3D printing for architects

Guide to 3D Printing Architectural Models

Despite a move from the drawing board to digital screens, physical architectural models still play a significant role in helping architects visualize blueprints.

3D printing technologies help bridge the gap between digital and physical worlds and empower architects and model makers to create high-precision architectural models quickly and cost-effectively directly from digital drawings.

This guide provides comprehensive information about using 3D printing to produce architectural models, the different 3D printing processes for architecture, and the workflow for creating 3D printed models from architectural computer-aided design (CAD) software.

White Paper

This white paper covers how to make smart modeling decisions, from choosing scale to designing for assembly to post-processing, and how to use these strategies in common software ecosystems.

Download the White Paper

Since the age of the Pharaohs, architectural models have served as physical representations during structures’ development to help sell a project, support fundraising efforts, and solve construction challenges.

Traditionally, model-making is a manual craft that involves working with materials such as wood, ceramic, cardboard, or clay, which can be extremely time-consuming and repetitive. Architecture studios and practices today have access to a wider range of tools, including CNC milling machines, laser cutters, and 3D printers that can reduce labor needs and speed up the workflow.

Modern 3D printing processes provide architects and model makers with the means to revolutionize how models are made. They do this by:

-

Speeding up the architectural model making process.

-

Translating CAD drawing directly into physical 3D models with a high level of precision.

-

Developing intricately designed parts that’d be hard or impossible to produce by hand.

-

Simplify communication and showcase specific areas that would be hard to convey through conventional 2D drawings.

-

Creating more design iterations at reduced production costs.

For example, model makers Renzo Piano Building Workshop (RPBW), founded by the Pritzker Prize laureate architect, use an SLA 3D printer to quickly develop and fabricate accurate models.

“Our models change every day or even every hour. Because the architects change the project very quickly, most of the time, we don't have enough time to do it by hand. Therefore, we have to find a way to do it quicker,” said Francesco Terranova, model maker at RPBW.

3D printers can create models within a few hours and even operate overnight to save time. “The good thing is that we can launch the printer in the night, and when we come back in the morning, we find the model done. This way, we don't lose time during the day,” said Mr. Terranova.

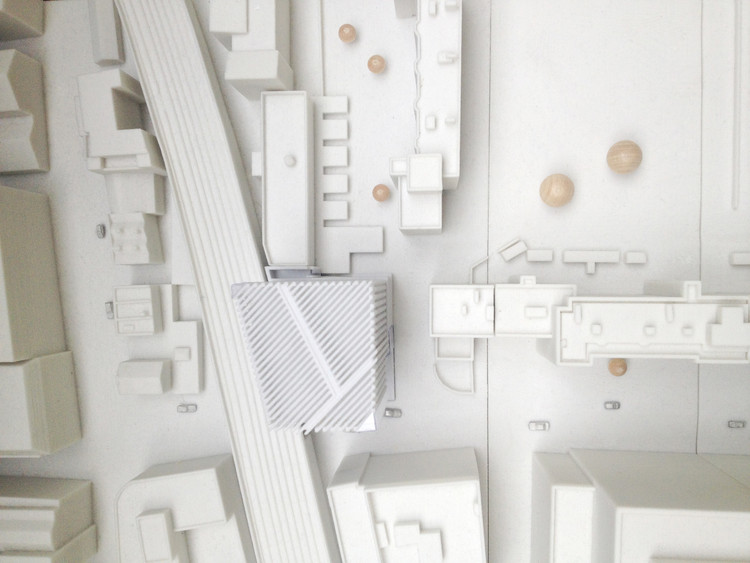

3D printing in architecture is ideal for intricate parts—the trees on this model were 3D printed on a Formlabs SLA 3D printer.

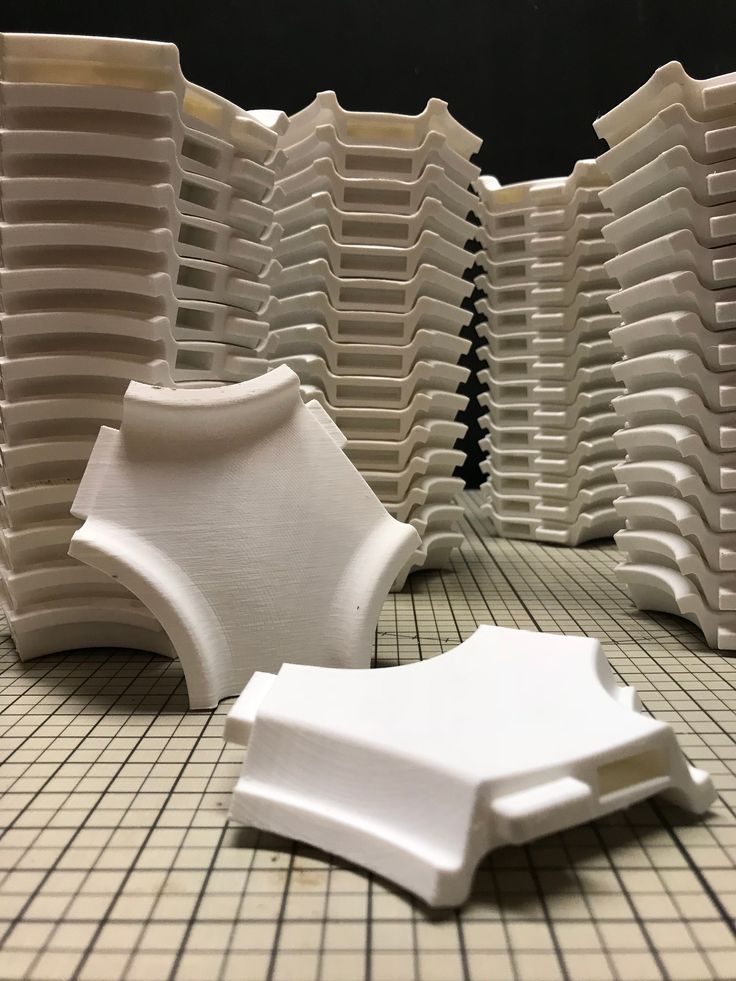

3D printing can be used to produce architectural models of entire buildings, but also in combination with other tools and processes. RPBW’s model builders may use CNC machining or laser cutting to produce the base parts of their architectural models and a 3D printer to develop more complex or intricate components like stairs, trees, spheres, and curved surfaces, which would be time-consuming to manufacture by hand. For example, the RPBW team 3D printed the complex joints of the columns for the model of the new San-Giorgio motorway bridge in Genoa that has recently replaced the Morandi bridge that collapsed in 2018. This combination of 3D printing alongside traditional manufacturing solutions speeds up the creative process and increases the accuracy levels of architectural models.

