House built using 3d printer

3D Printed Houses: Top Projects from Around the World

3D printing news News 3D Printed Houses: A Closer Look at Completed Projects from Around the World

Published on July 29, 2022 by Carlota V.

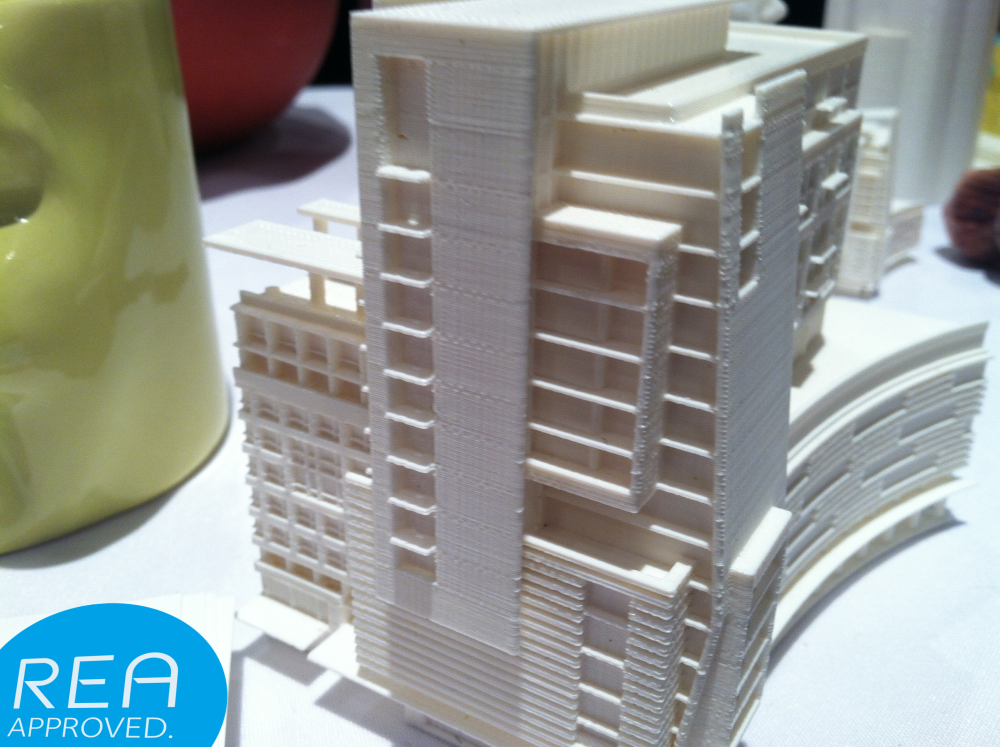

As you may know, additive manufacturing is becoming increasingly important in the construction market. The new technologies make it possible to create more complex shapes, build walls faster, and reduce labor costs. Many construction companies have already started to 3D print buildings or houses. Be careful, however, with the term 3D printed house: In most cases, only the walls are made by a 3D concrete printer, that prints them layer by layer. That in itself is already quite an innovation that has made it possible to build homes in hard-to-reach, disadvantaged, or conflicted areas. These days, we are starting to see more and more 3D-printed houses being inaugurated and the first families are starting to move in. Yet, at this point, it is still difficult to assess the sustainability of such a structure, and only time will show if this manufacturing method is more viable altogether. However, we can already share with you some 3D printed house-projects that have been completed around the world.

A 3D Printed House in Japan

In less than 24 hours and for less than $25,500, the company Serendix designed this small house with 3D printed walls. Even if it’s hard to imagine that anyone could live in it, the project is still interesting and shows all the agility of 3D concrete printing. With a surface area of only 10 square meters, the structure has a honeycomb shape and no reinforcements. Serendix’s objective is to create emergency housing in times of crisis, as earthquakes and typhoons regularly hit the country. It took three hours to assemble the different 3D printed parts and a total of 23 hours and 12 minutes to get the final result.

