How hot does a 3d printer get

Can You 3D Print in a Cold or Hot Room? – Temperature Solutions – 3D Printerly

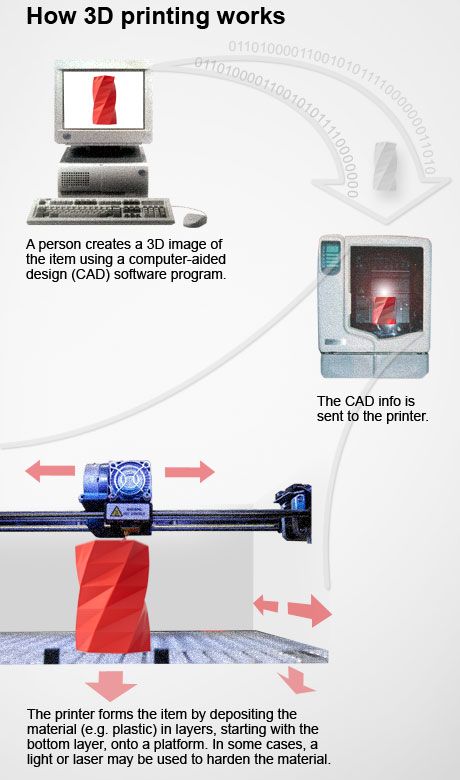

Getting the perfect 3D printing quality depends on many factors, the temperature is one of the main ones. Based on this, many people wonder whether you can 3D print in a cold or hot room. This article is going to answer exactly that so you have a better idea of your 3D printing capabilities.

You can 3D print in a cold or hot room as long as your 3D printer has the proper conditions, such as a constant printing temperature and the right kind of materials. If you try to 3D print ABS in a cold room, you are likely to run into massive warping problems, while PLA could be pulled off.

There are many more details that need to be discussed to get the real answer on 3D printing in a cold or hot room. Keep on reading to find out some key information on this topic.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Can You 3D Print in a Cold Room or Cold Weather?

Monitoring temperature while printing is one important step you need to ensure. It can be hard to print in a cold environment hence you need to carefully monitor your environmental temperature while printing.

Different print materials require different optimum temperatures. When you print with ABS, you should keep the entire build area fairly hot to prevent warping. However, PLA is not as meticulous as ABS.

Which means that you can get some 3D prints in a relatively cold environment if you are printing with PLA. Users started to see printing issues with PLA at temperatures below 59°F (15°C).

The main thing you have to control is temperature fluctuations because large changes in temperature can definitely mess a print up. Warping occurs because print layers are cooling down too quickly, meaning they contract too much.

This is when you see corners of your print start to curl away from the print bed, which is bad for print quality and can even lead to prints getting knocked over because it decreases bed adhesion.

Once you control for temperature fluctuations, 3D printing in a cold room isn’t impossible, but it can definitely be difficult. I’m sure there are certain temperatures which are just too cold to operate successfully.

It will come down to how good your power supply is and your heated bed part’s ability to generate enough power to overcome the cooler environment.

Check out this video by Uncle Jessy who actually 3D printed outside in the snow to test out the theory!

Can You Resin 3D Print in a Cold Room?

Yes, it is possible to resin 3D print in a cold room if you keep in mind a few pointers. The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The operating temperature for a Formlabs resin 3D printer is 64-82°F (18-28°C).

You must ensure your resin is at room temperature if you want it to work fine. Try to keep your workplace temperature stable and make sure humidity level is not above 50 per cent.1

Hence, it is quite possible to get resin 3D print if you ensure a few important steps. By avoiding any temperature fluctuations and high humidity levels, it is possible to get resin 3D print in a cold room.

Cold is actually ideal for storing your resin because the lower temperatures reduce chemical reactions which mature the resin. Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

You want to try avoiding storing your resin in temperatures below 50°F (10°C) or above 140°F (60°C).

Constant temperature is essential for successful prints. Temperature also has effects on how well your resin hardens from the light and cures with the help of UV. A high quality resin 3D printer will regulate the temperature inside the machine, as well as the curing chambers.

The Peopoly Maoi offers a heater for their printer which makes it much easier to resin 3D print in a cold environment.

Can You 3D Print in a Hot Room?

Most printing occurs efficiently under a hot environment however there is a certain limitation to the temperature.

To allow a better working environment for the printer if your surroundings are hot is to install efficient cooling fans and even a cooler. For even better temperature regulation you can also place an air conditioner.

PLA is relatively easy to work with and is not that sensitive to temperature changes as compared to ABS.

You just want to make sure you don’t have an extremely hot operating temperature because that can mess up some prints, depending on the material.

Materials with a low glass transition temperature like PLA won’t do very well in a hot environment as it won’t harden in time. If you have strong cooling fans it may be able to print successfully, but it does make it harder.

However, regardless of the filament you use, you need to make sure at all times that the overall room temperature even in a hot room doesn’t exceed above 50 Celsius. Beyond this temperature, your prints can get messy and spoiled.

Moreover, your printer can overheat resulting in many other complications.

Can You Resin 3D Print in a Hot Room?

To allow resin 3D printing in a hot room you must observe consistent temperatures. Consistency in your workplace temperature is the key to perfect your resin printing in a relatively hot environment.

You can improve your resin printing by heating the resin in a water bath before starting the printing process. Most resins work best in the temperature range of 25-30°C.

By decreasing the heated bed temperature and using efficient fans for cooling, you can enable printing in a hot room. You should be able to regulate your temperature around 20°C.

3D Printing in a Hot Garage

Yes, it is possible for you to 3D print in a hot garage but for this, you need to have some accurate climate control facilities. By ensuring control over the operating temperature and its fluctuations you can successfully print in a hot room.

In hot garage temperatures, it shall be unlikely to print in PLA, as that specific temperature is way above its glass transition temperature. This therefore could never let it solidify.

But, for ABS it will be great and would also decrease warping. It will also improve surface finish.

Does Room Temperature Affect 3D Printing?

Regardless of the environment, you are working in, you should at all times, ensure stability in temperature. It is best advised to regulate the temperature around 68°F (20°C).

It is best advised to regulate the temperature around 68°F (20°C).

So, yes, room temperature surely has a huge effect on the printer’s performance, efficiency and longevity. No printer likes to work in an extreme climatic environment, whether it’s too cold or too hot.

Extreme high temperature can result in deformation of parts, whereas the cold temperature may result in warping between the print layers.

What is the Best Ambient Room Temperature for 3D Printing?

Technically speaking, there is no exact ambient room temperature for 3D printing. There isn’t actually an ideal ambient room temperature for the 3D printing. Rather a temperature range is to be kept in mind.

But the most foremost factor to practice is temperature stability. Hence, for good print output and overall performance, it’s best you maintain an optimum room temperature preferably around 62-68°F (17-20°C).

Should I Use a Heater for my Printer Enclosure?

If you are printing in a cold environment, it’s good to use a heater so that the overall workplace temperature is suitable for the printer to work in. Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

So, you should place a heater to avoid the area from getting too cold. Extremely low temperatures can exist without there being no heater and this can result in your nozzle and filament getting spoiled.

How to Winterize your 3D Printer to Print in a Cold Room?

