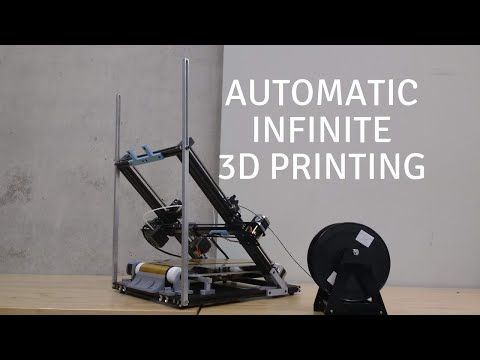

Infinite 3d printing

Infinite 3D printing - iFactory3D

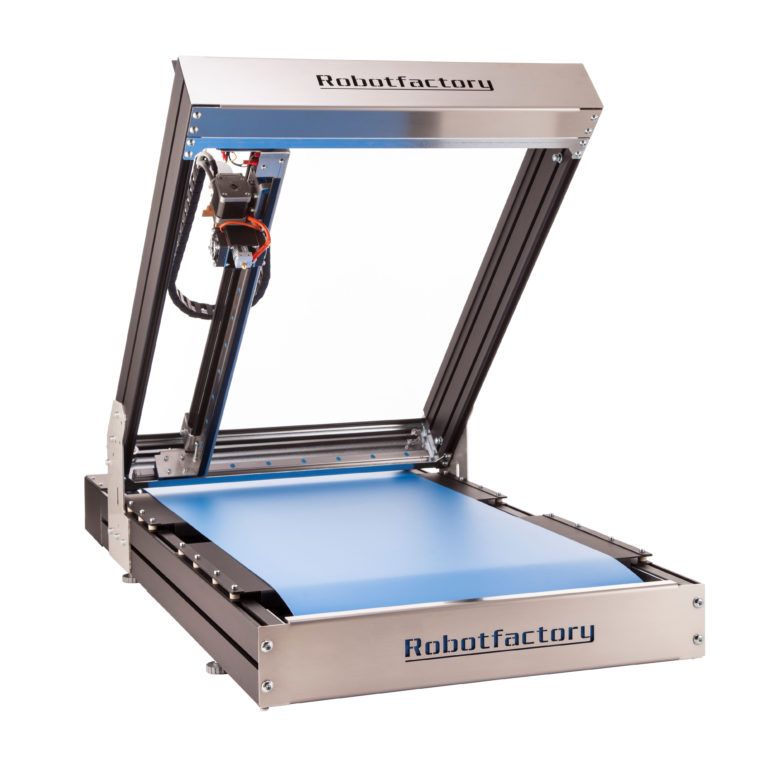

3D printing with iFactory3D’s belt technology in the new One Pro enables the production of objects,

in almost unlimited length and in the best 3D printed quality – in automated manufacturing.

Consultation in the showroom

Individual sample prints

Setup advice and training

Service and personal support

- One Pro

- Filament

- Care Package

PETG Filament

More about PETG Filament

Print examples

Your design possibilities become practically limitless with the 3D conveyor belt printing technique.

Our print examples offer you detailed visual insight as an introduction to 3D printing techniques and especially the 3D belt technology.

As an experienced 3D printing enthusiast, you will get an understanding of our innovative manufacturing technology and its abilities.

For the creative mind, we have some examples of useful or also decorative objects in the gallery, which were produced with our iFactory3D belt printers.

Get inspired in our gallery!

Explore printing gallery

Solutions

3D printing for business

A typical application of 3D printers today is the rapid and economical production of prototypes and scale models. Many companies use 3D printing technology to produce parts for their final product, but so far without the capability of automated additive manufacturing.

The constantly expanding number of printable materials and material combinations inspire the development of innovative technologies that, in combination, offer new and differentiated solutions to complex problems.

We at iFactory3D have developed a 3D belt printer that can produce particularly long or complicated hollow objects with overhangs in trouble-free serial printing. You can determine specifications for the printing process of small series and special productions just as differentiated and easily as you can produce a large number of identical products in a timely and cost-effective manner with the belt printer.