RPBW’s model builders may use CNC machining or laser cutting to produce the base parts of their architectural models and a 3D printer to develop more complex or intricate components like stairs, trees, spheres, and curved surfaces, which would be time-consuming to manufacture by hand. For example, the RPBW team 3D printed the complex joints of the columns for the model of the new San-Giorgio motorway bridge in Genoa that has recently replaced the Morandi bridge that collapsed in 2018. This combination of 3D printing alongside traditional manufacturing solutions speeds up the creative process and increases the accuracy levels of architectural models.

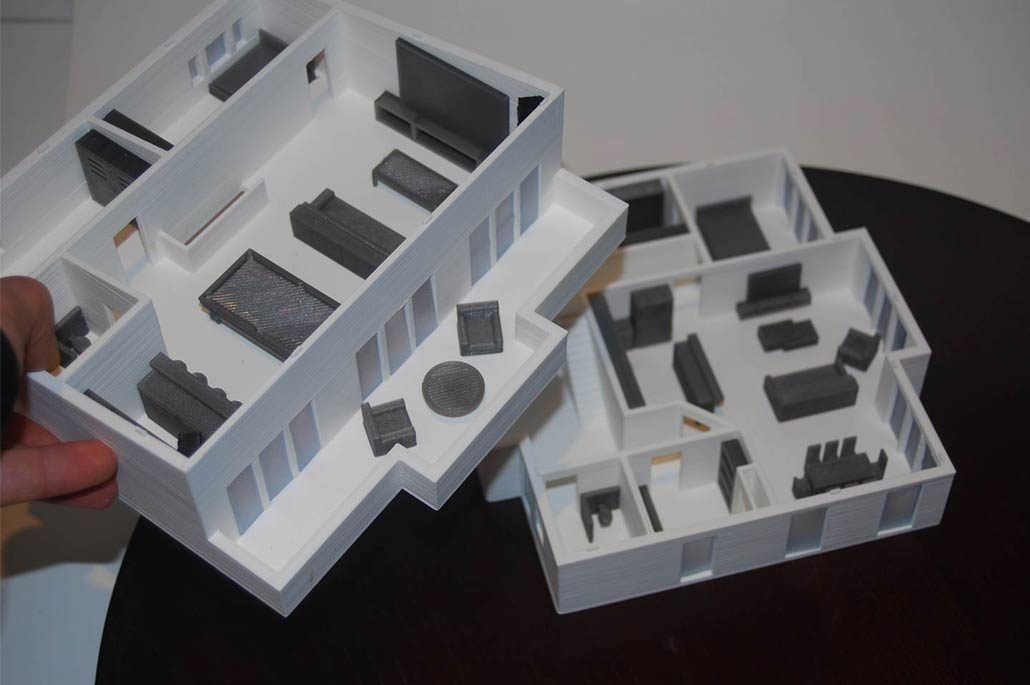

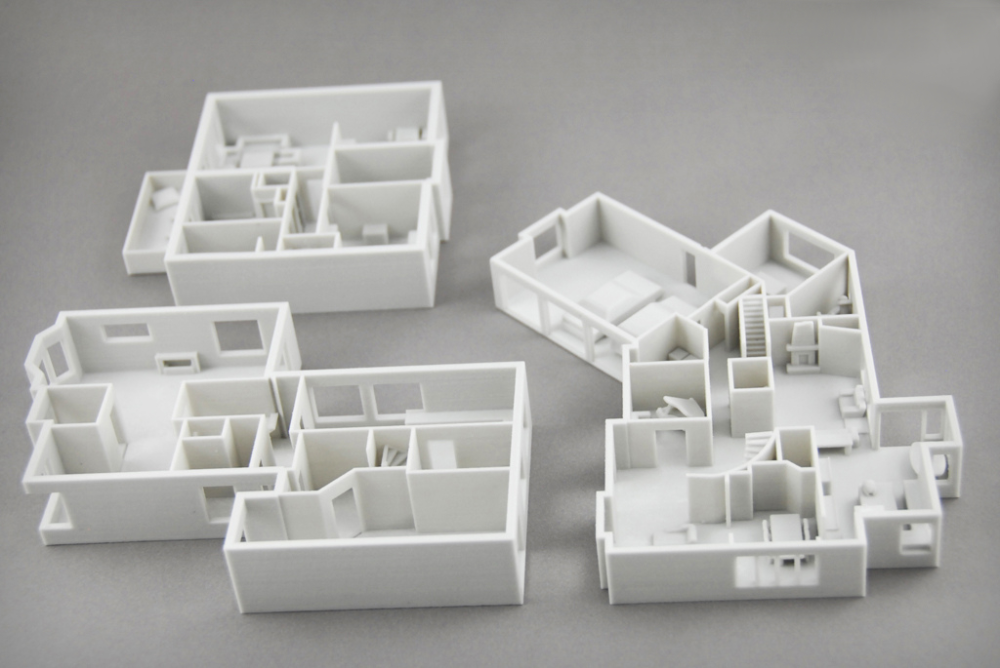

One of the main goals of 3D architecture models is to simplify communication between architects and to make it easier to showcase plans to clients. Los Angeles-based design firm Laney LA’s projects are mostly custom homes, so communicating the scale of a home or structure is particularly important. Architect Paul Choi and his team use 3D printing to showcase specific areas of the project that can be more complicated to convey through conventional 2D drawings.

Laney LA’s architects use 3D printing to create models that allow them to view the project from a fresh perspective while simultaneously providing vantage points.

“It's fun to always try to depict a certain idea about the project and isolate that through the model, whether it's a certain room or a space that we want to highlight through a section cut of the model, or even the topography of the site,” Choi said.

RPBW’s model makers use a Form 3 SLA printer to speed up the production of scale models.

When it comes to 3D printing architectural models, not all methods are created equal. It is important to choose the right printing technology for specific use cases.

The most popular 3D printing technologies for architectural models include stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), and binder jetting.

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA parts have the highest resolution and accuracy of all plastic 3D printing technologies. SLA parts also offer the smoothest surface finish that is easy to paint.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines that are ideal for highly detailed presentation models. This model was printed on a Form 3 SLA printer.

SLA is a great option for highly detailed presentation models for presenting concepts and ideas to clients or the public.

Thanks to fast-printing materials like Draft Resin, SLA is also the fastest 3D printing process for most parts. While desktop SLA printers offer a more compact build capacity, with large-format SLA 3D printers like the Form 3L, architects and model makers can create truly large-scale models.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM has the lowest resolution and accuracy from the four 3D printing processes and is not the best option for printing complex designs or parts with intricate features. It is ideal for basic concept design models produced during the initial stages of design as it can create relatively large models fast and at a low cost.

