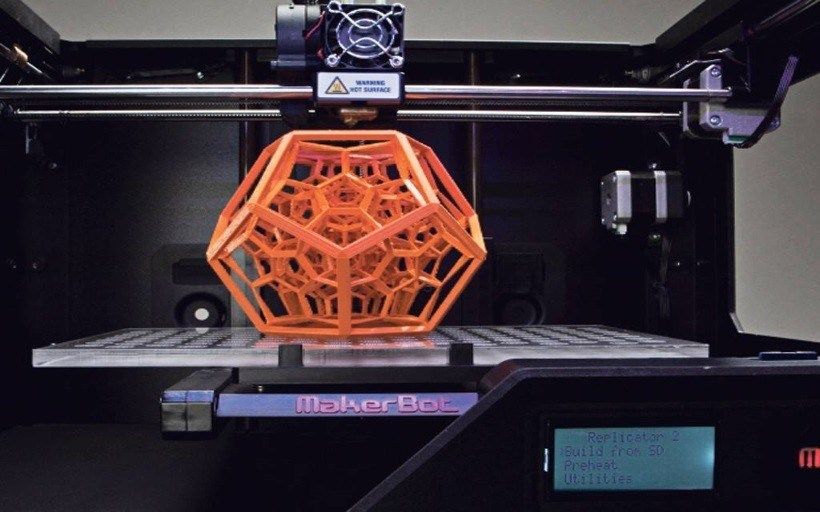

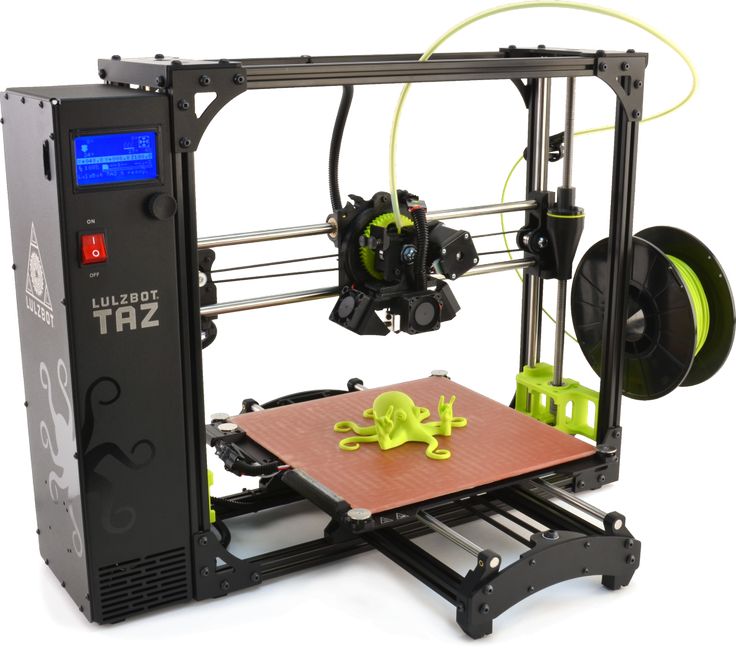

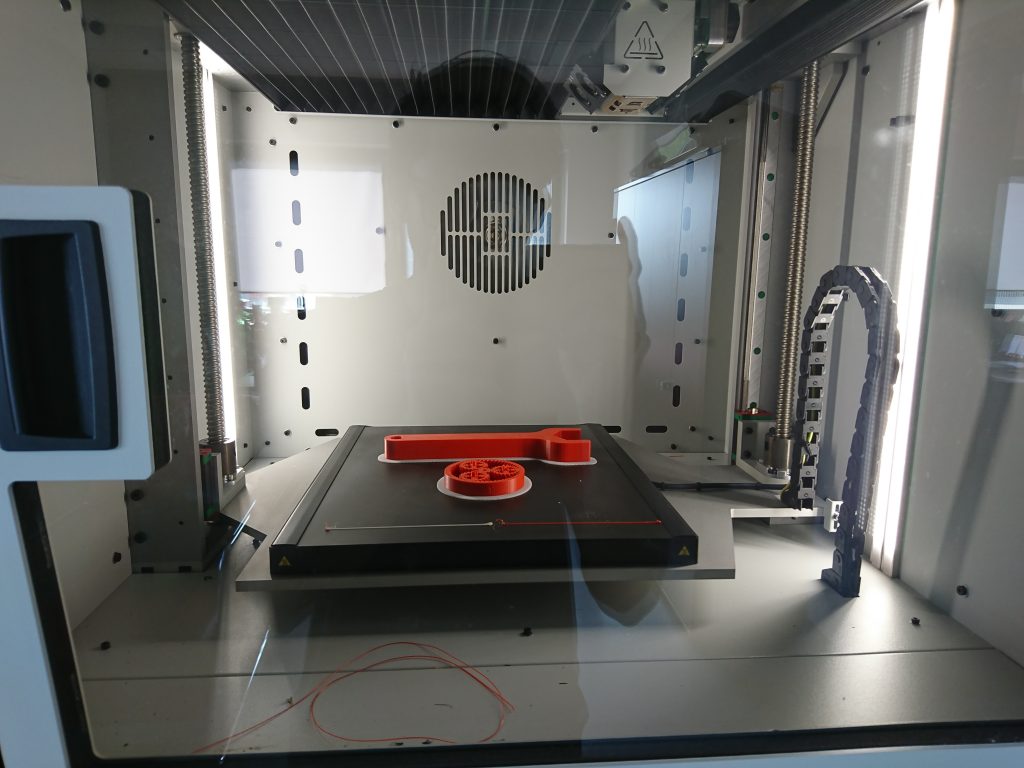

Hong kong 3d printing service

3D Printers, Filaments and Printing Service

New Arrival+

Quick View

HK$ 3,999.00

+

Quick View

HK$ 735.00 – HK$ 935.00

+

Quick View

HK$ 218.00

+

Quick View

HK$ 3,369.00

3D Printers+

Quick View

HK$ 77,800.00

+

Quick View

HK$ 5,199.00

+

Quick View

HK$ 7,159.00

+

Quick View

HK$ 3,369.00

+

Quick View

HK$ 3,999. 00

+

Quick View

HK$ 398.00

+

Quick View

HK$ 428.00

+

Quick View

HK$ 398.00

+

Quick View

+

Quick View

HK$ 508.00

Accessories+

Quick View

HK$ 735.00

+

Quick View

HK$ 864.00

+

Quick View

HK$ 735.00 – HK$ 935.00

+

Quick View

HK$ 185. 00

00

+

Quick View

HK$ 349.00 – HK$ 799.00

TestimonialsMy sincerest gratitude to the Addify group for being a great technical support for thenins and outs of 3D printing. Time and time again, when would face issues like our 3D printer breakingndown, or our prints were not optimal, you would be there to provide us with a solid explanation of thenissue, and of course the solution. Over time, I have learnt the ins and outs of 3D printing thanks to yournpatience and professionalism in providing us a truly wonderful customer experience. It is very rare to see such detailed advice, it is almost like you were our consultant with regards to 3D printing technologies. I look forward towards more future collaborations, especially in this interesting field of Soft, Compliant,nand Flexible Underwater Robotics!

Timothy Ng / Project Director, Vayu Project: Fastest Robotic Fish Bionics and Control Lab Dept. of Mechanical Engineering, The University of Hong Kong.

of Mechanical Engineering, The University of Hong Kong.

I would like to forward my sincere gratitude to you and Addify for working with me and my team, the Digital Materials Group, and providing exceptional services and the most relevant product options. Time and time again, your incredible knowledge base, outstanding expertise, and practical advices have boosted our confidence in a 3DP market filled with not only diverse but also rapid releases of new options and products. Your patience in learning the nature and needs of our project has been truly invaluable in helping us identifying the best solution possible. I can’t be more grateful with the feeling of “man, that was so informative and helpful!” every time we finish a meeting! So, thank you for all you do! A pleasure to be your customer!

Sarina Sun / Assistant Professor, Institute of Textiles and Clothing, The Hong Kong Polytechnic University

I am writing recommendation testimonial letter for Addify. Addify has worked with me in the past. Their knowledge in 3D printing technology and materials have helped me in my research studies. I feel confident in recommending Addify services.

Addify has worked with me in the past. Their knowledge in 3D printing technology and materials have helped me in my research studies. I feel confident in recommending Addify services.