3D printing for life

Conventional 3D printers are ideal for home use. Here, mostly individual pieces are created and therefore the still quite maintenance-intensive production process and the limited installation space are acceptable. These 3D printers, mostly PLA filament-based, can be used to individually produce a wide variety of items, such as useful kitchen utensils, vases, lamps, toys or creative pieces for artistic purposes. They can also be used to make functional repair items such as nuts, coasters for wobbly table legs or handles for drawers.

Increasingly, entire homes, hotels and manufacturing halls are now being built using 3D printing, and by that, the additive manufacturing process is gaining more and more relevance in our everyday lives.

The use of 3D printers is therefore also becoming increasingly important as a school subject in technology lessons.

About us

iFactory3D GmbH brings automated batch production to additive manufacturing and makes globally connected factories a reality. As the world of manufacturing shifts towards customization, adaptability, and local sites, agile manufacturing is clearly becoming the future of production technology.

As the world of manufacturing shifts towards customization, adaptability, and local sites, agile manufacturing is clearly becoming the future of production technology.

We are constantly keeping up with innovative new materials that are opening up new application possibilities, allowing more and more industries to once again perform their manufacturing independently and implement innovations in a timely manner.

Contact

Why Choose Us

Infinite printing

Infinite printing with iFactory3D’s low-maintenance conveyor belt technology. Objects of several meters in length with cavity printing possible.

Serial printing

Fully automated 3D printing without limits with the innovative 3D belt printing technology from iFactory3D.

Quality technology

Printing at 45° angle for more flexibility and new topologies with hollow printing and overhangs without support structures.

Reviews

AquaSys® GP: Water Soluble 3D Printer Filament

AquaSys® GP

AquaSys® GP

Starting at: $70

AquaSys GP is a water-soluble support material that is a replacement for PVA and is compatible with most polyesters.

Product advantages.

AquaSys GP technical information.

AquaSys GP is a soluble solution ideal for the entry-level user because of its fast dissolution, easy removal, and material compatibility. Access the technical specifications and safety information that showcase why this support material is so accessible.

Data sheets

See Full SpecsDisruptive benefits of AquaSys GP.

Suited for prototyping to production — and everywhere in between.

VIEW INDUSTRIES & APPLICATIONS

Dissolvable, hands-off support removal allows for complex design features, enabling new possibilities for everything from flightworthy plane parts to highly specific surgical molds.

Jigs & fixtures.

Replace traditional jig and fixture production methods with a smart, simple approach to FFF. Precision, specificity, and complexity are highly sought after and achievable with AquaSys GP.

Rapid prototyping.

Create and experiment with a broad range of materials and produce end-use parts with FFF — all without wasting time or risking damaged prototypes with breakaway support removal.

End-use products.

Compatible with commonly used plastics like PLA and PETG, AquaSys GP is uniquely suited to support the production of tough, functional parts.

Finish clean.

AquaSys GP is a completely water-soluble support material that doesn’t require toxic finishing chemicals, making it ideal for manufacturing, general purpose plastics, and educational uses—while also relieving the waste disposal burden for all users.

-

Whitepaper

AquaSys GP Whitepaper

Read our whitepaper on AquaSys GP, our general purpose water-soluble support material.

Discover its moisture mitigation properties, adhesion characteristics and more

Discover its moisture mitigation properties, adhesion characteristics and more -

Article

The cost savings of additive manufacturing

Compared to traditional methods, additive manufacturing can be more cost effective in purchasing materials, rapid prototyping, and producing end-use parts.

-

Article

Critical role of 3D printing support material

As the adoption of additive manufacturing continues, 3D printing support materials will fuel demand for new options and better-performing market alternatives.

-

Article

Material knowledge: common 3D printer filaments guide

This 3D printer filament guide will give you the basics of addictive manufacturing which allows you to innovate and create lighter and more complex products.

