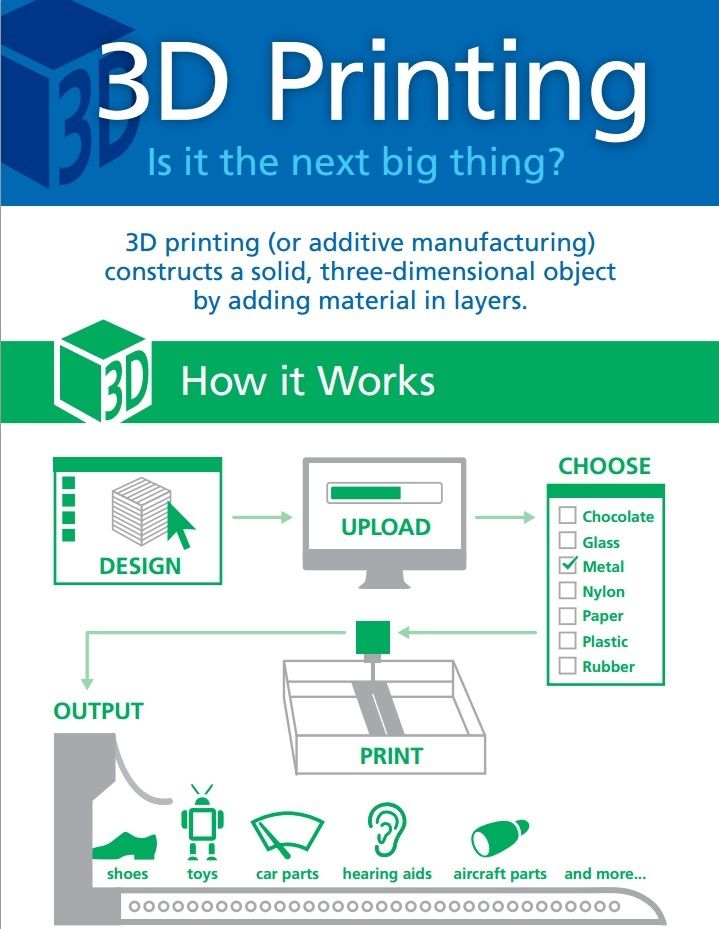

What is additive manufacturing 3d printing

What is Additive Manufacturing? (Definition & Types)

Additive manufacturing (AM) or additive layer manufacturing (ALM) is the industrial production name for 3D printing, a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.

Contents

Click the links below to skip down to a section in the guide:

- How does it work?

- Types of AM

- AM technologies

- Who invented AM?

- Advantages

- Services

- How long does it take?

- Which materials can be used?

- Where is AM used?

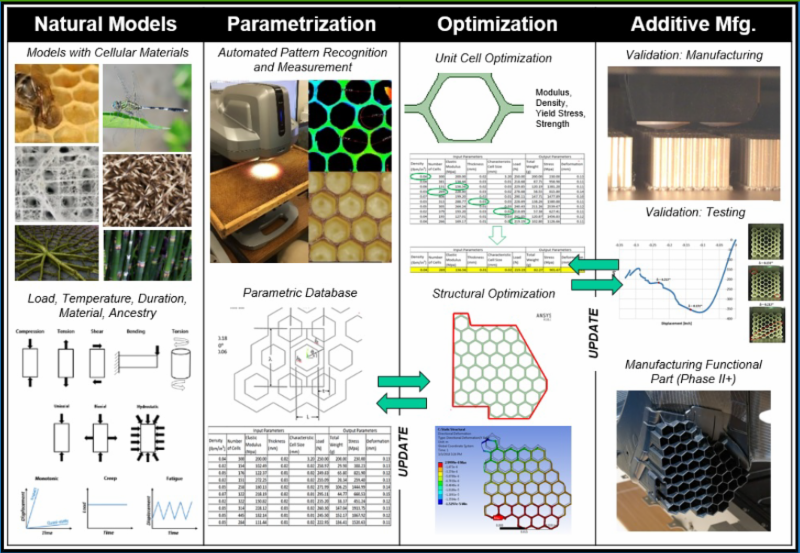

Using computer aided design (CAD) or 3D object scanners, additive manufacturing allows for the creation of objects with precise geometric shapes. These are built layer by layer, as with a 3D printing process, which is in contrast to traditional manufacturing that often requires machining or other techniques to remove surplus material.

There are number of distinct AM processes with their own standards, which include:

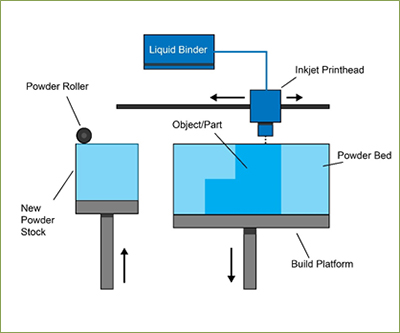

1. Binder Jetting

This technique uses a 3d printing style head moving on x, y and z axes to deposit alternating layers of powdered material and a liquid binder as an adhesive.

