3D printer gin

What Are 3D-Printed Guns, and Are They Legal?

For decades, weapons manufacturing has been the domain of arms industry heavyweights: Glock, Sig Sauer, Remington, Sturm, Ruger & Co. Making a gun from scratch at home required thousands of dollars of machining equipment and years of engineering expertise.

But in recent years, that has begun to change. Advancements in 3D-printing technology have yielded increasingly reliable 3D-printed firearms, many of which require no federally regulated components to function. Below, we break down the basics of plastic, 3D-printed firearms, and the controversy generated by the swelling movement to deliver them to the masses.

What is a 3D-printed gun?In the simplest terms, it’s any firearm that includes components manufactured with a 3D printer.

But 3D-printed guns vary a lot. Some models — like the 3D-printed gun company Defense Distributed’s “Liberator” — can be made almost entirely on a 3D printer. Others require many additional parts, which are often metal. For example, many 3D-printed gun blueprints focus on a weapon’s lower receiver, which is basically the chassis of a firearm. Under federal law, it’s the only gun part that requires a federal background check to purchase from a licensed dealer. To subvert regulators, some people print lower receivers at home and finish their guns using parts that can be purchased without a background check — metal barrels, for example, or factory buttstocks. Many gun retailers sell kits, which include all the components necessary to assemble a gun at home.

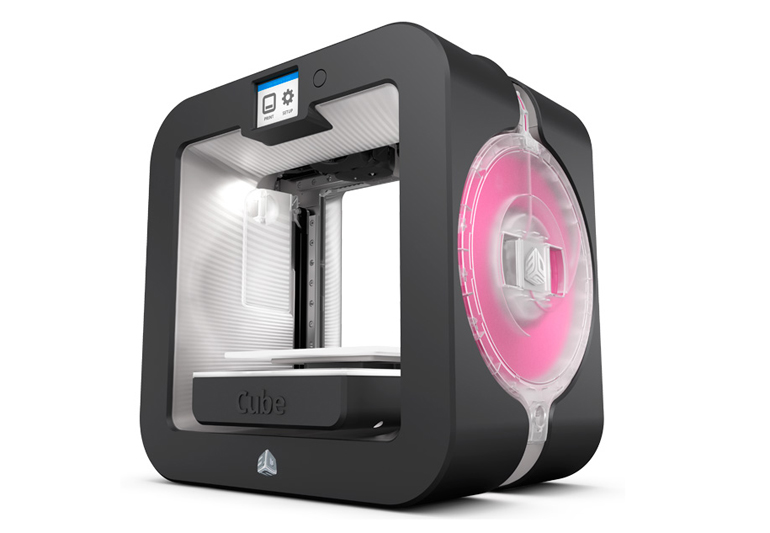

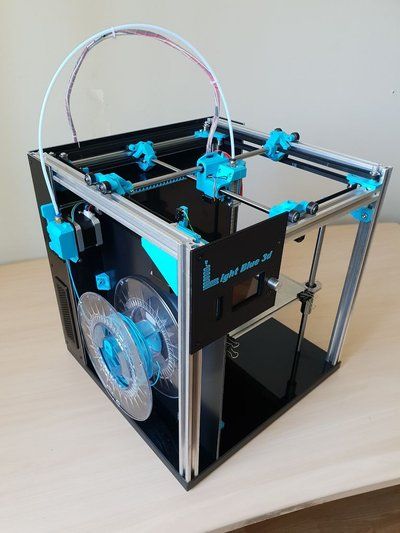

Advances in printing technology have driven the price of 3D printers down — they’re now around $200 on Amazon — and gun groups offer guides for getting started. These developments have lowered the barriers to entry for those in search of untraceable guns, which have turned up at crime scenes with increasing frequency over the past few years.

The process still remains more involved than most methods of obtaining a firearm, though. For instance, 3D printers require meticulous setup — the component that extrudes plastic must be calibrated, software must be downloaded to convert designs into 3D-printable slices, and the printer must undergo a slew of upgrades to reliably print weapons parts, which themselves require precise construction to ensure they can contain the explosion from a gunshot.

For instance, 3D printers require meticulous setup — the component that extrudes plastic must be calibrated, software must be downloaded to convert designs into 3D-printable slices, and the printer must undergo a slew of upgrades to reliably print weapons parts, which themselves require precise construction to ensure they can contain the explosion from a gunshot.

