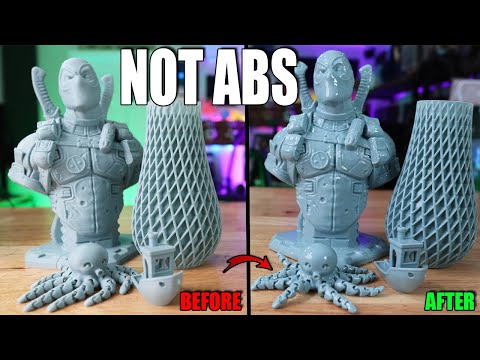

Gluing pla 3d prints

🔥 La guía visual definitiva para resolver problemas impresión 3D de Bitfab

Bitfab » Impresión 3D » 🔥 Guía visual para resolver problemas impresión 3D por Bitfab

¿Tienes problemas con tu impresora 3D? Has llegado al sitio adecuado.

En Bitfab hemos preparado la guía definitiva para resolver todos tus problemas de impresión 3D. Miles de horas de impresión 3D profesional a nuestras espaldas para ayudarte con los contratiempos que te surjan con tu impresora.

Y además no sólo te damos las claves para diagnosticar tus fallos de impresión sino también los mejores tips para arreglar tu impresora, calibrarla y evitar que vuelvan a aparecer. Imágenes, vídeos y nuestros mejores consejos en un mega artículo.

👇 Disfruta de la guía y usa el índice visual si quieres ir a la parte que te interese.

🤬 Los defectos y problemas más comunes de impresión 3D, en imágenes

Hemos reunido una colección de los problemas más comunes que surgen a la hora de usar nuestra impresora 3D. Son los mismos problemas que nos encontramos comúnmente en nuestro servicio de impresión 3D online, y por eso tenemos bastante experiencia tratándolos y solucionándolos.

Una impresora bien calibrada, un laminado correcto y un impresor con experiencia son claves para evitar estos problemas. Teniendo eso podrás solucionar cualquier problema de impresión.

Si te surge cualquiera de ellos sigue las instrucciones que te damos y si aún así no puedes solucionarlos tienes la caja de comentarios al final del artículo para comentarnos tus dudas.

Warping

La pieza se levanta de la cama

Delaminación

Grietas horizontales en la pieza

Desplazamientos de capas

Desplazamientos horizontales de la pieza

Bamboleo en el eje Z,

z-wobbleOndulaciones verticales en el eje Z

Hilillos,

stringingHilillos finos en la pieza

Sobrecalentamiento

Crestas hacia arriba en las esquinas de la pieza

Pie de elefante

Piezas más grandes en la primera capa

Ghosting

Ondulaciones horizontales en las esquinas de las piezas

❌ Warping, se despega la primera capa y se doblan las piezas

El warping es un problema cada vez menos común, ya que la inmensa mayoría de impresoras modernas cuentan con cama caliente. En cualquier caso, el warping se puede producir por los siguientes factores:

En cualquier caso, el warping se puede producir por los siguientes factores:

- Falta de adherencia a la cama: esto puede ocurrir por una altura incorrecta de la boquilla con respecto a la base o un mal nivelado, pero también falta de adherencia con la superficie de impresión.

- Contracción térmica de las capas superiores, que al “encoger” tiran de las capas inferiores. Si esto ocurre, puede hasta romperse la superficie de impresión si es de tipo BuildTak, ya que se arrancará la pegatina de la cama. Con el cristal también puede pasar. Esto ocurre en mayor medida con materiales como el ABS o el Nylon, y es muy difícil que pase imprimiendo PLA.

Dependiendo de nuestro problema podremos buscas una solución acorde:

Para la falta de adherencia hay varias soluciones. Si estamos usando una base de cristal, es muy recomendable utilizar algún adhesivo para aumentar la fijación de la pieza. Algunos adhesivos conocidos son la famosa Laca Nelly, o su versión más profesional 3Dlac. Si estamos usando ABS podemos aplicar una capa de la mezcla conocida como ABS slurry que podemos fabricar nosotros mismos disolviendo ABS en un recipiente con acetona.

Si estamos usando ABS podemos aplicar una capa de la mezcla conocida como ABS slurry que podemos fabricar nosotros mismos disolviendo ABS en un recipiente con acetona.

Si tu problema está relacionado con la contracción térmica, aumentar la adherencia no te ayudará en exceso ya que, como hemos dicho, el ABS al deformarse puede hasta romper nuestra base de impresión. Para solucionar este problema podemos simplemente tapar la impresora con lo que tengamos por casa. Una caja grande puede funcionar, así como un cerramiento más profesional hecho en un armario.

La idea en este caso es encerrar el calor que genera la cama, para que no haya mucha diferencia entre la temperatura a la que están las primeras capas y la temperatura de las capas superiores, más alejadas del calor de la cama.

Desde ya mismo nos disculpamos porque haya tantos nombres en inglés, pero gran parte de la documentación y del mundo profesional y aficionado de la impresión 3D habla en estos términos, por eso hemos puesto la denominación en inglés y la descripción de los problemas.

En cualquier caso, os dejamos un artículo que hicimos explicando este problema más en profundidad en nuestro artículo Cómo evitar el warping y el cracking en mis impresiones 3D.

❌ Cracking o delaminación

En la línea con el problema anterior está el cracking o delaminación. Hablamos de cracking cuando las capas de una pieza no están bien unidas, quedando estas separadas (de ahí el nombre delaminación). Este problema puede estar causado a su vez por dos causas diferentes:

- Mala adherencia entre las capas: las capas no se pegan bien entre sí.

- Contracción térmica: las capas se pegan bien entre sí, pero una diferencia de temperatura entre diferentes partes de la pieza hace que se deforme, pudiendo hacer que algunas capas se separen.

Si nuestro problema es la falta de adherencia, habitualmente se debe a una falta de temperatura. La mayoría de filamentos tienen un rango de temperatura en el cual pueden imprimirse.

Dentro de este rango, los valores más bajos nos darán una mejor apariencia estética, ya que la deposición será más “limpia”. Por el contrario los valores más altos nos darán una mejor adhesión de capas. Imprimir materiales como el ABS a menos temperatura de la apropiada, suele derivar en cracking cuando se intenta pegar dos capas sin aplicar el suficiente calor.

Por el contrario los valores más altos nos darán una mejor adhesión de capas. Imprimir materiales como el ABS a menos temperatura de la apropiada, suele derivar en cracking cuando se intenta pegar dos capas sin aplicar el suficiente calor.

Para comprobar si nuestra pieza sufre cracking por falta de adherencia entre las capas, podemos probar a subir la temperatura y/o reducir la velocidad del ventilador de capa, ya que un enfriamiento excesivo también puede afectar negativamente. Algunos materiales, como el ABS, serán siempre proclives a sufrir cracking y serán más difíciles de controlar, otros como el PLA son muy fáciles de imprimir sin cracking.

Por otro lado, si nuestro problema es la contracción térmica la solución es más complicada, ya que debemos conseguir crear un entorno más cálido en nuestro área de impresión. La solución óptima sería tapar nuestra impresora, como indicamos en el punto anterior. Esto puede resultar en algunos problemas, ya que una temperatura excesiva puede llevar a fallos en la electrónica: pérdida de pasos, artefactos en la impresión… también puede causar atascos, al no haber suficiente diferencia de temperatura entre la zona fría y la zona caliente del hotend.

En general, evitar corrientes de aire (y las consecuentes variaciones de temperatura) y tapar nuestra impresora ayudará, pero debemos tener precaución para evitar los problemas mencionados.

❌ Capas desplazadas, layer shift

El corrimiento de capas, o layer shifting es un problema que se manifiesta en forma de un desplazamiento en algún eje a determinada altura. Puede ocurrir en el eje X, el Y o incluso en ambas de manera simultánea. Las causas más comunes del layer shifting son:

- Exceso de temperatura en los motores, o los drivers: la electrónica en general no está pensada para operar de manera continuada a una temperatura muy alta.

- Falta de potencia en los motores, ocasionada habitualmente por un valor de voltaje muy bajo en los drivers.

- Fallo mecánico: puede ocurrir que tengamos algún diente de nuestra correa roto, o haya algún deshecho en los ejes que pueda causar un atasco en el movimiento de nuestra impresora.

A veces un componente mal apretado también puede ocasionar defectos de desplazamiento de capas al moverse el eje al completo libremente.

A veces un componente mal apretado también puede ocasionar defectos de desplazamiento de capas al moverse el eje al completo libremente.

Un consejo general sería el de poner disipadores, y a poder ser ventilación a los drivers de nuestra placa. Estos componentes básicamente se encargan de enviar toda la corriente necesaria a los motores, por lo que tienden a calentarse. De igual manera, si nuestra impresora opera en entornos muy cálidos sería adecuado añadir también algún disipador a los motores de los ejes X e Y. Si los drivers están muy calientes se suele oír un toc, toc, toc en los motores cuando los drivers se desconectan brevemente para que les de tiempo a enfriarse.

Adicionalmente, puedes comprobar si tu impresora tiene drivers con voltaje ajustable, y en caso afirmativo, puedes incrementar este voltaje ligeramente girando con cuidado el potenciómetro en cada driver. Ten cuidado al hacer esto, y hazlo siempre con la impresora apagada o usando un destornillador cerámico para evitar hacer algún cortocircuito con un destornillador metálico. Si subes demasiado la potencia de los motores corres el riesgo de caer en el problema del sobrecalentamiento de nuevo.

Si subes demasiado la potencia de los motores corres el riesgo de caer en el problema del sobrecalentamiento de nuevo.