FDM printers struggle with complex designs or parts with intricate features (left), compared to SLA printers (right).

Selective laser sintering is the most common additive manufacturing technology for industrial applications. SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures.

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures.

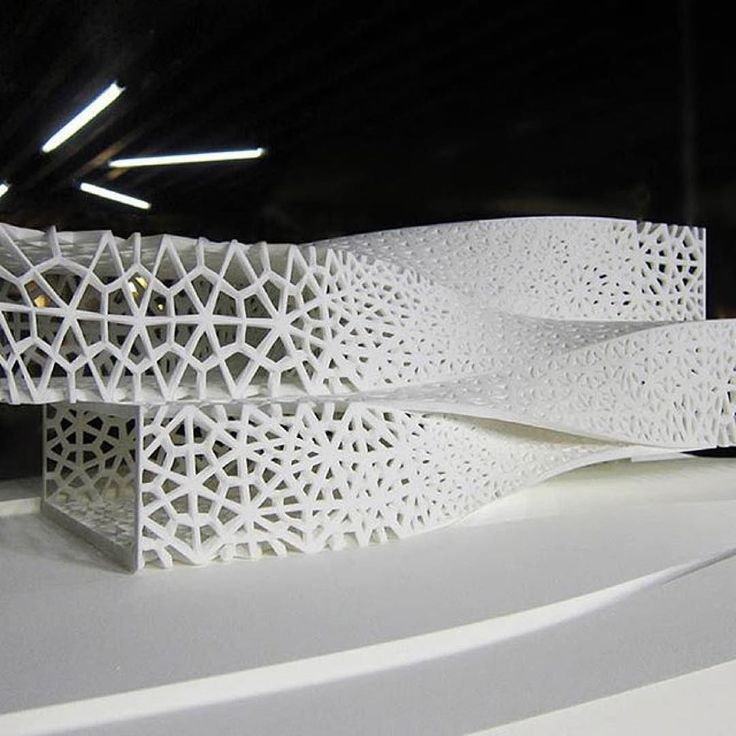

SLS printing is ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printers have excellent mechanical characteristics that make them suitable also for structural parts.

SLS is ideal for complex geometries and intricate details. The details on this model were printed on a Fuse 1 SLS printer.

Binder jetting 3D printing technology is similar to SLS printing but uses a colored binding agent to bond powdered sandstone material instead of heat. Binder jetting printers can produce vivid, full-color 3D architecture models.

Parts produced with binder jetting have a porous surface and are very brittle, which means that this process is recommended only for static applications.

Binder jetting printers can produce vivid, full-color architecture models.

| Stereolithography (SLA) | Fused Deposition Modeling (FDM) | Selective Laser Sintering (SLS) | Binder Jetting | |

|---|---|---|---|---|

| Resolution | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

| Accuracy | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Surface finish | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

| Ease of use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Complex designs | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Build volume | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) | Up to 254 x 381 x 203 mm (industrial 3D printers) |

| Price range | Professional desktop printers start at $3,500, large-format benchtop printers are available from $11,000. | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Benchtop industrial systems start at $18,500, and traditional industrial printers are available from $100,000. | Binder jetting 3D printers are expensive industrial machines, with prices ranging from $30,000 to $100,000+. |

A team from the Institute of Architecture at the Hochschule Mainz - University of Applied Sciences reconstructed the medieval german cities of Worms, Speyer, and Mainz with large-scale 3D printed models.

Most architects today already work in the digital space, using architectural CAD software like BIM (Revit and ArchiCAD), Rhino 3D, or SketchUp to create digital CAD designs. However, these digital files cannot always be used to create the physical scale models directly with 3D printing.

A successful transition from a CAD model to a 3D printable file relies on a baseline understanding of design for 3D printing, how regular modelmaking constraints relate to preparing a file for 3D printing, and how to approach and make smart modeling decisions, from choosing the right scale to designing for assembly to post-processing.

Architectural models are conventionally assembled with a variety of materials and components. 3D printers help fuse these components into as few individual parts as possible, but some assembly is still required for two reasons:

-

The constraints of the build volume: Unless you’re using a large-format 3D printer such as the Form 3L, you might need to divide the model into multiple parts to fit it inside the build volume of the 3D printer.

-

The need to show interior detail or materiality: Certain models require components that come apart to reveal more information about the design.

The size and geometry of different components within an architectural model are key considerations when preparing an architectural model for 3D printing. Generally, large models, models with multiple components, and models with intricate features are split into 3D printable components for assembly. Parts can then be easily joined together through chemical adhesion or mechanical assembly; the high accuracy of the prints with technologies like SLA and SLS ensures that the parts join together seamlessly.

Getting the best results requires applying modeling strategies for assembly, including:

Since each housing unit followed the same design, it made sense to simply print one removable unit that would allow the client to understand the generic unit typology. Model by Stanley Saitowitz | Natoma Architects Inc.

Advancements in CAD technology have drastically simplified the process of developing 3D printable files. Modern CAD platforms have dedicated 3D printing modules to help architects convert a CAD design into a printable model. However, do remember that you are still working at a 1:1 scale–some quick conversions will be required to achieve the correct dimensions at the print scale.

Developing architectural models require some important considerations depending on the CAD platform used. These CAD-specific considerations include:

-

BIM Workflow: Developing 3D printable models with BIM software that leverages parametric modeling such as Autodesk Revit or Graphisoft ArchiCAD requires some component management.

Components such as ductworks, double glazed windows, and HVAC systems do not translate in 3D prints and must be removed, while other parts such as doors, windows, walls, slabs need to be thickened.

Components such as ductworks, double glazed windows, and HVAC systems do not translate in 3D prints and must be removed, while other parts such as doors, windows, walls, slabs need to be thickened. -

Surface Modeling Workflow: This workflow is often an easier approach, starting from 2D drawings solely with the intention to 3D print. It involves exporting a simplified drawing, scaling it down, and extruding and trimming until there’s an external shell.

Download our white paper for step-by-step workflows in common architectural CAD software ecosystems.