QingYun Huang / PhD Fellow, City University of Hong Kong

3D Printing Workshop has widen my view a lot more. It has great potential to develop but the market is still very narrow when few people knows about it… From 3D printing a toy model, deco, home appliance etc. are just basics, while it has already been using to print food and testing to print organs

are just basics, while it has already been using to print food and testing to print organs

100% Biodegradable 環保物料❤️ 韌性高,耐高溫 並且可以生物降解 🤩完全符合循環經濟嘅原則,可以多次重複使用!減少浪費 🌍 呢隻物料係出自Filamentum 嘅 NonOilen 好多謝@FaychuCafe 同我哋購買左呢隻物料然後3D打印咗杯、筷子、醬汁碟同埋碗仔🫡 如果你都對呢隻物料有興趣嘅話,可以上我哋嘅網站研究研究❤️ #保護地球人人有責 #3d printing #addify3d #環保

Teletubbi ❤️ laa-laa 今期大熱嘅天使得得B laa laa 唔使捱貴價,想要嘅話就自己print 要幾大有幾大,要幾細有幾細🫣 小編特別想介紹呢一隻金色有暗閃嘅Filament 係由 Fillamentum 出嘅 Gold Happened 🤩 print出嚟嘅嘢好靚好高質 ,print 出嚟嘅料都幾實 (起碼唔會掂一掂就爛🫢)有興趣嘅話可以上我哋嘅官網睇睇 Credit: thingiverse.com/thing:5395534 玩具嘅存在價值係要令小朋友開心🙂 ,並唔係玩具所值嘅價錢 🧸 #addify3D #3Dprinting #teletubbies #laalaa #3D打印 #filament

連續咁多日落咁大雨空氣嘅濕度好高 小編建議大家,如果屋企冇防潮箱就記得將filament 放喺膠箱入邊再放無限包吸濕包 filament 處喺濕度太高嘅空氣中, print 出嚟嘅嘢會起晒絲,唔靚㗎! 🫠🫠 #fillament #addify3D #記得好好保養fillament #3dprinting

Miniature Hong Kong ❤️ 啱啱先發現咁正嘅場景竟然冇post🫠 自己畫圖自己3D print 係咪好正呢😏 #最正應該係塊廣告牌😆😆 #3Dprint #addifyhk #miniature #微縮場景 #香港 #譚仔 #陽光檸檬茶 #邊度都有陽光 #香港縮影 #3Dprinting #ilovehongkong #7仔

Happy Easter!!! 祝大家復活節快樂🥚❤️ 記得趁住呢幾日假期print多啲得意又正嘅 3D print 😉 We will be closed for Easter April 15th to 18th Office將會喺4月15號至4月18號休息!4月19號照常營業🈺️ We are wishing you a very happy Easter 🥳

仲未用晒消費券嘅話,係時候買返部3D打印機或者添加多啲唔同顏色嘅filament 喇❤️ 我哋接受 AlipayHK, Wechat pay 同埋 Tap&go 😉

用3D打印加樹脂黏土整嘅 迷你肯德基爆脆雞筒餐(堂食版) 睇完呢個post會唔會即刻想食? 🤤🤤🤤🤤 如果想睇教學video,就喺樓下留言話我知😎 KFC chicken bucket miniature using 3D printing & polymer clay ❤️ If you want to watch the Tutorial video, let us know in the comment below ! #KFC爆脆雞筒餐 #蘑菇飯#雞皇飯 KFC chicken bucket miniature using 3D printing & polymer clay ❤️ #addify3d #3D打印 #miniature #polymerclay #miniaturefood #KFC

你最鍾意食嘅麥當勞早餐係邊款? What’s your favorite breakfast @mcdonaldshk ? 3D print + polymer clay 3D打印加樹脂黏土 3D打印其實可以有好多可能性,配合樹脂黏土可以製造出好多迷你玩具😎 製作過程 video coming up soon ! #addify3D #3dprinting #3D打印 #miniature #polymerclay #微型 #早晨全餐 #bigbreakfast

3 D printed Chess Set ♟ Printer : Artillery Genius Print Time : One week 🥲 Material: PLA Credit : thingiverse. com/thing:4857660 #chess #3Dprint #artillerygenius #addify3d #3D打印 #kexcelledfilament

com/thing:4857660 #chess #3Dprint #artillerygenius #addify3d #3D打印 #kexcelledfilament

