3D prototype printers

Metal 3D Printing Service for Custom Parts

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars & Trade Shows

Blog Videos FAQs Educators & Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability & Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Get quality metal 3D-printed prototypes and production parts. Request an online quote today.

GET METAL PARTS

Certifications

ISO 9001:2015 | AS9100D | ITAR Registered

Jump to Section→ Capabilities

→ Available Alloys

→ Compare Material Properties

→ Surface Finishes

→ Post-Processing

→ Why Metal 3D Printing?

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.

A range of metals produce final parts that can be used for end-use applications.

Metal 3D printing technology is commonly used for:

- Prototyping in production-grade materials

- Complex geometries

- Functional, end-use parts

- Reducing metal components in an assembly

We hope you find this guide helpful. If the file did not download, you can find it here.

Jump start your metal 3D printing with this guide that covers material selection, design, post-processing, and quality inspections.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

Metal 3D Printing Capabilities

Our basic guidelines for metal 3D printing include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Metal 3D Printing Tolerances

For well-designed parts, tolerances of +0.003 in. (0.076mm) plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

Max Dimensions

Layer Thickness

Minimum Feature Size

Tolerances

*At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine

Metal 3D Printing Material Options

Below is our available metal alloys for 3D printing. Various heat treatments are available depending on material.

Various heat treatments are available depending on material.

Stainless Steel (17-4 PH)

Stainless Steel 17-4 PH is a precipitation hardened stainless steel that is known for its hardness and corrosion resistance. If needing a stainless steel option, select 17-4 PH for its significantly higher tensile strength and yield strength, but recognize that it has far less elongation at break than 316L. Final parts built 17-4 PH receive vacuum solution heat treatment as well as H900 aging.

Primary Benefits

- Heat treated for full hardness and strength

- Corrosion resistance

LEARN MORE>

Stainless Steel (316L)

Stainless steel 316L is a workhorse material used for manufacturing acid and corrosion resistant parts. Select 316L when stainless steel flexibility is needed; 316L is a more malleable material compared to 17-4 PH. Final parts built in 316L receive stress relief application.

Primary Benefits

- Acid and corrosion resistance

- High ductility

LEARN MORE>

Aluminum (AlSi10Mg)

Aluminum (AlSi10Mg) is comparable to a 3000 series alloy that is used in casting and die casting processes. It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- Thermal and electrical conductivity

LEARN MORE>

Inconel 718

Inconel is a high strength, corrosion resistant nickel chromium superalloy ideal for parts that will experience extreme temperatures and mechanical loading. Final parts built in Inconel 718 receive stress relief application. Solution and aging per AMS 5663 is also available to increase tensile strength and hardness.

Primary Benefits

- Oxidation and corrosion resistance

- High performance tensile, fatigue, creep, and rupture strength

LEARN MORE>

Cobalt Chrome (Co28Cr6Mo)

Cobalt Chrome (Co28Cr6Mo) is a superalloy is known for its high strength-to-weight ratio.

Primary Benefits

- High performance tensile and creep

- Corrosion resistance

LEARN MORE>

Titanium (Ti6Al4V)

Titanium (Ti6Al4V) is a workhorse alloy. Versus Ti grade 23 annealed, the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength, elongation, and hardness. Final parts built in Ti6Al4V receive vacuum stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- High temperature and corrosion resistance

LEARN MORE>

Compare Material Properties

20 μm = high resolution (HR)

30, 40, and 60 μm = normal resolution (NR)

- US

- Metric

| Materials | Resolution | Condition | Ultimate Tensile Strength (ksi) | Yield Stress (ksi) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 199 | 178 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 198 | 179 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 82 | 56 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 85 | 55 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 39 | 26 | 15 | 42 HRB |

| 30 μm | Stress Relieved | 50 | 33 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 43 | 27 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 182 | 112 | 17 | 39 HRC |

| 30 μm | As Built | 176 | 119 | 14 | 38 HRC | |

| Inconel 718 | 20 μm | Stress Relieved | 143 | 98 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 144 | 91 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 208 | 175 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 139 | 83 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 201 | 174 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 153 | 138 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 144 | 124 | 18 | 33 HRC |

| Materials | Resolution | Condition | Ultimate Tensile Strength (MPa) | Yield Stress (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 1,372 | 1,227 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 1,365 | 1,234 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 565 | 386 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 586 | 379 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 268 | 180 | 15 | 46 HRB |

| 30 μm | Stress Relieved | 345 | 228 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 296 | 186 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 1255 | 772 | 17 | 39 HRC |

| 30 μm | As Built | 1213 | 820 | 14 | 38 HRC | |

| Copper (CuNi2SiCr) | 20 μm | Precipitation Hardened | 496 | 434 | 23 | 87 HRB |

| Inconel 718 | 20 μm | Stress Relieved | 986 | 676 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 993 | 627 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 1434 | 1207 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 958 | 572 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 1386 | 1200 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 1055 | 951 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 993 | 855 | 18 | 33 HRC |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Surface Finish Options

Standard Finish

Expect roughness values of 200 to 400 µin Ra (0.005 to 0.010mm Ra), depending on material and resolution. Support structures are removed and layer lines are visible.

