Msu library 3d printer

3D Printing | Hollander Makerspace

| X We are excited to announce that we have moved to a new catalog. The old catalog will no longer be available beginning October 1st. Please report any problems you may experience to Discovery Services by calling (517) 353-8700 or by filling out our feedback form. Note: Borrowing from other Michigan libraries through MeLCat continues to be suspended until further notice. To learn more information, please see our FAQ page and our policy on Personal Data Collection and Usage for Library Accounts. |

Selma D. & Stanley C. Hollander

MakeCentral Makerspace

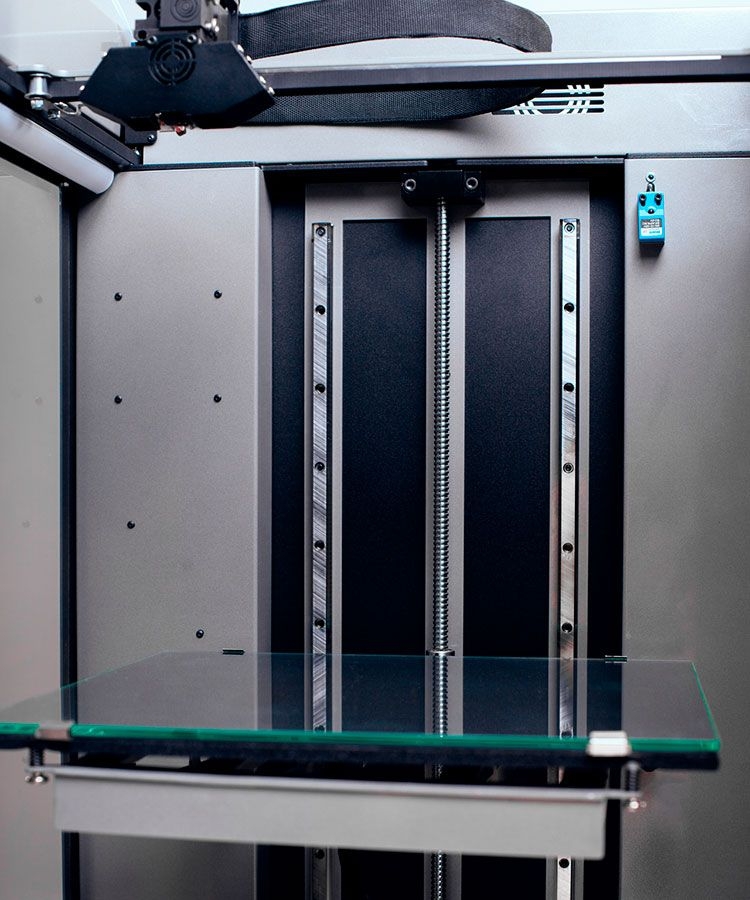

Prusa MK3s

AboutUltimaker S5

AboutPolymaker: Polysher

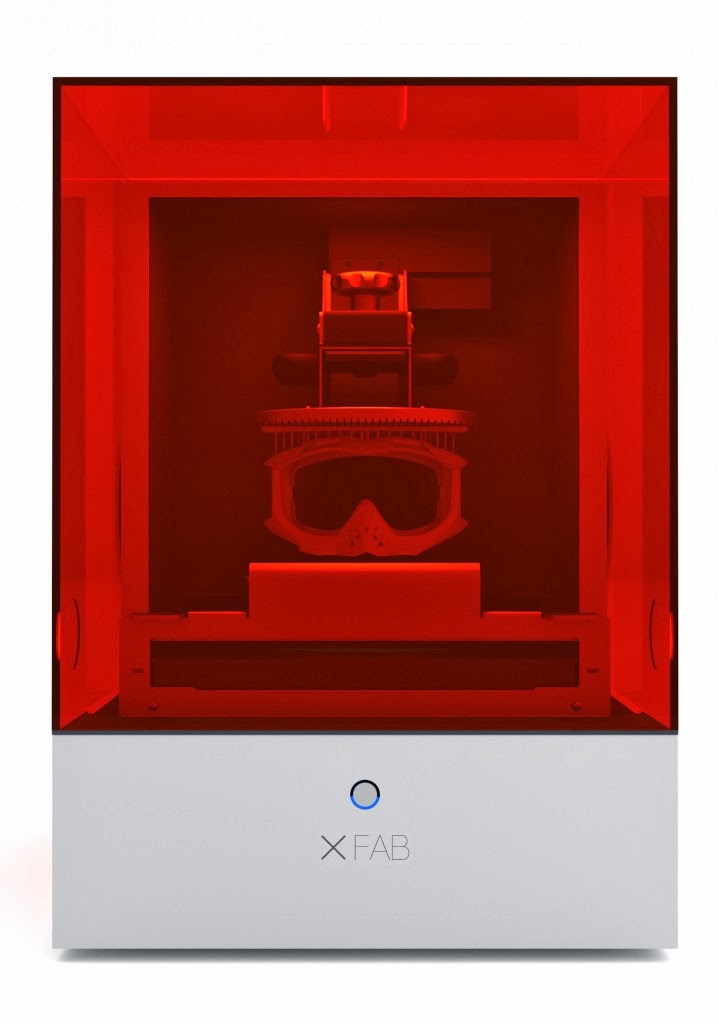

AboutPeopoly Phenom L

AboutPeopoly Moai 130

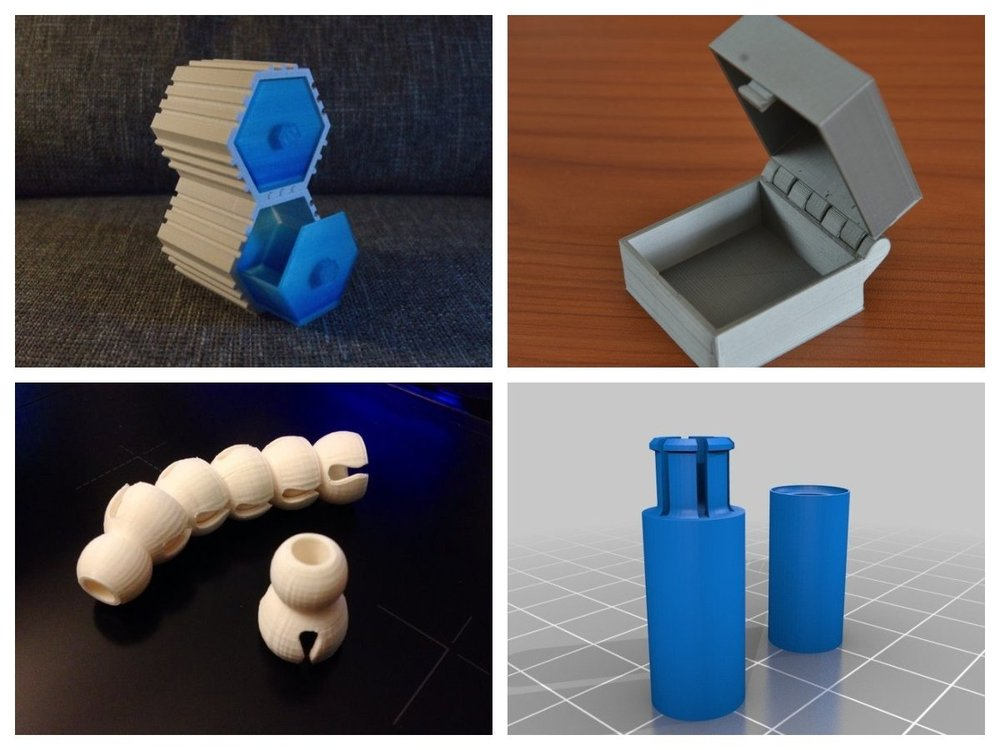

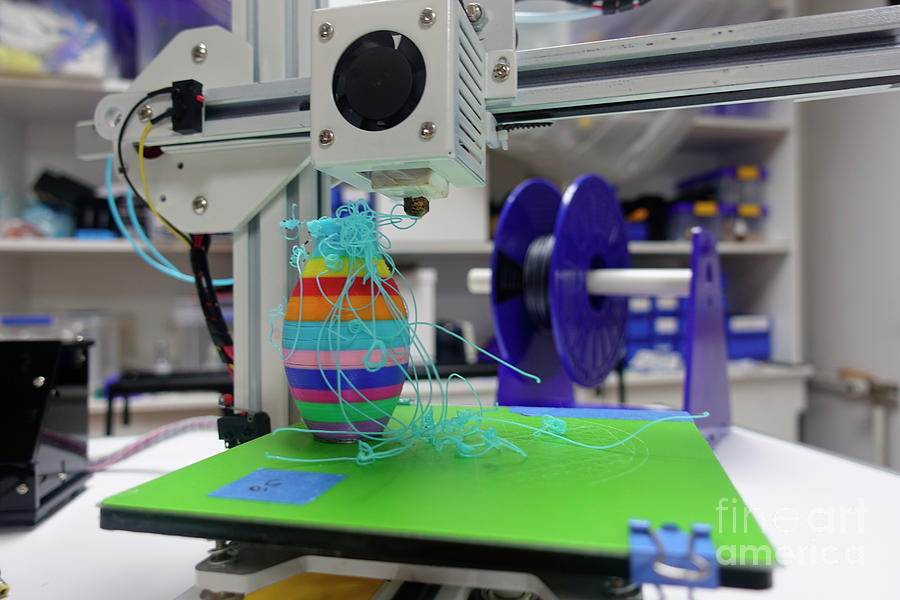

About Welcome to the wonderful world of 3D Printing! Whether you design your own object through software such as TinkerCad or find it on a website like Thingiverse, we can help bring what's on your screen into the real world.

Save your object as an .STL, upload your file to Make At State, and add it to your cart (green icon). Next you can select your desired printer, material, color, dimensions, and pick up option. Please add additional specifications to the notes field. You will get an email with a price quote and estimated delivery date. Once you pay, we can start printing your object. Your print might be completed before or after the estimated delivery date based on factors such as current demand, unexpected delays, printer errors, and when the price was approved.

You can select which 3D printer you would like to have your object printed on based on information provided below, or our staff can determine which machine would be most efficient for your object. Cost is based on the final weight of the object (support material included) and the material used. Prices can fluctuate depending on the material used in the process with a minimum cost of $3.00 per order.

| Type of Print: | Price per gram: |

|---|---|

| PLA | $0. 20 20 |

| ASA, PVB | $0.25 |

| PETG, TPU | $0.30 |

| Resin | $0.50 |

Equipment:

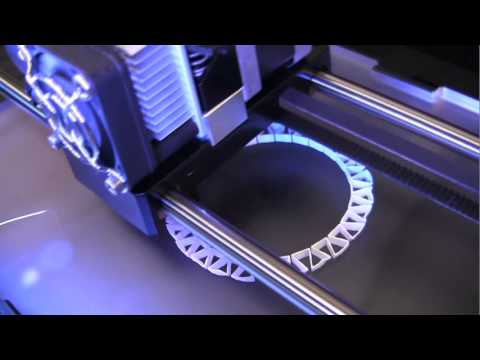

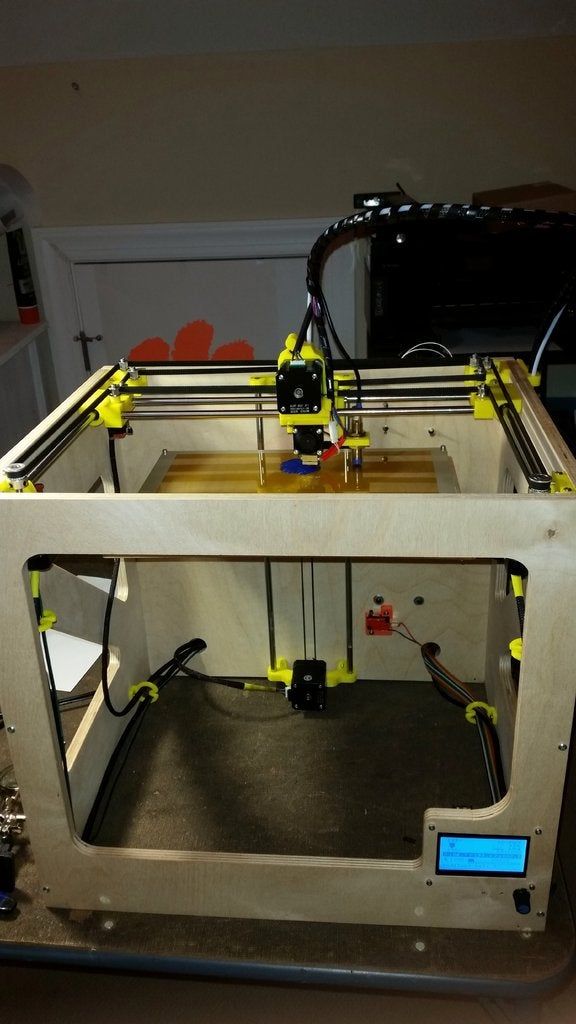

Prusa MK3S

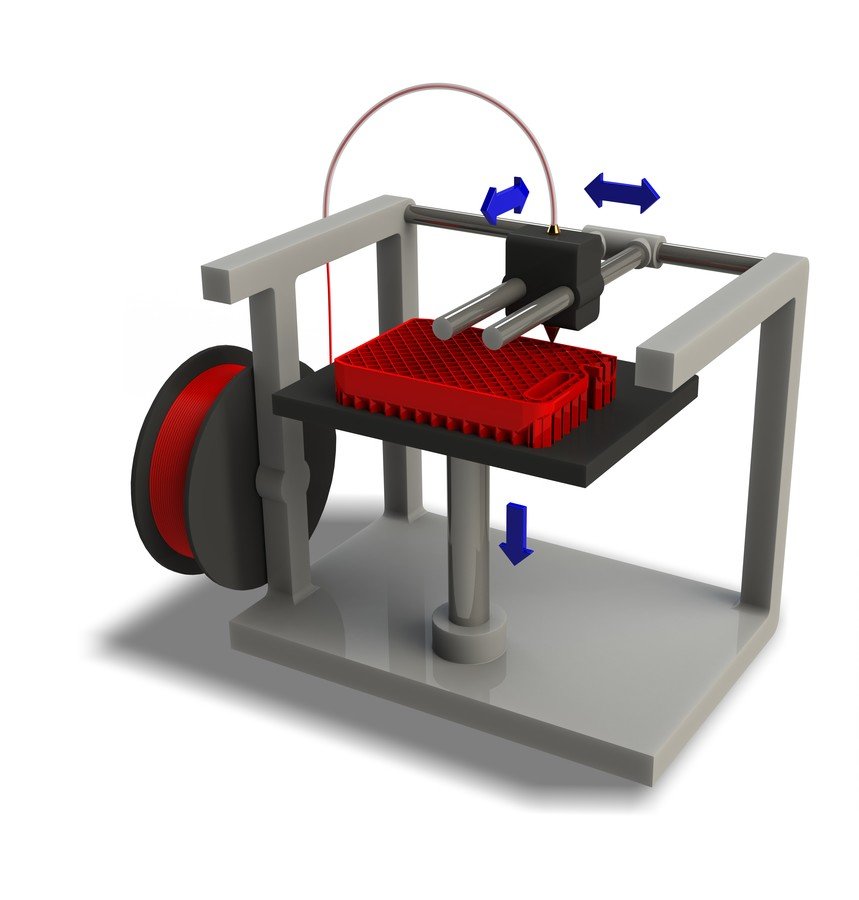

- Printer type: FDM (fused deposition modeling)

- Material: PLA - melting point of 215°C

- Build area dimensions: 9.8in x 8.1in x 8.1in

- Print quality: dynamic (0.15mm)

- Print price: $0.20 per gram; $3.00 minimum

The Prusa is best for mid-range prints, capable of covering a variety of designs and sizes.

Regular PLA

Black Red Green White Yellow Orange Blue LightGrey Dark

Grey Purple

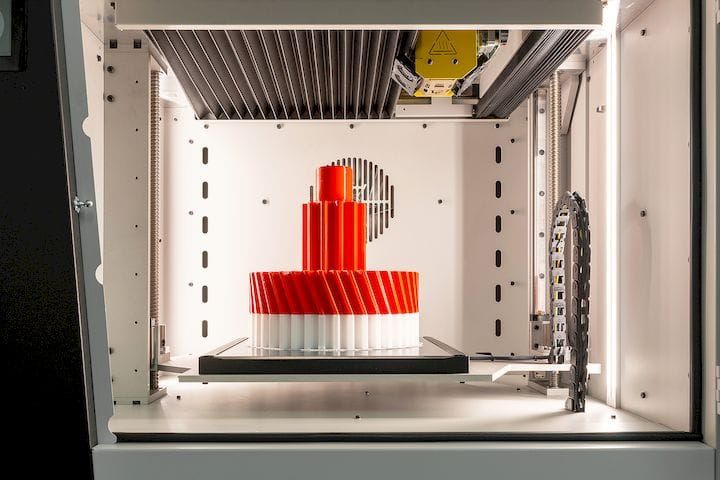

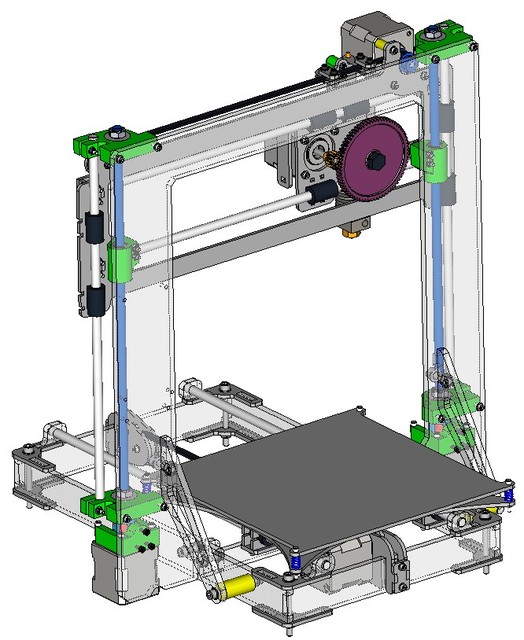

Ultimaker S5

- Printer type: FDM (fused deposition modeling)

- Material:

- PLA - melting point of 215°C

- ASA - melting point of 250°C

- PETG - melting point of 250°C

- Build area dimensions: 12.

