3D printer minneapolis

3D Printing Service for Minneapolis, Minnesota

CapabilitiesCustom Online 3D Printing ServiceMinnesotaMinneapolis

High Quality Minneapolis, Minnesota 3D Printing | 60+ Materials Available

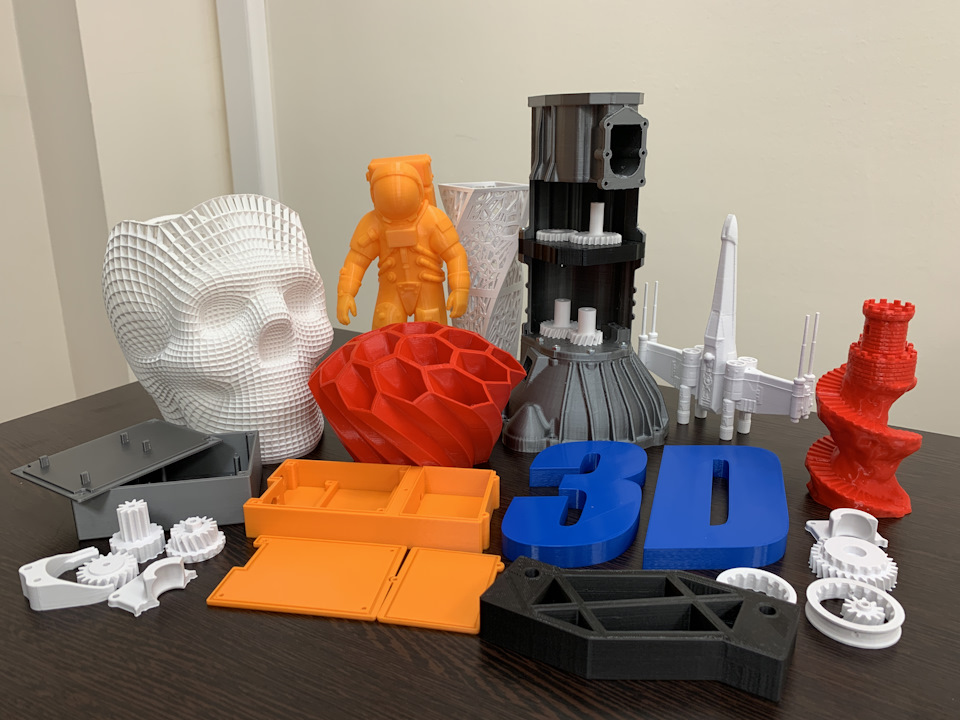

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Minneapolis, Minnesota 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