Because 3D-printed guns are made outside traditional supply chains, and don’t require background checks, they’re effectively invisible to law enforcement agencies. They are a form of ghost gun: unserialized, and unable to be traced if recovered by law enforcement.

There isn’t good data on the number of 3D-printed firearms that have turned up at crime scenes, though state attorneys general opposed to the technology insist that some have been recovered. On a few occasions, crimes involving the guns have made headlines. In February 2019, police arrested a Texas man after he was found test-firing a 3D-printed gun in the woods. He was prohibited from purchasing firearms and had a hit list of lawmakers on him.

He was prohibited from purchasing firearms and had a hit list of lawmakers on him.

Of particular concern to many law enforcement agencies are guns that can be completely 3D-printed at home without metal components. Politicians and law enforcement professionals fear that such guns would be able to evade metal detectors, and thus slip into places where firearms are prohibited, like airports or government buildings. At present, these fears are largely unfounded — 3D-printed gun designers have yet to develop an alternative to metal bullets, and security officials say that X-ray detection in place alongside most metal detectors can identify the outline of 3D-printed firearms with ease. Indeed, Transportation Security Administration officers have seized 3D-printed firearms at airports on several occasions.

Still, the weapons’ lack of traceability has already caught the attention of terror groups, according to Mary McCord, a former U.S. attorney and prosecutor in the Department of Justice’s National Security Division. “We know from a counterterrorism perspective that there’s great interest among terrorist organizations in being able to have workable, usable, efficient, functioning 3D-printed weapons.”

“We know from a counterterrorism perspective that there’s great interest among terrorist organizations in being able to have workable, usable, efficient, functioning 3D-printed weapons.”

In most cases, yes. Federal law permits the unlicensed manufacture of firearms, including those made using a 3D printer, as long as they include metal components.

In the absence of federal regulation, a handful of states have taken their own steps to clamp down on the creation of homemade guns. In California, anybody manufacturing a firearm is legally required to obtain a serial number for the gun from the state, regardless of how it’s made. In New Jersey, you are supposed to obtain a federal manufacturing license before 3D-printing a gun. The state also criminalizes the manufacture, sale, or possession of undetectable firearms, and made it illegal to purchase parts to make an unserialized gun. Several states — including New Mexico and Virginia — are considering bills that would enact similar restrictions.

The legality of sharing the files required to print guns and gun components is murkier territory. No federal legislation bans the practice. But in 2013, the State Department ruled that releasing blueprints online violated arms export laws. In 2018, after a lengthy court battle with Defense Distributed over the guidance, the State Department settled, and agreed to permit the files’ release. But before the prohibition was lifted, a coalition of states sued to keep it in place — and won. Now, gun groups intent on sharing the files online have exploited a loophole in the State Department’s policy, which allows for the distribution of blueprints exclusively to U.S. residents. Defense Distributed maintains it has established a vetting procedure to ensure only U.S. residents are able to download them.

In 2019, the Trump administration transferred oversight of gun exports from the State Department to the Commerce Department, which would have rolled back restrictions on releasing 3D-printed gun blueprints. But a second suit filed by the coalition of state attorneys general has kept oversight of the files with the State Department, pending future litigation.

But a second suit filed by the coalition of state attorneys general has kept oversight of the files with the State Department, pending future litigation.

New Jersey Attorney General Gurbir Grewal is a plaintiff in the case. “If a company like Defense Distributed can simply sell printable [gun blueprints] to their customers without running the usual required background checks to make sure someone’s not a criminal, it would blow up the entire regime of firearm laws that we have in this country,” he said.

In 2019, after Grewal sought an injunction to block Defense Distributed from releasing files to New Jersey residents, the company countersued. It alleges that the blueprint files are a form of speech, and that Grewal’s effort to block their release violates the First Amendment. The case has yet to go to trial.

Who is printing guns — and why?The first 3D-printed firearm to make a splash in the popular consciousness was the “Liberator” — a near fully plastic gun designed by a self-described anarchist and ghost-gun advocate named Cody Wilson. (Designs for the Liberator call for a small steel block to be sealed inside the plastic in order to comply with federal law.) Wilson founded Defense Distributed to advance and share the technology, and has initiated many of the group’s highest profile legal battles. In 2019, Wilson was sentenced to probation and ordered to register as a sex offender after soliciting sex from a minor.

