3D printers made in america

Best USA 3D Printer Manufacturer | American Made 3D Printer

OUR HISTORYFusion3 was conceived in 2012 in North Carolina, anticipating that 3D printing and 3D printer companies would eventually see mainstream adoption not necessarily by consumers, but by businesses and other organizations that will require an end-to-end experience that delivers both performance and reliability as a mission-critical tool for the organization. We set our goal to become one of the country’s best 3D printer companies, consistently producing the very best American made 3D printers.

3D PRINTERS MADE IN THE USASince our founding, Fusion3 has grown to become a leader in the design and manufacture of American made, professional 3D printers. All production takes place at our Greensboro, North Carolina, USA factory, ensuring both innovation and the highest quality in every device we ship to our customers.

3D printing is not overly difficult and we at Fusion3 are working to develop technologies to make the process easier and more reliable with each product generation.

For first time users in can feel overwhelming to adopt 3D printing technologies. In response, we at Fusion3 the best warranty and strive to provide the highest quality of technical service and support of any 3D printer company in the industry. Our technical support teams are also based out of our USA 3D printer factory and staffed by employees who have expert knowledge of the product as they too build and operate our American made 3D printers on a daily basis.

| Do you know the manufacturing locations for each of these 3D printer manufacturers? | |

| Raise3D | China |

| Ultimaker | Netherlands |

| Makerbot | China |

| Zortrax | Poland |

Provide

world-class, USA-Made 3D printers,to customers at best-in-class prices.

We accomplish this by building US 3D printers that delight the end-user AND

demonstrate value to the purchasing executive through:

Continual Improvement

Our customers require a product that works reliably AND provide best-in-class performance. We continually identify ways to improve the speed, print quality, reliability, and ease of use of our printers, ensuring we are consistently at the forefront of improvement among all 3D printer companies.

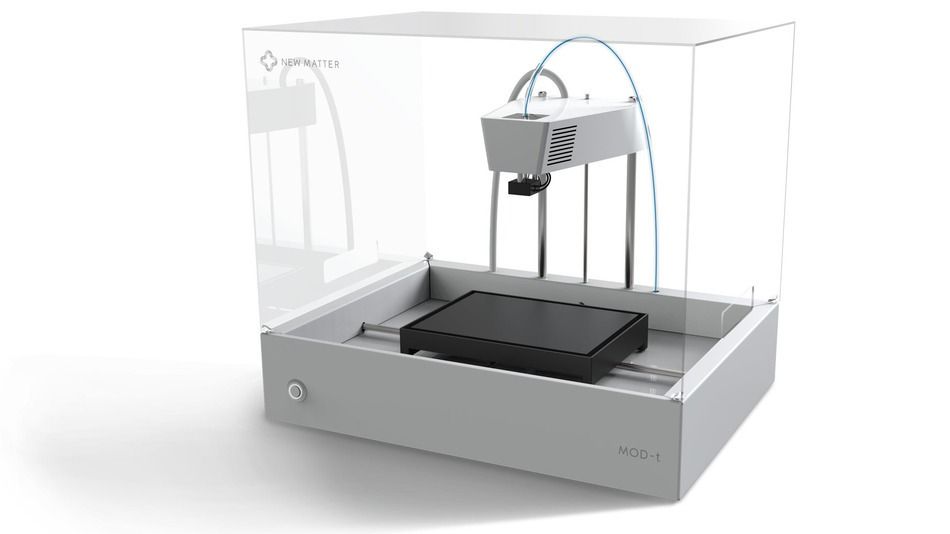

Features, Not Flash

Sexy industrial design is expensive and translates into a higher priced product for the customer. Unlike other 3D printer companies, Fusion3 invests its resources to improve performance. When we invest in industrial design, its because we see an opportunity to improve performance and reduce operating costs for the customer.

Customer Satisfaction

Not only do we strive to build a great American made 3D printer that can operate for thousands of hours, but we also make sure that the customer is able to generate great printing results. We’re happy to take your call whether solving an issue or helping you imagine ways to get more from our printers.

We’re happy to take your call whether solving an issue or helping you imagine ways to get more from our printers.