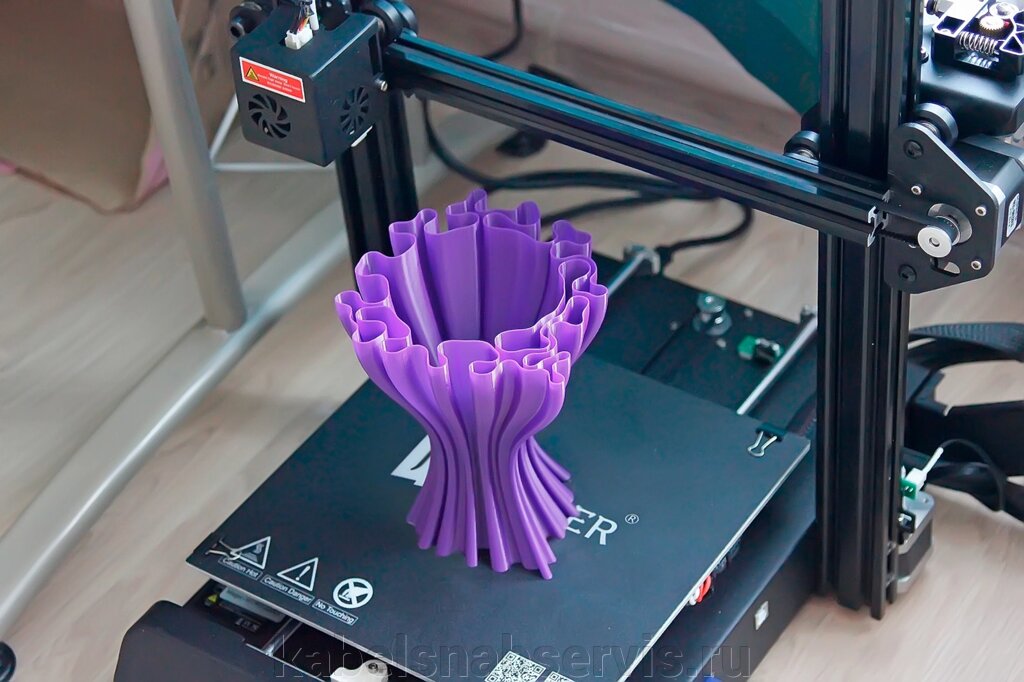

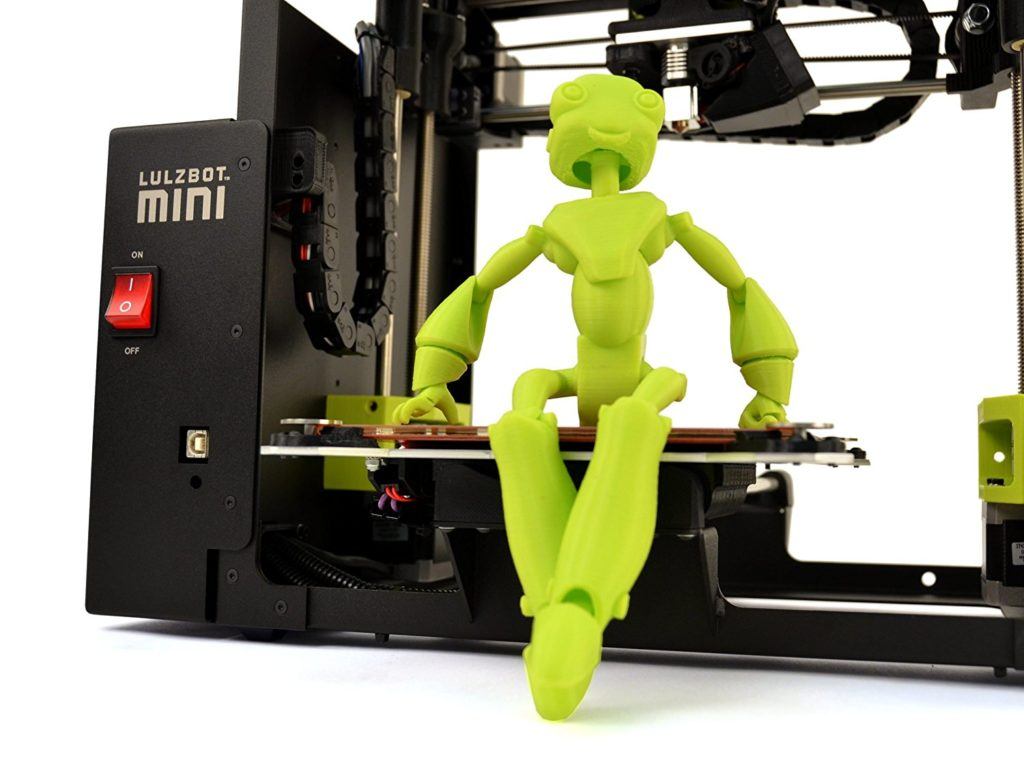

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Minneapolis, Minnesota

Saint Paul

MinnesotaDuluth

MinnesotaSioux Falls

South DakotaAmes

IowaFargo

North DakotaCedar Rapids

IowaMadison

WisconsinDes Moines

IowaIowa City

IowaGreen Bay

WisconsinMoline

IllinoisOmaha

NebraskaAurora

IllinoisLincoln

NebraskaEvanston

IllinoisPeoria

IllinoisChicago

IllinoisGrand Rapids

MichiganKansas City

MissouriSouth Bend

Indiana

Ready to start making custom 3D printed parts?