(Designs for the Liberator call for a small steel block to be sealed inside the plastic in order to comply with federal law.) Wilson founded Defense Distributed to advance and share the technology, and has initiated many of the group’s highest profile legal battles. In 2019, Wilson was sentenced to probation and ordered to register as a sex offender after soliciting sex from a minor.

Though Wilson’s is the best-known and formally recognized gun printing “company,” the practice is mostly advanced by informal collectives across the internet. These groups, like Deterrence Dispensed and Fosscad, gather anonymously in chat rooms and on social media platforms to crowdsource the development of new gun designs and spread them across the web. They have thousands of members, but remain mostly decentralized, making it difficult for technology companies or law enforcement agencies to police them.

Over the past two years, however, the groups have run up against censorship policies at major tech platforms, many of which prohibit weapons content. As a result, they’ve been forced to increasingly obscure corners of the internet. Most recently, the operations hub for most of the 3D-printed gun groups — an encrypted chat and file-sharing platform called Keybase — pledged to remove all weapons-related content, and told the groups they would be banned.

As a result, they’ve been forced to increasingly obscure corners of the internet. Most recently, the operations hub for most of the 3D-printed gun groups — an encrypted chat and file-sharing platform called Keybase — pledged to remove all weapons-related content, and told the groups they would be banned.

Proponents of the technology fall into several different camps. Some, like Mustafa Kamil, a creator of 3D-printable guns based in Romania, and a member of the Deterrence Dispensed team on Keybase, think that concerns over homemade weapons are overblown. Gun printing, he says, is mostly the domain of hobbyists like himself: technical experts interested in tinkering and engineering. To 3D-print a gun: “you need to have enough money to buy a printer. Then you need enough expertise and experience to know how to use the printer. If your axis is off by 0.15 millimeters the gun isn’t going to work,” he said. “To buy a black market firearm would be much easier.” Kamil said he’s owned 32 printers and completed two apprenticeships with gun manufacturers.

Others see the potential for armed conflict with the government as the driving force behind their creations. Members of Deterrence Dispensed and Defense Distributed have fashioned a brand out of this perceived threat, adopting popular Second Amendment slogans like “Come and Take It,” “Live Free or Die,” and “Free Men Don’t Ask.” Leaders of the groups share a deep conviction that gun ownership is the only way to ensure freedom: In an interview with Popular Front, a conflict journalism outfit, the founder of Deterrence Dispensed — a man who goes by the username jstark — continuously pointed to the threat of government tyranny as a justification for creating 3D-printed guns and distributing their blueprints. “Just look at the Uighurs in China,” he said, referring to the ongoing genocide of the ethnic minority. “Just look what’s happening to them. No one’s helping them. Nobody does shit. You know what would help them? If they were armed. That would be a deterrence.”

To jstark, identical threats exist anywhere where civilians are largely unarmed, including in Europe, where he lives. When asked if he would fight police who tried to confiscate his guns, he was frank: “Basically, yes. Live free, or die. These are not empty words.”

When asked if he would fight police who tried to confiscate his guns, he was frank: “Basically, yes. Live free, or die. These are not empty words.”

While politicians and law enforcement agencies have dubbed the advocates of 3D-printed firearms extremists, the movement has no unifying political ideology. Jstark, for his part, said in the Popular Front interview that Deterrence Dispensed has no tolerance for people who wish to harm others: “If they do show through [their actions] that they’re extremists, racists, islamic terrorists — then we would kick them out immediately,” he said. He did not respond to multiple requests for comment.

The alarmism about about looming government tyranny has attracted groups eager to ignite government conflict, particularly in the U.S. Members of groups connected to the boogaloo, a loose-knit coalition of anti-government extremists that advocates a violent civil war, have seen 3D-printed gun advocates as allies in an overlapping struggle. Last summer, Megan Squire, a professor at Elon University, tracked online boogaloo-connected groups as they navigated crackdowns from social media platforms. Many ended up on Keybase, drawn by the large and growing 3D-printed gun community.

Last summer, Megan Squire, a professor at Elon University, tracked online boogaloo-connected groups as they navigated crackdowns from social media platforms. Many ended up on Keybase, drawn by the large and growing 3D-printed gun community.

