3D printer advertised on facebook

SLA 3D Printer and Additive Manufacturing

Finally, fast and affordable 3D printing without compromises

Free Sample Part Browse 3D Printers

Increase Throughput. Improve Productivity. Reduce Total Cost of Ownership.

Nexa3D is a leading provider of ultrafast 3D printing solutions. Our photopolymer and thermoplastic range of industrial 3D printers offer unrivaled speed and throughput, superb surface finish, all on an open material platform. Our patented Lubricant Sublayer Photo-curing (LSPc) 3D printing process unlocks productivity gains by as much as 20x greater than those of conventional SLA or DLP processes. We offer a range of polymer solutions, spanning from a desktop resin 3D printer, industrial 3D printers, and a thermoplastic laser sintering solution for serial production.

Professional Desktop 3D Printer

4.8L build volume, unrivaled speed, and an open material platform made accessible to every professional user.

Explore XiP

Industrial 3D Printer

16L build volume, industrial accuracy, and fast print speeds delivering up 20x productivity gains to your factory floor.

Explore NXE 400Pro

Industrial 3D Printer

8.5L build volume, industrial accuracy, and fast print speeds at an attractive price point.

Explore NXE 200Pro

Photopolymer Dental 3D Printer

8.5L build volume, validated workflows, and dental materials delivering up to 20 flat dental models in just 30 minutes

Explore NXD 200Pro

Thermoplastic 3D Printer

Production-grade thermoplastic SLS system offering the highest throughput in its class, ideal for serial production.

Explore QLS 820

Compare 3D Printers

Our Customers

Customer Stories

“Our R&D Team is able to reduce time to obtain functional samples by as much 80%, and reduce tooling costs by as much as 90%.

With the NXE 400Pro, we’re able to go from CAD to scale in just 48 hours.”

Max Rodriguez,

Senior Manager of Global Packaging

View Case Study

Exponentially greater throughput with 6.5x greater speed

Optimized supply chain with scalable on-demand manufacturing

Superb surface finish quality with minimal post processing required

Open material platform unlocking many manufacturing use cases

Free Sample Part

Gain 20x Productivity

Nexa3D reduces prototyping and production cycles from hours or days to mere minutes. The combination of our larger-format build area, print speed, and post-processing automation delivers up to 20x productivity gains, making our 3D printing process comparable only to injection molding — without existing supply chain complexities, extended lead-times, and the substantial costs typically associated with tooled plastics.

Talk to an Expert

Open Material Platform

We believe in the power of an abundant material ecosystem. That’s why we continue to partner with leading material providers to deliver a comprehensive range of high-impact functional materials that are tailored to your mechanical requirements and performance needs.

That’s why we continue to partner with leading material providers to deliver a comprehensive range of high-impact functional materials that are tailored to your mechanical requirements and performance needs.

Nexa3D Material Selector

3D Printer Filament Supplier | Texas Filament Supply

Fiberlogy Filaments

All of TFS filaments are from Fiberlogy. Read about them below or click the button to learn more about their filaments from the manufacturers website!

"Fiberlogy was established in Poland and this is where it operates. We are proud to be part of an international technological revolution. A modern production line and the knowledge of our technologists allow us to offer filaments of unique properties and parameters for FFF/FDM printers." - Fiberlogy Website

Looking for Filament we don't have? -

Feel free to use our contact form, message us on our Facebook Page, or email us at: TexasFilamentSupply@gmail. com. We get customer requests all the time! We will always do our best to make it happen!

com. We get customer requests all the time! We will always do our best to make it happen!

You can also request a Fiberlogy Filament Catalog, and we will email you a pdf file! This is great for comparing filaments!

Learn More

Stay Up to Date

Make Sure you stay up to date by subscribing to our news letter, or by liking our Facebook Page! Our Facebook page is where we always announce our sales, new filaments, and restocks! Don't Miss Out! We are still growing and improving!

like us on facebook

Free Samples with Every Order!

Samples are a great way to discover your next favorite filament! When you go to your cart to checkout, there will be an option to add a note to your order. Please put your sample request there - feel free to mention a few filaments you are interested in, in case some are unavailable.

Gift Cards Available

Not sure which filament to get for your favorite 3D printing enthusiast? How about a Digital Gift Card!

