Glowforge 3d printing

Your At-Home 3D Laser Printer

Buy today - every US Glowforge Pro & Plus printer ships in 3 days.

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowFor a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

What will you create with your Glowforge?

What will you create with your Glowforge?

See what people are making

Your Glowforge works with hundreds of materials.

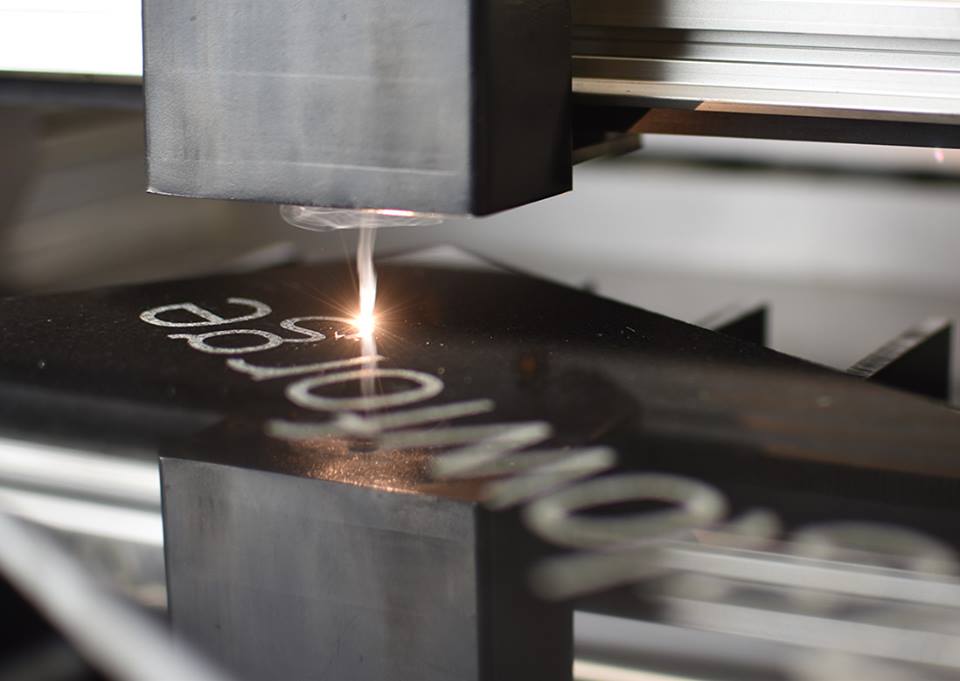

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

New York Times

Real people, real magic.

Discover what’s possible.

Discover what’s possible.For a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowWhat will you create with your Glowforge?

What will you create with your Glowforge?

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

New York Times

Real people, real magic.

Discover what’s possible.

Discover what’s possible.Glowforge

3D Laser Printer

Glowforge’s powerful desktop laser cuts, engraves, & scores hundreds of materials.

Learn more“…the next wave of computer-aided creativity.”

“…the next wave of computer-aided creativity.”

What will you create with Glowforge?

Swipe to see more ⭤

What will you create with Glowforge?

Craft with leather

Design home goods

Make custom signs & maps

Create intricate art

Personalize gifts

Start a side hustle

Customize anything

Bring your ideas to life.

Watch the magic happen.

Customize your prints.

Create with hundreds of materials.

Swipe to see more ⟷

Let's make something together.

Schedule a free virtual demo with a Glowforge Expert & experience the magic of Glowforge in real time.

Schedule a demoMade by creators like you.

Swipe to see more ⟷

Dear Glowforge,

Meet Glowforge | Glowforge

Great news! You can use your Glowforge from a Mac, PC, tablet, and smartphone, using our simple, powerful, and free web interface. To prepare your project, you can choose to use any software that saves a PDF (Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup and more) Glowforge can print JPG, PNG, SVG, PDF, and other file formats. To print a file, just drag-and-drop it directly on our app, and then adjust the preview to your liking.

To prepare your project, you can choose to use any software that saves a PDF (Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup and more) Glowforge can print JPG, PNG, SVG, PDF, and other file formats. To print a file, just drag-and-drop it directly on our app, and then adjust the preview to your liking.

Your Glowforge is yours to use, free of charge! The Glowforge cloud service gives you unlimited monthly prints, including all the features you see in our video. And don’t worry, there’s no paid subscription required.

Believe it or not - most of our customers tell us it takes them less than 30 minutes to get their printer out of the box, plug it in, set it up, and finish their first print!

