Can 3d printers make food

The Ten Food 3D Printers You Should Know

Published on December 16, 2021 by Madeleine P.

3D printing materials are becoming increasingly diverse, but when we talk about additive manufacturing, we often think of plastics or metals. But today, we wanted to focus on something very different namely food. And yes, some 3D printers do allow for the creation of sweets, pastries, chocolates, pizzas and dishes of all kinds. A food 3D printer offers more freedom and creativity in the kitchen and in some cases, can even reduce food waste. Even if we are not yet convinced that these machines will replace our ovens and microwaves, they have an interesting potential for all those who love to cook. In this listing, we introduce you to food 3D printers that are already being used!

3D Chocolate Shaper – byFlow

Food Tech company byFlow specializes in 3D printing of chocolate. To print with the notoriously tricky ingredient, the company has developed 3D Chocolate Shaper, based on a patented technology to design all types of chocolate parts. ByFlow provides you with the Online Chocolate Design Studio, where you can create your own chocolate designs in minutes. Any type of chocolate can be used with a fully automatic temperature control system. Note that you can also use this 3D printer to design other sweet or savory foods. ByFlow also opened one of the first restaurants to integrate a 3D food printer.

Photo Credits: byFlow

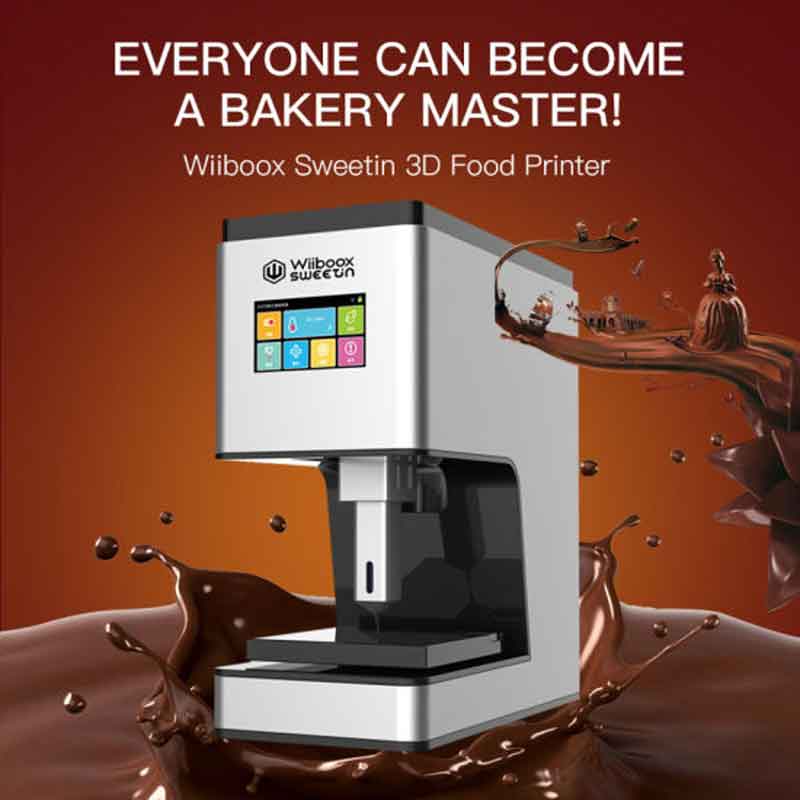

WiibooxSweetin

The WiibooxSweetin food 3D printer is a printer that combines precision, quality and creativity and is designed for professional use. Additionally, the machine is easy to use. All users need to do is download the 3D model files into the machine and start printing. The printing materials? There’s (really) something for everyone: chocolate, cheese, mashed potatoes, beans, caramel, honey, jam, cookies. The printer includes a real-time temperature control device that ensures food is perfectly sealed. The technology used is fused deposition modeling (FDM), has several types of nozzles included and is compatible with . stl .obj . amr files.

stl .obj . amr files.