HEADQUARTERS / FACTORY

MAILING/SHIPPING ADDRESS:

Fusion3 3D Printers

130 South Walnut Circle

Greensboro, NC 27409

Visits by appointment only

Phone / Main Switchboard:

877-452-0010

MAILING/SHIPPING ADDRESS:

Fusion3 3D Printers

620A South Elm Street

Greensboro, NC 27406

Visits by appointment only

Phone:

877-452-0010×1

how to add a map to wordpress

KEY CONTACTSSales: [email protected]

Technical Support: [email protected]

Reseller Inquiries: resellers@fusion3design. com

com

Testing of 3D Printable Materials: [email protected]

Shipping & Accounts Receivable: [email protected]

Accounts Payable: [email protected]

Corporate Inquiries / Partnerships: [email protected]

Employment: [email protected]

FREQUENTLY ASKED QUESTIONS:ABOUT FUSION3 3D PRINTERS

;">Where is Fusion3 based?

Fusion3 is based in the US in Greensboro, North Carolina. All of our production takes place in North Carolina and we are proud to produce some of the best USA made 3D printers.

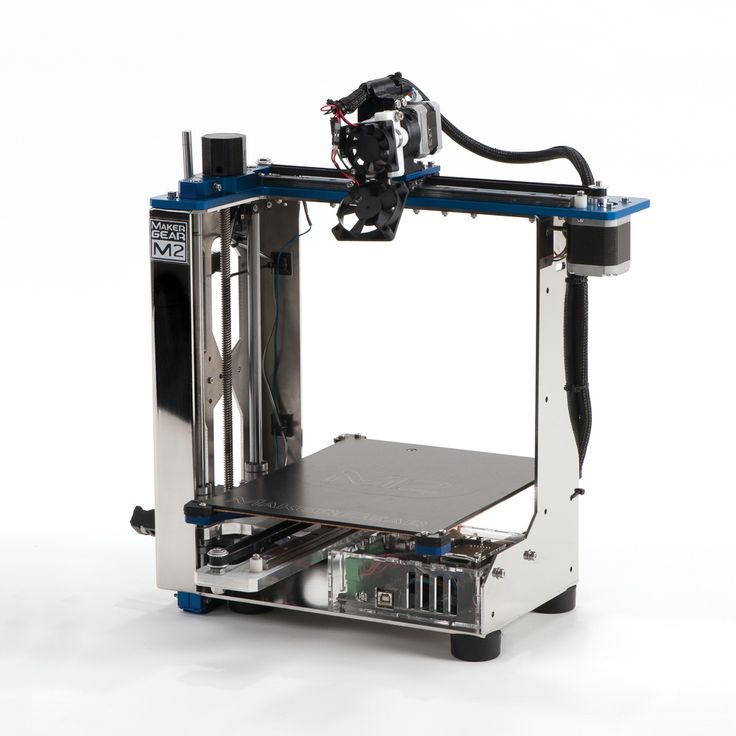

;">What 3D printers are made in the USA?

If buying a USA-made 3D printer is important to you, you should make sure the 3D company you are evaluating manufactures in the US. While many 3D printer companies have corporate offices based in the US, they often outsource their manufacturing to other countries. At Fusion3, we are proud to not only have our office located in the USA, but also our manufacturing in the USA.

At Fusion3, we are proud to not only have our office located in the USA, but also our manufacturing in the USA.