In early April, Deterrence Dispensed released blueprints for a printable auto sear — a component that can be used to turn a semiautomatic rifle into an illegal, fully automatic firearm — called the “Yankee Boogle,” an apparent boogaloo reference. In September, two boogaloo adherents were charged for allegedly attempting to sell auto sears to representatives of Hamas, the Islamist extremist group. In court documents, prosecutors alleged that one of the defendants in that case said he obtained the auto sears from a supplier who 3D-printed them. In a separate case, federal prosecutors charged a man from West Virginia with 3D-printing auto sears and selling more than 600 of them online, including to several boogaloo adherents. One man who bought the 3D-printed auto sears is accused of killing a police officer and a security guard in California. It is unclear if any of the auto sears used in these crimes were designed by Deterrence Dispensed.

It is unclear if any of the auto sears used in these crimes were designed by Deterrence Dispensed.

Correction: An earlier version of this article highlighted a case in which police in Rhode Island said a suspect used a 3D-printed gun in a murder. While police initially made that claim, an analysis by the state crime lab later ruled the method of manufacture “undetermined.” The story has also been updated to include that Defense Distributed’s “Liberator” gun model includes a small metal component for federal compliance.

▷ cotton gin 3d models 【 STLFinder 】

(WIP) Cotton gin

thingiverse

#In progress. ... This cotton gin probably will not work properly. If you want to make this, please prepare four bearings. Thank you! ...

Cotton_Ginning

grabcad

a Old type cotton ginning machine

Manual Driven Cotton Ginning Machine

grabcad

This machine is aimed at crashing the cotton seeds and separating crashed seeds from the lint.

Gin-Gin

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_size = 15 Font = write/orbitron.dxf stick_thickness = 3 message = Gin-Gin hole_radius = 2 stick_width = 8 flat_bottom = 1 font_thickness = 6

Sheet Metal Transition - 2 Rectangles to Round

grabcad

Used in cotton gin industry

Cotton

thingiverse

... ...http://www.thingiverse. com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 6 flat_bottom = 1 stick_thickness = 3 font_size = 12 message = Cotton Font = write/orbitron.dxf stick_width = 8 hole_radius = 3

com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 6 flat_bottom = 1 stick_thickness = 3 font_size = 12 message = Cotton Font = write/orbitron.dxf stick_width = 8 hole_radius = 3

Cotton

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 6 flat_bottom = 1 stick_thickness = 3 font_size = 12 message = Cotton Font = write/orbitron.dxf stick_width = 8 hole_radius = 3

cotton

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: hole_radius = 3 stick_width = 8 Font = write/orbitron. dxf stick_thickness = 3 message = cotton font_thickness = 6 flat_bottom = 1 font_size = 12

dxf stick_thickness = 3 message = cotton font_thickness = 6 flat_bottom = 1 font_size = 12

cotton

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: hole_radius = 3 stick_width = 8 Font = write/orbitron.dxf stick_thickness = 3 message = cotton font_thickness = 6 flat_bottom = 1 font_size = 12

Cotton

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: font_thickness = 6 flat_bottom = 1 stick_thickness = 3 font_size = 12 message = Cotton Font = write/orbitron.dxf stick_width = 8 hole_radius = 3

Gin

sketchfab

Japanese board game “Shougi” for 3D printing.

Gin

thingiverse

Customized version of http://www.thingiverse.com/thing:1148986 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1148986

Gin

sketchfab

milk

CE-45-11 Fan

grabcad

Used in the cotton gin industry

Gin Bottle

sketchfab

A simple Gin Bottle Labelled “Tony’s Crow Trees”

GinGer Gin

sketchfab

bottle Design of a Gin produced in Stuttgart.

Kraken Gin

sketchfab

Kraken Gin Bottle. ...Transitional coating, inkjet and screen printing

Gin lamp

pinshape

I printed on FDM ender 3 printer Model content: Gin_lamp_1(160mm) - i printed without generate support option Gin_lamp_2(34mm) - i printed with generate support option

Gin lamp

cults3d

I printed on FDM ender 3 printer Model content: Gin_lamp_1(160mm) - i printed without generate support option Gin_lamp_2(34mm) - i printed with generate support option

Gin Tonic stencil

thingiverse

gin tonic

DISPLAY FOR PISTON GIN

grabcad

DISPLAY FOR PISTON GIN

Gin Cucumber Smiley

thingiverse

Gin Cucumber Smiley

Gin Ichimaru stencil

thingiverse

Gin Ichimaru stencil

PISTON GIN-Bulgaria

grabcad

PISTON GIN-Bulgaria

gin bottle pendant keychain

thingiverse

gin bottle keychain. ...For all who like gin.