Alquist 3D and the Virginia Project

U.S.-based Alquist 3D recently announced the launch of one of its new projects for 3D printing homes. Located in the state of Virginia, the 200 homes that make up the project will be created through additive manufacturing with the aim of reducing the overall cost of infrastructure in communities with economic problems. According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

The Fibonacci House, the First 3D Printed House on Airbnb

The next house on our list is interesting not just for its design but because it holds the distinction of being the first fully 3D printed house to be listed on Airbnb. Twente Additive Manufacturing (TAM), one of the leading companies in concrete 3D printing, created this home in a spiral shape following the Fibonacci sequence, a famous mathematic sequence also known as the golden ratio that often occurs naturally, giving the home its name. The spiral allows for the progression of space from the wide-open exterior to the closed and warmer space in the tightest part of the spiral. The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

Mvule Gardens is Africa’s Largest 3D Printed Housing Project

Continuing the trend of 3D printed houses being used for affordable housing, Mvule Gardens is a neighborhood consisting of 52 houses, it is Africa’s largest 3D printed affordable housing project. Built by 14Trees, a joint venture between Holcim, a global leader in sustainable construction solutions, and CDC Group, the UK Government’s impact investor, the project hopes to address the housing shortage in Kenya. The homes were built using the BOD2 printer from COBOD and a 3D printable dry mortar called TectorPrint from Holcim, ensuring that the houses are adequately strong and can be made with a reduced carbon footprint. Both two-bedroom and three-bedroom homes are available and 14Trees notes that they hope they will help to make green, low-income and affordable housing a reality for Africa.

Azure 3D Printed Homes for Sustainable Construction

With the goal to develop homes faster, more economically, and with less environmental impact, Ross Maguire and Gene Eidelman brought Azure 3D Printed Homes to life in 2019. By combining years of experience in building and developing properties all over the world, the company has already been able to 3D print several environmentally friendly houses. The company uses recycled waste materials to create the structure of the houses, which are then produced with a large-scale 3D printer in only 24 hours. Azure 3D Printed Homes offers a variety of backyard offices and homes, one example is its Azure Marina Model. This 360 SQ/FT studio consists of a bedroom, kitchen, and bathroom, and can be customized and ordered on the company’s website.

Habitat for Humanity Uses AM For Homes in Low-Income Areas

Atlanta-based nonprofit organization Habitat for Humanity has been able to support millions of people all over the world by helping to construct and preserve houses and shelters. Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

House 1.0, Europe’s First 3D Printed Tiny House

The House 1.0 is the first 3D-printed Tiny House in Europe. It was made by Danish 3D printing startup 3DCP Group using concrete 3D printers. The company’s goal with this house is to build better, faster, greener, and reduce the amount of effort required in the construction process. The Tiny House is designed to be as cost-effective as possible and to provide owners with all the necessary amenities despite its small size of only 37 m2.

SQ4D Puts the First 3D Printed House on the Market

SQ4D is a company that has completed the construction of the world’s largest known 3D printed house. The house, which was printed and built entirely on-site, is approximately 180 m2 in size and required only forty-eight hours of printing time, which was spread over a period of eight days. The materials used in the manufacturing process had a total value of less than $6000. The company continues to strive for innovation and plans to cut the printing time in half for subsequent projects in the future.

Prvok, the 3D Printed Houses in the Czech Republic

Whether in the countryside, in the city, or even on water, the 3D-printed house called Prvok was born in the Czech Republic and was created through the collaboration of Buřinka, a visionary company from the construction sector, and sculptor Michael Trpák. Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Viliaprint, the Project Combining AM and Conventional Construction

This project combines additive manufacturing and conventional techniques for building houses. The project called Viliaprint was inaugurated in June of this year in the French city of Reims, more precisely in the eco-district there called Réma’Vert. A total of five houses, with each having living spaces ranging from 77 to 108 m2, were built thanks to the collaboration of stakeholders. The promising project aims at improvements in social, economic, and sustainable aspects. In the 3D printing process, which did not take place directly on site, the designers behind the 3D printed homes placed particular emphasis on concrete that dries as quickly as possible after each layer is applied so that it can hold its own weight.