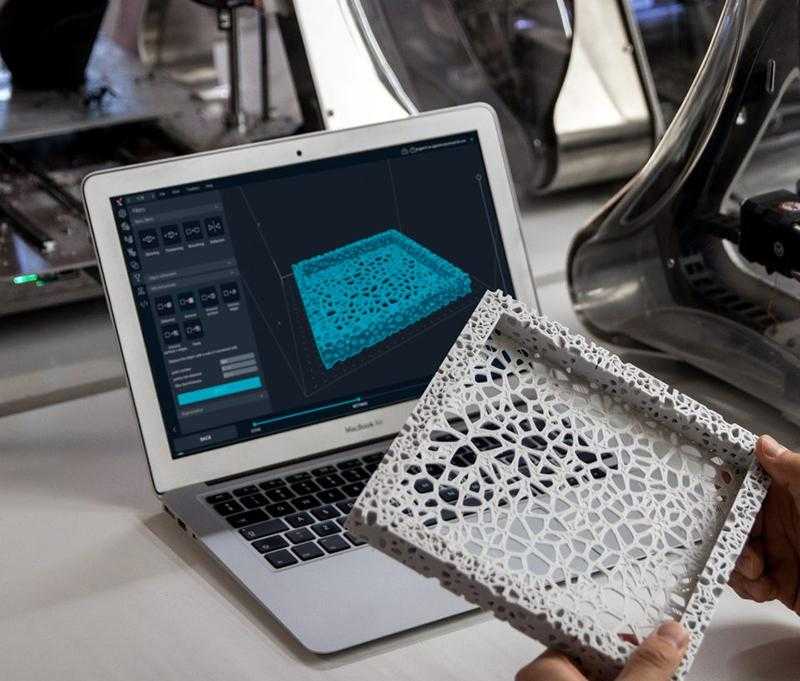

The next step in 3D printing architectural models is transcribing your digital 3D model into a language your 3D printer understands. Accomplishing this requires the use of slicing or print preparation software, such as PreForm. Whether you’re new or experienced, slicing software is generally intuitive to use. The software highlights details such as walls that may require strengthening, unsupported areas, and closed volumes that affect the structure of the 3D print, which can be addressed before printing. Using the software, you can also optimize settings such as resolution, build platform position, and support structures.

Using the software, you can also optimize settings such as resolution, build platform position, and support structures.

Materials play an important role in conveying the underlying concept of a design. It isn’t always imperative to simulate the exact color and texture of a material, but it can help to distinguish between different materials. Splitting a model by its components makes it possible to display materiality, as parts can be produced with various 3D printing materials, or individually painted with different colors.

This site model was created with laser-cut chipboard. The primary building was 3D printed with both Clear Resin and White Resin. Model by Schwarz Silver Architects.

Post-processing differs depending on your specific 3D printing technology, but generally includes sanding, bonding, and painting models.

Here’s an overview by 3D printing process:

| Post Processing Technique | Stereolithography (SLA) | Fused Deposition Modeling (FDM) | Selective Laser Sintering (SLS) | Binder Jetting |

|---|---|---|---|---|

| Sanding | Light sanding is recommended to remove support marks. | The lower quality of FDM prints means sanding is required to get a smooth finish. | No sanding is required due to the quality of the finished parts. | No sanding is required. |

| Bonding | Bonding of SLA components is done with super glue or liquid resins. | FDM components can be assembled using adhesives such as super glue. | SLA components can be assembled using adhesives such as super glue. | Components printed using binder jetting printers can be bonded using super glue. |

| Priming and painting | SLA components can be painted to achieve the desired finish. | FDM components can be painted to achieve the desired finish. | SLS components can be painted to achieve the desired finish. | No painting is required for full-color parts. |

Professional SLA and SLS 3D printers empower architects with the tools to create accurate and attractive 3D architectural models. Choose the Form 3 for a compact solution that can fit on a desktop, the Form 3L for high resolution large-format models, and the Fuse 1 for structural parts and the most complex shapes.

Choose the Form 3 for a compact solution that can fit on a desktop, the Form 3L for high resolution large-format models, and the Fuse 1 for structural parts and the most complex shapes.

See the Form 3See the Form 3LSee the Fuse 1

Download our white paper for an in-depth overview of modeling strategies, step-by-step workflows in common architectural CAD software ecosystems, as well as printing and post-processing recommendations.

Download the White Paper Now

Printing Architectural 3D Models | Life of an Architect

Architects have been using 3D printers for years so the process of printing architectural 3D models isn’t new, but over the last two weeks, we have been experimenting with the process of creating a model for one of our residential projects. I am definitely late to the party on this one but my last office didn’t see any value in this sort of design exercise – we built a lot of models by hand using more traditional materials. So I have been simply looking at the 3D printer that has been sitting in my office for the last two years and I finally decided to put it to work.

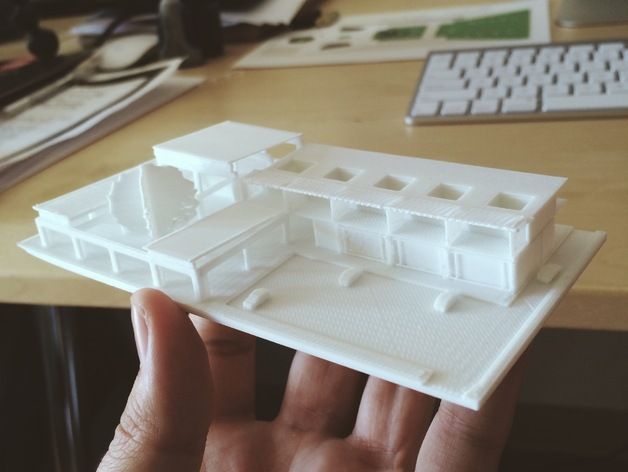

The image above represents the current fruit of our exploratory labors, and I have to say that while I’m not completely satisfied, it does look pretty good and the attention generated in the office regarding this particular project has been very interesting to watch develop.

But I’m getting in front of myself, let’s back up just a bit.