...For all who like gin.

Gin Doser/Dosador de Gin 60ml

thingiverse

I designed this with Rene because i wanted a 50ml doser to make gin tonic drinks. We actually made a 60ml so we give it a little margin every time we pour it. On version two we reduced the width of the doser to be 3mm instead of 5mm. ... Upper Inner...

It's gin o'clock

myminifactory

Gin!

Rose Gin Bottle

sketchfab

A simple glass bottle labelled “Romana’s Rose Gin”

N Gin -WIP

sketchfab

Work In Progress of N-Gin, villain from Crash Bandicoot

GIN Botanicals Holder

thingiverse

These holders are for glass containers from Gin Botanicals. ...You can get it from amazon

https://amzn.to/2wTUWaA

(xD #advertising, but it tastes really good)

...You can get it from amazon

https://amzn.to/2wTUWaA

(xD #advertising, but it tastes really good)

how 3D food printers can help you maintain a healthy diet April 24, 2018, 23:54

Anastasia Ksenofontova

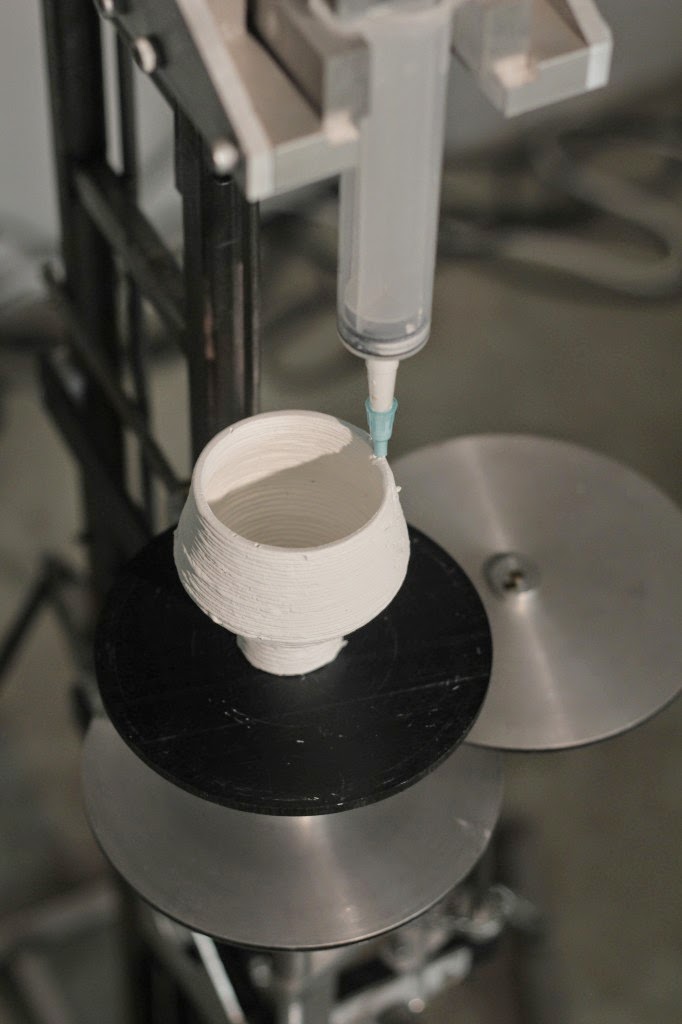

Scientists from Ewha Women's University (South Korea) have created a 3D printer that prints products with a given nutrient content and predetermined taste properties. The author of the development, Jin-Kyu Lee, presented his invention on April 24, 2018 at the annual meeting of the American Society for Biochemistry and Molecular Biology in San Diego. About the prospect of using "smart" food - in the material RT.

from 3 d- Products up to 3 D- kitchens

South Korean university of the NIGHA Women's University developed a 3D printer that turns powder ingredients into full-fledged food products with a given content of nutritional substances predetermined taste properties.