Instagram Image

3D Printing FAQ - ADDIFY Hong Kong 3D Printing

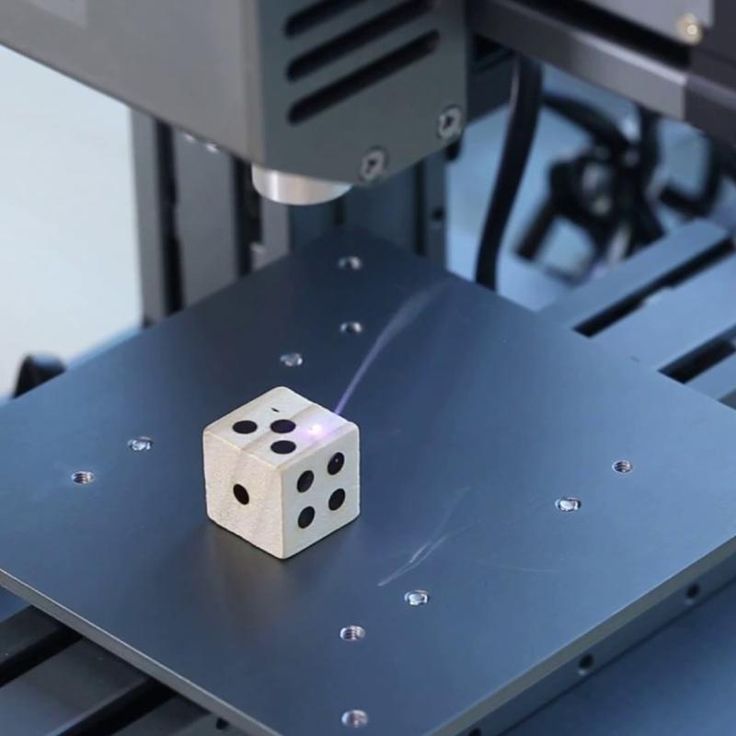

We will need a 3D model slicing software first, which slicer is recommended?

We would recommend Cura from Ultimaker as it is free and quite easy to use.

https://ultimaker.com/software/ultimaker-cura

https://www.youtube.com/watch?v=eUNTlb5pEWA

ideaMaker from Raise3D is also a great choice, its launching speed is super fast and it is also free.

Why are there so much strings? (We call them oozing/stringing/hairy)

– Retraction setting has not been fine tuned

– The filament is too wet. Hong Kong has high humidity, the moisture in the air can be absorbed by the filament. Dry it with dehumidifier or something like camera box.

– Another reason is about the calibration, try this below:

3D Printing encyclopedia

If you feel you have got some problems with your print but you can’t describe it, check this website below. Bookmark it. There are photos for you to match your problem and you will be able to find an answer.

https://all3dp.com/1/common-3d-printing-problems-troubleshooting-3d-printer-issues/

Creality Ender 3 V2 - 3D printer - Unbox & Setup

Creality Ender 3 Pro - 3D printer - Unbox & Setup

Creality Ender 3 Series - Easy way to level your bed

Being successful in 3D printing, first thing first, do your leveling right.

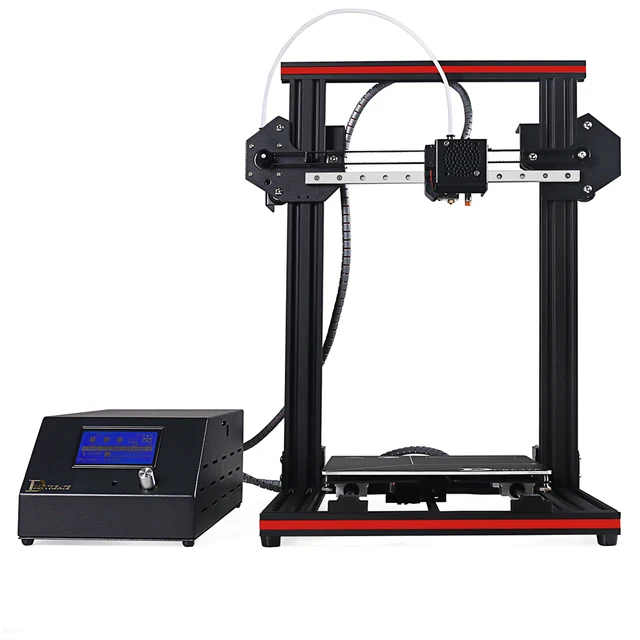

What material can I use with Artillery Genius?