Top 3D Printer Manufacturers and Suppliers in the USA and Canada

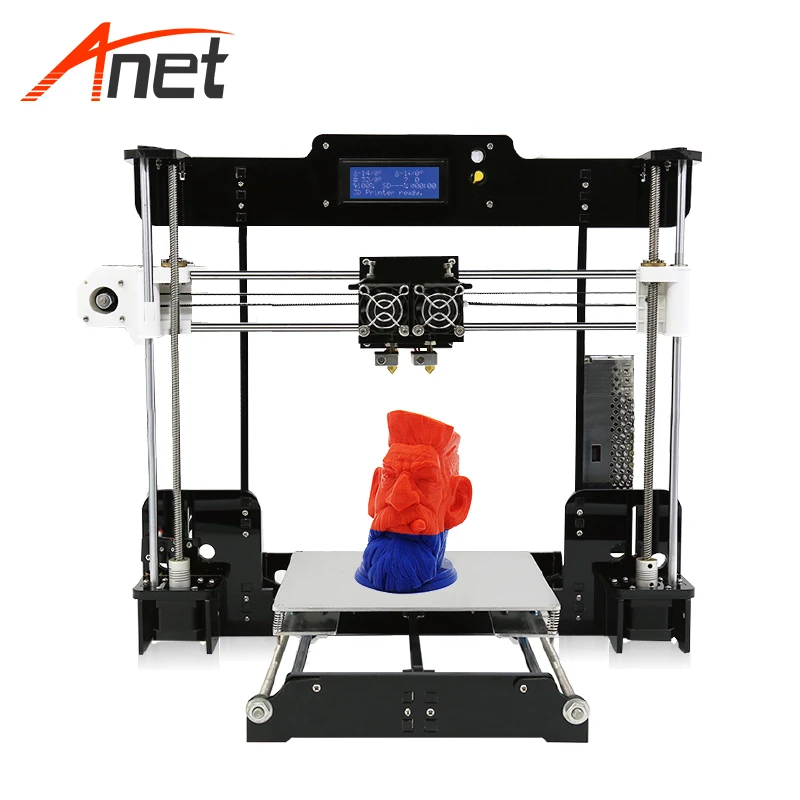

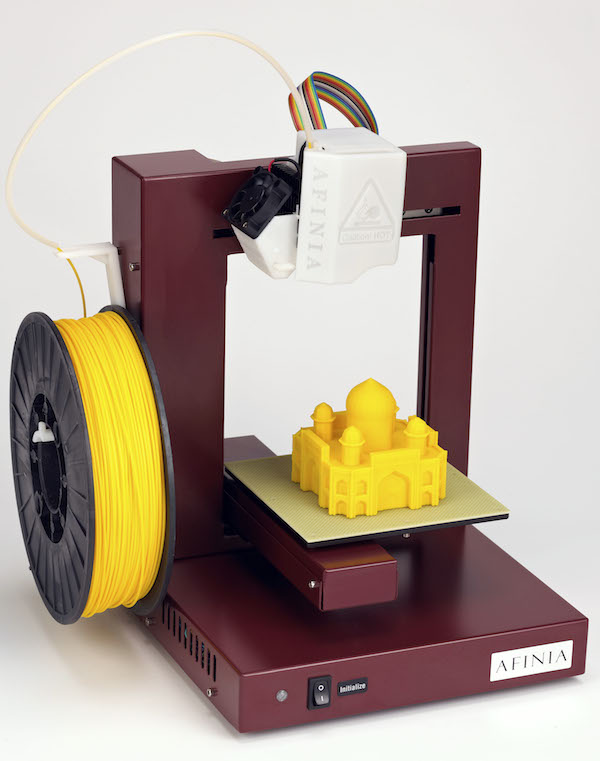

A 3D printer uses CAD to create 3D objects from a variety of materials,like molten plastic or powders