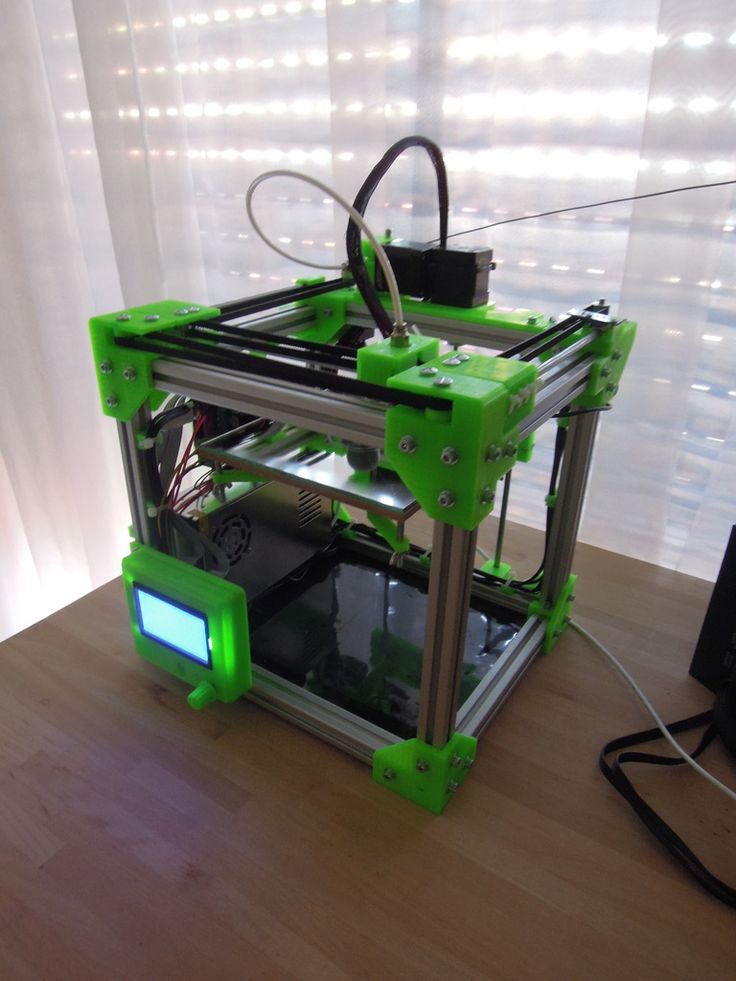

Printers might not be able to work in a very cold area, so you can install heating chambers for better results. It is also advised that you install wireless sensors which can monitor temperature and the humidity changes.

The main thing would be trying to increase your overall temperature in the cold room with a heater, or by using better insulation so the warm air doesn’t escape, and cold air doesn’t come in.

If you are having trouble with this, a heated chamber is going to be a lot more efficient compared to heating the whole room. It can be built out of many materials and there are guides on building DIY heated chambers that you can find on YouTube.

Furthermore, for a better printing experience you can also install carbon filters, and even an exhaust system which can filter out toxic fumes. Although you are working in a cold room, try to avoid your printer’s direct contact with sunlight.

This is suggested because, severe temperature fluctuations can prove to be really disadvantageous for the printer’s overall performance.

Apart from that, it is important that you store your materials and other supplies at room temperature and preferably in a vacuum free space.

Conclusion

Temperature regulation is a key step which can promise you a smooth printing experience. Other than that, the aforementioned guidelines will seem to be very effective if you practice them.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