-

Article

Quick study: Additive manufacturing in education & research

Learn how additive manufacturing technologies, including 3D printing and fused filament fabrication, play an ever-expanding role in education and research.

Additional products.

-

AquaSys® 120

A versatile, water-only soluble support filament that's stable at chamber temperatures up to 120ºC.

Starting at $100

-

AquaSys® 180

A high-temperature, water-only soluble support filament that's stable at chamber temperatures up to 180ºC.

Starting at $200

-

Caverna™ PP

A polypropylene build material with a microporous morphology.

Starting at $110

-

AquaSys® GP

Why you should buy AquaSys GP.

AquaSys GP isn’t just designed to make your 3D printing life easier—it’s meant to be the new standard in support materials. Engineered for a wide variety of customers—from hobbyists to seasoned professionals—it dissolves rapidly in room-temperature tap water while upholding outstanding print fidelity.

Favorable moisture mitigation properties.

AquaSys GP is engineered to protect against moisture uptake in humid conditions, reducing the need to dry or throw away the support material because of moisture during printing.

UP TO

30˚C

CHAMBER

40-60˚C

BUILD PLATE

225-255˚C

NOZZLE

UP TO

225-255˚C

EXTRUDER

Data Sheets

Material compatibility.

With excellent adhesion to polyester-type build materials, AquaSys GP is compatible with polylactic acid (PLA), polyethylene terephthalate (PET), polyethylene terephthalate glycol (PETG), and other common materials.

Printing parameters

See FAQS

AquaSys GP filament is designed for use in fused filament fabrication (FFF) printers.

Engineered for optimal pathway temperatures.

AquaSys GP will extrude properly at nozzle temperatures between 225° – 255°C. Keep below 80° C prior to extrusion.

Robust build plate adhesion.

AquaSys GP will adhere to build plate materials as long as the build plate temperature is under 60°C.

No adhesives required.

AquaSys GP can be printed with a wide variety of machines, including lower-cost dual extruder printers.

