Fab lab 3d printer

3D Printing – UVM FabLab

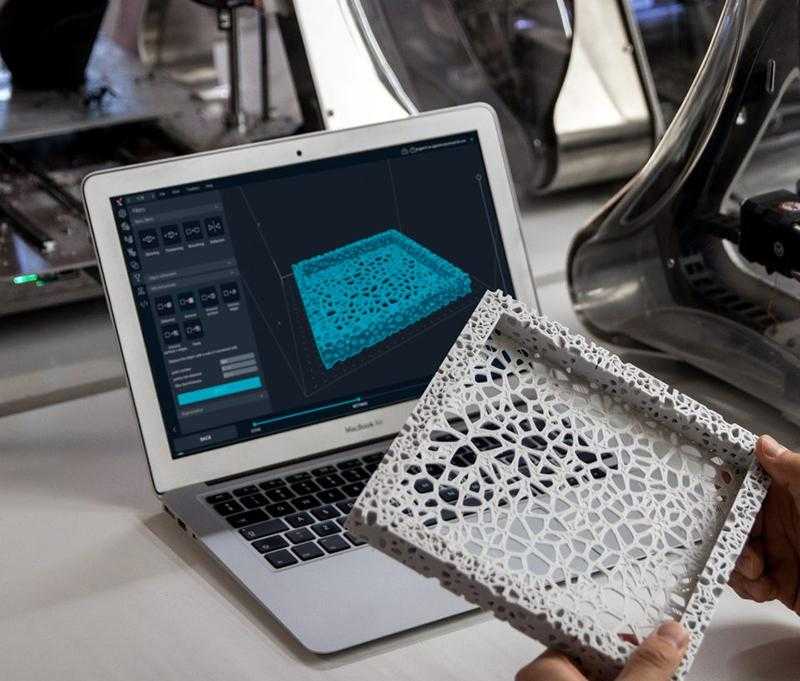

The UVM FabLab offers the use of its 3D printers to help students rapidly prototype small parts that would otherwise be difficult to manufacture or acquire. Keep in mind that FabLab resources can only be used for school-related projects and that, like any manufacturing process, 3D printing has physical and cost limitations that differ by machine.

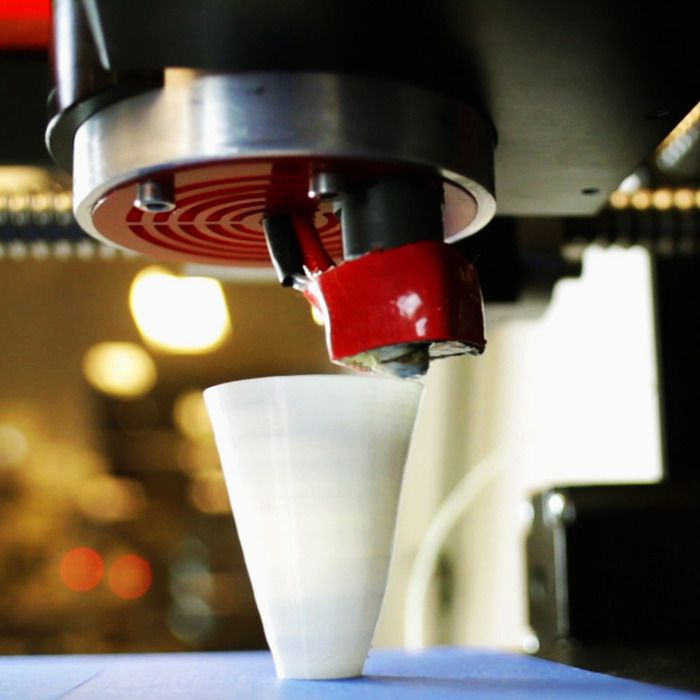

Extrusion-based 3D Printing:

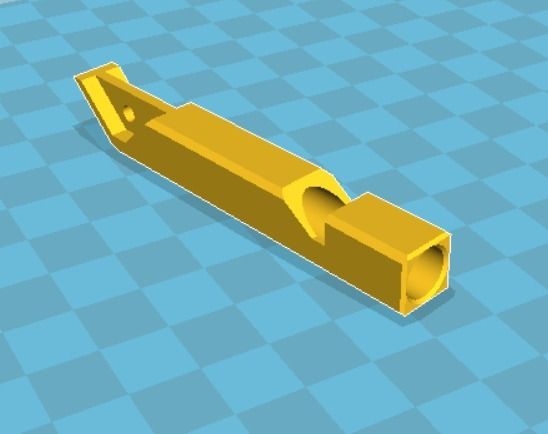

3D printing is a type of ‘additive’ manufacturing, which is the opposite of the traditional way of fabricating objects where material is removed to produce the desired product; like creating a clay sculpture. These machines heat thermoplastic filament (i.e. PLA and ABS) and extrude layer by layer to form the desired product. A 3D file is formatted within printing software to create a toolpath for the extruder that will create the shell of the product as well as an infill pattern within the shell to improve strength.

Some extrusion-based 3D printers can print model filament with a chemically soluble or breakaway support material simultaneously, which improves the resolution of the finished product and allows the fabrication of complex geometries and hollow shapes.

Stereolithography 3D Printing:

An alternative to extrusion-based printing, stereolithography is a type of ‘additive’ manufacturing that involves photopolymerization of resin in a bath via a laser that cures the resin into hardened plastic layer by layer. This process forms solid products with isotropic properties. Our photopolymer resin materials include grey, clear, and white colors, as well as wax resin for casting parts.

Guidelines:

The following guidelines will help you determine whether your design is suitable to print in the FabLab:

- Your part must not be too small:

- If features are smaller than the printer’s resolution, they will not print reliably.

- Your part must not be too big:

- It should not use too much material or print time.

- It must fit within the dimensions of the printer.

- Your part must be structurally suitable for printing:

- The part must not be too delicate or have large unsupported sections.

If your part is rejected for any of the reasons above, you are always welcome to modify the part and resubmit it for review. Our Fabbers are experienced and able to provide feedback on your designs throughout the design process.

Please keep in mind that 3D printed parts are not free! The FabLab sponsors each project for coursework, senior design, and some clubs and we only use approved materials for the safety of our Fabbers. For Engineering senior design budgets, prints are billed on a per-ticket basis, with the exception of the FormLab resin printer, in which case the SEED team should plan to purchase their own cartridge and tank. Beyond a single print, undergraduate students, graduate students, and faculty must pay the College of Engineering and Mathematical Sciences for the material used via a UVM chartstring.

Professional manufacturing options are available on and off campus. If you have a print job that is too large or time-consuming for the FabLab’s capabilities – for example, if you need a large number of parts made – this may be a better option. These facilities include the UVM Howe Library, Instrumentation and Modeling Facility (IMF) Labs, Shapeways, and the Generator Makerspace in downtown Burlington. If there is a well-founded reason this part must be 3D printed in the FabLab, such as extreme time constraints or lack of other options, please contact us at [email protected].

If there is a well-founded reason this part must be 3D printed in the FabLab, such as extreme time constraints or lack of other options, please contact us at [email protected].