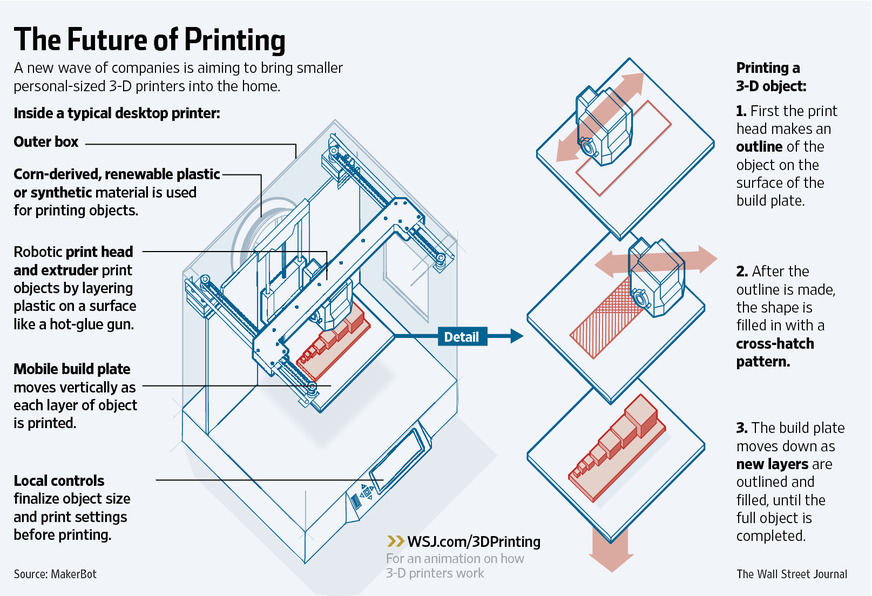

3D Printing Temperatures & Printing Guidelines

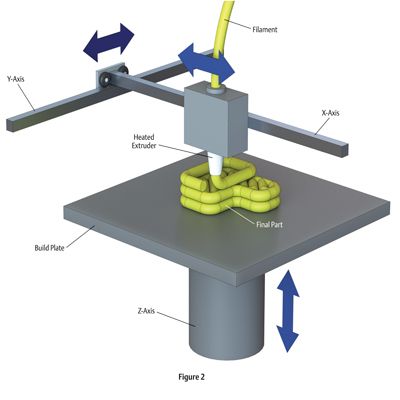

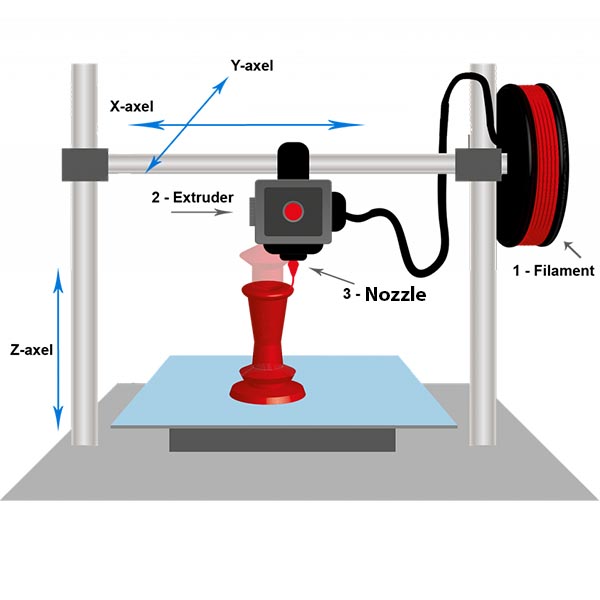

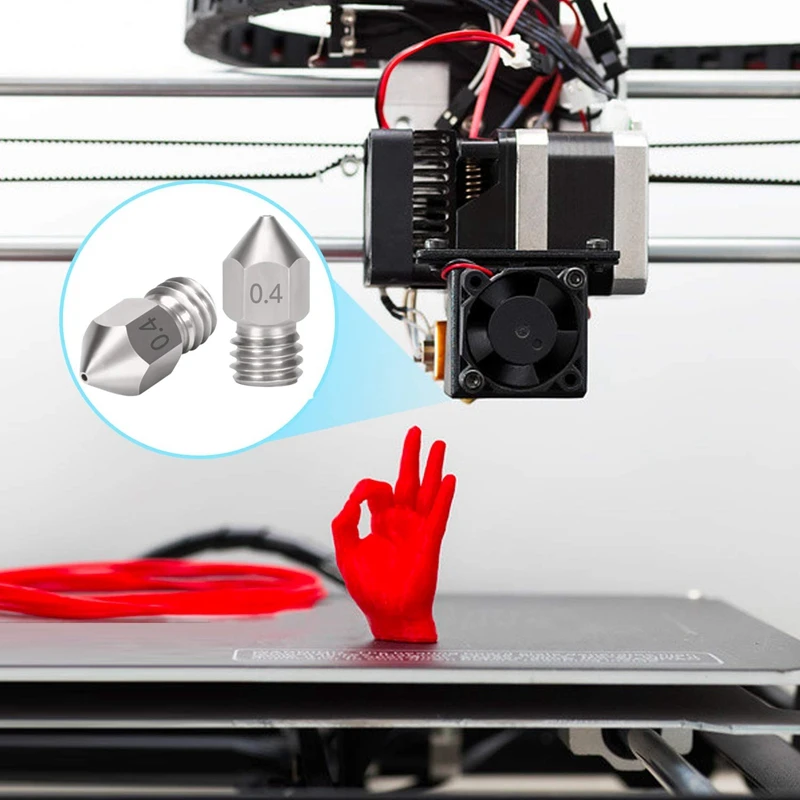

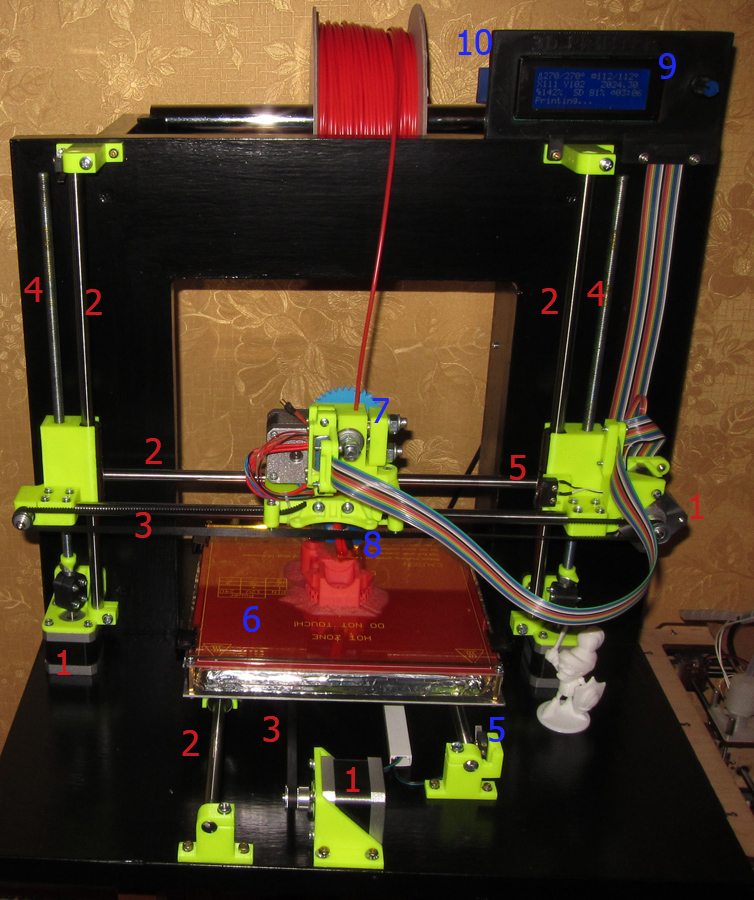

As each desktop 3D printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. To obtain optimal results for your prints you need to take into account variables like your 3D printer’s nozzle diameter, your printing speed settings, and layer height. Every printer is different, for each material/printer, make sure to take notes of what works and what doesn't.

Every printer is different, for each material/printer, make sure to take notes of what works and what doesn't.

Your print bed MUST BE LEVEL & CLEAN. You can use acetone and a towel (lint free) to clean your surface and make sure it is free from oils and dirt before printing.

If your printer is equipped with a heated print bed, make sure you turn it on, especially for ABS.

| PLA (Original Series) | PLA (Creative Series) | smart ABS |

| ABS (Original Series) | ABS (Creative Series) | Soft PLA |

| HIPS | TPU (Flexible Polyurethane) | Bendlay |

| PVA | Flame Retardant ABS | Laywood |

| Nylon PA6 | Wood | Laybrick |

| PETG | Conductive / Anti-Static ABS | Thermochrome PLA |

| Polycarbonate (PC) | EasyFil PLA | |

| PolyMax PLA | EasyFil ABS | |

| Taulman3D T-Glase | PolyFlex | EasyWood Coconut |

| Taulman3D Nylon 618 | Porolay Porous Gel | |

| Taulman3D Nylon 645 | NinjaFlex | |

| Taulman3D Bridge | Carbon Fiber PLA | |

| Taulman3D PCTPE | Polycarbonate ABS (PC-ABS) | |

| High Temperature PLA |

Material |

Temperature |

Comments |

| PLA (Original & Creative Series) | 215°C - 235°C |

|

| ABS (Original & Creative Series) | 230°C - 240°C |

|

| smartABS | Aprox. 250°C |

|

| HIPS | 230°C - 250°C |

|

| PVA | 190°C - 220°C |

|

| Soft PLA | 210°C - 220°C |

|

| NinjaFlex | 210°C - 225°C |

|

| BendLay | 215°C - 240°C |

|

| Laywoo-D3 | 165°C - 250°C |

|

| Laybrick | 165°C - 210°C |

|

| Thermochrome PLA | Aprox. 210°C |

|

| Nylon PA 6 | 240°C - 280°C |

|

| PETG | 230°C - 250°C |

|

| Taulman T-Glase | 207°C - 238°C |

|

| Taulman Nylon 618 | Aprox. 245°C |

|

| Taulman Nylon 645 | Aprox. 245°C |

|

| Taulman "Bridge" Nylon | Aprox. 245°C |

|

| Polycarbonate (PC) | 250°C - 320°C |

|

| PolyMax PLA | 180°C - 240°C |

|

| PolyFlex | 210°C - 240°C |

|

| Carbon Fiber Reinforced PLA | 190°C - 230°C |

|

| Polycarbonate ABS (PC-ABS) | 260°C - 285°C |

|

| High Temperature PLA | 190°C - 230°C |

|

| EasyFil 2.85mm PLA | 210°C - 220°C |

|

| EasyFil 2.85mm ABS | 220°C - 260°C |

|

| TPU (Flexible Polyurethane) | 195°C - 230°C |

|

| Flame Retardant/Resistant ABS | 230°C - 250°C |

|

| Wood | 200°C - 260°C |

|

| Conductive / Anti-Static ABS | 230°C - 250°C |

|

| EasyWood Coconut | 210°C - 220°C |

|

| Porolay Porous Gel | 225°C - 235°C |

|

| Taulman3D Flexible PCTPE | 225°C - 230°C |

|

| Revised: January 23, 2015 |

Fixing the 20 Most Common 3D Printing Problems

3DPrintStory 3D printing process Fixing the 20 Most Common 3D Printing Problems

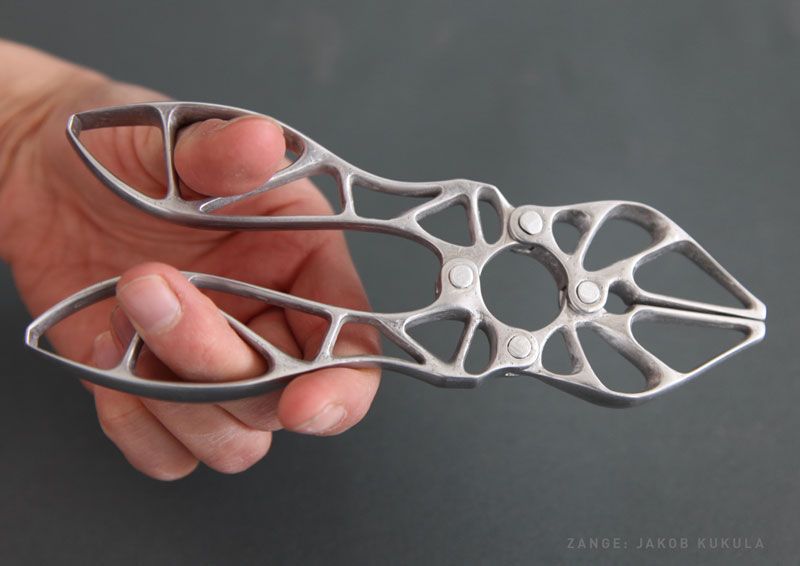

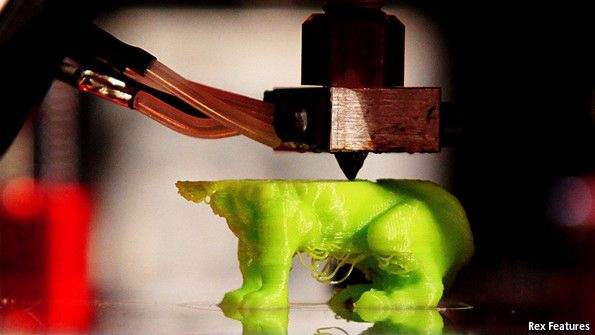

3D printing allows you to create amazing models. But everyone faces unpleasant moments when even a simple model does not print well.

But everyone faces unpleasant moments when even a simple model does not print well.

You checked the model, made sure that many people have already printed it and they had no problems. What are you doing wrong?

This article has collected 20 of the most common 3D printing problems. We hope that the article will help you quickly identify the problem and find a solution for it. In addition, the article details the causes of problems during 3D printing, which will help you avoid them in the future.

Model tearing off

Problem description

At the base, the model rises up relative to the table (English - warping). In addition to the quality of the manufactured part, this problem can prevent the printing of tall parts that can finally fall off the table.

What causes this problem during 3D printing?

Part breakage is a very common problem due to the nature of the printable plastic. As the ABS or PLA plastic cools, it begins to make poor contact with the surface, so the "warping" effect occurs when the plastic cools too quickly.