Photo Credits: WiibooxSweetin

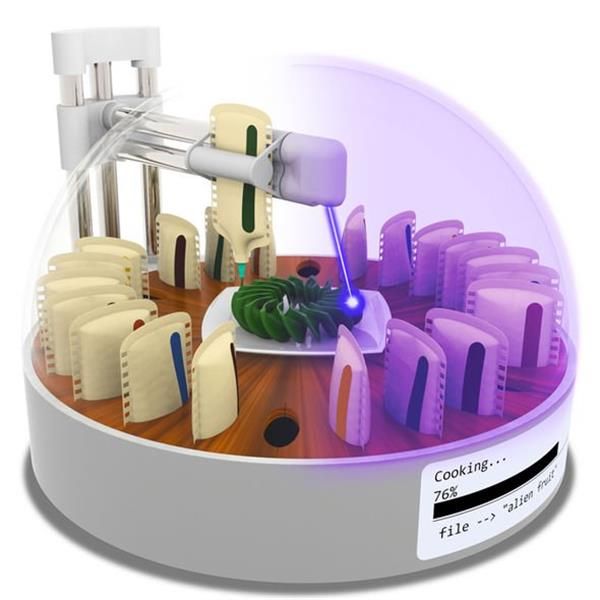

SMRC’s 3D Printing System for Space

When people think of 3D printed food, most of the time it is for projects for people on Earth. But this is not always the case. Enter SMRC’s 3D printed food system which has been developed to make food for long duration space missions in collaboration with NASA. The company aims to create food using 3D printing that has interesting flavors while including nutrient supplements that will set off nutritional degradation from long-term storage. Essentially, the system will dispense viscous food that has been made from powder and ingredients and they have already successfully made cheese pizza using it. They hope to provide healthy nutrition for astronauts.

nūfood from Dovetailed

nūfood, which was born from a hackathon, is the world’s first liquid-based 3D food printer and was created by Dovetailed. The company is tight-lipped on how exactly the 3D printing technology works, but the result is essentially edible, 3D printed flavor bubbles as the printer “offers the ability to create juicy bites in a variety of shapes, flavors and colors on-demand.” Users can just tap the available app, pour in the flavors and then print, with 3D food flavor bursts ready in minutes. Additionally, the ingredients are high-quality and vegan-friendly ranging from both savory to sweet. The printer is available to rent in the United Kingdom for events on their website, though they also note that it is ready for commercial manufacture.

The company is tight-lipped on how exactly the 3D printing technology works, but the result is essentially edible, 3D printed flavor bubbles as the printer “offers the ability to create juicy bites in a variety of shapes, flavors and colors on-demand.” Users can just tap the available app, pour in the flavors and then print, with 3D food flavor bursts ready in minutes. Additionally, the ingredients are high-quality and vegan-friendly ranging from both savory to sweet. The printer is available to rent in the United Kingdom for events on their website, though they also note that it is ready for commercial manufacture.

Photo Credits: Dovetailed

mycusini® 2.0

This chocolate 3D printer definitely steals the show from other kitchen appliances! The mycusini® 2.0 has been enhanced with interesting features since its predecessor and represents the latest generation of the machine. The first thing that catches the eye is the timeless design combined with pink elements. But the device is not only visually a real eye-catcher: the mycusini® 2.0 has an integrated library of over 1,000 objects that can be called up with the 3.5″ touch color display, including object preview. If you want to design your 3D objects yourself, you get free access to the mycusini Club. Objects can be printed with the provided Choco Refills with a size of up to 90 x 90mm. The removable platform allows easy cleaning of the device. The device is available at a special price of €758.70 on the manufacturer’s website.

But the device is not only visually a real eye-catcher: the mycusini® 2.0 has an integrated library of over 1,000 objects that can be called up with the 3.5″ touch color display, including object preview. If you want to design your 3D objects yourself, you get free access to the mycusini Club. Objects can be printed with the provided Choco Refills with a size of up to 90 x 90mm. The removable platform allows easy cleaning of the device. The device is available at a special price of €758.70 on the manufacturer’s website.

Photo Credits: mycusini

Choc Creator V2.0 Plus

After the success of the Choc Creator V1 and V2 devices (which are no longer sold), the Choc Creator V2.0 Plus is the optimized version of the Choc Edge chocolate 3D printer. The device scores with a larger design area of 180 mm x 180 mm x 40 mm and allows the production of creative chocolate creations with fine lines from 0.8 mm width. Common STL files can be used, which are transferred directly to the device with a USB stick. Two 0.8 mm metal nozzles are included and the machine comes with pre-installed ready-to-print 2D and 3D G-codes, making the Choc Creator V2.0 Plus ready for immediate use. The machine can be purchased for around €3,350.