Extrusion-based 3D Printers:

Stratasys Dimension Elite (1) Stratasys UPrint SE Plus (1) Makerbot Replicator+ (2) Ultimaker S5 (2) Makerbot Sketch (2)Stereolithographic 3D Printers:

FormLabs Form 2 (1)Build volume dimensions:

- Stratasys Dimension Elite: Base 8″x8″; Height 12″

- Stratasys Uprint SE: Base 8″x8″; Height 6″

- Makerbot Replicator+: Base 11.6″x7.6″; Height 6.5″

- Ultimaker S5: Base 13″x9.5″; Height 11.

8″

8″ - FormLabs Form 2: Base 5.7″x5.7″; Height 6.8″

- Makerbot Sketches Base 5.9″x 5.9″; Height 5.9″

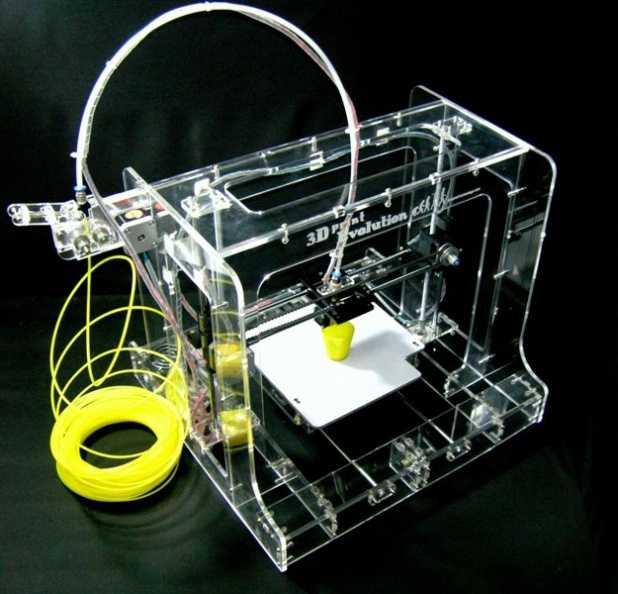

FDM 3D Printing - CAP Fab Lab

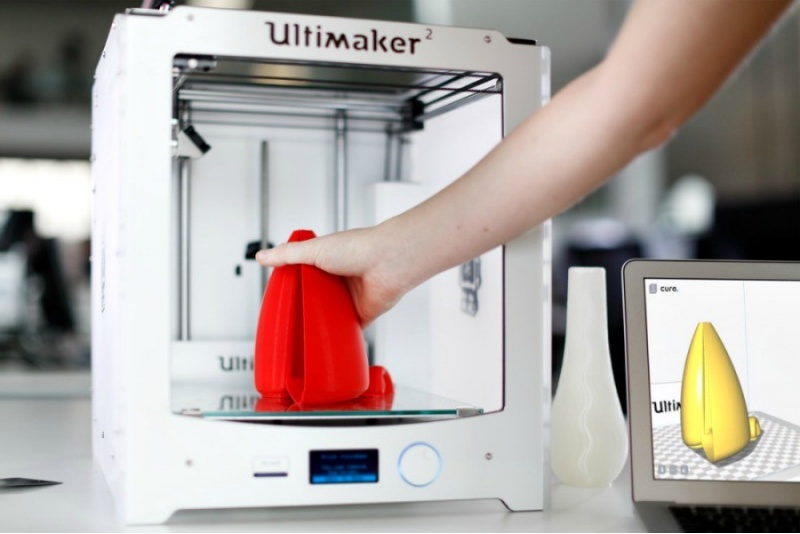

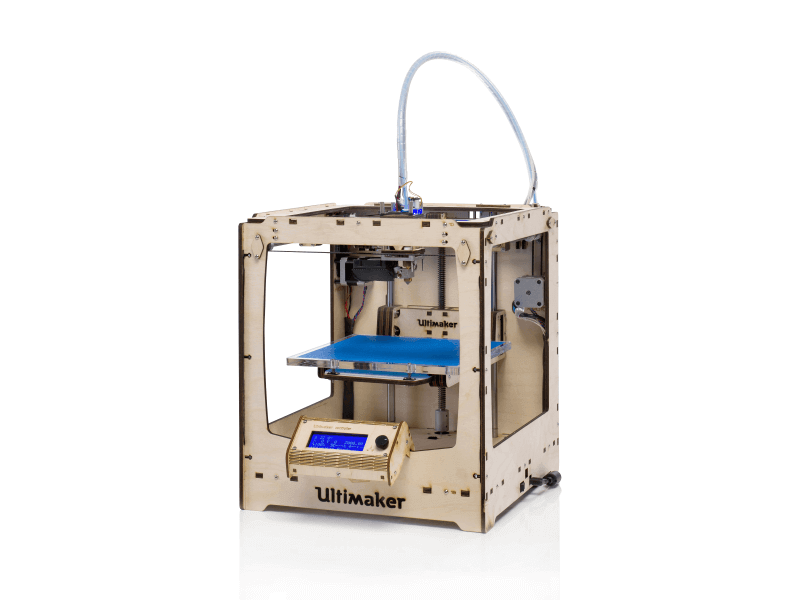

Fused Deposition Modeling (FDM) 3D printers operate by printing melted plastic line by line, layer by layer. These printers come in all shapes and sizes (and prices) and it is becoming more and more common to see personal units on student studio desks. CAP has several machines of this type, including three Ultimaker brand and two Creality brand 3D printers. Graduate studios have Creality machines. All of CAP’s printers use PLA plastic filament, a plant-based plastic material. For more information about this technology, see the FDM article on Additively.com, and see the relevant section below for printing help. Located in AB 005 and in select studios.

3D Printer Specifications

| Brand | Model | Qty | Build Volume (LxWxH)* | Filament Dia. |

|---|---|---|---|---|

| Ultimaker | 2+ | 2 | 8.75“ x 8.75” x 8“ (223 x 223 x 205 mm) | 2.85mm |

| Ultimaker | 2 Extended+ | 1 | 8.75” x 8.75“ x 12” (223 x 223 x 305 mm) | 2.85mm |

| Ultimaker | S5 | 1 | 13“ x 9.4” x 11.8“ (330 x 240 x 300 mm) | 2.85mm |

| Creality | CR-10S | 2 | 11.8” x 11“ x 15.75” (300 x 280 x 400 mm) | 1.75mm |

| Prusa | i3 MK3S | 3 | 9.84” x 8.3“ x 8.3” (250 x 210 x 210 mm) | 1.75mm |

Print Margins: Prints should be sized to allow for a minimum 0.25″ (7mm) margin between the edges of the print and the edges of the build plate to allow for a “brim”, which is added to improve adhesion of the print to the build plate. This is particularly important for prints with bases that cover most of the build plate.

Scaling Geometry for Printing

Unsure if your model is scaled to appropriately for one of our machines? Download our Rhino 3D Print Template, which includes the build volumes for each of our printers modeled as a wireframe box. You can paste your geometry into one of these templates, which will convert your geometry to millimeters and allow you to fit it to one or more of our printers.

You can paste your geometry into one of these templates, which will convert your geometry to millimeters and allow you to fit it to one or more of our printers.