You can print PLA/ TPU/ ABS/ PETG with a stock Artillery Genius. You can print more like PC, Nylon if you wish but you will need to modify the printer by uploading Marlin 2.X and TFT to unleash the beast. To modify it you will need to get access to the board and you will void the warranty.

You can find us to modify or you take your own risk. Reminder: No matter who is the one who modify the printer, the manufacturer will only provide limited warranty thereafter, if there is any malfunctioning afterwards produced by the modification, the manufacturer can reject the warranty.

Artillery Genius Setup & Installation

Artillery Sidewinder X1 Setup & Installation

WhamBam Build System For Better Adhesion

Addify Youtube Channel

https://www.youtube.com/channel/UCm6j4_cHcAz2Xs2UID32zTQ

Who lives at the bottom of the ocean: how Hong Kong 3D printed reefs

Photo: The University of Hong Kong

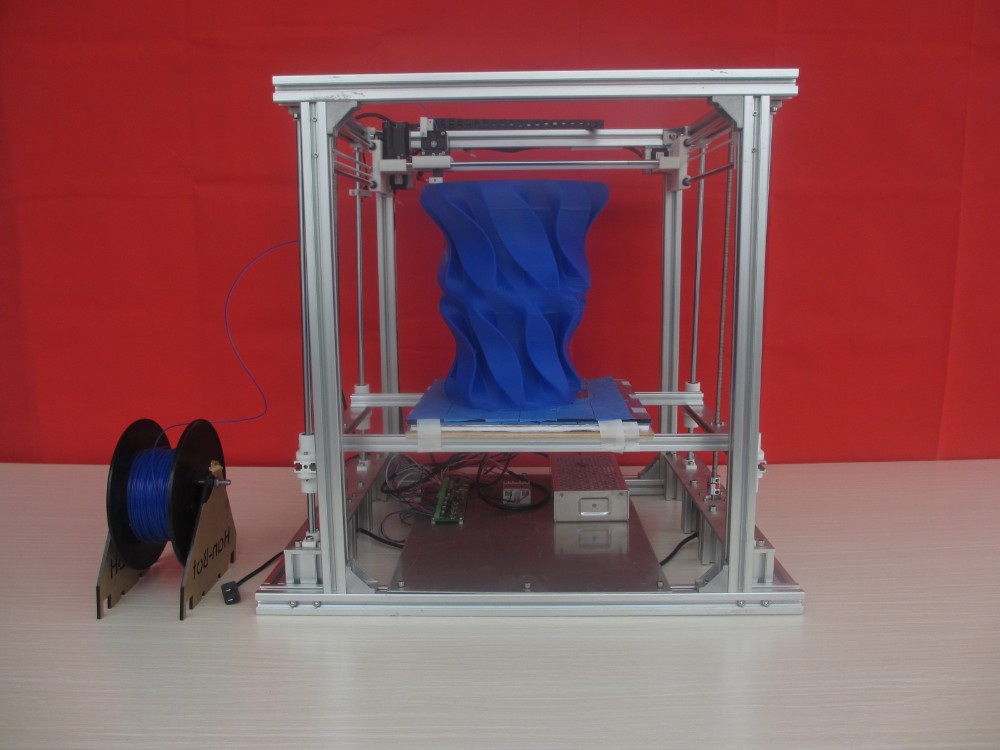

The ArchiREEF project team has created the world's first 3D printed artificial reef structure. So far, this is the most sustainable and efficient way to grow new coral reefs and restore the marine ecosystem

What's wrong with corals

In 2018, a super typhoon destroyed 80% of the corals in Hoi Ha Wan Bay off Sai Kung Peninsula in Hong Kong. Due to a strong storm with wind speeds reaching 250 km / h, only fragments of coral skeletons remained in place of the reefs. A few coral species have survived, but it will take decades for them to recover to their former state.

Coral reefs are rapidly disappearing from the world's oceans, largely due to the effects of global warming, which is increasing the frequency and intensity of storms. In 2016 and 2017 alone, 89% of new corals on the Great Barrier Reef died as a result of bleaching caused by global warming. Without decisive action to combat the climate catastrophe, overfishing and pollution, we will lose 70% to 90% of the world's remaining coral reefs within the next 20 years.

