China 3d print house

3D printed house takes shape in rural China »

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

A rural house in north China’s Hebei Province has been catapulted into fame recently for being the first 3D printed house in this rural area of China, built “scan by scan” with giant construction 3D printers.

With vaulted ceilings and concrete outer walls decorated by weave patterns, Zhao Xiujuan’s house in Wujiazhuang Village of Zhangjiakou, the co-host city for the 2022 Winter Olympics, covers an area of 106 square meters and boasts three bedrooms, a kitchen and a restroom.

When Xu Weiguo, a professor with the School of Architecture under Tsinghua University, came up with the idea of building a 3D printed farmhouse in Wujiazhuang, there was an outpouring of concern from villagers.

“How can a big house be printed?” “Is it strong enough?” Regardless of skepticism from her fellow villagers, Zhao asked Xu and his team to rebuild her old house with 3D printing technology.

At the construction site, 3D printing robotic arms built up concrete materials layer by layer to form the foundation and walls. After the roof was printed separately, it was put on the wall by a crane.

The construction of the house was completed in two weeks.

The Kickstarter brought success and brushed away concerns. “There were only two people on each device. They pressed the button, then a house was built. It’s amazing,” said a villager without giving his name.

In recent years, China’s 3D printing market has been growing fast, and the technology has been widely used in aerospace, construction, automobile, shipping and other fields.

Experts even tried to take 3D printing to the next level, by building 3D-printed houses in villages, thus improving the rural living environment.

“This technology can save manpower and construction cost while increasing efficiency and quality,” said Xu, adding that it can keep the design and construction of traditional houses while creating beautiful irregular curved surfaces.

Before the 3D printed farmhouse took shape, Xu and his team have applied 3D printing technology to build other structures at home and abroad, including a 26.3-meter-long pedestrian bridge in Shanghai.

China has made continuous efforts in technological innovation to transform and upgrade the traditional construction sector.

In July 2020, a guideline released by 13 central departments called for efforts to integrate intelligent construction technologies into the whole industrial chain, and set short- and long-term targets for the industry’s high-quality development.

“At present, there are still a large number of houses and infrastructure to be built in China. Intelligent technologies can solve the labor shortage problem faced by the construction industry, liberating workers from their heavy labor,” Xu said.

Source: Xinhua

Related Articles

Back to top button

Chinese Construction Company 3D Prints an Entire Two-Story House On-Site in 45 Days - 3DPrint.

com

comHow long does it take to build a house? Obviously it depends on the size of the house and other factors, but somewhere around six or seven months is a good estimate. Chinese construction company HuaShang Tengda thinks that’s pretty funny, and have essentially laughed in the face of traditional construction by 3D printing a 400-square-meter, two-story house in a mere month and a half.

Beijing-based HuaShang Tengda is a major competitor of fellow Chinese construction company WinSun, which we’ve followed in the past since they surprised us with their 3D printed homes, including a six-story apartment building and a mansion. Not long after that, WinSun’s reputation was tarnished by quite of bit of controversy when Dr. Berokh Khoshnevis, creator of the revolutionary Contour Crafting technique of 3D printing buildings, stated that the Shanghai company had blatantly stolen his patented technology and were passing it off as their own. Moreover, Dr. Khoshnevis said, WinSun’s claim that they were 3D printing entire homes was untrue; in fact, they were 3D printing small sections of walls and then cobbling them together on-site using other construction methods.

HuaShang Tengda appears to be something different altogether. Their two-story villa was printed entirely on-site in a unique process that looks quite different from other 3D printed construction techniques we’ve seen. The team first erects the frame of the house, complete with rebar support and plumbing pipes, and then prints over it with their gigantic 3D printer, which only recently completed testing after several years of development. The printer, as seen in the video below, has a sort of forked extruder that simultaneously lays concrete on both sides of the structural material, swallowing it up and encasing it securely within the walls.

The printing material itself is ordinary Class C30 concrete, an extremely tough, durable yet inexpensive material, and HuaShang Tengda states that any cement material can be used with the process, so that other construction firms can take advantage of what is locally available. Twenty tons of the concrete were used to print the 250cm-thick walls of the villa, and seismic testing showed that the structure should be capable of withstanding an earthquake as strong as 8 on the Richter scale – that’s a strength that has flattened cities.