Related

A spoon for the Earth: how a healthy diet can improve the ecology of the planet

June 2 is Healthy Eating Day. Research scientists show that changing eating habits and accustoming yourself to the right...

Key nutrients (such as carbohydrates and proteins) are ground into powder at a temperature of -100 °C. Then the resulting raw material is heated and turns into a porous film. After that, a three-dimensional product is created from several layers of films. The uniqueness of the development lies in the fact that by combining films with different content of proteins, carbohydrates, trace elements and vitamins, you can get a product saturated with nutrients in the required proportion. In addition, you can experiment with the flavor palette of the product, combining, for example, powdered pear and apple.

“We believe that one day anyone will be able to purchase cartridges containing powdered analogues of various ingredients that can be “collected” together using 3D printing and prepared a “dish” according to individual needs and preferences,” said the author of the development, the researcher from Ewha Women's University Jin-Kyu Lee.

A balanced diet

The developers believe the new technology will significantly reduce the amount of food waste and the financial costs of storing and transporting food. Also, according to scientists, their invention will help meet the food needs of the growing population of the planet. According to the Food and Agriculture Organization of the United Nations, by 2050 the world's population will increase from the current 7.6 billion people to 9.8 billion, and in 2100 it will reach 11.2 billion.

“If a family gets a 3D printer, then they don't have to be afraid of hunger. Of course, we are only at the beginning of the journey. We continue to optimize our development to create customized products that last longer than usual,” said Jin-Kyu Lee.

- © 3D Systems Corporation

The first 3D food printers appeared in 2015 and could only prepare simple meals. One of these devices works in the FoodInk 3D kitchen restaurant, opened in London in 2016. Everything in this establishment - from food to furniture and cutlery - is created on a 3D printer. The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse.

One of these devices works in the FoodInk 3D kitchen restaurant, opened in London in 2016. Everything in this establishment - from food to furniture and cutlery - is created on a 3D printer. The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse.

According to Russian nutritionists, the development of Korean scientists will help people maintain a balanced diet. However, experts emphasize that it is not worth doing “self-healing” with the help of a 3D printer - first you need to seek advice from a specialist.

“On complex developments that provide for a certain nutrient content, a person will not last long. In addition, it deprives him of the pleasure of eating. Such 3D food can be balanced and healthy, but quickly get bored. And of course, it’s better not to prescribe a diet for yourself, but to turn to a competent nutritionist who will make up a diet based on the state of your body, ”said Alla Pogozheva, professor at the Research Institute of Nutrition of the Russian Academy of Medical Sciences, in an interview with RT.

Russian developments

“In Russia, printers for printing products are not yet manufactured. For now, they remain a luxury item. However, in ten years, printers for printing products will most likely become more affordable for the average consumer, ”said Alexander Vinogradov, director of the chemical and biological cluster at ITMO University, in an interview with RT.

Related

"Printed" organ: Chinese scientists have grown and transplanted auricles to five children at once

Scientists from China have grown new ears for five children born with microtia - insufficient development or complete absence of the ear...

At the same time, 3D printing methods are actively developing in Russia, but in a more fundamental direction. So, domestic researchers from the Federal Research Center "Crystallography and Photonics" of the Russian Academy of Sciences developed in April 2018 the first 3D printer that immediately creates a three-dimensional structure. The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs.

The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs.

And scientists from Tomsk Polytechnic University use 3D printing technologies to develop the space industry. They made the first nanosatellite, the body of which is printed on a 3D printer, and they are also creating a printer for work on the ISS, which will help astronauts print the necessary part in the event of a breakdown. In addition, improved technology will make it possible to build bases and stations on the Moon using lunar soil as a material for three-dimensional printing.

An American who dreams of crushing the world order has tested a "epoch-making" weapon he created on a 3D printer (VIDEO)

YouTube

25-year-old American Cody Wilson is the inventor of a groundbreaking and frightening project. He printed a full-fledged model of a pistol on a 3D printer and was the first to test an innovative weapon. Now the drawings of this pistol can be found on the Web, every Internet user and the owner of a 3D printer can download and create their own weapons from them. Since the parts are plastic, weapons that shoot with real cartridges are not caught by metal detectors. The American authorities have begun to crack down on the spread of the blueprints, which have already been downloaded over a hundred thousand times.