How to save reefs

A team of marine scientists from the University of Hong Kong and Swire Institute of Marine Science is testing a unique reef restoration method through the archiREEF project. With the help of a 3D printer and a robotic arm, they created so-called "reef tiles" - terracotta hexagons - and placed them on the seabed in Hoi Ha Van Bay.

Photo: The University of Hong Kong

Tiles do not replace reefs, they only serve as a foundation for corals and encourage the return of their inhabitants. Terracotta is harmless to the ocean - it is similar to calcium carbonate, which is found in real coral reefs. And most importantly, terracotta clay naturally breaks down: scientists hope that in a few decades, the tile will disappear, and only new corals will remain in its place.

Terracotta is harmless to the ocean - it is similar to calcium carbonate, which is found in real coral reefs. And most importantly, terracotta clay naturally breaks down: scientists hope that in a few decades, the tile will disappear, and only new corals will remain in its place.

The reef tile design provides a structurally complex base, allowing coral fragments to find many nooks and crannies to gain a foothold. This prevents the buildup of sediment, which scientists say poses a serious threat to marine life.

Photo: University of Hong Kong

The first results of the experiment are promising. The survival rate of corals and other inhabitants was 98%, which is 4 times more than with conventional methods.

“It's encouraging to see small fish and crabs taking shelter in the tile almost as soon as it touches the seabed,” says David Baker, director of the Swire Marine Science Institute. “I hope the government will allow us to plant reef patches that will contribute to Hong Kong’s coral growth, important biodiversity hotspots, and enjoyable dive sites over the course of my lifetime. ”

”

Why 3D printing

Now 128 hexagonal tiles cover only 40 square meters. m. of the bottom, but if the experiment works, this practice can be scaled up. The idea of terracotta tiles is being tested all over the world: scientists are working on reef restoration in the Maldives, where the largest 3D-printed reef is located, as well as in France and the Caribbean.

Other artificial methods are being tested to save coral reefs. In a practice known as "rigs to the reefs", decommissioned offshore oil rigs have been turned into artificial reefs in the US, Brunei and Malaysia. Deliberate flooding of "end-of-life" ships is another method. The sunken US aircraft carrier USS Oriskany is considered the largest artificial reef in the world, and the aircraft carrier, nicknamed the "Great Carrier Reef", sunk in northwest Florida in 2006, is one of the most popular diving sites in the United States.

The Hong Kong team, however, believes that using terracotta is much more efficient and safer than other artificial reef building methods. “Concrete contains cement, which is very corrosive,” Baker says. “In seawater, it maintains a very high pH at the surface, which is detrimental to many types of marine species. In addition, concrete structures often appear strangely devoid of life or become covered in an unsightly biofilm of algae, much of which does not support corals or other marine life.”

“Concrete contains cement, which is very corrosive,” Baker says. “In seawater, it maintains a very high pH at the surface, which is detrimental to many types of marine species. In addition, concrete structures often appear strangely devoid of life or become covered in an unsightly biofilm of algae, much of which does not support corals or other marine life.”

Photo: The University of Hong Kong

Modern technologies, in particular the possibilities of 3D printing, create the conditions for revolutionary solutions in ecology. According to Virko Yu, co-founder and CEO of archiREEF, there are two reasons to use 3D printing:

“The first is adaptability. We wanted to create something that could adapt to any type of coral anywhere in the world. The design we have now is based on an algorithm, and changing the parameters allows you to change the design a bit. Since we see the restoration of corals anywhere as the ultimate goal, design flexibility is critical and 3D printing makes that possible. ”

”

Another reason is the increased complexity and detail of 3D printing compared to traditional molding. There are microorganisms in Hong Kong that need small and complex structures as a refuge. With a 3D printer, you can create structures with much more detail, which is very important for biodiversity restoration. The creators of the project dream of making this technology easy to implement, accessible and popular not only for the circle of narrow specialists, but also for ordinary people.

Virko Yu:

“When we first got the attention of the world media, we started getting messages from people from different countries asking if they could help and do the same on the reefs in their region. And I realized that coral restoration concerns everyone. We want it to be as easy as planting trees – easy and affordable.”

The challenge

Despite the promise of archiREEF, most scientists emphasize that no artificial reef technology is a panacea for coral reef decline.

“3D printing can really help create small, complex substrates on which to house and grow coral larvae,” says Alasdair Edwards, professor of coral reef ecology at Newcastle University. “But given that over the past 50 years, several tens of thousands of square kilometers of reefs around the world have already been destroyed, 3D printing is clearly not a solution, but may play a secondary role. The only solution is to limit greenhouse gas emissions.”