Solve the problem: part is torn off

- Use a heated table. The simplest solution is to use a heated table slightly below the melting point of the plastic. If the temperature is set correctly, the first layer will be in firm contact with the table. Most often, the platform temperature is set in the program to generate the g code for the model. The recommended temperature is often indicated on plastic packaging.

- Use glue. If your model still wraps around the corners, apply some glue to the print table.

- Try another table. Replace your print bed with a model that offers better adhesion. Manufacturers such as Lulzbot use PEI (Polyetherimide) surfaces. XYZPrinting add special tape to the printer box and that works great too (but they don't have heated tables). Zortrax 3D 3D printers solve the problem differently - with the help of small holes in the table.

- Level the print table.

The print bed may need to be calibrated. During calibration, make sure that the tip of the extruder is at a suitable, uniform height from the stage along its entire plane.

The print bed may need to be calibrated. During calibration, make sure that the tip of the extruder is at a suitable, uniform height from the stage along its entire plane. - Reinforce contact. Increasing the contact between the model and the print table is another easy way. Most 3D printing software has the ability to add additional layers to the base.

- Play around with the temperature. If none of the above work, try increasing the print bed temperature in 5-degree increments. Also pay attention to the operating modes of the coolers. Usually coolers start to work at full capacity when the model height is about 0.5 mm. Try increasing this height to 0.75mm so that the base layers have more time to cool naturally.

And finally, even if you have a heated table, applying a little glue is unlikely to hurt.

3D Printing Problem Checklist: Part 9 Tear Off0017

- Use a heated bed

- Add glue to the print bed

- Use a high-adhesion bed from quality manufacturers

- Calibrate the bed

- Add extra layers to the model base in your 3D printing software

- Play around with temperature and settings cooler

Elephant leg

Description of the problem

The base of the model is printed with a clear indentation to the outside. It is called - “elephant's foot”

It is called - “elephant's foot”

What causes this problem during 3D printing?

This undesirable effect is caused by the mass of the model itself, which presses on the first, insufficiently cooled layers. In particular, this problem occurs if you have a heated table.

Solve the problem: "Elephant's foot"

- Correct balance. In order to avoid this problem, it is necessary to properly cool the layers at the base of the model. The base layers must be able to support the mass of the part, but not overcool, so that the part does not start to come off the table. Finding the right balance can be tricky. Start by lowering the table temperature in 5 degree increments (within +/- 20 degrees from the recommended temperature). If your bottom and top layers are set to 0.6mm, start cooling earlier.

- Level the table. Most 3D printing problems are caused by improper table alignment. Start with calibration recommendations from your printer manufacturer.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table. - Raise the extruder. A simple increase in the distance between the extruder and the table can help. But if the distance is too large, the plastic will not stick to the table.

- Chamfer the base of the model. If none of the above work, you can chamfer the base of your model. Of course, this is only possible if you developed the print model yourself or have access to the original file. Start with a 5mm 45º bevel and experiment for the best result.

3D Printing Problem Checklist: Elephant Leg

- Adjust Table Temperature and Cooler Speed

- Calibrate Table

- Check the distance between the extruder and the table

- Chamfer the base of the model

If you are interested in more detailed information on this problem, we recommend that you read our detailed material on eliminating the "elephant leg" problem.

Other first layer problems

Description of the problem

The first layer does not adhere well to the table and some parts come off. Unwanted lines appear at the base of the model.

What causes this problem during 3D printing?

Such problems are a sign that the table has not been correctly calibrated (table calibration on the example of the Anet A8 3D printer). If the extruder is too far from the table, unwanted lines appear on the base and/or the first layer does not stick. If the extruder is too close, voids may appear.

Important: The print bed must be as clean as possible. Even fingerprints can cause the model to come off.

Solve the problem: The remaining problems of the first layer

- Calibrate the table. Each printer has its own table calibration features. For example, the latest Lulzbot models have an automatic calibration system. Ultimaker 3D printers are configured manually according to the corresponding guide.

With Prusa i3 printers, you have to tinker a little longer and think for yourself.

With Prusa i3 printers, you have to tinker a little longer and think for yourself. - Adjust the distance between the extruder and the table. If the extruder is too high, the plastic will not grip the platform. If too low, you may damage the table.

- Clean the print table. It is advisable to clean the table before each new print. Especially if you are using glue. Fingerprints and adhesive residue may cause the model to come off.

- Add glue. A small layer of adhesive can significantly improve adhesion. But do not forget that if you do not clean the table, then the use of glue can lead to the opposite effect.

- Special tape for non-heated table. If you are using an unheated platform, try applying tape to improve the contact between the base of the model and the table.

Cheklist of 3D Problem: the remaining problems of the first layer

- Calibrate the table

- Check the height of the extruder relative to the table

- Clean the table

- Use the special tape without heated 9009

- Check belts. Start by checking belt tension. You should feel resistance as you bring them together with your fingers. If the top of the belt is stiffer than the bottom, this is a clear sign that they need to be tightened.

- Check table top plate. Check the top plate and screw sets in the printer. Make sure everything is taut and aligned where needed.

- Check the Z-axis screws. Most 3D printers use a screw-nut pair instead of a ball screw. In general, this does not particularly affect the print quality, but over time, the screw may deform. Do not disassemble the printer to check the screws. It is enough to use a program like ‘Printrun’ and move the extruder up and down.

If one of the screws is deformed, you will notice it. Unfortunately, it's almost impossible to fix this. But, on the other hand, this is a great chance to modify your 3D printer and replace the screws with screw-nut pairs.

If one of the screws is deformed, you will notice it. Unfortunately, it's almost impossible to fix this. But, on the other hand, this is a great chance to modify your 3D printer and replace the screws with screw-nut pairs. - Check belt tension

- Check the reliability of fixation of the upper part of the table for printing

- Make sure that the Zears of the Z axis are not deformed 9009

Last layers

9000 9000 description of the problem 9000 the model has voids because some layers were simply skipped (partially or completely).What causes this problem during 3D printing?

The printer did not feed the required amount of plastic. This may be due to problems with the plastic (for example, it has a different diameter), the extruder, or the plastic feed mechanism.

Friction has caused the table to stop temporarily. The reason may be that the vertical screws are not calibrated.

There is a problem with one of the screws or the Z-axis nut. For example, the screw is damaged, dirty, or not well lubricated.

Troubleshooting: Missing layers

- Mechanics check. A 3D printer, like any other piece of equipment, needs maintenance. If you have this problem, this is a clear sign that you should pay attention to its service. Start by checking the screws. Make sure they are well seated in the bearings/holes, with no undue misalignment.

- Screw alignment check. Check that all screws are aligned and not bent. You can appreciate this by turning off the power and carefully moving the extruder along the coordinate axes (depending on the layout of your 3D printer). If you feel resistance, then something is wrong.

- Damaged bearings. Damage to the bearings is manifested in the characteristic vibration during the operation of the 3D printer. If you notice vibrations, turn off the power and manually move the carriage with the extruder to find exactly where the bearing failed.

- Check lubrication. Many people forget about the lubrication of joints. But this is a very important point for the correct operation of your 3D printer. Ordinary machine oil is inexpensive and is great for caring for connections in a printer. Before lubricating, check the guides. They must not be dirty. You need to apply a little oil. If you have applied too much lubricant, simply wipe off the excess with a rag. Naturally, after lubrication, check that the carriages run smoothly.

- Plastic feed problem. The last possible problem is insufficient plastic supply. The solution to this problem may not be simple, so it is considered separately below.

3D Printing Issue Checklist: Missing Layers

- Check mechanics and make sure all screws are tight

- Check screw alignment

- Check bearings

- 0016 Problem Description

Dimples form on the sides of the model, especially on tall models.

One of the most unexpected problems, the solution to which is usually not where you are looking for it.

One of the most unexpected problems, the solution to which is usually not where you are looking for it. What causes this problem during 3D printing?

In higher layers, the material cools faster because the heating from the table does not reach this height. Because of this, adhesion on higher layers is lower.

Solve the problem: Dimples on high models

- Extruder temperature. Start by raising the extruder temperature in 10ºC increments. The specifications for your plastic should list operating temperatures. Try to keep the temperature within the specified range.

- Cooler direction and speed. Check the coolers, make sure they work and point to the model. If so, try reducing their speed.