Available Filament

| Brand | Diameter | Type | Stocked Colors | Available Colors (may or may not be in stock) | Notes | Cost/g |

|---|---|---|---|---|---|---|

| eSun | 1.75mm | PLA | Cool White, Gray | Black (full list) | $0.03 | |

| 2.85mm | PLA | Cool White, Gray | Black (full list) | $0.03 | ||

| Makerbot | 1.75mm | PLA | * | Black, Blue, Green, Orange, Yellow | $0.05 | |

| * | Glow in the Dark, Neon Green, Translucent Orange, Translucent Purple | $0.07 | ||||

| Tough PLA | * | Slate Gray | $0. 07 07 | |||

| Taulman | 2.85mm | Bridge Nylon | Natural (translucent white) | Flexible material. Avoid geometry requiring supports. | $0.04 | |

| Ultimaker | 2.85mm | PLA | Silver | $0.05 | ||

| Tough PLA | Black | For use with S5 only. | $0.07 | |||

| PVA | N/A | Soluble support material for S5 dual extrusion (request in notes) | $0.13 |

Note: Since we have transitioned away from Makerbot brand 3D printers in our lab, we will no longer be restocking any variety of Makerbot brand filament, which is more expensive than other brands of equal quality such as eSun.

Estimating Print Cost

Print cost for FDM prints depends heavily on the types of geometric features in a model and the print settings for the print job, which makes it impossible to estimate print cost based on model volume alone. If you need an estimate before we start your print, you can indicate this on the form below when submitting your request. That being said, FDM 3D printing is the cheapest form of 3D printing in our lab, and even large prints can be printed economically.

If you need an estimate before we start your print, you can indicate this on the form below when submitting your request. That being said, FDM 3D printing is the cheapest form of 3D printing in our lab, and even large prints can be printed economically.

We charge only for filament consumed for a print. However, if you are comfortable with 3D printing and want to generate your own cost estimate. You can use programs such as Cura, which is what the lab uses to estimate print costs. With this program, we slice your model with typical print settings, generate a estimated weight of your print, and then multiply the weight of the estimated filament by the “per gram” pricing (listed above).

Note: A tutorial on Cura can get you started here from Ultimaker. After setting up your model in Cura, the slicing function will provide a few pieces of information, such as print time, where supports are placed, and given weight for the finished print.

Printing with your Own Filament

If you want to purchase your own spools of filament (PLA only), we can use it to print your models on our machines. Verify the filament diameter corresponds to the printer you want to use (see specifications table above). Please make sure your spool is clearly labeled with your name and bring it to the 3D Printer Lab during Consultation Hours. Select “Own Filament” under Requested Color on the form below.

Printing Form

If you have 3D printed on one of our FDM machines in the past, you can use the following form to submit a new print request.

If you have not 3D printed before or if you have not 3D printed with this type of machine before, we highly recommend that you set up a Consultation Session and work with a staff member to ensure your geometry is ready for printing. There are various considerations that might affect the success of your print, including those outlined on the 3D Printing Guidelines page.

Crunch time restriction: The maximum print time allowed per print will be 24 hours. Students may only occupy one machine at a time unless multiple machines are available (no queue) and the total print time on all occupied machines will be under 24 hours. Otherwise multiple requests from the same student will be processed sequentially.

Click here to create a new 3D Print Request

Note that beginning Spring 2022 all 3D Print Requests will be handled through the CAP Digital Fabrication Service Request form within the BSU Helpdesk system. Click the button above to open the form.

Equipment. Digital laboratory FABLAB

- Picaso 3D Designer

- MakerBot Replicator 2

- Dimension Elite

- Blueprinter

- Formlabs Form 2

Picaso 3D Designer

Picaso 3D Designer is a 3D printer from the Russian company PICASO , which uses a technology that allows you to print with a record high accuracy of 50 microns ! The heated chamber uses industrial printer technology and is ideal for printing large objects. Picaso 3D Designer is designed in such a way that all mechanics are hidden behind an ergonomic body. The printer has rather compact dimensions of 365×386×452 mm. The chassis of the printer is made of metal. Print area dimensions are 200 x 200 x 210 mm (L x W x H) . The automatic calibration mechanism is very useful, eliminating the problem of layer deformation when making complex models. The camera itself has the ability to set the temperature. This makes it possible to manufacture products that do not crack in layers as a result of thermal expansion.

Picaso 3D Designer is designed in such a way that all mechanics are hidden behind an ergonomic body. The printer has rather compact dimensions of 365×386×452 mm. The chassis of the printer is made of metal. Print area dimensions are 200 x 200 x 210 mm (L x W x H) . The automatic calibration mechanism is very useful, eliminating the problem of layer deformation when making complex models. The camera itself has the ability to set the temperature. This makes it possible to manufacture products that do not crack in layers as a result of thermal expansion.