Starting at $70

Creality 3DPrintMill CR-30: Creality

3D printersfrom Creality

Starting price 77 900 ₽ - starting price 77 900 ₽

Starting price

77 900 ₽

77 900 ₽ - 77 900 ₽

Current price 77 900 ₽

| /

Savings 0 ₽ Savings -77.900 ₽

Available on order

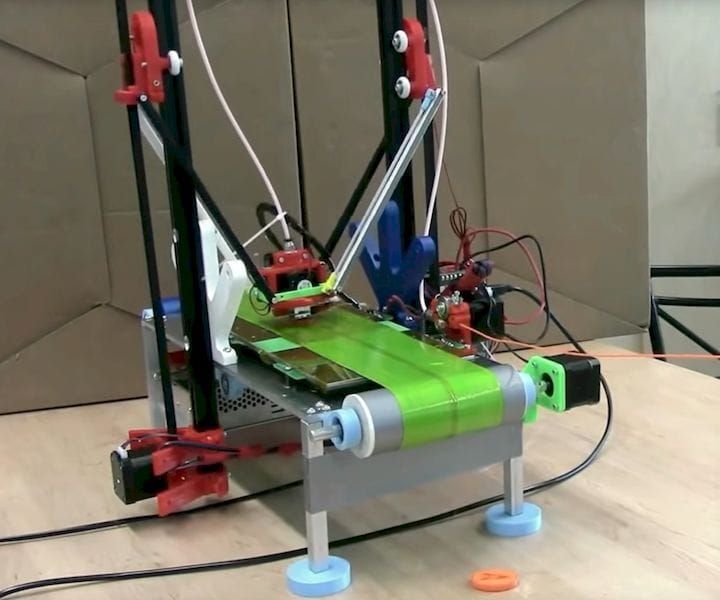

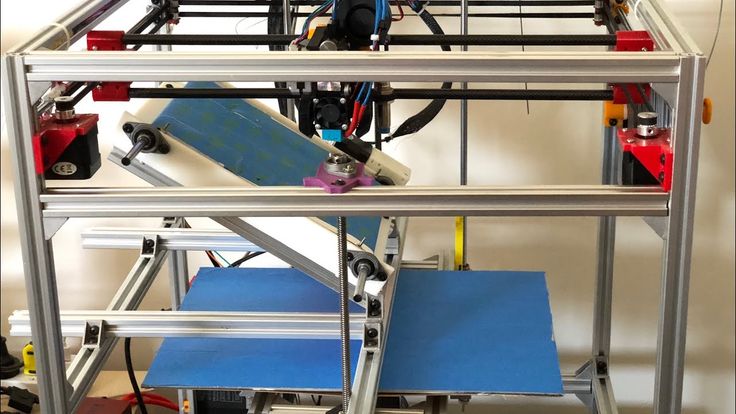

Creality CR-30 is Creality's first Z-axis endless printing model.

75 mm

75 mm Dimensions

Creality 3DPrintMill CR-30

This 3D printer comes with a detachable extension arm to prevent the model from falling off during printing. Its stable and durable precision CoreXY structure with isosceles right triangle support provides an exceptional printing experience. nine0003

Its stable and durable precision CoreXY structure with isosceles right triangle support provides an exceptional printing experience. nine0003

This printer features a conveyor belt made of wear-resistant nylon, which has excellent adhesion to the model. The printed model can automatically fall when the tape reaches the end, thus freeing the operator's hand. If necessary, the conveyor belt can be easily replaced.

Highlights

Naomi Wu Interview on Creality 3DPrintMill 3D Printer

Supermaker Naomi Wu answers our questions about the upcoming Creality 3D printer thirty. nine0003

Shenzhen-based Naomi is well known in the 3D printing community for her efforts to promote the achievements of manufacturers as well as creating some interesting designs. One of them, the T-beam impact-resistant TTGO case, was our project of the week a few months ago.

One of them, the T-beam impact-resistant TTGO case, was our project of the week a few months ago.

The project she is currently working on is the upcoming Creality CR-30 or 3DPrintMill 3D Printer. This unusual 3D printer prints at an angle on a moving conveyor belt to enable continuous 3D printing or the production of objects larger than the size of the 3D printer itself. In this video, Naomi introduces the device:

We asked a few questions to learn more about the project and what we can expect when it's released.

Fabbaloo : Can you tell us how this project started and how you got involved? What is your relationship with Creality and White Knight/NAK 3D?

Naomi Wu : “I learned about Infinite-Z printers around 2016 when Bill Steele showed off his designs. I immediately saw the potential, but at that moment both the creation and the purchase were beyond my means. In 2018, I arranged for Bill to meet the founders of Creality here in Shenzhen to develop a custom infinite Z-axis 3D printer for them. It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

In 2018, I arranged for Bill to meet the founders of Creality here in Shenzhen to develop a custom infinite Z-axis 3D printer for them. It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

For those of us who have been here for a while, the way previous open source 3D printer projects were brought to market in China. .. among other things, it was just disrespectful to the people who created these projects: by companies that took credit for "reinventing" the standard Prusa and Replicator clones. Yes, you can copy, but there is a correct way to do it. It was bad and I never liked it and you have to bite your tongue when the community complains about it because they are right. I waited for years to prove that it was unwise and not good to do so, that it was short-sighted. So far with 3DPrintMill that has been true and I owe a lot to Carl and Bill for letting me show some people here that if you do it right, play by the rules, the community will support you.” nine0003

Fabbaloo : Is this a CR-30 or a 3DPrintMill? Or are they different things?

Naomi Wu : “Creality model number is CR-30, product name is 3DPrintMill. It's really meant for small-scale production, so I needed a name that would resemble it: sawmill, rolling mill, etc. But at the same time, it's a treadmill game because of the belt."