COBOD and PERI Partner for Incredible Houses Build Using AM

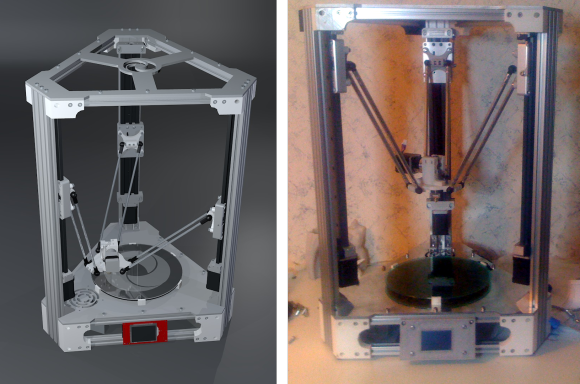

PERI is a company founded in 1969. In 2018, the group acquired a minority stake in COBOD, a leader in 3D design, and since then the two companies have been working together. In 2020, they built the first 3D-printed house in Germany and the largest apartment building in Europe. The house, printed in the Rhineland region of North Westphalia, is a 160-square-meter, two-story single-family home with three-layer insulated cavity walls. The COBOD BOD2 printer was used for the construction, which is characterized by its ability to extrude concrete at a speed of up to 100 cm per second, resulting in the desired project size, smooth and straight walls, and the highest quality requirements. With the CODOB printer, it is possible to build up to 300 square meters on 3 floors at an unprecedented speed. PERI firmly believes that 3D printing will one day, revolutionize the construction industry.

Project Milestone, the 5 3D Printed Homes in the Netherlands

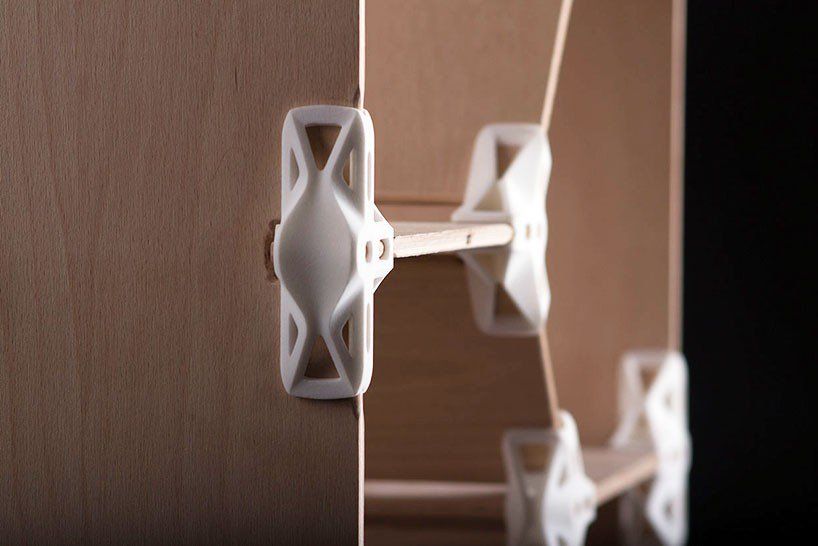

This next housing project is located in the city of Eindhoven in the Netherlands. It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

What do you think of these different projects? What is the impact of 3D printing in the construction sector? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Companies using 3D printing to build houses at half the cost

Home

A 3D printer can build the walls of a house in as little as two days versus weeks or months with traditional construction materials.