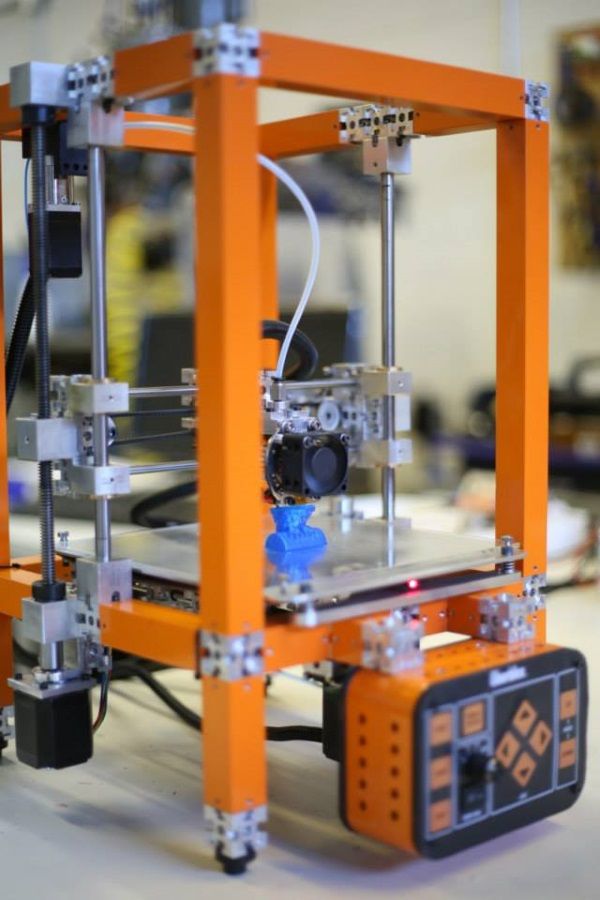

This is the 3D printer we have – a Ultimaker 3 Extended …which is no longer made and has since been replaced with the newer and improved Ultimaker S5 3D Printer but let me prepare you that these are definitely NOT cheap pieces of equipment. I don’t know how much the one we have in the office cost when it was purchased but the new ones will run you around $6,300 (ouch!). I will point out that this post is not intended to be a review of 3D printer equipment, since I am only 2 weeks into this experience I am not prepared to deep dive into the specific parameters of why one printer would be better than another with the exception to two things:

- The size of the “build area” of the printer.

The one I used has a 7″ x 7″ footprint which presented challenges to how delicate everything was once we shrank the house footprint down so that it would be small enough to fit within that area

The one I used has a 7″ x 7″ footprint which presented challenges to how delicate everything was once we shrank the house footprint down so that it would be small enough to fit within that area - Speed at which the printer prints. Speeds kills, and in this case, slow speed kills the quickest.

This piece of equipment is not very large relatively speaking and while it does make some noise and put out some heat, the people who sit immediately adjacent to the equipment had a pretty good attitude about it (they only “joked” that they wanted to kill me despite the fact I was printing for DAYS!!) You can see the giant roll of printing filament on the back of the enclosure. These rolls are pretty large and we were able to print continuously without worrying that we would run out mid print.

The image above was the roof from one of our initial prints … and it turned out terrible. It was printing out too thin and as a result, the heat from the printing bed, as well as from the printer head, was causing our model to deform and warp. We ended up solving this problem by slightly increasing the thickness of the planes we were printing, but we also changed the orientation of the print. Rather than printing it out horizontally – just like you see in the image – but we ended up rotating it on edge so that it printed vertically. Visually the end product looked vastly superior but the printing time changed from about 4 hours to 14 hours.

We ended up solving this problem by slightly increasing the thickness of the planes we were printing, but we also changed the orientation of the print. Rather than printing it out horizontally – just like you see in the image – but we ended up rotating it on edge so that it printed vertically. Visually the end product looked vastly superior but the printing time changed from about 4 hours to 14 hours.

Here is what one of the first test prints looked like – looked okay but we had problems again with the thickness of our walls and our window frames. You can even see on the bottom left where we printed out the entry overhang and you can actually see through it! (You can click here “The Front Door Experience” to see what that overhang was supposed to look like). We also had issues with the window frames breaking when we broke away the temporary construction material the printing process creates when forming the model.

In general, this model was not very good, but we could easily see what we needed to fix and the next model would be a lot better.

The other challenge we faced, which I mentioned earlier, was the limitations of the printing bed area. We had to keep everything to a 7″ x 7″ max footprint which meant the base we wanted to create to set the house would need to be made into 4 pieces and then joined together after that fact.

Easy enough, right?

Easy if you like waiting 35 hours to basically print out 4 sections of the base that are only 1/2″ thick … which I don’t.

Here is what the base looked like after an amazingly long time printing. The thing that was a little disappointing was coming to terms with the amount of extra work that would be prepared if we really wanted these sections to look clean … which I typically want. You can see all the striations in base sections and someone would have to take some additional time and care to sand all of these pieces to make them smooth.

Who has time for that?

To combat some of the printing irregularities, and to highlight the exterior and the interiors, we decided to paint the exterior black while leaving the interiors white – a little trick I picked up from my friend Anthony Laney at Laney LA – the person who showed me the first 3D printed model that actually made me think “WOW – that looks amazing”.

The process of making the exterior black, while keeping the interior white was pretty simple … but took more time and some additional effort. We ended up just masking everything off using tape and an X-acto knife to keep everything nice and tidy.

When you look pretty close, you can see all sorts of irregularities in the printing process, but you have to be looking for them. Keep in mind that this model is only 7″ square at its furthest dimension points.

At this scale, and with a coating of black spray paint, most of the things that would drive you crazy tend to disappear.

Mostly.

This model is shockingly small and because I am writing this post while on holiday from Mexico, I can’t just pop back into the office to take a picture that would help convey its size relative to something else. Due to its size, you really can’t see all these issues that appear so glaringly in your face in my pictures.

I am going to include a few gratuitous assembled shots here just to walk you through another problem we are working on options on how to solve. The heat of the printing filament caused some sections to flare in and out … meaning that of the 4 pieces of the site plan that we printed as out as the base, almost none of them had a true right angle on them. We had designed a few extra steps that would allow us to “snap” these pieces together on the underside but that extra move added a substantial amount of time to the printing process so we bailed on them.

The heat of the printing filament caused some sections to flare in and out … meaning that of the 4 pieces of the site plan that we printed as out as the base, almost none of them had a true right angle on them. We had designed a few extra steps that would allow us to “snap” these pieces together on the underside but that extra move added a substantial amount of time to the printing process so we bailed on them.

As a result, we had to force the pieces together and tape them to one another with the house placed onto the model so that that would stay together long enough for us to flip the model over and then tape them together on the underside.

Boring … and a bit of a pain.

This is the rear courtyard of the house and you can see how each quadrant of the site just doesn’t want to play nicely with the others.

Here is the finished view of the quadrants assembled and the tape removed. Looking around the edges you can see how each of these square blocks isn’t really square any longer. This is one reason – and a really good argument – for getting a 3D printer that has a much larger print bed. The fewer pieces you need the better.

This is one reason – and a really good argument – for getting a 3D printer that has a much larger print bed. The fewer pieces you need the better.

A look at the assembled from corner …

… and a look at the assembled back elevations.

This process was extremely rewarding but we have a long ways to go before I would recommend to others that this is a viable design tool. In the two weeks we have spent on this, what I’ve learned is that it takes an extremely long time to create a finished-looking product, but there are significant ancillary benefits this process created within the firm.