Fabbaloo : I first used a belt driven 3D printer in 2010 with MakerBot's "Automated Build Platform". Although the device was a little unstable, the ability to 3D print a continuous stream of objects seemed very powerful. Today, I still see skepticism about the tape concept from many people. Why do you think there was no interest in this concept? What do people not understand?

Naomi Wu : “Lack of interest is news to me, my inbox is full of requests for pre-samples. From most of my discussions, I've always been worried about the ABP patent, which is now owned by Stratasys. Infinite-Z doesn't break that, but people are still worried about objections from such a big player and don't want to take the risk.

The interest has been huge, and frankly, a bit of skepticism is great. I'm not trying to sell it to people who don't need it and convince them they need it. There won't be a single bearded hipster video on Kickstarter with a MacBook and ukulele music in the background. That's not who it's aimed at. People who need 3DPrintMill know exactly why they need it as soon as they see how it works. It's like a Bridgeport milling machine or a high-end gaming computer. People who look at them and ask "What is this for?" probably shouldn't buy them. nine0003

This is not for small figurines, not the best first printer for kids. I was really targeting people or companies that print long objects such as cosplay and prop makers, sign makers, molding restorers and other long decorative items, but mostly those who need to make 10-1000 items - small scale production, Etsy and eBay stores, local machine shops as a cheaper alternative to CNC to offer to customers, people printing PPE and daily necessities, all that sort of thing. nine0003

It has the potential to be fantastic for education when we can line up prints, which means little hands can get their part after they fall into the bin without touching the hot parts to tear them off heated base. But 3DPrintMill is not intended to replace traditional FDM 3D printers, and a little reality check is a good thing. If you're a pocket-saving teenager, for God's sake, buy an Ender-3 as your first $200 printer, not this thing." nine0003

But 3DPrintMill is not intended to replace traditional FDM 3D printers, and a little reality check is a good thing. If you're a pocket-saving teenager, for God's sake, buy an Ender-3 as your first $200 printer, not this thing." nine0003

Fabbaloo : The main problem with the MakerBot ABP was the tape itself, which after repeated heating could warp, becoming an uneven surface for subsequent prints. How has belt technology changed? How durable can a belt be over the long term? Will it be consumable?

Naomi Wu : “I think the first impression was that special belts were needed. I think the reality is that it took a larger belt ecosystem to find the right belt. When Charles Pax created ABP, he had at best what McMaster-Carr had to work with. And whatever relatively small assortment of conveyor belts they had, nothing worked, not in paper, Kapton, or other materials he tried to make his own out of. The straps they tried warped from the print or fell apart, so it was decided that more exotic straps were needed. nine0003

nine0003

The fact is that problems such as twisting, stretching, heat resistance are actually not all that unusual in a production environment. Here in Shenzhen, we have had no problem ordering dozens of different belts from local suppliers, designed in different materials to solve exactly these problems. So while I'd like to tell you that the belt is Creality's "secret sauce" or some ridiculous startup crap, it really isn't. There are well-established, proven materials that do exactly what we need really well and do it industrially for thousands of hours in much more severe conditions. Exactly how many hours remains to be seen, but far more than either Carl or I managed to put in even if we were typing 24/7 for weeks at a time.” nine0003