Shop Now

High Quality Filaments

No matter what level of experience in 3D printing you have, printing with Fiberlogy Filaments is sure to encourage you to pursue this versatile hobby! 3D printing is super rewarding when you get to see models come to life, but having high quality filament is a must!

Show Off Your 3D Prints!

Send pictures of your 3D Prints to TexasFilamentSupply@gmail. com or Message us on Facebook to have your prints shown off on our page and here on the website! Check out the Customer Print Gallery!

com or Message us on Facebook to have your prints shown off on our page and here on the website! Check out the Customer Print Gallery!

Go to customer print gallery

Are you a professional 3D Printer?

If you are offering professional 3D Printing Services using Fiberlogy Filaments, please email us or use our contact form. Customers have been reaching out to us, looking for 3D Printing Services using Fiberlogy Filaments. As a 3D printer filament supplier, we would like to advertise your business on the website and Facebook Page, to help customers find you!

Contact Us!

Eco-Friendly Solutions

Texas Filament Supply is Powered by Solar Energy!

Packing Material included in orders is either recyclable, or reused!

We recycle all incoming shipment materials!

3D printer filament supplier located in San Angelo, Texas

Local Pick Up and Delivery Available in San Angelo! Once you complete your order, we will reach out to you when your order is ready for pick up/delivery to make arrangements with you!

San Angelo is located in Central Texas! About 1. 5 hours from Abilene, 5 hours from Dallas, 3-4 hours from Austin, 6-7 hours from Houston!

5 hours from Abilene, 5 hours from Dallas, 3-4 hours from Austin, 6-7 hours from Houston!

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Which is better for outdoor advertising: milling or 3D printer?

Modern technologies are developing in kilometer steps and what seemed like science fiction a few years ago is now commonplace. So, before we watched films in which different things were simply printed in a special device, and today even ordinary people can afford a 3D printer. But is this technology suitable for making signs or plates? Can this technology replace conventional milling cutting? Let's find out. nine0003

Milling services vs. 3D printing

Standard in the outdoor advertising industry for the manufacture of three-dimensional figures, a mechanical method of processing on a milling machine is used. This is a relatively cheap and fast way to create structural elements. But it would seem that with the advent of 3D printers, the need for milling cutting should disappear, because it will be much cheaper to make signs or other advertising using 3D printing. No matter how. Currently, a 3D printer can print from a variety of materials. There are even special construction printers that can erect entire buildings. But here is their price... Only a large federal-scale company can buy something like this. Therefore, in order to recapture its cost, the prices for metal plate printing services will be prohibitive. nine0003

No matter how. Currently, a 3D printer can print from a variety of materials. There are even special construction printers that can erect entire buildings. But here is their price... Only a large federal-scale company can buy something like this. Therefore, in order to recapture its cost, the prices for metal plate printing services will be prohibitive. nine0003

And besides, printing still has many drawbacks and requires additional processing after the process is over. So, plastic or metal parts will have to be polished to achieve a smooth surface.

On the other hand, milling cutting has CNC - numerical control, thanks to which it is possible to produce parts with an accuracy of one thousandth of a millimeter. To achieve such precision with a 3D printer, you will have to overpay ten times more than with standard milling. nine0003

Sheet milling

The machine is used in the production of a huge range of promotional products:

- Decals

- Signage

- Letters

- Light panels

- Korobov

- Etc.

The format, size and shape of the final projects is limited only by the designer's imagination. At the same time, professional layout adjustment allows minimizing the consumption of materials and losses in production. Continuing to compare with a 3D printer, the milling machine also wins in that it is possible to produce objects that are quite complex in shape - the printer has some limitations in printing. nine0003

It is also worth mentioning the materials from which future outdoor advertising will be made. Let's take a look at the two most popular materials for creating advertising structures.

Plastic milling cutter

Plastic printing technology is probably the most refined to date. The essence of the process is that the printer heats the plastic thread, melting it and squeezing it out according to a certain pattern. A milling machine, on the other hand, grinds a part from a specific piece of plastic. If we compare these two processes, then this is what we get: nine0003

- The material - plastic, which is used in a 3D printer is quite expensive and in order to create a large outdoor advertising element, you will have to pay a tidy sum.

- Speed - the larger the object, the more layers the 3D printer will have to apply. The milling machine grinds it much faster.