Some of the most amazing 3D printing materials currently available

3D printing with classic materials such as plastic, metal or ceramic is widespread. In the meantime, there are many alternative materials that are not only unusual, but can make a 3D printed part even more special. In our selection, we introduce you to these unusual materials. From chocolate and salt to recycled plastic waste or ashes, now you can create the most extraordinary items. In some cases, these materials are even proving to be a great alternative to plastic, reducing overconsumption and the associated environmental impact. Today we're going to take a look at these amazing 3D printing materials.

Today we're going to take a look at these amazing 3D printing materials.

3D printing material from the sea

Today, filaments are still the most commonly used 3D printing materials, mainly because FDM machines are readily available. But did you know that some threads are made from shellfish and crustaceans? The French company Francofil offers materials from PLA and shells of mussels, scallops and oysters. Their shells come from recycled food service waste and are shredded to become threads. The materials are made in France and can be printed like normal PLA.

Photo: Francofil

Local Salt

Emerging Objects is an American company that uses new technologies with innovative materials to create impressive projects. Among the most prominent initiatives is Saltygloo, a salt 3D printed structure. The salt used was collected from San Francisco Bay. Due to climatic conditions, about 500,000 tons of sea salt are produced here annually. Salt has been used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects such as the GEOtube tower and building houses.

Salt has been used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects such as the GEOtube tower and building houses.

Photo: Matthew Millman

Chocolate is the sweetest 3D printable material

This 3D printable material may not be as exceptional as some of the others on the list, but it is certainly one of the most used. The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has grown over the years, prompting many companies to develop various designs and even chocolate 3D printers. Among the best known is the collaboration between 3D Systems and Hershey's, one of the world's largest chocolate makers. We also featured some 3D printers that can make delicious sweets like mycusini or Print2Taste. If you want to know more about this technology, don't miss the video below.

3D printed material from the ashes to remember your loved ones

The Spanish company Narbón is introducing new technologies and innovations in the funeral industry. 3DMemories uses 3D printing to create original, unique and exclusive ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the pattern must be processed and then combined with porcelain before the decorations can be 3D printed. Then the enamel is applied and the product is fixed. The service offers a wide range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry is an exceptional way to remember a loved one.

Photo: Narbón

Wood-Based Threads

Wood or vegetable threads have also been available on the market for some time. For example, the Dutch company ColorFabb offers several alternative threads in this category. What started in 2014 with BambooFill has expanded in subsequent years with CorkFill and WoodFill. Wood fibers, usually blended with a PLA/PHA base, give parts a natural, high-quality finish. Whether used to make figurines, pieces of furniture, or wall decorations, the threads can be used anywhere the look of wood is desired. Since ColorFabb discontinued BambooFill, a similar product can be purchased in Wood Bamboo form from AzureFilm. According to the company, 40% of recycled wood is mixed with 60% of polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the print speed.

Wood fibers, usually blended with a PLA/PHA base, give parts a natural, high-quality finish. Whether used to make figurines, pieces of furniture, or wall decorations, the threads can be used anywhere the look of wood is desired. Since ColorFabb discontinued BambooFill, a similar product can be purchased in Wood Bamboo form from AzureFilm. According to the company, 40% of recycled wood is mixed with 60% of polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the print speed.

Left: ColorFabb, Right: Azure Film

Other Uses for Linen

Another alternative to traditional filaments is a composite of PLA and linen from French manufacturer Nanovia. The company says the composite is not only a sustainable alternative to traditional filaments, but also offers the ability to achieve different shades of brown by applying different print settings. This can be achieved simply by changing the print temperature during production. As for the finish, the manufacturer recommends sealing the printed parts with UV protection to keep them intact for as long as possible.

As for the finish, the manufacturer recommends sealing the printed parts with UV protection to keep them intact for as long as possible.

Photo: Nanovia

Sugar 3D Printing

Sugar Lab was acquired by 3D Systems almost ten years ago and, as the name suggests, has focused on sugar 3D printing. Using the 3D Systems ChefJet Pro printer, the company creates intricately shaped candies and decorations. The Los Angeles-based company claims to be able to produce candy in all flavors and colors. Whether it's birthdays, weddings or Christmas parties, The Sugar Lab offers all sorts of 3D printed candies. As for quantity, the 3D printer seems to be capable of producing up to 100 candies a day. While The Sugar Lab is the most famous company using sugar as a printing material, other companies like The Modernist Cuisine are also trying their hand at 3D printing with sugar.