Image credit: Shutterstock/Aumm graphixphoto

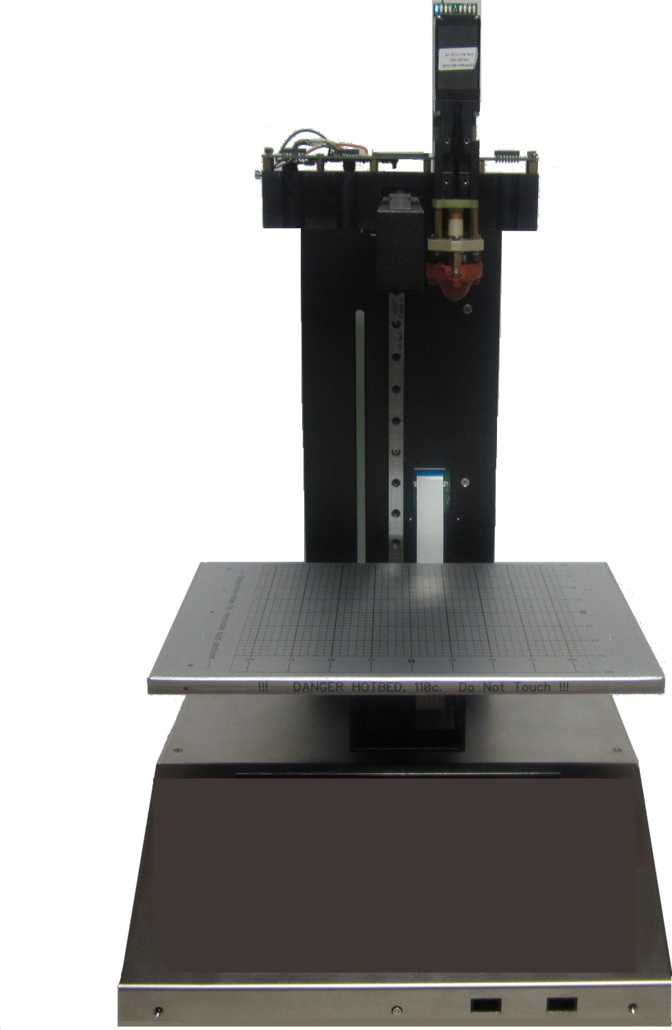

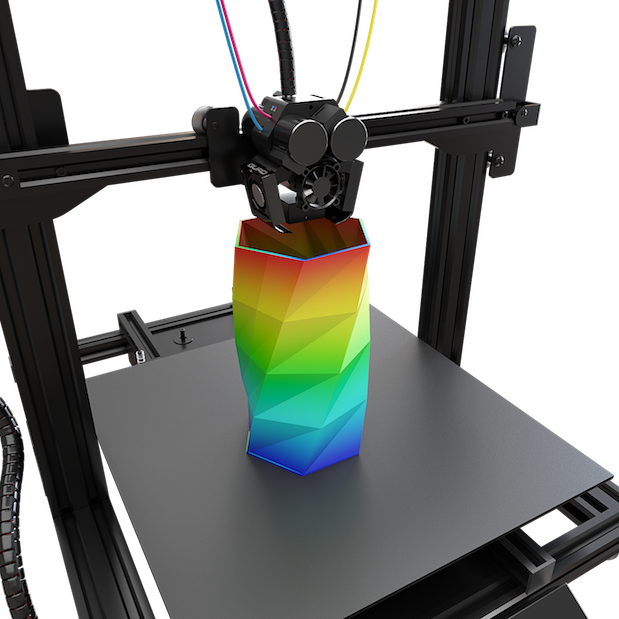

3D printers also called additive manufacturing printers or fabrication printers are a type of material design printer that designs and builds 3D models and products of devices and components using an additive manufacturing process.

3D printers design three-dimensional prototypes and create the end product by directly building them using computer-aided design (CAD) or software-created 3D design diagrams, figures, and patterns.

3D printers utilize additive manufacturing, where the printer designs the object by applying sequential layers of raw material to print a three-dimensional object.

In this article, we'll cover details on the top U.S. providers of 3D printers, along with our featured list of top 3D printer suppliers on Thomasnet.com.

Top Featured U.S. & Canada Suppliers of 3D Printers

Below is a list of featured suppliers of 3D printers from our platform. The company name, year, location, and employee count are also listed in the table.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Revenue |

| 1 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $100 - 249. |

| 2 | AON3D | 2015 | Montreal | QC | h3N1P4 | NA | NA |

| 3 | Nexa3D | NA | Ventura | CA | 93003 | 10-49 | $5 - 9.9 Mil |

| 4 | Terrafilum | 2017 | Cary | IL | 60013 | 1-9 | Under $1 Mil |

| 5 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $10 - 24. |

Company Summaries

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

Located in Montreal, QC, AON3D is an industry-leading manufacturer of high-temperature 3D printers. The company's printers prints with polyetheretherketone (PEEK), polyvinylidene fluoride (PVDF), polyphenylene sulfide (PPS), acrylonitrile butadiene styrene (ABS), thermoplastic elastomer (TPE), thermoplastic polyurethanes (TPU), polyphthalamide (PPA), polypropylene (PP), polyvinyl chloride (PVC), polycarbonate and nylon materials.

Nexa3D specializes in manufacturing 3D printers for engineering, dental, medical and education industries. The company is situated in Ventura, CA.

The company is situated in Ventura, CA.

Headquartered in Cary, IL, Terrafilum manufactures 3D printers since 2017. The company meets the demands of the commercial and educational sectors.