Custom Finish

We offer brushed surfaces in a range of grits and polished mirror finishes. Be sure to indicate if the custom surface finish is for functional or aesthetic purposes so we can best consult you on our custom options.

Post-Processing Capabilities for Metal 3D-Printed Parts

Improve strength, dimensional accuracy, and cosmetic appearance of final metal components with DMLS for production.

Surface Finishing

- 3- and 5-axis milling

- Turning

- Polish (Mirror or Brushed)

- Passivation

- Wire EDM

- Tapping and reaming

Heat Treatments

- Stress relief

- NADCAP heat treatment

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Mechanical Testing

- Tensile

- Rockwell Hardness

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

Why Use Metal 3D Printing?

See how metal additive manufacturing technology can be used to reduce components within an assembly, fabricate complex geometries, and ultimately save you time and costs.

Click to enlarge

How Does Metal 3D Printing Work?

The DMLS machine begins sintering each layer—first the support structures to the base plate, then the part itself—with a laser aimed onto a bed of metallic powder. After a cross-section layer of powder is micro-welded, the build platform shifts down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build finishes, an initial brushing is manually administered to parts to remove a majority of loose powder, followed by the appropriate heat-treat cycle while still fixtured in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any needed bead blasting and deburring. Final DMLS parts are near 100 percent dense.

Large Format Metal 3D Printing

We recently added the GE Additive X Line to our fleet of metal 3D printers to build large Inconel 718 and Aluminum (AlSi10Mg) parts. Have a project that might be a good fit? Contact us and we can discuss your requirements.

Have a project that might be a good fit? Contact us and we can discuss your requirements.

Learn More >

Metal 3D Printing for Production

Improve strength, dimensional accuracy, and cosmetic appearance for end-use metal components with post-processing options like CNC machining and heat treatments.

Learn More >

Resources

Design Tip

Post-Processing for Metal 3D Printing

Learn how to improve dimensional accuracy, surface roughness, and mechanical properties on metal parts with high-requirement applications.

Read Design Tip

White Paper

Combining Part Assemblies with Additive Manufacturing to Reduce Cost and Increase Performance

How to find the right opportunities to consolidate multi-part assemblies into single components with industrial 3D printing

Read White Paper

Blog

Inconel 718: A Workhorse Material for Additive Manufacturing

Inconel 718 is a go-to material for additive manufacturing of metal parts.

Read Blog

Blog

Large Format 3D Printing for Aluminum and Inconel Parts

When you’re printing really large parts in metal, it’s great to have a choice of materials. Aluminum and Inconel 718 both make a lot of sense, but which one is the best for your application?

Read Blog

Instant quotes on 3D-printed parts

Get A QuoteStereolithography (SLA) 3D Printing Service

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars & Trade Shows

Blog Videos FAQs Educators & Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability & Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

SLA 3D printing service for rapid prototyping. Get an instant online quote.

GET SLA PARTS

Jump to Section→ Capabilities

→ SLA Materials

→ Compare SLA Material Properties

→ Surface Finishes

→ Post-Processing

→ Our SLA 3D Printers

→ Why SLA 3D Printing?

Stereolithography (SLA) is an industrial 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries in as fast as 1 day. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA.

SLA 3D printing is primarily used for:

- parts requiring high accuracy and features as small as 0.002 in.

- good surface quality for cosmetic prototypes

- form and fit testing

If you have any issues getting your guide, click here to download.

3D Printing Surface Finish Guide

Get this quick reference guide to explore your surface finish options across our six 3D printing technologies.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

SLA Design Guidelines and Capabilities

Our basic guidelines for stereolithography include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

SLA Tolerances

For well-designed parts, tolerances in the X/Y dimension of ±0.002 in. (0.05mm) for first inch plus 0.1% of nominal length. (0.001mm/mm), and Z dimension tolerances of ±0.005 in. for first inch plus 0.1% of nominal length, can typically be achieved. Note that tolerances may change depending on part geometry.

Max Part Size

Layer Thickness

Minimum Feature Size

Minimum Wall Thickness

Minimum Hole Size

Tolerances

*Available for the following materials: ABS-Like White and Gray, ABS-Like Translucent/Clear, and PC-Like Translucent/Clear

SLA Material Options

ABS-Like White (Accura Xtreme White 200)

ABS-Like White (Accura Xtreme White 200) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between molded polypropylene and molded ABS, which makes it a good choice for functional prototypes. Parts as large as 29 in. x 25 in. x 21 in. can be built with ABS-Like White so consider it a primary option if you require an extensive part size build envelope.