The technology, according to HuaShang Tengda, was developed entirely in-house and is controlled by custom-designed software that consists of four “systems”: an electronic ingredient formulating system, a concrete mixing system, a transmission system and a 3D printing system. The versatile printer, the company says, can be used to print buildings of any size and shape, including high-rise apartment buildings as well as structures with unconventional shapes that wouldn’t be feasible with other construction methods.

“(This technology) will have immeasurable social benefits,” HuaShang Tengda states. “Particularly the use of the new rural construction can now improve farmers’ living conditions. Because of its speed, low cost, simple and environmentally friendly raw materials, (it can) generally improve the quality of people’s lives. If to be used in developing countries, international competitive bidding in a great competitive advantage, the use of mechanical devices to reduce administrative costs and operating costs.

”

I hesitate to use too many superlatives when talking about a new process, machine or material; we’ve heard a lot of 3D printing-related inventions described as being the next thing to turn a particular industry on its head, and that’s not always the case. WinSun’s claims turned out to be too good to be true, but HuaShang’s technology really does look like the real thing. Beyond the speed and low cost of the process, the fact that it can allegedly withstand all but the very strongest of earthquakes could save millions of lives – an idea that should be very appealing indeed to earthquake-prone China and many other regions. Watch the process for yourself below, and discuss further over in the Two-Story 3D Printed Villa forum at 3DPB.com.

[Images: HuaShang Tengda]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D concrete printing • 3d printed architecture • 3d printed building • 3d printed building materials • 3d printed buildings • 3d printed cement • 3d printed concrete • 3d printed construction • 3d printed house • china • concrete 3d printing • HuaShang Tengda • winsun

Please enable JavaScript to view the comments powered by Disqus.

Top 10 Chinese 3D Printers | 3D Print Expo

There is a wide range of 3D printers on the market today. The most reliable and high-quality devices for three-dimensional printing from American or European manufacturers are considered. However, not everyone can afford them due to the high cost. A good alternative to expensive devices is Chinese printers. Such equipment is functional, but inexpensive. Let's take a closer look at the top ten 3D printers from Chinese manufacturers.

How to choose a 3D printer: selection criteria

When choosing a 3D printer, pay attention to the following parameters and characteristics:

- scope of use of the device. Today, Chinese companies produce construction and industrial printers, equipment for commercial and home use. Before making a purchase, decide for what purpose you need a 3D device;

- printing technology. There are three most common 3D printing technologies: SLA, FDM and SLS.

- SLA is suitable for creating more "precise" products (jewelry, detailed objects, etc.

). FDM is realized by layer-by-layer deposition of molten material. SLS is the most reliable printing method. With its help, prototypes and full-featured products are produced;

). FDM is realized by layer-by-layer deposition of molten material. SLS is the most reliable printing method. With its help, prototypes and full-featured products are produced; - print materials. The most popular consumables for 3D printing include: ABS, PLA, PET, PETT, PVA, HIPS. Also, for the manufacture of three-dimensional products, more specific raw materials are used: metal, carbon fiber, concrete, etc.;

- printer mechanics. These are all moving and static elements of equipment: body, guides, bearings and much more. The reliability of the device, its speed and smoothness depend on their quality;

- print speed. The parameter depends on the quality of the mechanics and the printer body. If the frame of the apparatus is made of a more durable material, such as metal, then its moving elements move faster;

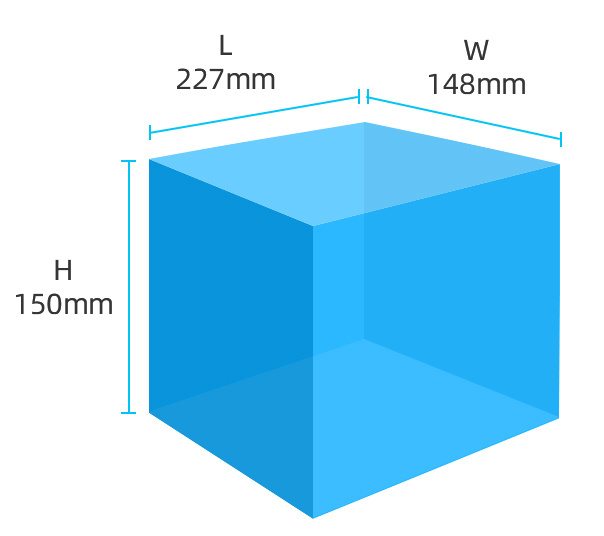

- print area. The larger the work area, the larger objects you can print on it.