3D Printing Problem Checklist: Dimples on Tall Models

- Check extruder temperature and raise it in 10 degree increments

- Check the location and speed of the coolers aimed at the 3D model

Dimples, holes on the top of the model

Description of the problem

Dimples or even holes form on the top of the model.

What causes this problem during 3D printing?

The two most common causes are improper cooling of the top layer or insufficient thickness.

Solve the problem:

hollows, holes on the top of model- Printable plastic diameter. Most common when printing with 1.75 plastic. Similar problems can appear in any 3D printer, but most often they appear when using plastic with a diameter of 1.75 mm, not 2.85.

- Check cooler location. Any cooling problems are naturally related to coolers. At the start of printing, the coolers run slowly or turn off altogether, but after the first coat they should work much harder. Be sure to rate the performance of the coolers at the end of the print. If everything works, just in case, check the direction of their rotation. Cold air should flow to the model, and not vice versa.

- Set the fan speed in G-code. As the last layers of the model are formed, the cooling must be very intense so that the plastic does not fall into the holes of your mesh in the model.

Cooler speed can be configured in G-code. The standard code for an on cooler is M106 and M107 for off. That is, adjust the maximum speed for the upper layers. An example would be a 1 cm by 1 cm cube with a layer thickness of 0.1 mm. In this case, the G-code obtained from CURA for the Prusa i3 3D printer will be 97 layers. Knowing we have the 'Bottom / Top Thickness' settings set to 0.6mm, we can look at ;LAYER:91 and add M106 S255 at the end of the line. The M106 kicks off the cooler, while the S255 makes it run at full capacity.

Cooler speed can be configured in G-code. The standard code for an on cooler is M106 and M107 for off. That is, adjust the maximum speed for the upper layers. An example would be a 1 cm by 1 cm cube with a layer thickness of 0.1 mm. In this case, the G-code obtained from CURA for the Prusa i3 3D printer will be 97 layers. Knowing we have the 'Bottom / Top Thickness' settings set to 0.6mm, we can look at ;LAYER:91 and add M106 S255 at the end of the line. The M106 kicks off the cooler, while the S255 makes it run at full capacity. - Increase the thickness of the top layer. The simplest solution is to increase the thickness of the top layer. In most applications, this can be done in the advanced settings under ‘Bottom / Top Thickness’. It is desirable to form a minimum of 6 layers and 8 for extruders with a smaller nozzle diameter and, accordingly, a smaller plastic diameter. So if the layer height is 0.1mm, set ‘Bottom / Top Thickness’ to 0.6mm. If this does not help, increase the thickness to 0.

8 mm.

8 mm.

3D printing problem checklist:

hollows, holes on the top of the model- Increase the diameter of the printing plastic

- Make sure the coolers are correctly installed and working

- Specify the speed of the cooler in manual mode - in G-code 9027 Increase the thickness of the top layer

Plastic residue

Problem description

Unwanted plastic residue forms between parts of the model.

What causes this problem during 3D printing?

When the extruder is moving and not printing (in idle mode), plastic residue is still coming out.

Solving the problem:

plastic residue (more detailed article on troubleshooting plastic residue between parts of the 3D model)- Activate the Retraction option. Retraction is a very useful option, especially when it comes to finishing. It works very simply - before the print head begins to move, the plastic flows back into the extruder, and is not fed.

Thus, the problem can be nipped in the bud.

Thus, the problem can be nipped in the bud. - One-click backfeed activation. Most apps like Cura offer a one-click option to activate this option. The default settings are used, which is sufficient for most cases. However, if you want more flexibility, there should be other options. For example, you can set the minimum printhead path before activating plastic backfeed.

- Minimum travel (mm). Reducing the minimum path is usually the quickest fix if the standard retraction settings didn't help. Decrease this value by 0.5 mm until the problem goes away. By the way, activating reverse feed will increase the speed of 3D printing.

- Just cut off the rest of the plastic. This is not the most elegant solution, but by far the easiest and fastest.

Cheklist of 3D Problem:

Residual plastic- Turn on the return submission of plastic (Retraction option)

- Set up the minimum path before starting feedback

- Just delete the remaining plastic with a knife

Regularly

The 3D printer cannot feed the required amount of plastic (or at the required speed).

As a result, thin layers are formed, layers with unwanted depressions or layers are completely absent.

As a result, thin layers are formed, layers with unwanted depressions or layers are completely absent. What causes this problem during 3D printing?

There may be several reasons. The first is that the diameter of the plastic for printing does not match the diameter specified in the software for forming layers. The second - the amount of plastic supplied is insufficient, due to incorrect settings in the software. Well, perhaps your extruder is very dirty.

Solving the problem: Insufficient supply of plastic

- Check the diameter of the plastic. Start with the simplest case - check the plastic diameter settings in your software. If you are not sure about the correct diameter, it and the temperature are usually indicated on the packaging of the plastic.

- Measure the plastic diameter. If the problem still persists, measure the plastic diameter manually and enter more precise settings in your G-code generation software.

- Check the print head. In most printers, the print head is retracted from the print table. Check extruder. There should be no obvious contamination on it.

- Set the extrusion ratio. If there is no difference between the actual plastic diameter and the settings in the software, check the extrusion coefficient (extrusion multiplier or flow rate or flow compensation). Perhaps these settings are too small. Each program handles these settings in its own way, but the principle is the same - increase the value in the settings by 5% and restart 3D printing.

In Simplify3D open Edit Process Settings and go to Extruder tab - extrusion ratio set to 1.0 corresponds to 100%; If you are using Cura, open the Material tab and increase the Flow setting (you may need to activate the Flow settings in the Preferences panel).

3D Printing Problem Checklist: Plastic Insufficiency

- Check Print Plastic Diameter

- Manually Check Plastic Diameter

- Check Extruder Cleanliness

- Increase extrusion ratio by 5%

Too much plastic feeding

Problem description

Your 3D printer is feeding too much plastic.

Because of this, the material peels off at the edges of the model.

Because of this, the material peels off at the edges of the model. What causes this problem during 3D printing?

This is usually caused by the Extrusion multiplier or Flow in your G-code generation software being set too high (see section above).

Solve the problem: Too much plastic feed

- Extrusion ratio. Open your layering software and make sure the extrusion factor is set correctly.

- Feed settings. If the previous point did not help, reduce the flow value (Flow).

3D Printing Problem Checklist: Too Much Plastic Feed

- Check extrusion ratio settings

- Decrease plastic feed value

Layer misalignment

Problem description

Bottom and top layers are shifting relative to each other during 3D printing. Usually the offset is not as large as in the figure, but the above case can also occur.

What causes this problem during 3D printing?

Layer misalignment can occur for a variety of reasons, including a blow to the printer during printing! This problem may manifest itself due to incorrect belt tension or misalignment of screws.

Or due to the fact that the extruder hooked the model and it shifted a little right during printing.

Or due to the fact that the extruder hooked the model and it shifted a little right during printing. Solving the problem: Layer misalignment

- Check the stability of the printer. The 3D printer must be placed on a stable surface. Even slight shocks can cause the layers to shift.

- Check table stability. Most 3D printers have removable tables. Although this is convenient in terms of replacing it, over time the mounting screws can loosen. So it's worth checking them periodically.

- Check the bottom layers. If you print at high quality, the underlying layers may break off due to cooling. If a break occurs, the plastic rises and the extruder can hit it. In most cases, the model will come off the table, but if there is no lift, the powerful motors can push the model and the table. So if you have problems with the first layers, try reducing the rotation speed of the coolers.

- The print speed is too fast.

Raising the temperature and increasing the feed can speed up 3D printing. However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’.

Raising the temperature and increasing the feed can speed up 3D printing. However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’. - Check belts. If the layers are still shifting, it's time to check the belts. The tension of all belts must be the same. Timing belts tend to stretch over time (this is clearly manifested when the belts begin to slip on the pulleys). If the tension is very weak, you should consider replacing them. Strong belt tension can also be a problem. But usually this is a problem with DIY 3D printers.

Some 3D printers (such as the Prusa i3) have special screws to adjust the tension.

Some 3D printers (such as the Prusa i3) have special screws to adjust the tension. - Guide shafts must be clean and lubricated. Over time, the guides become covered with dirt in places with maximum friction. This, in turn, can cause problems when moving and shifting layers. A quick cleaning and lubrication usually solves the problem.