Read more

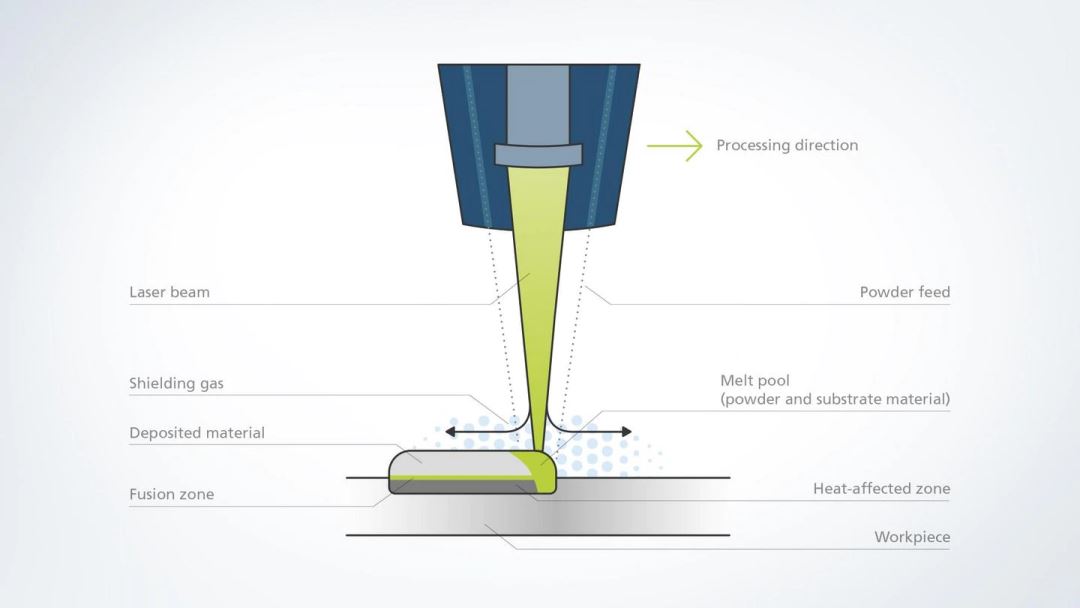

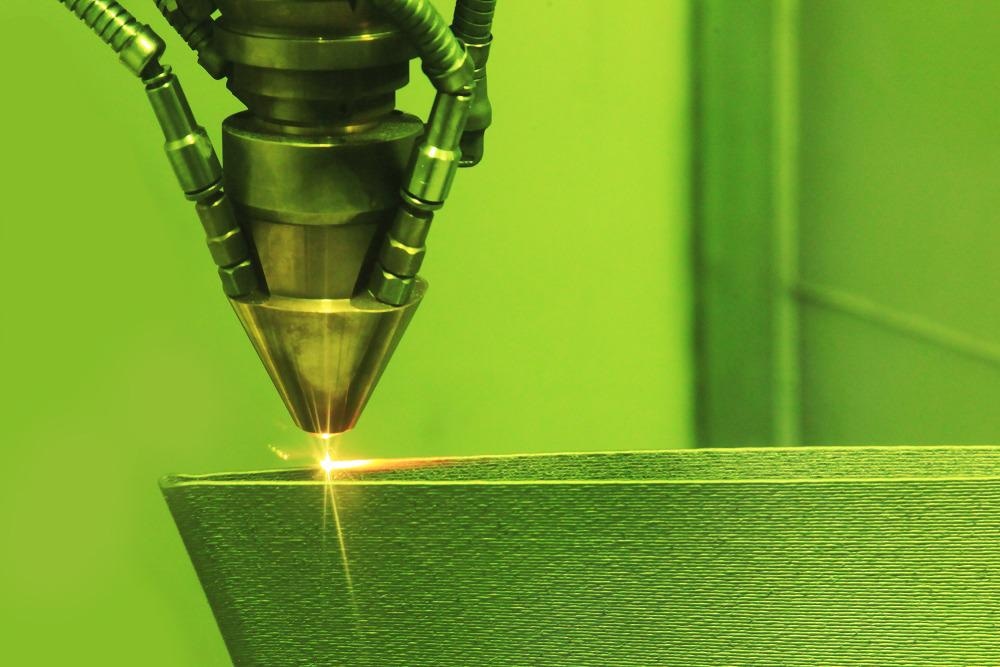

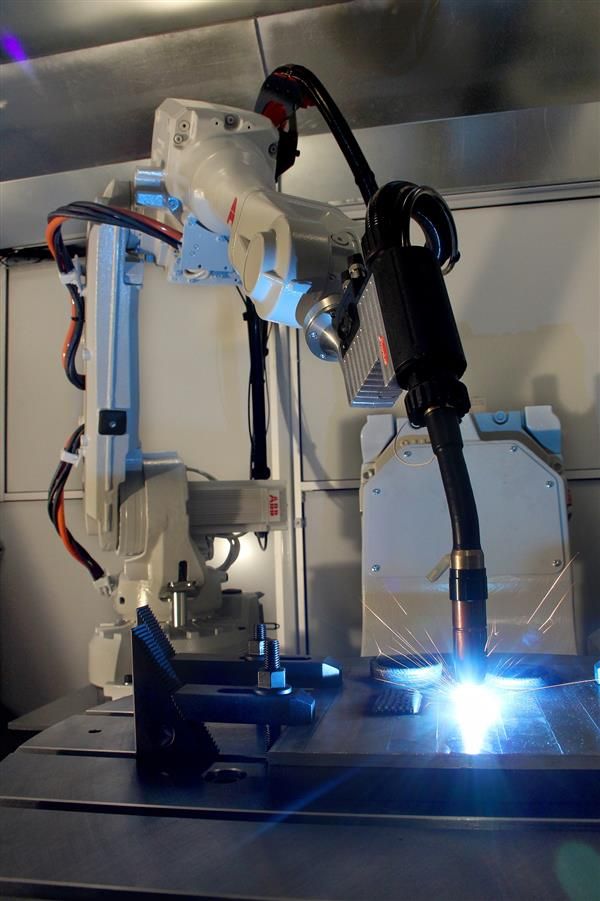

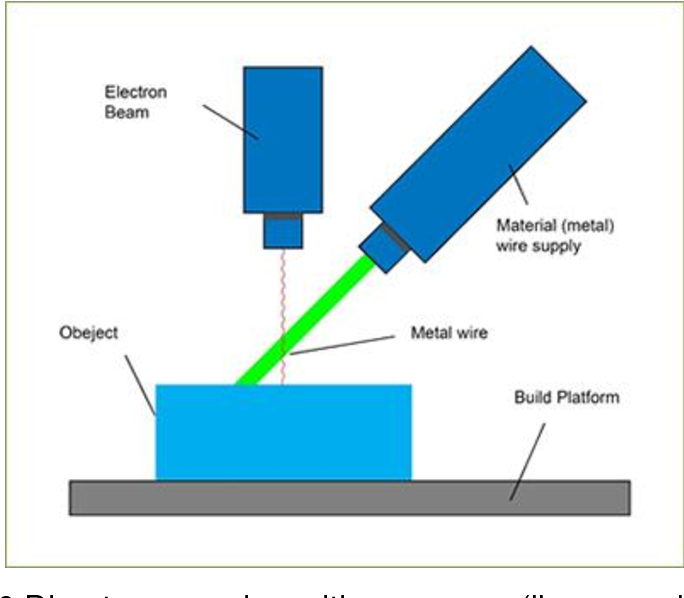

2. Directed Energy Deposition

Direct energy deposition additive manufacturing can be used with a wide variety of materials including ceramics, metals and polymers. A laser, electric arc or an electron beam gun mounted on an arm moves horizontally melting wire, filament feedstock or powder to build up material as a bed moves vertically.

Read more

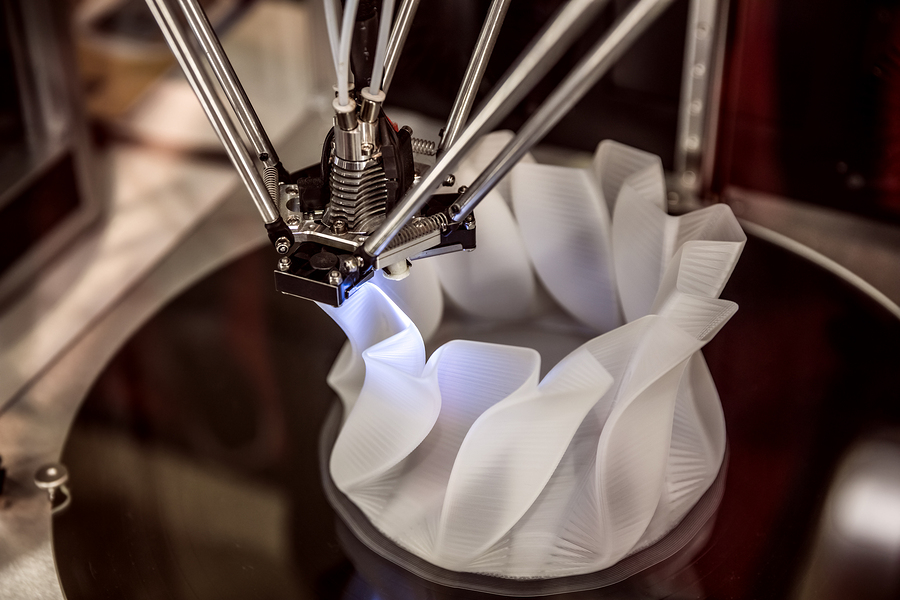

3. Material Extrusion

This common AM process uses spooled polymers which are either extruded or drawn through a heated nozzle which is mounted on a movable arm. This builds melted material layer by layer as the nozzle moves horizontally and the bed moves vertically. The layers adhere through temperature control or chemical bonding agents.