/ Source: TODAY

By Ronnie Koenig

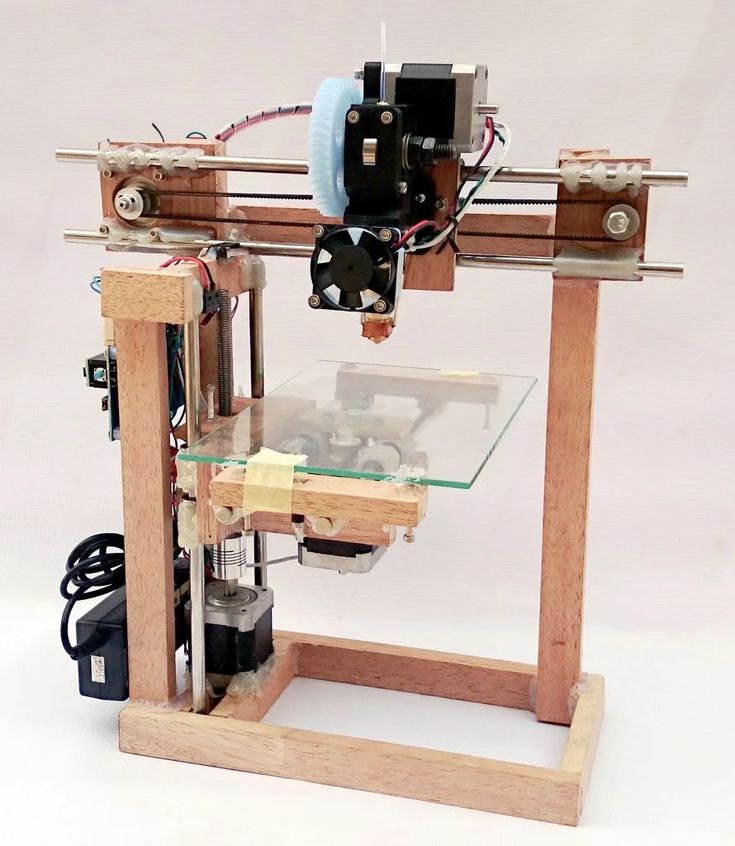

3D printing technology has led to the creation of an amazing array of three-dimensional objects and now it's being used to create something on a much larger scale — the house of your dreams.

The future of home building may be headed toward a 3D printing revolution with the technology being used to build homes at half the time and at half the price of traditional construction. It just might be an emerging market that builders and buyers simply cannot ignore.

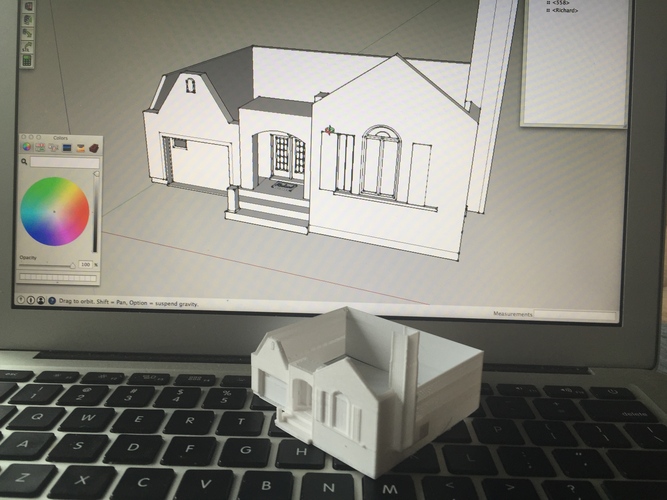

Jason Ballard, co-founder and CEO of ICON, a construction technologies company that uses 3D printing to create homes, told Weekend TODAY that picking out the house you want can be as simple as selecting a design and pushing print.

Check out the 3D printer in action: pic.twitter.com/TQkrV8BFWr

— TODAY (@TODAYshow) May 1, 2021

- Watch TODAY All Day! Get the best news, information and inspiration from TODAY, all day long.

- Sign up for the TODAY Newsletter!