In terms of flexibility and strength, this material falls between molded polypropylene and molded ABS, which makes it a good choice for functional prototypes. Parts as large as 29 in. x 25 in. x 21 in. can be built with ABS-Like White so consider it a primary option if you require an extensive part size build envelope.

Primary Benefits

- Durable, general purpose resin

- Accommodates extra-large parts

ABS-Like Gray (Accura Xtreme Gray)

ABS-Like Gray (Accura Xtreme Gray) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between molded polypropylene and molded ABS, which makes it a good choice for functional prototypes. ABS-Like Gray offers the highest HDT of the ABS-like SLA resins.

Primary Benefits

- Durable, general purpose resin

- Highest HDT of the ABS-like SLA resins

ABS-Like Black (Accura 7820)

ABS-Like Black (Accura 7820) is a widely used general purpose material. Its deep black color and glossy up-facing surfaces in a top profile offer the appearance of a molded part, while layer lines may be visible in a side profile. RenShape 7820 also has low moisture absorption (0.25% per ASTM D570) so that parts are more dimensionally stable. Compared to other SLA materials, it has midrange values for all mechanical properties.

Its deep black color and glossy up-facing surfaces in a top profile offer the appearance of a molded part, while layer lines may be visible in a side profile. RenShape 7820 also has low moisture absorption (0.25% per ASTM D570) so that parts are more dimensionally stable. Compared to other SLA materials, it has midrange values for all mechanical properties.

Primary Benefits

- Low moisture absorption

- Glossy cosmetic appearance

ABS-Like Translucent/Clear (WaterShed XC 11122)

ABS-Like Translucent/Clear (WaterShed XC 11122) offers a unique combination of low moisture absorption (0.35% 0.25% per ASTM D570) and near-colorless transparency. Secondary operations are required to achieve functional part clarity, and the part will also retain a very light blue hue afterward. While good for general-purpose applications, WaterShed is the best choice for flow-visualization models, light pipes, and lenses.

Primary Benefits

- Lowest moisture absorption of SLA resins

- Functional transparency

MicroFine™ (Gray and Green)

MicroFine™ is a custom formulated material available in gray and green that is exclusive to Protolabs. This ABS-like thermoset is printed in Protolabs’ customized machinery to achieve high resolution features as small as 0.002 in. MicroFine is ideal for small parts, generally less than 1 in. by 1 in. by 1 in. In terms of mechanical properties, MicroFine falls in the mid-range of SLA materials for tensile strength and modulus and on the low end for impact strength and elongation.

This ABS-like thermoset is printed in Protolabs’ customized machinery to achieve high resolution features as small as 0.002 in. MicroFine is ideal for small parts, generally less than 1 in. by 1 in. by 1 in. In terms of mechanical properties, MicroFine falls in the mid-range of SLA materials for tensile strength and modulus and on the low end for impact strength and elongation.

Primary Benefits

- Produces highest resolution parts

- Ideal for extra-small parts

PP-Like Translucent White (Somos 9120)

PP-Like Translucent White (Somos 9120) is the most flexible SLA option outside of Carbon RPU 70 and FPU 50. In direct comparison to the average values of an injection-molded polypropylene, 9120 has similar tensile strength, tensile modulus, flexural modulus, and impact strength. The only departure from molded PP is its elongation value, which is only 25% of the molded thermoplastic.

Primary Benefits

- Semi-flexible

- Translucency

PC-Like Advanced High Temp (Accura 5530)

PC-Like Advanced High Temp (Accura 5530) creates strong, stiff parts with high temperature resistance. A thermal post-cure option can increase HDT as high as 482°F at 0.46 MPa loading. Accura 5530 has the highest E-modulus of all the unfilled SLA materials, and it is known for being resistant to automotive fluids. However, the thermal curing process does make Accura 5530 less durable, resulting in a 50% reduction to elongation.

A thermal post-cure option can increase HDT as high as 482°F at 0.46 MPa loading. Accura 5530 has the highest E-modulus of all the unfilled SLA materials, and it is known for being resistant to automotive fluids. However, the thermal curing process does make Accura 5530 less durable, resulting in a 50% reduction to elongation.

Primary Benefits

- High elastic modulus

- Higher resistance to heated fluids

PC-Like Translucent/Clear (Accura 60)

PC-Like Translucent/Clear (Accura 60) is an alternative to the general purpose ABS-like materials and WaterShed XC 11122 when stiffness is desired. Like WaterShed, this material can be custom finished to achieve functional transparency with secondary processing. Accura 60 has the highest tensile strength of and elastic modulus compared of all SLA materials outside of the Advanced High Temp options that are most often thermal cured.

Primary Benefits

- High stiffness

- Functional transparency

Ceramic-Like Advanced HighTemp (PerFORM)

Ceramic-Like Advanced HighTemp (PerFORM) exhibits the highest tensile strength and E-modulus making it the stiffest performance material of the SLA materials. When the thermal cure option is applied to parts made from PerFORM, it exhibits the highest HDT (as high as 514°F at 0.46 MPa loading) of the SLA materials.