Glowforge uses a beam of light the width of a human hair to cut and engrave with incredible accuracy within a thousandth of an inch. Further, your Glowforge can engrave images in stunning high-resolution - comparable to what you see on your phone or computer screen now. You can learn more, here.

Further, your Glowforge can engrave images in stunning high-resolution - comparable to what you see on your phone or computer screen now. You can learn more, here.

Glowforge opens up a world of materials. While traditional 3D printers are confined to layers of plastic, Glowforge is completely different. Delve into hundreds of beautiful materials like leather, acrylic, hardwood, fabric - even chocolate! Glowforge can cut wood, fabric, leather, paper, Plexiglas (acrylic), Delrin (acetal), mylar, rubber, Corian, foods, and more. Glowforge can also engrave all of the above plus glass, coated metal, marble, anodized aluminum, titanium, some phones, tablets, and laptops, and more laser safe materials. For a by-the-minute update on what folks are printing: check out #glowforge on Instagram.

No matter which Glowforge you choose, you’ll be able to use materials measuring 12 x 20. 4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

The Glowforge has a compact 3’ x 2’ footprint and fits well in any craft space, workshop, or family area.

Whichever Glowforge model you choose, you can be sure your Glowforge will be easy to set up and use, and will allow you to work with hundreds of materials. It comes will free printing software, everything you need to get started, and a free supply of premium materials to get you started. But there are some differences between our three models.

Not sure which model is right for you?

- The Glowforge Basic is our introductory model, perfect for moderate home use.

- The Glowforge Plus is a great solution for people who want to print frequently and quickly.

- The Glowforge Pro is our most powerful and capable model, ideal for a small business, or when more than one person will be using it.

Here are a few more details to help you decide:

Speed (Pro is fastest): The Glowforge Pro top engraving speed is 3x as fast as the Glowforge Basic, and cutting is 1.2x as fast. The Glowforge Plus top engraving speed is 2x as fast as the Glowforge Basic.

Warranty (Plus and Pro have 12 months): The Glowforge Basic has 6 months of warranty coverage, while the Plus and Pro offer a double warranty of a full 12 months warranty.

Material Size (Pro has Passthrough): All Glowforge printers can accommodate materials measuring up to 18” deep, 20.4” wide, and 2” tall. The maximum printable area is about 11 x 19.5”. The Glowforge Pro allows you to make enormous oversized prints.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.Laser Class: The Plus and Basic models are a Class 1 laser (like a DVD player). The Passthrough slot makes the Pro model a Class 4 laser which requires the person using it to have laser safety training (included with your purchase). You should not use the Pro in public or around kids without installing Pro Shields, which are included with your purchase.

Temperatures (Pro prints up to 81°F (27°C)): The Pro is designed for printing all day in temperatures up to 81°F (27°C). The Basic and Plus will pause periodically to cool if used continually in warm temperatures; they’re designed for environments up to 75°F (24°C).

Technology. The Glowforge Plus has an upgraded linear system to support faster motor speeds. The Glowforge Pro adds a solid state cooling unit and an upgraded 45 watt laser for the fastest possible prints.