Two 0.8 mm metal nozzles are included and the machine comes with pre-installed ready-to-print 2D and 3D G-codes, making the Choc Creator V2.0 Plus ready for immediate use. The machine can be purchased for around €3,350.

Photo Credits: Choc Edge

Foodini, the 3D food printer par excellence

Foodini is surely one of the most popular 3D food printers today. It is a kitchen appliance developed by the company Natural Machines, which allows food customization and 3D printing. They claim that this solution allows eating healthier dishes, improving kitchen efficiency and reducing food waste. The competitive advantage is that users can create all kinds of dishes using their own natural and fresh ingredients. In terms of user experience, the Foodini stands out for its ease of setup and interaction when working with the machine. From loading the stainless steel capsules to interacting with the large touch screen, Foodini guides the user through every step of the process. What better way to get started in food 3D printing?

Photo Credits: Natural Machines

Brill 3D Culinary Studio, 3D printing in the culinary arts

Brill Inc. and 3D Systems have teamed up to develop an innovative new additive manufacturing system that aims to revolutionize the culinary arts. The result of a multi-year collaboration, this professional, full-color 3D printing technology offers culinary enthusiasts a unique opportunity to create original, customized dishes, figures, garnishes and anything else they can imagine. As for the 3D printing process, users must begin by separating the wet and dry ingredients, so that the machine can mix them with automated precision, and then create the models layer by layer. This system includes 3D Systems’ software, the Brill 3D Culinary Printer machine and finally the powders and binders that allow the production of an unlimited range of original creations.

and 3D Systems have teamed up to develop an innovative new additive manufacturing system that aims to revolutionize the culinary arts. The result of a multi-year collaboration, this professional, full-color 3D printing technology offers culinary enthusiasts a unique opportunity to create original, customized dishes, figures, garnishes and anything else they can imagine. As for the 3D printing process, users must begin by separating the wet and dry ingredients, so that the machine can mix them with automated precision, and then create the models layer by layer. This system includes 3D Systems’ software, the Brill 3D Culinary Printer machine and finally the powders and binders that allow the production of an unlimited range of original creations.

Photo Credits: Brill Inc

Procusini 5.0

The Procusini 5.0 food 3D printer was developed by the German company Print2Taste and is based on an extrusion process. It has a printing plate of 25 x 15 cm and weighs only 9 kilos making it easy to transport and integrate into the kitchen. It is considered today as a machine for the professionals of the restoration. It offers automatic calibration and connectivity via an SD card. It is a printer that has cartridges that can be heated up to 60 degrees, easily cleaned and simple to change. The Procusini 5.0 user will be able to access the Procusini Club allowing him to download more than 1,000 templates, logos, messages, etc. as well as to get tips and tricks.

It is considered today as a machine for the professionals of the restoration. It offers automatic calibration and connectivity via an SD card. It is a printer that has cartridges that can be heated up to 60 degrees, easily cleaned and simple to change. The Procusini 5.0 user will be able to access the Procusini Club allowing him to download more than 1,000 templates, logos, messages, etc. as well as to get tips and tricks.

Photo Credits: Print2Taste

The Mmuse food 3D printer

Chinese manufacturer Mmuse is behind the eponymous machine, which specializes in chocolate extrusion. It is a food 3D printer that has a printing volume of 160 x 130 x 150 mm, a nozzle of 0.8 mm in diameter and a printing speed of 30-60 mm / s. The Mmuse printer uses cocoa beans that it melts, all in a controlled environment in terms of temperature. It also incorporates a touch screen to facilitate the operations of the user and monitor in real time its prints. Today, this food 3D printer is available from 5 700 dollars.

What do you think of our list of food 3D printers? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

What in the World is 3D Food Printing?

Revo Foods’ plant-based seafood alternatives are developed with the help of 3D food printing technology. A group of specialized food technologists and engineers constantly experiment with new recipes to create new revolutionary products that are both delicious and nutritious. And they achieve that with the help of state-of-the-art 3D food printers, and 3D food printing is one of Revo Foods’ unique selling propositions.

Now you may be wondering… “what in the world is 3D food printing; do you download fish images and print them on paper?” – we get the confusion. Here is everything you need to know about 3D food printing.

Here is everything you need to know about 3D food printing.

What is 3D Printing?

Also called “additive manufacturing”, 3D printing is the process of making three-dimensional objects from a digital file. As the name suggests, the creation of a 3D printed object is achieved using additive processes. That means that the object is created by laying down layers of material on top of each other.