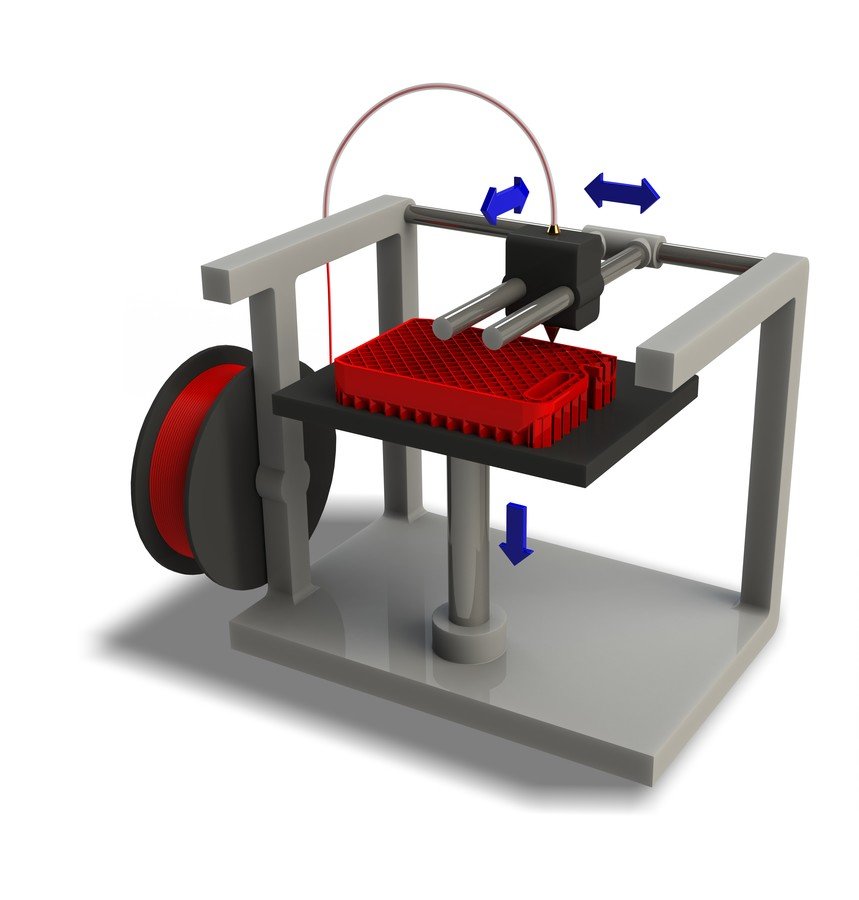

"3D printing is taking a digital file of a house design and layer by layer, depositing material to build up the house in three dimensions, one layer at a time," Ballard told NBC's Kathy Park.

And unlike traditional homes, which can take weeks or even months to frame out, the walls and foundation of a 3D-printed home can be ready in as little as two days, with only a three or four person crew. All of these factors brings the production costs of a 3D-printed house down to as little as $4,000 per unit.

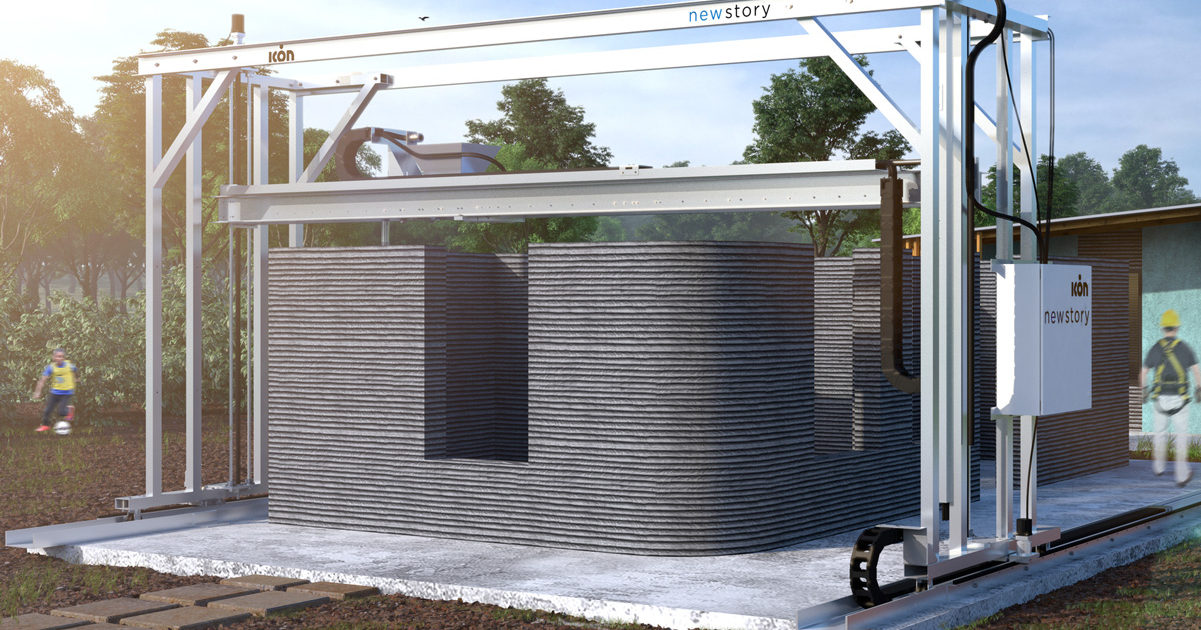

3D-printed homes are a cost-effective way to build from the ground up. Production costs for one 3D-printed home can be as low as $4,000.TODAYCompanies like ICON are creating homes from the ground up, using a massive printer and a special concrete formula. The proprietary concrete used to make the homes is inherently resilient and this cost-effective yet sturdy construction could help make homes nationwide more affordable, making it a major contender in the fight against homelessness and the effects of climate change.