When the thermal cure option is applied to parts made from PerFORM, it exhibits the highest HDT (as high as 514°F at 0.46 MPa loading) of the SLA materials.

Primary Benefits

- Stiffest SLA resin

- Highest HDT of SLA resins

Compare SLA Material Properties

- US

- Metric

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| ABS-Like White (Accura Xtreme White 200) | White | 7.9 ksi | 479 ksi | 9% |

| ABS-Like Gray (Accura Xtreme Gray) | Gray | 5.8 ksi | 290 ksi | 9% |

| ABS-Like Black (Accura 7820) | Black | 7.0 ksi | 435 ksi | 5% |

| ABS-Like Translucent/Clear (WaterShed XC 11122) | Translucent/Clear | 7. 9 ksi 9 ksi | 421 ksi | 6% |

| MicroFine™ (Gray and Green) | Gray or Green | 8.7 ksi | 377 ksi | 8% |

| PP-Like Translucent White (Somos 9120) | Translucent/White | 5.0 ksi | 232 ksi | 25% |

| PC-Like Translucent/Clear (Accura 60) | Translucent/Clear | 10.8 ksi | 508 ksi | 7% |

| PC-Like Advanced High Temp* (Accura 5530) | Translucent/Amber | 6.5 ksi | 566 ksi | 1.5% |

| Ceramic-Like Advanced HighTemp* (PerFORM) | White | 10.9 ksi | 1523 ksi | 1% |

*Properties listed are based on thermal cure

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| ABS-Like White (Accura Xtreme White 200) | White | 54.47 Mpa | 3300 Mpa | 9% |

| ABS-Like Gray (Accura Xtreme Gray) | Gray | 39. 98 Mpa 98 Mpa | 2000 Mpa | 9% |

| ABS-Like Black (RenShape SL7820) | Black | 48.26 Mpa | 3000 Mpa | 5% |

| ABS-Like Translucent/Clear (WaterShed XC 11122) | Translucent/Clear | 54.47 Mpa | 2600 Mpa | 6% |

| MicroFine™ (Gray and Green) | Gray or Green | 59.98 Mpa | 2600 Mpa | 8% |

| PP-Like Translucent White (Somos 9120) | Translucent/White | 34.47 Mpa | 1600 Mpa | 25% |

| PC-Like Translucent/Clear (Accura 60) | Translucent/Clear | 74.46 Mpa | 3503 Mpa | 7% |

| PC-Like Advanced High Temp* (Accura 5530) | Translucent/Amber | 44.81 Mpa | 3902 Mpa | 1.5% |

| Ceramic-Like Advanced HighTemp* (PerFORM) | White | 75.15 Mpa | 10,500 Mpa | 1% |

*Properties listed are based on thermal cure

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Surface Finish Options for SLA Parts

Material: ABS-like Translucent/Clear

Finish: Unfinished

Material: MicroFine Gray™

Finish: Unfinished

Material: ABS-like Translucent/Clear

Finish: Standard

Material: MicroFine Gray™

Finish: Standard

Material: ABS-like Translucent/Clear

Finish: Natural

Material: MicroFine Gray™

Finish: Natural

Material: ABS-like Translucent/Clear

Finish: Custom

Material: MicroFine Gray™

Finish: Custom

Additional Finishing Options

Custom finishing is a mix of science, technology, and fine art that can transform a part to your exact specifications. Finishes include:

- Soft-touch paint

- Clear part finishing

- Paint finishes

- Masking

- Color matching

- Decals/graphic

- Texture

Metal Plating

Our metal-plating process for SLA coats a ceramic-filled PC-like material (Somos PerFORM) with a nickel that gives parts the look, feel, and strength of metal, but without the weight. The combination of the material’s strength, rigidity, and temperature resistance with nickel plating, takes strength, stiffness, and impact and temperature resistance to a degree previously unattainable in SLA parts.

The combination of the material’s strength, rigidity, and temperature resistance with nickel plating, takes strength, stiffness, and impact and temperature resistance to a degree previously unattainable in SLA parts.

Microfluidics

Our microfluidic fabrication process is a modified form of high-resolution SLA that uses a clear ABS-like material (WaterShed XC 11122). Parts are resistance to water and humidity, and work well for lens and flow-visualization models.