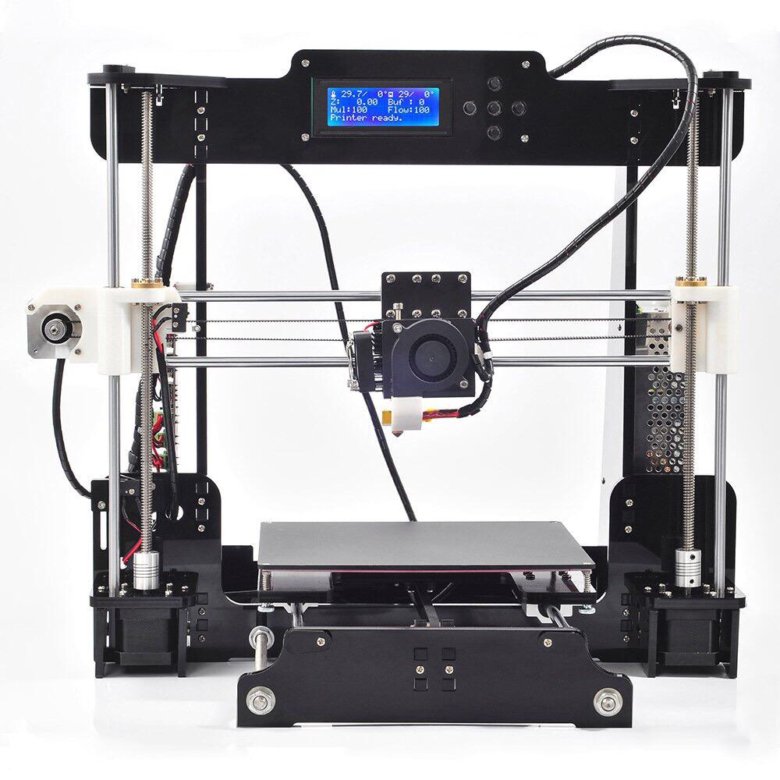

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Top U.S. Suppliers of 3D Printers Based on Sales

Below we have assembled information on the top suppliers of 3D printers in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Volume |

| 1 | HP Inc. | 1938 | Palo Alto | CA | 94304 | 500-999 | $118,004,000,000 |

| 2 | Trumpf, Inc. | 1934 | Farmington | CT | 06032 | 1000+ | $2,700,000,000 |

| 3 | Stratasys Ltd. | NA | Eden Prairie | MN | 55344 | 200-499 | $672,458,000 |

| 4 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $107,000,000 |

| 5 | 3D Systems - Quickparts Solutions | 1986 | Atlanta | GA | 30346 | 50-99 | $99,999,999 |

| 6 | XYZprinting, Inc. | NA | San Diego | CA | 92121 | 200-499 | $75,000,000 |

| 7 | MakerBot Industries, LLC | 2009 | Brooklyn | NY | 11201 | 100-199 | $74,716,906 |

| 8 | MarkForged | NA | Cambridge | MA | 02138 | 100-199 | $30,000,000 |

| 9 | Mimaki USA | 1999 | Suwanee | GA | 30024 | 50-99 | $26,785,966 |

| 10 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $24,999,999 |

Company Summaries

With over 80 years of experience, HP Inc. is a manufacturer of 3D printers. The company meets the demands of consumer goods or electronics, orthotics, prosthetics, health care, medical, higher education, transportation, automotive, and aerospace industries.

Located in Farmington, CT, Trumpf, Inc. manufactures laser metal fusion (LMF) and laser metal deposition (LMD) printers for over 20 years. Data communications, electronics, photovoltaics, science, tool or mold making, transport, display, dental, aviation, aerospace, medical technology, jewelry, automotive, construction, and sheet metal processing are some of the industries served by the company.

Stratasys Ltd. manufactures 3D printers serving industries such as consumer products, aerospace, automotive, dental, medical, education, railway, art, fashion, and government. PolyJet, stereolithography (SLA), and fused deposition modeling (FDM) technology 3D printers are offered by the company.

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

3D Systems - Quickparts Solutions manufactures metal, plastic, and casting 3D printers. The company meets the demands of motorsports, aerospace, defense, automotive, consumer technology, jewelry, semiconductor, truck, bus, rail, and turbomachinery markets.

Founded in 2013, XYZprinting, Inc. specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

MakerBot Industries, LLC manufactures 3D printers that print with polymers, composites, and metal materials. Aerospace, automotive, education, and manufacturing are some of the industries served by the company.

MarkForged is a leader in manufacturing 3D printers that prints using materials such as continuous fibers, plastics, stainless steel, tool steel, copper, and Inconel®. The company serves consumer packaged goods, electronics, automotive, aerospace, education, research, energy, defense, federal, energy, and medical markets.

Founded in 1975, Mimaki USA specializes in manufacturing 3D printers. The company is headquartered in Suwanee, GA.

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Summary

With the help of the provided details on the 3D printer suppliers in the United States and Canada in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

You can also look at our Supplier Discovery page, which has information on more than 150 suppliers of 3D printers.

Trademark Notice

Sources

-

3D Printers

Other 3D Printing Articles

- Types of 3D Printing Technologies

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- All About Material Jetting

- All About Multi-Jet Modeling (MJM) 3D Printing

Other Top Suppliers Articles

- Top RFID Antenna Manufacturers USA and Internationally

- Top Thermocouple Manufacturers in the USA - By Revenue, Location and Product Type

- Top Suppliers of Integrated Circuit Design Services in the USA and Globally

- Top Industrial Automation Software Companies in the USA and Globally

- Top Cloud Services Providers and the USA and around the Globe

- Top Battery Enclosure Manufacturers and Suppliers in the US and Globally

- Top Proximity Sensors Suppliers and Manufacturers in the USA and Worldwide

- Top Resistor Suppliers and Manufacturers in the US and Globally

- Top RFID Tag Manufacturers in the USA and Internationally

- Top Temperature Sensors Manufacturers and Suppliers

- Top Cable Assembly Manufacturer Companies in the USA

- RFID Software Companies in the USA and Internationally

- Top Predictive Maintenance Companies in the USA and Globally

- Top Pipe and Tube Bending Companies in the USA

- Top EDM Services Suppliers in the USA

- Top RFID Reader Manufacturers and Suppliers in the USA and Internationally

- Top RFID Inventory Control Software Companies in the USA and Internationally

- Top U.

S. Screw Machining Service Suppliers

S. Screw Machining Service Suppliers - Top Sensors Manufacturers and Suppliers in the USA

- Top Graphene Companies and Manufacturers in the USA

- Top Suppliers of Polyvinyl Chloride (PVC)

Top Laboratory Supply Companies in the USNext Story »

More from Custom Manufacturing & Fabricating

USA builds largest metal 3D printer

News

Subscribe author

Subscribe

Don't want

2

Ingersoll, MELD Manufacturing and Siemens will build the largest metal 3D printer. The system will rely on adapted friction welding technology and will be able to grow parts up to ten meters long.

The work is carried out in the interests of the US military: such 3D printers are planned to be used primarily in the production of mine protection for army vehicles. During the Vietnam War, 73 percent of equipment losses were due to explosions on anti-personnel and anti-tank mines. Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

An American Cougar armored vehicle that hit a mine in Iraq in 2006 and drove another three kilometers to the safe zone. The personnel escaped with minor injuries. Photo: Marine Sergeant Christopher Clare

Previous work on the Jointless Hull project of the Army ManTech research program has looked at forging, forming and welding at high current density to reduce weld porosity. The results were rated as satisfactory in terms of strength, but at the same time, there was a lack of geometric freedom and manufacturing flexibility.

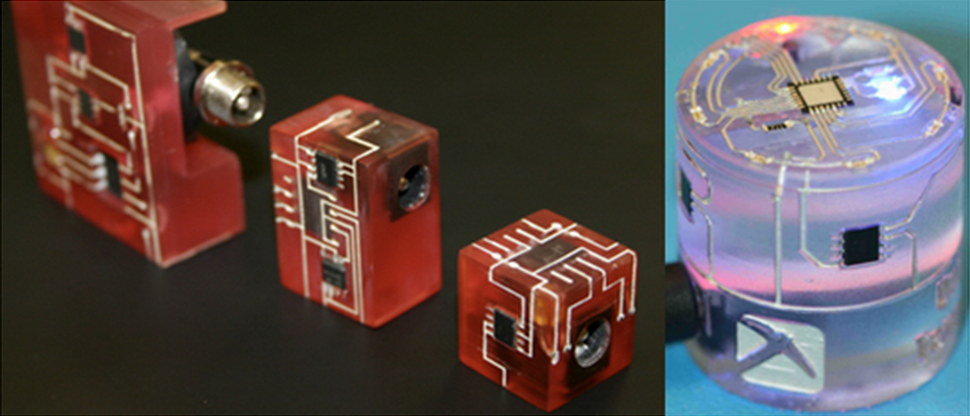

As a result, they decided to abandon forging, forming and welding in favor of another technology - production by the method of additive friction deposition with mixing (Additive Friction Stir Deposition, AFSD), that is, Friction Stir Welding, adapted for 3D printing, FSW).

Development work consists of two stages. Not the first one is planned to assemble a demonstrator with a construction area measuring 1x1x1 meter to test the technology and software. The design must then be scaled up to a working volume of 10x6.5x4 meters - the largest among "metal" 3D printers. Length is a conditional characteristic, since the portal structure will move along the rails. Siemens is responsible for the control systems and software.

The large-format version is already being assembled by Ingersoll, which has considerable experience in working on large additive systems. In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

The new 3D printer, as already mentioned, will deposit metals using friction stir deposition. This technology is being developed by MELD Manufacturing using the Edison Welding Institute (EWI). The build-up is carried out by plastic deformation at temperatures below the melting threshold, thereby achieving high isotropy and density without shrinkage and the risk of hot cracks, without the need for a vacuum chamber or protective gas environment. The technology also allows you to create gradient structures from different metals or alloys. Consumables are usually rounded bars with the possibility of using powders of different fractions and even metal shavings.

MELD Manufacturing already offers several models of additive systems. The latest commercial offer is the L3 3D printer released in 2020 with a working area of 1143x584x584 mm, although the K2 system with a useful volume of 2100x1100x1000 mm is the leader in terms of dimensions. The equipment allows you to work with various steel grades, as well as aluminum, copper, titanium, magnesium and nickel alloys. As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

Siemens MELD Ingersoll rotary welding

Follow author

Follow

Don't want

2

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

On October 21, the solemn opening of the production site for the production of so-called. ..

..

Read more

5

Follow the author

Subscribe

Don't want

Cosmonaut Oleg Artemyev, who recently returned from the International Space Station, spoke about the experimental...

Read more

41

Subscribe author

Subscribe

Don't want to

Release includes a new perimeter generator called Arachne, support for STEP files, order...

Read more

residential buildings

Stepan Ikaev

American startup Icon, which specializes in building houses using 3D printers, has announced the largest project in the industry. The company has entered into a deal with real estate developer Lennar and architecture firm Bjarke Ingels Group, under which the partners will build 100 private homes in suburban Austin, Texas. Icon promises to start construction in 2022.

Icon promises to start construction in 2022.

At the heart of Icon technology are Vulcan 3D printers. The large-scale construction relies on proprietary software and the fast-curing Lavacrete mixture that makes up the foundations, walls, and roofs of the Icon houses. The system erects full-fledged buildings with an area of up to 278 meters - work with buildings of such dimensions takes from 12 to 24 hours. An additional feature of the Icon offer is that upon completion of construction, the startup installs solar panels on the roof of each house.

“Additive manufacturing has the potential to revolutionize the building environment as it scales the industry. Through partnerships with ICON and Lennar, we can see how this technology will reach the widest possible audience. 3D printed architecture and photovoltaic roofs are innovations that pave the way to reduce waste in the construction process and make our homes more sustainable and self-sufficient,” said BIG-Bjarke Ingels Group spokesman Martin Folkle. .

.

Much of Icon's workflow is automated. The operating system independently translates the floor plans of the future building into printing and monitors the operation of the 3D printer during the laying of materials. And built-in machine learning algorithms detect printer errors in real time, alert builders to problems, and speed up construction of new homes. When the Vulcan work is completed, contractors are called in to carry out cosmetic repairs, install doors and windows, and connect plumbing and electricity to the house.

“ICON exists as a response to the global housing crisis. 3D printing in construction is delivering higher quality homes faster and cheaper, and a fleet of printers can make a difference in the construction of entire neighborhoods,” added Icon co-founder and CEO Jason Ballard.

According to New Atlas, Icon and partners have not yet disclosed the exact timing of the project and do not name its cost. It is known that construction will begin in 2022, and the approximate cost of Icon 3D printer services can be estimated using the example of past startup projects — the cost of family houses ranged from $40,000 to $450,000, depending on the client’s requirements.

9 Mil

9 Mil 9 Mil

9 Mil