Read more

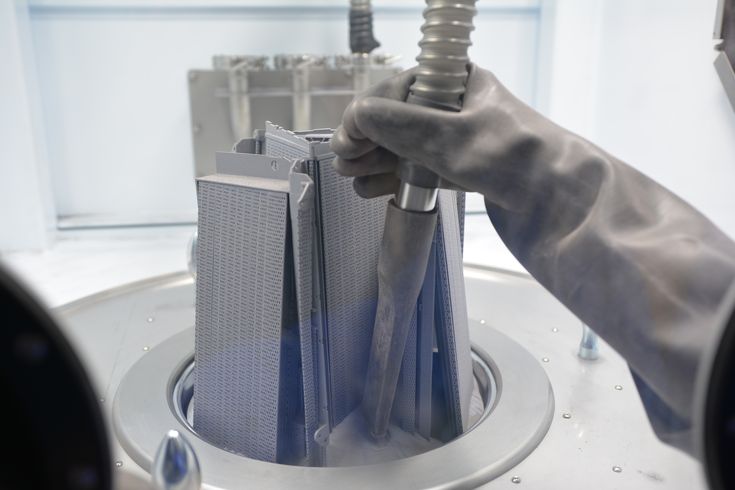

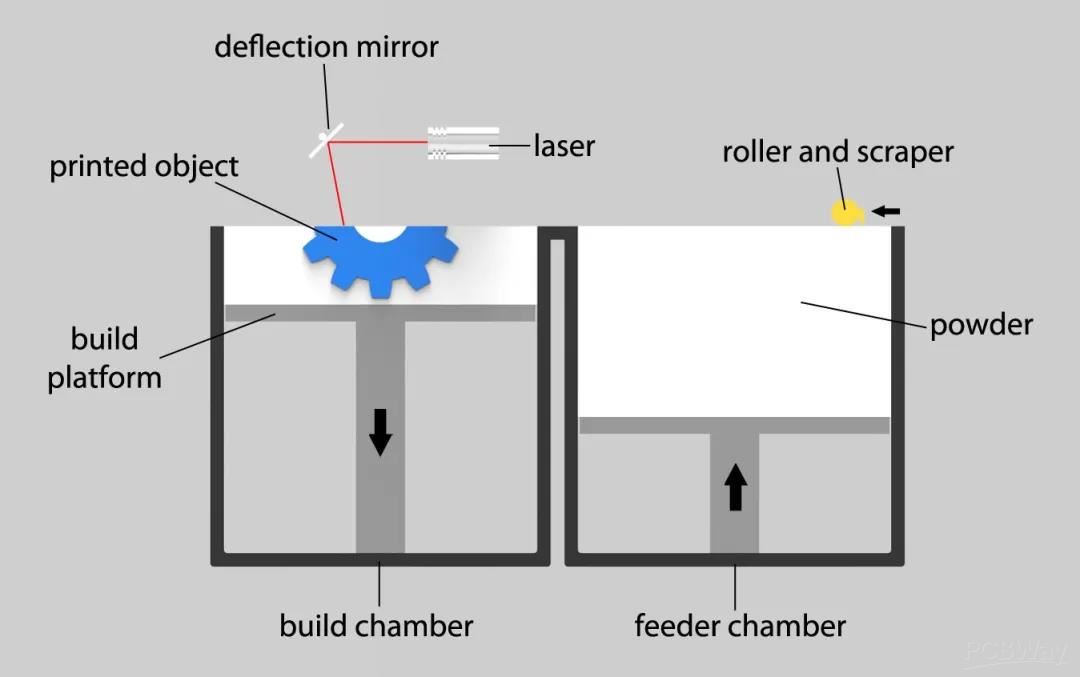

4. Powder Bed Fusion

Powder bed fusion encompasses a variety of AM techniques including direct metal laser melting (DMLM), direct metal laser sintering (DMLS), electron beam melting (EBM), selective laser sintering (SLS) and selective heat sintering (SHS). Electron beams, lasers or thermal print heads are used to melt or partially melt fine layers of material after which excess powder is blasted away.

Read more

5. Sheet Lamination

Sheet lamination can be split into two technologies; laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). Laminated object manufacturing is suited to creating items with visual or aesthetic appeal and uses alternate layers of paper and adhesive. UAM uses ultrasonic welding to join thin metal sheets; a low energy, low temperature process, UAM can be used with various metals such as aluminium, stainless steel and titanium.

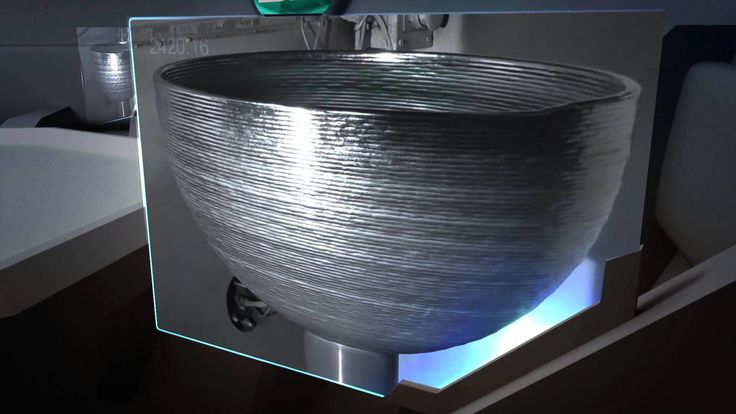

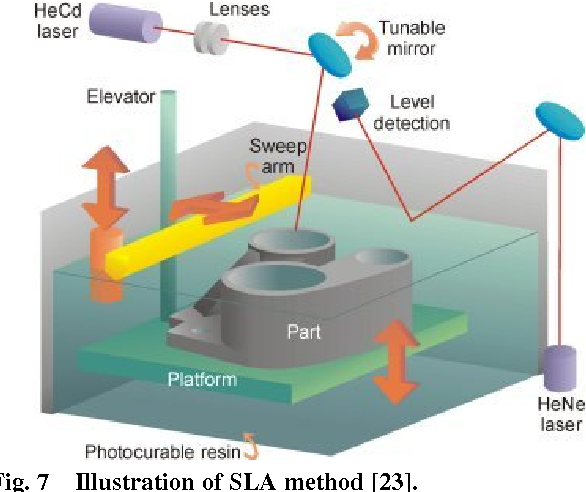

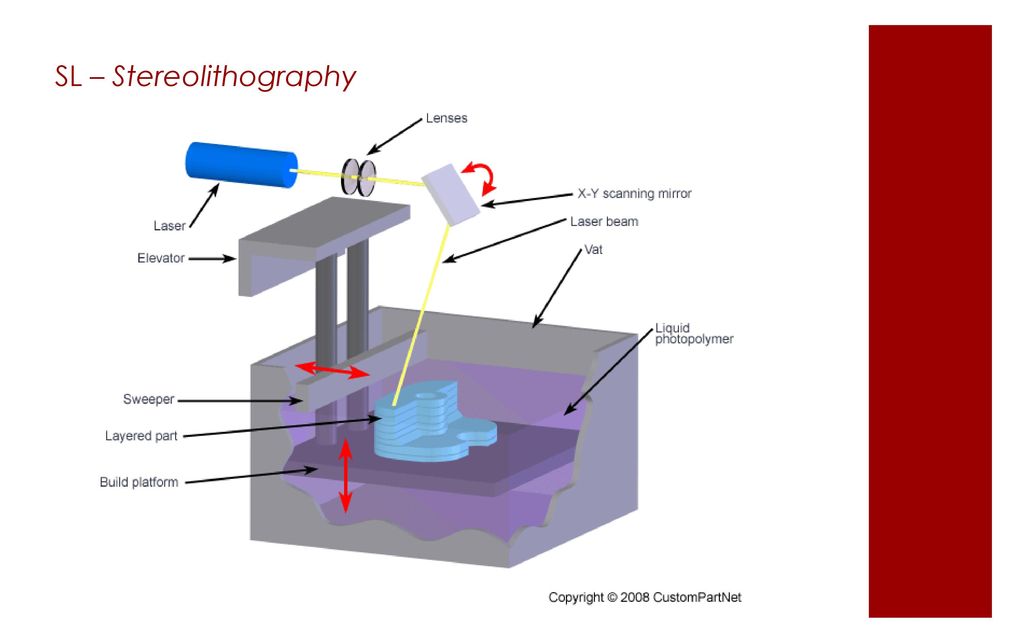

6. Vat Polymerisation

This process uses a vat of liquid resin photopolymer to create an object layer by layer. Mirrors are used to direct ultraviolet light which cures the successive layers of resin through photopolymerisation.

Mirrors are used to direct ultraviolet light which cures the successive layers of resin through photopolymerisation.

7. Wire Arc Additive Manufacturing (Now known as Directed Energy Deposition-Arc (DED-arc))

Wire arc additive manufacturing uses arc welding power sources and manipulators to build 3D shapes through arc deposition. This process commonly uses wire as a material source and follows a predetermined path to create the desired shape. This method of additive manufacture is usually performed using robotic welding equipment.

AM technologies can be broadly divided into three types.

The first of which is sintering whereby the material is heated without being liquified to create complex high resolution objects. Direct metal laser sintering uses metal powder whereas selective laser sintering uses a laser on thermoplastic powders so that the particles stick together.

The second AM technology fully melts the materials, this includes direct laser metal sintering which uses a laser to melt layers of metal powder and electron beam melting, which uses electron beams to melt the powders.

The third broad type of technology is stereolithography, which uses a process called photopolymerisation, whereby an ultraviolet laser is fired into a vat of photopolymer resin to create torque-resistant ceramic parts able to endure extreme temperatures.