3D printing with glass

Glass has been popular in many industries for many years and is also used in additive manufacturing. Several researchers, such as those at MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to print on glass. For example, an MIT team has developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers were able to create three-meter-high glass columns at Milan Design Week. Recently, the Glassomer startup has also unveiled its glass 3D printing technology. The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers.

Several researchers, such as those at MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to print on glass. For example, an MIT team has developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers were able to create three-meter-high glass columns at Milan Design Week. Recently, the Glassomer startup has also unveiled its glass 3D printing technology. The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers.

Photo: Glassomer

Recycled plastic filament

Sustainability is gaining more and more attention in additive manufacturing, and many companies are looking for alternatives. In recent years, several exciting products have been developed to make 3D printing more sustainable by making filaments from recycled plastic. One such project is Print The City by The New Raw, in which plastic from the waste of the people of Amsterdam and Thessaloniki is turned into 3D printed filament and used to print benches and other outdoor furniture. Another initiative is the Million Wave Project, which aims to produce recycled PET filaments for 3D printed prosthetic limbs for those in need. Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70kg of plastic waste from supermarkets in Vienna.

Another initiative is the Million Wave Project, which aims to produce recycled PET filaments for 3D printed prosthetic limbs for those in need. Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70kg of plastic waste from supermarkets in Vienna.

Photo: New Raw

Ivory Inspired 3D Printing Material

Among the many materials used for 3D printing, there are some that have been specifically designed to meet specific requirements and solve old problems in an innovative way. One such material is Digory, which was developed by the University of Vienna in collaboration with Cubicure GmbH to meet the need for the restoration of ancient ivory monuments and objects. It is a synthetic resin containing calcium phosphate particles and silica powder. Researchers have developed this new material with ivory-like characteristics and properties to restore objects using 3D printing or SLA technology. The similarity between these two materials is striking - there is almost no difference!

The Digory material on the right is very similar to the real ivory on the left (photo courtesy of Vienna University of Technology).

Clay as a more sustainable material for 3D printing

One of the unusual 3D printing materials that has certainly attracted attention in recent years is clay. Technically, this is a subset of ceramic 3D printing that, although difficult to print, is known for its incredible properties, in particular the use of clay was especially popularized by the work of the Italian company WASP. For example, we recently saw WASP and Honda use 3D clay printing to create greener vehicles. There are many other uses, although many of them focus on sustainability due to the clay's properties. This can be seen in projects such as archiREEF terracotta tiles for coral restoration in Hong Kong, or 3D printed clay containers designed to reduce food waste.

Photo: Jonathan Keep

Diamond - 3D Printing of the Hardest Material on Earth

It may surprise many that one of the hardest materials on Earth, diamond, can actually be printed. Back in 2019, Sandvik Additive Manufacturing announced the first ever 3D printed diamond composite. It is not shiny, but will allow manufacturers to 3D print super-hard material, which will help revolutionize, especially in the tool industry. Diamond is often used in industries such as mining and drilling, machining, and medical implants, especially for its wear-resistant properties, but it is difficult to process. Sandvik claims that this breakthrough in composites will now allow very complex shapes to be 3D printed, and the company has high hopes for its use in the near future.

Back in 2019, Sandvik Additive Manufacturing announced the first ever 3D printed diamond composite. It is not shiny, but will allow manufacturers to 3D print super-hard material, which will help revolutionize, especially in the tool industry. Diamond is often used in industries such as mining and drilling, machining, and medical implants, especially for its wear-resistant properties, but it is difficult to process. Sandvik claims that this breakthrough in composites will now allow very complex shapes to be 3D printed, and the company has high hopes for its use in the near future.

Human cell printing

When it comes to 3D printing in the medical sector, people often think of bioprinting. In bioprinting, cellular structures, including human structures, are made from bioink loaded with stem cells. As with conventional 3D printing, the biomaterial can be applied layer by layer to create things like skin, tissues, bones, and even organs. Although it is still in its infancy as a technology when it comes to creating viable long-term solutions, we have already seen a number of interesting projects using this technology.