There is no question that we will continue utilizing this tool – but I don’t think we will print out “finished models” unless they are actually finished and we are prepared to put some time in to clean up the surfaces prior to painting (or not) the surfaces. One of the interesting not-anticipated effects this process had was the amount of interest in the process that was generated. My office is constantly working on dozens of amazing projects at any one moment and we have to make an effort to show the entire staff what is happening on projects that they aren’t specifically working on – pretty easy to understand really. When we were printing out this model and had various parts strewn about our work area, dozens of people came but to check out what we doing and as a result, we basically explained the project to most of them along the way. I will also confess that I like the optics of printing out models – even hand-built models will work – because it helps support a design culture in the office. To that end, we prepared this model as a personal exploration into the process and not for the benefit of the client whose house we modeled. Sure, they will reap the benefits of us going through this process but this model was not a “deliverable” to them – it was purely a result of a process and effort of us trying to be better at our craft.

My office is constantly working on dozens of amazing projects at any one moment and we have to make an effort to show the entire staff what is happening on projects that they aren’t specifically working on – pretty easy to understand really. When we were printing out this model and had various parts strewn about our work area, dozens of people came but to check out what we doing and as a result, we basically explained the project to most of them along the way. I will also confess that I like the optics of printing out models – even hand-built models will work – because it helps support a design culture in the office. To that end, we prepared this model as a personal exploration into the process and not for the benefit of the client whose house we modeled. Sure, they will reap the benefits of us going through this process but this model was not a “deliverable” to them – it was purely a result of a process and effort of us trying to be better at our craft.

Cheers my friends –

even better stuff from Life of an Architect

Virtual Conventions??

Ep 078: Redlines

3D printer for architect and designer, pros and cons, examples of use

3D technologies are becoming good helpers in various fields. In architecture and design, 3D printers are successfully used mainly to create architectural models.

In architecture and design, 3D printers are successfully used mainly to create architectural models.

Illuminated layout

Architectural layouts can be divided into several types:

Layouts can be used for a variety of purposes:

-

Visualization for buyers or to coordinate the project with the client. Many customers find it much more difficult to perceive a digital layout of a building or interior. 3D printing allows you to quickly and inexpensively produce, for example, a miniature apartment model with a furniture model. The client himself will be able to visually see a variety of interior options and choose the one he likes the most.

-

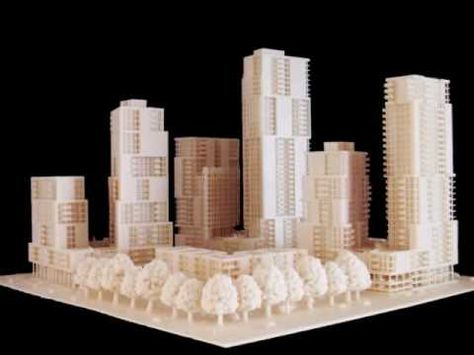

Project presentation. A presentation with a beautiful layout looks much more colorful and effective, for example, a building or an entire microdistrict. But making an architectural model in the classical way is a long and painstaking, often manual, work.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

The cost of the layout depends on several factors - this is the complexity of manufacturing and artistic value. The use of a 3D printer allows you to speed up and significantly simplify the production of complex and simple layouts. For example, making a layout of modern buildings with non-linear geometry becomes a real headache for layout designers. 3D printing allows you to quickly and accurately reproduce an exact copy of any building, regardless of its geometry.

Non-linear building layout

FDM printers for architecture and design

FDM is a technology for layer-by-layer deposition of plastic to obtain a physical model. As a consumable material, a plastic thread is used - a filament.

FDM printers are very popular due to their large working area, printing speed and inexpensive consumables.

The choice of printer model depends on what needs to be produced. Some devices are poorly designed to work with some engineering plastics.

Pros and cons

pros

Models of 3D printers appeared with an “infinite” printable area along one of the axes. These printers use a conveyor belt instead of a printtable. Such printers are suitable for mass production.

For the manufacture of simple layouts, you can give preference to models with a single extruder. But if a 3D printer is required to solve a variety of tasks, then models with two extruders and a closed chamber should be preferred. Such devices are universal and can print on almost any material.

Minuses

Application and printing examples

Model of the city of Astana. Production took 1 month.

Building kit

Prefabricated house model

San Francisco layout

Furniture and interior elements made on a 3D printer

Layout of the floor of the building for arranging furniture

Printer Rating

CreatBot D600 Pro

CreatBot D600 Pro

Features:

Print technology: FDM/FFF

Workspace size: 600x600x600

Number of extruders: 2

Max. extruder temperature: 420 degrees

extruder temperature: 420 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, Decorative plastics, others

CreatBot D600 Pro is a professional device that has many options that will be useful not only for a beginner, but also for an experienced user. Two extruders with a high heating temperature and a closed chamber allow you to print on all available types of plastics. And automatic table calibration using the BL-Touch sensor eliminates the need to level the table plane.

Raise3D E2

Raise3D E2

Features:

Print technology: FDM/FFF

Working area size: 330 * 240 * 240 mm - when printing with the 1st extruder

295x240x240 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Raise3D E2 is a small device with unusual kinematics. Raise3D E2 has two independent extruders that allow the printer to work in several modes:

Raise3D E2 has two independent extruders that allow the printer to work in several modes:

In addition, Raise3D E2 is equipped with a convenient touch screen, automatic table calibration, an assistant for calibrating the height of extruders relative to each other and other nice features that do not affect the final print, but make working with the printer easier and more comfortable.

Raise3D Pro2 and Pro2 Plus

Raise3D Pro2 left and Pro2 Plus right

Features:

Print technology: FDM/FFF

Stage size: Raise3D Pro2

305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Raise3D Pro2 Plus 305x305x605 mm - when printing with the 1st extruder;

280x305x605 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

As you can see from the specifications, the only difference between Raise3D Pro2 and Pro2 Plus is the size of the workspace in height. Pro2 Plus has twice as much.

Pro2 Plus has twice as much.

The Raise3D Pro2 series has proven itself in various fields. These are reliable workhorses with a set of all the necessary options for high-quality printing, and the presence of two extruders allows you to make models of any complexity.

PICASO 3D Designer XL Pro

PICASO 3D Designer XL Pro

Characteristics:

Print technology: FDM/FFF

Working area size: 360 x 360 x 610 mm

Number of extruders: 2

Max. extruder temperature: 410 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, PC, Decorative plastics, others

PICASO 3D Designer XL Pro is a Russian-made professional printer with an enlarged working area. Designer XL Pro is equipped with automatic table calibration, plastic feed control sensor and other nice features.