9in x 9.4in x 11.7in

9in x 9.4in x 11.7in - Print quality: dynamic (0.15mm)

- Print price: $0.20-$0.30 per gram; $3.00 minimum

Large enough to handle most prints, the Ultimaker also provides the option of water-soluble supports, making it capable of printing complex designs that would be difficult to produce using standard breakaway supports.

Ultimaker Nylon

ClearUltimaker TPU

BlackUltimaker PETG

White BlackUltimaker PLA

Black Red Green White Yellow Orange BlueUltimaker ASA

Black White Grey NaturalIvory

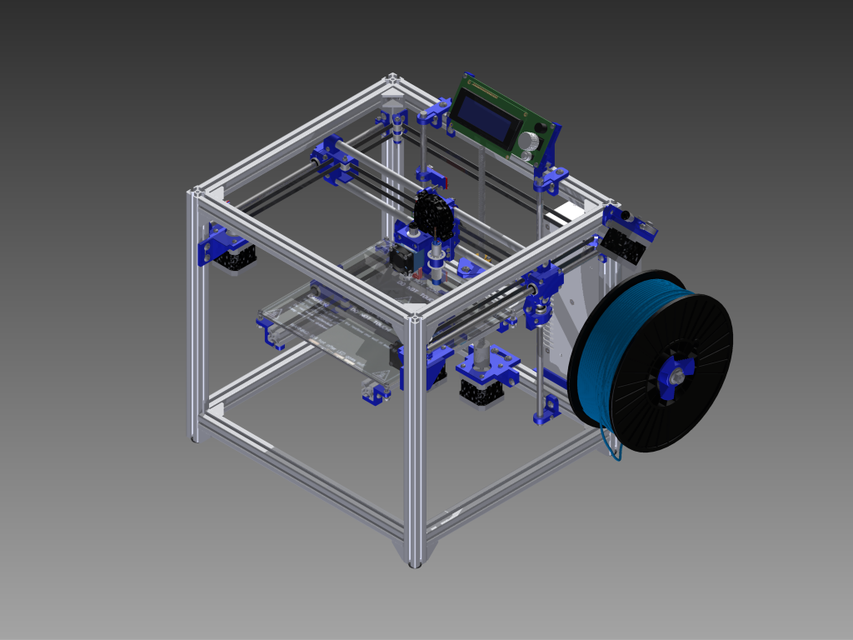

Polymaker: Polysher

Rates:

Cost is based on the final weight of the object (support material included) and the material used. Prints using PVB are $0.25 per gram with a minimum cost of $3.00 per order.

- Printer type: FDM (fused deposition modeling)

- Printer brand: Ultimaker

- Material: Polysmooth PVB

- Maximum part size: 5.

9in x 5.9in x 7.1in

9in x 5.9in x 7.1in - This process adds a minimum of 24 hours to the turnaround time of a print

- All jobs must be submitted through Make At State

The Polysher is a unique post-processing service that eliminates layer lines from items printed with PVB. Due to its sleek and glossy finish, this is a great option for artistic models and decorative parts. While the final product is not resistant to water or chemicals, it can serve as a more professional looking prototype.

Materials:

The Makerspace currently offers a limited range of colors that are compatible with the Polysher. These colors include clear, blue, green, teal, red, white, blue-grey, and black.

Peopoly Phenom L

- Printer type: MSLA (masked stereolithography)

- Material: Resin

- Build area dimensions: 13.6in x 7.6in x 15.7in

- Print quality: ultrafine (0.

09mm)

09mm) - Print price: $0.50 per milliliter, $3.00 minimum

The Phenom creates high quality detailed prints faster and larger than the Moai! The print quality is extremely fine with very few visible print lines. This printer is best used for small, highly detailed objects or large but hollow prints.

Peopoly Moai 130

- Printer type: SLA (stereolithography)

- Material: Resin

- Build area dimensions: 5in x 5in x 7in

- Print quality: ultrafine (0.05mm)

- Print price: $0.50 per milliliter

Allowing for highly-detailed prints, the Moai produces extremely fine pieces with very few visible print lines. Due to its limited printing area and the delicate nature of resin, it is best used for small projects.

