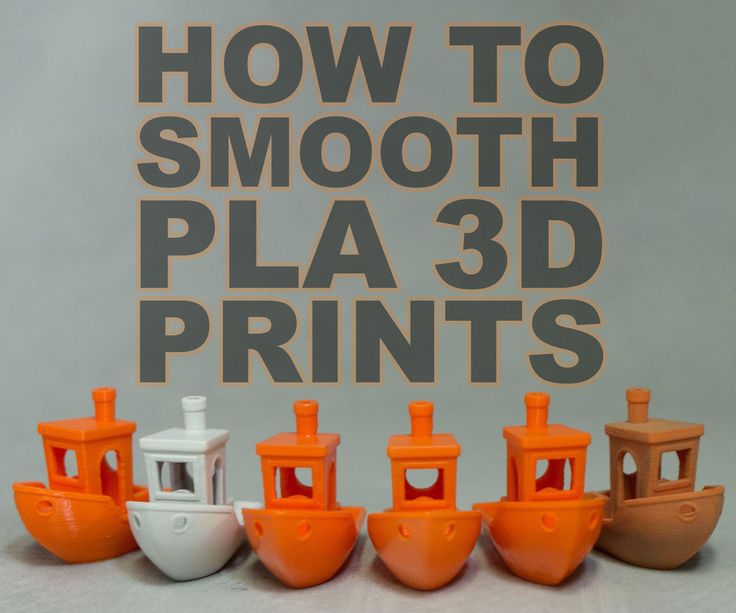

Smooth out pla 3d print

How to Get Perfectly Smooth PLA 3D Prints – Clever Creations

Are you interested in smooth PLA 3D prints but aren’t sure where to start? You’re not alone! PLA smoothing is one of the most common concerns among 3D printing enthusiasts who want glossy prints without the hassle of working with ABS.

While you won’t find a direct equivalent of ABS acetone smoothing for PLA, there are several other methods you can use to achieve a smooth outer surface on your prints. Whether you just don’t like the 3D printed look, want to sell your 3D prints, or need a smooth piece for certain applications, PLA smoothing is fast and easy.

In this article, you’ll find the most common products and techniques used in PLA smoothing, how to use them, the benefits and disadvantages of each method, and when one method should be used over another.

What is PLA Smoothing?

PLA smoothing is the process of removing the visible layer lines that are generated on 3D printed parts during the printing process. A smoothed 3D print becomes just that: smooth. The outside of the print loses the 3D printed look and appears more like injection-molded plastic.

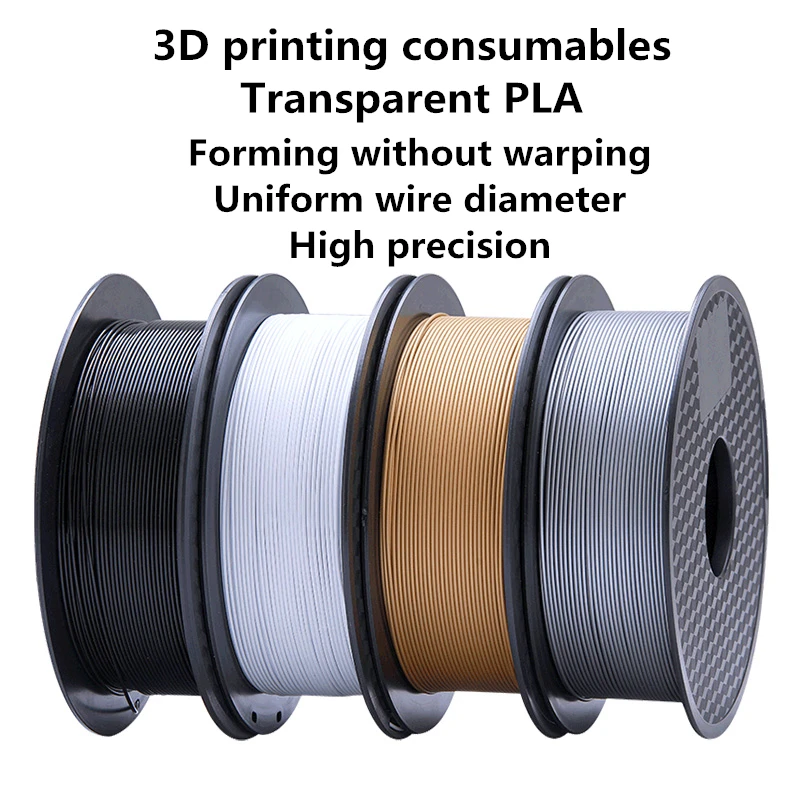

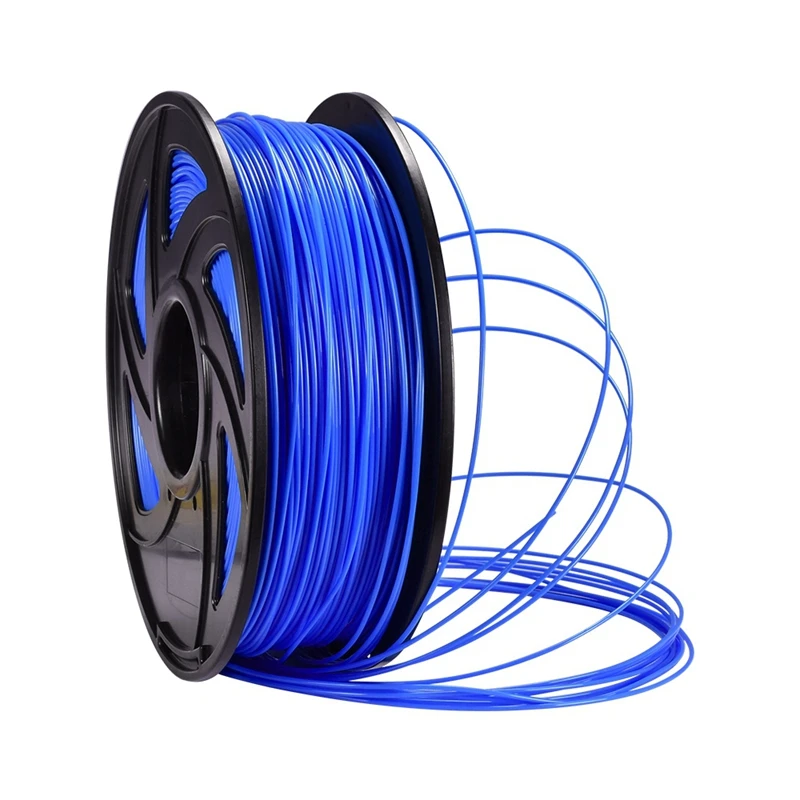

PLA is one of the most common 3D printing materials available because it is easy to use, cheap, and readily available. PLA prints at a low temperature and does not have a strong tendency to warp (unlike ABS filament), making it a good choice for beginners.

Recommended:

PLA vs ABS: Which Filament is Better?

There are many methods to achieve a smooth look on PLA prints, and they usually require either by removing the excess plastic that causes the visible layers or filling in the tiny gaps between the layers with some sort of brush-on coating. Each method has its pros and cons and some are better for certain projects than others.

Why Smooth PLA 3D Prints?

There are several reasons for smoothing PLA 3D prints, but the most common one is aesthetic. Many enthusiasts don’t like the lined look of 3D prints and would prefer to remove them. This is especially true if they are making money with their 3D printer by selling 3D prints, since their customers may not appreciate the rough texture.

This is especially true if they are making money with their 3D printer by selling 3D prints, since their customers may not appreciate the rough texture.

You also may need to fill in or remove your layer lines for certain applications. For example, if you are using the print as a master for making a silicone mold, you may want to smooth it so the texture isn’t transferred and so that casting materials like resin end up being glossy instead of matte.

Some of the methods used for smoothing PLA prints, like epoxy coatings, also make your prints more resilient. The coatings seal the layers and protect them from moisture and dirt. This is especially helpful if you plan to use your prints outside. Even sanding and spray painting your prints gives them more water and heat resistance.

An additional benefit of epoxy coatings is that they can help make your PLA food safe.

Methods to Smooth PLA Filament Prints

XTC-3D

XTC-3D is a high-performance two-part epoxy resin coating formulated to smooth 3D prints. Epoxy resin generates heat as it cures, so typical epoxies can warp 3D prints made from low-temperature materials like PLA. XTC-3D is formulated to cure at a lower temperature, so it won’t damage your prints.

Epoxy resin generates heat as it cures, so typical epoxies can warp 3D prints made from low-temperature materials like PLA. XTC-3D is formulated to cure at a lower temperature, so it won’t damage your prints.

Like most resins, XTC works by mixing the dormant resin with a proportionate amount of hardener. Once the hardening agent is added, the resin will go from liquid to solid within a certain amount of time. While it’s still in its liquid phase, you can paint a thin layer of it on your print and let it cure.

Resin coats like XTC are a great option for smoothing 3D prints because they are relatively simple to use and produce great results. The resin coating fills in the layers and adds a glossy shine. You can even sand and paint the resin coating as needed to easily achieve the look you want.

Epoxy resins should be handled with care and proper personal protection equipment. Always use XTC-3D in an area with good ventilation (while ideally wearing a respirator) and wear protection like latex or nitrile gloves and goggles to protect your skin and eyes. Be sure to check the product’s MSDS for more information on safe handling.

Be sure to check the product’s MSDS for more information on safe handling.

XTC-3D - High Performance 3D Print Coating - 6.4 Ounce Unit

1,328 Reviews

Check PricePros:

- Paints on easily

- Clear glossy finish

- Protects your prints

Cons:

- Expensive

- Fumes while uncured

3D Gloop

One of the most versatile 3D printing products you can buy, 3D Gloop is an adhesive meant for coating the print bed and gluing 3D printed parts together. However, it also works well as a brush-on coating to smooth PLA, ABS, or PETG 3D prints.

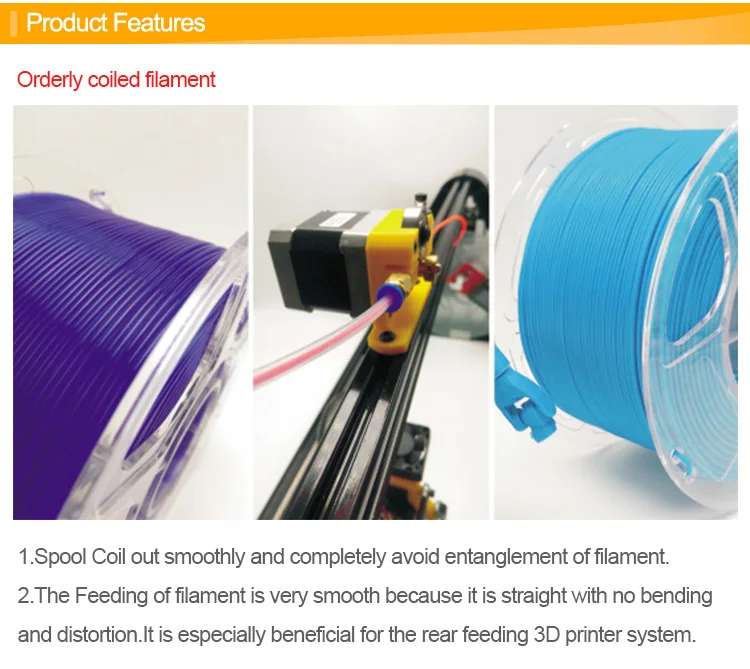

Unlike resin formulas like XTC-3D, you don’t need to mix or otherwise prepare 3D Gloop—you can brush it on in thin layers directly from the bottle and let it dry. They have formulas specifically made for different types of filament, so make sure you are using the PLA product for smoothing PLA parts.

3D Gloop does produce a lot of fumes while in use, so always use it in a well-ventilated area or with a respirator. You should also wear gloves and goggles and try to avoid direct contact with your skin (and be sure to wash it off quickly if skin contact does happen). If you also resin 3D printing, you might already have this equipment at hand.

You should also wear gloves and goggles and try to avoid direct contact with your skin (and be sure to wash it off quickly if skin contact does happen). If you also resin 3D printing, you might already have this equipment at hand.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

Pros:

- Easy to use

- Versatile

- Made for 3D prints

Cons:

- Hazardous fumes

Sanding and Painting

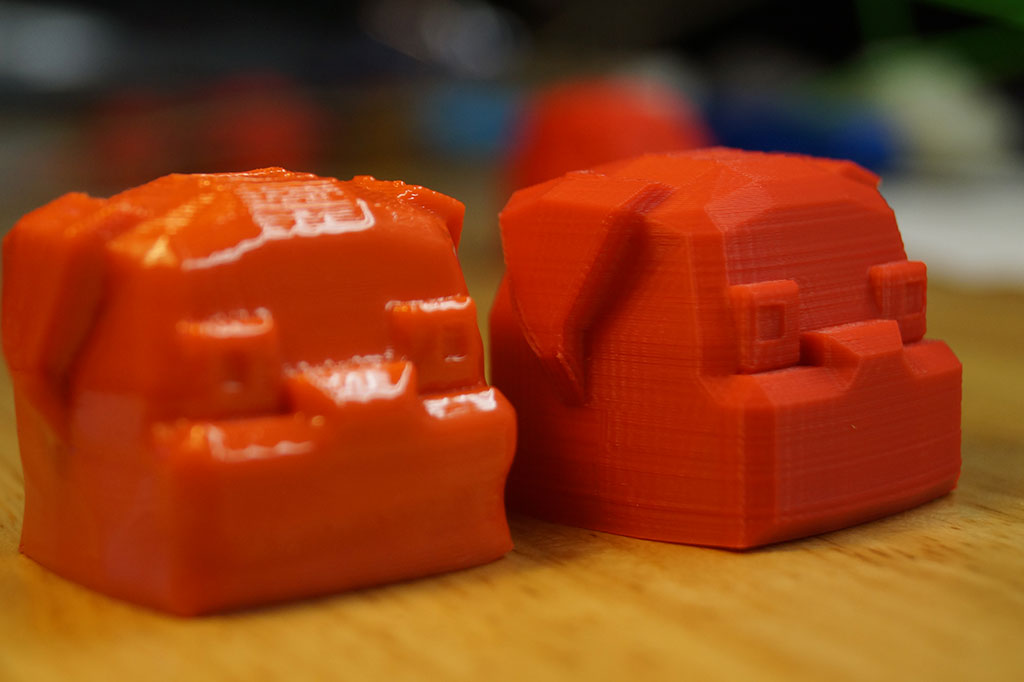

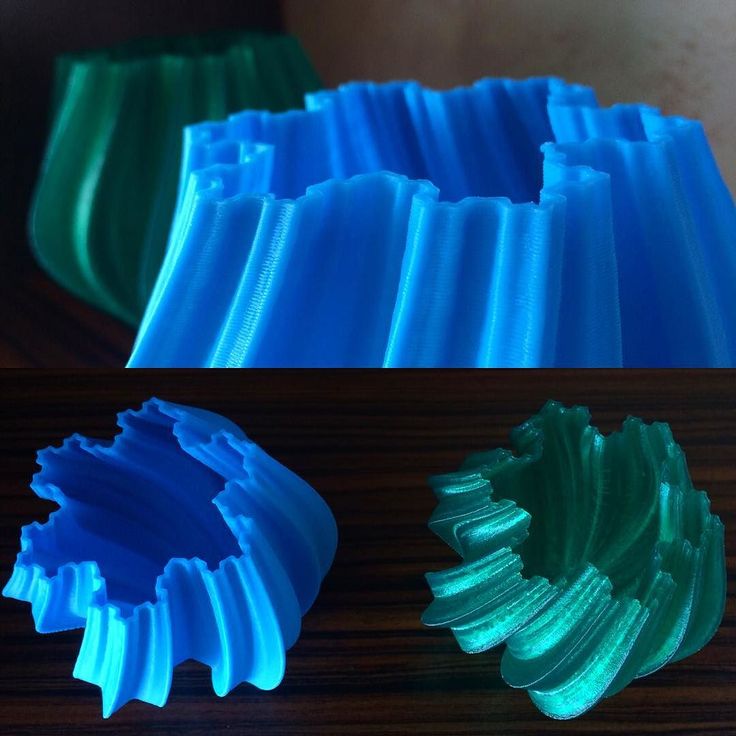

Image: AxeCatAwesome via Reddit

Sanding PLA can give great resultsThe easiest and most common way to smooth PLA 3D prints is to sand and paint them. This process is the most time-consuming, but it yields excellent results when done thoroughly. With sanding, you are physically removing the layer lines, whereas with other methods, you are filling them in.

Sanding and painting will give you the most control over your finished piece. If you want to 3D print a helmet or create 3D printed cosplay armor, this is the method to go for.

To sand a PLA print, start with a rough quality sandpaper like 100 grit and sand down all the layer lines and areas you want smooth. Use the next size like 200 grit to sand it again, and keep repeating the process while you work your way up to finer sandpaper sheets.

Image: 3D Printed Props via Youtube

Make sure you don’t skip grits when sanding PLAYou can keep sanding until you reach 2000 grit paper for a very smooth 3D print surface, but this may be more than you need for your print. If you plan to prime and paint your piece, you likely won’t have to go that high. Assess your print after each grit and stop when you reach the texture you want.

You can use a wood filler or other filler primer before sanding to fill in some of the layers. This will cut down on a lot of the sanding needed and give your print a nice surface texture for holding paint.

From there you can paint your print as needed using whatever type of paint you prefer. Spray paint works well for large prints, while gloss paint adds shine to your new smooth surface.

Keep in mind that wet sanding (using wet sandpaper or keeping your print submerged in water while sanding) is best for PLA prints since it keeps the friction from melting the plastic and keeps you from inhaling the dust particles from the PLA. It can take a while to finish using this method, but it holds paint very well and looks great.

3M 88619NA 99419 Sand Paper, 9" x 11"

175 Reviews

Check PricePros:

- Gives you the most control

- Most affordable option

Cons:

- Time-consuming

- Takes a lot of effort

Heat Gun

Image: Tinkerine via Youtube

Be careful not to overheat your PLA prints when smoothing with a heat gunIf you want a non-chemical method that doesn’t require quite as much elbow grease as sanding, you can try using a heat gun. This method can be very effective at smoothing 3D prints when used correctly. However, it is rather difficult to do without accidentally melting your prints (especially ones made from PLA), so be sure to practice on failed or broken prints first.

Smoothing a PLA 3D print with a heat gun melts the outside layers of plastic just enough to remove the layer lines and give the print a shiny gloss. You carefully move the heat gun around the print, never staying on one area too long in order to heat the whole print evenly. When the surface of the print looks wet, you can turn off the heat gun and let the print cool.

Recommended:

How to Melt and Dissolve PLA Filament

This is a helpful technique to quickly get a smooth, shiny look with a tool you might already have on hand. Since it’s so difficult to get consistent results, this method is probably best kept as a last resort or when the results don’t matter as much.

Wagner Spraytech 0503008 HT1000 Heat Gun, 2 Temp Settings 750ᵒF &...

Check PricePros:

- Quick

- Uses a common tool

- Gives a shiny surface

Cons:

- Hard to do well

- Results are inconsistent

PolyMaker PolySmooth PVB Filament

Image: Polymaker

Printing under similar settings and conditions as PLA, PolySmooth is a special low-temperature filament that can be smoothed with isopropyl alcohol. For fans of the ABS acetone smoothing, this is one of the closest equivalents you can get to that process with PLA or PLA+ filaments.

For fans of the ABS acetone smoothing, this is one of the closest equivalents you can get to that process with PLA or PLA+ filaments.

PolySmooth is easy to use. It prints at a low temp like PLA and doesn’t require a heated bed or 3D printer enclosure. You can spray alcohol onto your finished model and have a smooth print within minutes. The alcohol breaks down the outermost layer of plastic, leaving behind a shiny and smooth surface similar to that of a vapor-smoothed ABS.

Image: Polymaker

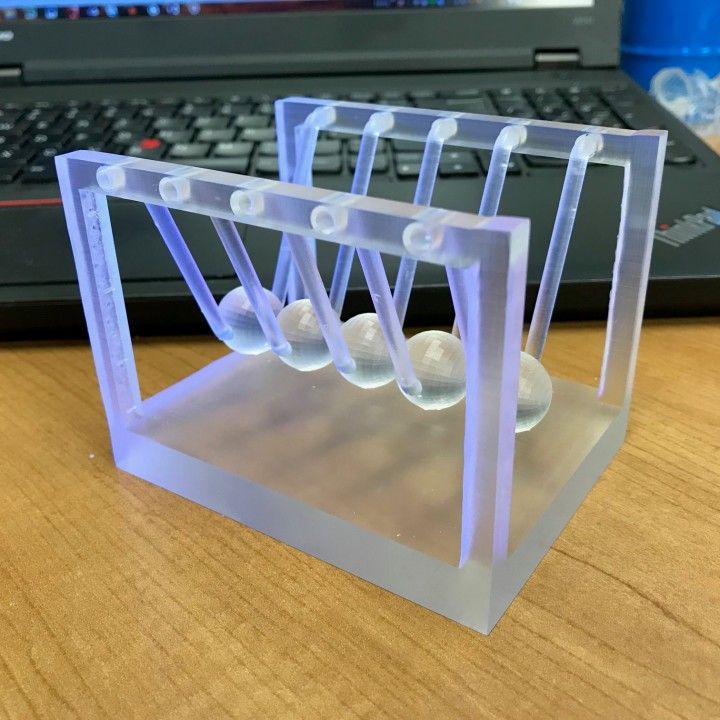

You can also use the PolyMaker Polysher to smooth 3D prints. Similar to a wash station for resin prints, the Polysher machine evenly coats the prints with vaporized alcohol. You can set the start and end times for the Polysher, ensuring smooth 3D prints every time.

While you don’t need to purchase the Polysher to use PolySmooth, it is a good way to automate the smoothing process if you have a lot of prints to do. It gives more consistent results across many prints.

Polymaker PolySmooth PVB Filament 1. 75mm 3D Printer Filament Green...

75mm 3D Printer Filament Green...

276 Reviews

Check PricePolymaker Polysher - Post Processing Device to Smooth Print Surface...

276 Reviews

Check PricePros:

- Prints like PLA

- Safer than vapor smoothing

- Uses isopropyl alcohol

Cons:

- Costly

Chemical Smoothing

If you are wondering if there are chemicals available that smooth PLA similar to how acetone smooths ABS, the short answer is yes. There are some chemicals like ethyl acetate that can vapor smooth PLA, but they are not ideal for many reasons.

We also don’t recommend using them since they are highly toxic (especially when vaporized), expensive, and difficult to source. Ethyl acetate in particular poses a significant health hazard if inhaled and is highly flammable.

With products like PolySmooth on the market, you can already smooth 3D print layer lines without needing to use hazardous chemicals.

Abrasive Smoothing Methods

Abrasive smoothing methods like tumbling and sandblasting are another possibility to smooth 3D prints. These methods are fairly versatile because different tumbling media and blasting mixtures will give you different results.

However, the processes tend to work best with metal-filled PLAs. Regular PLA prints have mixed results. Sticking to the best PLA filament brands does help get better results.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Tumbling 3D prints has been met with limited success. Vibratory bowls tend to work better than rotary tumblers. Using an actual tumbling media instead of the cheaper options like steel nails/shot or walnut shells also gives more consistent results.

Tumbling regular PLA prints usually softens the layer lines but doesn’t completely remove them. Metal and wood-filled PLA filaments, on the other hand, tend to have better results in a tumbler and look nicely polished and smoothed from the process.

Sandblasting is another option for smoothing PLA prints that offers varied success. Like tumbling, how efficient sandblasting is depends on the media used. Using fresh sand produces the best results. Like with tumbling you usually won’t completely remove your lines, but it will make them less noticeable.

Frequently Asked Questions

What is the best way to smooth PLA prints?

The “best way” really depends on what you’re trying to accomplish with your finished print. If you just want it to look nice and smooth with minimal effort, XTC-3D resin coating is probably your best option. However, this adds another layer of materials on top of your print, so if you plan to paint it afterward, you will lose your small details.

If you want more control over the detailing of your smoothed prints, sanding is the best method to use. Since you are doing the process by hand, you have the most control over where the sandpaper goes. This method is best when used on prints that are going to be painted after.

Finally, for a quick smoothing effect that still leaves most details and doesn’t require much time, using PolySmooth filament instead of your usual PLA is a fast and easy way to get smooth results, so this will be the best option for everyday prints or when you need to smooth many prints quickly.

How do you smooth PLA without sanding?

To smooth 3D prints without sanding, you can use a liquid coating or filler primer to fill in and seal the layers. XTC-3D and 3D Gloop are the best choices for this, but there are other products available as well.

You can use the heat gun method detailed in this article, but that one takes quite a bit of practice to use well and doesn’t always produce consistent results.

Can you acetone smooth PLA?

No, acetone does not react with PLA plastic in the same way it does ABS, so it will have little to no effect on your 3D print. ABS is acetone soluble, meaning it will break down in acetone. PLA has few chemical reactions (and even less so that work like acetone and ABS), so finding a chemical smoother is not feasible.

If you want the experience of printing with PLA and the easy smoothing of acetone, you’ll need to buy PolySmooth or some other filament made for easy post-processing.

Can you smooth PLA with heat?

Yes, you can use heat to smooth your PLA parts, but your results will vary since it is very easy to damage your prints this way. The best way to heat smooth 3D prints is to only heat the outermost layers of plastic. Being too aggressive will also melt or warp the inside layers, causing the print to deform.

Heating the print in an oven or similar appliance often results in uneven heating. Your prints can overheat or burn in some areas while other areas haven’t even started to smooth. This is because the heat is coming from a static source, so it doesn’t distribute evenly within the oven.

Image: Tinkerine via Youtube

Your results with smoothing PLA in an oven will varyUsing a heat gun gives you more control to evenly heat the print and overall better results than a static heat source, but even that produces inconsistent results. More aggressive heat sources like an open flame almost always damage the prints, even when they can be moved around.

More aggressive heat sources like an open flame almost always damage the prints, even when they can be moved around.

Does isopropyl smooth PLA?

No, isopropyl alcohol (IPA) will not smooth PLA. However, you can get the desired results with Polymaker’s Polysmooth. This is a special PLA filament that has been treated to be more responsive to IPA.

Can you vapor smooth PLA?

Yes, technically you can smooth PLA 3D prints using a vapor deposition process, but the chemicals required are not safe for human exposure.

How do you smooth a 3D printed figure?

There are a few ways to smooth out a 3D printed figure. One is to use sandpaper to lightly sand down the rough edges. Another is to use a heat gun to slightly melt the edges and give them a smoother appearance.

You can also use chemicals like acetone or XTC-3D to smooth out the surface of the print. Whichever method you choose, make sure to take your time and be careful not to damage the figure.

Finally, the best way to create a smooth 3D printed figurine is by using resin 3D printing instead of FDM printing. There are plenty of 3D printers for miniatures that work well for this purpose.

There are plenty of 3D printers for miniatures that work well for this purpose.

How do I get a smooth finish with PLA?

There are a few things you can do to get a smoother finish with PLA. First, make sure your printer is calibrated correctly, for example by using a temperature tower to set the right temperatures. This will help ensure that the layers are printed evenly.

Second, use a higher-quality PLA filament. Some brands of PLA filament are known for having a smoother finish than others.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Finally, try using a different nozzle size. A smaller nozzle size (and thus smaller layer heights) will result in a smoother finish.

Final Thoughts

Whether you enjoy the cleaner look of finished prints or need a smooth surface on your prints for functionality, you have several options for making your PLA prints look amazing.

Smoothing layer lines from PLA isn’t as easy as some other 3D printing materials, but there are several methods and products available to help you do it as painlessly as possible. From brush-on epoxy resin products that fill in layers to special filaments to basic sandpaper, there is a smoothing method that works for most projects.

From brush-on epoxy resin products that fill in layers to special filaments to basic sandpaper, there is a smoothing method that works for most projects.

Do you still have questions about smoothing PLA prints? Let us know in the comments!

How to smooth PLA? 4 techniques and tricks

PLA is undoubtedly the most widely used material for 3D printing worldwide, but it has some disadvantages. In particular, one of the things that often makes people prefer ABS over PLA is the ability to smooth it out using acetone.

If you think that PLA cannot be smoothed to get the same results as ABS, let me tell you that you are wrong. Want to know more? Then hang around because we’re just getting started.

📖 What do you want to read?

What do we mean when we talk about smoothing PLA?

Well, it’s very simple: when we talk about smoothing PLA we mean applying some kind of post-processing to our PLA printed parts to make the additive manufacturing layers invisible and eliminate possible imperfections.

What are the advantages of smoothing a PLA printed part?

Smoothing our PLA printed parts offers several advantages, not all of which are obvious:

- It allows us to print at higher layer heights, saving printing time. By smoothing the parts the layers will be almost invisible so it will not matter so much if we have used a small or large layer height.

- It allows us to use more conservative printing parameters. We will be able to use more supports without fearing the marks they leave, print at higher temperatures to prevent jams at the cost of losing some aesthetic quality…

- Depending on how we smooth our part, we may be able to increase its mechanical strength as well as improve its appearance.

- It saves a lot of sanding time if our goal is to paint the part later.

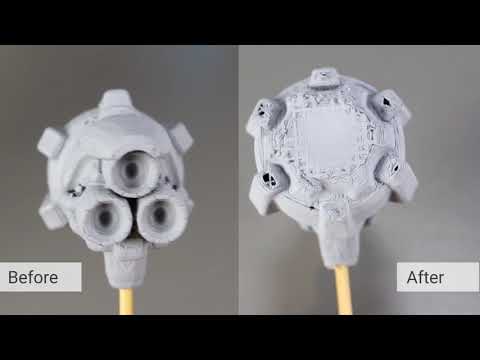

As you can see in the photo above, a figure printed with 0.35 mm layers and then smoothed has a better finish than a part printed with 0.1 mm layers that would have taken more than three times as long to print. The example of the figure is a piece of ABS smoothed with acetone vapor, but a piece of PLA smoothed with one of the methods that we will suggest would work exactly the same.

The example of the figure is a piece of ABS smoothed with acetone vapor, but a piece of PLA smoothed with one of the methods that we will suggest would work exactly the same.

What methods are available to smooth out PLA?

There are several ways of smoothing parts printed on PLA to obtain the benefits described above. Today we are going to talk about three of them: Chemical smoothing using dichloromethane, smoothing by applying epoxy resin and smoothing using a specific PLA of the polymaker brand.

Smoothing with dichloromethane

Before explaining this method to you, we must warn you that it is not something you should do at home without the proper precautions. In Bitfab we believe that safety comes first, so we recommend that you do not try this method if you do not have adequate protective measures to deal with potentially dangerous chemicals. Wearing glasses and gloves is essential, as well as doing all the work in a very well ventilated place. We insist on the importance of this, as the products used, while not extremely dangerous, can cause problems if not handled carefully.

Now, let’s start with the explanation. To smooth PLA we need to find a chemical that dissolves this polymer, just as acetone dissolves ABS. PLA itself is a plastic that is formulated in many different ways depending on brand and color, so some solvents do not work with all PLAs. Acetone itself, used with ABS parts, can be used in some types of PLA depending on its formulation, but it is not the most common.

For most cases the less dangerous solvent that usually works is dichloromethane or methylene chloride. This chemical is relatively safe if handled carefully and consciously because of some of its properties such as its characteristic sweet smell that prevents it from evaporating unnoticed.

The instructions for use are very simple, although there are two alternatives: direct application or application by means of steam. If we want to apply the product directly we can use some element such as a brush or a paintbrush. If the piece to be smoothed is small, it can be immersed for a few seconds in a container filled with this product. We have tested it by applying the product with a brush and we got amazing results.

We have tested it by applying the product with a brush and we got amazing results.

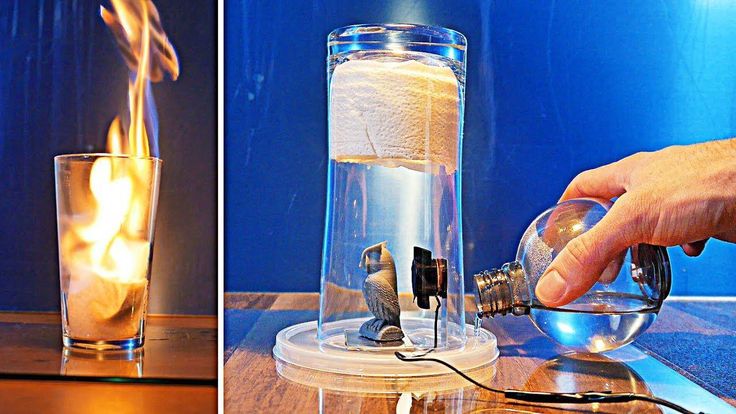

An alternative, and slightly more demanding, way is to smooth the part by leaving it in a container with methylene chloride steam. We can do this in several ways, but the simplest would be to use an airtight container and place inside our part and one or more pieces of paper soaked in dichloromethane. This technique is basically the same as the one used for smoothing ABS pieces using acetone and you can find many videos on youtube. Here is one that explains in a very simple way how you can do it:

Smoothing PLA using epoxy resin

The one that we have tested, and that we can guarantee works is this one of the XTC-3D brand.

In the picture on the right you can clearly see the effect of this type of resin. Even in a model like this, where the original model was already very well printed, applying a layer of resin leaves a perfect finish, which almost looks like a piece produced by injection.

Even in a model like this, where the original model was already very well printed, applying a layer of resin leaves a perfect finish, which almost looks like a piece produced by injection.

The method of application will vary depending on the resin we choose, and you should follow the manufacturer’s instructions. Usually it is a two-component compound that we must mix and then apply with a brush or spatula.

Smoothing PLA using Polymaker branded products

There is a type of PLA whose formulation makes it soluble in isopropyl alcohol, a much less dangerous product than acetone or methylene chloride. This is why this material, of the Polymaker brand, has become quite popular among those who want to smooth their parts without getting too complicated. This brand’s PLA, called Polysmooth, is printed like regular PLA and has the same properties. Once printed we can apply alcohol directly or through steam, as explained above. Additionally, the people at Polymaker have developed their own steam chamber to smooth out your parts in a professional manner.

This is probably the most professional way of smoothing your pieces, since by using a material specifically designed for this purpose you will get more consistent results than if you use one of the previous more “homemade” methods.

You can find the PLA here and the polisher here. It is priced at around 300 euros at the time of writing. In our opinion it is an excellent investment for the professional sector, since it provides the best results in a simple and consistent way, with guaranteed good finishings and without requiring any special skill

The most demanding solution: sanding and painting

There is another solution, but it is the most time-consuming of all. It is to post-process the part completely by priming, sanding and painting.

To prepare a part for sanding you can use the epoxy resin we talked about or a body primer spray, which fills the gaps in the coats. It is also possible to do this without any surface treatment, which involves sanding a little more to completely remove the marks from the coats.

After sanding you can prime the part and paint it using spray, brush… or the method of your choice.

To conclude

We have taught you several methods to smooth your PLA parts so you can find the one that best suits your needs. There are other methods to do this, in addition to other materials that can serve as an alternative to PLA if you want to get excellent finishes.

In Bitfab we are experts in additive manufacturing and post-processing, so you can trust us if you need help to manufacture your parts or want advice on this issue.

Beginner's Guide to Smoothing 3D Models

3DPrintStory 3D printing process Anti-Aliasing PLA: A Beginner's Guide to Anti-Aliasing 3D Models

Sooner or later, all owners of 3D printers think about smoothing the surface of printed 3D models. In this article, we will look at how to achieve a smooth surface of the printed model if you are using PLA plastic for 3D printing.

In this article, we will look at how to achieve a smooth surface of the printed model if you are using PLA plastic for 3D printing.

Sanding the printed model

Almost any model will require sanding to smooth it out. It is best to use sandpaper with different levels of grit. You can start with a grit of 200, and continue to increase the grit up to 4000. It is best to sand in a circular motion against the fibers of the layer lines.

Resist the urge to use a power tool because the strong vibrations generated by power tools will easily melt plastic, deforming the surface. Even when sanding by hand, remember that friction generates heat that can damage the 3D model by melting the plastic.

The best sandpaper is waterproof or wet/dry because you can wet it to cool the plastic. You should also constantly rinse the 3D model to remove any particles that form during the sanding process. An added benefit is that the water prevents small plastic particles from getting into the air and being inhaled. Wet/dry sandpaper can be distinguished by color. Its grains are black, not brown or beige.

Wet/dry sandpaper can be distinguished by color. Its grains are black, not brown or beige.

Polishing options with pastes and special coatings

With PLA smoothing, sanding will never completely eliminate layer lines. One effective method is to apply polishing paste to the remaining lines of the layer. Polishing pastes have varying degrees of quality, following the example of sandpaper. These compounds are usually designed for use with metals, but work quite well with plastics. Simply apply the compound to a sanding wheel or similar rotary tool attachment, then apply it to the plastic for a smooth and shiny finish. As with sanding, remember that polishing creates friction and therefore heat. When smoothing PLA with a grinding wheel, it is better to use a lower speed.

Another method for smoothing PLA is to use a sandable primer with a high filler content. Thin, even coats dry quickly, after which the primer can be sanded down to plastic so that it remains only in the recesses of the layer lines. Repeat the process until all 3D printing flaws are gone.

Repeat the process until all 3D printing flaws are gone.

For both procedures, always use primer and paint from the same manufacturer and never mix acrylic and enamel. This can crack the paint and put an end to all the hard work you've done before.

Another product worth mentioning is Smooth-On's XTC3D Finish Coat. It uses two liquids, one of which catalyzes the other, to create a resin-like material that can be brushed onto a 3D model. The coating is evenly leveled, leaving no brush strokes. Although Smooth-On claims that XTC3D does not melt plastic, the resin definitely gets hot as the mixture begins to set. The end result is a smooth and hard appearance that can be painted over or used as a final coat.

Heat gun

A less popular option for smoothing PLA plastic is to use a heat gun. This method requires some practice because the tool obviously generates a lot of heat which can destroy your 3D model. Pre-sanding the model helps to expose the plastic, making the final effect much more effective. The key is to keep the gun moving across the surface of the model, never letting the gun linger on one area that could easily melt the plastic.

The key is to keep the gun moving across the surface of the model, never letting the gun linger on one area that could easily melt the plastic.

While PLA does not generally emit odors when extruded, heat will certainly produce fumes as the plastic softens. Regardless of which PLA flattening method you choose, always try to work in a well-ventilated area because heated plastic, resins, and spray paint release potentially harmful fumes.

Using Polymaker's Polisher

A well-known method to get smooth 3D models out of ABS is to place the model in a sealed container filled with acetone mist. The acetone interacts with the ABS and slowly melts the plastic, creating a super smooth model. Note : be sure to read the necessary precautions if you decide to try this method.

Unfortunately, you cannot do the same procedure with PLA because it does not react in the same way with acetone. Some other chemicals will do the same but are difficult to obtain and very dangerous and toxic to use.

Polymaker, best known for its 3D printing materials, has introduced its own anti-aliasing agent called Polysher. Using a proprietary PLA-like filament formula, the 3D model is lowered into a sealed chamber where isopropyl alcohol is sprayed, creating a mist around the object to be smoothed out. The 3D model rotates in an alcohol mist that reacts with the plastic and melts it. The longer the process, the smoother the model will be. When you take the 3D model out of Polysher, its surface will be sticky, so it's best to leave it for about half an hour. It also improves the final look, which may not be as smooth as you would expect.

As with the other procedures described here, a little sanding helps the process but is not necessary. Tip : Expose the 3D model to shorter Polysher sessions and flip the model between sessions. Surprisingly, this method also produces near-transparent models when used with Polymaker's transparent PolySmooth material.

Conclusions

Creating smooth surfaces on 3D models will require some work. Sanding will either prepare your model for other processes, or it will create a nearly flawless surface on its own. No matter which procedure you choose, there are always some caveats to any PLA smoothing process.

Sanding will either prepare your model for other processes, or it will create a nearly flawless surface on its own. No matter which procedure you choose, there are always some caveats to any PLA smoothing process.

All processes remove material from your model. Sharp edges will be smoothed out, and it will be very difficult to get around fine details. So if you break your model into separate nodes, each of them can be smoothed using the most appropriate process. And as a result, it will be possible to assemble the final, smooth and professional looking model.

How to smooth 3D printing?・Cults

Objects created with a 3D printer don't always look as good as they should. Even if visualization of 3D printed parts is usually acceptable, this may not be enough if the object is for sale or display. Some people just want a perfectly smooth and shiny surface for 3D printing. Fortunately, it is possible to achieve this level of perfection with the help of some suitable tools. This guide will show you how to smooth out ABS and PLA 3D prints for the best results.

This guide will show you how to smooth out ABS and PLA 3D prints for the best results.

The FDM 3D printer opens up endless possibilities for creating PLA 3D prints. However, parts may be printed with bad layers that need to be removed. If you want to give your 3D printed parts a shinier look, there are some easy ways to align your 3D printed PLA.

Use spray paint and polyurethane

The sanding method used to be the most common technique for leveling PLA 3D printing. Today there are new alternatives. You can use spray paint mixed with polyurethane to line up 3D printed PLA parts. To do this, you need to purchase the right tools:

- spray paint,

- polyurethane,

- fan for drying parts.

The smoothing process is one of the simplest. First of all, it is necessary to clean the product so that dust or other dirt does not linger on the surface of the object. Use a spray can to cover the 3D print with a layer of paint. Then a layer of polyurethane can be applied to the part. Be very careful and place the freshly coated 3D print under a fan to speed up the drying process .

Then a layer of polyurethane can be applied to the part. Be very careful and place the freshly coated 3D print under a fan to speed up the drying process .

After a few minutes, you will find that the mixture of polyurethane and paint starts to fill in unwanted holes and imperfections on your PLA 3D print. Once completely dry, the part can be recoated with mix to remove any remaining surface imperfections. This method is less tiring than sanding.

Opt for XTC-3D Clear Epoxy

Although highly effective, using a mixture of paint and polyurethane to line a room can be too messy for some people. There are other alternative methods for anti-aliasing PLA 3D printing. Transparent epoxy resin XTC-3D has been specifically designed to align PLA 3D parts for an optimal finish . The product consists of two bottles that need to be mixed for 3D printing.

Remember to mix the product well and follow the instructions correctly. Using a brush, apply the resin to the printed parts. The dried product will harden into a smooth transparent layer. PLA 3D printing becomes smoother and shinier. XTC-3D can also be mixed with dyes and stains if you wish to color your parts. You can also add effects such as metallic highlights or palettes.

Using a brush, apply the resin to the printed parts. The dried product will harden into a smooth transparent layer. PLA 3D printing becomes smoother and shinier. XTC-3D can also be mixed with dyes and stains if you wish to color your parts. You can also add effects such as metallic highlights or palettes.

Use 3D Gloop

This adhesive has been specially developed for smoothing PLA 3D prints. 3D Gloop can be used for various purposes. To smooth out a 3D print with this product, simply apply it to the printed part with a brush. It works like the XTC-3D, except it only has one bottle. This is a great advantage if you only want to use a small amount of glue. However, 3D Gloop is not without flaws. The product contains a number of toxic components. It should be used in a well ventilated area.

Acetone is a chemical stripper used by professionals to sand and clean certain materials. Due to its high toxicity, it should be handled with care in a well-ventilated area. Acetone can be used to level ABS 3D printing.