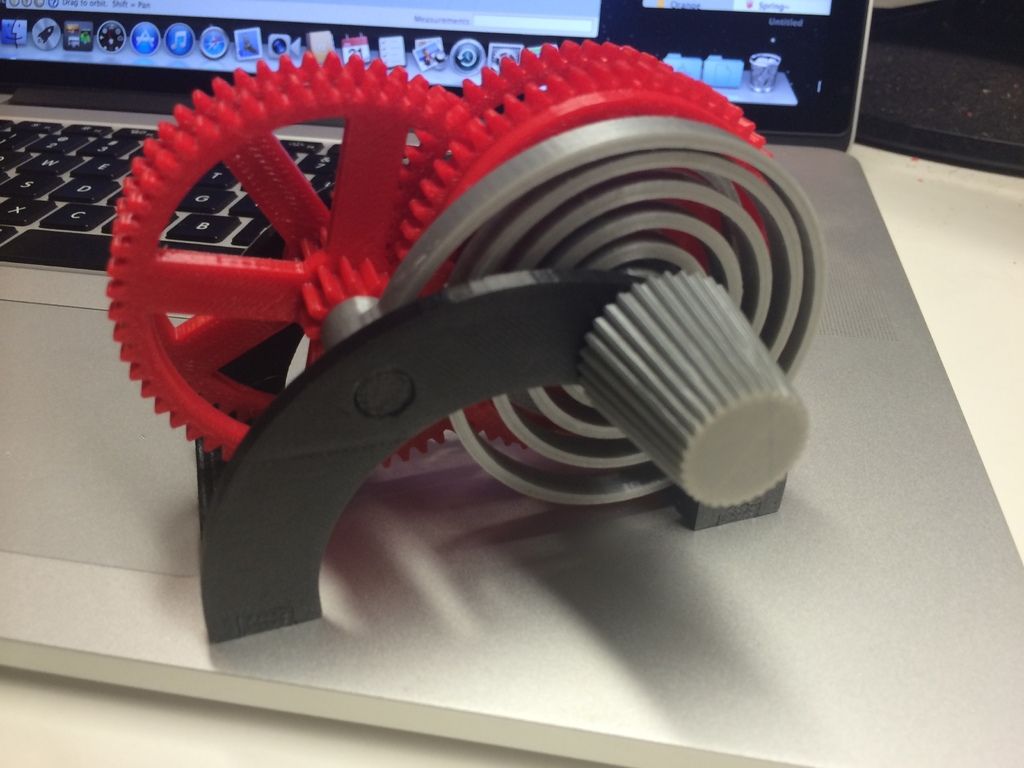

A design in CAD software (left screen), slicing software (right), and the finished print

How to design parts for 3D printing?

When designing for 3D printing, there are best practices to help you get the best results from your 3D printer and the parts it creates. Design parts optimized for 3D printing will improve print success rates, reduce costs through lower wastage, and boost the speed of your product development cycle.

Design parts optimized for 3D printing will improve print success rates, reduce costs through lower wastage, and boost the speed of your product development cycle.

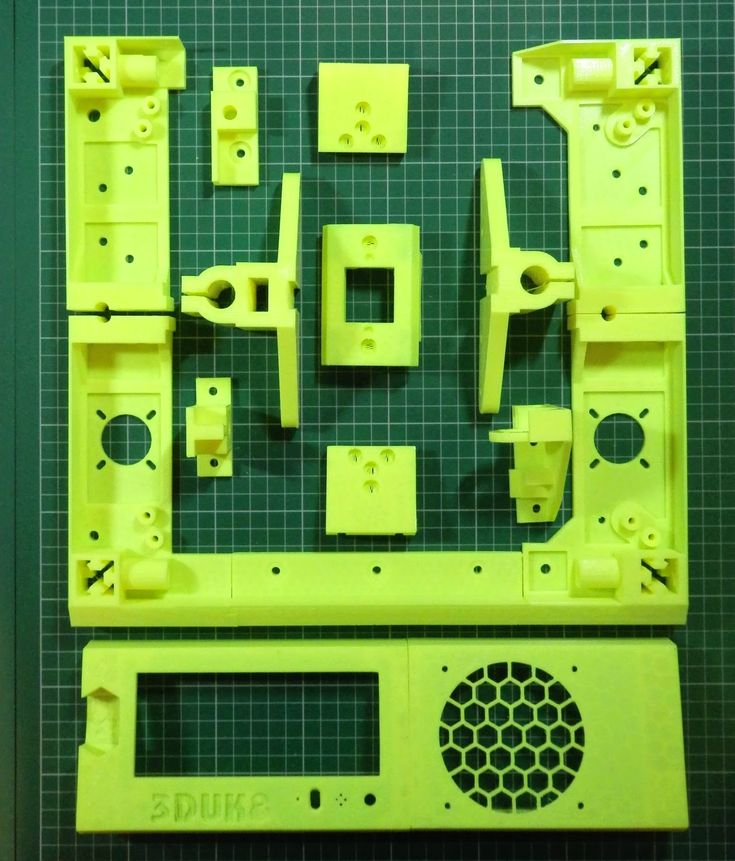

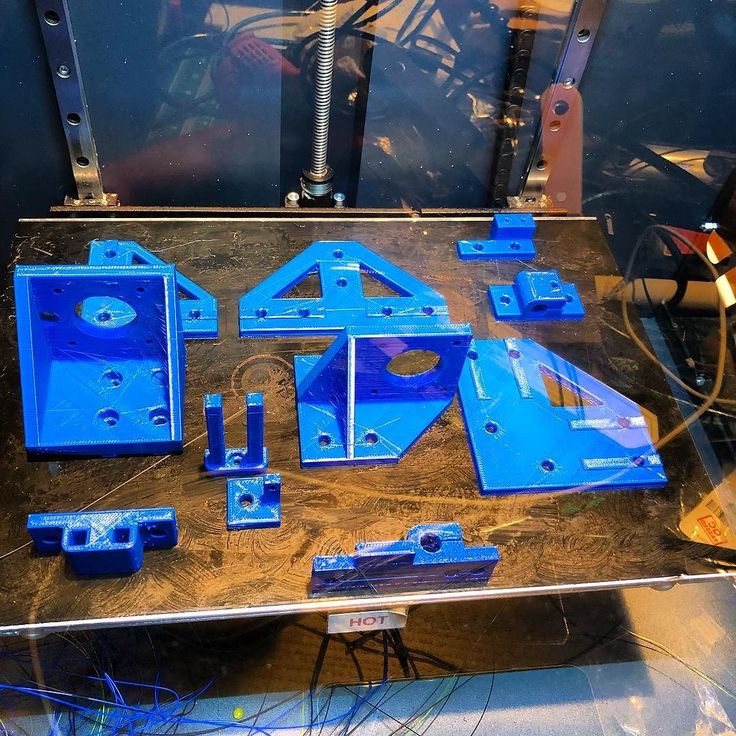

Consider build volume. Your 3D prints can only be as large as your printer’s build volume. Be sure to know its dimensions, then create a part that can either be printed within those dimensions in one go, or plan to use modularity (printing then combining separate parts).

Decide orientation early. Because FFF prints layer by layer, determining the print orientation early in the process helps drive design choices, text alignment, and snap features.

Evaluate overhang support requirements. FFF printed parts are self-supporting up to 45 degrees. Overhangs below 45 degrees must be supported from below with support material.

Follow bridging support guidelines. For most basic filaments, FFF printing does not need support when bridging materials within a 10 mm gap.

Pay attention to nozzle size. When designing small features, you should consider height, wall thickness, and nozzle size. Larger nozzles will print faster than smaller nozzles, but at a cost of increased minimum thickness and height for your models.

When designing small features, you should consider height, wall thickness, and nozzle size. Larger nozzles will print faster than smaller nozzles, but at a cost of increased minimum thickness and height for your models.