**No longer providing ABS or nylon**

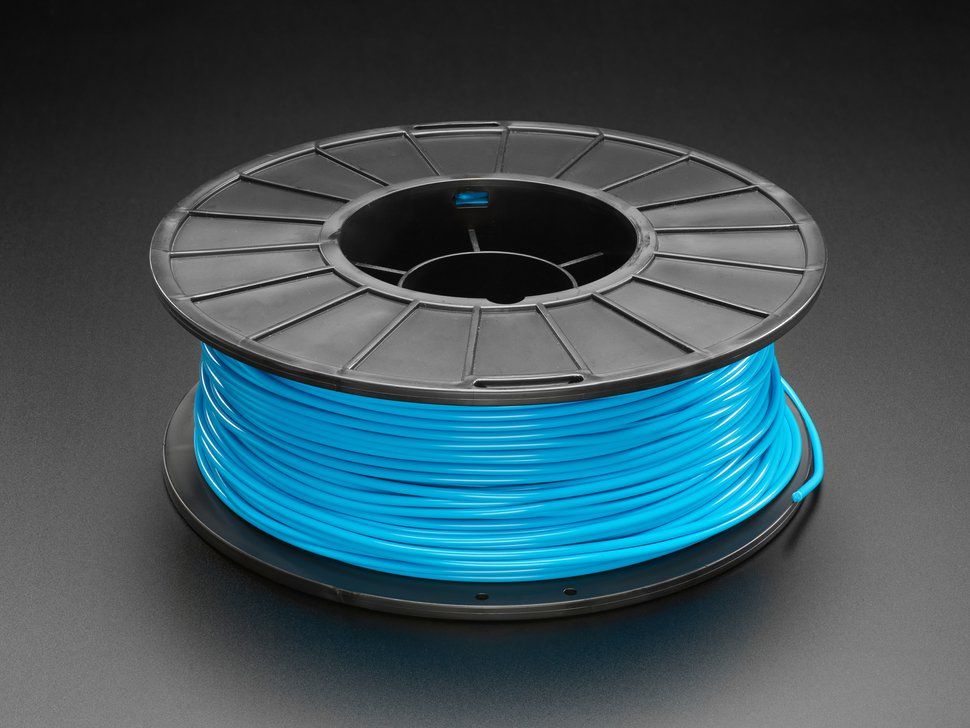

PLA

This versatile plastic is a great choice for most projects. Whether you are just beginning your journey into the world of 3D printing or designing advanced artistic models, PLA offers the widest variety of color options and a great surface quality. It accepts paint and super glue well. PLA is made from corn starch and is the most environmentally friendly filament. It will biodegrade but in an ordinary room it will last for hundreds of years. PLA is very brittle and will snap under pressure.

Whether you are just beginning your journey into the world of 3D printing or designing advanced artistic models, PLA offers the widest variety of color options and a great surface quality. It accepts paint and super glue well. PLA is made from corn starch and is the most environmentally friendly filament. It will biodegrade but in an ordinary room it will last for hundreds of years. PLA is very brittle and will snap under pressure.

- Attributes: Variety of Color, Surface Quality, Paint/Glue friendly

- Resistances: Water

- Weaknesses: Brittle

- Best uses: Most 3D projects

- Similarities: PVB

ASA

A more durable and high impact plastic that is perfect for most 3D printing projects such as engineering or outdoor purposes. ASA is very similar to ABS but because of its mechanical properties and strong UV resistance it would be considered a successor to ABS. It is dissolvable in acetone, which works well for post processing. Overall ASA is a tough, durable, and water resistant plastic that works well for many projects.

It is dissolvable in acetone, which works well for post processing. Overall ASA is a tough, durable, and water resistant plastic that works well for many projects.

- Attributes: Durable, high impact

- Resistances: UV Light, Water

- Weaknesses: Acetone

- Best uses: Most projects, including engineering and outdoor

- Similarities: (Superior to) ABS

PETG

PETG is an exceptionally durable material that resists breakdown from water and other chemicals. It is more impact resistant but less rigid than ASA. Under stress it will flex or deform before breaking. The surface quality is not as good as other materials and it is nearly impossible to glue or paint. This is a great material for models that need to be slightly flexible, very durable and UV resistant, but not meant for aesthetics. Please anticipate a longer printing time with this material.

- Attributes: Durability, Flexibility

- Resistances: Water, Chemicals, UV Light

- Weaknesses: Cannot be painted, difficult to glue/repair

- Best uses: Utility models

- Similarities: ASA (more impact, less rigid)

PolySmooth PVB

A unique material used to create visual models or design parts. When exposed to isopropyl alcohol, PVB transforms into a glossy and smooth material with transparency. This material is not water or chemical resistant so soluble supports would not be recommended to be printed with this material. PVB also has similar mechanical properties to PETG but melts at a lower temperature.

When exposed to isopropyl alcohol, PVB transforms into a glossy and smooth material with transparency. This material is not water or chemical resistant so soluble supports would not be recommended to be printed with this material. PVB also has similar mechanical properties to PETG but melts at a lower temperature.

- Attributes: Smooth/glossy transparency with Isopropyl alcohol exposure

- Resistances:

- Weaknesses: Water, Chemicals

- Best uses: Visual Models, design parts

- Similarities: PETG (but melts at lower temps)

TPU 95A

TPU 95A is a rubber-like material that is best used for prints that need to be durable and flexible. Its resistance to wear and tear is proven by its Shore A hardness of 95 and up to 580% elongation before breaking. TPU 95A also has quality resistance to chemicals and common industrial oils when it comes to corrosion. Painting a model is possible with a proper primer/adhesion promoter.

- Attributes: 95A hardness, rubber-like

- Resistances: Chemicals, Abrasion

- Weaknesses: Difficult to paint and allow flexibility

- Best uses: Simple models and shapes that need to be flexible

- Similarities: none

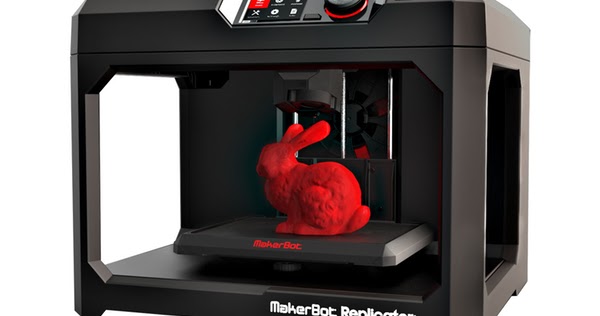

Resin

Our most detailed option, resin has many advantages not found in our other materials. Resin prints are great for small figurines that need to retain detail, or complex research prototypes. Layer lines are less visible and the overall surface quality is very high and smooth. Please anticipate a longer printing time with this material.

FAQ | Hollander Makerspace | MSU Libraries

| X We are excited to announce that we have moved to a new catalog. The old catalog will no longer be available beginning October 1st. Please report any problems you may experience to Discovery Services by calling (517) 353-8700 or by filling out our feedback form. Note: Borrowing from other Michigan libraries through MeLCat continues to be suspended until further notice. To learn more information, please see our FAQ page and our policy on Personal Data Collection and Usage for Library Accounts. |

Selma D. & Stanley C. Hollander

MakeCentral Makerspace

If you are not sure where to start, take a look at our FAQ, ask us, find out where we are, or come to one of our events.