All this makes advertising printing unprofitable compared to turning.

Metal milling

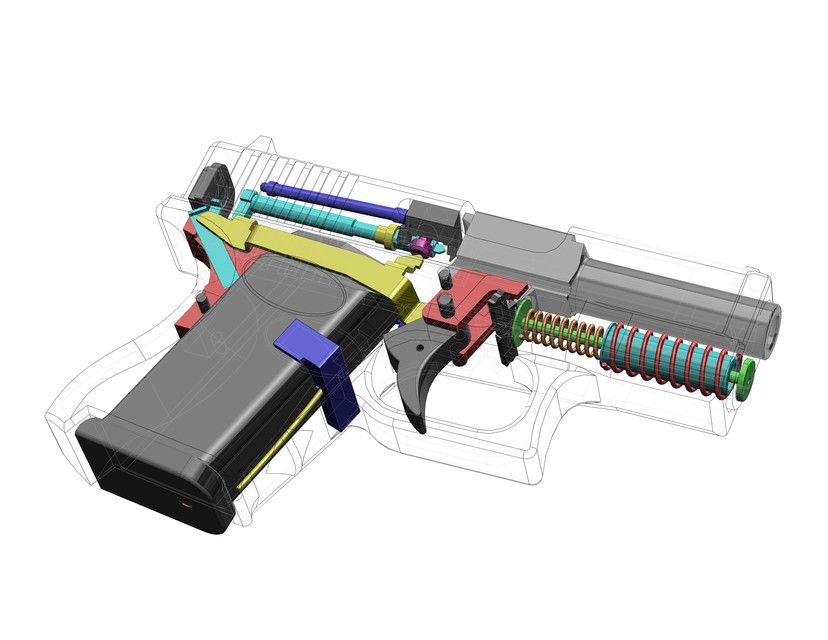

The second most popular material is metal. The process of creating metal structures on a specialized 3D printer looks like this: a special powder is used, which is also dispensed according to a special scheme, and then baked to form a monolithic structure. There are the same drawbacks as when creating objects from plastic - the speed and price of the material. In addition, you will have to try to find a company that has an industrial 3D printer that prints from metal. nine0003

Instead of a conclusion

Thus, no matter how new technologies seem to be a breakthrough in the industry, at the moment they are still quite limited, therefore they are inferior in efficiency to classical methods of creating advertising.

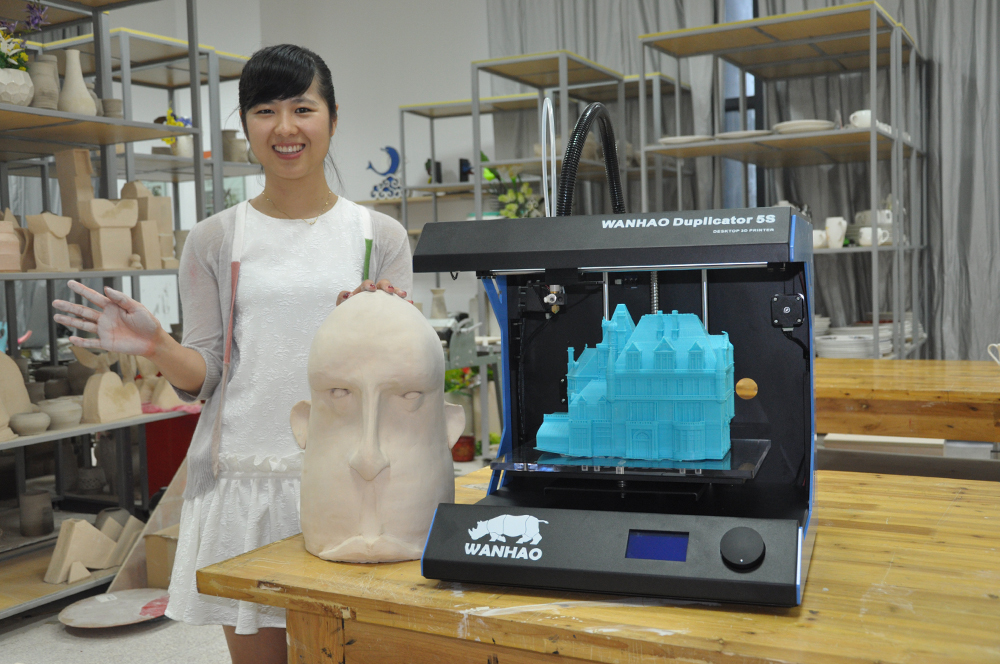

What can be done with a 3D printer? Everything is possible!