This process differs from traditional printing methods. When printing a file from your computer via a regular printer, you simply print an image of it on paper. When, however, you print a file with a 3D printer, you create a replica of it with the materials of your choice. Imagine seeing an object in your computer screen and having it in your hands a few minutes or hours later. Quite fascinating, isn’t it?

Δείτε αυτή τη δημοσίευση στο Instagram.

Η δημοσίευση κοινοποιήθηκε από το χρήστη Revo Foods (@revo_foods)

This revolutionary method was first imagined by writers and creatives in the 1940s. Writer Murray Leinster had written a story named “Things Pass By”, where he described a futuristic production method that “makes drawings in the air following drawings it scans with photo-cells. But plastic comes out of the end of the drawing arm”. It took over 40 years to materialize these revolutionary ideas. Early additive manufacturing equipment and materials were developed in the 1980s. But it was the 2010s that helped 3D printing gain massive popularity. That is partly because Fused Deposition Modeling (FDM)* printing process patents expired in 2009.

What is 3D Food Printing?

Although 3D printing mostly focused on the production of products made of plastic, it became quite handy in food manufacturing. Believe it or not, NASA has been looking into the technology to limit food waste and to make food that is designed to fit an astronaut’s dietary needs. Additive manufacturing of food is being performed by depositing food, layer by layer, into three-dimensional objects. The most common way of doing that is by using food-grade syringes to hold the printing material, which is then deposited through a food-grade nozzle layer by layer. This is not too unusual from other food production methods, which today already often can produce in a 3D shape. The main novelty with 3D food printing is that is can be performed in a much more controlled way, leading to products which could not be produced otherwise (such as plant-based fish fillets).

Additive manufacturing of food is being performed by depositing food, layer by layer, into three-dimensional objects. The most common way of doing that is by using food-grade syringes to hold the printing material, which is then deposited through a food-grade nozzle layer by layer. This is not too unusual from other food production methods, which today already often can produce in a 3D shape. The main novelty with 3D food printing is that is can be performed in a much more controlled way, leading to products which could not be produced otherwise (such as plant-based fish fillets).

This method offers endless possibilities in terms of texture and flavor, which can come in handy when developing meat and fish substitutes. Since 2020, Revo Foods has been using this technology to develop high-quality seafood alternatives, such as smoked salmon slices made of peas and algae extracts!

The Benefits of 3D Printing Food

- Unlimited design freedom

- Texture variety

- Food waste reduction

- Time-saving

- Personalized nutrition (in the future)

- Less inventory

About Revo Foods

Revo Foods is an Austrian start-up that develops and produces plant-based seafood alternatives with the goal of ending overfishing. Our first product, Revo Salmon, is already available in more than 15 European countries. In June 2022, the first texturized salmon fillet by Revo Foods was presented at “Have a Taste of the Future” tasting event in Vienna. It is worth mentioning that 3D food printing has played a major role in the development of our revolutionary products.

Our first product, Revo Salmon, is already available in more than 15 European countries. In June 2022, the first texturized salmon fillet by Revo Foods was presented at “Have a Taste of the Future” tasting event in Vienna. It is worth mentioning that 3D food printing has played a major role in the development of our revolutionary products.

*FDM is an additive manufacturing technology that creates 3D components using a continuous thermoplastic or composite material thread in filament form.

how 3D food printers can help you maintain a healthy diet April 24, 2018, 23:54

Anastasia Ksenofontova

Scientists from Ewha Women's University (South Korea) have created a 3D printer that prints products with a given nutrient content and predetermined taste properties. The author of the development, Jin-Kyu Lee, presented his invention on April 24, 2018 at the annual meeting of the American Society for Biochemistry and Molecular Biology in San Diego. About the prospect of using "smart" food - in the material RT. nine0003

The author of the development, Jin-Kyu Lee, presented his invention on April 24, 2018 at the annual meeting of the American Society for Biochemistry and Molecular Biology in San Diego. About the prospect of using "smart" food - in the material RT. nine0003

from 3 d- Products up to 3 D- kitchens

South Korean university of the NIGHA Women's University developed a 3D printer that turns powder ingredients into full-fledged food products with a given content of nutritional substances predetermined taste properties.

Related

A spoon for the Earth: how a healthy diet can improve the ecology of the planet nine0014

June 2 is Healthy Eating Day. Research scientists show that changing eating habits and accustoming yourself to the right...