Who can use the Makerspace?

The Makerspace is open to all MSU students/faculty/staff and members of the community. For some services, community patrons may need to get a community patron card which can be acquired from Circulation.

What equipment can I use?

Only Makerspace staff can operate the 3D printers, laser cutter and CNC router. Patrons are welcome to utilize our Makestations. Please note that the self-service 3D printer is intended for learning the entire 3D printing process and is available for short prints. Additionally, we have a wide range of equipment that can be checked out.

Additionally, we have a wide range of equipment that can be checked out.

What workshops do you have?

Take a look at our workshops and events. Is there something else you would like to see? Send us an email and let us know!

How do I get started with 3D printing?

There are plenty of cool 3d models on Thingiverse, many of which are free for personal use, but you should always check the licensing to make sure you are not infringing on anyone’s intellectual property rights.

If you are new to 3D modeling, TinkerCad is a great place to get started. It is very intuitive and easy to learn. If you need something more advanced, we highly recommend learning Fusion 360. There are free and educational licenses for Fusion 360 and it has a wealth of different functionalities. Check our workshops, we often run Intro to 3D Modeling workshops!

Free or freemium programs: Meshmixer, Mesh Lab, Blender, Fushion 360, OnShape, ZBrush Core Mini (Previously Sculptris. )

)

Paid programs: AutoCad, Inventor, Solidworks, ZBrush, Rhino.

Also see the software available in the Digital Scholarship Lab.

I have a special project and need access to specific equipment or materials, can you help me with that?

We love to help, send us an email and we will figure out if your project is something we can accommodate.

Can I use the makerspace for a class?

If you would like to take your class on a tour of the Makerspace or for other questions, please email the Makerspace Coordinator, Jamie Moriarty.

If more than 10 students will be submitting files or you are using a department account, please contact us at least 2 weeks before students submit files. We will set up a special MakeAtState submission for your class.

Please submit your class request 2 weeks before files will be sent and allow for 2 weeks for jobs to be completed. That means the form should be submitted a total of 4 weeks before students receive their prints. Depending on the size of the class and size and complexity of each student’s design, printing may take more or less time.

Depending on the size of the class and size and complexity of each student’s design, printing may take more or less time.

If you are using a department account you will need to provide the following information:

- Account # (sub account and sub object code if applicable)

- Highest amount the student can charge

- Name of all students authorized to use the account (can be sent when files are submitted)

- Authorized personnel for the account

- Their department

- Their campus address

- Their campus phone

- Their email

How do I submit a file?

Please submit your files on MakeAtState. We will no longer be accepting files in person or via email. If you need help using MakeAtState please call or email us and we will gladly walk you through the process. After submitting a file, we will send a price estimate in 1-3 business days. You must pay for your job before we can begin your job. Please fill out our online form if you are submitting files for a class.

Please fill out our online form if you are submitting files for a class.

What if I need a faster turnaround time, higher resolution, hundreds of copies, or special material?

We are a prototyping facility, not a production facility. If you are unsure if your project is production level, your needs will be best suited at a more industrial facility. We may be able to accommodate several copies depending on how busy our queue is and the size and complexity of your job. Please contact us if you have any questions.

There are lots of companies online that can print with higher resolution machines, faster production level machines, and print with different materials. Some of these are Shapeways, Protolabs, Stratasys, CraftCloud, and Makerstock, but there are many more.

How much will my job cost?

When you submit your file online through MakeAtState, we will send you a price estimate. If you agree with the price, please pay first and then we will get working on your job. We do not print anything until you have paid.

We do not print anything until you have paid.

3D printing - We charge by the gram, including the weight of support material, using the estimate provided by our slicing programs. See our 3D printing page for details on each printer.

Laser cutting - We sell material by the half sheet and full sheet and charge by the amount of time that the laser cutter needs to complete your job. This time is dependent on the settings required for the material you choose, and the size and complexity of your design. See our laser cutting page for more details.

CNC routing - currently in a soft launch stage. Please email us for CNC routing!

MakeStations - There is no charge for the soldering or cricut maker station. We do charge for our button makers. 2 ¼” buttons are $0.18 each and 1” buttons are $0.11 each. To use our self-service 3D printer, you may only use PLA filament. You can purchase a roll from us for $20. See our MakeStation page for more details on what is and is not included for each MakeStation.

Why do you charge money?

We operate on a cost recovery model meaning the money that we make goes to covering the cost of supplies, maintenance of our equipment, and our student employees.

How do I pay and pick up my job?

We are currently not offering in person payments for all MakeAtState jobs. We accept credit card payments through CashNet and MSU department account payments. When a price is set for you job you will get an email with more information.

Orders can be picked up at the MakeCentral Service Desk. If using a department account payment, you may opt to have your order sent through campus mail.

Can I get a refund?

We do not allow refunds with the exception of patron over/under payment errors. Refunds will be processed within 10 business days. The Makerspace is not responsible if a project is damaged due to thin parts or inappropriate use, does not print correctly, or does not work. We have hobbyist level machines and 3D printing tolerances are subject to variability and subtle warping. Please prepare your CAD file accordingly.

Please prepare your CAD file accordingly.

Can I bring my own materials?

3D printing, laser cutting, and CNC routing - Materials for 3D printing and laser cutting will require a Safety Data Sheet, staff approval, extra material for testing, and extra time to complete your job. Please email us if you absolutely need a specific material.

You can bring your own materials for all MakeStations, however, many have specific requirements. Check our MakeStation page for additional details. If you don't see what you are looking for, let us know!

What software should I use for laser cutting?

Any vector based program such as Illustrator. Inkscape is a great open source free alternative. If you are using AutoCad or Solidworks you will need to export your file as a drawing in a pdf format.

See our laser cutting libguide for more detailed instructions and tutorials!

Where can I check out equipment?

All equipment checkouts, returns, or renewal requests must be completed in person at the MakeCentral: Service Desk. If you want to see what equipment is currently available, please go to the lending technology page, locate the item, then click the "Availability" button.