| Print Technology | FDM |

| Print area | 200 x 200 x 210 mm |

| Print speed | up to 30 cm3/h |

| Minimum layer thickness | 50 micron [0.05 mm] |

| Positioning accuracy | XY: 11 microns; Z: 1. 25 micron 25 micron |

| Plastic thread diameter | 1.75±0.1 mm |

| Nozzle diameter | 0.3 mm |

| Media | ABS, PLA, HIPS, ASA, ABS/PC, NYLON, PET |

| Heated platform | Yes |

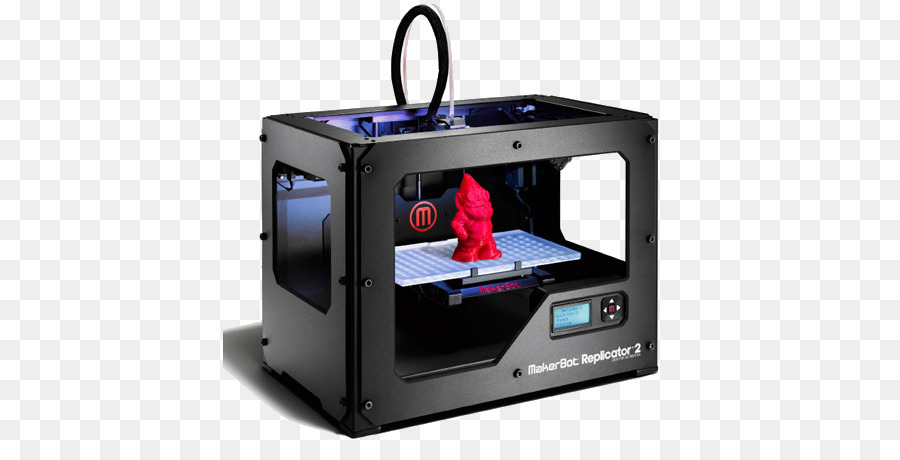

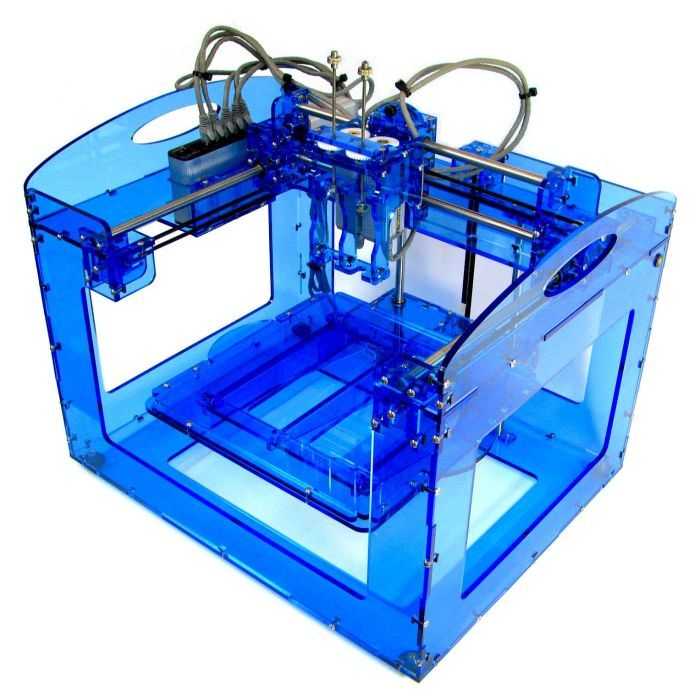

MakerBot Replicator 2

The MakerBot Replicator 2 3D Printer delivers superior product quality. For MakerBot Replicator 2 the following modes are defined: 340 micron - fast , 270 micron - normal , 100 micron - high . In the latter case, the thickness of the plastic applied to the product is comparable to the thickness of a standard sheet of paper. Environmentally friendly PLA plastic perfectly fits on a perfectly smooth surface. The chamber size is 410 cubic inches , which allows you to work with objects up to 28. 44 x 15.49 x 15.24 cm . Thanks to this improvement, the 3D printer is able to create quite large items , as well as many small items in one pass . The printer is controlled by the proprietary MakerWare software. Thanks to a simple and understandable shell of the program, everyone can work with the device - you do not need additional training. The developers managed to reduce the printing time by software optimization of the process. Object details are considered in the most common formats - .stl and .obj.

44 x 15.49 x 15.24 cm . Thanks to this improvement, the 3D printer is able to create quite large items , as well as many small items in one pass . The printer is controlled by the proprietary MakerWare software. Thanks to a simple and understandable shell of the program, everyone can work with the device - you do not need additional training. The developers managed to reduce the printing time by software optimization of the process. Object details are considered in the most common formats - .stl and .obj.

| Print Technology | FDM |

| Printable area | 285 x 153 x 155 mm |

| Print speed | up to 15 cm3/h |

| Minimum layer thickness | 100 micron [0.1 mm] |

| Positioning accuracy | XY: 11 microns; Z: 2. 5 micron 5 micron |

| Plastic thread diameter | 1.75±0.1 mm |

| Nozzle diameter | 0.4 mm |

| Media | PLA |

| Heated platform | No |

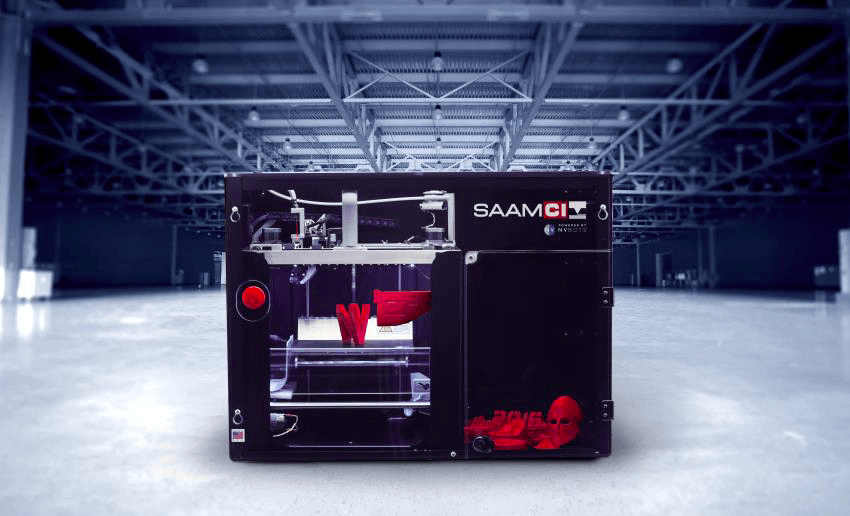

Dimension Elite

3D printer Dimension Elite belongs to the class of professional industrial 3D printers. The printer is capable of printing with two materials at the same time, and the closed chamber allows you to maintain the desired temperature for the entire printing period. Print chamber size 203x203x305mm. Installing and connecting the printer is quick and intuitive and easy to use. It is enough to press only one “print” button - and your virtual prototype will become a functional product in a matter of hours. With software Catalyst® EX , the build chamber automatically orients the STL file, splits it into layers, calculates the necessary support structure, specially generates the print head movement file in accordance with the model geometry, and sends it to the printer. For maximum efficiency, the printer's build chamber can accommodate multiple models at the same time. The printer works with the unique material ABSplus ™ and allows you to grow durable parts. Specially developed new ABSplus™ material is stronger than traditional ABS plastic. The work of parts as snaps, reaming holes, tightening with screws, gluing, sanding pliability are just some of the many advantages of this technology. Developers using Dimension Elite can build robust functional prototypes by finer detailing in the shortest possible time.

For maximum efficiency, the printer's build chamber can accommodate multiple models at the same time. The printer works with the unique material ABSplus ™ and allows you to grow durable parts. Specially developed new ABSplus™ material is stronger than traditional ABS plastic. The work of parts as snaps, reaming holes, tightening with screws, gluing, sanding pliability are just some of the many advantages of this technology. Developers using Dimension Elite can build robust functional prototypes by finer detailing in the shortest possible time.