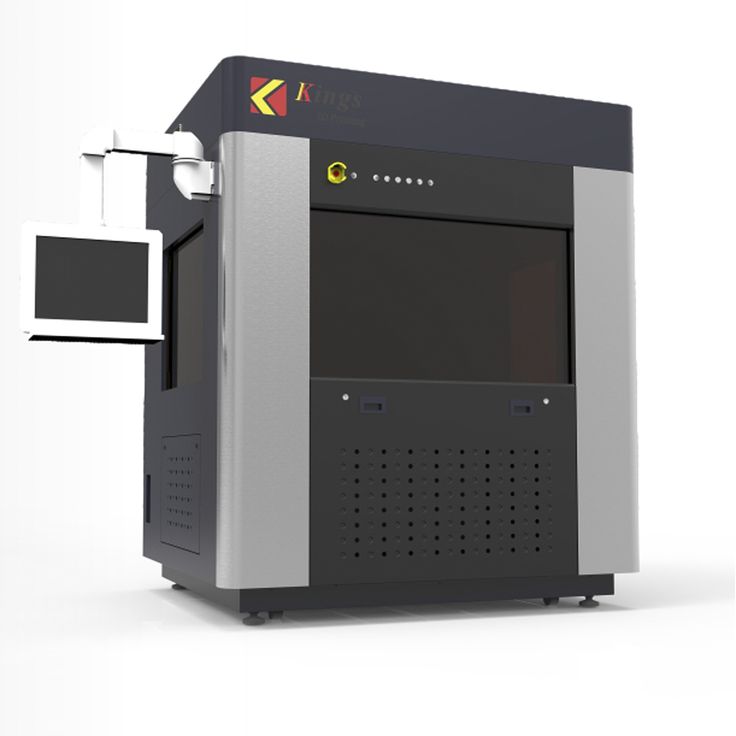

Our SLA 3D Printers

Our stereolithography machines consists of Vipers, ProJets, and iPros. In high-resolution mode, Vipers and ProJets can make parts with extremely tiny features and crisp details, while in normal-resolution mode, they can build cost-effective parts very quickly.

iPros have extremely large build volumes at 29 in. by 25 in. by 21 in. (736mm by 635mm by 533mm), yet are still able to image highly detailed parts easily.

Why Use SLA?

Stereolithography (SLA) is an additive manufacturing process that can 3D print parts with small features, tight tolerance requirements, and smooth surface finishes.

How Does SLA 3D Printing Work?

The SLA machine begins drawing the layers of the support structures, followed by the part itself, with an ultraviolet laser aimed onto the surface of a liquid thermoset resin. After a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is repeated layer by layer until the build is complete.

Newly built parts are taken out of machine and into a lab where solvents are used to remove any additional resins. When the parts are completely clean, the support structures are manually removed. From there, parts undergo a UV-curing cycle to fully solidify the outer surface of the part. The final step in the SLA process is the application of any custom or customer-specified finishing. Parts built in SLA should be used with minimal UV and humidity exposure so they don’t degrade.

SLA Resources

Design Tip

An Introduction to Stereolithography (SLA) 3D Printing

Stereolithography, a staple of 3D printing, can deliver complex prototypes quickly and accurately.

Read Design Tip

Design Tip

Selecting a Material for Stereolithography (SLA) 3D Printing

Compare materials for stereolithography with one another and with injection-molded plastics.

Read Design Tip

Blog

SLA vs. FDM: Comparing Common 3D Printing Technologies

See how these two 3D printing technologies stack up for prototype parts. Understanding the advantages of each will help accelerate design.

Read Blog

Guide

What is 3D Printing?

Gain an understanding of additive manufacturing and how it can be leveraged to improve product development through rapid prototyping and production.

Read Guide

Get an instant online quote for 3D printing.