Finalmente, comprueba que los ejes de tu impresora están libres de suciedad y obstrucciones. Comprueba también que las correas no estén demasiado tensas ni los rodamientos demasiado apretados (en caso de que los rodamientos se aprieten con bridas o tornillos). Unos ejes que no se mueven bien, correas sobreapretadas… ocasionan que los motores tengan que trabajar más y puedan perder pasos.

❌ Bamboleo en el eje Z, z-wobble

Este problema puede ser difícil de identificar, ya que a menudo no es fácil distinguirlo de una simple inconsciencia en la extrusión. Para identificarlo debemos mirar si esta inconsistencia se repite de manera periódica. Si la inconsistencia parece aleatoria, o ruido en general, probablemente tu problema no sea z-wobble sino un problema de extrusión. Por el contrario, si parece haber un patrón que se repite de manera periódica, como olas en la superficie, es muy posible que tengas un problema con tu eje Z.

Este problema se debe en la mayoría de casos a fallos estructurales en la construcción de la máquina, y es complicado de solucionar sin hacer modificaciones importantes en el chasis de nuestra máquina. Antes que nada comprueba que todas las piezas estén bien montadas, manteniendo la perpendicularidad y asegurándonos de que no hay tornillos flojos.

Prueba a ajustar bien todos los tornillos de los acopladores que unen los motores del eje z a los husillos. También comprueba que no exista “juego” entre el husillo y la tuerca trapezoidal. Es complicado dar una solución correcta, ya que el eje necesita cierta libertad para moverse para compensar pequeños errores en el chasis, como esquinas que no son perfectamente perpendiculares.

Una buena solución que no es demasiado costosa es sustituir el conjunto motor-acoplador-husillo por un motor con husillo incorporado. También podemos añadir refuerzos a nuestra impresora para que el marco de esta no tenga juego en su parte más alta.

❌ Hilillos en mis piezas, stringing

El stringing es uno de los problemas más comunes en las piezas de los novatos en el mundo de la impresión 3D, así que si tus piezas tienen muchos hilillos no te preocupes, es totalmente normal y bastante fácil de solucionar.

Los hilillos aparecen cuando, al moverse el hotend entre dos piezas de nuestra impresión, gotea una pequeña cantidad de plástico, que se adhiere a ambas partes dejando un pequeño hilo entre medias.

Este problema puede estar causado por el uso de un fusor de mala calidad, pero habitualmente las máquinas suelen tener un fusor de calidad suficiente, por lo que el problema casi siempre proviene de un mal laminado en el slicer.

Los parámetros más importantes que debes revisar en tu slicer para minimizar el stringing son los siguientes:

- Temperatura

- Distancia de retracción

- Velocidad de retracción

La temperatura es un factor vital y probablemente uno de los 5 ajustes más importantes en tu perfil. Si tienes mucho stringing casi seguro que estás fundiendo a una temperatura demasiado alta. Recuerda que todos los materiales tienen un rango de temperaturas en los que pueden imprimirse, así que prueba a bajar la temperatura y a acercarla el límite inferior recomendado por el fabricante. Si ya estás usando una temperatura muy baja y sigues teniendo stringing, verifica los siguientes puntos.

Si tienes mucho stringing casi seguro que estás fundiendo a una temperatura demasiado alta. Recuerda que todos los materiales tienen un rango de temperaturas en los que pueden imprimirse, así que prueba a bajar la temperatura y a acercarla el límite inferior recomendado por el fabricante. Si ya estás usando una temperatura muy baja y sigues teniendo stringing, verifica los siguientes puntos.

Si bien no es posible “succionar” plástico de la boquilla, ya que no se puede crear presión negativa, sí que es posible minimizar la presión en la boquilla al sacar el filamento de la zona caliente de nuestro fusor. La distancia de retracción depende mucho de nuestra impresora, ya que hay que tener en cuenta tanto el fusor como el extrusor y el tipo de extrusión (directa o bowden). La mayoría de impresoras bowden se comportan bien con un valor de retracciones de entre 3 mm y 6mm, y las de extrusión directa entre 0,5 mm y 2mm.

La velocidad de retracción es otro factor importante, ya que a mayor velocidad menor stringing. Esta velocidad dependerá del motor de nuestro extrusor y también del tipo de extrusión (1:1 vs 3:1 como el extrusor Titan). Generalmente valores de entre 40 mm/s y 60 mm/s suelen funcionar, pero ante la duda consulta en algún foro o grupo dedicado a tu impresora concreta.

Esta velocidad dependerá del motor de nuestro extrusor y también del tipo de extrusión (1:1 vs 3:1 como el extrusor Titan). Generalmente valores de entre 40 mm/s y 60 mm/s suelen funcionar, pero ante la duda consulta en algún foro o grupo dedicado a tu impresora concreta.

Adicionalmente, casi todos los slicers o laminadores disponen de diferentes ajustes más avanzados que pueden ayudar a reducir el stringing, pero estos sólo serán de importancia si los tres anteriores están bien ajustados. Es un tema muy amplio y podríamos hacer una guía exclusiva sobre este problema, así que si quieres verla ¡Déjanos un comentario!

❌ Sobrecalentamiento de las piezas, overheating, curling

Uno de los problemas más fáciles de diagnosticar, es el exceso de temperatura.

Como podemos ver en la imagen, fundir nuestro plástico a una temperatura excesiva provocará que las piezas se vean deformadas, con el centro de la capa hundida. Esto se debe a que al fundirse a una temperatura demasiado alta, el material no tiene tiempo de enfriarse, y es por esto que las capas pueden quedar caídas o hundidas.

Estas deformaciones serán mucho más acusadas en áreas pequeñas, como pequeños picos de nuestra pieza, donde en vez de quedar una figura limpia, quedará un churro deformado.

La solución a este problema es simple, bajar la temperatura. También debemos jugar con los valores del ventilador de capa, ya que una temperatura alta puede favorecer una extrusión más fluida y podemos compensar esta temperatura con una buena refrigeración. De esta manera se enfriará rápidamente el material y podremos obtener resultados óptimos.

❌ El pie de elefante

El pie de elefante es un defecto consistente en la expansión en el plano horizontal de las primeras capas de nuestra pieza. Puede ocurrir por dos cosas o, normalmente, una combinación de ambas: el nozzle está demasiado cerca de la cama o la temperatura de la cama es demasiado elevada.

Si el nozzle está demasiado pegado a la cama es obvio que las primeras capas van a quedar más aplastadas y, por lo tanto, se van a expandir en el plano XY. Para solventar este problema deberemos nivelar correctamente nuestra primera capa, tal y como se indica en un apartado anterior de este artículo.

Para solventar este problema deberemos nivelar correctamente nuestra primera capa, tal y como se indica en un apartado anterior de este artículo.

Una temperatura excesiva de la cama (digamos, por ejemplo 90 o 100 grados para PLA) puede hacer que el plástico recién depositado se expanda y deforme, causando este efecto tan característico

❌ Vibraciones en mis piezas, ghosting, ringing

El mejor artículo sobre este tema que existe en internet es el post de 3D Campy de 3DSpana sobre ghosting, porqué se dedicó a probar diferentes combinaciones y componentes, haciendo fotos a los resultados, para que veas cómo se nota cuando disminuye el peso de los ejes sobre el ghosting. Si lo prefieres en vídeo también tienes el resumen aquí:

😍 Las claves para imprimir correctamente con tu impresora

Ya has visto la colección de problemas que hemos recopilado. Ahora tienes que saber cómo SÍ que se hacen las cosas.

Conocer tu impresora y tu laminador es la clave para imprimir sin errores y defectos, aquí tienes algunos consejos para evitar problemas y para ayudarte a diagnosticar y arreglar los que te surjan:

✅ Las velocidades de impresión

Uno de los errores más comunes que encontramos a los principiantes es querer imprimir demasiado rápido en sus primeras piezas.

La velocidad de impresión es uno de los parámetros de impresión más importantes a la hora de obtener la mejor calidad de impresión y un exceso de velocidad afecta muy negativamente a la pieza por muchas razones: vibraciones, problemas de extrusión, sobrecalentamiento, pérdida de pasos…

Una de las primeras cosas que tienes que hacer cuando encuentras un problema es reducir la velocidad de impresión para ver si se soluciona. Nosotros solemos imprimir casi todas las piezas entre 40 y 60mm/s, no hace falta más para la mayoría de los casos. En un servicio de impresión lo más importante es la fiabilidad y cuándo buscas fiabilidad lo mejor es imprimir a velocidades razonables para no tener que tirar las piezas a la basura.

No hace falta imprimir a 100mm/s tus piezas, especialmente las primeras. Sí, todos conocemos a alguien que lo hace y lo consigue, pero no es lo mejor para asegurarse de que salgan bien.

✅ Ajuste y nivelado de la cama

Aprender a dejar la cama correctamente nivelada y el extrusor a la altura correcta es uno de los primeros pasos que damos con una impresora 3D nueva.

Aquí tienes cómo se ve una cama correctamente ajustada, la altura de la primera capa tiene que ser correcta en toda la superficie de la misma.

Primera capa muy pegada

Si tu primera capa está muy pegada a la superficie de impresión podrás ocasionar atascos, ralladuras en la cama, piezas con las dimensiones incorrectas, pie de elefante…

Primera capa correcta

Cuando la primera capa es correcta los hilos depositados por el extrusor se tocan entre ellos y no están demasiado aplastados contra la cama.

Primera capa muy separada

Una primera capa muy separada se puede notar por los hilos separados.

Las piezas que se imprimen así se suelen despegar de la cama o sufrir warping.