Design with hole diameters in mind. Generally, 3D printed hole features should not be smaller than 2 mm. If accurate holes are required, it is recommended to design the holes smaller than intended and post-process with a drilling operation.

Avoid sharp corners. Sharp corners can be modelled in CAD, but the print may warp. Increasing the area of the surface in contact with the bed will decrease the likelihood of the warpage.

For a deep dive into these factors and more, check out our blog on design for 3D printing.

What software do I need to start a 3D print?

This depends on how much of the 3D printing workflow you need to perform.

As long as you already have access to a 3D model, you will typically need software that can slice that model, so your printer can get to work. Once you have started to print, you can also use software to manager your 3D printer (or printers) remotely.

Once you have started to print, you can also use software to manager your 3D printer (or printers) remotely.

But as we saw earlier, the slicing step can be avoided if you have a 3D printer integration installed in your CAD tool. If you already have access to a 3D printable file (such as a G-code on a USB stick) you can also go ahead and print without the need for any slicing software, as your digital file is already ready to print.

Controlling 3D printers remotely with Ultimaker Digital Factory software

Managing 3D printers remotely

Ultimaker S-line printers, the Ultimaker 2+ Connect, and the Ultimaker 3 can make use of a network connection to access cloud-based services on Ultimaker Digital Factory. By linking a printer to your Ultimaker account, your printer can then be controlled remotely, from outside of its local area network.

Want to learn more about 3D printing software?

Download our free white paper, “Important 3D printing software features,” which will help you determine the best 3D printing software for your business needs, as well as examine settings, print profiles, and other features that can help you get the most out of your printing experience.

Get the white paper

How to design parts for FDM 3D printing

Learn how to optimize common design features - such as bridges, overhangs, pins and vertical axis holes - for FDM 3D printing.

As the most affordable 3D printing technology on the market, fused deposition modeling ( FDM ) is a great choice for quick, low-cost prototyping and can be used for a wide variety of applications. It can also be an effective solution for functional parts, such as enclosures.

Like all manufacturing methods, FDM has some limitations and constraints on what can be printed. This article explains how you can adjust your designs for optimal FDM print quality.

What is the FDM printing process?

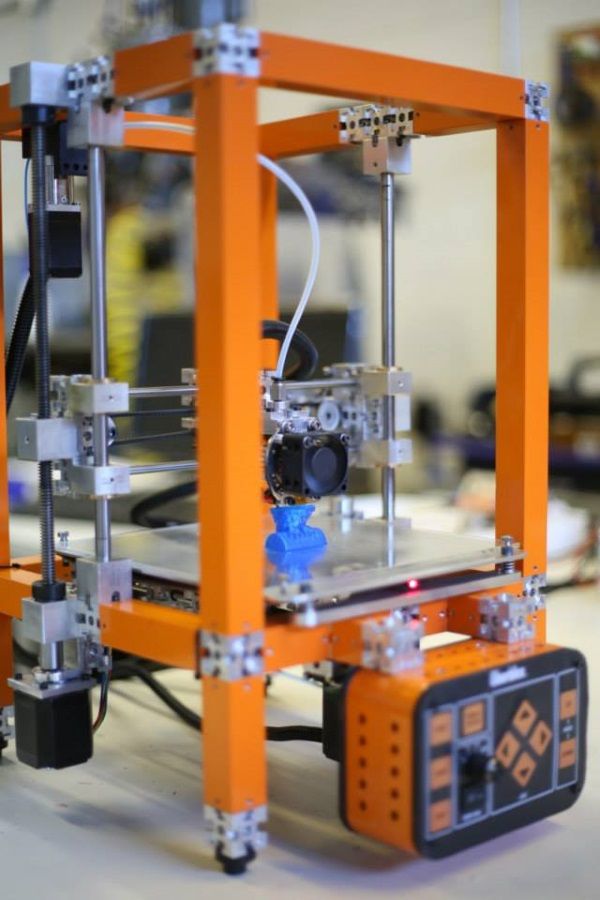

Fused deposition modeling (FDM) is an additive manufacturing process that uses the technique of material extrusion. Also known as fused filament fabrication (FFF), FDM is the most widely used 3D printing technology.

Also known as fused filament fabrication (FFF), FDM is the most widely used 3D printing technology.

To achieve the best results, keep FDM’s capabilities and constraints in mind when designing a part for FDM printing .

Bridging

Bridging in FDM occurs when the printer is required to print between two supports or anchor points. Because there is nothing to build on, no support is offered for the initial layer being printed and the material tends to sag. Bridges most often occur in horizontal-axis holes found in the walls of objects or in the top layer (or roof) of hollow parts.

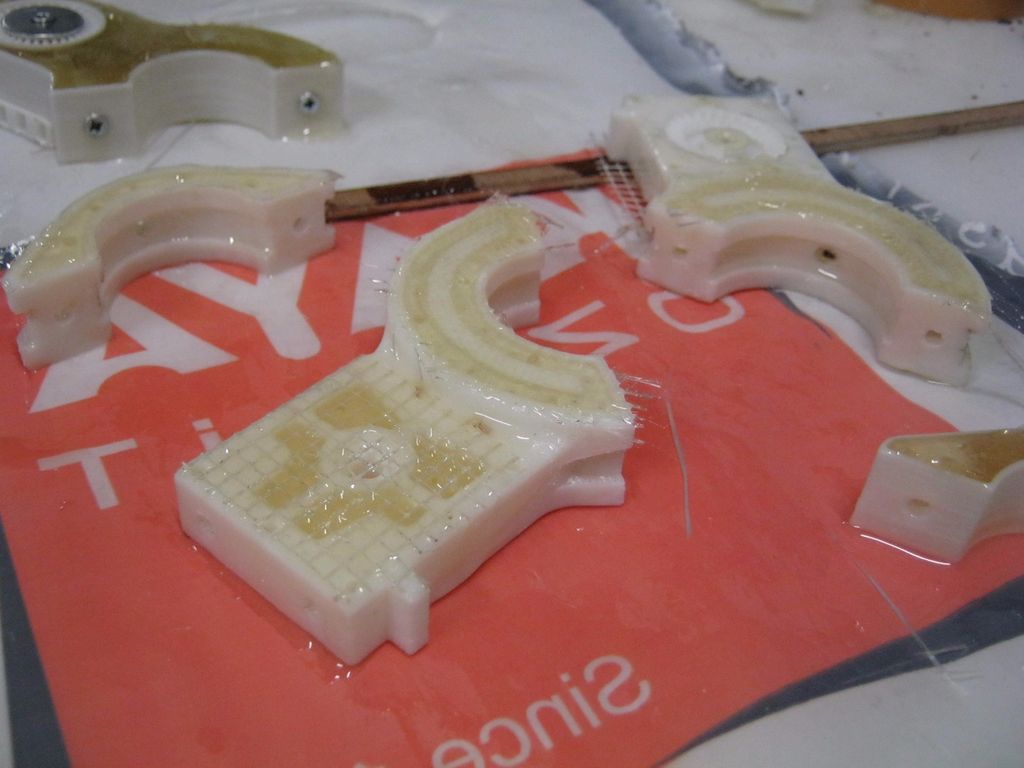

One solution is to reduce the distance of the bridge, but the impact of this depends on the part’s design constraints. Another solution to avoid sagging is to include support. Support offers a temporary platform for the bridging layer to be built upon. The support material is removed once the print is completed, although it can leave marks on or damage the surface where the support was connected to the final part.

Key design consideration: Due to the nature of FDM, sagging or marks from support material are to some extent always present unless the bridge is less than 5mm. If a smooth, level surface is required, an advanced solution is to split the design into separate parts or do some form of post-processing.