Now the drawings of this pistol can be found on the Web, every Internet user and the owner of a 3D printer can download and create their own weapons from them. Since the parts are plastic, weapons that shoot with real cartridges are not caught by metal detectors. The American authorities have begun to crack down on the spread of the blueprints, which have already been downloaded over a hundred thousand times.

According to Forbes , Wilson spent more than a year perfecting his brainchild, which he named "Liberator" (Liberator) in honor of the cheap single-shot pistols of the Second World War. Unlike the steel original, Wilson's pistol is almost entirely made of thermoplastic: 15 of the 16 parts of the weapon are made from this material.

- The author has already been promised to be shot with his own pistol

- USA demands removal of pistol drawings from the network

All printed on a used $8,000 Stratasys Dimension industrial 3D printer. The developer made an exception for the striker, which was used as an ordinary nail. It took four hours to print the largest part. The pistol fires real 9x17mm bullets.

The developer made an exception for the striker, which was used as an ordinary nail. It took four hours to print the largest part. The pistol fires real 9x17mm bullets.

In August 2012, Wilson, a University of Texas student and radical libertarian anarchist, co-founded the Austin nonprofit Defense Distributed to implement a 3D weapon project available to anyone. Digital drawings of the pistol, which in the drafts the creator called Wiki Weapon , can be found on the net and downloaded by every Internet user.

This not only calls into question the existing parameters of the regulation of the arms market, but also exacerbates the conflict between the state and supporters of a free society. "You can print a deadly device. It sounds scary, but that's our goal. Wherever there is a computer and the Internet, users will have access to weapons," explains Wilson.

On May 1, 2013, he assembled the Liberator parts for the first time and agreed to have a Forbes photographer capture the components on camera. A day later, the pistol passed its first marksmanship test at a private property about an hour from Austin.

A day later, the pistol passed its first marksmanship test at a private property about an hour from Austin.

The verdict is this thing works. The pistol fired a standard 9x17 cartridge without any visible technical flaws. True, the first misfire also happened: the striker did not hit the primer and instead of a shot, only a dull thud was heard.

So far, the technology of weapons allows the use of only cartridges of a certain caliber. When Wilson tried to load the 5.7x28mm into the pistol, the Liberator simply exploded when the trigger was pressed. So the debut tests of the invention ended "lethally".

Wilson raised funds for the project using the digital currency Bitcoin, in which 99% of Defense Distributed's assets are accumulated today. In March, the group received a federal license to manufacture weapons.

The goal of Defense Distributed is to adapt the technology to more affordable printer models, like Makerbot's $2,200 Replicator and the even cheaper RepRap, made by enthusiasts and using free software. In case of damage to the barrel, Wilson has a way out: his pistol uses a removable barrel that can be changed within a few seconds.

In case of damage to the barrel, Wilson has a way out: his pistol uses a removable barrel that can be changed within a few seconds.

Take it with you wherever you want

Reporters from The Daily Mail tested the experiment by carrying a handgun made according to Wilson's designs on the Eurostar train, famous for its high level of safety, without any obstacles.

Metal detectors did not react to plastic parts in any way. Reporters assembled weapons from parts printed on a printer right in the toilet of the train.

The author has already been promised to be shot with his own weapon

The figure of Wilson, in connection with the growing arsenal of his inventions, is increasingly criticized. Many opponents emphasize the enthusiasm of the leader of the group, which today brings together about 15 volunteers - designers and engineers - around the world. The ambitious libertarian has already received a dozen death threats, and often anonymous spiteful critics promise to shoot the demiurge of a 3D weapon from his own brainchild.

Wired Magazine even listed Wilson as one of the 15 most dangerous people in the world. The Coalition to Stop Gun Violence labeled the inventor as an "ardent rebel" and advocate for anti-state violence. "This guy is actually sending the signal 'print your own guns and be prepared to kill civil servants'," spokesman Ladd Everitt said. “The fact that we still don’t talk about it in those terms even after the Boston bombing is unimaginable.”

Wilson dismisses suspicions of a desire to organize a rebellion. He sees the global goal of his activity in demonstrating the advantages of technology over the desire of the state to regulate the circulation of weapons. Ultimately, people must realize the helplessness and uselessness of the authorities in their current form. “We need to inspire the population to build their own independent space. The government will increasingly find itself overboard in private life and babble there: “Hey, wait a minute,” the inventor argues. “This is the beginning of a new order on the ruins of the old order.