¿Y cómo se nivela correctamente una cama caliente? Nuestra técnica preferida es la del papel en las esquinas. No es necesario tener una impresora con autonivelado, lo mejor es tener una impresora fiable y bien calibrada para imprimir con calidad.

✅ Como prevenir y arreglar atascos del extrusor

Los atascos de la extrusión son la causa número 1 de fallos en una granja como la nuestra. Puedes tener dominada tu impresora pero los atascos siempre van a estar ahí, por eso es fundamental entenderlos y ser capaces de prevenirlos y arreglarlos.

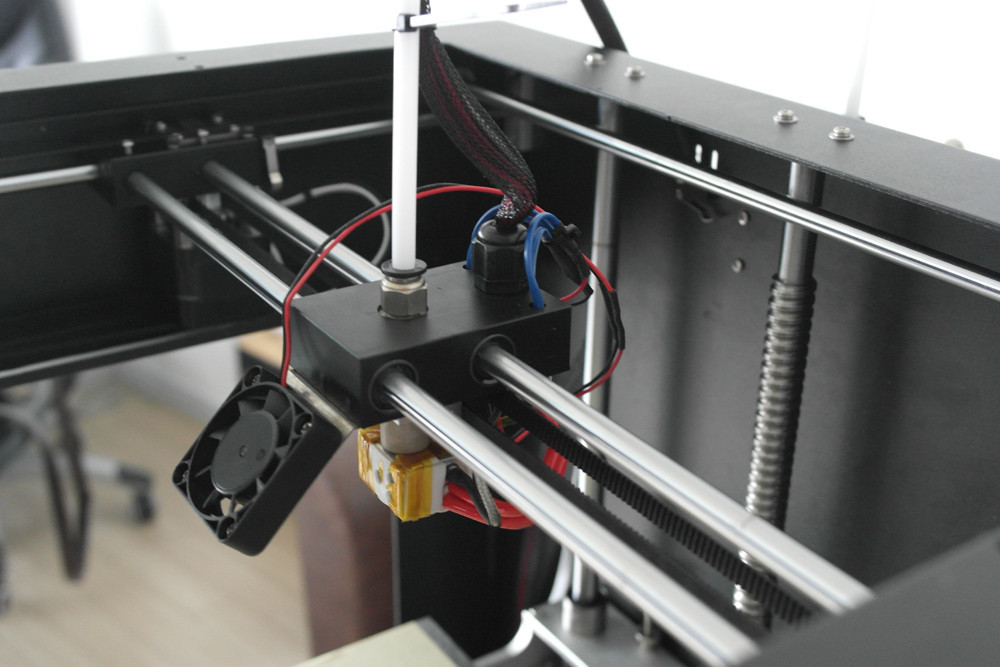

Si no entiendes bien aún cómo funciona la extrusión de una impresora 3D y cuáles son los términos que se usan para hablar de ellos puedes consultar primero nuestra guía sobre extrusores 3D.

Las causas de los atascos

Los atascos surgen por muchas causas diferentes, a veces en conjunción unas con otras. Creo que la mejor manera de solucionarlos es entender primero todas esas causas y luego intentar una serie de técnicas que ayudan a arreglarlos.

- Impurezas en la punta y el canal de impresión. Impurezas que se depositan en el canal de impresión o en la punta de la boquilla y dificultan o atascan completamente el flujo de filamento.

- PTFE/teflón degradado. Los fusores con teflón en la zona caliente requieren un mantenimiento del teflón, que cuando se degrada atasca el paso del filamento.

- Problemas en el extrusor. Tal vez tu extrusor no esté funcionando correctamente:

- Demasiada tensión o demasiado poca tensión en el muelle

- Poco voltaje en el driver que no da fuerza suficiente al motor

- Rueda de empuje sucia, con los dientes cubiertos de restos de filamento

- Alguna pieza suelta o rota

- Rascado del filamento.

Esto es muy muy importante comprenderlo. Cuando nos aparece el filamento rascado, mordido por la rueda del extrusor, no siempre es la causa del atasco. Todos los atascos de impresión, sea por la causa que sean, acaban con rascado en el filamento. Y sólo los atascos que se deben a la tensión del muelle y a las retracciones excesivas la causa raíz del atasco es el propio rascado.

Esto es muy muy importante comprenderlo. Cuando nos aparece el filamento rascado, mordido por la rueda del extrusor, no siempre es la causa del atasco. Todos los atascos de impresión, sea por la causa que sean, acaban con rascado en el filamento. Y sólo los atascos que se deben a la tensión del muelle y a las retracciones excesivas la causa raíz del atasco es el propio rascado. - Punta rascando la base. Si la primera capa está demasiado baja puede interrumpir el flujo del plástico fundido y producir rápidamente un atasco en el sistema de extrusión.

- Cuidado con las retracciones. Una pieza con muchas retracciones muy rápidas puede acabar rascando el filamento. Y las retracciones largas y lentas pueden recalentar la zona fría del extrusor y acabar causando atascos también. En general las retracciones no serán la causa de tus atascos, pero siempre hay que tener un ojo puesto en ellas.

- Mala refrigeración. La refrigeración es una variable fundamental en los hotend all-metal.

Si tu extrusor es 100% metálico como el E3D V6 tienes que tener mucho cuidado con esto y con las retracciones excesivas.

Si tu extrusor es 100% metálico como el E3D V6 tienes que tener mucho cuidado con esto y con las retracciones excesivas.

Desatascar la boquilla con agujas de acupuntura

La técnica de pasar una aguja de acupuntura por el cabezal de la impresora es la más útil si la causa real de tu atasco es una impureza. Las boquillas por sí mismas duran muchos cientos o incluso miles de horas de uso, así que casi nunca las vas a tener que cambiar.

Lo más probable es que se haya depositado una partícula en la boquilla y debes ser capaz de sacarla de ahí con la aguja. Nosotros calentamos el cabezal y metemos la aguja en caliente, para después sacar el filamento con las partículas que pudieran estar causando el atasco embebidas en el filamento fundido.

Repetir este proceso hasta que el plástico vuelva a salir con facilidad por la boquilla.

Tirones en frío y en caliente

Los tirones llevan un poco más de tiempo de hacer que pasar la aguja de acupuntura, pero limpian mejor las impurezas y además se llevan la suciedad no sólo de la punta, sino de todo el interior del hotend.

Son más fáciles de explicar con un vídeo como el siguiente, pero el mejor que he encontrado está en inglés:

Cambio de teflón

En los hotends con liner teflón es necesario cambiar esta pieza, en general, cada varios cientos de horas. El liner de teflón o PTFE es una pieza que va en la zona de caliente de tu fusor para guiar el filamento en los últimos centímetros de recorrido, y que se degrada por la temperatura que alcanza. Cambiarlo es un trabajo que vas a tener que aprender a hacer para mantener correctamente tu impresora.

Antes de que se degrade por completo el tubo vas a notar como tu impresora cada vez le cuesta más imprimir, el hilo de filamento que sale es más fino y le puede costar depositar material en las piezas que imprimas más rápido.

En cada impresora el cambio de teflón es diferente, pero aquí tienes el ejemplo de la Hephestos 2 de BQ para que lo entiendas mejor.

Ajustar los parámetros de impresión

Hay atascos que se pueden producir porque nuestro laminado no está bien adaptado al tipo de pieza y de impresora que vamos a usar.

Para permitir que tu impresora extruya con más facilidad puedes probar a:

- Imprimir más despacio

- Imprimir a más temperatura

- Imprimir capas más finas

- Reducir el flow rate si lo tienes a más del 100%

Todos esos son trucos que reducen los requerimientos sobre el extrusor y el fusor porque requieren menor flujo a través del hotend y calientan el plástico para que sea más fluido.

Las retraciones también pueden influir en los problemas de extrusión:

- Demasiadas retracciones o demasiado rápidas pueden acabar produciendo que se rasque el filamento en el extrusor.

- Retracciones demasiado largas o lentas pueden producir problemas de refrigeración en tu fusor (especialmente si es all metal) o acabar atascando el plástico en la zona fría del fusor.

Si no sabes cómo arreglarlo, desmonta el extrusor y el hotend

La mejor manera de atacar un problema mecánico que no sabes resolver es proceder a desmontar lo que quieres arreglar. Desmontar un hotend y un extrusor es bastante sencillo y te permitirá ver por dentro lo que está pasando y reflexionar sobre el problema.

Cuando desmontes tu extrusor podrás darte cuenta de que hay alguna pieza rota, suciedad en alguna parte, algún tornillo suelto…

Si desmontas el hotend podrás ver el estado del teflón, la tensión de las roscas del hotend y si hay depositados residuos de impresión en el canal del filamento.

En cualquiera de los dos casos aprovecha para limpiar las piezas para prevenir errores en el futuro.

👋 Hasta aquí la guía para solucionar problemas de impresión 3D de Bitfab

Muchas gracias por haber llegado hasta aquí.

Si tienes cualquier duda o un problema diferente sólo tienes que ponerlo en los comentarios y te ayudaremos a solucionarlo, o quizás hasta lo añadamos al resto de problemas 😁

👋 ¡Un saludo y gracias de nuevo!

The Best Glue for PLA, PETG & ABS – Clever Creations

Gluing 3D printed parts together is something you will most likely have to do when you are starting to get into 3D printing. Maybe your printer’s build plate wasn’t large enough to print a model in one piece, or your print failed partway through and you are trying to fix it.

Whatever the reason for needing to glue 3D printed parts, there are a lot of things to consider before you get started. For example, choosing the right glue for your filament and project type. Gluing PLA, ABS, and PETG filament all prefer different adhesives.