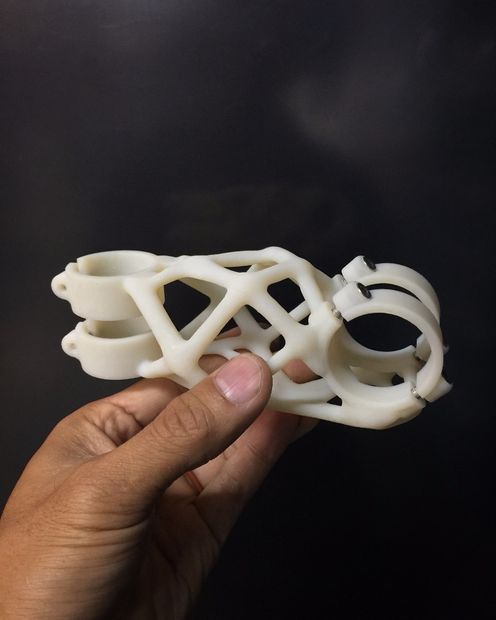

FDM printed puzzle piece with support removed showing surface roughnessVertical axis holes

FDM often prints undersized vertical-axis holes. The printing process for such a hole and the reason its diameter gets reduced can be summarized as follows:

-

As the nozzle prints the perimeter of a vertical axis hole, it compresses the newly printed layer down onto the existing build layers to help improve adhesion.

-

The nozzle’s compressing force deforms the extruded round layer shape from a circle into a wider, flatter shape (see image below).

-

This increases the area of contact with the previously printed layer, improving adhesion but widening the extruded segment.

-

This causes a decrease in the hole diameter being printed. This decrease can be an issue, particularly when printing small-diameter holes, whereby the effect is greater due to the ratio of hole diameter to nozzle diameter.

The amount of undersize depends on the printer, slicing software, hole size and material. The reduction in diameter of vertical axis holes is often taken into account by the slicing program, but accuracy can vary. Several test prints may be needed to achieve the desired accuracy. If a high level of accuracy is required, it may be necessary to drill the hole after printing.

Key design consideration: If the diameter of the vertical axis hole is critical, the recommendation is to print it undersized and then drill the hole to the correct diameter.

Overhangs

Issues with overhang are one of the most common FDM print-quality problems. Overhangs occur when the printed layer of material is only partially supported by the layer below. As with bridging, the inadequate support provided by the surface below the build layer can result in poor layer adhesion, bulging or curling.

The effect of increasing overhang angle (in increments of 5°) on print quality. Maximum angle shown is 70°.Depending on the material, an overhang can usually be printed up to 45° without compromising quality. At 45°, the newly printed layer is supported by 50% of the previous layer. This creates sufficient support and adhesion to build upon. Above 45°, support is required to ensure that the newly printed layer does not bulge down and away from the nozzle.

Another issue that occurs when printing overhangs is curling. The newly printed layer becomes increasingly thin at the edge of the overhang. This results in differential cooling, causing it to deform upwards.

Key design consideration: You can overcome the limitations of overhangs by using support for wall angles above 45°. For larger overhangs needing support, expect marks to be present on the final surface unless post-processed.

Corners

Because FDM printing nozzles are circular, corners and edges have a radius equal to the nozzle size. This means that these features are never perfectly square.

For sharp edges and corners, the first layers of a print are especially important. As discussed above for vertical holes, with each print layer, the nozzle compresses the print material down to improve adhesion. For the initial print layer, this creates a flare often called an “elephant's foot”. Protruding outside the specified dimensions, this flare can impact the ability to assemble FDM parts.

Another common issue concerning the first layer of an FDM print is warping. Compared to PLA , ABS is more vulnerable to warping due to its high printing temperature. The base is the first layer to be printed. It cools as the other hot layers are printed on top. This causes differential cooling, and can result in the base layer curling up and away from the build plate as it shrinks and contracts.

The addition of a chamfer or radius along the edges of the part that is in contact with the build plate reduces the impact of these problems. This also helps with removing the component from the build plate once the print has been completed.

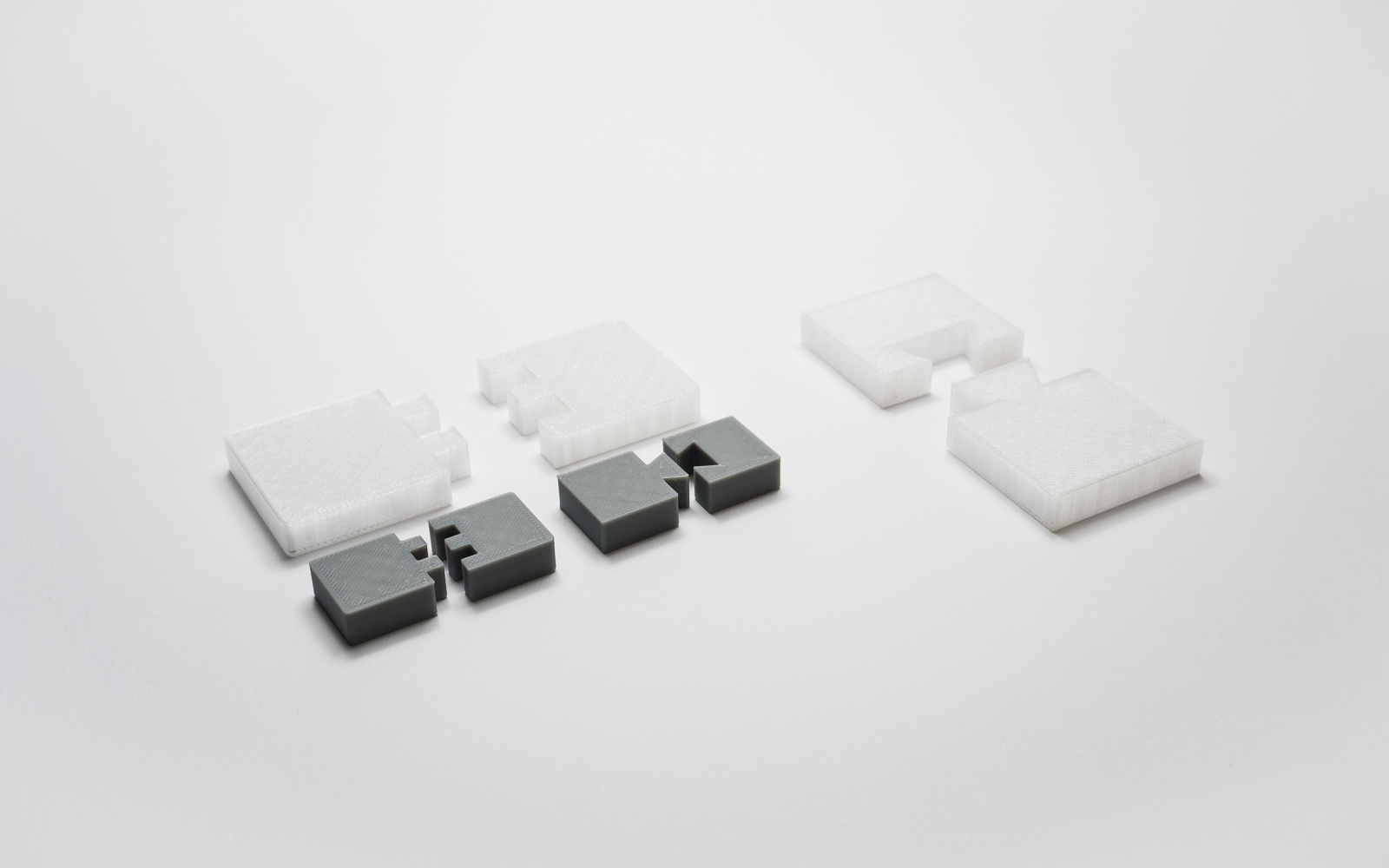

Key design consideration: If assembly or overall dimensions are critical to the function of an FDM part, include a 45° chamfer or radius on all edges touching the build plate. For high-precision form-and-fit testing, we recommend other technologies such as SLA or PolyJet.