If you want to see what equipment is currently available, please go to the lending technology page, locate the item, then click the "Availability" button.

How long can I borrow equipment?

Most of our equipment is either a 72 hour, 14 day, or a 21 day loan. Check the lending technology page for more information. Renewals are subject to demand, renewals can be requested in person and are subject to staff approval.

Can I renew my equipment?

Most of the time, yes. Renewals are subject to demand and must be requested in person. We are rarely able to offer renewals on cameras, tripods, and audio equipment towards the end of the semester.

Is there a late fee?

Yes, 72 hour loans have a fine of $1 per hour. 14 day and 21 day loans have a fine of $1 per day. Your due date is written on the checkout tag. See our full lending policies.

When can I use a Makestation?

MakeStations are available during normal business hours. Reservations are required for use. When you make a reservation you will receive a link to self-enroll in our D2L page which includes safety and operation training for most MakeStations. You can also enroll at any time with the self-enroll link. Community patrons will need to make a guest account. You must complete the training prior to using the MakeStation except the button makers. Though training is not required for the button makers, it is highly recommended. See our appointments page for more details.

When you make a reservation you will receive a link to self-enroll in our D2L page which includes safety and operation training for most MakeStations. You can also enroll at any time with the self-enroll link. Community patrons will need to make a guest account. You must complete the training prior to using the MakeStation except the button makers. Though training is not required for the button makers, it is highly recommended. See our appointments page for more details.

Can I make a reservation?

Reservations must be made online. If you are more than 15 minutes late for your reservation we may let other patrons use the equipment.

How do I complete the training for a Makestation?

When you make a reservation to use the MakeStation, you will receive a link to access the training. If you do not see the link, you can self-enroll. Community patrons will need to make a guest account.

Does it cost money to use the Makestations?

Check the MakeStation page for the most up to date information on what is and is not provided.

Button makers - 2 ¼” buttons are $0.18 each and 1” buttons are $0.11 each.

Filament for the self-service 3D printer can be purchased for $20.

Plastic for use with the vacuum former can be purchased as well, we have a variety of sizes and materials to choose from. See the vacuum former page for more details.

Welcome / Centralized Library System of Kanavinsky District

Attention! Announcement!

News

All news

| "School of Magic" 07 Nov |

| The Year of Folk Art ends! 03 Nov |

| "Alarm call" 01 Nov |

All news

| LitSoviet Subscribe Archive | Unfashionable Reading Archive | |||

| LitSovet - the author's blog of our colleague, writer Andrey Kuzechkin. Last review: Roman Senchin. "Petersburg stories" New of the year 2020 - video blog LitSovetOnline . Read also Andrey's articles in the Literary Calendar. Last publication - about the work of K. Simak Write your comments, argue, discuss, express your personal reader's point of view!

| We are returning the fashion for good books, undeservedly forgotten, on which many generations of educated, cultured people grew up. Librarian Olga Vladimirovna Kuzmina is with you. Latest publication: Boris Lavrenyov. "Forty-first" Next - November 21, 2022. DO NOT MISS! We invite you to discuss! We are waiting for your comments!

| |||

| Kanavino | Nizhny Novgorod chronotope | |||

| This is the local history section of the site, dedicated to the history and present day of the Kanavinsky district.

| We continue to work on the virtual project Nizhny Novgorod Chronotope , which was launched on our website in 2014 and was originally dedicated to the Year of Russian Culture and the 300th anniversary of the formation of the Nizhny Novgorod province. We invite everyone to take part in it. Read more on the main page of the project. Latest publications: Tatyana Mavrina. To the birthday of the master | |||

| Playground | Attempt at writing | |||

| Playground of our site is addressed to children, teenagers, their parents, grandparents. We invite you to visit our virtual reading room, listen to audio book trailers and watch book trailers of children's books that we have made ourselves; find out which children's clubs and associations work in the libraries of the Kanavinskaya Central Library Library, and much more. Attention! New book trailers!

| Dear site users! We invite you to take part in our literary blog ProbaPera. Register on the site and publish your poems, prose, journalism, reviews of books, films, performances. We are glad to cooperate with creative people! Introducing a new author!Mikhail Kravchenko

| |||

| Interview | Photo gallery All photos | |||

| All surveys Questionnaires | ||||

Pancakes on a 3D printer

Next article

At the NAUKA 0+ festival, they talked about new prospects for the development of 3D printing in the food industry

Author:

Maria Vorobieva

Eduard Shibanov, Chief Designer of the Laboratory of Additive Technologies at MGUPP, spoke at the NAUKA 0+ festival about new trends in the development of 3D printing and traditional food technologies.