| Print Technology | FDM |

| Printable area | 203 x 203 x 305 mm |

| Print speed | up to 15 cm3/h |

| Minimum layer thickness | 174 micron [0.174 mm] |

| Positioning accuracy | XY: 11 microns; Z: 1. 25 micron 25 micron |

| Plastic thread diameter | 1.75±0.1 mm |

| Nozzle diameter | 0.4 mm |

| Media | ABS+ |

| Heated platform | Yes |

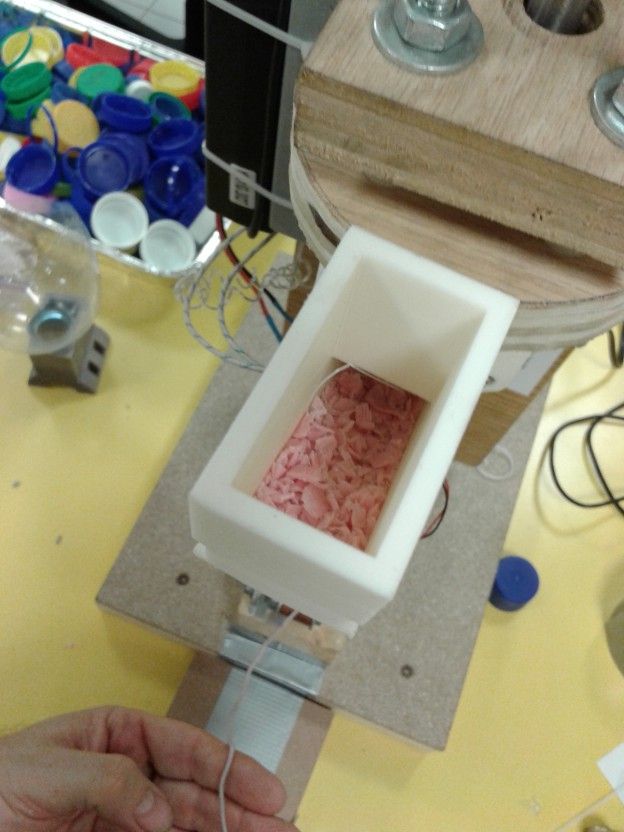

Blueprinter

The Blueprinter 3D printer is a professional desktop 3D printing solution using the unique innovative SHS (Selective Thermal Sintering) technology. This technology is very similar to the expensive SLS (selective laser sintering) technology, but unlike SLS, which uses an expensive laser to sinter a composite material (polyamide), the Blueprinter 3D printer uses a thermal head. All unused thermoplastic powder can be 100% recycled, no support material, thermoplastic powder acts as support. The ease of maintenance of the device will allow even those who have never encountered 3D printing to work with it. Pour the thermal powder into the tray of the 3D printer, open the 3D image with a special program on your computer and click the "Print" button - that's all, then Blueprinter will cope with the task on its own. All information about the digital model is immediately downloaded to the printer, which allows you to turn off the computer after starting printing. The Blueprinter combines quality professional 3D printing technology with ease of use and low maintenance costs. This device is a great solution for those whose activities lie in the fields of engineering design and design, architecture and design.

Pour the thermal powder into the tray of the 3D printer, open the 3D image with a special program on your computer and click the "Print" button - that's all, then Blueprinter will cope with the task on its own. All information about the digital model is immediately downloaded to the printer, which allows you to turn off the computer after starting printing. The Blueprinter combines quality professional 3D printing technology with ease of use and low maintenance costs. This device is a great solution for those whose activities lie in the fields of engineering design and design, architecture and design.

| Print Technology | SHS |

| Printable area | 160 x 200 x 140 mm |

| Print speed | up to 60 cm3/h |

| Minimum layer thickness | 100 micron [0.1 mm] |

| Media | Copolymer powder |

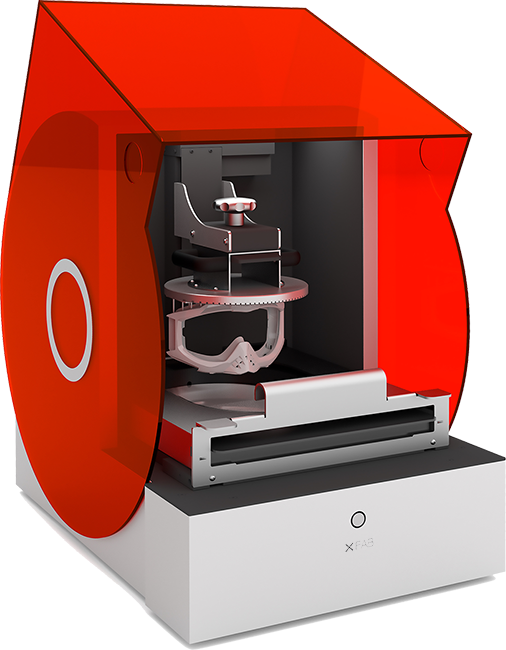

Formlabs Form 2

A new desktop stereolithography 3D printer from Formlabs. The device is ideally suited to the needs of designers who require jewelry precision. SLA printing allows you to achieve a resolution unattainable for the vast majority of printers using the layer-by-layer fusing method: the layer thickness is only 25 microns. Unlike the previous model, now the resin in the cuvette is automatically replenished from a special tank. The device is equipped with a system for supplying photopolymer resin through cartridges. The cuvette is heated so that the resin is always at the optimum temperature. Very nice and the presence of a preview of the printed object on the touch screen of the printer.

The device is ideally suited to the needs of designers who require jewelry precision. SLA printing allows you to achieve a resolution unattainable for the vast majority of printers using the layer-by-layer fusing method: the layer thickness is only 25 microns. Unlike the previous model, now the resin in the cuvette is automatically replenished from a special tank. The device is equipped with a system for supplying photopolymer resin through cartridges. The cuvette is heated so that the resin is always at the optimum temperature. Very nice and the presence of a preview of the printed object on the touch screen of the printer.

Form 2 print results are just great: even the thinnest structures look perfect. Surfaces are smooth and even, so post-treatment is only needed where retaining structures are attached to the part. To remove adhering resin, you need to use isopropyl alcohol. The advantage of printing with resin (professional parlance, stereolithography) compared to conventional 3D printing with PLA or ABS filaments is that the variability in the material properties of the finished parts is much wider. In addition to the standard resin, which is suitable for most applications, there are resins that are more flexible, stiffer, or suitable for dental use. A special resin is specifically designed for the manufacture of molds for casting. In a 3D printer, a model of the molded part is created, which is printed in a special mass and then sent to the furnace. In this case, the printed part completely burns out and leaves a void in the mass. It can then be filled, for example, with a metal alloy.

In addition to the standard resin, which is suitable for most applications, there are resins that are more flexible, stiffer, or suitable for dental use. A special resin is specifically designed for the manufacture of molds for casting. In a 3D printer, a model of the molded part is created, which is printed in a special mass and then sent to the furnace. In this case, the printed part completely burns out and leaves a void in the mass. It can then be filled, for example, with a metal alloy.

| Print Technology | SLA |

| Printable area | 145 x 145 x 175 mm |

| Minimum layer thickness | 25 micron [0.025 mm] |

| Laser size | 140 micron |

| Laser power | 250 mW |

| Polymers |

Roland MDX-20

Easy to use and compatible with many popular 3D CAD programs, the Roland MDX-20 is a 3D scanner and milling machine ideal for many applications, from modeling and jewelry industry to injection mold making, rapid prototyping, small batch production and portable product design. The Roland MDX-20 is used to make test samples, reduce production errors, reduce time and cost when creating a new product. With a scan head installed, the Roland MDX-20 is capable of digitizing 3D objects, creating accurate computer models of them. By changing the scanning head to a milling head, the Roland MDX-20 becomes a complete 3D milling machine that can process jewelry wax, model materials, plexiglass and soft metals such as aluminum and brass. Working field 200 mm x 150 mm x 60 mm. The Roland MDX-20 scans a wide range of objects, including glass objects that are difficult for optical scanners, as well as soft objects such as plasticine models, fresh fruit, and more. Roland's unique RAPS technology allows you to scan with an accuracy of 0.05mm. Roland MDX-20 machines are equipped with a transparent housing that protects the user from contact with the tool during operation and collects dust and chips without interfering with the process.

The Roland MDX-20 is used to make test samples, reduce production errors, reduce time and cost when creating a new product. With a scan head installed, the Roland MDX-20 is capable of digitizing 3D objects, creating accurate computer models of them. By changing the scanning head to a milling head, the Roland MDX-20 becomes a complete 3D milling machine that can process jewelry wax, model materials, plexiglass and soft metals such as aluminum and brass. Working field 200 mm x 150 mm x 60 mm. The Roland MDX-20 scans a wide range of objects, including glass objects that are difficult for optical scanners, as well as soft objects such as plasticine models, fresh fruit, and more. Roland's unique RAPS technology allows you to scan with an accuracy of 0.05mm. Roland MDX-20 machines are equipped with a transparent housing that protects the user from contact with the tool during operation and collects dust and chips without interfering with the process.