For high-precision form-and-fit testing, we recommend other technologies such as SLA or PolyJet.

Vertical pins

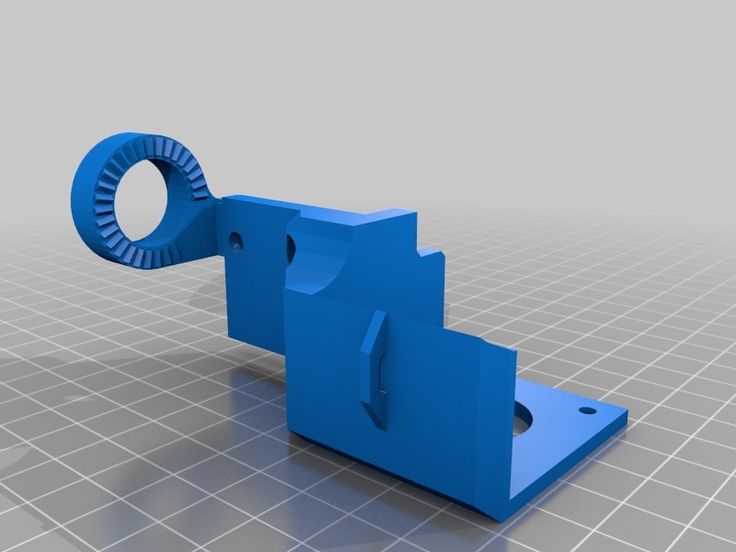

Vertical pins are often printed with FDM when assembly of parts or alignment is required. It is critical to understand the size of vertical pins that FDM can accurately print since these features are often functional.

Large pins (greater than 5mm diameter) are printed with a perimeter and infill, affording a strong connection to the rest of the print. Smaller diameter pins (less than 5mm diameter) can be made up of only perimeter prints with no infill. This creates a discontinuity between the rest of the print and the pin, resulting in a weak connection susceptible to breaking. In a worst-case scenario, small pins may not print at all because there is not enough print material for the newly printed layers to adhere to.

Print of vertical pins with decreasing diameter (from 25 to 5mm), illustrating the upper diameter becoming too small to print accurately.

Correct printer calibration (encompassing optimal layer height, print speed, nozzle temperature, etc.) can often reduce the likelihood of small-pin failure. The addition of a radius at the base of the pin eliminates that point as a stress concentration and adds strength. For critical pins smaller than 5mm in diameter, an off-the-shelf pin inserted into a printed hole may be the optimal solution.

Key design consideration: If your design contains pins smaller than 5mm in diameter, add a small fillet at the base of the pin. If function is critical, consider including a hole in your design in the location of the pin, drill the hole to the correct size and insert an off-the-shelf pin.

When printing with FDM, consider how to reduce the amount of support required, a part’s orientation and the direction the part is built on the build platform.

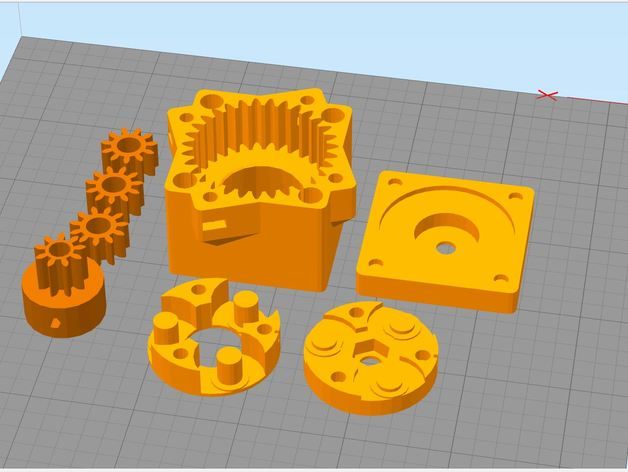

Splitting your model

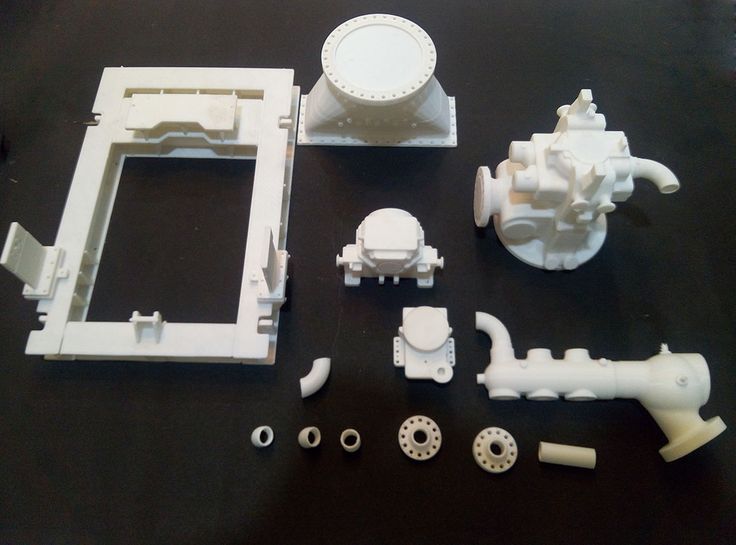

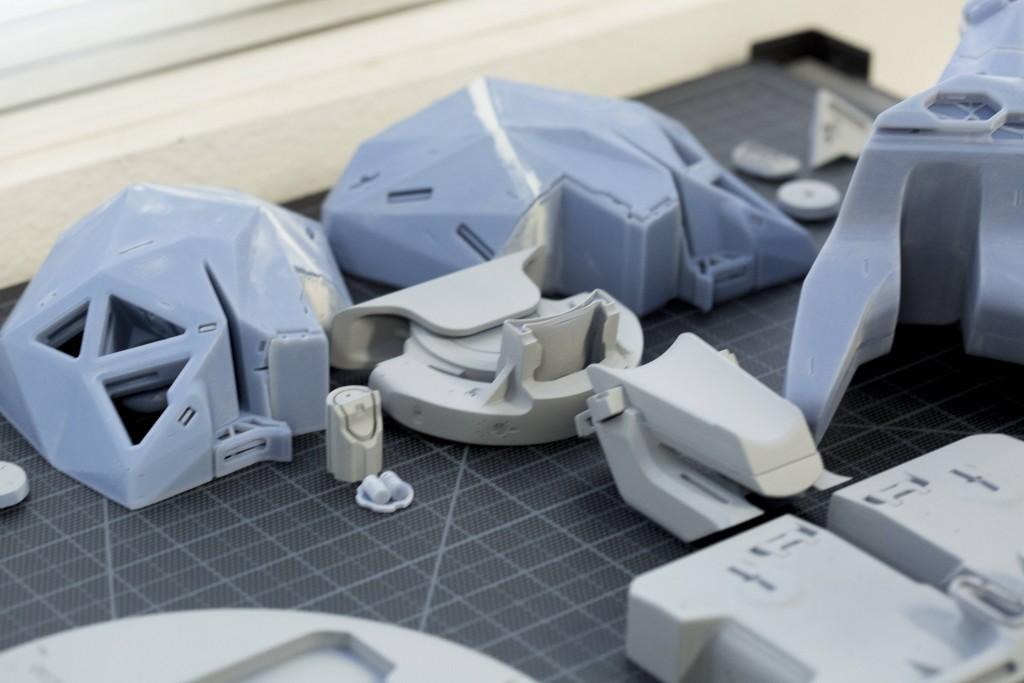

Splitting a model can often reduce its complexity, saving costs and time. Overhangs that require a large amount of support may be removed by simply splitting a complex shape into sections that are individually printed. If desired, the sections can be glued together once printing is completed.

Overhangs that require a large amount of support may be removed by simply splitting a complex shape into sections that are individually printed. If desired, the sections can be glued together once printing is completed.