If you aren’t sure which glues work on which materials, when to use one type of glue over another, and what brands are the best choice for each type of glue, keep reading! We’ve covered all of that and more in the sections below.

What Makes a Good Adhesive for Gluing 3D Prints?

While there are dozens of adhesives on the market, very few are suitable for gluing 3D prints together. 3D printing is a versatile technology that uses different types of materials to create prints that are used for a variety of applications. Most adhesives aren’t formulated to work with some of these materials and lack the properties needed for the finished print’s intended purpose.

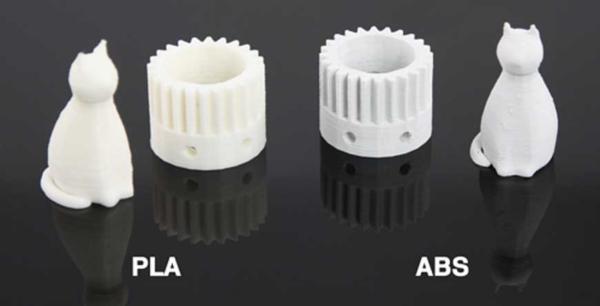

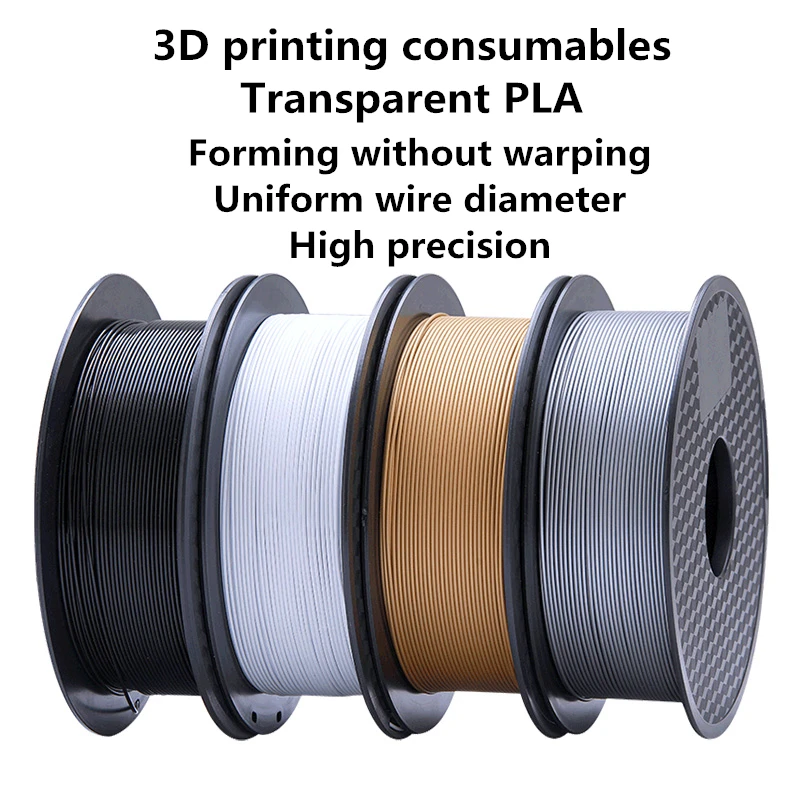

First and foremost, any adhesive used for gluing 3D printed parts together should be formulated to work with the type of plastic the 3D print is made from. Commonly used 3D printing filaments are PLA, ABS, PETG, and TPU. Some adhesives contain chemicals that react poorly or do not bond well with certain types of plastic.

A good adhesive for 3D prints will form a strong bond between the parts, leave as small of a seam between the two parts as possible, dry quickly, and not produce a lot of heat while curing.

What is the Best Glue for PLA?

Super Glue (Cyanoacrylate)

The best glue for PLA filament is standard super glue or cyanoacrylate glue. It’s widely available, forms a strong bond between printed parts within seconds, and dries clear.

It’s widely available, forms a strong bond between printed parts within seconds, and dries clear.

Image: Proto3000 via Youtube

Cyanoacrylate superglue is one of the best glues for PLACapable of bonding surfaces with very thin layers of adhesive, super glue lets you create flush seams that are easy to hide. It also doesn’t produce any heat while bonding, so there is no worry about it warping low-temperature filaments like PLA.

One of the most common cyanoacrylate glue brands is Gorilla Glue, which is known for being one of the best glue products in its category. However, most super glue brands should suit your purposes just fine in this case.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,535 Reviews

Check Price3D Gloop

An adhesive specifically made for 3D printing, 3D Gloop is a versatile glue that can be used in several ways. 3D Gloop comes with a built-in brush in its cap to easily apply it to 3D printed parts. It creates an ultra-strong bond between parts that mostly cures within an hour (and fully cures in six hours).

While this brand offers separate formulas for PLA and ABS, you can use either on both materials. This allows you to bond different materials together with little to no visible difference in the bond. However, when bonding the same materials together, you should try to use the glue formula for that type of material for the best results.

You can also brush 3D Gloop onto glass and mirrored print beds to help with print adhesion and eliminate warping. They don’t recommend using it on coated or PEI beds since it can permanently bond to the surface.

One consideration that should be made with 3D Gloop is that it needs to be used carefully. It produces fumes when uncured (and on the print bed) that should not be breathed in, so use in a well-ventilated area and/or with a respirator is ideal.

3D Gloop can also be an irritant, so you should wear gloves and safety goggles when working with it and try to avoid getting it on your skin. Using it requires similar precautions as when working with 3D printing resin and dealing with 3D printer fumes, so you might already have some of the equipment you need available.

Urethane Glues

With similar bond strength to superglue but with added flexibility, urethane glue is a great option for gluing PLA 3D printed parts together. They take several days (sometimes up to a week) to fully cure, however, so they are not a great option for projects that need to be finished quickly.

Urethane glues are popular in the construction industry and are made for both indoor and outdoor use. This makes them more resilient than other glues to things like moisture, freezing, UV light, and so on. If your 3D prints will spend time out in the elements, urethane glue is a good choice for bonding any seams.

They also produce some heat during their curing process. While it doesn’t reach the temperature needed to warp PLA, it may still affect small or thin pieces. Despite the curing process, urethane glues form a very strong bond between glued PLA plastic and are a favorite of many 3D printing enthusiasts.

Gorilla Original Gorilla Glue, Waterproof Polyurethane Glue, 8. ..

..

Hot Glue Gun

If you’re in a pinch and need to glue PLA parts together, using a hot glue gun will technically do the trick. Hot glue doesn’t have the same bond strength as other adhesives mentioned so far in this article, so it shouldn’t be used on anything that is going to have a lot of mechanical stress on it.

Hot glue is also quite thick and stringy, so it is hard to apply an even, thin layer. It is equally difficult to get a close seam with it, and you can expect your joins to be messy. On the other hand, it dries incredibly fast, so you don’t need to wait around for long cure times.

Recommended:

The Essential Guide to Hot Glue

The interesting thing about using a hot glue gun is that you can also melt PLA filament in it and use it as a rudimentary 3D pen. If you 3D print PLA cylinders in the diameter your hot glue gun uses, you can feed them through your gun like a regular glue stick for good results when gluing PLA parts together!

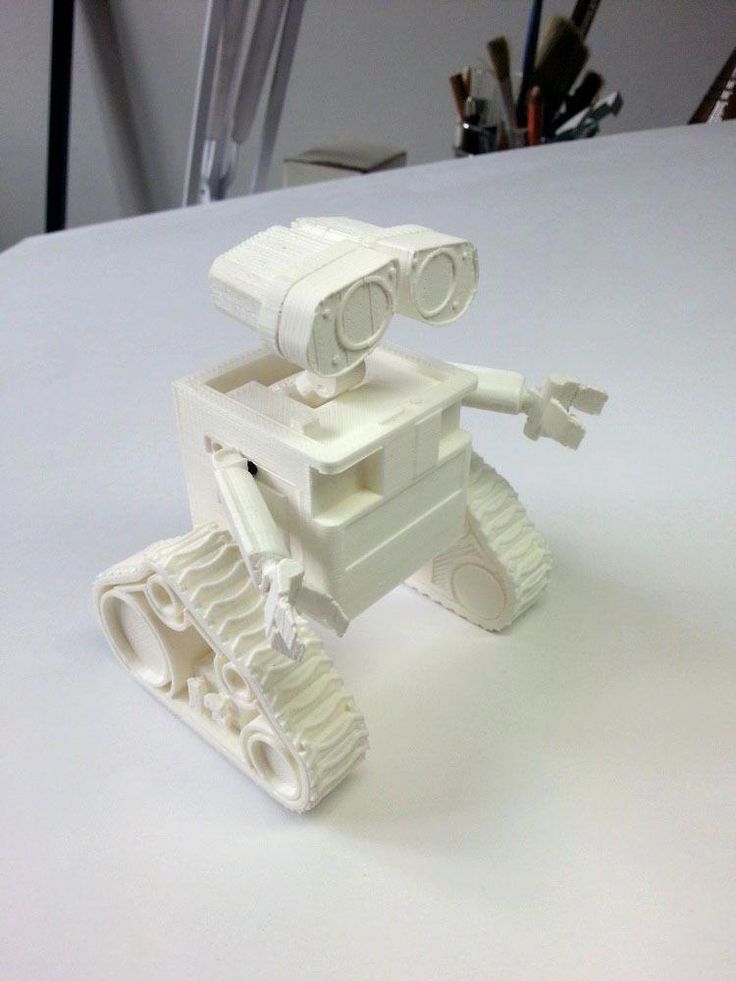

Image: Brodie via MyMiniFactory

3D printing a PLA glue stick let’s you glue with PLA!This will produce better results than traditional hot glue sticks, but the process can clog up your glue gun (especially cheaper ones) so don’t use it this way if you are concerned about switching back to plain glue after.

Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks

Check PriceEpoxy Resin

Epoxy resin is another great PLA glue that can be used to join PLA plastic pieces. Usually sold as a two-part kit (the resin and a hardener), the components need to be mixed to start the curing process. How long they take to cure depends on the brand and can vary from minutes to days.

The Bob Smith Industries Quik-Cure Epoxy is a good choice for gluing PLA plastic since it starts to cure in five minutes, is mostly cured in 15 minutes, and reaches full cure within an hour. It is designed to be slightly flexible when cured, so like the urethane glues we looked at earlier, it is a good option for parts that need vibration dampening or impact resistance.

The bond strength on the epoxy resin is excellent, and it allows you to make very thin invisible seams. Most emit some heat during the curing process, so it is important to ensure it won’t reach the temperatures needed to melt your prints.

Bob Smith Industries BSI-201 Quik-Cure Epoxy (4.5 oz. Combined),Clear

Check Price3D Pen

A more sophisticated version of the process we outlined in the hot glue gun section, a 3D pen is a handheld device that melts and extrudes filaments. 3D pens can be used to pipe on melted PLA material and weld two parts together.

One big advantage to this method is that you can use the same filament as the prints, making the seam less noticeable. In terms of adhesion strength, however, a 3D pen is not the best glue for PLA.

The bonds created with this method will most likely hold under most light applications, but the strength won’t be as good as other methods outlined on the list. This technique should not be used for joining parts that will undergo mechanical stress or impacts.

While you can find several different 3D pens currently on the market, the 3Doodler Create+ is our favorite. It works with both PLA and ABS, so you have a lot of versatility in what you can use your pen for. It also has a dual extruder motor to push the filament through on both sides for more even feeding.

It also has a dual extruder motor to push the filament through on both sides for more even feeding.

3Doodler Create+ 3D Printing Pen for Teens, Adults & Creators! -...

3,522 Reviews

Check PriceSoldering Iron

Image: ubcengphysprojectlab via Youtube

PLA welding with a soldering iron does not provide a lot of strengthAs a last resort, you can use a piece of PLA filament and a soldering iron to weld two PLA prints together. Using the tip of the soldering iron on the piece of PLA, you slowly melt the material along the line where the two parts meet. This process works better on something with a groove or curve to hold more PLA material, so this process is especially bad for adding two flat pieces together.

The most common use for PLA welding is trying to fix failed prints. Cracks, holes, and other issues can be somewhat resolved with PLA welding, so if you need to adhere split layers, this process is worth knowing.

However, for joining two separate 3D printed pieces, you are better off using one of the other solutions on this list. For this, a soldering iron is not optimal.

For this, a soldering iron is not optimal.

SOLDER STATION,40W,120V,W/ST3 TIP

Check PriceHow to Glue PLA 3D Printed Parts

- Sand down any rough or uneven edges with sandpaper until the edges of the two pieces are flat.

- Make sure both surfaces are clean and free of debris. If you need to wipe them with a wet cloth or wash them with soap and water, make sure to dry them thoroughly before gluing.

- Apply glue near the center of the printed parts. Don’t apply it too close to the edges to avoid it getting on the outside of the print.

- Spread the glue with a toothpick, the nozzle of the glue bottle, or some other small applicator until the part is evenly coated.

- Carefully press the parts together, making sure they are properly lined up. Hold them together with your hands or a clamp until a strong bond forms.

What is the Best Glue for ABS?

Acetone

The best way to glue ABS prints together is with acetone. ABS is acetone-soluble, meaning it breaks down when it comes into contact with it. Spreading a small amount of acetone on both surfaces being glued will break down the outer layers of ABS. When these layers are pressed together, the edges will reform as a single piece. This is called solvent welding.

ABS is acetone-soluble, meaning it breaks down when it comes into contact with it. Spreading a small amount of acetone on both surfaces being glued will break down the outer layers of ABS. When these layers are pressed together, the edges will reform as a single piece. This is called solvent welding.

Not only is the bond between the two printed parts very strong with this method, but it also eliminates the seam where the two parts meet. If done properly, they will look and act like they were printed as a single part. This is ideal if you want to 3D print cosplay armor or make a 3D printed helmet.

However, using too much acetone on the edges can damage them and leave an ugly or unstable join. It is therefore important to have some practice before potentially wasting your best ABS filament.

Acetone also poses some risks while using. It has strong fumes, so you should keep your workspace well ventilated. It is also highly flammable, so take care around open flames and high temperatures.

While acetone works well with ABS, it can’t be used with most other plastics the same way. PLA isn’t acetone soluble like ABS, so you can’t use it to glue PLA prints together.

Recommended:

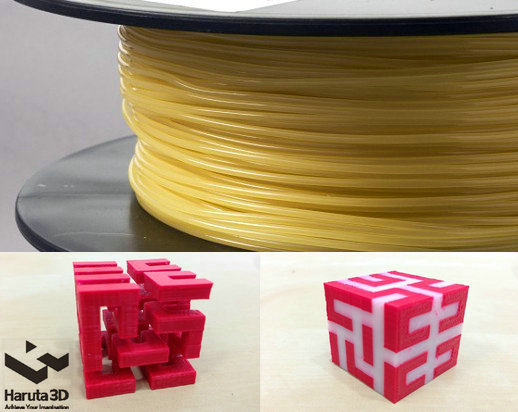

PLA vs ABS: Which Filament is Better?

ABS Plumber’s Cement

ABS Plumber’s Cement is a thick paste-like adhesive that works extremely well with ABS. Since it is solvent-based glue, it works like acetone to form a solvent weld in the ABS. This creates a very strong bond between the parts, but it won’t be as clean as acetone welding since the putty is colored.

While it is best used with ABS, a plumber’s cement can also work to glue PLA parts together. Since you can find it in most hardware and general stores, it’s an easy solution if you are in a pinch. However, it doesn’t work well with PETG plastic.

Oatey 30889 Medium Bodied Solvent Cement, 8 Oz, Can, Liquid, Black

Check PriceABS Juice / Glue / Slurry

Easy to make yourself from ABS scraps (supports, failed 3D prints, etc. ), ABS juice, glue, and slurry are the byproducts of ABS dissolving in acetone. All three of these products are great for forming bonds between two printed parts.

), ABS juice, glue, and slurry are the byproducts of ABS dissolving in acetone. All three of these products are great for forming bonds between two printed parts.

ABS juice is a thin milky substance that is brushed onto build plates for better print adhesions. ABS glue is a bit thicker and is ideal for joining parts together. The ABS slurry is the thickest in consistency and is used to fill in gaps, cracks, and holes in 3D prints.

You can make ABS juice, glue, or slurry by adding scrap ABS to a container of acetone and letting it dissolve (eventually the acetone used for ABS smoothing turns into a slurry as well). The more scrap you add, the thicker the resulting adhesive becomes.

Since these glues are made from acetone and ABS plastic, they are solvent-based. They will work well on ABS and similar plastics using solvent welding, but they aren’t the best glue for PLA and PETG.

Other Glues

The other adhesives listed above for PLA will also work with ABS. Superglue, urethane glue, and epoxy resin all work just as well with ABS as they do PLA. The 3D Gloop brand even has a formula specifically for ABS.

Superglue, urethane glue, and epoxy resin all work just as well with ABS as they do PLA. The 3D Gloop brand even has a formula specifically for ABS.

While all of these products technically can be used for ABS, solvent welding with acetone will almost always produce the best results.

What is the Best Glue for PETG?

PETG is one of the harder plastics to post-process. Paints, glues, and other materials don’t bond well with even the best PETG filament, but some work better than others. Superglue, Gorilla glue, silicone glue, and epoxy resin all work relatively well with PETG. 3D Gloop’s PETG formula is also worth trying, as it is one of the few products specifically formulated for the material.

Frequently Asked Questions

Can you superglue PLA?

Superglue is the best option for gluing PLA together. It bonds quickly and forms a strong, lasting bond. However, it won’t work as well with other 3D printing filament types like ABS. For those plastics, solvent welding tends to be a better option.

Does Gorilla Glue Gel work on PLA?

Yes. Gorilla Glue Gel is a water-based contact adhesive that is specifically designed to work on both porous and non-porous materials. It forms an instant, permanent bond on contact and can be used on a wide range of materials, including wood, metal, plastic, rubber, glass, and more.

PLA (polylactic acid) is a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane. It is often used for 3D printing because it has a low melting point and does not release any harmful fumes when melted. Gorilla Glue Gel can be used to adhere PLA prints together or to attach them to a surface.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,535 Reviews

Check PriceAre there special glues for 3D printing?

Yes, there are some adhesives specifically designed for gluing 3D prints. The 3D Gloop products we mentioned above are some of the most popular options, but your glue doesn’t necessarily need to be formulated for 3D printing. Many standard glues and adhesives work just as well (if not better) on printed plastics.

Many standard glues and adhesives work just as well (if not better) on printed plastics.

What glues work with all filaments?

Basic adhesives like superglue, Gorilla glue, epoxy resin, urethane glue, silicone glue, etc. all work with most of the common filament types. While some will work better with certain filaments than others, you can use any of them for finishing your 3D printing projects if they are all you have available.

The most effective way to use them is to focus on the best in each category rather than to try to find a one-size-fits-all product. The best glue for PLA and PETG is super glue, while solvent welding is the best glue for ABS.

How do you bond 3D printed parts together?