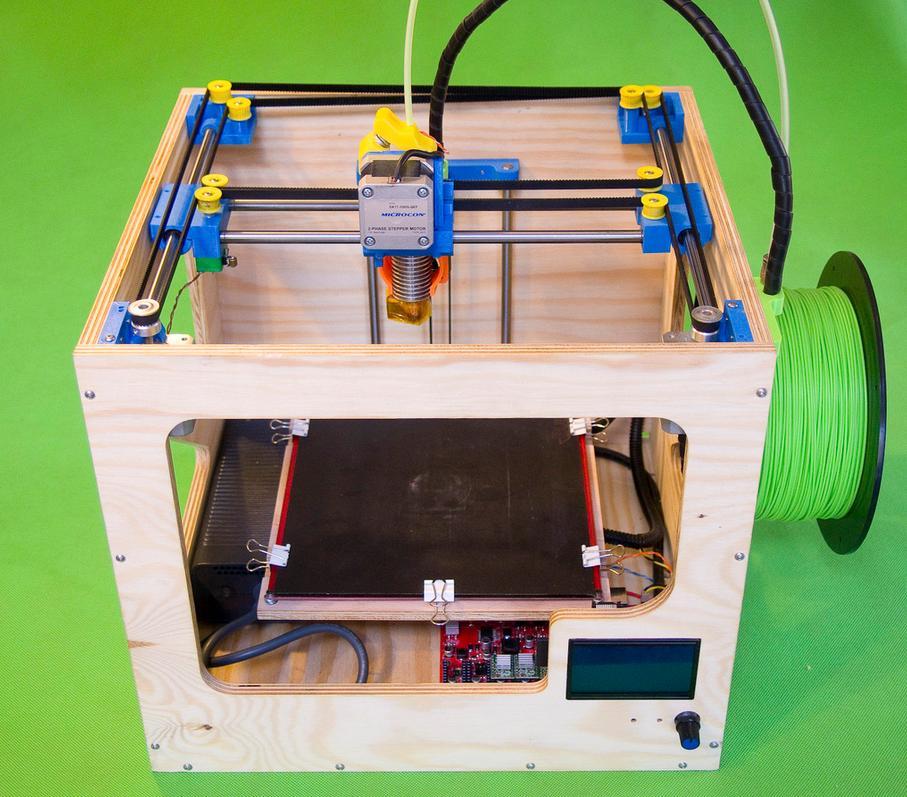

3D Lab :: Twin Cities Maker

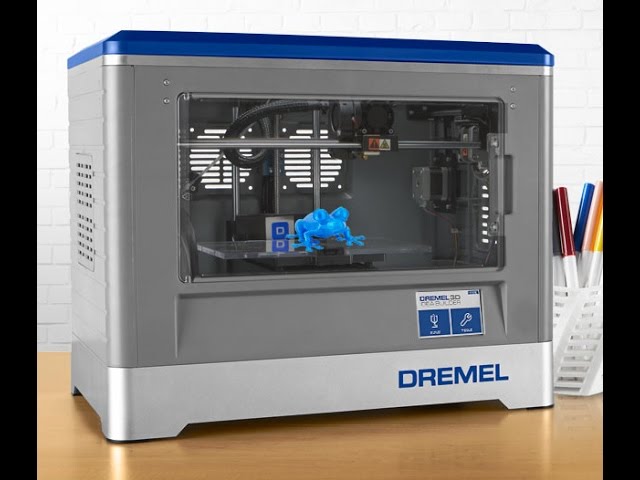

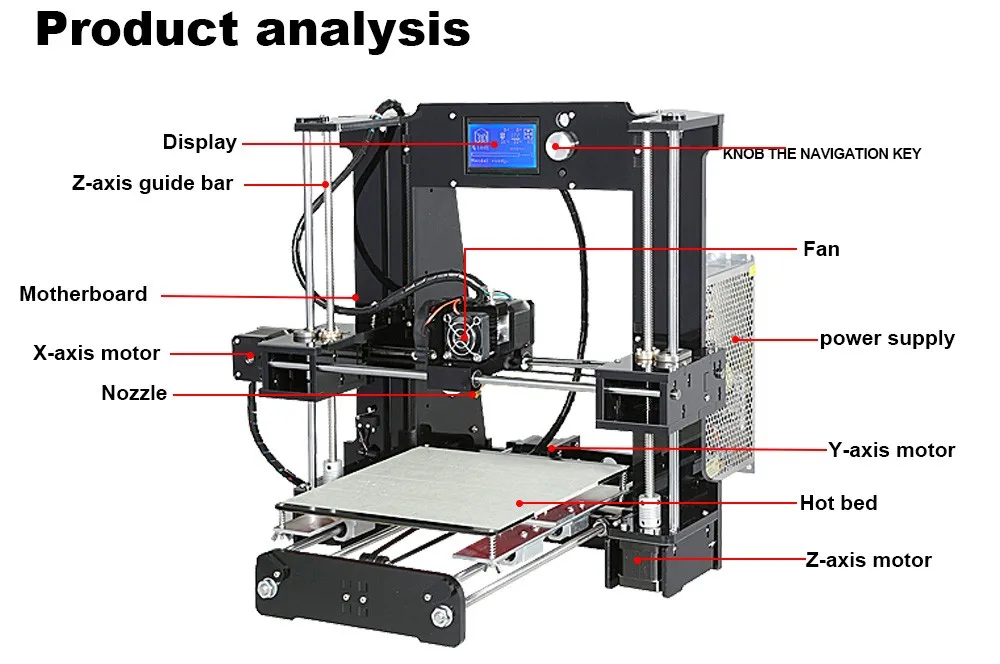

The 3D Lab contains all of our various 3D printers.