Hole orientation

The best way to avoid support for holes is by changing the print orientation. Removal of support in horizontal-axis holes can often be difficult, but rotating the build direction 90° eliminates the need for support. For components with multiple holes in different directions, prioritize blind holes, followed by holes with smallest to largest diameters and then the criticality of hole size.

Reorientation of horizontal axis holes can eliminate the need for support.Build direction

Due to the anisotropic nature of FDM printing , understanding the application of a component and how it is built are critical to the success of a design. FDM components are inherently weaker in one direction due to layer orientation.

FDM components are inherently weaker in one direction due to layer orientation.

A lack of continuous material paths and the stress concentration created by each layer joint contribute to this weakness. Since the layers are printed as a round-ended rectangle, the joints between each layer are actually small valleys. This creates a stress concentration with a tendency to crack.

FDM materials

The most commonly used 3D FDM materials are summarized in the table below.

| Material | Characteristics |

|---|---|

| ABS | + Good strength + Good temperature resistance - More susceptible to warping |

| PLA | + Excellent visual quality + Easy to print with - Low impact strength |

| Nylon (PA) | + High strength + Excellent wear and chemical resistance - Low humidity resistance |

| PETG | + Food Safe* + Good strength + Easy to print with |

| TPU | + Very flexible - Difficult to print accurately |

| PEI | + Excellent strength to weight + Excellent fire and chemical resistance - High cost |

FDM 3D printing best practices

-

If a bridge exceeds 5mm, sagging or marks from support material can occur.

Splitting the design or post-processing can eliminate this issue.

Splitting the design or post-processing can eliminate this issue. -

For critical vertical-hole diameters, drill after printing to achieve higher accuracy.

-

The addition of support will allow FDM printers to print wall angles greater than 45°.

-

Include a 45° degree chamfer or radius on all edges of an FDM part touching the build plate.

-

For applications with small vertical pins, add a small fillet at the base or consider inserting an off-the-shelf pin into a printed hole instead.

-

Splitting a model, reorienting holes and specifying build direction are all factors that can lower cost, accelerate the printing process and improve a design’s strength and print quality.

Want to learn more about 3D printing? Read our full guide: What is 3D printing?

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quote

Get an instant quote3D Printing Basics / Sudo Null IT News

KolianM

Working with 3D graphics *Prototyping *3D printers DIY or Do it yourself or milling. This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

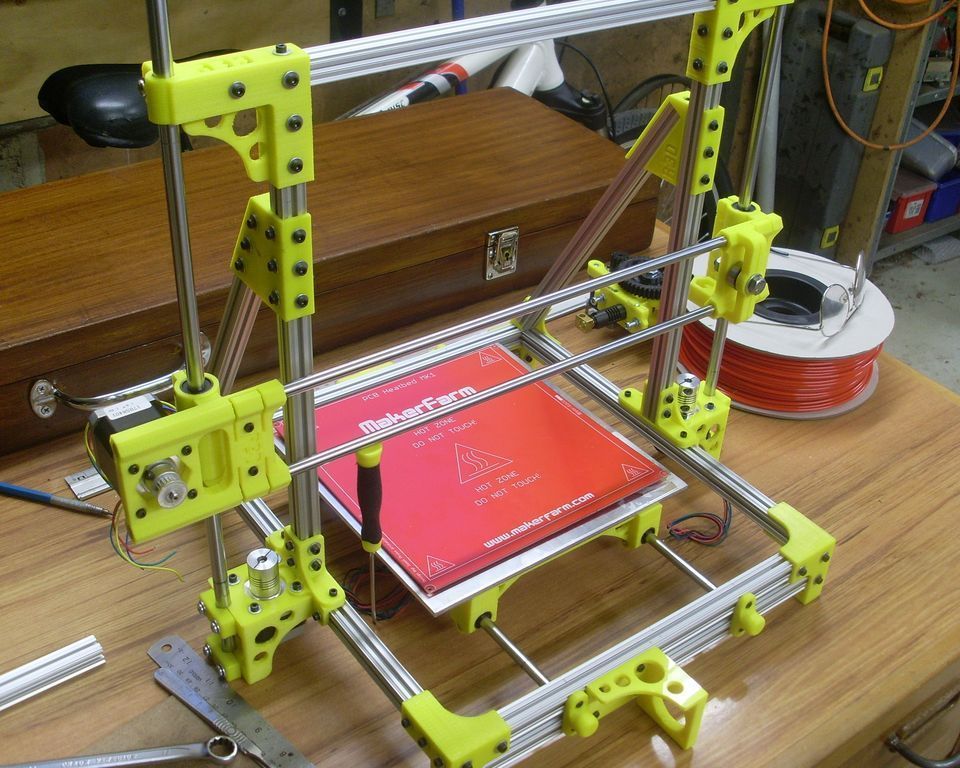

From the reservations, I note that these recommendations relate mainly to the FDM (FFF) 3D printing method, in which a plastic rod is heated by a moving extruder that forms the part layer by layer.

3D model development starts with a sketch. It can be a drawing on paper, a material prototype, a mental image, etc. What is important to pay attention to when creating such a sketch and the model itself, we will analyze in detail.

Part strength

Here and further down the text there are several sub-points that must be taken into account at the same time, kept in mind from the very beginning.

- Be aware of the layering or anisotropy of the material: it is much easier to break a part in layers than across. This must be taken into account in advance, given the location of the 3D model on the 3D printer table.

- Add fillets. The leg of the stool and the tabletop at the junction should have a rounded corner. At the same time, the larger the radius of curvature, the stronger the leg will be fixed on the tabletop. Similarly for various body parts. Modeling a box All right angles are rounded. It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses.

- Wall thickness and filling. The maximum strength at 100% infill is a fact, but if you need to lighten the part or save plastic, you can make a much larger wall thickness in the print settings, while setting the infill much lower.

This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

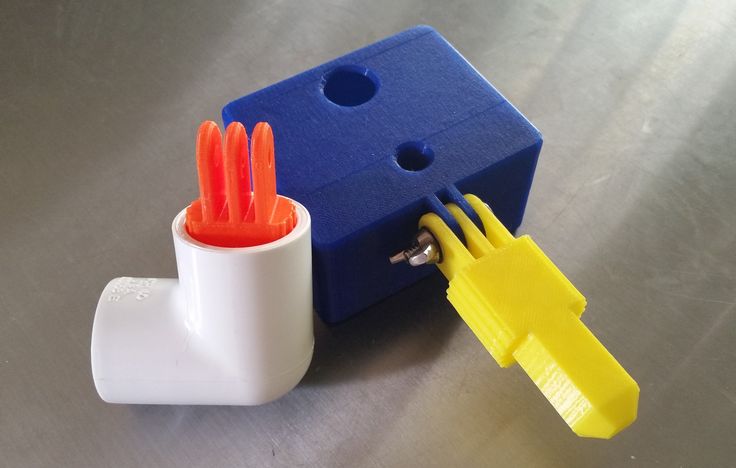

- Support. This element affects the strength in that the layers supported by the support are not always ideal in structure. This can be solved by increasing the wall thickness, filling, but it is better not to do support at all. Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped.

In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print.

In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print.

Geometric restrictions

- The wall thickness is limited from below by the size of the 3D printer nozzle. Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part.

- 3D printing of thin cylinders and "needles". For 3D printing of such products, special 3D printer settings are needed: low 3D printing speed, allow time for cooling, otherwise such a structure will bend. Vertically standing thin elements are best avoided at all costs. Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

- 3D printed holes. I note that if the hole is straight and through, then it can be drilled, if it is curved and requires support, then it may turn out that it will be impossible to get support.

- When 3D modeling, it is important to consider the overall dimensions of the 3D printer. We use convenient 3D printers, table 250x250 mm, diagonal 353 mm. This is where you need to enter the dimensions, if possible. Otherwise, you need to order either an industrial 3D printer with a large print area, or use gluing, but assembly is better, so the assembly process will be controlled by the developer, and not by the 3D printing master.