Get a Quote

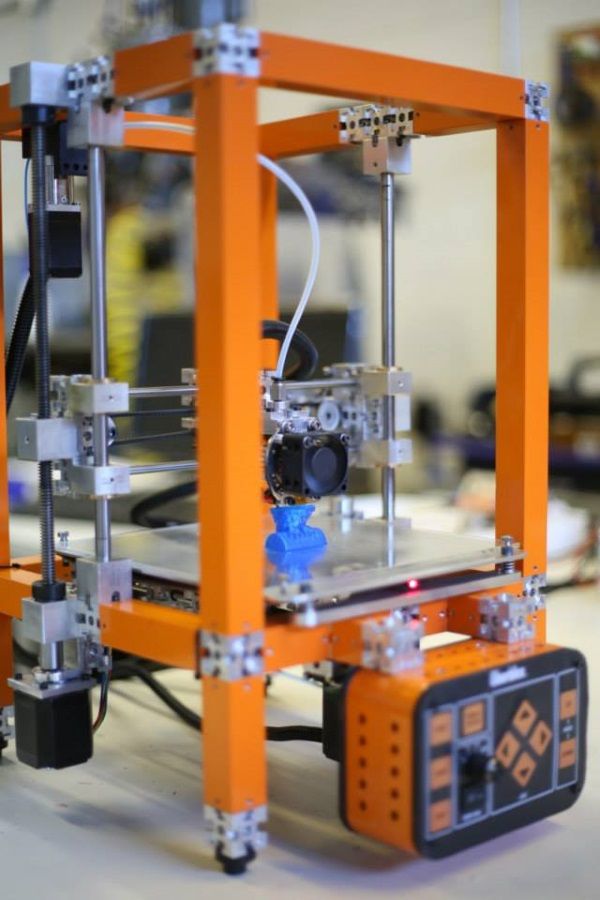

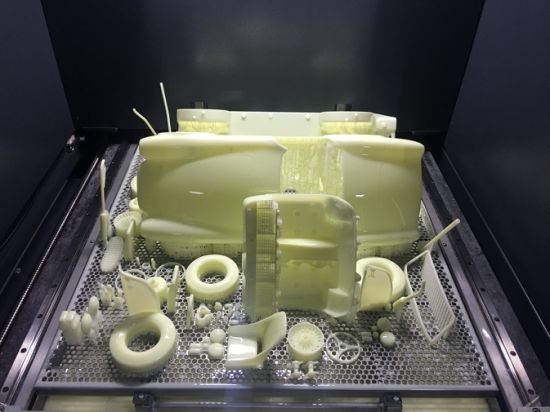

3D printed functional test prototypes

3D printed functional test prototypes3D hardware supplier since 2010

+7 495 646-15-338 800 333-12-82

3D scanners3D printersSoftwareServices

About the CompanyClients and ProjectsDemo HallGovernment ProcurementDeliveryService3D Encyclopedia BlogContacts

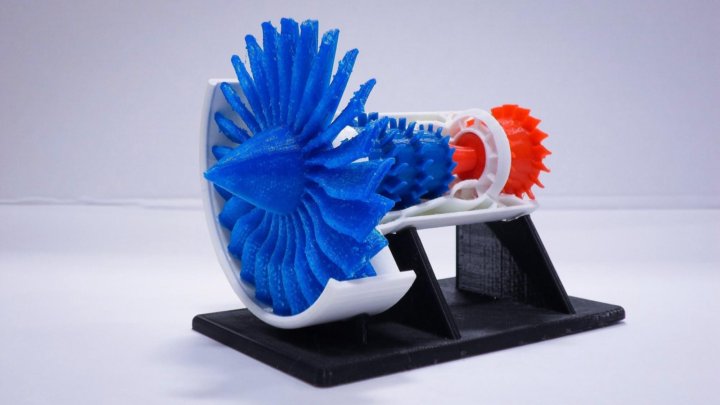

Testing product prototypes, individual components and parts is the most important part of any production chain. With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- to check strength, wear resistance;

- blow through objects in a wind tunnel.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- to check strength, wear resistance;

- blow through objects in a wind tunnel.

Benefits of functional prototyping with 3D printing

- Speed.

You don't have to wait weeks for contractors to build a prototype for you.

You don't have to wait weeks for contractors to build a prototype for you. - High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems.

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

The Ford Nascar racing team is actively using 3D printers to redesign and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines. This allows us to change the characteristics of cars incredibly quickly and prepare for the race.

Victor Martinez, Chief Engineer, Ford Team

Benefits of Functional Prototyping with 3D Printing

- Speed. You don't have to wait weeks for contractors to build a prototype for you.

- High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems.

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar 9 engines0043

The Ford Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel systems.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines.

This allows us to change the characteristics of cars incredibly quickly and prepare for the race.

Victor Martinez, Ford 9 Team Chief Engineer0066

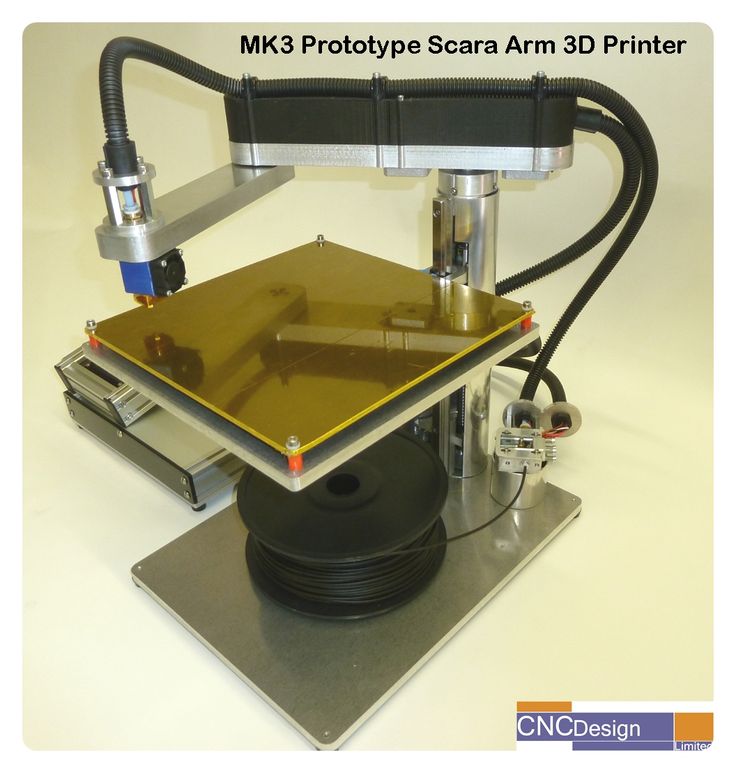

Example: 3D repair of a prototype of the step motor for conducting tests

Example: 3D-tobate a prototype of the step motor for conducting tests

3D-printers for printing functional models

Stratasys F370

9 9000 9000 -Z AnyForm 650 PRO

3DLAM Mid

0106

3DLAM MID

UnionTech RSPRO 800

- +7 495 646-15-338 800 333-12-82

2012-2022, GLOBATTEC (GLOBATEC ). All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