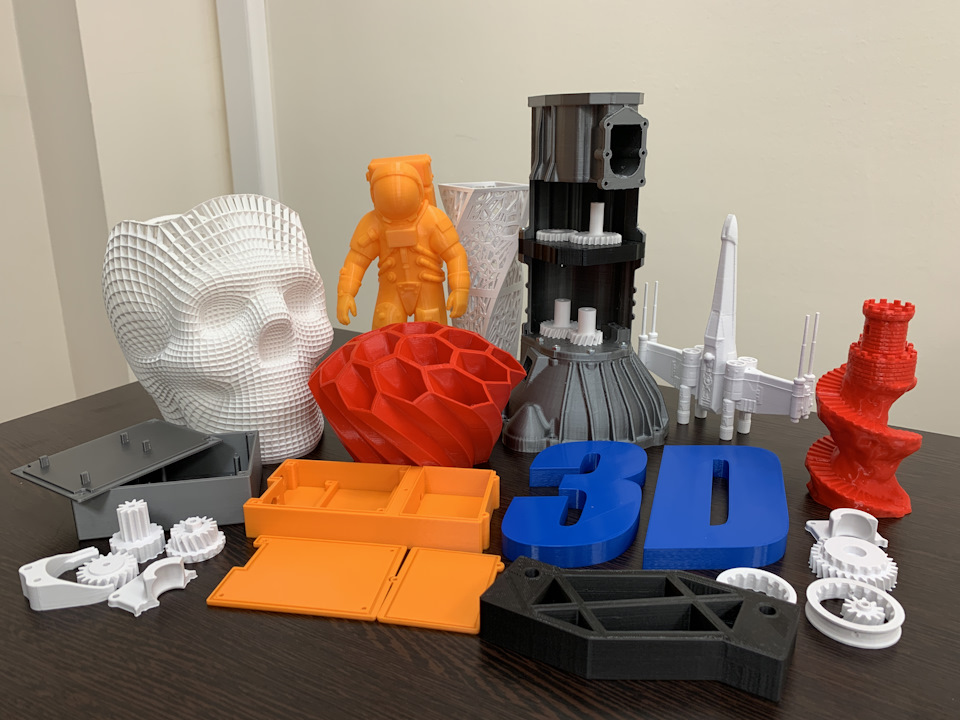

Similar to standard 3D printing, AM allows for the creation of bespoke parts with complex geometries and little wastage. Ideal for rapid prototyping, the digital process means that design alterations can be done quickly and efficiently during the manufacturing process. Unlike with more traditional subtractive manufacturing techniques, the lack of material wastage provides cost reduction for high value parts, while AM has also been shown to reduce lead times.

In addition, parts that previously required assembly from multiple pieces can be fabricated as a single object which can provide improved strength and durability. AM can also be used to fabricate unique objects or replacement pieces where the original parts are no longer produced.

TWI has one of the most definitive ranges of AM services.

Additive Manufacturing

TWI provides companies with support covering every aspect of metal additive manufacturing (AM), from simple feasibility and fabrication projects to full adoption and integration of metal AM systems.

Laser Metal Deposition

TWI has been developing LMD technology for the last ten years. For full details of our capabilities in this area, and to find out more about the process and the benefits it can bring to your business.

Selective Laser Melting

TWI has been developing selective laser melting technology for the last decade. Find out full details of our capabilities in this area and the benefits it can bring to your business.

The printing time takes in a few factors, including the size of the part and the settings used for printing. The quality of the finished part is also important when determining printing time as higher quality items take longer to produce.

AM can take anything from a few minutes to several hours or days - speed, resolution and the volume of the material are all important factors here.

There are a variety of materials used for AM, these include biochemicals, ceramics, metals and thermoplastics.

1. Biochemicals

Biochemicals used in AM include silicon, calcium phosphate and zinc while bio-inks fabricated from stem cells are also being explored. These materials are generally used for healthcare applications.

2. Ceramics

A range of ceramics are used in AM, including alumina, tricalcium phosphate and zirconia as well as powdered glass which can be baked together with adhesives to create new types of glass product.

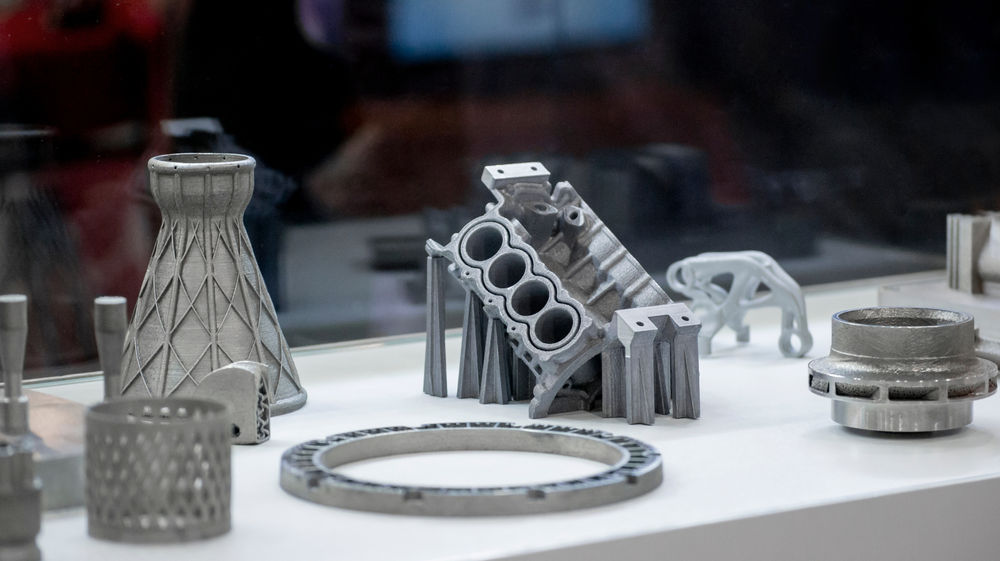

3. Metals

A wide variety of metals and metal alloys are used for additive manufacturing, including gold and silver, stainless steels and titanium amongst others. These can be made to create a variety of different metal parts, ranging from jewellery to aerospace components.

These can be made to create a variety of different metal parts, ranging from jewellery to aerospace components.

4. Thermoplastics

Thermoplastic polymers are the most commonly used of AM materials and include a variety of types with their own advantages and applications. These include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC) as well as water-soluble polyvinyl alcohol (PVA) which can provide temporary support before being dissolved.

AM is used to create a wide range of products across a growing number of industries, including:

1. Aerospace

AM is particularly suited to aerospace applications due to its weight saving capability and ability to produce complex geometric parts such as blisks.

2. Automotive

A variety of materials are widely additive manufactured for the automotive industry as they can be rapidly prototyped while offering weight and cost reductions.

3. Medical

The medical sector is finding an increasing number of applications for additively manufactured parts, especially for bespoke custom-fitted implants and devices.

FAQs

Who Invented AM?

Although the concept had been around since the 1940s, Hideo Kodama of the Nagoya Municipal Industrial Research Institute developed the earliest 3D printing manufacturing equipment in 1980, when he invented two additive methods for fabricating 3D models.

When was Additive Manufacturing Invented?

The concept of additive manufacturing dates back to 1945 and the publication of Murray Leinster’s short story, ‘Things Pass By.’ However, this early idea was not really developed until 1971 when Johannes F Gottwald patented the Liquid Metal Recorder, a continuous inkjet metal material device that could form a removable metal fabrication on a reusable surface.

This was developed further with Hideo Kodama’s invention of 3D printing equipment in 1980, although even then the funding and interest for the technology was limited. Further patents quickly followed, including for stereolithography process and Bill Masters’ Computer Automated Manufacturing Process and System in 1984.

Further patents quickly followed, including for stereolithography process and Bill Masters’ Computer Automated Manufacturing Process and System in 1984.

Which is the Oldest Additive Manufacturing Technique?

The oldest fully realised additive manufacturing technique is stereolithography, which was developed in 1987 by 3D Systems. The system works with a lithograph printer that uses UV light and a laser to solidify thin layers of liquid polymer to create three-dimensional objects.

Is Additive Manufacturing the same as 3d Printing?

3D printing is a synonym for additive manufacturing, they are two terms for the same process which both mean the same thing. However, ‘additive manufacturing’ is generally the term used by industry.

Are Companies using Additive Manufacturing?

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.