"My hometown's been destroyed multiple times by hurricanes and tropical storms," said Ballard. "I've spent Christmas in a FEMA trailer. An ounce of prevention is worth a pound of cure," he added, pointing out that it takes a lot of money and time for a town to try and recover from disasters.

3D printing might be a solution for the country's housing shortage and homeless crisis.TODAYICON built the nation's first community of 3D homes in Austin, Texas to uplift the local homeless population.

Tim Shea was the first person to move in.

"I could never have imagined from where I came from that I would ever have this beautiful a place to live in," he told TODAY. "I'm so thankful."

Austin resident Tim Shea is grateful to live in a 3D-printed home.TODAY3D homes are starting to hit the wider market. On Long Island, New York, SQ4D constructed the first 3D-printed home for sale to the public.

"We're trying to build houses in half the time for half the price," SQ4D's director of operations Kirk Andersen said. "Our profits will be higher and we'll be able to show that with more projects that we do."

A three-bedroom, 2-bathroom house built in just two days using 3D printing technology was listed for just under $300,000 — approximately half the cost of a comparable home in the same area. Offers poured in by the thousands.

"It's just impossible to find anything at this price," said potential buyer Mitch Johnson.

"And this quality," added Patty Johnson.

And with a housing shortage and a labor shortage, it seems that 3D-printed homes couldn't have come at a better time.

Ronnie Koenig

Ronnie Koenig is a writer for TODAY.com, covering the food and pop culture beats. She also writes about health and wellness, parenting and relationships for NBC Better and TMRW x TODAY, serves as a senior editor for New Jersey Family, and contributes to The New York Times and Real Simple. She is a graduate of Barnard College and a mom of twins.

What Europe's first fully 3D printed house looks like

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Project Milestone

Europe's first fully 3D printed home welcomes its new occupants, a couple from Amsterdam

What's happening

What it means

The creation of the first fully 3D printed house in the Netherlands is just the beginning of a new phase in the industry. Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

In addition, in an era of global concern about the state of the environment, such "green" technologies help to reduce environmental damage to the environment - with 3D printing, the consumption of cement and waste of building materials is much less than with "traditional" construction.

Finally, with the help of a 3D printer, almost any design idea can be realized, which will allow you to move away from the concept of residential buildings in the form of "concrete boxes". The development of this technology makes it possible to erect buildings of such forms that are difficult and expensive to build using traditional methods.

The technology of printing houses on a 3D printer is actively developing in Russia, France, the USA and other countries. It is assumed that this will help solve the problem of providing citizens with affordable and decent housing.

Updated on 07/30/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

How much does a 3D printed house cost?

3DPrintStory News How much does a 3D printed house cost?