- Curved or misaligned rails. If you notice that the print head position error occurs in a certain place, this may be a sign that one of the guides is deformed. You can check this by turning off the 3D printer and moving the print head along the coordinate axes. Check axle alignment. If everything is in order, remove the guides and lay them on a flat surface. If there is a bend, you will immediately see it.

3D Printing Problem Checklist: Layer Misalignment

- Check the stability of the 3D printer base.

- Check table stability.

- The first layers of the model should not form cliffs.

- The print speed is too fast.

- Check belts.

- Guide shafts must be clean and lubricated.

- Curved or misaligned rails.

Blocked plastic feed mechanism

Problem description

You start 3D printing, but no plastic comes out of the extruder. You took the rod out of the extruder, put it back in, but it didn't work.

What causes this problem during 3D printing?

After replacing the plastic, a small piece of bar remained in the feed mechanism. Most often, the break occurs at the very end. When you insert a new rod, the remnants of the old one block the flow of plastic.

The second option - the remnants of the old plastic dried up at the end of the extruder. In this case, the remnants of the frozen plastic must be removed manually.

Solving the problem: blocked plastic feed mechanism

- Unlock with a needle. If you're lucky, unlocking the feed mechanism is quick and easy.

Start by removing the plastic. After that, on the control panel, select the option “heat up nozzle” (heat up the extruder) and increase the temperature to the level of plastic melting. If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder.

Start by removing the plastic. After that, on the control panel, select the option “heat up nozzle” (heat up the extruder) and increase the temperature to the level of plastic melting. If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder. - Push through the old plastic. If the extruder is still blocked, you may be able to push the stuck plastic through with a new rod. Remove the plastic supply tube from the print head. Preheat the extruder to 220 C for PLA plastic and then, using a new rod, try to push the stuck plastic through the extruder. It may take some effort, but be careful not to bend the printer's horizontal guides. After that, you can clean the nozzle with a needle in accordance with the instructions from point 1.

- Remove and reassemble the extruder. In extreme cases, you will have to disassemble and reassemble the plastic feed mechanism. If you've never done this before, consider taking photos or recording your every step as you take apart the feed mechanism, as you'll need to put it back together afterwards. First remove the plastic bar. After that, read the instructions for dismantling the print head in the instructions for your 3D printer. Wear gloves while doing this, as the nozzle will be hot. Let's take a closer look at the Ultimaker 2 3D printer as an example. Move the print head to the center of the printer. Loosen the four screws on the print head. Preheat the nozzle to 220 C (for PLA). When the extruder reaches the desired temperature, turn off the power. Holding the cooler's plastic case, remove the rest of the interfering plastic. Clean the nozzle with a needle. You can also clean its outer surface. When the nozzle is cool, assemble the extruder, turn on the 3D printer and load the new plastic.

3D printing problem checklist: blocked plastic feed mechanism

- Warm up the nozzle and clean it inside and out with a needle.

- Remove the plastic feed tube and try pushing through the remaining plastic with a new rod.

- Disassemble the feed mechanism and try to remove any remaining plastic.

Faulty plastic

Problem description

Plastic appears to be fine, correctly seated in the feed mechanism, and exits the nozzle when printing. This happens most often in Bowden-feed 3D printers rather than straight-feed 3D printers, as the plastic isn't visible or noticeable when it's broken.

What causes this problem during 3D printing?

Printing plastic breakage can occur for various reasons, but mostly because the plastic is old or cheap. Most plastics like PLA and ABS last a long time, but if stored in poor conditions (such as direct sunlight), they can become brittle. If you use such plastic, no settings will help.

The second possible reason is the bar diameter, which may vary slightly depending on the manufacturer. And if the pressure in the feed mechanism is too high, it can break.

Troubleshooting: broken plastic

- Remove the plastic. The first thing to do is to remove the plastic from the 3D printer. If you are using Ultimaker, you can use the Maintenance and Change Material option. Heat up the extruder and remove the plastic.

- Try another plastic. If the problem persists after reinstalling the plastic, try a different one to make sure the media quality is not the problem.

- Reduce feeder pressure. If the new plastic also breaks, loosen the pressure on the feed mechanism. Start 3D printing and increase the pressure until the slip is complete.

- Check nozzle. Check nozzle for cleanliness.

- Check flow and temperature. If problem persists, check nozzle heating.

Also make sure the pitch is 100% and no more.

Also make sure the pitch is 100% and no more.

3D Printing Problem Checklist: Plastic Breakage

- Check the shelf life of plastic

- Check the diameter of the plastic

- Set up the pressure in the supply mechanism

- Check the cleanliness of the nozzle and its temperature

- set the supply of 100%

Glorment of the rod

Description of the problem

Prrukta can start slipping for love. 3D printing stage. And it does not depend on the type of plastic. As a result, no plastic is fed.

What causes this problem during 3D printing?

Clogged nozzle, insufficient feed force, incorrect nozzle temperature. As the motor rotor rotates, the small wheel that normally grips and feeds the plastic will pinch the bar and prevent it from being printed.

Solving the problem: bar slippage

- Help the feed system. If the plastic has just begun to slip, this will show up as a characteristic noise.

Try applying some pressure to the bar to get this section through. This often helps and the 3D printer continues to print well.

Try applying some pressure to the bar to get this section through. This often helps and the 3D printer continues to print well. - Adjust the feed force. Start by depressurizing. After that, start increasing the force until the bar stops slipping. Heads vary in diameter, so some require fine tuning.

- Remove the plastic. More one solution is to remove and reload the plastic into the feed mechanism. After removing the bar, cut off the plastic over the place where the slip marks are visible and reload it into the feeder. If slippage remains, try this operation again. If that doesn't help, replace the plastic as this one is most likely no longer printable.

- Check nozzle temperature. If you installed a new plastic and the problem persists, or vice versa, check the temperature of the nozzle.

Cheklist of 3D Problem: slippage of the rod

- Help the supply mechanism with an additional force

- Set up the force in the supply mechanism

- Eliminate the plastic and load a re -

- Check the temperature of the nozzle

Bad Semit 9d Seal Seal 9D SEMS0016 Description of the problem

The printed product is missing an internal mesh or it is obviously incorrect

What causes this problem during 3D printing?

There can be several reasons why the internal structure of the 3D model does not print well.

The most common is incorrect settings in your software for generating a G-code. It may turn out that the problem is a clogged nozzle.

The most common is incorrect settings in your software for generating a G-code. It may turn out that the problem is a clogged nozzle. Solving the problem: Poor 3D printing of the inner mesh

- Check the fill factor. This is checked in your software. A value of about 20% is quite acceptable. If less, problems may arise. This parameter should be increased for large models.

- Speed for printing inner layers. The speed at which printing takes place can have a direct effect on the quality of the inner grid. If you see problems, try reducing the print speed of the inner mesh.

- Change the mesh configuration. Most programs allow you to change the grid configuration. Squares, triangles, hexagons, etc. Experiment with these settings.

- Check nozzle. It may be that the cause is a clogged nozzle. At the same time, the outer parts of the model will be printed well, since plastic is fed more intensively on them.

3D Printing Problem Checklist: Poor 3D Printing of Inner Mesh

- Check and Adjust Inflation Ratio of Model

- Reduce Inner Mesh Print Speed

- Change Mesh Configuration

- Check Inner Nozzle

- 0013

Description of the problem

The printed model generally looks normal, but the internal mesh is visible through the outer walls of the model.

What causes this problem during 3D printing?

See-through problem occurs when your model has thin walls and the internal structure intersects with the outer wall line.

Normally the outer wall thickness should be proportional to the nozzle diameter. That is, if your nozzle diameter is 0.4 mm, the wall thickness of the model should be 0.5, 0.8, 0.12 mm, etc. If the proportion is not maintained, the effects of the clearance of the internal structure may occur.

Problem Solved: Inner mesh showing through

- Check the outer wall thickness of your 3D model.

Check that the wall thickness value is proportional to the nozzle diameter.

Check that the wall thickness value is proportional to the nozzle diameter. - Increase the outer wall thickness. The simplest solution is to increase the wall thickness. Doubling the thickness will most likely help solve the clearance problem.

- Use the filling option after the walls have been formed. Most g-code programs have the ability to generate the internal structure after printing the outer walls.