The most common way to bond 3D printed parts together is with adhesives. Many different types of adhesives can be used, but the most effective ones usually contain cyanoacrylate (CA) molecules. These adhesives are fast-acting and can be used to bond parts together in a matter of seconds.

Another popular way to bond 3D printed parts together is through the use of screws and bolts. This approach is often used when assembling large or complex structures. By using screws and bolts, it’s possible to create assemblies that are much stronger than those that can be created with adhesive bonding alone.

Will plastic glue work on PLA?

It depends on the type of plastic glue you’re using. Some glues will work better than others on PLA, so it’s worth doing some research to find the right one for your needs. If you’re looking for a strong bond, we recommend using an epoxy or cyanoacrylate adhesive.

Final Thoughts

When you need to bond 3D printed parts together, there are several options to choose from. While your standard super glue and epoxies work well for most types of 3D printing filament, things like homemade ABS glues, PLA welding, and friction welding are just a few of the other ways you can join 3D prints.

Whether you need to piece together a large model, fix a failed print, or join two different materials together, understanding how each glue works with the different plastics will make sure your bonded 3D prints are as strong as possible. The best glue for PLA is Cyanoacrylate super glue.

The best glue for PLA is Cyanoacrylate super glue.

Do you still have questions about how to glue PLA or other filaments? Let us know in the comments!

(There is a solution) What adhesives for PLA?

PLA is good, and bonding has been a topic on some of our most favorite maker channels. For example, Stefan from the CNC kitchen (this video) and Joel 3DPrinting Nerd (this video). Here is some information from them along with my own experience. By the way, most of these adhesives are not exactly specific to PLA and work for many other materials as well. However, be careful with PLA containing infilt, as this can seriously change its properties. nine0003

Step 0: Safety First!

Some of these methods work with chemicals that can irritate the skin (resin, cyanoacrylate), have irritating fumes (acetone), or are flammable (acetone). Others (cyanoacrylate) are not heat resistant and break down into their components when exposed to heat.

Use proper protection when handling adhesive! If necessary, use eye and respiratory protection, as well as gloves.

Read the manual for the products you work with! nine0009

Read the manual for the products you work with! nine0009 Preparation

For most adhesives, it is desirable to prepare the surface: sand it to increase surface area, remove grease from fingerprints, etc. Follow instructions!

Adhesives

- Cyanoacrylate - yes, one-size-fits-all is also the solution for PLA: Superglue. However, be careful what type you get! Some are clearly better than others, and the use of an accelerator can change the properties of the adhesive.

- Together with talcum powder, CA glue can easily fill gaps. nine0020

- CA is not heat stable and decomposes into quite toxic smoke if heated too much! This can be handy for breaking metal-CA-metal bonds when machining small parts, but keep this in mind if you want to use inserts or plastic soles in the same areas! Do not contact CA in these cases.

- Epoxy is a favorite for very hard bonding, a few drops can stick a car to the roof... and it gets warm when cured.

If you use a slow curing resin, you can safely use it to bond PLA without deforming the part. nine0016

If you use a slow curing resin, you can safely use it to bond PLA without deforming the part. nine0016 - Uncured resins and their hardeners are highly irritating to the skin.

nine0016

nine0016 Adhesive? Why glue?!

"Solder"

What better way to join parts than welding or soldering?! Often, none. My personal favorite is PLA glue is PLA itself, using it as PLA solder. This method also works for most other types of filaments, but is not recommended for ABS and other plastics that emit fumes without the use of respiratory protection!

- Take the pieces and make sure there is a cavity on both sides that can be filled.

nine0020

nine0020 - Take a soldering iron and set it to about 200°C.

- Take the length of the PLA filament.

- Melt the thread with a soldering iron and use it as solder when joining the two parts. Make sure at least some filament gets into the cavities and gets stuck there - it can help to stick the soldering iron into the goop there to get it to fuse with the filler/walls and press the hot pieces of PLA goop together against the iron before pulling it out by pressing pieces together.

- As the PLA cools and solidifies, the joint usually becomes more rigid than the actual layer boundaries. nine0020

Pen

Instead of using a soldering iron, you can also use the 3D printing pen , which eats filament, not PCL or some kind of gel! , but personally I don't like them.

Inserts!

On the other hand, a soldering iron is also a very good solution for making inserts in PLA - heat up a metal insert (like a nut) and press it against a smaller hole and it will mold the plastic around itself into a perfect fit without glue. nine0003

nine0003

Friction Welding

An alternative to using direct heat from a soldering iron is Friction Welding . To do this, take a rotating power tool and some filament. Insert the thread into the tool, tighten and cut so that about an inch comes out of the claw. Turn it on at medium speed, around 800 to 1200 rpm. Now, as soon as you press the tip of the spinning thread against another PLA, it heats up and melts, creating a weld. Joel has a good explanation. nine0003

Plastic processing for 3D printer. Plastic post-processing after 3D printing ABS, PLA, Nylon, Petg

Contents:

- Post-processing of FDM parts

- Remove supports

- Removing Soluble Supports When Printing 3D Printer with Dual Extruders

- Sanding plastic 3D printed products

- Acetone for ABS plastic

- Filling irregularities in ABS plastics

- Polishing ABS/PLA

- Priming and painting 3D printed products

- Acetone baths for ABS products

- Chemical solvent baths

- Using epoxy to finish prints

Hello everyone, Friends! With you 3DTool!

With the FDM 3D printing you can quickly and economically produce plastic parts of any geometric shape. Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties. nine0131 This article will discuss the most common post-processing techniques in FDM 3D printing .

Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties. nine0131 This article will discuss the most common post-processing techniques in FDM 3D printing .

Catalog of FDM 3D printers

Post-processing of FDM parts

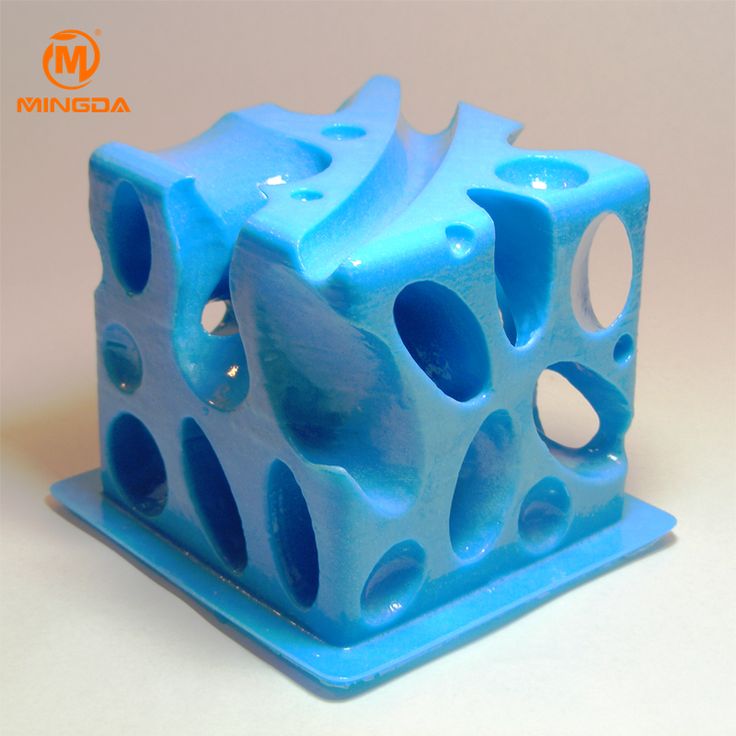

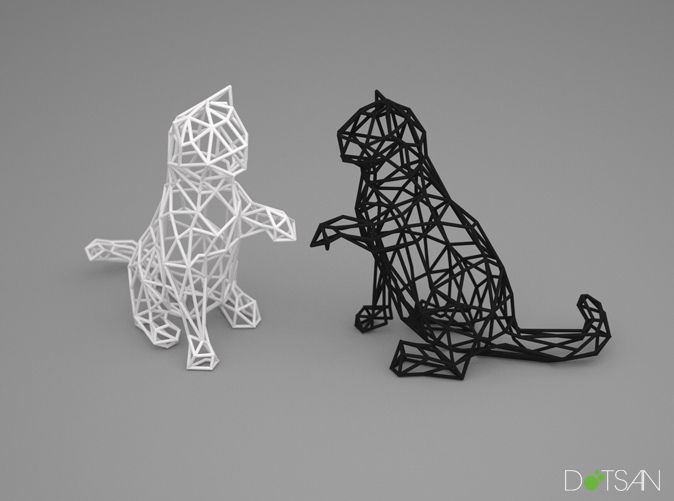

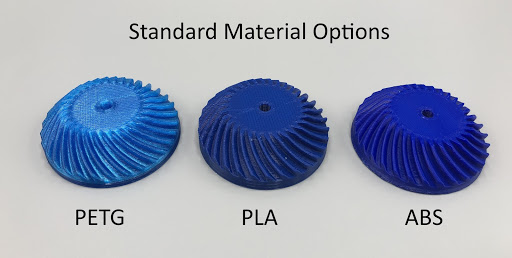

This picture above (from left to right) shows the post-processed parts FDM :

- gap filling

- raw

- sanded

- polished

- painted

- epoxy coated

Remove supports

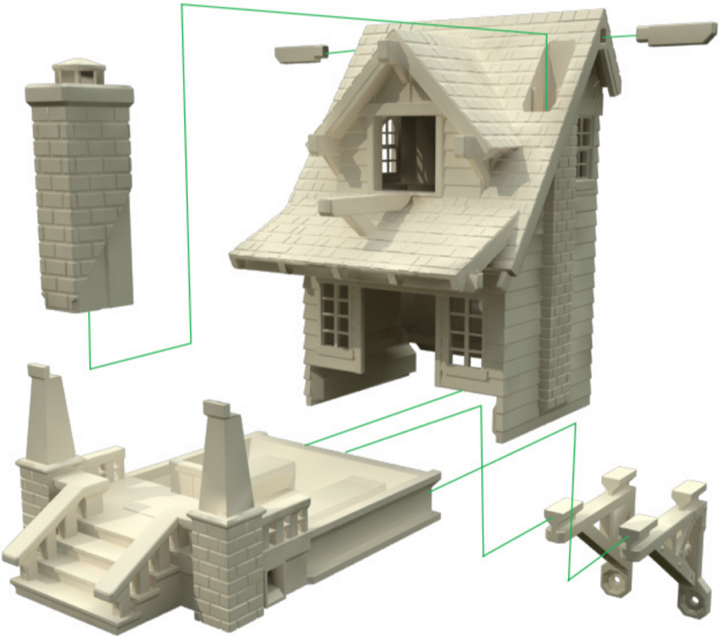

Support removal is typically the first step in post-processing for any 3D printing technologies if the part requires support for precision manufacturing. Supports can usually be divided into 2 categories: standard and instant .