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

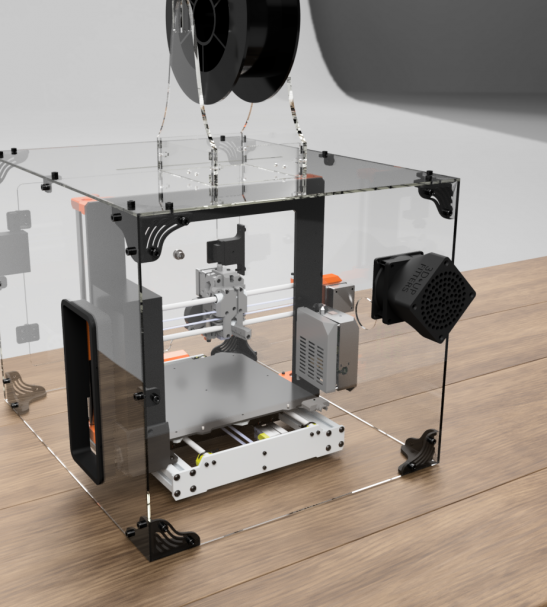

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

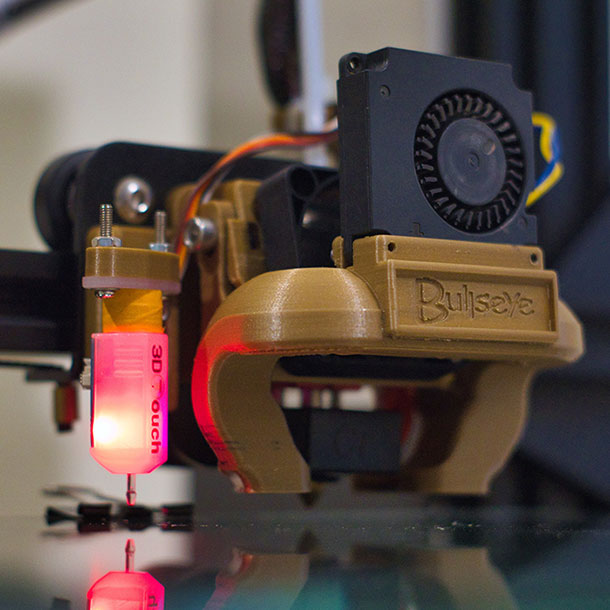

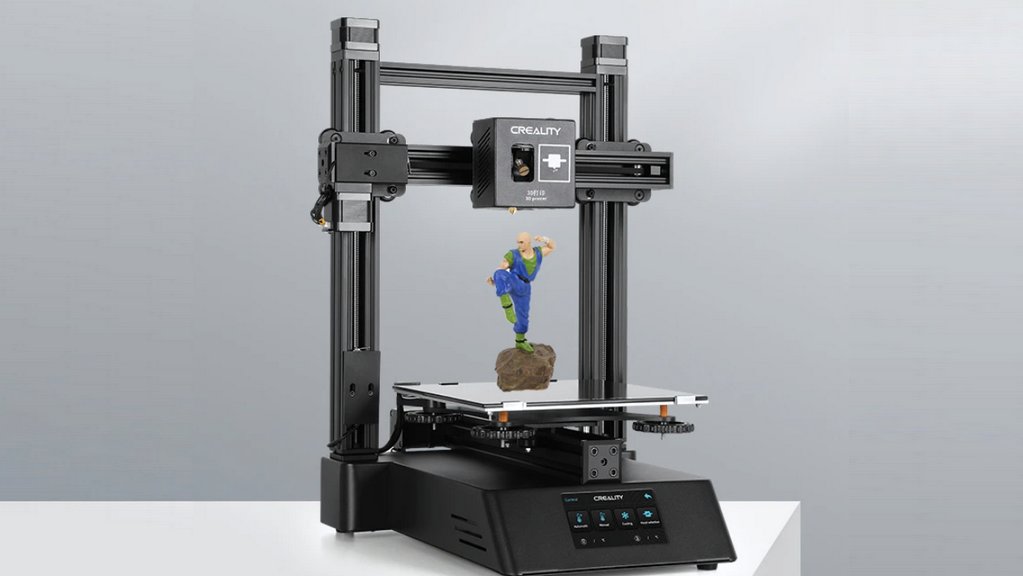

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

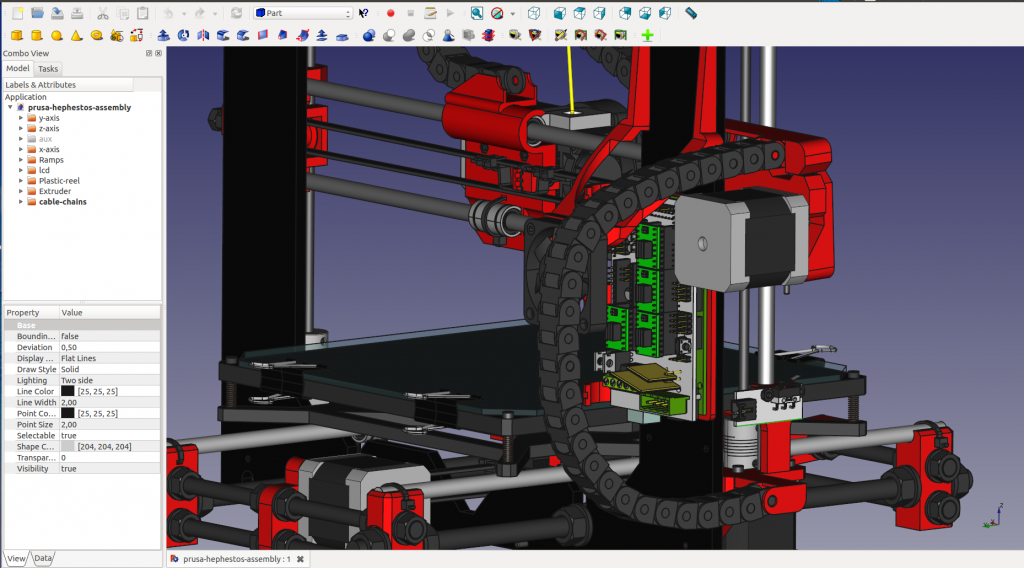

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer;

- 3D model reproduced.