- In Cura open 'Expert Settings' and in the Infill section activate the option 'Infill prints after perimeters'

- In Simply3D click on 'Edit Process Settings', then select 'Layer' and in 'Layer Settings' select 'Outside-in' next to 'Outline Direction'.

- Check the print table. Examine the printed model. If the effect is more on one of the sides, the cause may be in the calibration. If so, calibrate.

- Use this effect to your advantage. Depending on the task, you can use the print sequence to your advantage.

If you need a model of high quality, with a good outer surface and at the same time the rigidity of the model is not critical, choose Outside-in printing (first the outer layer, then the inner filling). If the rigidity of the model is important, print inside-out, doubling the wall thickness.

If you need a model of high quality, with a good outer surface and at the same time the rigidity of the model is not critical, choose Outside-in printing (first the outer layer, then the inner filling). If the rigidity of the model is important, print inside-out, doubling the wall thickness.

3D printing problem checklist: inner mesh shows through

- Check the outer wall thickness of the model.

- Thicken the outer wall.

- Use the filling option after wall formation.

- Check print bed and calibrate if necessary.

- Use this effect to your advantage.

Gaps between inner mesh and outer walls 3D Model

Problem Description

If you look at the bottom or top surfaces of the model, you will see gaps between the inner mesh and outer walls.

What causes this problem during 3D printing?

Gaps between outer wall and inner mesh used to be a common problem, but with the increasing accuracy of 3D printers, this is now a rare bug.

However, there are new materials for 3D printing that can cause this problem again.

However, there are new materials for 3D printing that can cause this problem again. The most common cause of these gaps is that your software does not have an overlap of the mesh and outer walls set, or this value is set to "0". Your 3D printer considers this so that the wall and mesh should not intersect, and gaps may occur.

Another possible reason is the sequence in which you set the printing of the inner mesh and the outer wall. If you print the outer wall first, there may be no or minimal overlap. Accordingly, there is a chance of occurrence of these gaps.

Solving the problem:

gaps between the inner mesh and the outer walls of the 3D model- Check the parameter of the intersection of the walls and the inner mesh of the model. This is the most common problem and is very easy to fix. Find the "Infill Overlap" option in your gcode generation software and increase this value.

- Cura defaults to 15%.

Increase it to 30%.

Increase it to 30%. - In Simplify3D these settings are in the ‘Edit Process Settings > Infill > Outline Overlap’ tab. Again, increase this value. This setting is directly related to the thickness of your head. So the % value will be % of the bar thickness to be printed. When tuning, do not set this value above 50%, as you will go beyond the walls.

- Cura defaults to 15%.

- Form the inner mesh before printing the walls. If at the same time the inner mesh begins to show through, increase the thickness of the outer wall of the model as indicated in the section above.

- Increase extruder temperature. Some newer 3D printing materials (such as XT-CF20) may require finer temperature settings. Try increasing the extruder temperature by 5-10º. It might work.

- Reduce speed. You probably want to print your model faster, but faster speeds can cause a lot of problems. Especially if the 3D printer is not perfectly calibrated.

If print speed is still important to you, try lowering it for the top layer only.

If print speed is still important to you, try lowering it for the top layer only.

3D printing problem checklist: gaps between inner mesh and outer walls of the 3D model

- Check the intersection parameter between the walls and the inner mesh of the model.

- Print the inner mesh first and then move on to the outer walls.

- Increase extruder temperature.

- Reduce the print speed.

Intersection of objects

Problem description

Parts of the model are missing or the final model is not rigid enough. The finished product and the 3D model are different and there are incomprehensible errors in the geometry of the printed product.

What causes this problem during 3D printing?

Virtual walls are one of the most common causes. Vertical walls only exist in 3D space, not in the real world.

For example, if you have two cubes in the real world and you try to match them, it won't work because the outer walls won't let the two objects intersect.

In the 3D world you can combine two objects and still exist as two separate objects and your slicing program will also allow them to intersect in the virtual world.

In the 3D world you can combine two objects and still exist as two separate objects and your slicing program will also allow them to intersect in the virtual world. For correct printing, these two objects must be combined into one so that the inner walls disappear and one object remains.

Another possible problem - for example, you have a cube object and you have deleted one of its surfaces. In fact, you have an object with a hole. It may look like a 3D correct object, but it only exists as such in 3D space. Such an object cannot exist in the real world.

Deleting one of the surfaces leaves only two coordinates. The wall thickness, the third coordinate, has no dimension in the real world. We only see it in 3D modeling software. And when we start to form the layers of the model, the program will try to fix this bug and add the third coordinate. However, in more complex models, this can lead to unpredictable effects.

Solving the problem: object intersection

- Use the latest slicing software.

Most recent versions of slicing programs support automatic correction of intersecting objects, but it's still better to make sure that your 3D model is formed correctly.

Most recent versions of slicing programs support automatic correction of intersecting objects, but it's still better to make sure that your 3D model is formed correctly. - Set the Fix Horrible settings in Cura. In Cura, open the Expert Settings tab with the 'Fix Horrible' option set to match all (Type-A).

- Set Silmplify3D's Non-manifold settings. In the 'Process settings' select the 'Advanced' menu and then 'Heal' next to Non-manifold.

- Use layered representation. Use the layer view in your slicing software to check for problem areas in your model. A superficial view of the layers can help you quickly identify problem areas and fix the problem.

- Use your software to fix object intersections. One of the easiest solutions is to use additional software to solve the problem. Blender and Meshmixer have built-in mechanisms for identifying problems and fixing the 3D model before slicing.

- Merge objects. It's better to fix your 3D model before importing it into the slicing software. When doing this, make sure that if your two objects intersect or overlap, you use the appropriate intersect, merge, or subtract function.

3D Printing Problem Checklist: Object Intersection

- Please use the latest version of your slicing software.

- Use the "Fix Horrible" option (in Cura).

- Use the “Fix Non-manifold” option (in Simplify3D).

- Use layered view to identify the problem.

- To fix errors, use additional software like Blender or Meshmixer.

- Merge objects.

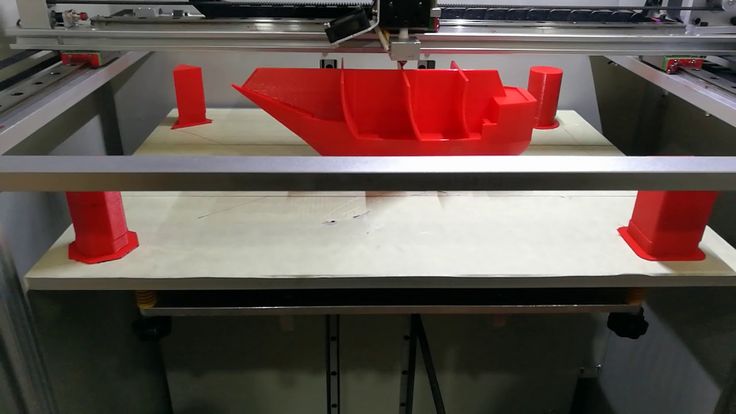

No base for next layers

Description of the problem

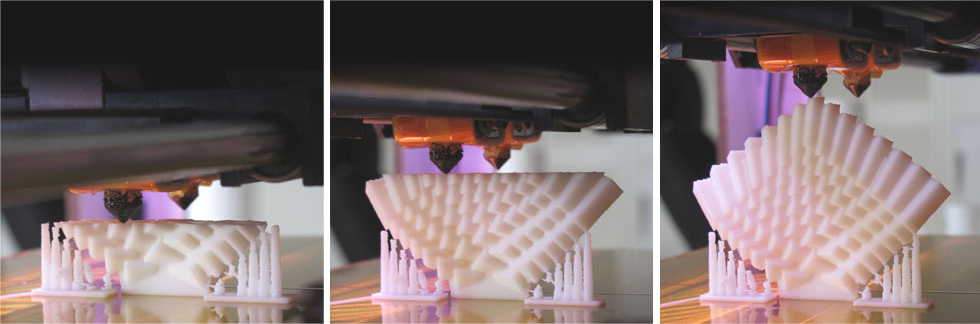

You have loaded your 3D model into the slicing software and everything looks good. We started printing and as a result part of the model was printed well, and some parts - badly. This is a fairly common problem in 3D printing.

What causes this problem during 3D printing?

During 3D printing, each layer is built on top of the previous one.

Naturally, if your model has a part that does not have plastic underneath (for example, as shown in the figure above - horizontally outstretched arms), printing problems will arise.