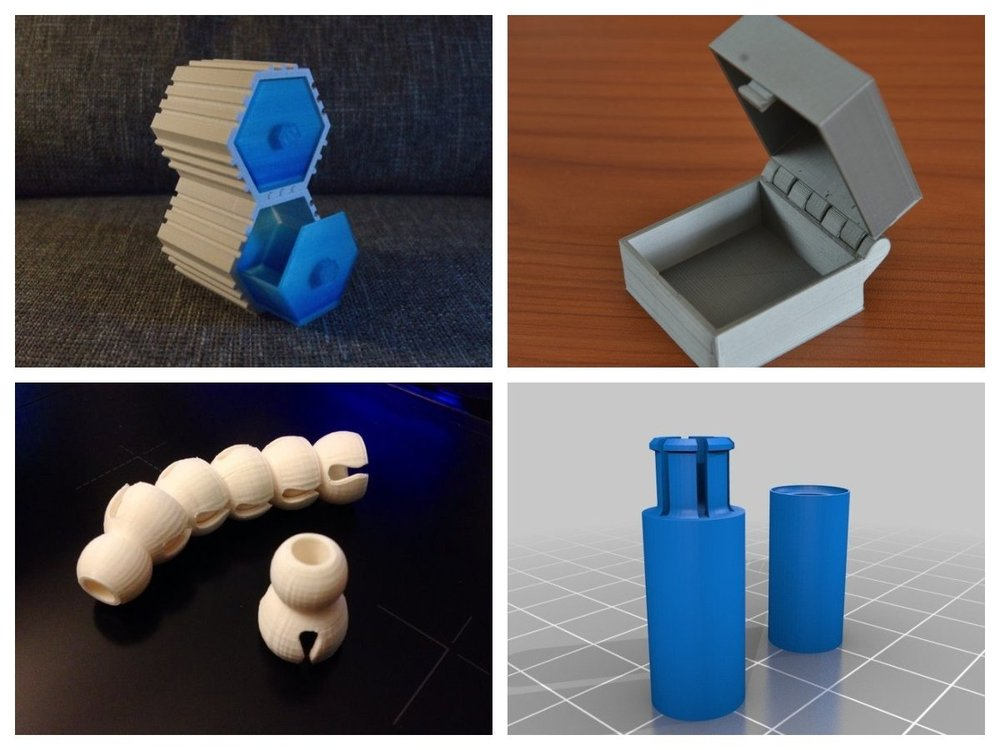

Every new innovation comes to market with a price. For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

Since there are a number of 3D printed building projects around the world, it is impossible to give an exact price for a 3D printed house. Instead, we'll take a look at some of the most recent and promising projects and their prices.

However, in general, jumping ahead a bit, you'll see that a 3D printed house can cost as little as $10,000, sometimes less. Let's take a look!

Example 1 Apis Cor house

One rather promising project from Russia. Apis Cor is a Russian company that specializes in the development of a mobile 3D construction printer capable of printing entire buildings on the spot.

Apis Cor built a 410 square foot home to showcase the potential and capabilities of its mobile 3D construction printer. The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house.

The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house.

Here is a more detailed list of costs, according to the company's website:

- Foundation: $277

- Walls: $1624

- Floor and roof: $2434

- Wiring: $242

- Windows and doors: 3 $

- Exterior: $831

- Interior (including stretch ceiling): $1,178.

The company even decorated the house both inside and out. The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like.

Example 2. Is ICON a house for less than $4,000?

Look at the picture above. This house was 3D printed by Texas-based ICON.

ICON specializes in low cost building solutions, so their main project is a 3D printed house.

In partnership with New Story, a non-profit organization, ICON plans to build an entire block of these affordable 3D printed houses in El Salvador. The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions.

The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions.

A prototype 3D printed house cost about $10,000, but the company claims it can bring that down to $4,000, which is amazing and impressive news. The approximate assembly time for such a house from ICON is approximately 24 hours.

Example 3 Winsum - 10 houses in one day

Shanghai-based Winsun became famous in 2014 by reaching the 3D printing milestone of 10 houses in just one day!

Winsun used large concrete 3D printers, 10 meters wide and 6.6 meters high. The company said that each 3D printed house costs $4,800, which is surprisingly low for 2014!

Although Winsun's 3D houses are not as exquisite, they have generated a lot of public interest. This project has definitely contributed to the increase in the number of houses made with 3D printers and the development of 3D printers themselves for their production.

Winsun is also known for producing one of the most advanced 3D printed buildings to date, which we will discuss in the next section. ..

Example 4 Office Building in Dubai in the world, printed on a 3D printer. What it is? Beautiful and futuristic office building in Dubai.

The entire 3D printing process took Winsun only 17 days. Up to this point, we have mentioned fairly cheap 3D printed houses, but this building was clearly more expensive - around $140,000. However, compared to what it would have cost had it not been 3D printed, the final price is impressively low.

Conclusions

As we mentioned above, it is difficult to give an exact price for 3D printing at home, since the price depends on the size and complexity of the design.

But keep in mind that these days you can 3D print a house for as little as $4,000. This price covers the frame of the house (base, walls, roof) and, in some cases, wiring.

As you may have noticed, the cost of an office building in Dubai is quite high compared to cheaper and smaller 3D printed houses. For high-tech concrete 3D printed projects, expect construction costs to be around $100,000, which is actually quite low compared to the cost of building the same building using traditional building techniques.