Objects are reproduced gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Various 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio.

Printing occurs by layer-by-layer supply of a thread of molten plastic;

Printing occurs by layer-by-layer supply of a thread of molten plastic; - Laser stereolithography (SLA) . The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

- Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

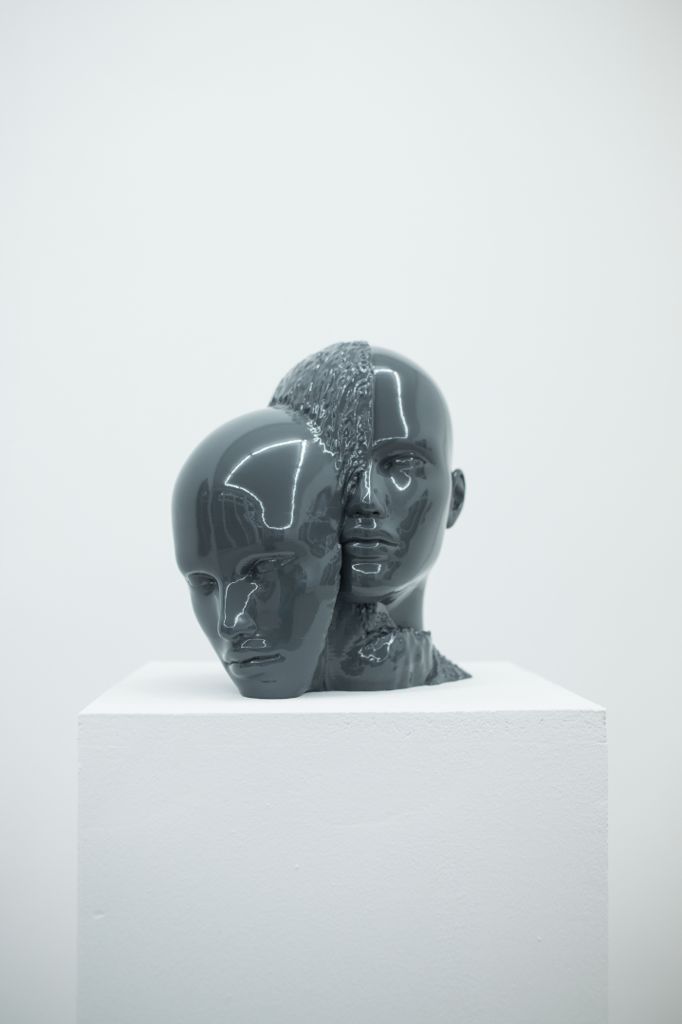

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We also want to remind you about the possibility to order 3D printing, 3D scanning, 3D modeling services or purchase of related equipment and consumables with delivery throughout Ukraine in 3DDevice. If you have any questions, please contact us at one of the phone numbers listed here. We look forward to collaborating!