Photopolymer printing in architecture and design

The principle of operation of a photopolymer printer is based on the illumination of a special resin using directional UV radiation. Photopolymer printers can work on one of three technologies:

Photopolymer printers can work on one of three technologies:

Photopolymer printers allow you to get a product with an ideal surface. It is not for nothing that LCD, DLP and SLA devices are actively used in the jewelry and dental industries, where accuracy and the ideal surface of the finished model are important.

Currently, LCD technology has gained particular popularity due to its availability and inexpensive printers.

Pluses and minuses

pros

Minuses

-

After printing, it is necessary to rinse and dry the product in a UV chamber. After printing, it is necessary to wash off excess polymer from the surface of the finished print. For this, isopropyl alcohol is usually used, although resins have now appeared that can be washed with plain water. In order for the photopolymer to gain the declared strength, it must be additionally illuminated under an ultraviolet lamp or in a special box.

Application and printing examples

Miniature model of building

Model of the Cathedral of the Intercession of the Most Holy Theotokos on the Moat (St. Basil's Cathedral)

Basil's Cathedral)

City map

Miniature “extras” for layout

Printer rating

Prismlab RP400

Prismlab RP400

Features:

Print Technology: DLP/LCD/SLA

Material: Photopolymer resin

Construction area size: 384x216x384 mm

XY positioning accuracy: 100/67/50 microns

Z-axis positioning accuracy: 100/50 microns

Prismlab RP400 is a professional photopolymer machine with a large printable area. Humidity and temperature sensors in the build chamber allow Prismlab to adjust print settings for the best print quality, while open source software allows the use of third-party photopolymer resins.

Peopoly Phenom XXL

Peopoly Phenom XXL

Characteristics:

Print Technology: DLP/LCD/SLA

LCD display resolution: 3840x2160 (23. 8", 16:9, UHD 4K)

8", 16:9, UHD 4K)

Material: Photopolymer resin

Construction area size: 527x296x550 mm

XY positioning accuracy: 137 µm

The Peopoly Phenom XXL is a large format photopolymer printer with a huge printable area. The improved monochrome LCD matrix allows you to quickly and accurately produce large models or small batches of small products.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Features:

Print Technology: DLP/LCD/SLA

LCD resolution: 15" 8K Mono LCD

Material: Photopolymer resin

Build area size: 330 x 185 x 400 mm

XY Positioning Accuracy: 43 µm

Sonic Mega 8K is the first LCD printer with a matrix resolution of 8k, but the accuracy of printing depends on the resolution of the matrix. Sonic Mega 8K allows you to produce large models with amazing clarity, without “blurring” or smoothing small elements.

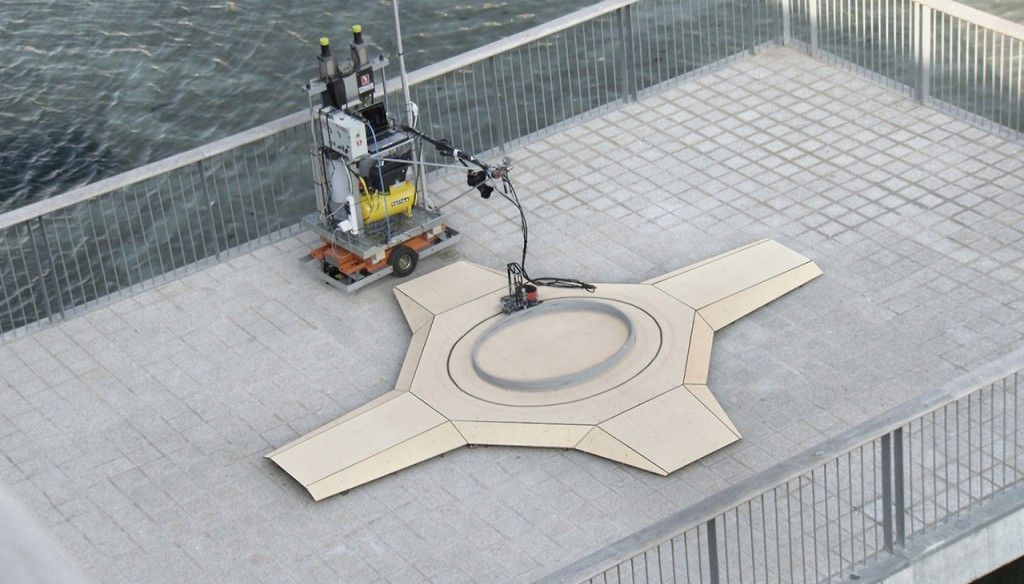

Construction printers

Construction printers are just groping for their niche for application, and the technology itself is still far from ideal. But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

Application and printing examples

Bridge in Shanghai.

In Shanghai, using a construction 3D printer, a whole bridge was printed and installed over a pond in the Baoshan area. The new bridge is 26.3 meters long and 3.6 meters wide.

Shanghai Bridge

Before making a concrete, full-size model, a reduced copy of the bridge 1: 4 was printed for testing the strength and safety of the structure. 3D printing took 450 hours. A load and deformation monitoring system was installed in the finished bridge. This allows you to explore the properties of printed concrete elements in real time.

Up close, you can see the concrete layers that appeared due to the peculiarities of printing

Bridge in Amsterdam

In Amsterdam, a printed steel bridge was installed. It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

Bridge in Amsterdam

Sensors were installed in the bridge to track the deformation of the structure and count the number of people passing through it. For the manufacture of a modern "crossing" 4 robots for 6 months layer-by-layer made a construction of stainless wire.

Bridge manufacturing process

Printed house in Germany

In Germany, builders built an entire house using a 3D construction printer. The house is designed for 5 families, the total area is 380 sq.m.

Almost finished house

In the model of the house, cavities are initially laid for all communications, which the builders will later install. Thus, while the printer is building walls, the workers are solving other tasks.

The structure of the walls is hollow, after hardening it is filled with a special insulating material.

After all the work, the apartments in the house will be rented out, and one, the manufacturer, will be used as an exposition to demonstrate the possibilities of construction 3D printing.

Totals

Architecture and design are already firmly established digitally, making it possible to more visually demonstrate models of future buildings and interiors. It is already difficult to meet an architect who draws his masterpieces only on paper.

Three-dimensional technologies make the visualization process simpler and more visual. Already today, 3D technologies make it possible to partially abandon painstaking manual labor in the manufacture of models, and perhaps in the future, with the help of construction 3D printers, it will be possible to build beautiful architectural structures much faster and easier.

Architectural 3D printing

3D hardware supplier since 2010

+7 495 646-15-338 800 333-12-82

3D Scanners3D PrintersSoftwareServices

About the CompanyClients and ProjectsDemo HallGovernment ProcurementDeliveryService3D Encyclopedia

BlogContacts

3D printing has become an indispensable assistant not only for large companies, but also for small architectural and design studios around the world. Why is 3D printers so popular? The reason is that 3D printing has become a real revolution in the field of building prototyping, design engineering and the creation of new creative objects.