Supports can usually be divided into 2 categories: standard and instant .

Unlike other post-processing methods discussed in this article, support removal is a requirement and does not result in improved surface quality.

Removing supports mechanically is necessary when printing with a 3D printer with a single extruder (for example, PICASO Designer X, Hercules 2018, Zenit, Prusa i3 Steel Bizon) When using 3D printers with two extruders, as a rule, the supporting part of the product is made of special soluble materials. nine0003

Catalog of 3D printers with two extruders

Left to right. Original printing with support, poor support removal and quality support removal.

Tools and materials you will need for this job:

- Pliers

- Set with small tools (eg watchmaker's set).

nine0187 Support Removal Process: The support material can usually be removed from the finished model without much effort. Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Plus

- The overall geometry of the part does not change

- Fast on time

Cons

- Does not remove visible layer lines, streaks or smudges on print surface

- If support structures leave behind excess material or marks, the accuracy and appearance of the part will be reduced

Removal of soluble supports when printing with a 3D printer with two extruders

As we said earlier, the removal of supports printed from soluble materials is done differently than manually, mechanically, so the use of 2 or more extruder printers is preferable. (e.g. PICASO Designer X PRO, Raise3D PRO2) nine0003

Catalog of 3D printers with two extruders

Tools and materials you will need for this job:

- Solvent safe container

- Thinner

- Ultrasonic cleaner (optional)

Process : the final model is placed in a bath with the appropriate solvent (for example, for PVA plastic it will be ordinary water, for material HIPS it will be D-limonene ) until the support material dissolves. Support is usually printed with:

Support is usually printed with:

- HIPS (in conjunction with ABS )

- PVA (in conjunction with PLA )

Glass storage containers such as jars are excellent receptacles for diluting limonene. For dissolution in water, any non-porous container will do. For prints using HIPS/ABS bath with a 1:1 ratio of limonene to isopropyl alcohol works very well for quick support removal. Many other auxiliary materials such as PVA (used with PLA ) are water soluble.

Helpful Hint: Speed up the dissolution time of the support material by using an ultrasonic bath and changing the solution as soon as it becomes saturated with plastic dissolved in itself. Using a warm (not hot) solvent will also speed up the dissolution time if you don't have an ultrasonic cleaner available. nine0131

Catalog of ultrasonic baths

Pros

- Great for complex geometries where standard support removal would be impossible without damaging the base model.

- The result is a smooth surface where the support structure is in contact with the base piece.

Cons

- Improper dissolution of the material can lead to discoloration and deformation of the entire part. nine0020

- Does not remove visible layer lines, streaks or spots on part surface

- May cause small spots or holes in the final print if soluble material gets on the object during printing

-

3D plastic sanding

Sanded brown ABS plastic part

Tools and materials you will need for this job:

- Sandpaper up to grit 1000

- Rags

- Toothbrush

- Soap

- Face mask

Sanding Process: After removing or dissolving the supports, sanding can be performed to smooth the part and remove any visible stains or traces of the supports. The initial grit size of the sandpaper depends on the layer height and print quality.

The initial grit size of the sandpaper depends on the layer height and print quality.

For layers with a height of 0.2 mm or less, or if there are no spots left on the part after printing, sanding can be started with a paper grain of - 150.

If there are visible spots or the object was printed at a layer height of 0.3 mm or more, start sanding with 100 grit paper.

purity. The print should be cleaned with a toothbrush in soapy water and then with a rag, between sanding steps to prevent dust build-up and " sintering ". Your FDM parts can be sanded down to 5000 grit to achieve a shiny part surface. nine0003

Helpful Hint:

Always sand in small circular motions evenly over the entire surface of the part. Of course, it is more convenient to sand perpendicular or even parallel to the print layers, but this can lead to indentations in the model. If the part becomes discolored or if there are many small scratches after sanding, you can use a blow dryer. With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether. nine0003

With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether. nine0003

Pros

- With this method, you get an extremely smooth surface

- This method facilitates additional post-processing (such as painting, polishing, or epoxy coating)

Cons

- Not recommended for thin wall prints as this may damage part

- Difficult for surfaces with difficult geometries and fine details

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

Acetone for ABS plastics

Two white printed halves of ABS bonded with acetone and diluted plastic.

Tools and materials you will need for this job:

- Acetone

- Cotton swabs or brush

Machining process: When the size of the finished part exceeds the maximum size of the 3D printer's camera, the model often has to be broken into smaller parts and reassembled later by gluing. For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together. nine0003

For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together. nine0003

Helpful Hint: increasing the contact area with acetone will increase the strength of the joint. This can be done by including block connections in the design.

Pros

- Acetone will not discolor the surface of the part like other adhesives

- After drying, the seam will exhibit ABS properties, making further processing easier and more uniform

Cons

- The joint formed by this cold welding is not as strong as a solid impression

- Excessive use of acetone can lead to aggressive dissolution of the part and adversely affect the final result and tolerances

-

Filling irregularities in ABS plastics

The gray ABS model had voids after sanding. The surface became smooth. nine0003

The surface became smooth. nine0003

Tools and materials you will need:

- Epoxy resin (for small voids only)

- Automotive Putty (large voids and joints)

- ABS plastic and acetone (for small voids only and for ABS parts only)

Process: After sanding or removing soluble backings, gaps often appear in the print. During printing, gaps are sometimes formed, and often this pattern is unavoidable. Small gaps and voids can be easily filled with epoxy and no further treatment is required. Large gaps, or gouges, left from attaching model assembly parts can be successfully filled with automotive putty, which will require additional sanding after drying. nine0131 The putty gives excellent results and can be easily sanded and painted after it has fully cured. The connection will be strong, and will not weaken the plastic. Conversely, autofiller parts tend to be stronger than native plastic.

Gaps in an ABS print can also be filled by making a slurry of ABS filament and acetone ( ABS juice or ABS juice ) that chemically reacts with the part and penetrates any surface voids. A ratio of 1 to 2 between ABS and acetone is recommended. This method will not significantly affect the cleanliness of the surface around the gap if properly applied. nine0003

Tip : If gaps are visible on FDM parts before sanding, fill them with epoxy and then sand once until dry. This will greatly reduce the overall time required to achieve a smooth surface.

Pros

- Epoxies are easy to sand and prime, making the surface easy to paint

- ABS juice will be the same color as your part, as long as you use the same filament by color and manufacturer. Therefore, there will be no discoloration of the surface

Cons

- Auto putty or other polyester epoxy will dry opaque resulting in discolored spots on the print

- Requires additional sanding to achieve uniform coverage

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

ABS and PLA polishing

nine0494 ABS plastics catalog

Catalog of PLA plastics

Tools and supplies you will need

- Polish

- Sandpaper

- Nonwoven wipe

- Toothbrush

- Microfibre cloth or polishing pad

Process: Plastic polish can be applied after sanding the surface to give standard filament products such as ABS and PLA a glossy finish. After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

Allow the piece to dry completely and buff it with a buffing pad, or by hand with a microfiber cloth and a jewelry polish designed specifically for plastic and synthetics that provides a long lasting shine.

Other plastic polishes, such as car headlight polishes, work on the same principle, but some may contain chemicals that can damage the original material. nine0003

Helpful Tip: For polishing small parts, attach the polishing pad to the Variable Speed Drill (or other rotating tool such as a drill) . Bench grinders equipped with a polishing wheel can be used for larger, stronger prints, but don't polish too long in the same place. This can cause the plastic to melt due to friction.

Pros

- Polishing is applied without the use of any solvents that can deform the part and change the accuracy tolerances.

- When properly ground and polished, the part will give the impression of a mirror finish, imitating plastic injection molding

- Plastic polish and cleaner is very economical, making this method quite profitable for a quality finish

Cons

- The part must be carefully sanded before polishing if a mirror finish is required. This may affect tolerances

- Primer/paint may not adhere to surface after polishing and you will need additional products

Priming and painting 3D printed products

White PLA part spray painted gray

Tools and materials you will need:

- Non-woven cloth

- Toothbrush

- Sandpaper

- Aerosol Acrylic Primer

- Polishing agents

- Masking tape (only if using multiple colors)

- Gloves and petal mask

Finishing process: after the part is properly sanded (up to 500 grit sandpaper is required at this stage) , the print can be primed. The primer should be applied in two coats using an aerosol can.

The primer should be applied in two coats using an aerosol can.

An aerosol primer designed for painting models will provide an even coverage and be thin enough not to darken the part before painting.