2689 Link

Business

06/12/2018 16:00

Author:

Advertising Department Berdsk-online

In honor of the Day of Russia until 19June - 10% discount for customers

A 3D printer is essentially an automatic 3D pen that can draw a three-dimensional model using meltable plastic of any color. About 3D pens and other smart gadgets, you can find out more information here.

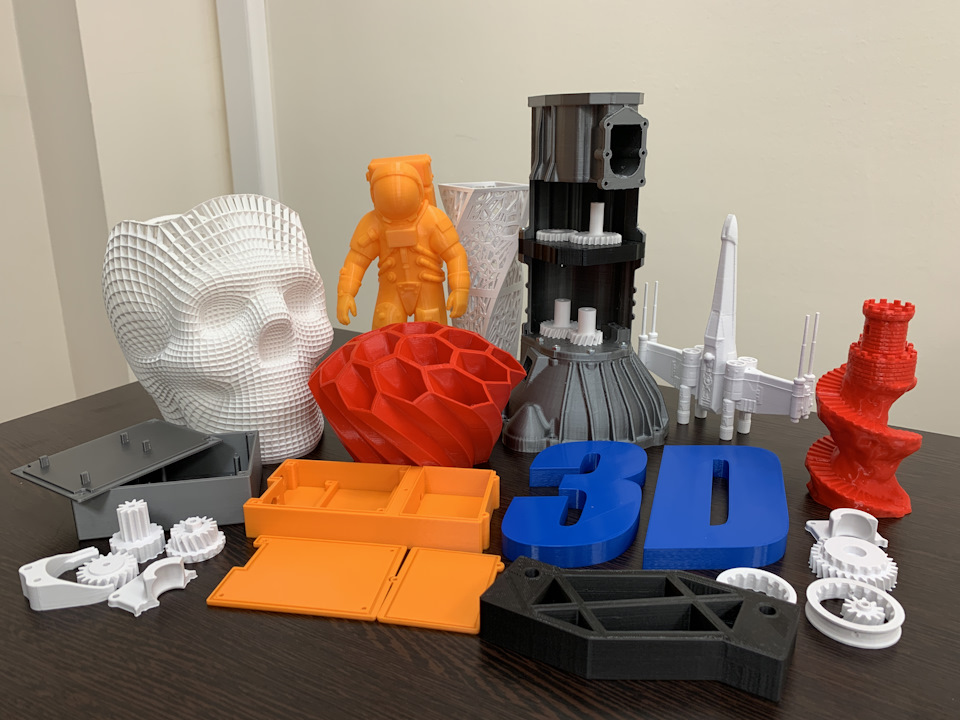

With a 3D printer, you can really create almost anything! The same plastic as for the 3D pen is inserted into a special hole, models can contain two colors and two layers. Author's souvenirs, key chains, plastic business cards, signs - this printer will do everything according to your sketches! nine0003

Few people know that such a 3D printer creates lost or broken parts from household appliances, which are sometimes so difficult to find in ordinary stores.

In the store of smart gadgets and 3D printing "Filament" residents of Berdsk have already tried and recreated parts from toy cars, a gear from a meat grinder, a toy bow with arrows and even a nameplate for a Nissan car.

Models are created using a computer program. You can bring your ready-made sketches for printing on flash media. If you need to create something broken or lost, Filament store consultants will help you and together with you create what you want to 3D print. nine0003

According to Filament managers, there is no such center in Berdsk that would print 3D models on such a 3D printer according to any sketches. This is an exclusive service that you can get by coming to the Orbita shopping center on the 2nd floor.

According to the time of creating a 3D product, it can take from an hour to several days to work, it all depends on the complexity of the model itself. The price varies accordingly and depends on the complexity, size and time of creation of the part. The principle is this: the slower the print, the better the final result will be! nine0003

Here they can create ready-made molds for casting, for example, chocolate products or designer soaps. You can discuss your orders with store managers right now by phone: 8–913-008-48-25.