When is lab orientation?

The third Saturday or every month at 9:30am unless there is a conflicting holiday then it will be moved to an adjacent weekend. Check the classes page for the next class.

I cannot make that time. Is there another way to get trained?

Yes, but this is reserved for people who cannot make the normal class time work. We try to limit the number of one-on-one trainings because it takes a lot of volunteer time and it is more effective to train groups at once at the monthly class. Please post in #dept-3d-lab on slack to request one-on-one training if you cannon make the normal class.

What tools in the lab need training to use?

All of them. 3D printers have a lot of moving and, frankly, dangerous parts. Even if you are a seasoned 3D printing veteran you still need to go through orientation to make sure you know the ins and outs of our particular machines.

A machine is broken. What should I do?

Clogged nozzle? Something making a bad sound? Things happen. Please label the machine with an orange “Borked” tag and post in #dept-3d-lab on slack with what is happening so we can get it up and running again.

Please label the machine with an orange “Borked” tag and post in #dept-3d-lab on slack with what is happening so we can get it up and running again.

Can I use my own filament in the lab machines?

Absolutely. You are free to use your own materials in the lab printers whenever you like but there are a few ground rules.

- Only use approved materials

- Unload and store the filament that was loaded into the machine properly

- When you are done using the printer reload the material that was in the printer before

you started.

How do I use <insert machine name here>?

Orientation. Or, If you have already been through orientation and this is some new arrival, track down a 3D Lab manager or email us at [email protected] and we can set up a time to get you checked off on the new equipment if it needs special training.

Who takes care of the lab’s machines?

It is everyone who uses the 3D printers responsibility to maintain the machines. This is a shared work space and these are shared tools that we all need to care for. The 3D Lab managers will do routine maintenance as needed and deal with major issues as they arise but everyone is allowed and encouraged to help out.

This is a shared work space and these are shared tools that we all need to care for. The 3D Lab managers will do routine maintenance as needed and deal with major issues as they arise but everyone is allowed and encouraged to help out.

How can I help out?

Talk to one of the 3D Lab managers or email us at [email protected] There are always projects that need to get done. If you want to help out we would love and be grateful for any assistance.

Can I teach a class of some kind in the 3D Lab?

Email [email protected] and cc [email protected]. We would love to hear what you have to teach and help you make it happen.

How can I stay up to date with all the latest 3D Lab news?

Sign up for the Slack and/or mailing list.

How do I contact you?

The #dept-3d-lab Slack channel or by email at [email protected].

Minneapolis Azur Lane 3D File・3D Printer Design Download・Cults

NCR Ranger - Fallout New Vegas

19. 01 €

01 €

Ash Williams

19.01 €

Valkyrie - Apex Legends

19.01 €

Midna - The Legend of Zelda

19.01 €

nine0003 Necron Sylvanas - WoW x Warhammer 40k19.76 €

Sailor Moon Sister of Battle - Sailor Moon x Warhammer 40k

19.01 €

Ciri & Geralt - The Witcher 3

14.26 €

Ermac - Mortal Kombat

19.01 €

Best Files for 3D Printers in the Art Category nine0037

Steven Universe Pumpkin

Free

Philippine Jeepney

0. 62 €

62 €

Dragon Ball GT Baby

19.01 €

Stegosaurus (light seal without support)

0.50 €

Mew (pokemon)

Free

Lion face II wall sculpture

1,50 €

Hollow Knight - 3D Print Model

5.67 €

Gibson Keyring Collection | Gibson keyring collection

2,50 €

Art category bestsellers

Cute fox with flexi print

2.38 €

Cute sloth with flexi print

2,80 €

Kangaroo and Joey on flexi printer

2,80 €

Annoying gift box

2. 85 €

85 €

Cute turtle with flexi print

1,85 €

nine0003 Articulated toy "Rattlesnake", body with prints, head with latches, cute flexi3,75 €