- Large footprint may cause edges to peel off the table. We use special glue, but this does not always help. We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

- Tall and thin "towers" may not work well due to vibrations that occur when the 3D printer is running closer to the top, and layer shifts are also possible.

Dimensional stability, accuracy

- Precise 3D printing is quite rare. I don’t want to speak in engineering terms here, but the likelihood that a complex composite structure will assemble the first time is very low. Here, rather, you need to take into account the fact that you can then mechanically refine the details.

- Holes for fasteners are best done with a margin of 0.5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it. It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases.

- Heat shrinkage is not always compensated, more precisely, it is very difficult to catch it, it is not the same in different directions, so it is extremely difficult to take it into account. It's easier to print a test version, and then make adjustments.

When appearance matters

- Think about how the craftsman will orient the part on the 3D printer table.

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

- Support. First, the surface it supports has significantly more defects than without it. Secondly, thin and high support is weak, wobbly, which leads to the fact that the supporting part may have serious defects, or not work at all.

- First layer quality improvement. You need to add a bevel. Even where a sharp corner is not needed, I recommend adding a chamfer of 0.5 mm. It will not be clearly visible, but the edge will be neat.

What you need to know in order not to make a mistake when ordering 3D printing

If appearance is important

- Placement of the part on the table.

Remember about anisotropy.

Remember about anisotropy.

- Wall thickness and filling. What you can run into here: the filling is 20% cells, which are either visible through a thin outer wall, or the filling slightly tightens the outer wall during shrinkage, but at the same time it is visually easy to determine that there is support inside. Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering.

Postprocessing

The elimination of stepping is achieved by mechanical and chemical methods. It is possible to use putty. Acrylic paint available. If the part has a complex color structure, then we use the ProJet 4500 printer, which works on a different technology. He glues the powder particles together with colored ink glue. It turns out well.

Morality

In conclusion, I would like to note that these recommendations and the accumulated experience will make it possible to produce parts by 3D printing, which in their properties will not be inferior to cast ones, which makes it possible to save significant funds in the presence of a customized printer and small production volumes. From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey.

From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey.

Only registered users can participate in the survey. Come in, please.

Do I need to buy a 3D printer, or should I outsource it?

66.67% It is better to control everything yourself, modeling and printing 60

21.11% I model, and let those who live it print 19

10% I prefer designing and printing to narrow-profile specialists 9

14.44% I don't believe in 3D printing, I try to avoid it altogether 13

90 users voted. 24 users abstained.

Tags:

- 3D-modeling

- 3D -ip

Habs:

- Work with 3D graphics

- Prototypery

- 3D prinches

- DIY or do

900 CAD models for a printed object / Sudo Null IT News

was withdrawn from publication due to a technical error.Please be understanding. Thank you!

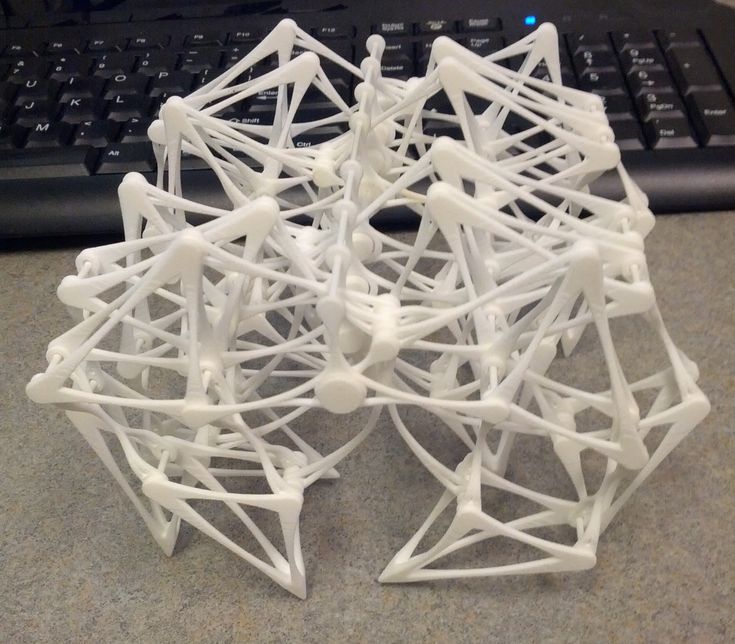

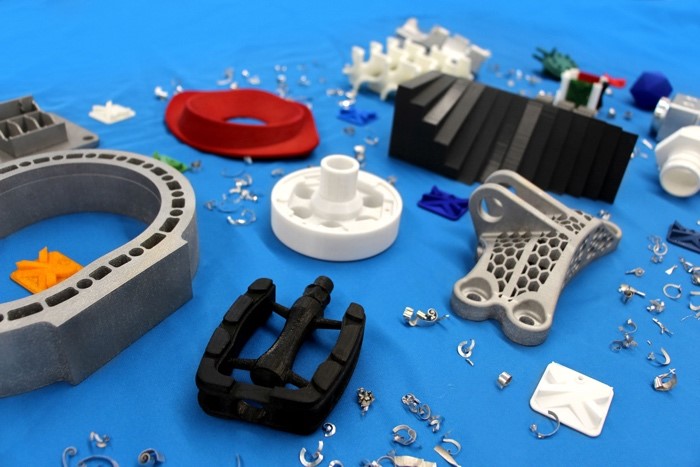

Whether it's just a hobby or a source of income, 3D printing is always based on product design. Those accustomed to traditional technologies will have to rethink the entire approach to product design and manufacture.

When the project is ready, a number of additional operations are performed: setting the orientation of the model and other parameters that ensure the proper printing process. In addition, it is necessary to take into account the fact that most 3D printers allow you to choose the degree of filling the model with cellular structures. The correct choice of this parameter provides protection of the object from deformation and destruction during the printing process, as well as significant savings in material and reduction in production time.

Finally, the last factor influencing the success or failure of the 3D printing process is the strength of the connection between the model and the table. If the workpiece is separated from the table during printing, then all the work will go down the drain.

If the workpiece is separated from the table during printing, then all the work will go down the drain.

Here, we'll walk you through the 3D printing process and give you some simple guidelines for using additive manufacturing in the design phase. In addition, we will dwell on the methods of preparing a finished project for printing, and also consider ways to securely fasten the workpiece to the table.

These guidelines apply primarily to Fused Deposition Printers (FDM) printers, but may apply to other types of printers as well. The process of obtaining a finished part by 3D printing is basically the same regardless of the method used.

Designing an object

Any 3D printing starts with construction. If you are developing a product yourself, then you need to build a 3D model of it in a computer-aided design (CAD) system to turn the designer's idea into reality. In this case, the object can be both very simple and very complex. However, too thin and too small models should be avoided.

However, too thin and too small models should be avoided.

3D-CAD from Siemens from this article for 49900r (90% discount), the promotion is valid until March 20, 2020. Read more>>

Saving the file in a special format for printing

To print an object, its model must be saved in a special file format - for example, STL, which has become the de facto standard in the world of 3D printing. In this format, model surfaces are represented as a grid of triangles. Simple surfaces are broken down into a small number of triangles. The more complex the surface, the more triangles you will need. Today, other formats are used in 3D printing, in particular, the 3MF format developed by Microsoft. But the most common is still STL.

CAD systems make it very easy to save the model in the desired format: just click the Save As command. To improve print quality, it is desirable to set a number of settings for saving to the STL format - for example, the tolerance during transformation and the angle of the plane. The lower the conversion factor and the better the angle, the smoother the printed part will be.

The lower the conversion factor and the better the angle, the smoother the printed part will be.

Opening the file in the slicer program

Most, if not all, 3D printers come with their own slicer software. The slicer loads the STL file created in the CAD system and cuts it into layers, and then creates a control program for the printer.