Please note that many Chinese 3D printers are sold unassembled. You need to collect them with your own hands. In addition, some devices need additional upgrades. Buying them is for those who have a high level of technical literacy.

You need to collect them with your own hands. In addition, some devices need additional upgrades. Buying them is for those who have a high level of technical literacy.

Top 10 Chinese 3D printers

We bring to your attention an overview of the best 3D printers from Chinese manufacturers. Here you will find budget devices for home use and more expensive models that can be used for commercial purposes.

1. Anet A8

Minimum purchase: $110.

The body of the printer is made of acrylic and the work platform is made of aluminum. The maximum print size is 220x220x240 mm, the print speed is 10-120 mm/s. The device allows you to create products from various materials. For best results, experts advise using PLA and ABS plastics.

Among the shortcomings of the printer: the main elements of the device are made of poor quality materials. Because of this, in some cases, parts are damaged during transportation to the buyer.

Features. 3D printer needs an upgrade. For it to work properly, you need to install additional parts and calibrate it correctly. As a result of such an upgrade, you will receive a device that, in terms of its characteristics, will not be inferior to more expensive models.

3D printer needs an upgrade. For it to work properly, you need to install additional parts and calibrate it correctly. As a result of such an upgrade, you will receive a device that, in terms of its characteristics, will not be inferior to more expensive models.

2. Anycubic 3D Printer

Minimum cost: $151.

3D Printing Equipment is shipped unassembled. If you decide to buy such a device, then you will have to assemble and configure it yourself.

The printer prints at a speed of 20-60 mm/s. However, this does not prevent him from creating products of good quality. The positioning accuracy along all axes of the device is 0.01 mm, the nozzle diameter is 0.4 mm. The model supports work with such types of plastic as PLA, ABS, Wood, HIPS.

Features: is compact and lightweight - only about 7 kilograms. This makes the printer easy to use and transport.

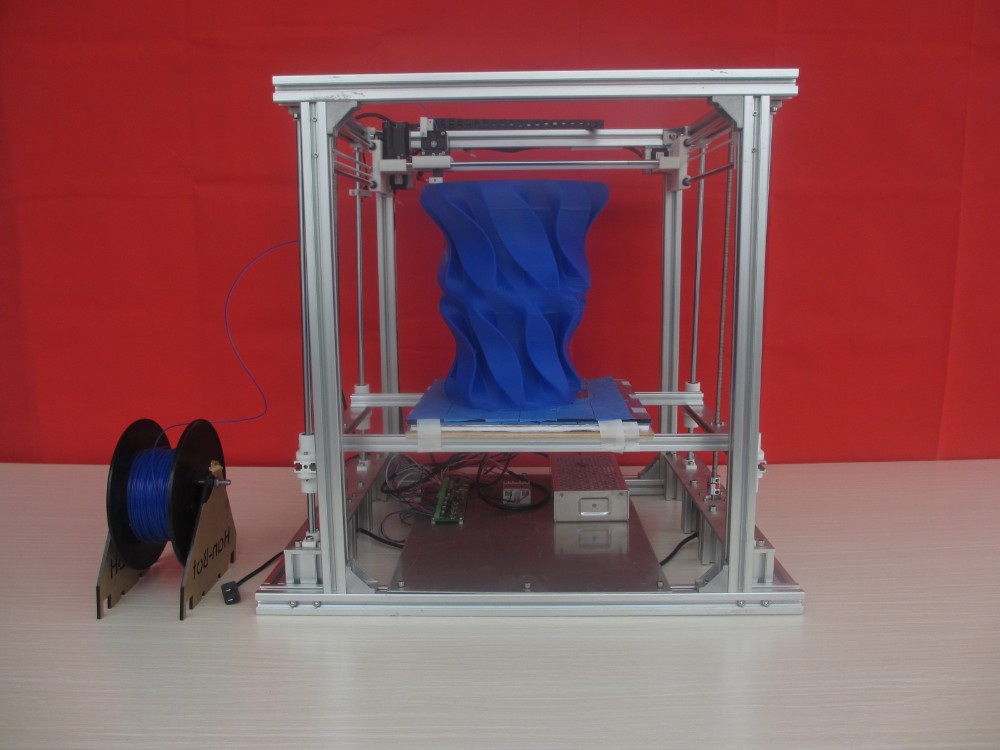

3. Flsun 3D

Minimum cost: $160.