Why is 3D printers so popular? The reason is that 3D printing has become a real revolution in the field of building prototyping, design engineering and the creation of new creative objects.

- Why is it profitable for

- Technologies and materials

- Examples of use

- Choosing 3D-printer

- Why is it profitable

- Technologies and materials

- Sections of use 3D-printer

3 architecture - why is it beneficial?

Making architectural models is an important task for any design or architectural office. The quality of the model of the future project depends on the impression of customers, clients, potential investors. Prototyping by traditional methods is a long, laborious and very expensive process. 3D printing technology can significantly reduce the time needed to make a layout, improve quality, bringing it as close as possible to the original. At the same time, the main part of the design work is carried out on a computer using modern 3D modeling software.

Advantages of 3D printing of architectural models:

- manufacturing speed - just a few hours of 3D printer work replace 2-3 months of manual labor;

- low production cost - uses a special available material based on VisiJet PXL gypsum;

- finished models do not require coloring, 3D printing completely repeats any shades and colors in the CMYK palette;

- high quality 3D printing: layer thickness from 90 microns, up to 390,000 colors, resolution 600x540 dpi; visual sample.

3D printing in architecture - why is it profitable?

Making architectural models is an important task for any design or architectural office. The quality of the model of the future project depends on the impression of customers, clients, potential investors. Prototyping by traditional methods is a long, laborious and very expensive process. 3D printing technology can significantly reduce the time needed to make a layout, improve quality, bringing it as close as possible to the original. At the same time, the main part of the design work is carried out on a computer using modern 3D modeling software.

At the same time, the main part of the design work is carried out on a computer using modern 3D modeling software.

Advantages of 3D printing of architectural models:

- manufacturing speed - just a few hours of 3D printer work replace 2-3 months of manual labor;

- low production cost - uses a special available material based on VisiJet PXL gypsum;

- finished models do not require coloring, 3D printing completely repeats any shades and colors in the CMYK palette;

- high quality 3D printing: layer thickness from 90 microns, up to 390,000 colors, resolution 600x540 dpi; visual sample.

Technologies and materials

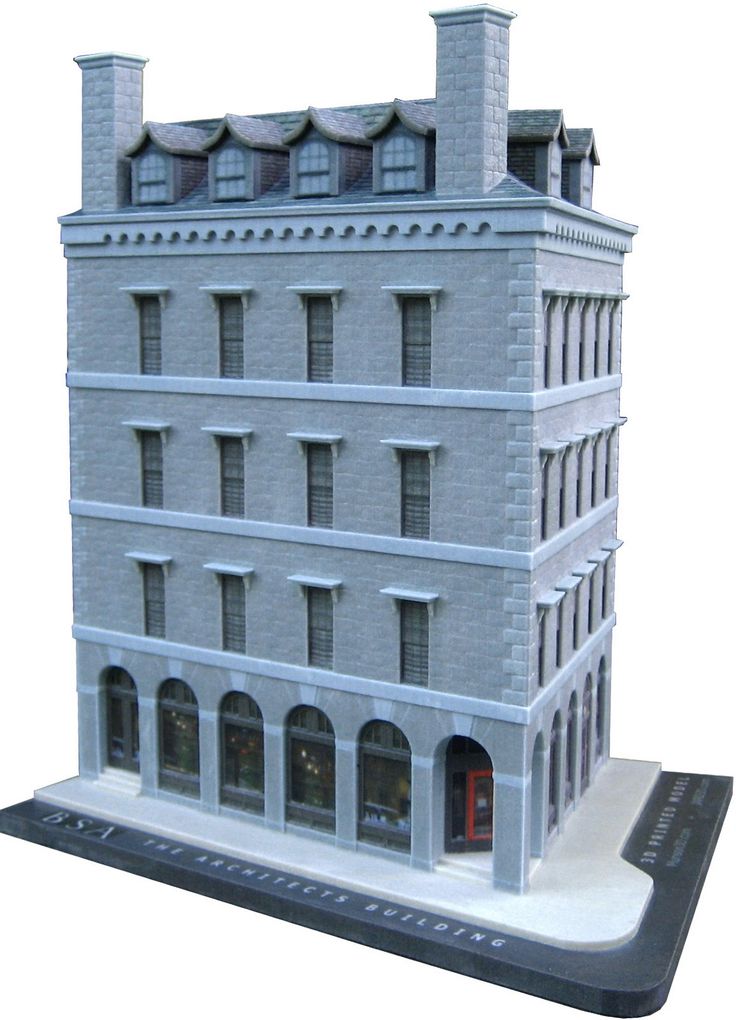

To create full-color architectural models , 3D Systems ProJet x60 series 3D printers are used. They are ideal for making bright, high-precision display models. ProJet x60 series 3D printers create CJP models from a special gypsum-based composite powder. The main advantages of such systems are high productivity, quality and low cost of materials.

The main advantages of such systems are high productivity, quality and low cost of materials.

Full color 3D printers >

In addition, large and complex mock-ups often use photopolymer 3D printers to produce . With their help, complex highly detailed parts of projects are made, with very small (less than a millimeter) elements. However, such 3D printers are not capable of printing colored objects, and the materials for them are much more expensive than gypsum.

Photopolymer 3D printers >

Some architects and designers also use ABS 3D printers. This is Opportunity to save on the production of the layout, since the cost of plastic is lower than that of gypsum and photopolymers. However, it cannot be used to create full-color and highly detailed projects.

Technologies and materials

To create full-color architectural models , 3D Systems ProJet x60 series 3D printers are used. They are ideal for making bright, high-precision display models. ProJet x60 series 3D printers create CJP models from a special gypsum-based composite powder. The main advantages of such systems are high productivity, quality and low cost of materials.

They are ideal for making bright, high-precision display models. ProJet x60 series 3D printers create CJP models from a special gypsum-based composite powder. The main advantages of such systems are high productivity, quality and low cost of materials.

Full color 3D printers >

In addition, photoresin 3D printers are often used when making large and complex layouts. With their help, complex highly detailed parts of projects are made, with very small (less than a millimeter) elements. However, such 3D printers are not capable of printing colored objects, and the materials for them are much more expensive than gypsum.

Photopolymer 3D printers >

Some architects and designers also use ABS 3D printers. This is Opportunity to save on the production of the layout, since the cost of plastic is lower than that of gypsum and photopolymers. However, it cannot be used to create full-color and highly detailed projects.

Full color mock-up created with a ProJet 660 Pro 3D printer.