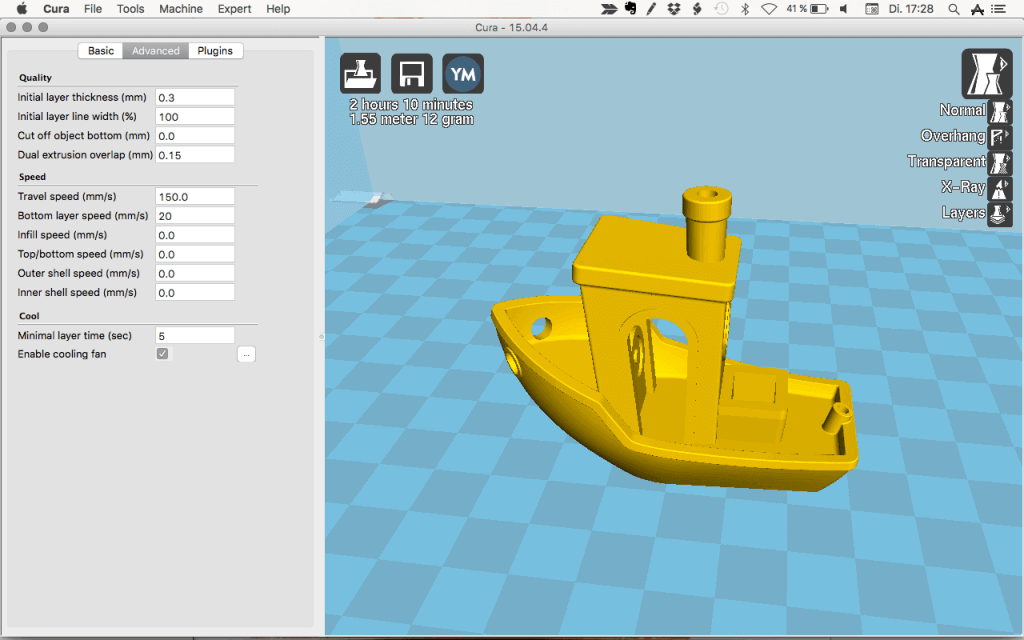

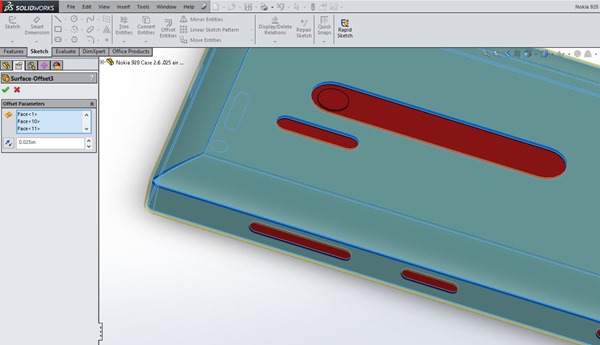

Fabbaloo : Obviously, modified versions of the current cutting software must be used to prepare a 3D print job for 3D tape printers, and this has been known to work. But how do you think tape printer slicing software will evolve? For example, do we want to randomize the location of a repeating print on the tape to avoid wear, or do we want to automatically generate serial numbers to keep track of the prints that go into the collection container? What other slicing features on a tape printer do you see in the future? nine0003

Naomi Wu : “Well, BlackBelt3D has been a huge contributor to the development of BlackBelt Cura and deserves a lot of credit for that. Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Fabbaloo : What was the most difficult technical challenge when creating 3DPrintMill? What advice would you give to others intending to develop a belt 3D printer?

Naomi Wu : “I think Carl, Nak3D, really solved the biggest problem when he proved that there is not a single insurmountable problem that stands in the way of inexpensive infinite Z printers. Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with." nine0003

Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with." nine0003

Fabbaloo : Complex 3D printing is much easier if you can use a soluble support material, but it requires the ability to use multiple materials. Do you think it is possible to implement multi-material capabilities on the 3DPrintMill or future versions of the 3D printer? What is the best way to do this?

Naomi Wu : “Multiple printheads is definitely the next step. It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users." nine0003

It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users." nine0003

Fabbaloo : While I'm sure 3DPrintMill will be of interest to hobbyists, what features are coming to 3DPrintMill and its software to attract the attention of small manufacturers? What will make the device attractive for business?

Naomi Wu : “Automatic printing. The old knock off base trick is cute, but it's time consuming in the real world to set up because each shape of the piece fits the base slightly differently, so it's not a standard practice written into firmware or software slicing. Tray robots work, but they cost as much as the annual salary of two employees. Tape printers - you just put a basket in front of it and the parts pile up. The real key feature we need to implement there is the ability to have one GCODE file of an object on the map and choose in the machine interface how many copies you want.