CHRISTMAS TREE WITH LEGS

2,89 €

Leopard gecko ball joint toy, imprinted body, snap head, cute flex

3,31 €

Flexi-print Imperial Dragon

3,75 €

nine0003 CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE2,80 €

Jointed toy "Python snake", body with prints, head with latches, cute flexi

3,75 €

Crystal Dragon, Articulating Animal Flexi Wiggle Pet, Print on the Spot, Fantasy

3,80 €

Cute circus baby elephant with flexi print

€2. 80

80

Bearded Dragon toy, body with imprint, head with latch, cute flexi

3,31 €

Biting dragon

3 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3.31 €

Do you want to support Cults? nine0037

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

MIS Implant System Prosthetics for CAD/AM

CAD/CAM Prosthetics

For implants with hexagonal compound

Titanium bases for CAD/CAM

Titanium premiums

Scanned abutments

Digital Library

Digital analogues for 3D printers 9000,

Titanium bases for CAD/CAM (Ti BASE) 9000 9020

| nine0204 | for CAD/CAM with |

| MN-TB002 |

| | MN-TBC15

|

| MN-FTB15 |

| | MN-TBC30 | | MN-FTB30 |

| | GI-SCh21 | ||

| Standard Orthopedic Platform |

| MD-TB001 |

| MD-TB002 Titanium base for CAD/CAM without anti-rotation component Shoulder height - 0.5 mm | ||

|

| MD-TBC15 Titanium base for CAD/CAM with anti-rotation component Shoulder height - 1.5 mm |

| nine0203 MD-FTB15 ||

|

| MD-TBC30 Titanium base for CAD/CAM with anti-rotation component. Step height - 3 mm |

| MD-FTB30 Titanium base for CAD/CAM without anti-rotation component .  Step height - 3 mm | |

|

| GI-SCh21 Burn-out plastic cap direct scan | |||

| nine0203 |

| Wide orthopedic platform |

| MW-TB001 | MW-TB002 | ||

| MW-TBC15 | MW-FTB15 | ||

| MW-TBC30 | MW-FTB30 | ||

|

| GI-WCh21 | ||

EZ-Base titanium bases

| MN-EZB15 |

| MN-E0160 * | |

|

| |||

| nine0203 | |||

| MD-EZB15 |

| MD-E0220 * | |

|

| |||

| MW-EZB15 | nine0204 | MD-E0220 * | |

* Screws MD-E0220 and MN-E0160 are used only with special screwdrivers (below).

** Screws MD-E0220 and MN-E0160 are included with EZ-BASE Abutments.

Instrumentation for EZ-BASE 9 Abutments0006

|

|

|

| |

| MT-ELR10 | MT-ELM10 | ||

| nine0005 | |||

| MT-ESR10 Short screwdriver for key | MT-ESM10 |

| Download EZ-Base Brochure >>> |

Titanium blanks (premiums) for CAD/CAM

| Narrow orthopedic platform |

|

| MN-MAB10 Implant analogue (holder for milling machine) NT TRADING | ||

| MN-AGT12 Titanium premium CAD/CAM Diameter - 12 mm AMANN GIRRBACH |

| Standard Orthopedic Platform |

|

| ||

| MD-IB091 Premium Titanium CAD/CAM Diameter - 9mm NT TRADING | MD-IB121 Premium Titanium CAD/CAM Diameter - 12mm NT TRADING | MD-MAB10 Implant analog (holder for milling machine) NT TRADING |

| nine0209 | ||

| MD-AGT12 Premium Titanium CAD/CAM Diameter - 12 mm |

| Wide orthopedic platform |

|

| ||

| MW-IB091 Premium Titanium CAD/CAM Diameter - 9mm NT TRADING | MW-IB121 Premium Titanium CAD/CAM Diameter - 12mm NT TRADING | MW-MAB10 Implant analogue (holder for milling machine) NT TRADING |

| nine0203 | ||

| MW-AGT12 Premium Titanium CAD/CAM Diameter - 12mm AMANN GIRRBACH | 4

* All titanium blanks come with 2 screws.

** Titanium blanks (premily) NT Tading used with holder NT Trading

Scannable abutments (scan posts)

| MN-SP102 Scannable abutment (narrow) | MD-SP102 Scannable abutment (standard size) | MW-SP102 Scanned Abutment (Wide) |

The patented shape and unique surface of the scanned abutments allow them to be used without pretreatment with a special spray. |

5 mm

5 mm  5 mm

5 mm  5 mm

5 mm  5 mm

5 mm