The printer is easy to assemble and quickly set up, making it the right product for newcomers to the world of additive manufacturing.

Machine with aluminum legs and stainless steel moving parts. The device is complemented by a touch screen, which provides comfortable control.

The dimensions of the working area are 260x260x350 mm. Supported print materials: PLA, ABS, Flexible PLA, HIPS, PVA. The minimum layer thickness is 0.05 mm.

Features: double extruder. This allows you to simultaneously use plastic of different colors and set the intensity of melting of a particular material at the program level.

4. Geeetech A10

Minimum cost: $186.

The size of the working area reaches 220x220x260 mm. The extruder is capable of heating up to 250 degrees Celsius, and the printing platform - up to 100 degrees Celsius. Print speed - up to 180 mm / s. The printer allows you to create products from such types of plastic as ABS, PLA, PVA, HIP. The machine is equipped with a remote file printing function.

The machine is equipped with a remote file printing function.

Features: is based on the open source GT2560 platform. Thanks to this, you can write a program to work with the printer yourself and configure it according to your needs.

5. Anet A3S

Minimum purchase: $194.

3D printer suitable for home use. With it, you can make prototype parts and various household items.

Budget machine with an open body, equipped with an LCD display and one extruder. Print speed - 40-120 mm / s. The nozzle can heat up to 260 degrees Celsius. Supported materials: PLA, ABS. Printing can be done directly from a computer or via an SD card.

Features: comes to the buyer assembled and does not require assembly. Equipped with a durable housing. Due to this, the printer is more stable, works well and is used for a long time.

6. Flying bear P905X

Minimum purchase: $285.

The P905X is an open cabinet printer with an aluminum frame. The size of the working area is 280x340x360 mm. The maximum print speed is 150 mm/s. To obtain better products, experts recommend operating the machine at lower speeds.

Supported media types: ABS, PLA, PVA, PETG and flexible filaments. The layer thickness is adjustable and ranges from 0.05 mm.

3d printer needs an upgrade. When using two extruders, you will need to install a larger cooler.

Features: is equipped with a high-quality and quiet ventilation system.

7. TEVO Tornado

Minimum purchase: $288.

Tornado is suitable for printing large sizes. However, it should be borne in mind that their creation can take up to several days.

The 3D printer prints products at speeds up to 150 mm/s. Supports work with plastic PLA, ABS, PETG, Wood, PVA. The extruder is heated up to 260 degrees Celsius. However, the manufacturer recommends printing at 210 degrees Celsius.

Among the disadvantages of the device: the inability to install a second extruder and the lack of an automatic calibration function.

Features: large print area - 300x300x400 mm, as well as ease of installation. The device is delivered to the buyer assembled with a pre-configured and calibrated system. Also, the device is equipped with an extruder that allows you to print high quality products at medium speeds.

8. FlyingBear Ghost

Minimum purchase: $318.

This is a convenient and reliable 3D printer that allows you to print products at high temperatures. The size of the print construction area is 230x230x210 mm. The device works with filaments: PLA, ABS, Wood and HIPS. Print speed - up to 150 mm / s.

Features: closed on three sides. If desired, glass can be installed on its facade. Another plus of the device is the high positioning accuracy of the extruder and Wi-Fi support.

9. Creality 3D CR-10

Minimum purchase: $345.

This 3D printer model is suitable for those who want to print large items. The size of its working area is 300x300x400 mm. Due to the high printing speed (up to 200 mm/s), products are printed in the shortest possible time.

Printer frame made of aluminium. Experts advise installing a closed case on the device if you plan to make models from ABS plastic or PETG threads when the table is heated up to 95 degrees Celsius. This will make the printing process more reliable.

Features: high printing precision. The error is only one millimeter.