A thick primer, such as one available at the hardware store, may stick together and require more sanding.

Apply the first coat in short, quick strokes at a distance of about 15 - 20 cm from the part to avoid the formation of a thick layer of primer. Let the primer dry and sand down any imperfections with 9 grit sandpaper.0022 500. Apply the final coat of primer with light, quick strokes.

Once the primer is complete, painting can begin. Painting can be done with acrylic paints and artist's brushes, but using an airbrush or spray can give a smoother surface.

Hardware store spray paint tends to be thicker and harder to control, so it's best to use paints made specifically for painting models. nine0131 The primed surface should be sanded and polished (sanding and polishing sticks used in nail salons are ideal for this application) and then cleaned with a non-woven cloth.

Paint over the model using very light layers; the first few layers will look translucent. Once the paint has formed an opaque coat of (usually after 2-4 coats) , allow the model to dry for 30 minutes to allow the paint to set. Carefully polish the paint layer with nail sticks. nine0003

Multi-colour models can be painted with masking tape. Once all layers of paint are ready, remove the tape and buff the paint using polish paper. Polishing paper such as 3M or Zona can be purchased in a variety of grit sizes. You can buy it in a pack in many online stores. It will give the paint a shine that cannot be achieved in any other way.

Helpful Hint: Do not shake the can when using spray paint! The goal is to mix the pigment or primer, shaking the propellants will cause bubbles to form in the aerosol. Instead, rotate the jar for 2-3 minutes. The stirring ball should roll, not rattle. nine0003

Pros

- Professional results with attention to detail

- Excellent appearance of the final product, regardless of the material/color in which the object was originally printed

Cons

- Paint and primer will increase the volume of the model, which will change the tolerances and can cause problems if the part is part of the assembly

- Buying a high quality spray paint or airbrush is not cheap

Acetone baths for ABS products

Smoothed black model of a petal with a spherical surface made of ABS plastic after an acetone bath.

Tools and materials you will need:

- Non-woven cloth

- Sealed container

- Thinner

- Paper towels nine0017 Aluminum foil (or other solvent resistant material)

Process: Line the chosen container with paper towels along the bottom and, if possible, up the sides. It is very important that the steam does not disturb the chamber itself. The chamber may be sealed.

It is recommended to use glass and metal containers.

Pour in enough solvent to dampen but not drown the paper towels. This will also help them stick to the side walls of the container. nine0131 Acetone is well known for its ability to smooth out ABS parts. For PLA, smoothing is possible with various solvents, they work well, but as a rule, with PLA, it is more difficult to get a smooth surface, unlike ABS.

IMPORTANT! When working with any solvent, please follow the safety regulations for the chemical and always follow the appropriate safety precautions !

A small "raft" of aluminum foil or other solvent-resistant material should be placed in the middle of a lined paper towel container. nine0131 Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

nine0131 Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

Steam polishing can vary in duration, so check the print periodically. Heat can be used to increase polishing speed, but care must be taken to prevent the buildup of potentially explosive fumes.

When removing the part from the chamber, try not to touch it at all, leaving it on the raft and removing it from the container. Any points of contact with the part will generate surface defects because the outer shell will be half dissolved. Allow parts to dry completely before use. nine0003

NOTE . Many aerosol and/or spray solvents are flammable/explosive and solvent vapors can be harmful to human health. Be especially careful when heating solvents and always work in a well ventilated area.

Pros

- Smoothes out many small spots and reduces layer lines present in the print without any additional work nine0017 Creates a very smooth "shell" around part

- A very fast method that can be implemented with improvised means

Cons

- Doesn't "heal" gaps or completely mask layer height

- The dithering process "dissolves" the outer skin of the print and therefore the tolerances are greatly affected

- Negatively affects print strength due to changes in material properties nine0025

- Solvent safe container

- Thinner

- Hook or small screw

- Wire

- Drying rod or rack

- Face mask and chemical resistant gloves

- Print surface smoothes much faster than steam polishing

- Much less fumes than other solvent polishing methods and is safer

- Very aggressively smoothes the surface of the part, so the tolerances deviate greatly from the specified

- Immersion for too long can lead to complete deformation of the part and a significant change in material properties

- Two part epoxy resin (e.g. XTC-3D)

- Foam applicator

- Brushes

- Mixing container

- Sandpaper 1000 grit or higher

- A very thin coat of epoxy will not significantly affect part tolerances (unless the part has been sanded first)

- Resin provides an outer protective sheath around the part

- The layer lines will still be visible, they are under the "smooth" shell

- Applying too much epoxy can cause surface dripping and over-smoothing of print details

- Plating solution. It can be prepared by mixing a metal salt with acid and water, but if the proportions are not accurate, it will be difficult to get a professional result.

Buying a ready-made solution guarantees that there are no problems with plating. nine0020

Buying a ready-made solution guarantees that there are no problems with plating. nine0020 - Sacrificial anode. The anode material must match the metal of the plating solution, so if copper sulfate is used in the solution, then a copper anode should be used. You can use any item made of metal plating (copper wire, for example), or you can purchase a thin strip of metal plating that is made specifically for electroplating.

- Conductive paint or acetone and graphite. The print surface must be conductive for coating, which can be achieved with conductive paint or a 1:1 solution of graphite and acetone. Conductive ink will work on any printed material, but a solution of acetone and graphite will only work on ABS. nine0020

- Power Rectifier - A battery can be used instead of a rectifier, but a battery is not as efficient and will not produce results as quickly and consistently as a rectifier. A rectifier is also a safer option. It can simply be turned off to stop the current flow during electroplating.

- Conductive screw or eyelet

- Non-conductive vessel

- Lead set

- Non-conductive gloves and goggles. nine0020

- The metal shell increases the strength of the plastic part, which greatly expands the possibilities of its application and use

- The outer metal coating is very thin so if properly applied, tolerances of 9 can be held tightly0020

- Creates a beautiful surface that, if done correctly, will not look like a 3D printed object

- Typically very expensive to do this at a professional level, and home plating requires a fair amount of professional processing equipment

- Electroplating at home can cause electric shock if not followed

- Email: Sales@3dtool.

Chemical solvent baths

Tools and supplies you will need:

Process: Make sure the container you are using is wide enough and deep enough to hold the part and solvent. Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS. nine0131 PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS. nine0131 PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Prepare the part for dipping by screwing an eye hook or small screw into an inconspicuous surface of the imprint. Pass the wire through the eye of the hook or around the screw so you can lower your piece into the wire bath. If the wire is too thin, you won't be able to submerge the part in the solvent.

Once the part is prepared, quickly immerse the entire object in the solvent for no more than a few seconds using wire. Pull out the print and attach it to a wire over a dryer rod or rack to allow the solvent to completely evaporate from the surface. The part should be gently shaken after you remove it to facilitate drying and avoid solvent build-up in depressions on the surface. nine0003

Helpful Hint: If the part has an opaque whitish color after drying, it can be hung over a solvent bath for a while so that the evaporating vapors slightly dissolve the surface. This will restore the color of the print and provide a glossy outer layer.

This will restore the color of the print and provide a glossy outer layer.

Pros

Cons

Using epoxy to finish prints

The part is sanded and coated with epoxy resin.

Tools and materials you will need:

Process : After the print has been sanded (sanding first will give better end results) , completely clean it with a non-woven cloth. nine0131 Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

nine0131 Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

Containers specifically designed for mixing epoxy resins are recommended. The wrong ratio will lengthen the drying time and the epoxy may never be able to fully cure, resulting in a disastrous and sticky part. nine0003

Mix resin and hardener thoroughly according to instructions. Stir gently to minimize air bubbles. The faster the epoxy dries, the better. Most epoxies have a working dry time of only 10-15 minutes, so do your post-processing in the proper order.

Apply the first coat of epoxy using a foam applicator and try to minimize resin buildup on recessed surfaces or other details of the print. Once your part is sufficiently covered with resin, allow it to fully cure according to the manufacturer's instructions. One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or finer) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or finer) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

Pros

Cons

Tools and supplies you will need:

Electrophoresis solutions are acids and can cause eye damage if splashed, so appropriate goggles are required. Also, these solutions can irritate the skin and conduct a charge when used. Therefore, non-conductive gloves should always be used.

Process: metal plating can be electroplated at home or in a professional workshop. Proper plating requires a deep knowledge of materials, and what you can do at home has certain limitations compared to what can be done in a professional workshop. nine0131 For a better finish and a wider range of plating options, including chrome plating, a workshop would be the best option. For clarity, the copper plating process will be described below.

At home, galvanization can be done using copper or nickel plate. It is imperative that the surface of the print to be processed is as smooth as possible before coating; any unevenness and visible lines of the layers will start to stand out after coating.

Prepare a cleaned and sanded print. By coating the plastic with a thin layer of high quality conductive paint or a solution of acetone and graphite (if made of ABS) . Allow the conductive coating to dry completely and sand if necessary to ensure a smooth finish. It is extremely important to minimize contact with the print or wear gloves as the sebum on your fingers will interfere with the coating process.

Insert a screw or hook with an eye into an inconspicuous surface of the part, similar to dipping in solvent.

Attach to one of the rectifier leads. This will serve as the cathode. The connection must be made to the negative terminal of the rectifier. Connect the copper anode to the positive terminal of the rectifier using the second power wire and fill the container with enough electroplating solution so that the imprint and the copper anode are completely hidden. Turn on the power rectifier. After the rectifier is turned on, make sure that the part does not touch the anode in any way. nine0003

nine0003

IMPORTANT! Be very careful at this stage. After the part is lowered into the bath and the system is energized, any contact with the solution, anode or cathode may result in personal injury !