Naturally, if your model has a part that does not have plastic underneath (for example, as shown in the figure above - horizontally outstretched arms), printing problems will arise. Ideally, the slicing software should somehow detect and point out this problem. However, in most cases, the programs will allow us to print without indicating that additional supports are needed for the model.

Problem solved: no base for next layers

- Add supports. The quickest and easiest solution is to add calipers. In most programs, this is done quite simply. For example, in Simplify3D go to Edit Process Settings > Support > Generate support material; you can customize the quantity, shape and specify other caliper settings. If you are using Cura, just select Support type in the Basic settings.

- Make your own calipers. Software generated calipers may not suit you, so you can create your own in the base 3D model. This will require a little more skill, but can give fantastic results.

- Add an additional object to your 3D model. Most often, problems occur when printing hands and similar details. In this case, adding supports from the base of the model to the arm can also result in a problem, since the distance can be quite large. Considering that the calipers should be easy to remove, the high height may prevent them from being printed correctly. You can get around this by adding an additional object to your model (a piece of wall, a bench, a box, a flower, etc.) and printing an additional rack already from this object.

- Change the angle. For example, models of people whose arms are raised at 45º will print well and it is absolutely impossible to print arms stretched horizontally at 90º relative to the body.

- Divide the model into separate parts. Another option is to divide the model into separate parts and print two pieces instead of one. The only problem that will need to be solved is how to combine the resulting parts into one model after printing.

3D printing problem checklist: no base for next layers

- Add Software for Slosing

- Add calipers in the original model

- Add an object that can be replaced by a caliper

- Change the angle of the problem node

- Separate the

Slove

description problems

As the model builds, the layers begin to shift. As a result, instead of a straight vertical model, displacements appear. In this case, the offsets are not the same over the entire height of the model. The offset can increase/decrease at different heights.

What causes this problem during 3D printing?

The reason is quite simple. One of the belts connected to the stepper motor has lost tension. To eliminate model drift, it is enough to check the tension of the belts and the pulleys that keep the belts in tension.

At first glance, the solution to the problem is simple. However, before you fix it, you should find out which belt is causing it, as getting to the belt can be a difficult task.

Solving the problem: layer shift

- Check the X and Y axes. If the model moves to the left or right, the problem is in the X axis. Forward or backward, the problem is in the Y axis. Once you have decided on the coordinate, check the belts and pulleys. If you have a Prusa i3 3D printer, this shouldn't be a problem since the pulleys are mounted on the stepper motors themselves. In printers like Ultimaker, you will have to tinker.

- Tighten the pulleys on the stepper motors. Check all belts and pulleys. More complex arrangements such as the Ultimaker 2 have multiple belts and pulleys. On the main axes X, Y, eight pulleys are installed on top of the printer. Review and pull up each of them.

3D Printing Problem Checklist: Layer Offset

- Check the X and Y axes.

- Tighten all pulleys along the problem axis.

(There is a solution) Anycubic i3 MEGA does not heat up above 140 ºC

hotend anycubic-i3-mega

[SOLVED] to [EDIT 3]

I just finished changing the i3 Mega's PTFE tubing and brass cap, reassembled it, always being careful not to damage the heating element and thermistor wires.

I then checked the temperature and it was cooling down despite the set temperature being higher (210°C). I turned it off, let it cool down and turned it back on. I set it back to 210°C and it only reaches around 135°C-140°C without going over it. So I change the heating element and thermistor to new ones (the original ones that came with the printer) and the same thing happens: the heating does not exceed 140°C.0005

I then checked the temperature and it was cooling down despite the set temperature being higher (210°C). I turned it off, let it cool down and turned it back on. I set it back to 210°C and it only reaches around 135°C-140°C without going over it. So I change the heating element and thermistor to new ones (the original ones that came with the printer) and the same thing happens: the heating does not exceed 140°C.0005 Any ideas why this is happening or how to fix it? I checked the connectors and they all seem to be ok. The cooling fans also work fine.

Printer: Anycubic i3 MEGA. All spare parts except new nozzle (standard brass nozzle) and PTFE tube (blue tube with 1.9 mm ID). I set the temperature through the printer interface, as always.

[EDIT]

I actually tested something with a multimeter and this is what I came up with:

- Cables to print head OK;

- The heating element voltage is correct and the MOSFET appears to be , works fine both when checking the voltage, and from the LED, which lights up when it sends current to HE;

- "OH" resistance is also correct;

Shape, I'm assuming the problem is that current is being applied to the OH.

Later today I will try to heat both the nozzle and the table to a (safe) maximum temperature and see if heating the table is problematic. If so, then the problem must be related to the current one.

Later today I will try to heat both the nozzle and the table to a (safe) maximum temperature and see if heating the table is problematic. If so, then the problem must be related to the current one. If anyone has other ideas, they are appreciated! :)

[EDIT2]

Heating the platen and hotend at the same time didn't affect the plate at all. He warmed up at the same pace as usual. Since the cables are fine, this shouldn't be a power-related issue.

So, I'm thinking about the motherboard problem (Trigorilla 1.1). At first glance, it seemed to me that there were no burnt components in it, but I will check with a multimeter.

[EDIT3]

Turns out I messed up the heat churn so the heatsink was cooling the hotend too much... That's one way of knowing that I need to be careful with the heat protector I guess. I'll leave the solution here for newbies like me who end up in a similar situation.

@Lurosset, 👍0

Talk

2 answers The problem is that I screwed the heat shield into the cold end radiators and the heated block is now touching it.

It chilled him too much.

It chilled him too much. The solution was to switch to a new, undamaged cold+hotend.

, @ Lurosset

▲ 1

I recently had a similar problem with my Prusa i3 MK2.5. He was unable to maintain the set temperature. I measured the catridge heater (which was new) and its resistance was correct (about 4 ohms). So I changed the hotend MOSFET on the stock board with no result. So I changed the catridge heater to an older one and the problem went away.

Since you've changed your heater, it's unlikely you have a few bad ones. Thus, only the MOSFET and the power supply remain. Make sure your power supply is stable under load and can provide enough current.

Most likely a MOSFET. It behaves like a resistor in the path for current. If it's off, it's like a large resistor (units or tens of megaohms) in series, so no or very little current can flow.

If it is on (units or tens of milliohms), there is very little resistance, allowing current to flow through the heater. If the MOSFET is bad, then when turned on, it can have a higher resistance (units of ohms) and thereby limit the current and create a voltage divider. which you can measure.

If it is on (units or tens of milliohms), there is very little resistance, allowing current to flow through the heater. If the MOSFET is bad, then when turned on, it can have a higher resistance (units of ohms) and thereby limit the current and create a voltage divider. which you can measure. You must reach the bare wires that lead to the heater. Turn on the heater. Place the voltmeter wire on one wire and the other on the oter wire. The voltmeter should read close to the voltage of your power supply. If it reads less then the MOSFET is bad and needs to be replaced.

You will need tools and soldering skills for this. You probably have an SMD MOSFET soldered directly to the board. I suggest removing it and replacing it with a THT MOSFET that you would place separately from the board with its own heatsink. When on the board, the board acts as a heatsink.

If you cannot do it yourself, ask someone else to do it for you.

Before replacing the MOSFET, check if it is an N-channel or a P-channel MOSFET.

- Check the outer wall thickness of your 3D model.

Slid of the layer 9000.

Description of issue

Description of issue Some layers in the model are misaligned.

What causes this problem during 3D printing?

Your 3D printer belts are not tight enough. The top of the print table is not stable. One of the Z guides is not a straight line.

Also, the extruder must support the filament between the exit of the drive gear and the entrance to the melt chamber.

Also, the extruder must support the filament between the exit of the drive gear and the entrance to the melt chamber.

Best results achieved on Garolite. Other/cheaper alternatives include poplar wood or PVA/UHU Glue.

Best results achieved on Garolite. Other/cheaper alternatives include poplar wood or PVA/UHU Glue. (if the print bed is not heated, consider using brim instead, 5 or more mm wide.)

(if the print bed is not heated, consider using brim instead, 5 or more mm wide.)

75mm, the recommended printing temperature is 185°C - 200°C with a heated print bed OR 200°C - 230°C without a heated print bed.

75mm, the recommended printing temperature is 185°C - 200°C with a heated print bed OR 200°C - 230°C without a heated print bed.