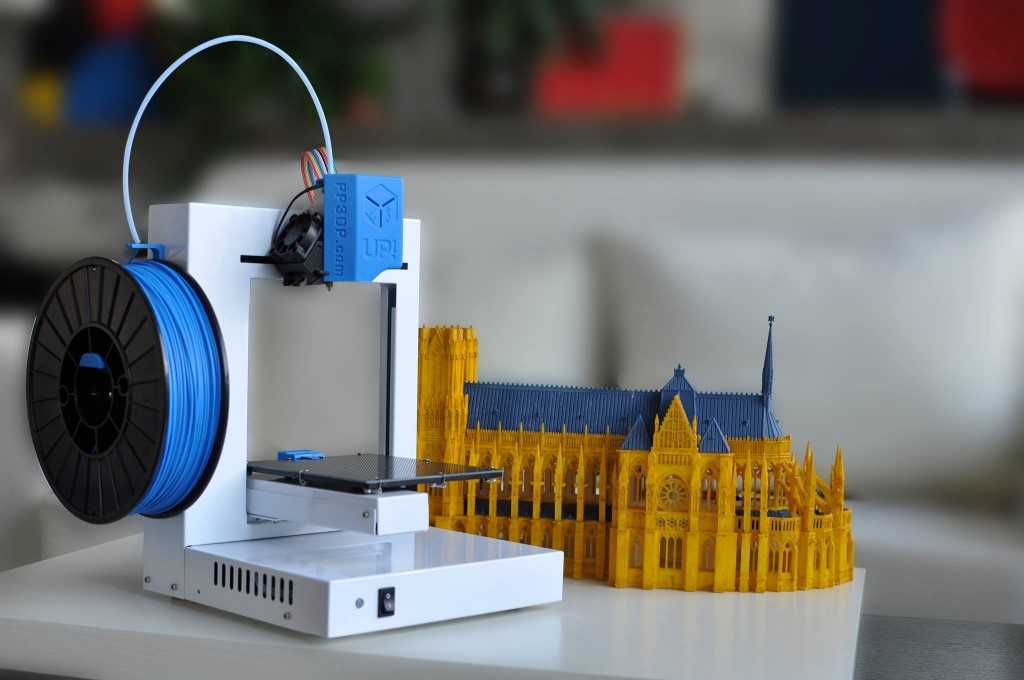

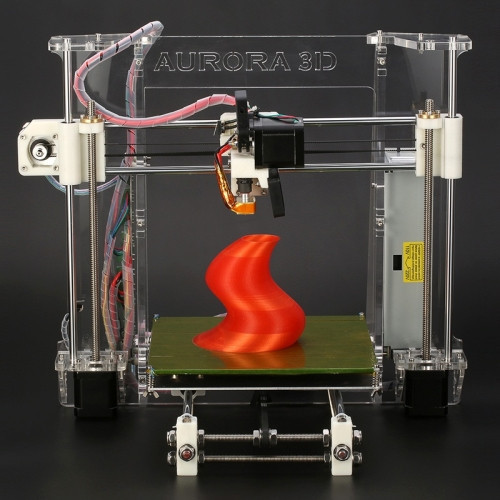

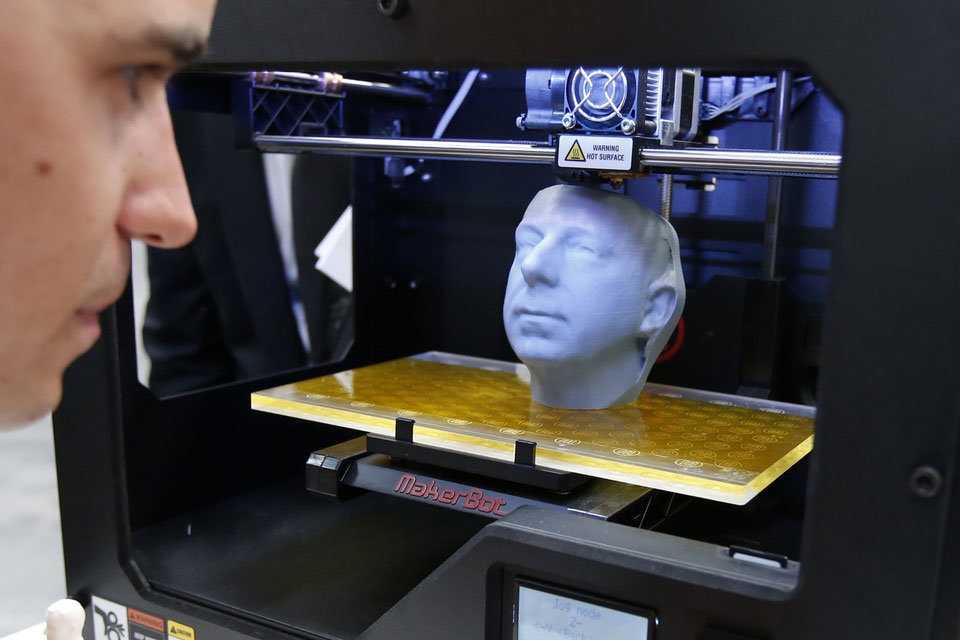

3D Printing Applications: Rapid Prototyping

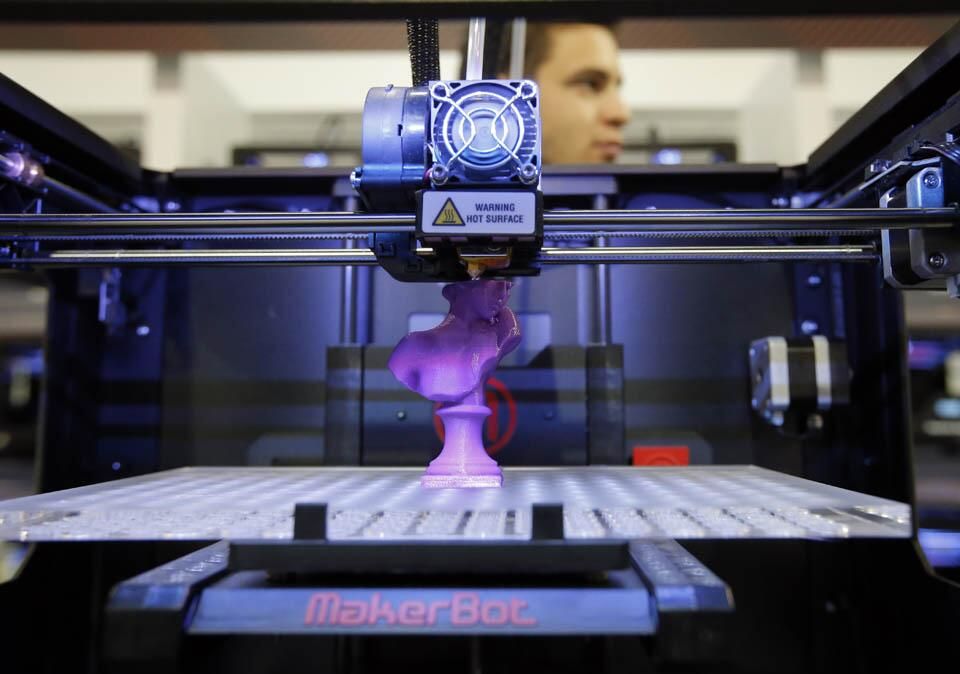

Rapid prototyping enables companies to turn ideas into working proofs of concept, turn concepts into high-quality prototypes that look and work like finished products, and test products for mass production.

No more waiting weeks for prototypes to arrive. With your own 3D printing, you can create rapid prototypes in one day, test, redesign, and print again.

STAGE 1

Design

Design the object in CAD during business hours.

STAGE 2

3D Print

Create 3D prototypes overnight.

STEP 3

Test

Clean, measure, test, build and collect feedback on your design in the morning.

STEP 4

Repeat

Adjust design and repeat process.

Although the cost of setting up a printer may seem high, it pays for itself in just a couple of weeks or months. Believe me, you will spend much more on outsourcing or an alternative production method.

| Speaker cabinet prototyping | Form 3 and Draft Resin | Third party |

|---|---|---|

| Time | 9 hours | 7 days |

| Cost | $80 | $450 |

Calculate time and cost

Prototyping speaker cabinet

16.5 x 13.5 x 13.5 cm

6.5 x 5.3 x 5.3 inches

Formlabs' ecosystem of affordable 3D printers and high performance materials can be used to create highly detailed prototypes. With Draft Resin you can print models up to four times faster than standard Formlabs resins, making Draft Resin ideal for initial prototyping and print iterations to bring products to market faster.

High Efficiency Stereolithography 3D Printer

Form 3 creates molds with very high surface quality and detail, allowing you to meet all design requirements in their production, as well as virtually eliminating the need for post-processing. Build industrial-quality prototypes at an affordable price so your team can print new models in just a few hours.

Use the Form 3 at various stages of production for faster return on investment. The Formlabs ecosystem seamlessly integrates into any product development process, from 3D printing prototype models to manufacturing molds for small-scale production.