How is Additive Manufacturing different from Traditional Manufacturing?

Additive manufacturing is different from traditional manufacturing as it allows a part to be built layer-by-layer, whereas traditional manufacturing often requires a part to be made by joining separate components or by machining away unwanted material to produce the part.

Will Additive Manufacturing Replace Conventional Manufacturing?

Additive manufacturing is unlikely to fully replace conventional manufacturing due to the time taken to manufacture parts. Conventional manufacturing is still preferable for simple and easy to produce items, but additive manufacturing is becoming the chosen method for manufacturing smaller batches of more complex parts.

Why is AM Important?

AM is important for the creation of lighter, complex designs that may be too difficult or expensive to produce using traditional manufacturing techniques. Removing the need for moulds, milling or machining, AM offers a range of advantages for both prototyping and production.

How will Additive Manufacturing Change the World?

It may be something of a stretch to say that AM will ‘change the world,’ but it is already having a positive impact. It allows for the creation of complex design with less material wastage when compared to parts that require machining, as well as allowing for the creation of lighter structures. When these lighter structures are applied to aerospace or automotive applications, for example, they lead to fuel savings and the related environmental (and financial) benefits. AM also allows for the replacement of parts that may otherwise be impossible to replace, meaning that machines can be repaired rather than scrapped. In addition to these benefits, AM has also seen a level of democratisation in manufacturing, as more people set up domestic 3D printing stations to produce their own bespoke items.

What is Binder Jetting? (Definition, Pros, Cons and Uses)

Part of the wider family of additive manufacturing technologies and processes, binder jetting, or binder jet 3D printing, is regarded as the fastest additive manufacturing process for production-to-volume output of functional and highly dense precision parts.

Binder jetting uses powder materials - such as metals, composites, sand and ceramics - that are spread to create a fine powder bed in a method similar to that used in selective laser sintering (SLS). Except, where SLS uses a laser to bond successive layers of powder, binder jetting instead uses an industrial printhead that selectively deposits a liquid binding agent onto the powder. In this manner, layers of material are built up based upon a CAD file until the desired layer thickness is reached and the final 3D object is complete. Once formed, the parts need to be cured (if made from plastic) or sintered (if metal) to finish the part.

Sometimes called ‘inkjet,’ binder jetting is a cost-effective and low-energy method for fabricating parts from powdered media. Using less energy than comparable methods due to the lack of a laser in the process, binder jetting also makes use of affordable materials, while the fast production times result in low operating costs per part produced, making it ideal for precise and scalable mass production of small yet accurate objects.

Contents

Click the links below to skip to the section in the guide:

- History

- How does it works?

- Printing Parameters

- Materials

- Advantages

- Disadvantages

- What is Binder Jetting Used For?

- Is Binder Jetting Sustainable?

- Is Binder Jetting the same as Material Jetting?

- How Accurate is Binder Jetting?

- Conclusion

The printing process was originally developed at the Institute of Technology (MIT) in the early 1990s in order to to print complex parts in industrial-grade materials.

ExOne obtained the exclusive licence for the binder jet method of additive manufacturing in 1996 and launched the first commercial binder jet 3D printer for metals, the RTS-300, in 1998. Launching their first sand 3D printer, the S15, in 2002, ExOne were acquired by Desktop Metal in 2021.

Here is a step-by-step guide to the binder jetting process:

Step 1:

Firstly, a recoating blade spreads a fine layer of the powder material across the build platform.

Step 2:

A carriage of inkjet nozzles, similar to those used for 2D desktop printers, travels over the bed and selectively releases droplets of binding agent to bond the powder particles together. With full colour binder jetting, coloured inks are also deposited alongside the bonding agents during this step. Each drop is around 80 μm in diameter, allowing a good resolution to be achieved.

Step 3:

Once the first layer is complete (based upon a CAD design), the build platform moves down and the surface is recoated with more powder.

Step Four:

Repeat steps two and three until the final part is complete.

Step Five:

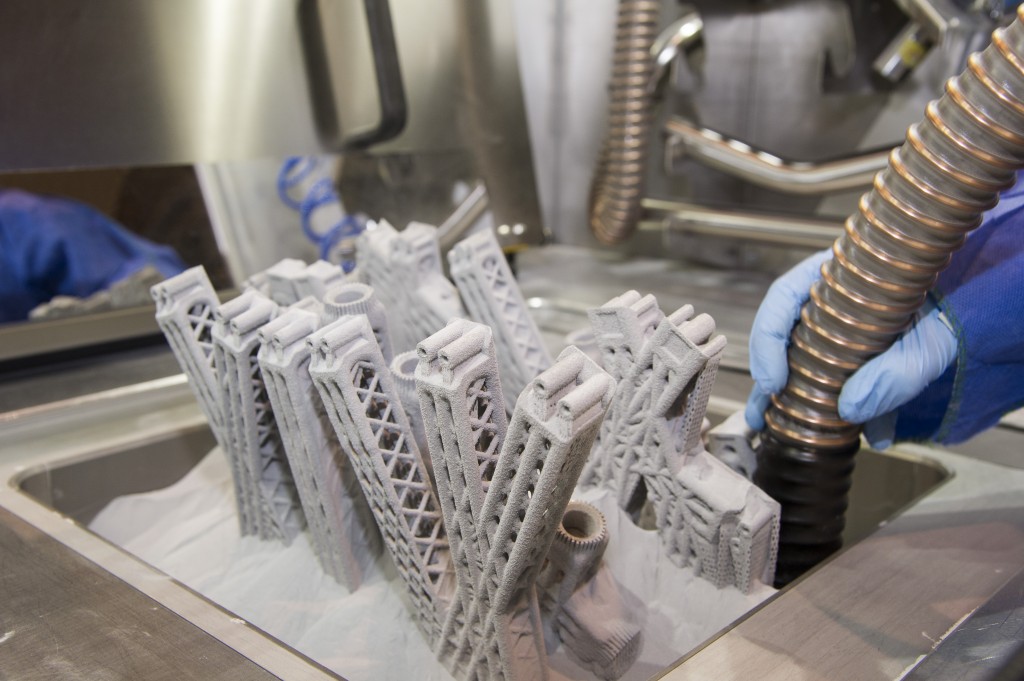

Once the build is complete, the part needs to be left to cure and gain strength ready for use, after which pressurised air can be used to remove any excess powder.

Step Six:

Some materials will require a post-processing step to finish the part. Metal binder jetting parts need heat treating (sintering, for example) or infiltrating with a metal with a low melting point, such as bronze. This step is because some materials leave the printer in what is called a ‘green’ state, which means they have poor mechanical properties and may be brittle and highly porous. Sand casting parts do not typically need a post-processing step, but full-colour parts are infiltrated with acrylic to improve the vibrancy of the colours.

This step is because some materials leave the printer in what is called a ‘green’ state, which means they have poor mechanical properties and may be brittle and highly porous. Sand casting parts do not typically need a post-processing step, but full-colour parts are infiltrated with acrylic to improve the vibrancy of the colours.

Almost all of the process parameters used in binder jetting are preset by machine manufacturers. This automation makes the process easy to use, but the typical layer height varies according to the material being used.

Full colour models typically use a 100 micron layer height while metal parts use a layer height of just 50 microns. Sand casting materials typically use a much higher layer height of between 200 and 400 microns.

Metals and ceramics are widely used materials in binder jetting applications, although it is also possible to use other powdered materials, like sand. In addition, polymers like ABS or PLA can also be used in binder jetting operations.

Metal alloys, including titanium, stainless steels and copper, are used regularly due to the their characteristics, which allow for the manufacture of strong yet light parts.

Outside of industrial applications, binder jetting type processes have even found their way into baking, with businesses like The Sugar Lab using 3D printing with granules of sugar and water to create complex culinary structures.

The primary advantage of binder jetting is that the process occurs at room temperature, meaning that the distortion of parts associated with thermal effects is not a problem. As a result, the build volume of binder jetting machines are among the largest of any of the 3D printing technologies. The largest machines (up to 2200 x 1200 x 600 mm) are generally used to produce sand casting moulds. Metal binder jetting systems are smaller (up to 800 x 500 x 400 mm) but still larger than DMSL / SLM systems, allowing for multiple parts to be built simultaneously.

Binder jetting also requires no support structures. Instead, the powder itself provides its own support as the build grows. Not only does this remove the need for post-processing to remove supports, but also allows for parts to be positioned so as to maximise build volume.

Instead, the powder itself provides its own support as the build grows. Not only does this remove the need for post-processing to remove supports, but also allows for parts to be positioned so as to maximise build volume.

Binder jetting produces metal parts with low surface roughness (as low as Ra 3 μm if a bead-blasting step is employed) compared to DMLS/SLM (Ra 12-16 μm). Such low surface roughness is beneficial for parts with internal channels and geometries that can be difficult to post process.

Binder jetting is also faster and more cost-effective than many other additive manufacturing techniques, being able to build quickly using multiple print head nozzles or holes to create several parts at once.

Despite the advantages of binder jetting, there are also some challenges associated with the process.

The main problems associated with binder jetting are accuracy and tolerance, which can be difficult to predict as a result of part shrinkage during post processing steps. For example, metal parts can shrink by up to 2% for smaller items and by more than 3% for larger items as a result of infiltration. Sintering can cause average shrinkage of 20% and also lead to warping caused by friction between the furnace plate and the bottom surface of the part. The heat used in sintering can also soften the part and cause unsupported areas to deform under their own weight. While these problems can be compensated for in the build, non-uniform shrinkage can be more difficult to account for.

For example, metal parts can shrink by up to 2% for smaller items and by more than 3% for larger items as a result of infiltration. Sintering can cause average shrinkage of 20% and also lead to warping caused by friction between the furnace plate and the bottom surface of the part. The heat used in sintering can also soften the part and cause unsupported areas to deform under their own weight. While these problems can be compensated for in the build, non-uniform shrinkage can be more difficult to account for.

Binder jetting parts may also show poor mechanical properties as a result of internal porosity. This porosity can be reduced by sintering (producing 97% dense parts) or infiltration (90% dense parts), but it can leave voids that lead to crack initiation. As a result, fracture and fatigue strengths can be an issue.

Taking account of the advantages and disadvantages of the binder jetting process, it is clear that it is more suited to some applications than others.

Binder jetting is used for the production of full-colour prototypes, low-cost metal parts and for producing large sand casting cores and moulds. Because of the low cost and fast production times, the process is even used to make accessories for the film industry and used by mobile printing systems to produce replacement parts in the field for US Army troops. Binder jetting has also been used in the production of jewellery.

Because of the low cost and fast production times, the process is even used to make accessories for the film industry and used by mobile printing systems to produce replacement parts in the field for US Army troops. Binder jetting has also been used in the production of jewellery.

Sustainability covers a range of factors, but binder jetting certainly offers some environmental benefits when compared to other manufacturing methods.

Firstly, because binder jetting uses a wide range of powdered materials, it may be possible to source them locally to reduce logistics. As with all additive manufacturing methods, binder jetting has very low levels of material wastage and low energy use compared to conventional manufacturing methods. However, the speed and high volume production possible with binder jetting reduces the carbon footprint further.

A less obvious area that needs considering are any debinding and cleaning methods used, along with the cleaning fluids that are used for these steps. Common binding agents for metal parts, like carnauba, paraffin or special polyethylene waxes, need to be selectively removed from the part before sintering. This reduces the sintering time and can now be achieved using modern, sustainable debinding fluids. Furthermore, applying these fluids to vapour degreasing techniques offers a range of additional environmental advances, including reducing the amount of power or water required for the process, without compromising performance.

Common binding agents for metal parts, like carnauba, paraffin or special polyethylene waxes, need to be selectively removed from the part before sintering. This reduces the sintering time and can now be achieved using modern, sustainable debinding fluids. Furthermore, applying these fluids to vapour degreasing techniques offers a range of additional environmental advances, including reducing the amount of power or water required for the process, without compromising performance.

There are similarities between binder jetting and material jetting, in that they both lay particles onto a build plate to create a 3D object in layers. However, material jetting involves the depositing of droplets of photosensitive resin that are then hardened with an ultraviolet light, while binder jetting deposits layers of powdered materials that are bound together with a binding agent.

The accuracy of binder jetting depends on which materials are being used for the process and whether colour is being introduced into the part.

In addition, those materials that require post processing can shrink as a result (see ‘disadvantages’ above), although this shrinkage is often taken into account during the build stage.

For example, the dimensional accuracy of metal, full colour or ceramics/sands are:

Dimensional Accuracy: | Metal: ± 2% or 0.2 mm (down to ± 0.5% or ± 0.05) Full-color: ± 0.3 mm Sand: ± 0.3 mm |

Binder jetting uses a binding agent deposited onto layers of powder. This agent acts as an adhesive to bind the powders together before more powder is added on top and bound to build up a part layer-by-layer.

The process doesn’t require the use of support structures but may require post processing, depending on the materials being used. In addition, coloured binders can be used to create full colour parts or prototypes.

Compatible with a range of materials, the exact manufacturing steps will differ accordingly. Metal parts will require sintering or annealing to properly bind the powder particles together, but sand moulds created with binder jetting will be ready for use right away. Although, in all cases, you will need to remove excess powder from the build before it is finished.

Metal parts will require sintering or annealing to properly bind the powder particles together, but sand moulds created with binder jetting will be ready for use right away. Although, in all cases, you will need to remove excess powder from the build before it is finished.

The advantages of binder jetting include less warping as it takes place at room temperature, as well as being less expensive than many other methods and able to deliver high-volume production.

However, parts tend to have only moderate mechanical properties and a high porosity, meaning that they may not be suitable for all requirements.

What is additive technology? The most important thing about 3D printing

Basics of 3D

Author: Semyon Popadyuk

Author: Semyon Popadyuk

What is additive manufacturing | Processes | 3D printing technologies | Consumables | Applications | Additive manufacturing in Russia

Additive manufacturing is the process of combining materials to create objects based on 3D model data, usually in layers, as opposed to the subtractive method and the molding method. Terms such as additive manufacturing, additive processes, additive methods, additive layer-by-layer manufacturing, layer-by-layer manufacturing, freeform solids manufacturing, and freeform manufacturing have been used at various times. nine0003

Terms such as additive manufacturing, additive processes, additive methods, additive layer-by-layer manufacturing, layer-by-layer manufacturing, freeform solids manufacturing, and freeform manufacturing have been used at various times. nine0003

In this dynamic industry, new terms are rapidly emerging. 3D printing, according to the ISO/ASTM 52900 standard, is the production of objects by applying material with a printhead, nozzle, or other printing technology. In the past, the term was associated with low cost, low productivity machines. However, this is no longer the case: the terms "additive manufacturing" and "3D printing" mean the same thing.

"Additive Manufacturing" is an official industry term approved by the ASTM and ISO standards bodies, but "3D printing" is more common and has become the de facto standard. It is especially widely used in the media, the terminology of startups, investors and other communities. nine0003

Can 3D technology help you optimize production in your organization? Order iQB Technologies services: expert consultation, training, test 3D printing/3D scanning, equipment demonstration, site visits and others:

One of the advantages of additive technologies is the ability to create objects of complex shape and structure with high accuracy.

Processes

Additive manufacturing (AM) includes seven different processes. Products can be created in layers by: nine0003

- extrusion,

- spray (jet spray),

- UV Curing,

- lamination,

- fusion materials.

3D printing technologies

Modern FDM installations, such as the Discovery 3D Printer, allow you to print one-piece large-sized products up to 2.5 m

The main technologies used in the creation of products on additive installations: nine0003

- SLM (Selective Laser Melting) - selective laser melting of metal powder according to mathematical CAD models using an ytterbium laser;

- FDM (Fused Deposition Modeling) - a method of layer-by-layer deposition using a plastic thread or granules;

- SLA (Laser Stereolithography) - laser stereolithography, based on the layer-by-layer curing of a liquid material under the action of a laser;

- DLP (Digital Light Processing) - a stereolithographic 3D printing method using digital LED projectors; nine0028

- LCD (Liquid Crystal Display) - another type of photopolymer printing, when the photopolymer resin is illuminated by an LED UV matrix through an LCD screen mask;

- SLS (Selective Laser Sintering) - selective laser sintering under laser beams of particles of powdered material until a physical object is formed according to a given CAD model;

- Binder Jetting - layer-by-layer bonding of a composite powder (sand, polymer, metal, etc.

) with a binder; nine0028

) with a binder; nine0028 - MJP (MultiJet Printing) - multi-jet modeling with photopolymer or wax;

- CJP (ColorJet Printing) is a full-color 3D printing technology by gluing a special gypsum-based powder.

Consumables

The main materials used in additive processes are:

- thermoplastics in the form of filaments or granules;

- UV and photocurable liquid photopolymers; nine0028

- ceramic-filled liquid photopolymers;

- polystyrene powder;

- glass-filled, carbon-filled and metal-filled polyamides in powder form;

- wax;

- gypsum powder;

- sand in powder form;

- metal alloys in powder form, etc.

Applications of additive technologies

Additive technologies are used to create physical models, prototypes, samples, tooling and production of plastic, metal, ceramic, glass, composite and biomaterial components. The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners. nine0003

The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners. nine0003

Design and manufacturing enterprises use AP for the manufacture of consumer, industrial, medical and military products, and that's not all. Cameras, mobile phones, engine parts, car interiors, aircraft parts and components, machine tools and medical implants are just the beginning of the vast list of additive manufacturing products.

AM simplifies and speeds up the product development process. Companies are turning to additive technologies to reduce production time, improve product quality and reduce costs. As a visualization tool, 3D printing helps businesses determine the likelihood of creating defective or unsatisfactory products. In addition, methods, processes and systems for tooling are being developed. nine0003

3D printing is actively used in the aerospace, automotive, oil and gas industries, shipbuilding, medicine, jewelry and many other industries.

3D printing is actively used to improve the quality of injection molding tooling. In some areas, AM is used to obtain results that are unattainable using conventional machines. In other industries, AM is being used to create fabrication and assembly tools such as fixtures, fixtures, templates, and guides for drilling and cutting. nine0003

3D printing has a big impact on the production of many products. Enterprises, large and small, successfully apply technology to the production of finished products. According to experts, direct manufacturing will become the largest application area for additive technologies. This technology can affect production more than other traditional methods.

The industry continues to evolve with new methods, technologies, materials, applications and business models emerging. The geography and scope of industrial application of AP is expanding. Additive technologies have already had a huge impact on the development of design and manufacturing; in the future, their role will increase more and more. nine0003

The geography and scope of industrial application of AP is expanding. Additive technologies have already had a huge impact on the development of design and manufacturing; in the future, their role will increase more and more. nine0003

Additive manufacturing in Russia

The laboratory of additive technologies of Samara University performs unique metal 3D printing projects using the SLM Solutions installation / Photo: Ekaterina Vinokurova

In Russia, the 3D technology market is quite young, but it is already showing dynamic growth (according to Rosnano, about 30% per year). More and more companies are realizing the need to apply additive methods in manufacturing and research. There are organizations that are actively involved in the certification of materials and are already testing 3D printers of their own production. At the enterprises there are laboratories for the development and implementation of 3D solutions in certain sections of the technological cycle. nine0003

nine0003

Today, we are not talking about a complete transition to additive technologies - so far they are able to effectively complement classical processes or replace them at some particular stage of the cycle. However, industry experts argue that in the near future, additive manufacturing will become an integral part of the technological processes in the enterprise.

Want to learn more about 3D technology? Subscribe to our blog and get advice from iQB Technologies experts: +7 (495) 223-02-06.

Article published on 08/16/2017, updated on 12/12/2022

What are additive technologies

The use of new technologies is the main trend of recent years in any area of industrial production. Every enterprise in Russia and the world strives to create cheaper, more reliable and high-quality products using the most advanced methods and materials. The use of additive technologies is one of the clearest examples of how new developments and equipment can significantly improve traditional production. nine0003

nine0003

- What are additive technologies

- Advantages

- Technologies and materials

- Additative technologies in Russia

- What are additive technologies

- Advantages

- Additive technologies in Russia

-

Improved finished product properties. Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining.

-

Great savings in raw materials.

Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%. nine0003

Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%. nine0003 -

Ability to manufacture products with complex geometry. Equipment for additive technologies makes it possible to produce items that cannot be obtained in any other way. For example, a part within a part. Or very complex cooling systems based on mesh structures (this cannot be obtained either by casting or stamping).

-

Mobility of production and acceleration of data exchange. No more drawings, measurements and bulky samples. At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin. nine0003

-

Great savings in raw materials. Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%.

-

Ability to manufacture products with complex geometry. Equipment for additive technologies makes it possible to produce items that cannot be obtained in any other way. For example, a part within a part. Or very complex cooling systems based on mesh structures (this cannot be obtained either by casting or stamping). nine0003

-

Mobility of production and acceleration of data exchange. No more drawings, measurements and bulky samples.

At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin.

At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin.

. ?

Additive manufacturing technologies make it possible to produce any product in layers based on a 3D computer model. This process of creating an object is also referred to as "growing" due to the gradualness of the production. If in traditional production at the beginning we have a workpiece, from which we cut off everything superfluous in bulk, or we deform it, then in the case of additive technologies, a new product is built from nothing (more precisely, from an amorphous consumable material). Depending on the technology, an object can be built from the bottom up or vice versa, receiving different properties. nine0003

The general scheme of additive manufacturing can be represented as the following sequence:

The first additive manufacturing systems worked mainly with polymeric materials. Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

What is additive technology?

Additive manufacturing technologies make it possible to produce any product in layers based on a 3D computer model. This process of creating an object is also referred to as "growing" due to the gradualness of the production. If in traditional production at the beginning we have a workpiece, from which we cut off everything superfluous in bulk, or we deform it, then in the case of additive technologies, a new product is built from nothing (more precisely, from an amorphous consumable material). Depending on the technology, an object can be built from the bottom up or vice versa, receiving different properties. nine0003

nine0003

The general scheme of additive manufacturing can be represented as the following sequence:

The first additive manufacturing systems worked mainly with polymeric materials. Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

Advantages of additive technologies

Schematically, the differences between conventional and additive manufacturing can be depicted as follows:

Advantages of additive technologies

Improved finished product properties. Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining. nine0003

Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining. nine0003

Schematically, the differences between conventional and additive manufacturing can be depicted as follows:

Additive manufacturing technologies

Additive manufacturing is the process of growing products on a 3D printer from a CAD model. This process is considered innovative and is opposed to the traditional ways of industrial production.

Today, the following additive manufacturing technologies can be distinguished:

FDM (Fused deposition modeling)

Layer-by-layer construction of a product from a melted plastic thread. It is the most widely used 3D printing method in the world, and is used by millions of 3D printers, from the cheapest to industrial 3D printing systems. FDM printers work with various types of plastics, the most popular and affordable of which is ABS. Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

See all FDM printers >>

Additive manufacturing technologies

Additive manufacturing is the process of growing products on a 3D printer from a CAD model. This process is considered innovative and is opposed to the traditional ways of industrial production.

Today, the following additive manufacturing technologies can be distinguished:

FDM (Fused deposition modeling)

Layer-by-layer construction of a product from a melted plastic thread. It is the most widely used 3D printing method in the world, and is used by millions of 3D printers, from the cheapest to industrial 3D printing systems. FDM printers work with various types of plastics, the most popular and affordable of which is ABS. Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

See all FDM printers >>

FDM example, ULTEM material 9085

FDM example, PEEK material

FDM example, ABS material

FDM example, ULTEM material 9085

3 Example

3 FDM printing, PEEK material

Example of FDM printing, ABS material

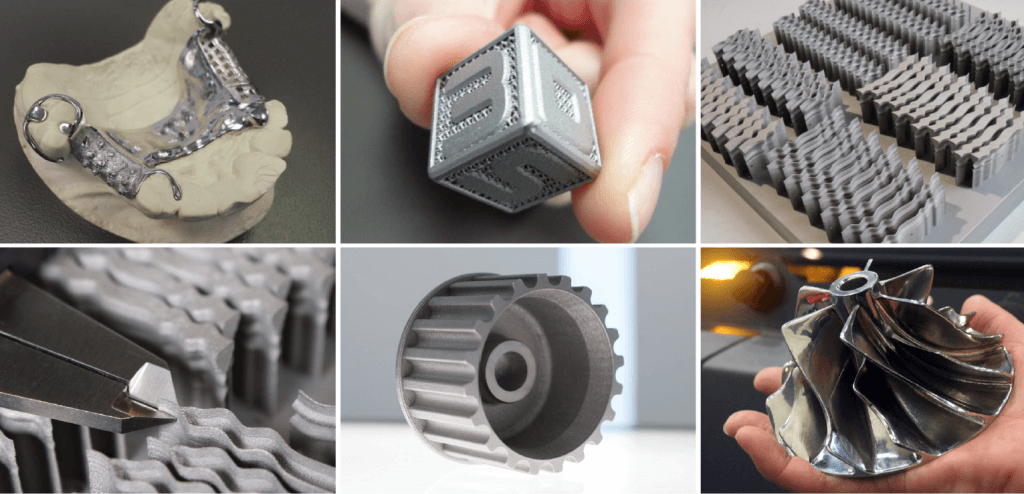

SLM (Selective laser melting)

Selective laser melting of metal powders. The most common metal 3D printing method. Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

See all SLM printing systems >>

SLM (Selective laser melting)

Selective laser melting of metal powders. The most common metal 3D printing method. Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

See all SLM printing systems >>

SLM printing example, material - steel

SLM printing example, material - titanium alloy

SLM printing example, material - aluminum

SLM printing example, material - steel

SLM printing example, titanium alloy material

SLM printing example, aluminum material

SLA (short for Stereolithography)

Laser-assisted stereolithography, the curing of a liquid photopolymer material by laser action. This additive digital manufacturing technology is focused on the manufacture of high-precision products with various properties. One of the leading manufacturers of professional SLA printers is the Chinese company UnionTech. nine0003

nine0003

See all SLA printers >>

SLA (short for Stereolithography)

Laser-assisted stereolithography, the curing of a liquid photopolymer material by laser action. This additive digital manufacturing technology is focused on the manufacture of high-precision products with various properties. One of the leading manufacturers of professional SLA printers is the Chinese company UnionTech.

See all SLA printers >>

SLS (Selective laser sintering)

Selective laser sintering of polymer powders. Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

See all SLS printing systems >>

Rapid prototyping technologies

Rapid prototyping technologies should be placed in a separate category. These are 3D printing methods designed to obtain samples for visual evaluation, testing, or master models for creating molds. nine0003

nine0003

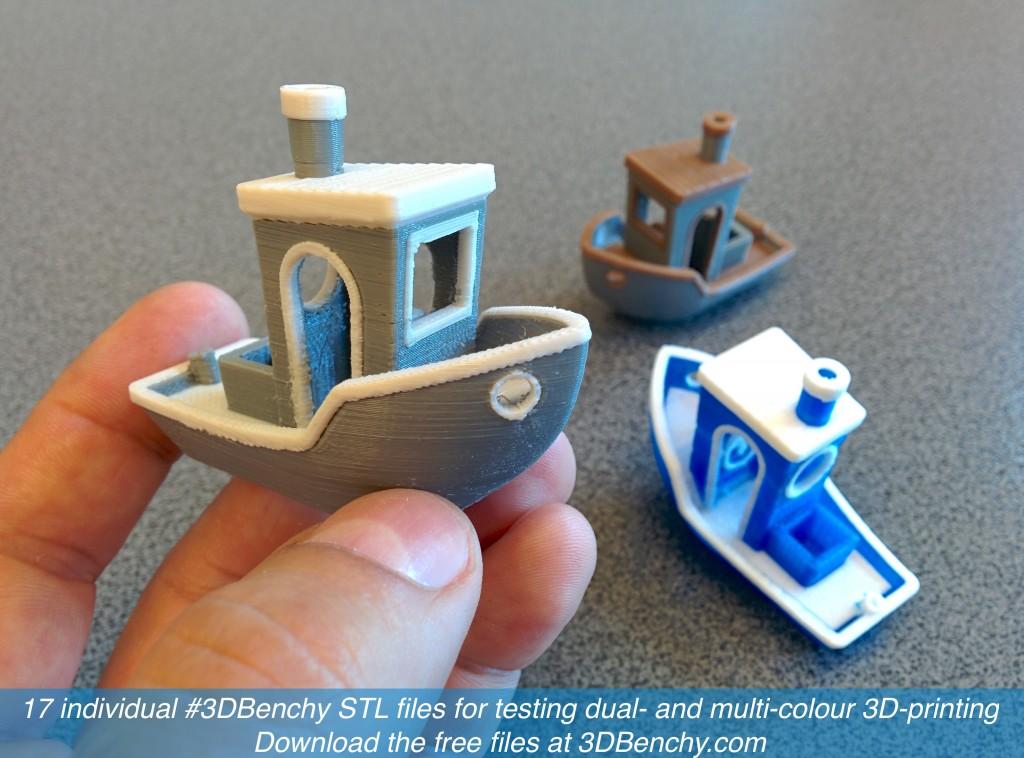

MJM (Multi-jet Modeling) - multi-jet modeling using photopolymer or wax material. This technology makes it possible to produce burnt or smelted master models for casting, as well as prototypes of various products. Used in 3D Systems ProJet series 3D printers.

PolyJet - Liquid photopolymer curing with UV light. It is used in the Objet line of 3D printers from the American company Stratasys. The technology is used to obtain prototypes and master models with smooth surfaces. nine0003

CJP (Color jet printing) - layer-by-layer distribution of the adhesive on powdered gypsum material. Gypsum 3D printing technology is used in the ProJet x60 series 3D printers (formerly called ZPrinter). To date, this is the only industrial technology for full-color 3D printing. With its help, bright colorful prototypes of products are made for testing and presentations, as well as various souvenirs, architectural models.

SLS (Selective laser sintering)

Selective laser sintering of polymer powders. Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

See all SLS printing systems >>

Rapid prototyping technologies

Rapid prototyping technologies should be placed in a separate category. These are 3D printing methods designed to obtain samples for visual evaluation, testing, or master models for creating molds. nine0003

MJM (Multi-jet Modeling) - multi-jet modeling using photopolymer or wax material. This technology makes it possible to produce burnt or smelted master models for casting, as well as prototypes of various products. Used in 3D Systems ProJet series 3D printers.

PolyJet - Liquid photopolymer curing with UV light. It is used in the Objet line of 3D printers from the American company Stratasys. The technology is used to obtain prototypes and master models with smooth surfaces. nine0003

nine0003

CJP (Color jet printing) - layer-by-layer distribution of the adhesive on powdered gypsum material. Gypsum 3D printing technology is used in the ProJet x60 series 3D printers (formerly called ZPrinter). To date, this is the only industrial technology for full-color 3D printing. With its help, bright colorful prototypes of products are made for testing and presentations, as well as various souvenirs, architectural models.

Additive technologies in Russia

Every year, domestic enterprises are increasingly using 3D printing systems for industrial and scientific purposes. Additive manufacturing equipment, intelligently integrated into the production chain, allows not only to reduce costs and save time, but also to start performing more complex tasks.

Globatek 3D has been supplying the latest 3D printing and 3D scanning systems to Russia since 2010. The equipment installed by our specialists works in the largest universities (MGTU named after Bauman, MEPhI, MISIS, Privolzhsky, SSAU and others) and industrial enterprises, institutions of the military-industrial complex and the aerospace industry. nine0003

nine0003

Report of the Rossiya TV channel on the use of the SLM 280HL installed by Globatek 3D specialists at the Samara State Aerospace University:

Additive technologies in Russia

Every year domestic enterprises increasingly use 3D printing systems for industrial and scientific purposes. Additive manufacturing equipment, intelligently integrated into the production chain, allows not only to reduce costs and save time, but also to start performing more complex tasks. nine0003

Globatek 3D has been supplying the latest 3D printing and 3D scanning systems to Russia since 2010. The equipment installed by our specialists works in the largest universities (MGTU named after Bauman, MEPhI, MISIS, Privolzhsky, SSAU and others) and industrial enterprises, institutions of the military-industrial complex and the aerospace industry.

Rossiya TV channel report on the use of SLM 280HL installed by Globatek 3D specialists at Samara State Aerospace University:

GLobatek 3D experts help professionals from various fields to choose 3D equipment that will most effectively solve the problems facing the enterprise.