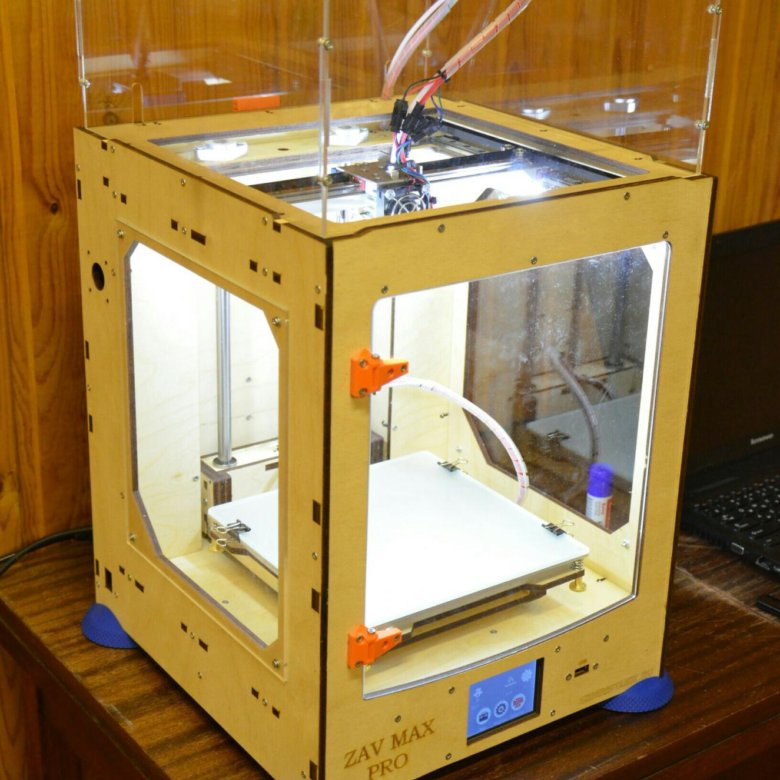

10. Flying Bear Tornado 2

Minimum purchase: $592. Flying Bear

Tornado 2 is one of the highest quality 3D printers from Chinese manufacturers.

Machine body, extruder, guides and other parts are made of aluminium. The heating temperature of the table is 120 degrees Celsius, and the extruder is 240 degrees Celsius. The maximum print speed is 150 mm/s.

The maximum print speed is 150 mm/s.

The printer can be supplied as standard, with two extruders or with a color touch screen. Its assembly and further modernization require knowledge in the field of electrical engineering and engineering.

Features: The 3D printer is large and allows you to create parts with a size of 360x360x360 mm. The minimum layer thickness is 0.03 mm. Thanks to these characteristics, the device prints high-quality products that do not require additional refinement.

A park decorated with 3D printed architectural forms has opened in China

News

, walls and curbs made using 3D printers based on multi-axis robotic arms.

According to Xu Weiguo, professor of the Department of Architectural Design at Tsinghua University, who led the technical team, the park's improvement took two and a half months. All concrete objects are printed on in-house developed additive systems using recycled materials.

According to Professor Xu, 3D printing with concrete is much cheaper than the production of traditional reinforced concrete structures, since computer simulation of additive processes helps to optimize structures at the design stage and identify possible technical problems in advance.

Other projects by the professor and his team include experimental gazebos that automatically open or close depending on weather conditions, affordable housing for the poor in Africa, and a concrete bridge in Shanghai that opened in 2019year ( in the illustration below ).

This 26m structure is made up of 3D printed blocks on a steel arch and was for some time considered the longest 3D printed concrete bridge in the world.

In 2020, the record was broken by colleagues from the Hebei Polytechnic University with a 28-meter bridge, and just a week ago, work was completed on a new record holder ( in the illustration above ) - a 29-meter pedestrian and bicycle bridge in the Dutch city of Nijmegen , now by Royal BAM Group, Saint-Gobain Weber Beamix and Eindhoven University of Technology.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Article comments

More interesting articles

fourteen

Subscribe to the author

Subscribe

Don't want

This used to happen in cases of revocation of airworthiness certificates for storks and poor harvest of cabbage children came ...

Read more

four

Subscribe to the author

Subscribe

Don't want

Hello everyone!

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci.