3D print laten maken

3d laten printen kosten en voorbeelden

Wat kost nou een 3d print en waar moet ik rekening mee houden?

3d printen wordt steeds populairder! En dat is ook niet gek. Met een 3d-printer kun je digitale modellen snel en precies tot echte objecten maken. Het is een geweldige techniek. Jouw digitale model wordt zomaar werkelijkheid!

Bij de 3d-printservice van 3DMarc kun je terecht voor vrijwel alle objecten die je maar kunt verzinnen. Wij kunnen ieder digitaal model uitprinten. Van gepersonaliseerde sleutelhanger tot uitgebreid kunstproject, van maquette tot zeer precieze modellen voor medisch gebruik: er is heel veel mogelijk.

Wat moet iets 3d laten printen kosten? Mensen denken vaak dat het printen van objecten erg duur is. Maar in werkelijkheid is dat niet het geval. Als je jouw modellen laat printen door een professional, hoef je geen eigen 3d-printer aan te schaffen en te bedienen. Je hoeft ons alleen je 3d-model te sturen, en wij regelen de rest!

Hoe werkt 3d printen precies? En wat kost het om een object 3d te laten printen? Dat leggen we je graag uit aan de hand van een aantal voorbeelden van populaire modellen, die onze klanten bij ons laten printen.

3d laten printen – de Kosten

Is het 3d printen duur? Dat valt heel erg mee! Natuurlijk: wil je zelf thuis 3d kunnen printen, dan moet je een flinke investering doen. Je hebt dan een eigen printer nodig, en de materialen om te printen. Maar als je een model aanlevert bij onze professionele printservice, is het allemaal zo geregeld!

Hoeveel het kost om een 3d-model te laten printen? Hierboven heb je al wat 3d print service kosten voorbeelden gezien. De kosten zijn per object weer verschillend. Dat heeft niet zoveel te maken met de complexiteit van het model.

Hoeveel dat kost?

Dat hangt af van de grootte van het te printen object, en van het materiaal dat je wil gebruiken. Ook de precisie waarmee geprint wordt, maakt uit voor de uiteindelijke kosten. We hebben meerdere printers die we in kunnen zetten, afhankelijk van jouw eisen.

Is het 3d-printen altijd goedkoper? Dat hangt er een beetje vanaf wat je wil laten printen. Om een voorbeeld te geven: als er bij jou thuis de hendel van de koelkast afbreekt, ben je waarschijnlijk goedkoper uit door het onderdeel bij te bestellen bij de winkel. Het laten printen komt dan duurder uit.

Het laten printen komt dan duurder uit.

Maar wil je een uniek object laten maken? Of heb je zelf iets ontworpen dat je nu in het ‘echt’ wilt hebben? Dan is een 3d print service een hele aantrekkelijke optie!

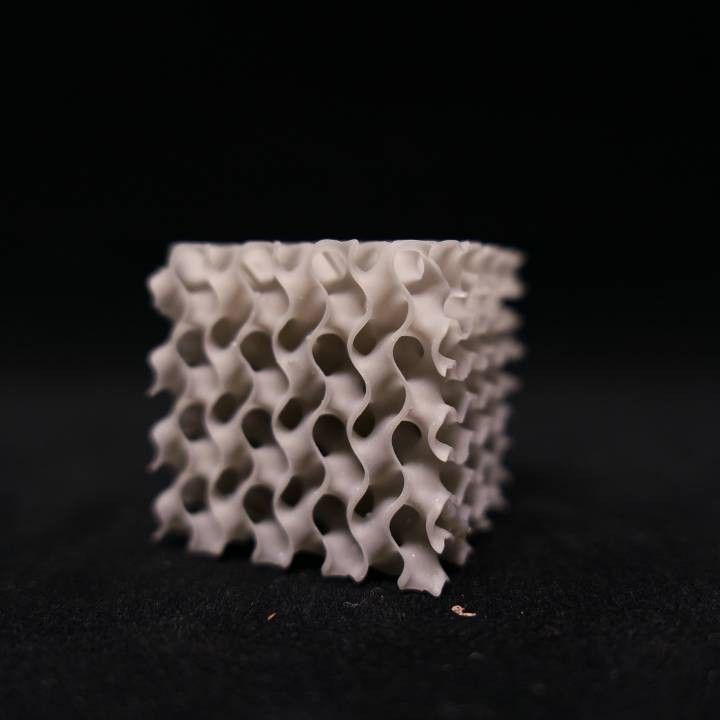

Voorbeelden van unieke 3D-objecten

Wat kun je zoal laten printen door onze 3D-printservice in Nederland? We geven je een aantal voorbeelden van unieke objecten, die je alléén door ons kunt laten maken.

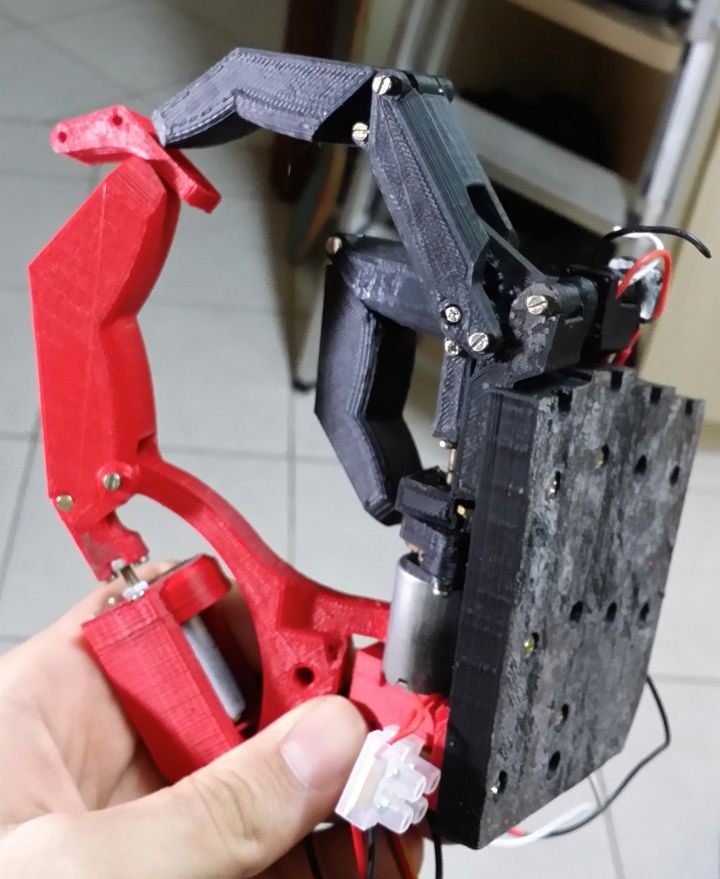

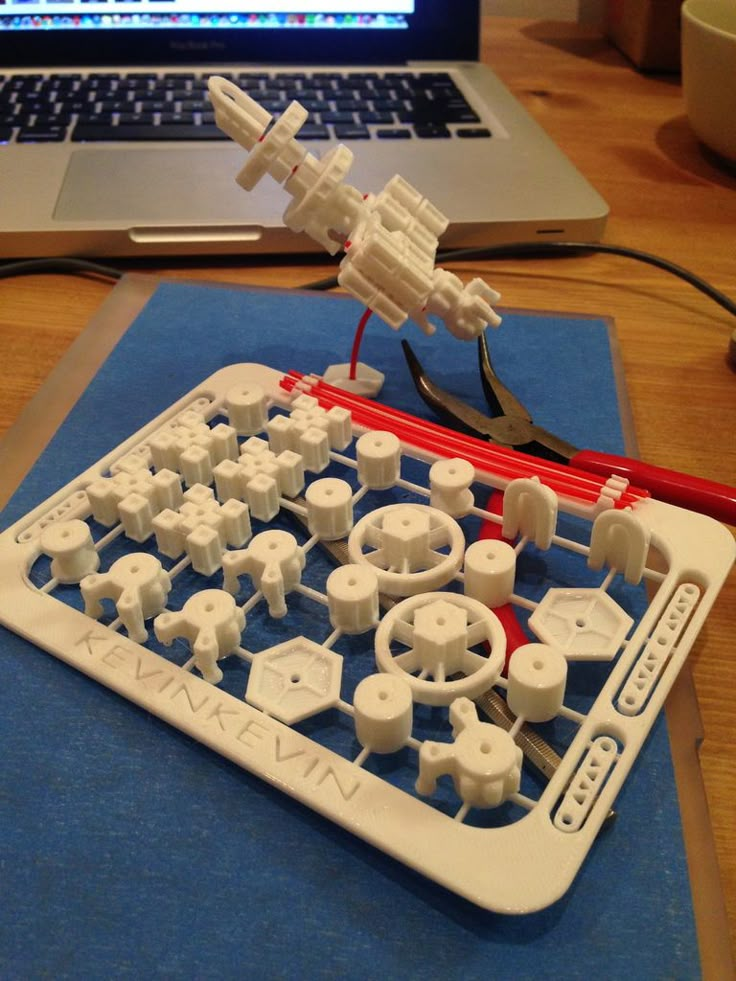

Voorbeeld #1

PLA (Polymelkzuur)

Polymelkzuur is een biologisch afbreekbare kunstof.

Wat erg goed tegen een stoot kan. Is Perfect voor prototypes. kan ook gebruikt worden voor leuke mooie objecten.

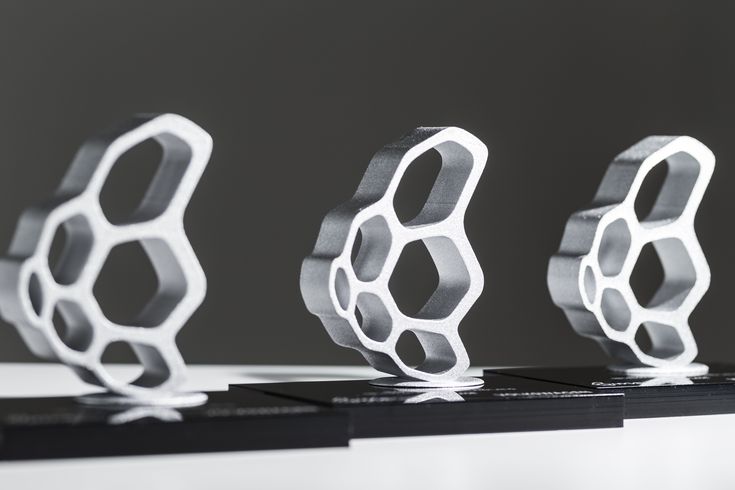

prijs indicatie van onderstaande foto:PLA:€9.32. of PETG:€12.08

Kleur: glitter zwart.

Er is veel mogelijk neem gerust contact op voor u ideeén of uitvindingen. We helpen graag met het ontwerpen. En uw product op de markt te krijgen. 1 of 100K stuks

Ik wil wat laten printen

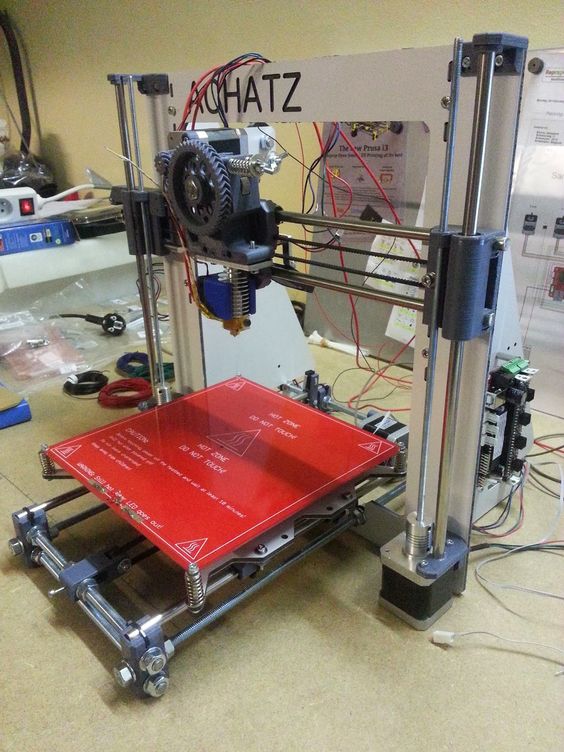

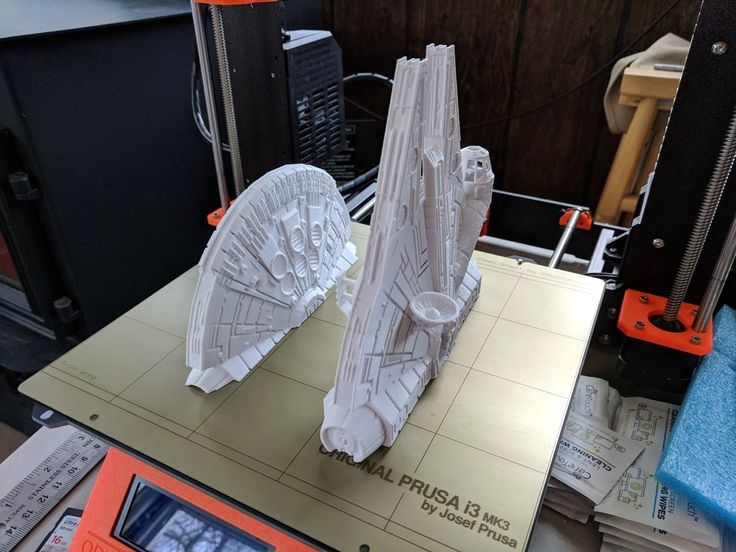

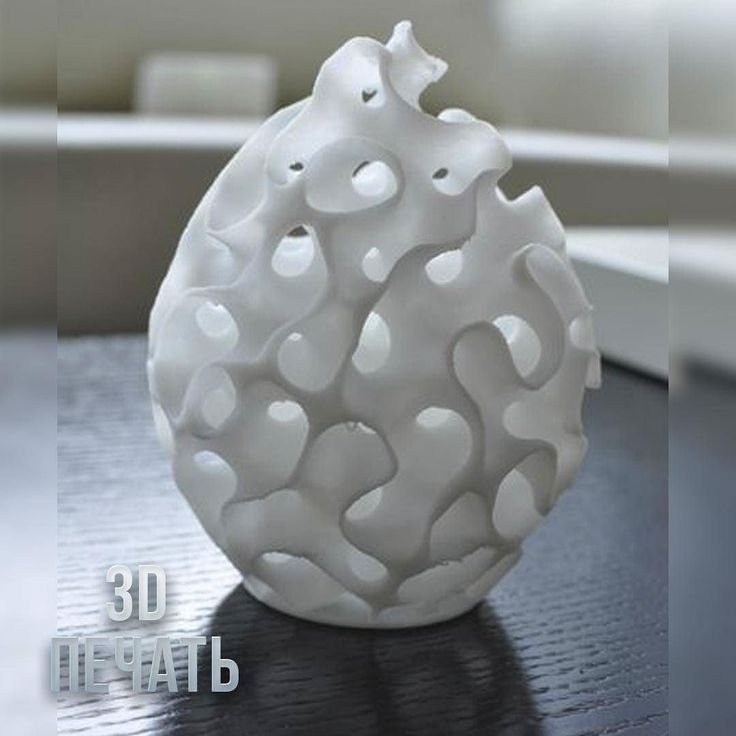

Voorbeeld #2PETG (Polyethyleentereftalaatglycon)

PETG is een zeer sterk materiaal. Wat al goed gebruikt kan worden voor sterkte objecten.

Wat al goed gebruikt kan worden voor sterkte objecten.

En om het heel erg sterk te maken is er ook PETG CARBON om het ook nog een future look te geven.

Is waterafstotend en geschikt voor buiten in de zon.

prijs indicatie van onderstaande foto:PETG:€13.70 of PLA:€10.72

Kleur: Zwart

Mijn bestand door sturen

wilt u iets laten ontwerpen? neem contact op wij werken met autocad.

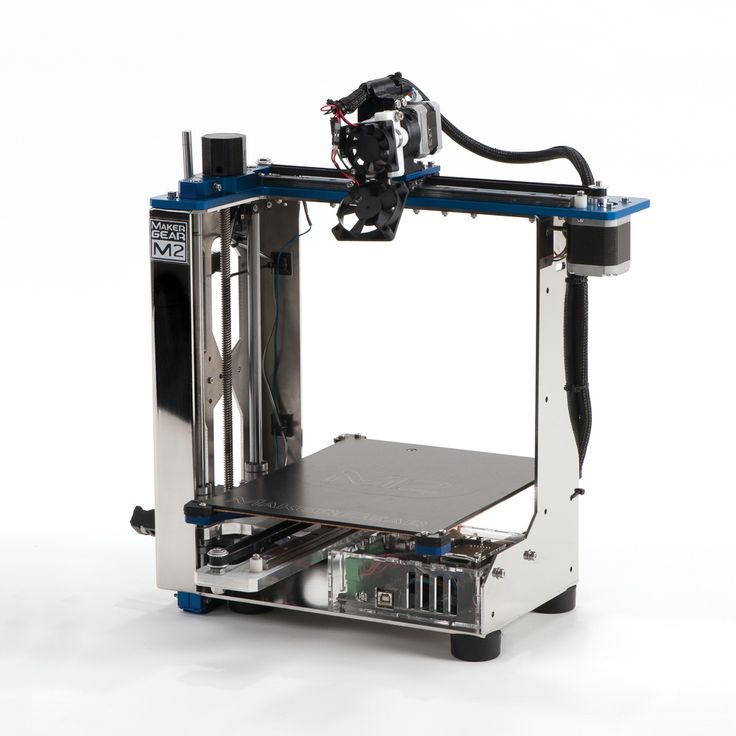

Hoe werkt het 3D printen?

Een 3d-printer échte objecten produceren. Dat lijkt wel iets uit de toekomst, maar het is werkelijkheid! De printtechniek werkt als volgt. De printer werkt met een digitaal model, waarin precies is uitgewerkt hoe het model eruit moet komen te zien. De printer deelt dit model op in extreem dunne laagjes. Vervolgens wordt het object laagje voor laagje opgebouwd, doordat de printer steeds een laagje opspuit met een vloeibaar materiaal (bijvoorbeeld plastic). Dat materiaal hardt uit, waardoor de laagjes kunnen opstapelen. Dat kan met ongelofelijke precisie: de meest precieze printers bij 3DMarc printen een object tot wel 0,g001mm nauwkeurig.

Doordat de printer objecten laagje voor laagje opbouwt, is er heel veel mogelijk. Alle vormen en kleuren die je maar wilt, kunnen gerealiseerd worden. Van coole gadgets tot een animatiepoppetje op maat, van gepersonaliseerde sleutelhanger tot complete architecturale maquette: er zijn ontzettend veel toepassingen te verzinnen. Kunstenaars en ontwerpers ontdekken steeds meer de mogelijkheden van het 3d printen. En ook in de industrie en in de medische sector wordt 3d printen steeds belangrijker. De mate van precisie en de grote keuze aan materialen, zoals verschillende soorten plastics, speelt daarin een grote rol.

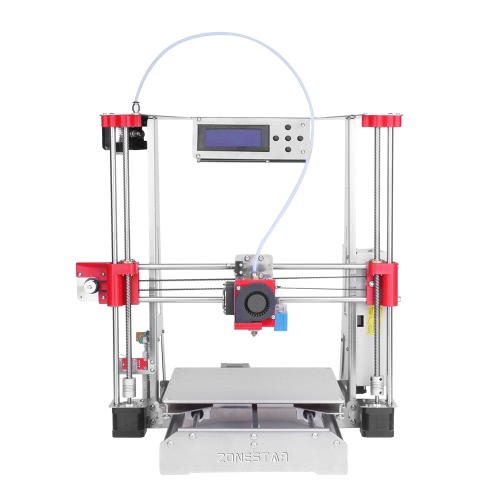

De 3D-printtechniek werkt aan de hand van zeer kleine laagjes plastic of ander materiaal, die opgestapeld worden. 3DMarc maakt gebruik van twee soorten printers, zodat we altijd het beste resultaat kunnen garanderen:

- Een FDM-printer, voor een precisie tot 0.01mm

- Een SLA-printer, die tot op 0.001mm precies kan printen (kleinere objecten).

Door de manier waarop de techniek van het printen werkt, is er erg veel mogelijk. Van vette gadget tot animatiepoppetje op maat, van gepersonaliseerde sleutelhanger tot compleet maquette: er zijn ontzettend veel toepassingen te verzinnen. Steeds meer ontwerpers en kunstenaars gebruiken deze methode dan ook om bijzondere en complexe objecten te laten maken. Maar ook in de medische sector wordt 3d printen steeds gebruikelijker. De mate van precisie speelt daarin een grote rol.

Met uitzonderlijke precisie bouwt de 3D-printer een object op, laagje voor laagje. Het uiteindelijke resultaat is een tastbare versie van het gewenste voorwerp. Van vette gadget tot animatiepoppetje op maat, van gepersonaliseerde sleutelhanger tot compleet maquette: er zijn ontzettend veel toepassingen te verzinnen.

Welke 3d print dienst zoek jij?

Wij helpen jouw idee en wensen tot realiteit te maken

Offerte aanvragen

Samen sparren we over de praktische toepassing van jouw idee

Neem contact op

Een offerte op maat voor jouw 3d print?

Wil je iets laten 3D-printen? Bij 3DMarc krijg je altijd een offerte op maat. Daarin wordt rekening gehouden met al jouw wensen. De belangrijkste factoren die de prijs bepalen zijn.

Daarin wordt rekening gehouden met al jouw wensen. De belangrijkste factoren die de prijs bepalen zijn.

Neem contact op

Een offerte op maat voor jouw 3d print?

Wil je iets laten 3D-printen? Bij 3DMarc krijg je altijd een offerte op maat. Daarin wordt rekening gehouden met al jouw wensen. De belangrijkste factoren die de prijs bepalen zijn:

Met 3d printen is meer mogelijk dan je kan voorstellen, dus bedenk wat je wilt printen, maak tekeningen en vraag ons naar advies.

Alle kleuren van de regenboog zijn er, maar ook bijvoorbeeld met glitter of doorzichtig. Daarnaast is het ook belangrijk om te weten of je juist hard of zacht materiaal wilt?

3d printers zijn bijvoorbeeld gelimiteerd in grootte, dus een formaat olifant is helaas nog niet mogelijk.

Zijn details bij jouw ontwerp minder belangrijk of wil je haarfijn alle kleine groeven kunnen zien?

Heb je deze vragen concreet of advies nodig? Dan staan wij voor je klaar!

Offerte aanvragen

3D ontwerp laten printen — GAGAT AM

Eigen productie- en 3D-print experts voor uw behoeften voor zakelijk & prive.

Hoe kies je het juiste materiaal voor 3D printen?

Verschillen tussen 3D printen materialen soorten

3D Printservice Nederland voor zakelijk en particulieren

Professioneel 3D printen wordt steeds toegankelijker. Zo ook bij GAGAT Studio. Werk uw ideeën en uitvindingen uit in een ontwerp, vraag een offerte aan en vervolgens kunt u uw 3D ontwerp laten printen. Bij GAGAT garanderen we betrouwbaarheid, professioneel advies en industriële kwaliteit.

3D-PRINT PRIJSAANVRAAG

ONTWERPGIDS VOOR 3D PRINTEN

HOE KUNT U UW 3D ONTWERP LATEN PRINTEN

Na het maken van een 3D ontwerp is het tastbaar maken van het ontwerp, dus daadwerkelijk laten produceren de volgende stap. Tegenwoordig zijn hier goede en professionele mogelijkheden voor. Een 3D ontwerp laten printen bij GAGAT gaat als volgt:

Upload: u kunt uw ontwerp uploaden via onze overzichtelijke en gebruiksvriendelijke offerte- en besteltool.

Wij werken met vele ondersteunde 3D-formaten, zoals .STL .3MF .STEP en .IGS.

Wij werken met vele ondersteunde 3D-formaten, zoals .STL .3MF .STEP en .IGS. Materiaal: bij GAGAT kunt u kiezen uit diverse soorten materialen. Afhankelijk van elasticiteit, sterkte, gewicht en andere factoren kiest u het materiaal dat het beste bij uw ontwerp past. Weet u niet zeker welk materiaal voldoet aan uw behoefte? Raadpleeg dan de materiaalgids of neem contact op met onze klantenservice.

Behoeft u extra informatie over één van de bovenstaande stappen? Neem dan gerust contact met ons op. Wij zijn bereikbaar van maandag tot zaterdag van 09:00 tot 18:00.

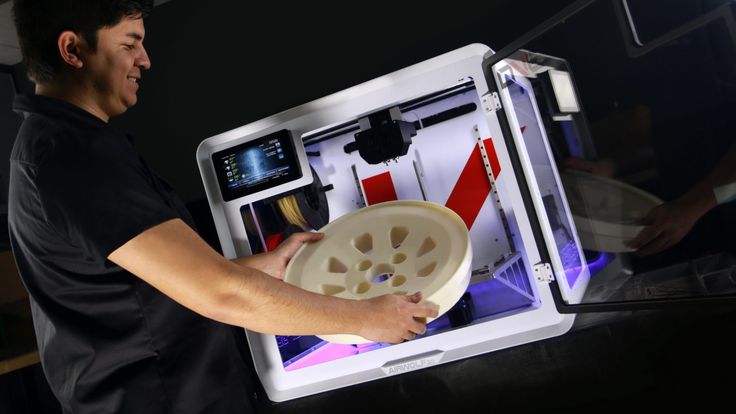

WAAROM 3D ONTWERP LATEN PRINTEN BIJ GAGAT?

Als u een ontwerp laat printen door onze 3D printservice in Nederland, geniet u van verschillende voordelen. Zo bespaart u met professioneel 3D printen bijvoorbeeld flinke kosten. De aanschaf van een 3D printer is namelijk erg prijzig en betaald zich bij beperkt gebruik niet snel uit. Hetzelfde geldt voor het filament van het apparaat. Ook de kwaliteit van de 3D printers op de markt laat in veel gevallen te wensen over. Bij GAGAT werken we uitsluitend met de beste 3D printers en bent u verzekerd van kwalitatieve en betrouwbare eindproducten van industriële kwaliteit.

Ook de kwaliteit van de 3D printers op de markt laat in veel gevallen te wensen over. Bij GAGAT werken we uitsluitend met de beste 3D printers en bent u verzekerd van kwalitatieve en betrouwbare eindproducten van industriële kwaliteit.

kwalitatief & betrouwbaar

Professioneel advies

Industriele kwaliteit

Uw 3D ontwerp laten printen door GAGAT Studio scheelt u veel tijd en geld. De doorloopsnelheid is hoog en veel goedkoper dan wanneer u voor de productie van uw ontwerp een producent moet vinden. U kent uiteraard uw ontwerp het beste. Wanneer u toch nog twijfels over uw ontwerp heeft of als u met vragen over het printproces of gebruikte materialen zit, schroomt u dan niet om contact op te nemen met het team van GAGAT Studio. We zijn altijd bereid om u met uw ontwerp te helpen, zodat het eindresultaat ook écht is wat u voor ogen had.

DE SERVICE VAN GAGAT

Het ontwikkelen van een 3D ontwerp is een ingewikkeld proces. Bij GAGAT hebben we daar echter zeer veel ervaring mee en kunnen we vrijwel alle vragen over 3D printen en -ontwerpen oplossen. Er bestaat altijd een mogelijkheid dat u toch nog vragen heeft over uw ontwerp en hoe deze aan te leveren. Zo is bijvoorbeeld de oriëntatie van uw geüploade 3D ontwerp van belang, ook voor de prijs die getoond wordt. Maar ook vragen over het te gebruiken materiaal zijn goed denkbaar. Voor al uw vragen staat GAGAT Studio altijd telefonisch of per mail tot uw dienst.

Er bestaat altijd een mogelijkheid dat u toch nog vragen heeft over uw ontwerp en hoe deze aan te leveren. Zo is bijvoorbeeld de oriëntatie van uw geüploade 3D ontwerp van belang, ook voor de prijs die getoond wordt. Maar ook vragen over het te gebruiken materiaal zijn goed denkbaar. Voor al uw vragen staat GAGAT Studio altijd telefonisch of per mail tot uw dienst.

OFFERTE VOOR 3D PRINT

VEELGESTELDE VRAGEN

-

We hebben een minimale bestelling van 50 EUR. Als uw bestelling onder de 50 EUR ligt, wordt u gevraagd een toeslag te betalen.

Verdere informatie vindt u op deze pagina.

Verdere informatie vindt u op deze pagina. -

Wij bieden geen garanties als het onderdeel niet door ons is ontworpen, en als er geen consultancy is geweest voordat een bestelling bij ons werd geplaatst. In alle andere gevallen geven wij altijd advies over de materialen die voor het project zullen werken en helpen wij bij het maken van een prototype van 3D-modellen op de juiste manier die geschikt is voor het 3D-printproces. Deze werkwijze biedt garanties voor kwalitatief hoogwaardige en sterke onderdelen.

-

Gemiddeld genomen ontvangt u een bestelling in twee tot vijf werkdagen. In de meeste gevallen sneller dan later.

Wat mensen zeggen

Meer dan 400 tevreden klanten, particulier en zakelijk!

“Heb hier 2 keer een object besteld. Duidelijke website met uitleg over te kiezen materialen. Direct een prijs en evaluatie van je 3D model, en ook kleine objecten in kleine oplage te bestellen voor een prima prijs. Snelle service en duidelijke communicatie van status en track&trace info. Zeker 5 sterren!”

Duidelijke website met uitleg over te kiezen materialen. Direct een prijs en evaluatie van je 3D model, en ook kleine objecten in kleine oplage te bestellen voor een prima prijs. Snelle service en duidelijke communicatie van status en track&trace info. Zeker 5 sterren!”

— Rens

“Super helpful, quick and professional service. They went the extra mile to ensure the product arrived quickly.”

— Trixie

“Prettig bedrijf om zaken mee te doen. Ze denken goed mee over de beste manier van printen en materiaal keuze voor de toepassing. De bestelde artikelen worden snel geprint en goed verpakt geleverd. Aanrader.”

— R. Maas

“Het is heel goed en nauwkeurig geprint alle maten kwamen aardig overeen met de tekeningen.

Ik ga zeker vaker bij jullie printen.”

— Jari

“I had an amazing experience with this 3D printing service! They even helped me fix my 3D files so they could print them without any issues! The quality of the prints is absolutely great and I would order anytime again!

Would absolutely recommend!”

— Tabby

“Professional service. Print quality is great with an unbeatable price. It took less than 24 hours to print two small models (14 x 2 x 10 cm). Very pleased with the prints and had a great experience overall. Highly recommended!”

Print quality is great with an unbeatable price. It took less than 24 hours to print two small models (14 x 2 x 10 cm). Very pleased with the prints and had a great experience overall. Highly recommended!”

— Fahmy

digital manufacturing

3D printing for "dummies" or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.1 Consumables

- 3.2 Extruder

- 3.3 Working platform

- 3.4 Positioners

- 3.5 Control

- 3.6 Varieties of FDM printers

- 4 Laser stereolithography (SLA)

- 4.

1 Lasers and projectors

1 Lasers and projectors - 4.2 Cuvette and resin

- 4.3 Types of stereolithographic printers

3D printing term

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

3D printing technologies are numerous, and there are even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

However, you can try to divide technologies into main areas:

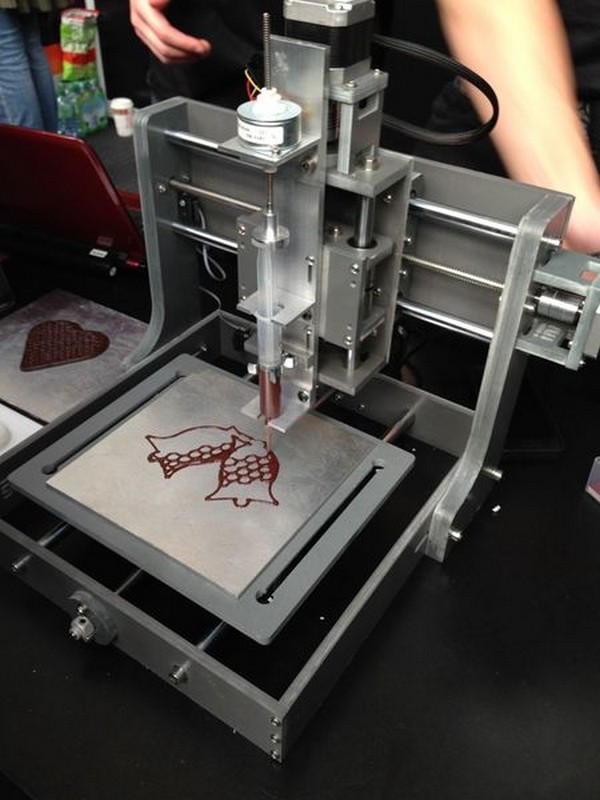

Extrusion printing

This includes methods such as deposition deposition (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on Voxeljet's SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut to the contours of the digital model using a laser or a blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused Deposition Modeling (FDM) and Laser Stereolithography (SLA) are the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D construction method, which makes it very popular.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a binding element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

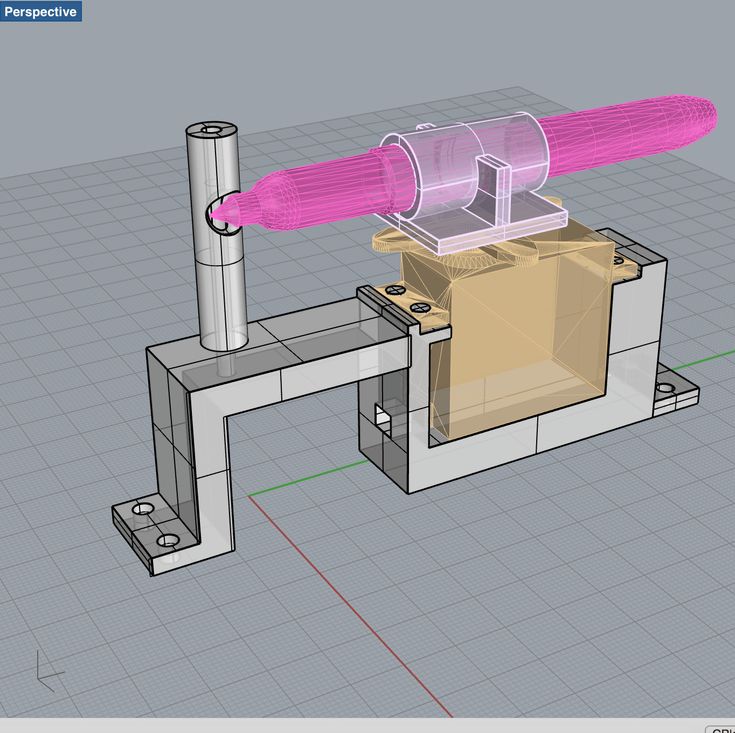

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

PrintBox3D One FDM Printer Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single printhead. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, the same water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can be simply dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

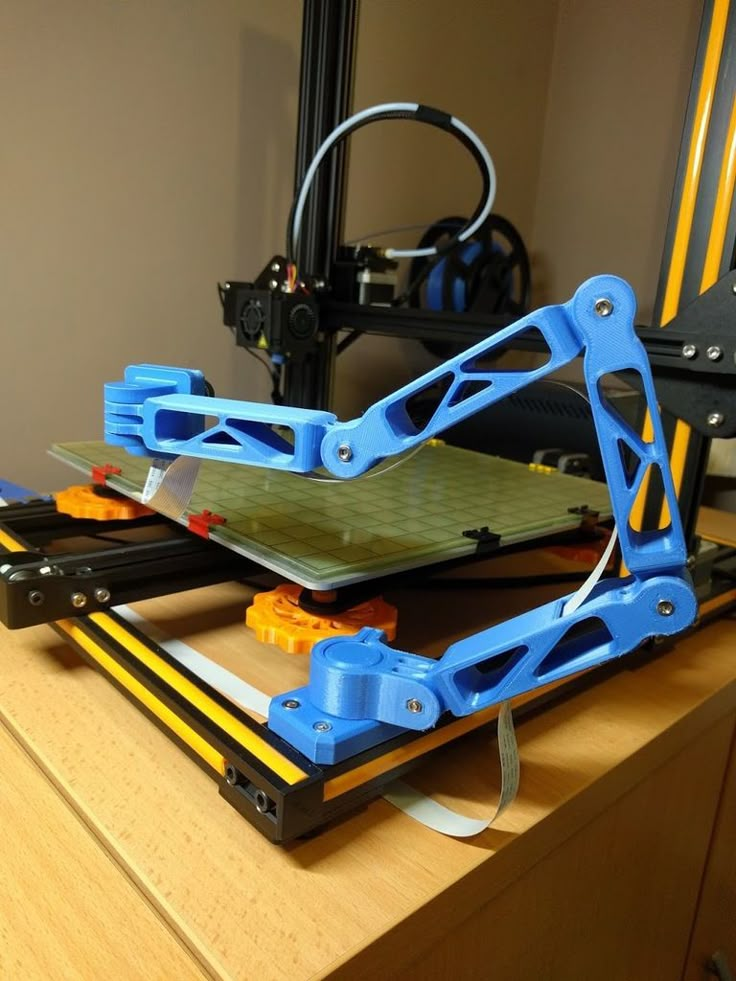

Working platform

Heated platform covered with removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle does not hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

Positioning mechanisms

Scheme of operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be carried out not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

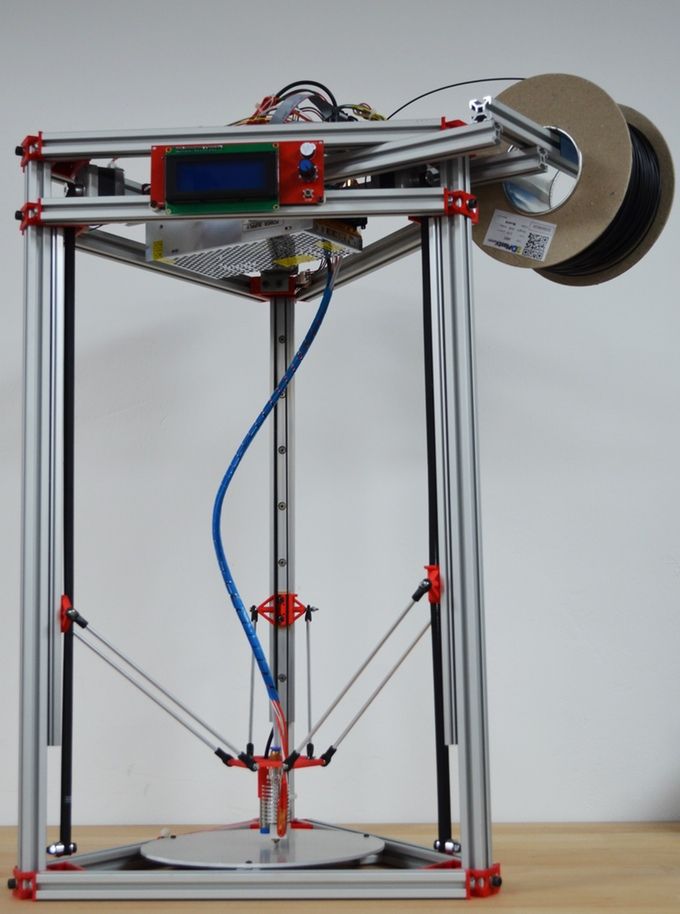

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by extending the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

The operation of the FDM printer, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by the printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

Some companies make printers that require proprietary software.

Program code for printing is generated using slicers

As an example, we can mention Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

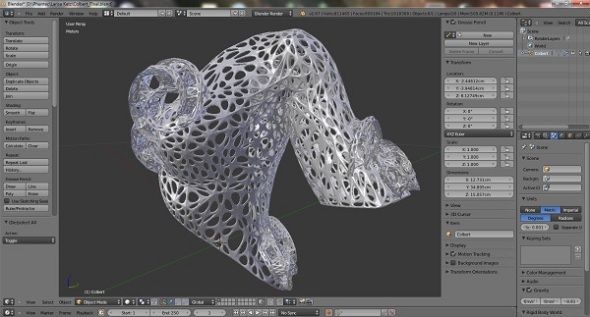

Slicers are not intended for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

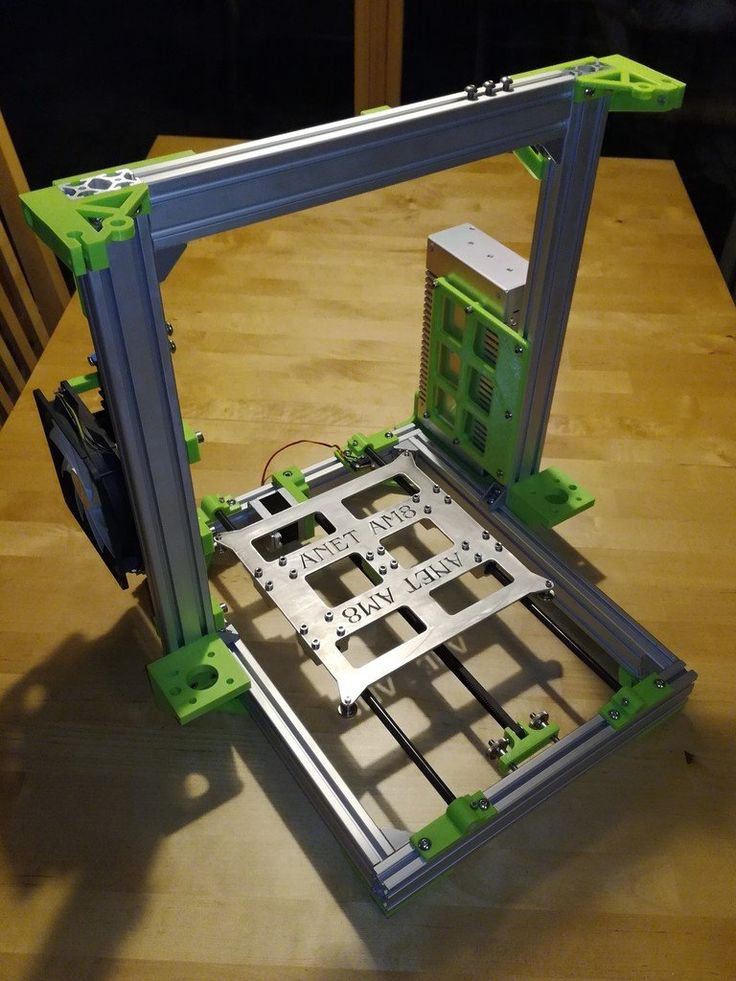

Varieties of FDM printers

Professional Stratasys Fortus 360mc FDM printer that allows printing with nylon

FDM printers are very, very diverse, ranging from the simplest homemade RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by Scott Crump, the inventor of FDM technology, is a leader in the production of industrial installations.

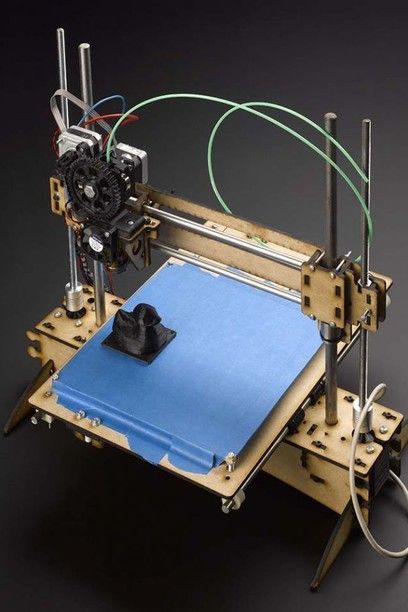

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom built plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology. RepRap Printers

And, despite their "homemade nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print “right out of the box” and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speeds, or superb build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu.be/51rypJIK4y0

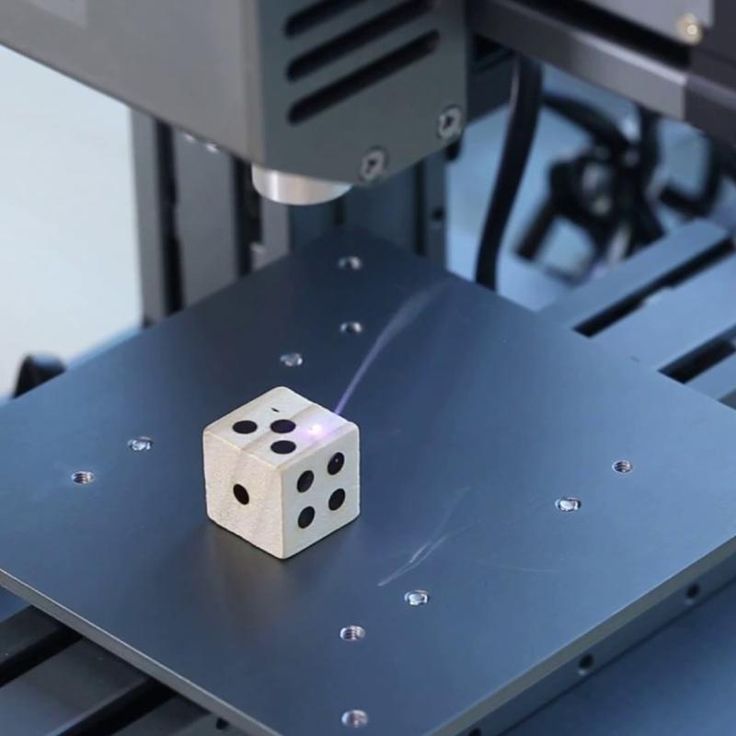

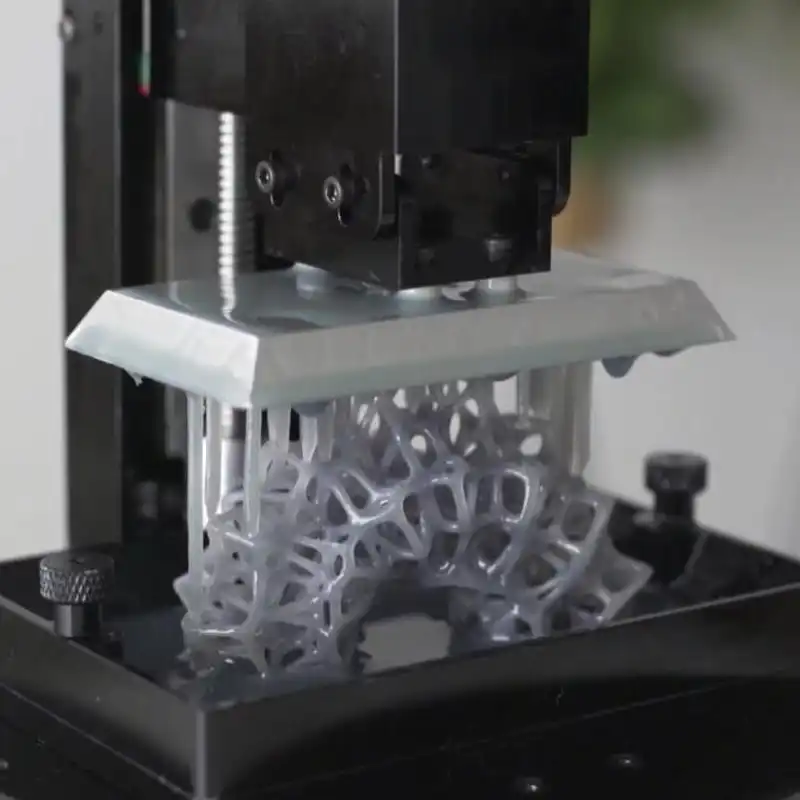

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using Kudo3D Titan DLP printer as an example

The cost of stereolithography printers is rapidly declining due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is generically referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithographic printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithography printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

Thus, SLA printers and consumables pay for themselves very quickly.

Example of a model printed on a laser stereolithographic 3D printer

Resin is poured into a cuvette, which can be equipped with a lowering platform. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer

As with FDM printers, SLA printers come in a wide range in terms of size, features and cost. Professional installations can cost tens if not hundreds of thousands of dollars and weigh a couple of tons, but the rapid development of desktop SLA and DLP printers is gradually reducing the cost of equipment without compromising print quality.

Professional installations can cost tens if not hundreds of thousands of dollars and weigh a couple of tons, but the rapid development of desktop SLA and DLP printers is gradually reducing the cost of equipment without compromising print quality.

Models such as the Titan 1 promise to make stereolithographic 3D printing affordable for small businesses and even home use at around $1,000. Formlabs' Form 1 is available now for a factory selling price of $3,299.

The developer of the DLP printer Peachy generally intends to overcome the lower price barrier of $100.

At the same time, the cost of photopolymer resins remains quite high, although the average price has fallen from $150 to $50 per liter over the past couple of years.

Of course, the growing demand for stereolithographic printers will stimulate the growth in the production of consumables, which will lead to further price reductions.

Go to the main page of the Encyclopedia of 3D printing

We found out why 3D printing is dangerous.

The main myths about technology

The main myths about technology Vladislav Kochkurov General Director of the Center for Additive Technologies

The first product was 3D printed in 1983 - it was a small container in the form of a bowl. Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Read Hi-Tech at

Myth No. 1. 3D printing takes place almost without human intervention

When many people hear about 3D printing, they think of a 3D printer as the central part, which distributes consumables in layers - this is how a new product is born. One gets the false impression that the entire cycle of additive manufacturing consists only of the operation of equipment, and a person hardly participates in this - he only turns on a 3D printer and loads a polymer, metal powder or other material into it.

One gets the false impression that the entire cycle of additive manufacturing consists only of the operation of equipment, and a person hardly participates in this - he only turns on a 3D printer and loads a polymer, metal powder or other material into it.

But the key role in building an object is played by its 3D model. It is a map on which the finished product will be built. The quality and characteristics of the future subject depend on its detailed study. Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

In industrial production, the construction of a 3D model is carried out in AutoCAD computer-aided design systems. The design engineer, in accordance with the terms of reference and using various calculation methods, creates the geometry of the future product. Even if the 3D model already exists and does not need to be built from scratch, AutoCAD programs carry out its topological optimization - redesign for additive manufacturing.

This process aims to eliminate stress raisers and thin-walled features that can cause cracks or other damage during the printing process. Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Further, based on the prepared 3D model, the printer prints on its own, sometimes working for several days in a row. But before that, the equipment needs to be prepared - make sure that the build platform is level and all the mechanisms move as they should. Even the powder in the 3D printer is not just poured, but goes through the stages of incoming control and preparation.

Even the powder in the 3D printer is not just poured, but goes through the stages of incoming control and preparation.

Another mandatory stage in the production cycle of a product that requires human participation is post-processing.

Myth #2: A finished product comes out of a 3D printer. Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

To relieve internal stress that occurs during the printing process, the product undergoes alternating heating and cooling procedures. This way it achieves full mechanical properties. Then technological supports are cut off - they have already fulfilled their function. Removal of excess powder and surface treatment of the product are carried out using a sandblasting chamber. If it is necessary to achieve absolute smoothness of surfaces, then milling, turning, electrochemical and grinding machines are used. For plastic products, chemical post-treatment with acetone or other solvents is sometimes used.

For plastic products, chemical post-treatment with acetone or other solvents is sometimes used.

Myth #3: You can 3D print anything

Innovations in additive manufacturing are emerging every year and already surpass our imagination. Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

For example, the Center for Additive Technologies has an installation with a build chamber up to half a meter, the largest printer in Russia based on selective laser melting technology. Elements of Russian aircraft engines are already being “grown” there.

"Innovations in the field of additive technologies appear every year" The capabilities of polymer printers are much wider - one of them, listed in the Guinness Book of Records, can create objects up to 30 m long. In 2017, a monolithic boat was printed on it, weighing 2 tons and 7 m long. The smallest object printed on a 3D printer is a ship. Its length is 2-3 times less than the thickness of a human hair - only 30 micrometers (0.03 mm).

In 2017, a monolithic boat was printed on it, weighing 2 tons and 7 m long. The smallest object printed on a 3D printer is a ship. Its length is 2-3 times less than the thickness of a human hair - only 30 micrometers (0.03 mm).

3D printers are already being used to create even at home. A construction printer works by analogy with an FDMD printer that prints plastic products, but instead of polymeric materials, cement mixtures are used as “inks”. In size, such a mechanism is much larger. The world's largest 3D printed building has an area of 641 square meters. m. and is located in the UAE.

Other limitations in additive manufacturing are not related to the size of the 3D printer's build chamber, but to the material used. During the printing process, it is in a liquid or molten state, therefore, it should melt normally. Wood, fabric, or paper objects cannot yet be printed, as they will burn before the material can be melted. Although here you can find a loophole: if you mix crushed cellulose fibers with a water-based gel, and then freeze the object, gradually removing water from it, you will get products made of a material similar to wood.

Myth No. 4. Products printed on a 3D printer are worse in quality

Visually, the 3D printing process looks like a layer-by-layer application of material. This may raise the question: how firmly are the layers interconnected?

3D printing can introduce several defects, so it is important to follow the workflow. A lot depends on the quality of the materials. In industrial production, all metal powders undergo input control, this process is regulated by standards. Even if the material is certified, it is very important to observe the conditions for proper storage: avoid moisture and dampness, place in a special package. If you do not check the condition of the nozzle, set the temperature or print speed incorrectly, misalignment of layers, overheating, or other defects may occur.

If all conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods. If you compare two aluminum objects under a microscope, the printed product will have a denser structure.

If you compare two aluminum objects under a microscope, the printed product will have a denser structure.

Myth #5. 3D printing is environmentally friendly

3D printing is considered to be environmentally friendly, as this type of production leaves little waste. In fact, this is a complex issue, in which there is no consensus yet.

3D printers use a lot of electricity and leave a large carbon footprint: The ATKINS project found that the production of a product using additive technologies emits approximately 7 times more CO2 emissions than the production of injection molded products.

But the use of additive technologies significantly reduces waste and the amount of materials used. CIM (material utilization factor) in the manufacture of casting does not exceed 40%, for additive technologies this figure approaches 100%.