Positioning the model correctly in the print space

After entering the print settings, the model (or several models) needs to be placed on the printer table. You can print many objects on one table at once. At the same time, compared to printing a single object, the time slightly increases, but in general it still turns out to be less. Here are some tips for choosing the right model orientation.

Set parameters

In the slicer program, the user sets parameters such as print speed, material consumption, nozzle and desktop temperatures. Most slicers have simple settings for beginners. In this case, most often there are also advanced settings so that experienced professionals can achieve optimal results. Advanced settings include percentage infill, amount of backing material, and type of backing or raft (this is a small, thin base that keeps the printed part stable. The backing is removed when it's finished). The number of options is truly endless. Specific settings vary depending on the brand of printer. It's easy enough to set them up.

Most slicers have simple settings for beginners. In this case, most often there are also advanced settings so that experienced professionals can achieve optimal results. Advanced settings include percentage infill, amount of backing material, and type of backing or raft (this is a small, thin base that keeps the printed part stable. The backing is removed when it's finished). The number of options is truly endless. Specific settings vary depending on the brand of printer. It's easy enough to set them up.

Sending the control program to the printer

After setting the print settings, the placement of future objects on the table, their orientation and quality, it's time to finally start the printer. It is enough to press the Print button and find something to do while the production is in progress. Depending on the complexity of the design, the process takes from several minutes to several hours.

Finishing

Finishing includes removing the printed part from the table, as well as removing the support material by melting, mechanical separation or dissolution (depending on the design of the printer). The part may require some light sanding or polishing, but overall a properly printed object looks good from the start. Other types of finishing are placing plastic parts in a container with acetone to smooth out surface roughness, gluing (if the dimensions of the structure exceed the dimensions of the 3D printer or individual elements of the object must have different orientations), drilling holes and painting.

The part may require some light sanding or polishing, but overall a properly printed object looks good from the start. Other types of finishing are placing plastic parts in a container with acetone to smooth out surface roughness, gluing (if the dimensions of the structure exceed the dimensions of the 3D printer or individual elements of the object must have different orientations), drilling holes and painting.

3D printing process

3D printer design considerations

Eliminate sharp corners

If the direction of the surfaces changes abruptly (for example, a vertical wall intersects with a horizontal overlap), then such a model is difficult to print. The printer will build excessive inner surfaces, wasting too much material. There are two easy ways to prevent this: add chamfers to smooth out where the surfaces meet, or round the corners so the printer gradually builds a vertical surface. In addition, rounding will increase strength, since destruction most often occurs at sharp corners.

In addition, rounding will increase strength, since destruction most often occurs at sharp corners.

Elimination of thin walls and small geometries

Layer by layer fusing technology consists in supplying hot plastic through a nozzle with the formation of a printed object layer by layer. The thickness of the extruded plastic layer cannot be made smaller than a certain limit, depending on the diameter of the nozzle and the speed of the print head. Excessively thin-walled details are difficult to print - often the result is a chaotic weave of fibers. If the part can be printed, it is very fragile and breaks easily.

Too thick walls - also bad

On the other hand, if the walls are too thick, they become brittle and crack easily. This is especially important when printing from materials other than resins, as excess thickness during the manufacturing process leads to internal stresses in the part. Even when printing from plastics, material is wasted on walls that are too thick and time is wasted.

Even when printing from plastics, material is wasted on walls that are too thick and time is wasted.

Removing large overhangs

3D printers allow you to create amazing shapes and surfaces, but they are not capable of printing directly in the air. If there is a void in the part with material above it, additional support material must be used. Most slicers add material automatically, but require you to specify the orientation and volume of the support structure. Printers with a single nozzle create an array of thin columns, which then have to be broken off. The result is an uneven surface. Therefore, it is recommended to avoid large overhanging elements whenever possible in order to reduce the need for support material.

If such an element is unavoidable, you can try to flip the object. Most printers are capable of printing overhanging elements with an angle of about 45 degrees. At a certain height, the edge of such an element may sag somewhat. The actual capabilities of a particular printer are determined by trial and error.

The actual capabilities of a particular printer are determined by trial and error.

Holes shrink

Remember that the part is made of heated plastic. As it cools, it inevitably shrinks. Therefore, holes and other critical structural elements have to be made larger so that after shrinkage their size is as close as possible to the required one.

However, if you need to make a tight tolerance hole, it is better to print it with a smaller diameter and then ream it with a suitable tool. This is especially true for holes whose axis is parallel to the printer table.

Increasing the footprint

If the area of contact between the object and the base is small, the part may separate from the table during printing. To prevent this from happening, wide bases are added to the model legs, which are installed on the printer table. In general, the closer to the table, the more material must be added to the support. There are other ways to securely fasten the part to the table, which we will discuss a little later.

There are other ways to securely fasten the part to the table, which we will discuss a little later.

Special moves

The right approach to design makes printing easier. In addition, there are special post-processing techniques that are important to be aware of.

Arrange round surfaces vertically

The model should be oriented so that the minimum amount of support material is used. Ideally, it should rest on the table with a large flat edge. In addition, circular geometry must be placed so that the circular faces are vertical. If we look at the printer table from above, we should see a round silhouette of the object. In this case, the part comes out as symmetrical as possible with the formation of a solid round structure.

Place voids and holes vertically

If there are voids in the model (for example, it is a rectangular pipe), it is desirable to place such voids vertically in order to reduce the volume of the support material. If you print the pipe in a horizontal position, you will have to provide support for the entire interior. If you put the pipe on the end, then no support is required at all.

If you print the pipe in a horizontal position, you will have to provide support for the entire interior. If you put the pipe on the end, then no support is required at all.

The same is true for holes: to get a hole with a straight axis, it is best to print it vertically - in the form of a stack of rings, which avoids warping or deforming a round hole into an oval one.

Set print quality settings

Proper selection of print parameters, such as STL conversion tolerance and slicer software settings, allows parts to be produced with a surface quality that matches that of cutting. However, this entails an increase in print time. When choosing quality parameters, one should proceed from the purpose of the object: is it a finished product or a prototype? Will the part be visible or hidden?

The quality parameters also affect the shape of the holes in the part. In CAD files, holes are represented as a set of straight lines at an angle to each other. The higher the quality of the model in the saved STL file, the less the circle looks like a polygon.

The higher the quality of the model in the saved STL file, the less the circle looks like a polygon.

Reducing the layer thickness

To obtain the best quality, especially when using layer-by-layer deposition technology, it is necessary to reduce the thickness of the layers. It does increase the print time, but the end result is worth it!

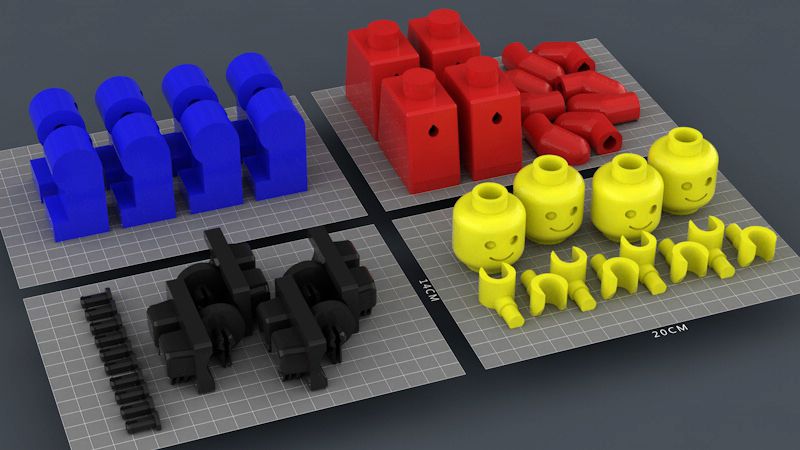

Optimizing the filling with honeycomb structures

In terms of strength, objects do not have to be solid. Similar to a honeycomb, printers can create a honeycomb infill that balances strength and saves expensive polymer material. However, if the printed part serves as a prototype for strength testing, and the serial product will be manufactured by traditional methods, and also if the part is subjected to certain types of mechanical stresses and pressures, a solid design will be preferable.