Key nutrients (such as carbohydrates and proteins) are ground into powder at a temperature of -100 °C. Then the resulting raw material is heated and turns into a porous film. After that, a three-dimensional product is created from several layers of films. The uniqueness of the development lies in the fact that by combining films with different content of proteins, carbohydrates, trace elements and vitamins, you can get a product saturated with nutrients in the required proportion. In addition, you can experiment with the flavor palette of the product, combining, for example, powdered pear and apple. nine0003

Then the resulting raw material is heated and turns into a porous film. After that, a three-dimensional product is created from several layers of films. The uniqueness of the development lies in the fact that by combining films with different content of proteins, carbohydrates, trace elements and vitamins, you can get a product saturated with nutrients in the required proportion. In addition, you can experiment with the flavor palette of the product, combining, for example, powdered pear and apple. nine0003

“We believe that one day anyone will be able to purchase cartridges containing powdered analogues of various ingredients that can be “collected” together using 3D printing and prepared a “dish” according to individual needs and preferences,” said the author of the development, the researcher from Ewha Women's University Jin-Kyu Lee.

A balanced diet

The developers believe the new technology will significantly reduce the amount of food waste and the financial costs of storing and transporting food. Also, according to scientists, their invention will help meet the food needs of the growing population of the planet. According to the Food and Agriculture Organization of the United Nations, by 2050 the world's population will increase from the current 7.6 billion people to 9.8 billion, and in 2100 it will reach 11.2 billion.

Also, according to scientists, their invention will help meet the food needs of the growing population of the planet. According to the Food and Agriculture Organization of the United Nations, by 2050 the world's population will increase from the current 7.6 billion people to 9.8 billion, and in 2100 it will reach 11.2 billion.

“If a family gets a 3D printer, then they don't have to be afraid of hunger. Of course, we are only at the beginning of the journey. We continue to optimize our development to create customized products that last longer than usual,” said Jin-Kyu Lee.

- © 3D Systems Corporation nine0048

The first 3D food printers appeared in 2015 and could only prepare simple meals. One of these devices works in the FoodInk 3D kitchen restaurant, opened in London in 2016. Everything in this establishment - from food to furniture and cutlery - is created on a 3D printer. The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse. nine0003

The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse. nine0003

According to Russian nutritionists, the development of Korean scientists will help people maintain a balanced diet. However, experts emphasize that it is not worth doing “self-healing” with the help of a 3D printer - first you need to seek advice from a specialist.

“On complex developments that provide for a certain nutrient content, a person will not last long. In addition, it deprives him of the pleasure of eating. Such 3D food can be balanced and healthy, but quickly get bored. And of course, it’s better not to prescribe a diet for yourself, but to turn to a competent nutritionist who will make up a diet based on the state of your body, ”said Alla Pogozheva, professor at the Research Institute of Nutrition of the Russian Academy of Medical Sciences, in an interview with RT.

nine0003

Russian developments

“In Russia, printers for printing products are not yet manufactured. For now, they remain a luxury item. However, in ten years, printers for printing products will most likely become more affordable for the average consumer, ”said Alexander Vinogradov, director of the chemical and biological cluster at ITMO University, in an interview with RT.

Related

"Printed" organ: Chinese scientists have grown and transplanted auricles to five children at once nine0014

Scientists from China have grown new ears for five children born with microtia - insufficient development or complete absence of the ear...

At the same time, 3D printing methods are actively developing in Russia, but in a more fundamental direction. So, domestic researchers from the Federal Research Center "Crystallography and Photonics" of the Russian Academy of Sciences developed in April 2018 the first 3D printer that immediately creates a three-dimensional structure. The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs. nine0003

The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs. nine0003

And scientists from Tomsk Polytechnic University use 3D printing technologies to develop the space industry. They made the first nanosatellite, the body of which is printed on a 3D printer, and they are also creating a printer for work on the ISS, which will help astronauts print the necessary part in the event of a breakdown. In addition, improved technology will make it possible to build bases and stations on the Moon using lunar soil as a material for three-dimensional printing.

3d printed food

3D food printing

Who needs it and why?