Cutter GT

This is a full-fledged industrial-level three-axis CNC milling machine with working area 900x600x300 and additional 4th axis . A distinctive feature of this machine is the fast speed of movement of the milling head along the desktop and high rotational speed: up to twenty-four thousand revolutions per minute. The tolerance for the accuracy of the spindle stroke is three hundredths of a millimeter. Simultaneous movement in three planes makes it possible to form three-dimensional surfaces, wood milling in three planes. The CNC program has a thread cutting function. The machine can be controlled both with the help of a computer program, as well as from the machine control panel. Processing of all types of materials is possible: Milling on plastic, aluminum, firm grades of metals, granite.

A distinctive feature of this machine is the fast speed of movement of the milling head along the desktop and high rotational speed: up to twenty-four thousand revolutions per minute. The tolerance for the accuracy of the spindle stroke is three hundredths of a millimeter. Simultaneous movement in three planes makes it possible to form three-dimensional surfaces, wood milling in three planes. The CNC program has a thread cutting function. The machine can be controlled both with the help of a computer program, as well as from the machine control panel. Processing of all types of materials is possible: Milling on plastic, aluminum, firm grades of metals, granite.

Artec Eva Lite

3D scanner Artec Eva is a fast portable 3D scanner for professionals. Eva is the ideal choice when you need to quickly create an accurate 3D model of a medium-sized object with texture, such as a bust of a person, a die-cast car rim, or a motorcycle exhaust pipe. Eva scans objects in high resolution with accurate colors, which opens up almost unlimited possibilities for using this scanner. Eva is an incredibly lightweight, fast and versatile scanner. Ease of use, speed and accuracy have made the Eva scanner an indispensable solution in a wide range of applications such as rapid prototyping, quality control, computer graphics, heritage preservation, forensics, medicine, prosthetics, automotive and aerospace. Eva is used to develop unique products, innovate and improve efficiency in cutting-edge manufacturing areas. This scanner was used to create the first 3D portrait of the head of state, US President Barack Obama.

Eva is an incredibly lightweight, fast and versatile scanner. Ease of use, speed and accuracy have made the Eva scanner an indispensable solution in a wide range of applications such as rapid prototyping, quality control, computer graphics, heritage preservation, forensics, medicine, prosthetics, automotive and aerospace. Eva is used to develop unique products, innovate and improve efficiency in cutting-edge manufacturing areas. This scanner was used to create the first 3D portrait of the head of state, US President Barack Obama.

MakerBot Digitizer

MakerBot Digitizer allows you to create digital 3D models of real objects. You can scan an object and modify it on a computer, add details, reduce, enlarge, or simply print it on a 3D printer. To scan , the MakerBot Digitizer uses a laser beam, the process itself takes about 12 minutes on average . The result is STL file , which can be further processed in the appropriate software.

The MakerBot Digitizer is useful in modeling, prototyping, and for saving 3D images of various objects. It is designed for objects that can "fit" into a cylinder with a diameter of 203 mm and a height of 203 mm, and is not less than 50 x 50 mm. Permissible mass of the scanned object is 3 kg. The resolution of the scanner is 0.5 mm. The accuracy of the transmission of overall dimensions is (+/-) 2 mm. The manufacturer notes the ease of use and the ability to save scanned data in common file formats that can be imported into CAD and 3D modeling packages.

Roland CAMM-1 PRO

The CAMM-1 PRO GX-640 is exceptionally reliable, flexible and easy to use. With the help of plotters, you can quickly prepare stickers, graphics for transport and shop windows, signs and templates with the highest cutting accuracy.

The plotters are equipped with an optical system that recognizes printed cut marks. Create professional-looking prints with your printer and precisely cut them to contours with your plotter. This is a convenient option for printing and cutting products.

Create professional-looking prints with your printer and precisely cut them to contours with your plotter. This is a convenient option for printing and cutting products.

This machine is capable of cutting all conventional materials including vinyl, polyester, polyurethane, metallized film. A powerful motor and sufficient blade pressure will allow you to cope with more durable materials: flex, flock, rigid fluorescent and reflective vinyl. CAMM-1 PRO GX-640 cuts wide materials up to 184.2 cm . Buttons for the most important parameters are placed on the control panel of the device: cutting force, speed and starting point of the cut. Using eight presetting modules, the operator can easily select the desired options.

Laser Pro GCC Spirit

The Spirit is equipped with DuraGuide laser head movement technology and Kevlar reinforced belts to improve speed, accuracy and quality of work. Excellent engraving and cutting performance combined with high quality performance make the Spirit one of the best engravers. LaserPro Spirit is a high quality machine and contains many smart features that meet the demands and needs of professionals. LaserPro Spirit has a large table size 600x900 mm . The movement system and the laser module are controlled by a built-in computer unit with a liquid crystal display and a control panel. The input of graphic programs for processing materials is carried out via a standard parallel interface. The formation of graphic processing programs is carried out using the well-known integrated Windows graphic editors (Corel Draw, Photoshop, etc.). The model is optimal and most efficient for cutting and engraving various materials. Key features of the LaserPro Spirit: The closed DuraGuide carriage movement system ensures stable laser operation when working with materials that emit a lot of soot, dirt, smoke and other substances (rubber, plastics, marble, painted metals, etc.

Excellent engraving and cutting performance combined with high quality performance make the Spirit one of the best engravers. LaserPro Spirit is a high quality machine and contains many smart features that meet the demands and needs of professionals. LaserPro Spirit has a large table size 600x900 mm . The movement system and the laser module are controlled by a built-in computer unit with a liquid crystal display and a control panel. The input of graphic programs for processing materials is carried out via a standard parallel interface. The formation of graphic processing programs is carried out using the well-known integrated Windows graphic editors (Corel Draw, Photoshop, etc.). The model is optimal and most efficient for cutting and engraving various materials. Key features of the LaserPro Spirit: The closed DuraGuide carriage movement system ensures stable laser operation when working with materials that emit a lot of soot, dirt, smoke and other substances (rubber, plastics, marble, painted metals, etc. ) Reinforced Kevlar belts provide the most excellent quality high speed engraving Function Drag & Engrave allows you to freely move the laser head to the desired position on the table Various easy-to-use software features such as SmartCenter, Defocus by pen allow users to reduce setup time and achieve high quality output Patented SmartGuard fire alarm system. The device provides maximum safety when operating the machine. Workable materials: Wood, acrylic glass, stone, single-layer and multi-layer plastics, rubber, cardboard, paper, leather, glass, ceramics, vinyl film, coated metals. Works well with most organic materials.

) Reinforced Kevlar belts provide the most excellent quality high speed engraving Function Drag & Engrave allows you to freely move the laser head to the desired position on the table Various easy-to-use software features such as SmartCenter, Defocus by pen allow users to reduce setup time and achieve high quality output Patented SmartGuard fire alarm system. The device provides maximum safety when operating the machine. Workable materials: Wood, acrylic glass, stone, single-layer and multi-layer plastics, rubber, cardboard, paper, leather, glass, ceramics, vinyl film, coated metals. Works well with most organic materials.