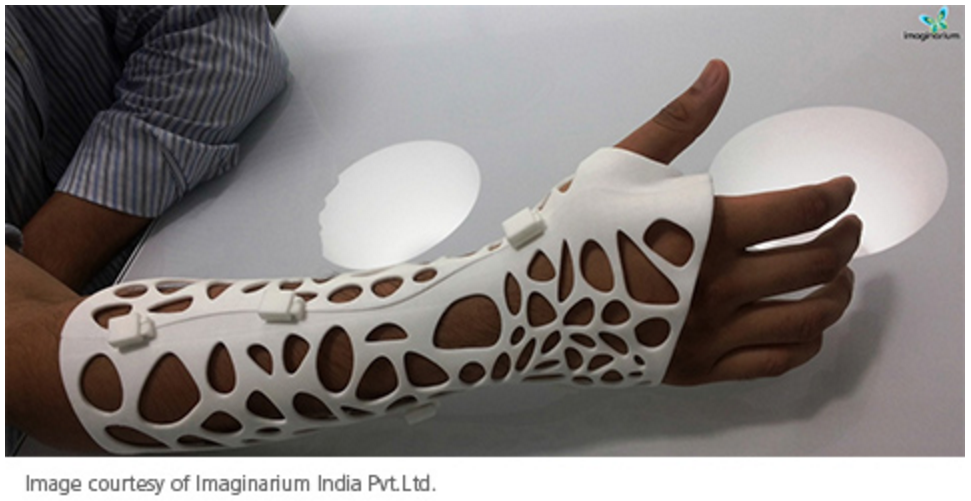

©https://pixabay.com/

Eduard Shibanov gave an online lecture in which he highlighted the success of 3D printing technologies in various areas of production: mechanical engineering, robotics, medicine, construction and clothing. He also spoke about interesting facts related to 3D printing. The most curious of them is associated with the film "007: Skyfall Coordinates" by Sam Mendes. It used a car that, according to the plot, was supposed to explode in the finale. The filmmakers developed a three-dimensional model of this car, reduced by three times and printed it on a 3D printer. So the movie used a real car to move around, and the shot where the car explodes was a 3D model. Made of plastic, it looked like a real one and was also blown up, really. But Eduard Shibanov devoted the main part of the lecture to the role of 3D printing in the food industry.

A bit of history

Back in 2013, NASA discussed building 3D printers to feed astronauts during space flights. In space, it is quite problematic to cook any kind of food, and 3D printers could solve this problem.

In space, it is quite problematic to cook any kind of food, and 3D printers could solve this problem.

In 2017, scientists from Denmark expected that 3D printed food would supplement the standard diet of people based on the needs of the individual. 3D food printing will open up possibilities for the nutrition of every person. If a certain person does not like a certain product, the 3D food printer can exclude that ingredient.

In the same year, scientists from Australia came to the conclusion that 3D printers can be used in hospitals. For example, there is such a disease as a disorder of swallowing food. For people with such an ailment, food should be in a consistency convenient for them, namely in the form of a liquid mass. 3D printing can help such people in the form of creating food that is comfortable for them, while it will be varied and palatable. Printers can be placed in each hospital.

3D food printing in the world

Barilla, an Italian pasta company, uses 3D printing to create pasta. The device allows you to print pasta of a given complex shape, then you just need to cook them.

The device allows you to print pasta of a given complex shape, then you just need to cook them.

Many cafes in the world focus on somehow standing out from the rest, creating their own unique dishes. For example, many of us have tried coffee with foam from someone's portrait.

There are also 3D printers for making chocolate figures. They are quite difficult to make by hand, so 3D printers work on their creation instead of people. They provide 100% product repeatability from a given pattern.

There is also a pancake 3D printer that can print pancakes in various patterns. They can have a different color, shade. This is achieved due to the fact that the material that is applied earlier on the hot printer platform becomes darker. Accordingly, knowing the right time to apply the mass for each area, you can create different patterns. The printer does this automatically.

3D printers have been created that allow you to print dishes from several ingredients. Many chefs buy these printers for their restaurants and use them to serve food in a more beautiful and interesting way. If we talk about the technique itself, then the printer squeezes the liquid material onto the platform for printing, forming an integral structure over time.

If we talk about the technique itself, then the printer squeezes the liquid material onto the platform for printing, forming an integral structure over time.

There is also a 3D printer that can print pizza. He can use three ingredients to create a pizza. The mechanism uses a remote feed system that allows you to use the printer continuously. Thus, more ingredients can be loaded in order to print a large number of pizzas.

Thanks to 3D technologies, a number of new possibilities for catering for individual nutrition for each person open up. Today, this question is becoming more and more acute. Every year, the number of people suffering from allergies or intolerance to certain ingredients (for example, lactose or gluten) is increasing. There is a growing demand among the population for healthy food, which is expensive or time consuming. A 3D food printer will be able to prepare beautiful and healthy food with precisely defined ingredients. Also, another advantage is that the 3D printer prints unique dishes. Recently, it has become more and more difficult to surprise people, manufacturers are trying in a highly competitive environment to find new recipes, new production methods so that their product is interesting and different from competitors. 3D food printing can open up completely new horizons and directions in food production. For example, if we recall the well-known fast food chain McDonald's. Before its appearance, people could not even think that a dish can be prepared in advance and served as a sandwich wrapped in a package.

Recently, it has become more and more difficult to surprise people, manufacturers are trying in a highly competitive environment to find new recipes, new production methods so that their product is interesting and different from competitors. 3D food printing can open up completely new horizons and directions in food production. For example, if we recall the well-known fast food chain McDonald's. Before its appearance, people could not even think that a dish can be prepared in advance and served as a sandwich wrapped in a package.

Forecasts and prospects

“The 3D food printing market will reach $525.6 million by 2023. Every year the amount of funds in this area increases. Food will always be relevant."

“North America and Europe are currently the market leaders in 3D food printing, with high penetration in countries such as the US, the Netherlands, the UK, Spain, Italy and France. With rapid technological advances, food 3D printing is expected to open up great opportunities to revolutionize the global food industry. ”

”

“In the future, this technology could change the way we prepare and eat food. Production of food directly at the place of consumption. This may be relevant for hospitals, for the military, space industry, for educational institutions and in the future it is possible for ordinary home users.

“Also, 3D technologies allow you to design your own food (shape, color, taste). This may lead to the emergence of a new profession of food architect, food designer.

“Successful mastering of 3D printing technology requires trained specialists who, in turn, understand all the possibilities and features of such production. This is at least the emergence of two new professions on the market - a 3D food designer and a 3D food printer operator.

“At the first stages of development and implementation of 3D food printing, it is necessary to create a database of digital recipes for a 3D printer. These will be both recipes and dishes already familiar to us, as well as unique options that have a completely different look.

His reviews are the advice of a professional writer that will help you navigate the world of modern literature.

His reviews are the advice of a professional writer that will help you navigate the world of modern literature.  We invite you to create it with us! Share interesting facts from the history of the region, tell us about the Kanavians you know on pages Kanavin's Living Encyclopedia ! People, events, facts - all this will someday become a distant history for posterity...

We invite you to create it with us! Share interesting facts from the history of the region, tell us about the Kanavians you know on pages Kanavin's Living Encyclopedia ! People, events, facts - all this will someday become a distant history for posterity...