Choosing material

The success of printing largely depends on the correct choice of material. Materials have different properties. For example, the melting point of thermoplastic polyurethane (TPU) and polylactic acid (PLA) is lower than that of acrylonitrile butadiene styrene (ABS). In addition, the material is taken into account when choosing the type of support structures. For an object made of polylactic acid, supporting elements can be made from the same polylactic acid, since it will be quite easy to separate them from the finished part. If the part is printed from ABS plastic, then the support elements must be made from a different material, and it is better not to use such elements at all in thermoplastic polyurethane parts.

Materials have different properties. For example, the melting point of thermoplastic polyurethane (TPU) and polylactic acid (PLA) is lower than that of acrylonitrile butadiene styrene (ABS). In addition, the material is taken into account when choosing the type of support structures. For an object made of polylactic acid, supporting elements can be made from the same polylactic acid, since it will be quite easy to separate them from the finished part. If the part is printed from ABS plastic, then the support elements must be made from a different material, and it is better not to use such elements at all in thermoplastic polyurethane parts.

Cellular filling

A solid body is not always the best choice for 3D printing. Printing solid parts has its advantages, but the internal honeycomb structure saves both expensive material and time.

Creating objects with a specified degree of filling with honeycomb structures is a unique opportunity for 3D printing. Moreover, it is not required to design such a structure: this is done by the slicer program. As a rule, it is enough to set only the percentage of filling (the closer it is to 100, the more solid the object will turn out) and select the type of cells, if the printer has such an opportunity.

Moreover, it is not required to design such a structure: this is done by the slicer program. As a rule, it is enough to set only the percentage of filling (the closer it is to 100, the more solid the object will turn out) and select the type of cells, if the printer has such an opportunity.

In addition to saving time and material, the internal honeycomb structure has many other advantages.

Cellular filling prevents warping

Printing large objects as a single piece introduces a danger of warpage. By reducing the infill percentage, the air during printing passes through the part, providing more uniform cooling and eliminating warping.

Cellular filling does not lead to loss of strength

Printing cells instead of solid material does not reduce the strength of the part. In many cases, a honeycomb part is strong enough for the chosen application, but lighter and less material intensive.

The function determines the choice of cell geometry

Most slicers support a wide variety of cell geometries. The optimal option is determined by the functional purpose of the object. Standard box padding simplifies printing, while hexagonal and triangular boxes add strength. Wave fill allows the object to bend or twist.

How do I choose the right filling percentage?

In general, the strength of an object increases as the percentage of infill increases. Most printers have a default infill percentage of 20, which is optimal in some cases but too high or too low in others. Consider mechanical stresses in the printed object and increase the percentage of infill in areas where greater strength is required. If high strength is not required, choose the lowest possible filling. This saves material and speeds up printing. Most often, the selection of the optimal percentage of filling is done by trial and error.

Ways of fastening the workpiece to the table

“Rafts”, “brims”, “skirts” – these terms sound funny, but they just refer to the three main ways of attaching a 3D printed part to a printer table. Let's take a look at each of these methods and their areas of application.

Skirt

The skirt involves creating a few rings around the object at the beginning of the print to make sure the plastic is extruded normally. The skirt is not in contact with the object at all. It surrounds the printable area and helps start the fusing process. When creating a skirt, a large volume of hot thermoplastic polymer passes through the nozzle. This prepares the printer for printing the part itself. This guarantees good adhesion to the table and obtaining smooth surfaces of the object.

Brim

The brim is a wide, flat area connected to the main object as a support base (think of a brim of a hat). It is very similar to a skirt, but connected to the model. In addition to all the advantages of a skirt, the brim keeps the edges of the object being made on the table.

It is very similar to a skirt, but connected to the model. In addition to all the advantages of a skirt, the brim keeps the edges of the object being made on the table.

When printing, the outside of an object often cools faster than the middle, causing the edges to curl. Brim prevents this phenomenon by holding the edges.

Raft

A raft is a detachable base, made in the form of a thin mesh platform, located under the entire object (which lies on the raft). To create a raft, the printer first prints a flat plate in two or three layers, and then begins to manufacture the object.

The rafts provide excellent adhesion to the table surface and also provide a strong print base. This is especially useful when making small and oddly shaped parts that do not fit well on the table, as well as thin-walled objects.

After printing is completed, in most cases the raft will separate easily from the part.

If the printer does not have a heated desktop function

Rafts are used if the printer does not have desktop heating. In this case, excessive adhesion becomes a problem.

In this case, excessive adhesion becomes a problem.

An alternative method is to apply adhesive paper tape to the printer platform, with the edges down if possible (this protects the platform itself). You can also use packing tape, but it is usually more expensive.

If buckling does occur or if the object separates from the table, apply a dissolvable glue stick to the adhesive tape. This will enhance adhesion.

Find out the features of a specific 3D printer and take them into account when preparing your model

3D printing is not only a science, but also an art. Effective design for subsequent 3D printing requires an understanding of the technological process, taking into account its features and the purpose of the future object. This will greatly improve print performance.

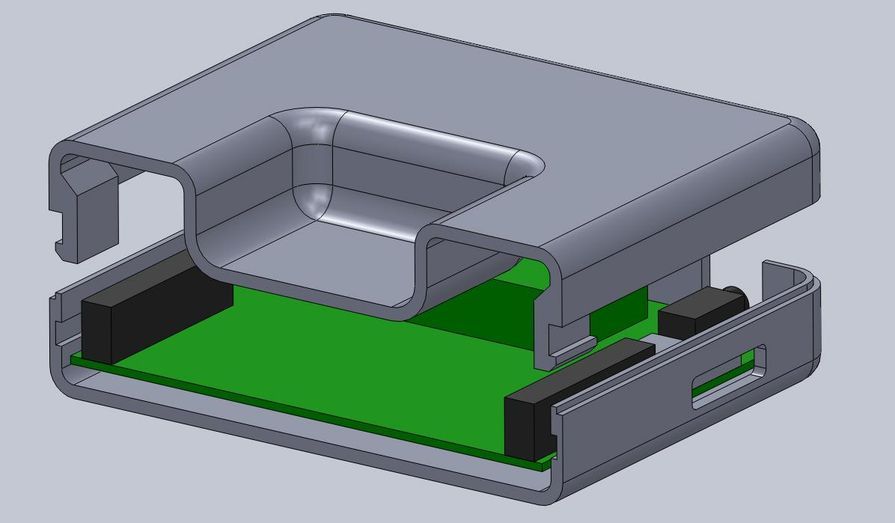

Using Solid Edge in 3D printing

Not all CAD systems are suitable for 3D printing

The capabilities of the applied system should not limit the designers. Our Solid Edge system is designed with the latest 3D printing technologies in mind. Various 3D printers and 3D printing services are supported.

Our Solid Edge system is designed with the latest 3D printing technologies in mind. Various 3D printers and 3D printing services are supported.

Take it to the next level with specific techniques for designing 3D printed parts

Generative modeling in Solid Edge opens up new possibilities: the designer selects a specific material, sets the design space, allowable loads, restrictions and target mass of the part, and the system automatically calculates the desired geometry. As a result, 3D printing methods can produce the most complex shapes.

In addition, when building models, the use of the results of three-dimensional scanning is provided. Solid Edge successfully combines the traditional boundary representation of solid models (B-Rep) and the representation of surfaces in the form of a grid of triangles, which avoids time-consuming transformations that are fraught with errors.

If you've already downloaded an STL file for printing, our unique synchronous technology makes it quick and easy to edit your imported models in Solid Edge in preparation for the process.