Wacom Cintiq HD13

Drawing tablet Wacom Cintiq 13HD will allow you to reach the pinnacle of mastery in drawing, drafting. The pen input method is accurate, the slightest touch and manipulation will affect the image quality. The wireless pen, which has a special stand, features pressure sensitivity of 2048 levels, and interchangeable tips allow you to choose the optimal line thickness. Extremely accurate color reproduction, high touch sensitivity - that's what you get using this device. The maximum resolution is 5080 lpi, working area size - 299x171 mm. The Wacom Cintiq 13HD features a 13.3" screen and is tilt adjustable.

Extremely accurate color reproduction, high touch sensitivity - that's what you get using this device. The maximum resolution is 5080 lpi, working area size - 299x171 mm. The Wacom Cintiq 13HD features a 13.3" screen and is tilt adjustable.

Wacom Cintiq HD24

The Wacom Cintiq 24 HD pen tablet is an interactive display designed for professional designers and experienced artists. inch touch screen with a resolution of 1920x1080 pixels, providing a color palette of 16.7 million shades . The kit includes a graphic pen that distinguishes 2048 pressure levels . The capabilities of the tablet are enough for drawing, creating drawings, processing photos and other similar creative tasks. The tablet is equipped with a stand, with which you can easily change the display orientation from landscape to portrait and vice versa, as well as set the screen in the most convenient position for the owner. The Touch Strips on the back of the display make it quick and easy to zoom, scroll, change brush size, and more. There is also on-screen gesture support for Adobe Illustrator, MudBox, and other popular graphics applications. ExpressKeys can be configured to perform the functions that the owner uses most often.

The Touch Strips on the back of the display make it quick and easy to zoom, scroll, change brush size, and more. There is also on-screen gesture support for Adobe Illustrator, MudBox, and other popular graphics applications. ExpressKeys can be configured to perform the functions that the owner uses most often.

Spray booth

Spray booths are modern, high-tech and safe equipment that is actively used for painting various materials and parts. Spray booth OKS 0110.10 is distinguished by compact and convenient design, high degree of reliability and stability of operation, excellent quality of work performed, long service life, as well as the convenience and safety of the operator. The camera body is made of high-strength galvanized steel , which ensures stable and accurate operation of the equipment, as well as a long period of its effective operation under high loads. The excellent quality of the paint and varnish treatment of the surfaces of parts and blanks is guaranteed by the design features that allow to uniformly distribute the air stream throughout the working area of the machine. The machine is able to carry out high-quality surface treatment of workpieces with a variety of materials, which significantly increases its functionality. Dry air filtration : using inertial type separator filters (have a high retention capacity and can withstand 15 kg of collected material per 1 square meter of material processing area), as well as filter systems made of non-woven material. This two-stage purification system guarantees 97% purification of the air used.

The machine is able to carry out high-quality surface treatment of workpieces with a variety of materials, which significantly increases its functionality. Dry air filtration : using inertial type separator filters (have a high retention capacity and can withstand 15 kg of collected material per 1 square meter of material processing area), as well as filter systems made of non-woven material. This two-stage purification system guarantees 97% purification of the air used.

Workbench

Metal workbench is designed for convenient organization of the workplace in workshops and educational institutions. Workbench load - 300 kg . Load on a box - 30 kg. shelf load - 100 kg . The workbench is used as a space for assembling and processing products, equipped with hand and power tools: drilling machine, grinding machine, Drimel drill, sets of screwdrivers, clamps, pliers, wire cutters, etc.

HTC VIVE Pro

Complete immersive virtual reality workstation. The kit includes: helmet (HMD with cable), controllers (manipulators for interacting with virtual reality), base stations (for tracking the user's position inside the workspace), link box (for connecting the helmet to a PC via a USB 3.0 and DisplayPort cable), adapters power supply for base stations, controllers and link boxes. The laboratory has 2 sets for parallel or joint development and testing of VR applications.

Oculus Quest

All-in-one virtual reality system. Allows you to immerse yourself in virtual reality [almost] everywhere. The kit includes: Touch controllers (manipulators for interacting with virtual reality, movements are transmitted with high accuracy), Oculus Quest headset (HMD), 15 W power adapter, 2 AA batteries. To run the apps, you need a smartphone with the ability to install the official Oculus app and an Oculus account. The laboratory has 2 sets for parallel or joint development and testing of VR applications.

Graphic stations

There are 3 workstations equipped with graphics stations that allow you to work with various CGI graphics, game engines, and run VR applications with any system requirements. Developing and testing VR applications requires significant computing power, here the following configuration of our equipment comes into play:

- CPU - Intel Core i7-8700

- Video card - Nvidia GeForce GTX 1080 Ti (2 graphics stations) / Nvidia GeForce RTX 2080 Ti (1 graphics station)

- RAM - 32 GB

- HDD - 1TB

- SSD - 250 GB

Do it yourself - you are in the XXI century. What is a fab lab and what can be done in it

— How does a fab lab differ from a conditional workshop in a grandfather's garage?

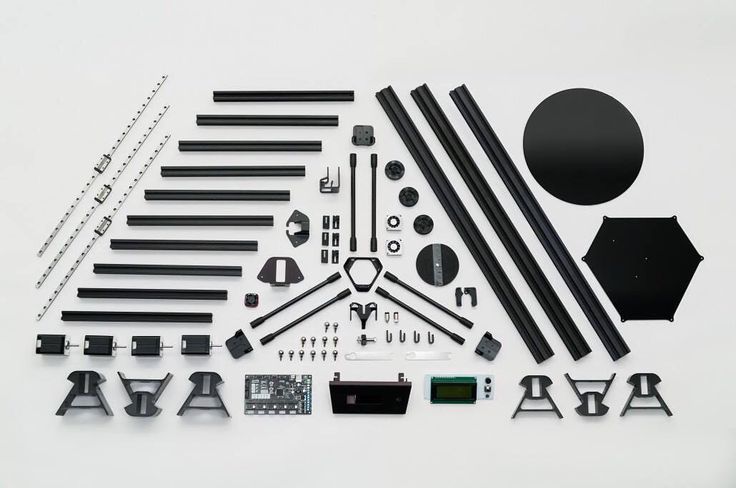

- The idea of fab labs really partly came from such "grandfather's garages". However, to be called a fab lab, the lab needs to install certain rather expensive equipment, such as CNC milling machines and 3D printers.