Today, progress is progressing by leaps and bounds: robots are being invented, medicines for previously incurable diseases, people's lives are getting easier every year more and more. One of the young inventions with broad development prospects is 3D printing. Machine parts that are difficult to make by hand, prostheses and even food are printed

Machine parts that are difficult to make by hand, prostheses and even food are printed

In March, the world was delighted by the news of a breakthrough in the field of cooking: in Sweden (in hospitals and nursing homes) they began to prepare food using 3D printing for those who can no longer chew food on their own. For such people who have difficulty chewing and swallowing food, there used to be only one way out - to switch to a "children's" diet, mashed potatoes, cereals, and so on. But if, for example, you want normal food, you still need to grind it. And in the end, no matter how tasty it is, aesthetically it will still be disgusting. nine0088

“When you have trouble swallowing, you have to settle for food that isn't particularly appetizing. The idea is to make special dishes more attractive by recreating the original shape of the product. That is, the food will look, for example, like a chicken leg, but the consistency will resemble a cream pudding, ”explains Richard Asplund, head of the municipal catering department of the Halmstad district.

The program is currently being implemented on an experimental basis. The project involves researchers from Lund University and the University of Kristianstad, the equipment is offered by Cellink, and 3D printing services are provided by the service bureau Addema. nine0088 Residents of nursing homes in Halmstad and Helsingborg will serve as the jury for the pilot project.

So, it's worth understanding how 3D printing appeared, how printing devices work and what prospects await this technology in the future.

How did it all start?

History

1948

1948

The history of 3D printers dates back to 1948, when the American engineer Charles Hull developed a technology for layer-by-layer growth of physical three-dimensional objects. She got the name Stereolithography (stereolithography).

1985

1985

Mikhailo Feigen proposed to form three-dimensional models in layers from film, polyester, plastic, paper, fastening the layers together using a heated roller.

1986

1986

Carl Descartes invented layer-by-layer sintering of powder material (powder polymers, metals, foundry wax, nylon) with a laser beam.

1987

1987

The world saw the first 3D printer in history.

True, at that time the apparatus was called a "installation for stereolithography".

In 1987, the Israeli company Cubital developed a layered sealing technology. However, it requires the use of expensive, toxic, and fairly rare polymers.

1988

1988

Scott Crump described the FDM method.

Printers using this technology print objects with a molten thread of a substance (plastic, metal, etc.), which was later used to print food.

1995

1995

Until 1995, 3D printing was only used in industry, until MIT students Jim Bredt and Tim Anderson introduced layer-by-layer material synthesis technology into the body of a conventional desktop printer. nine0003

nine0003

Early

2000s

Early

2000s

3D Systems also released its first "home" 3D printer. After that, these devices began to actively penetrate into everyday life.

How does it work?

Technology analysis

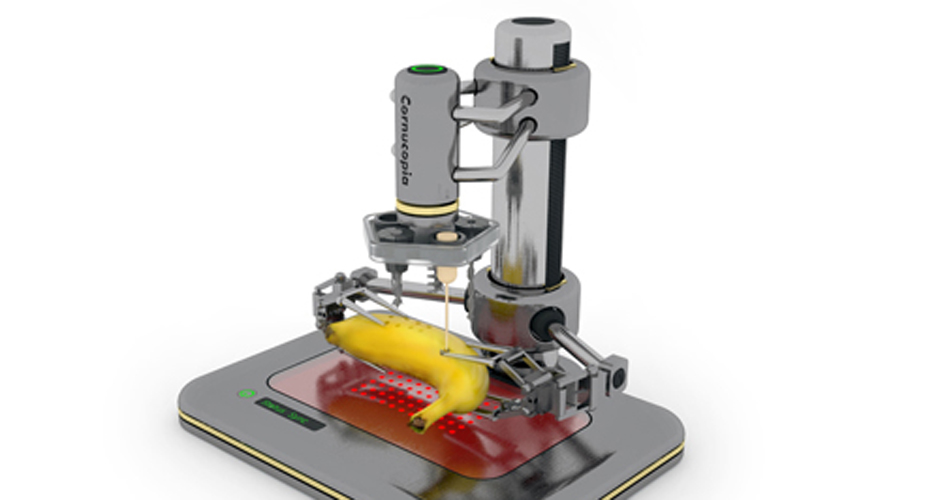

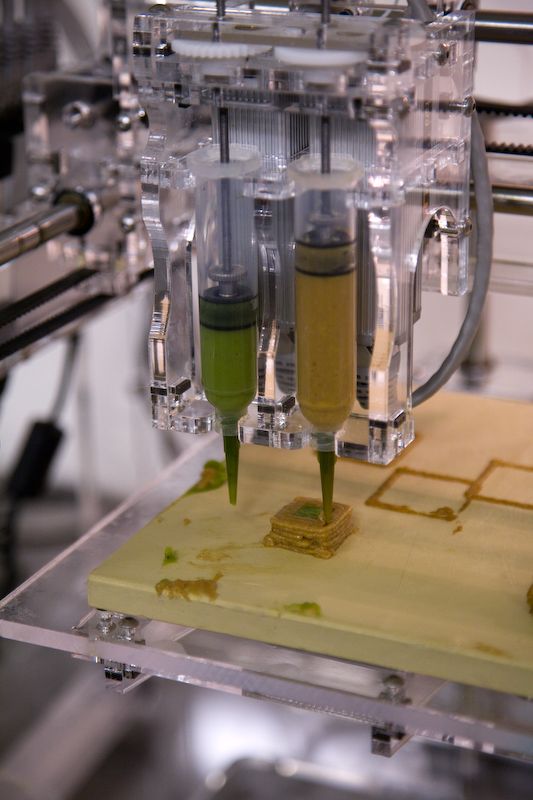

The first food from a 3D printer was obtained several years ago using the Fab@Home printer. The heart of the machine is a syringe that works on the same principle as inkjet printers. Layer by layer, he lays down a viscous liquid, forming an object of a given shape. nine0003

The university made the drawings of this printer publicly available, to the delight of many enthusiasts. People began their own experiments with epoxies and silicones. At the same time, gourmets appeared who began to put cheeses, glazes, etc. into the printer. It can use anything that is forced through the head of the syringe.

Instead of repeating already existing organic objects, it is much more important to learn how to create new products with individualized nutritional value. nine0003

nine0003

Let's say a person needs more calcium or omega-3 fatty acids in their diet, why not print out the appropriate foods for them. Van Bomel's team is addressing just such a problem, it is they who are developing food printing technology for people with impaired chewing and swallowing functions. Printed products can use cheaper protein sources. It is more convenient, and besides, the cost of such products will be less. But a significant obstacle is the slow speed of 3D printing from edible components, after each layer is applied, one or another time is required for it to solidify. nine0088

What are printers?

Great variety of food printers

- Pancakebot. Structurally, it is similar to any food 3D printer, but it only prints pancakes of any given shape and immediately fries them;

- Choc Creator 2.0 Plus, Chocola3D, etc. - specialized printers for printing chocolate;

The above examples were taken from the sales site, that is, these printers can already be bought, they have entered the general sales market. But there are also more complex devices that exist almost in a single copy. nine0088

But there are also more complex devices that exist almost in a single copy. nine0088

- Foodini by Natural Machines is the answer to the eternal question of healthy eating. Foodini users can cook with fresh ingredients, create a variety of pastas, and place them in reusable capsules, which are then printed in any 3D shape;

- Food printer for NASA from SMRC. Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to print a wider variety of foods; nine0003

Future prospects

What's in store for this relatively new but rapidly evolving technology? Will it develop in highly specialized areas or will it go to a wide market, or will it succeed everywhere?

3D food printing is not justified these days. But in space it can be a real salvation. Michel Terfansky of the University of Southern California explored this concept in his thesis project. He learned about the occasional annoyance of astronauts on the International Space Station with poor diets. With the help of 3D printers, friends and family could send recipes to Earth messengers. 3D printers will help save space and rid the ship of warehouses of meat and vegetables. Terfansky believes that this technology will make people happier. nine0003

With the help of 3D printers, friends and family could send recipes to Earth messengers. 3D printers will help save space and rid the ship of warehouses of meat and vegetables. Terfansky believes that this technology will make people happier. nine0003

Also, 3D printed food can be used to create foods with a specific nutritional value and texture for the elderly that are easy to chew and swallow.

Other uses include home cooking and personalized candy and sweets.

One way or another, 3D printing will one day, if not completely replace the product market, then at least displace a significant part of it. It will become more convenient, less expensive, more environmentally friendly. It will give more opportunities and more problems associated, for example, with device maintenance. Whether this is good or bad is your food for thought. nine0088

Text: Koryakina Anastasia, Krylova Lyubov, 2nd year student of the Faculty of Journalism, Lomonosov Moscow State University

Photo: site https://make-3d.