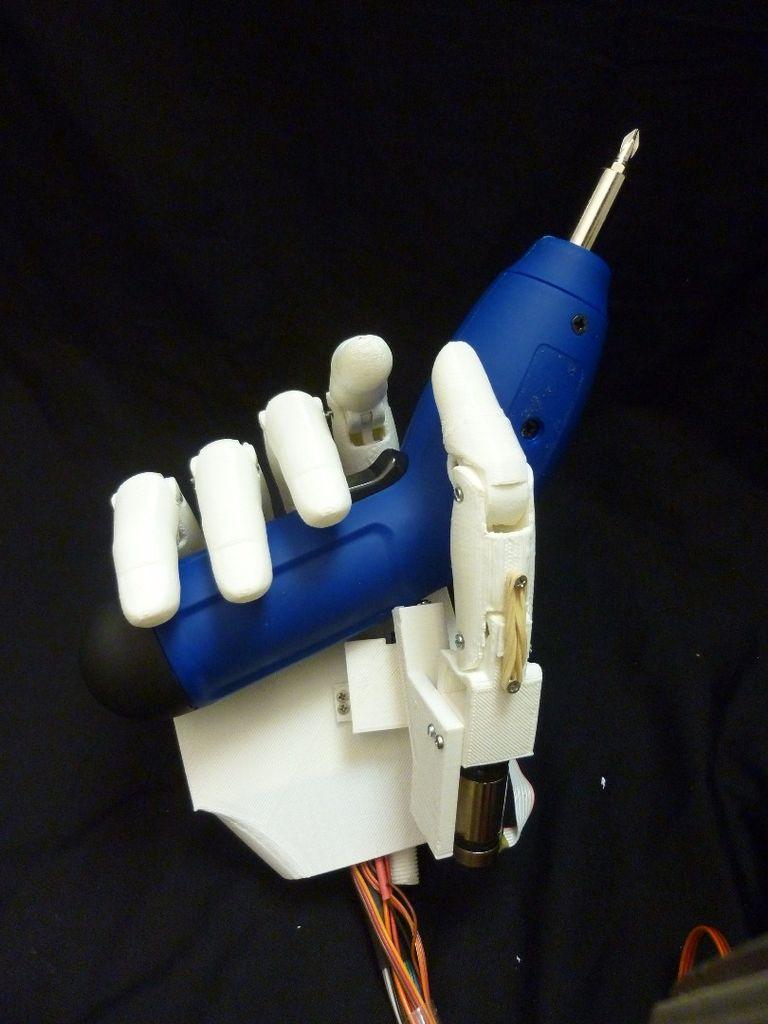

Such equipment opens up completely new possibilities for industrial design. Relatively speaking, to reduce the weight of an aircraft wing, you can make it from lightweight aluminum, or you can 3D print a wing from plastic and carbon fiber, which, thanks to its unusual internal structure and shape, will be as strong as aluminum, only lighter and cheaper. .

High speed video of the wing printing process at the American Oak Ridge National Laboratory, in real time the process took 30 hours. As of February 2017, it was the largest object printed on a 3D printer

Fablabs and similar design labs can be centers for the emergence and dissemination of these kinds of ideas. There are far more people brewing here than in research centers, and technology is getting cheaper: a 3D printer was a curiosity a few years ago, and now it costs 300 bucks. All this allows you to conduct many engineering experiments in a short time and quickly get working prototypes.

All this allows you to conduct many engineering experiments in a short time and quickly get working prototypes.

- What's going on in your fab lab?

- Fab labs try to do everything. They come to us with commercial orders, for example, when people need to print or cut out some detail. In more complex cases, you need to not only cut out a part, but also make a device with electronic filling and program it. But our main focus, of course, is on educational events in digital manufacturing, microcontroller programming, robotics, and design activities.

— I broke my vacuum cleaner handle. What is cheaper: to make the same one in fablab or buy a new vacuum cleaner?

- Small series is expensive, especially because if you do something new, it may not work out right away. Sometimes people come to us to make some small detail and are surprised how much it turns out to cost. It may be easier to buy a new thing.

But small series is really needed. For example, when you need a prototype or a pre-production sample, which may have to be redone 10 more times before the final version is obtained. And here fablabs have an advantage over serial production, because in production everything is done at once in a circulation of thousands of pieces.

For example, when you need a prototype or a pre-production sample, which may have to be redone 10 more times before the final version is obtained. And here fablabs have an advantage over serial production, because in production everything is done at once in a circulation of thousands of pieces.

— What do you do in fab lab?

— I originally worked in sports robotics: I made robots that ride, swim, crawl and fly. They needed details, and because of this, I got into the fab lab. Among my latest projects in the laboratory is a drawing robot: a pen, marker or pencil is inserted into its teeth and it can draw a picture from a photograph. You can call it a craft printer.

Next were the projects made in the process of studying at the MIT digital production course. The final project was an electric longboard. I rode existing longboards and realized that they have problems that I would like to solve. This is unlikely to become a commercial project, but it works and I like it.

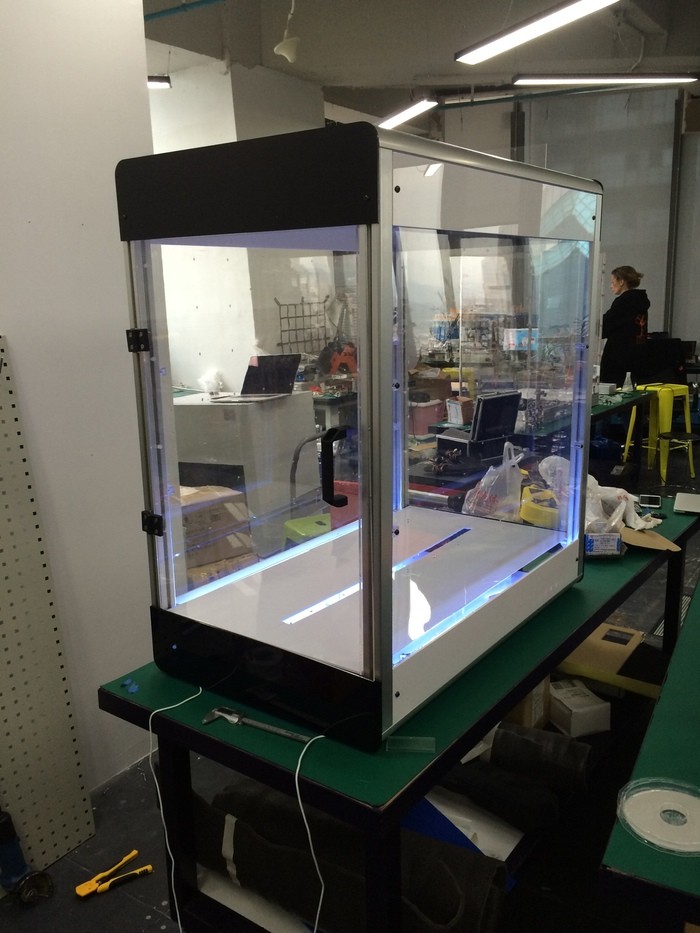

There are also large commercial projects. For example, we are now making equipment for schools so that schoolchildren can work with a 3D printer and scanner, laser and milling machines during technology lessons. The problem is that, according to safety requirements, schoolchildren are forbidden to use power tools under the age of 18: no electric jigsaws, grinders or milling machines. Therefore, our task is to pack these tools in a closed case, so that it is impossible to get into it during the lesson and so that the machine turns off automatically if the student succeeds.

- Will it be difficult for a person "from the street" to work with the equipment?

— Now technology is generally aimed at simplifying life. This trend can be seen in industrial equipment, and in programs for simulation and control of machine tools - everything is moving in the direction of simplifying the user experience.