Return to the main page

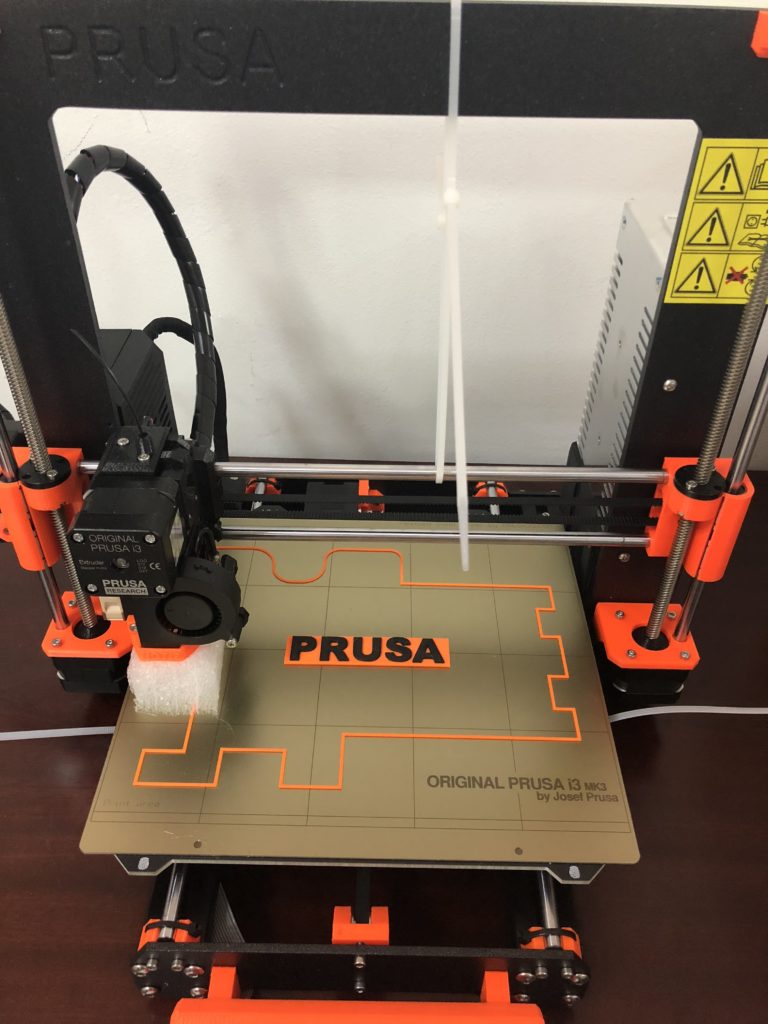

3D printing on order in Nizhny Novgorod, cost of services

The cost of printing on a 3d printer allows you to use the service not only for commercial and state enterprises, but also for individuals - innovative production technologies have become widely available. Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of ordered samples, the material from which they will be made and the method of prototyping.

ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of ordered samples, the material from which they will be made and the method of prototyping.

3d printing and prototyping - the latest technologies in practice

The combination of computer technology with production allows you to multiply the speed of production, reduce the cost of creating the necessary items. Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

Where created 3d models and prototypes are used

Prototyping on 3d printers allows you to quickly and at low cost get a sample of the desired part from a polymer material, made with a high degree of accuracy, without roughness or distortion. Depending on the technology used and the material from which the sample is made, the product acquires high-tech properties: ideal shape, strength, plasticity, temperature stability. Models have found application in many areas, so they make custom 3d printing companies of different specializations:

- medicine;

- automotive;

- serial industrial production: mechanical engineering, instrumentation, metallurgy;

- architecture - when creating models of buildings and complexes;

- designs;

- souvenir production.

How 3d prototyping is carried out

The basis for prototyping is a 3d image of an object, compiled by a computer program with three-dimensional modeling functions. 3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

- FDM (Fused Deposition Modeling). A moving molten polymer thread forms an object of complex geometric shape in layers, which can subsequently withstand high mechanical and thermal loads.

- SLS (Eng. Selective Laser Sintering). This is the sintering of a powder in a container under the targeted action of a laser beam.

- MJM (from the English. Multi Jet Modeling - modeling with many nozzles). Multi-nozzle 3d printer prototyping , applying molten material with multiple inkjet heads, based on the principle of a laser printer.

- LOM (from the English Laminated Object Manufacturing - the production of an object by lamination). Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass.

- SLM (from English Selective Laser Melting - selective laser melting). Selective fusion of metal with a targeted laser beam, resulting in a solid object.

- EBM (from the English Electron Beam Melting - electron beam melting). Creation of a product from a powder that is melted by a directed electron beam.

- STL (from English stereolithography - stereolithography). Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber.

Benefits of 3d printing and prototyping

What are the advantages and benefits for a customer who decides to order a 3D printing with a printer?

Before launching a new product into mass production, an enterprise can purchase a prototype, test it, make changes to avoid errors in the design development of the product, and reduce the cost of production.

If a private or public enterprise needs to produce a small batch of products, it is more profitable for him to apply for a small-scale prototyping service than to carry out design and engineering development and testing of prototypes, reconfigure production, use labor resources and equipment. Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

The desired samples can be obtained in a short period, regardless of the degree of complexity of the object being created. Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time.

The cost of 3d printing with the printer is low, which allows customers to reduce their own costs for design development, testing and sample production. LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

The cost of prototyping and creating 3d models

Answer to question how much it costs to print on a 3d printer depends primarily on the number of ordered products, the material from which the product is made, the size of the object, and the technology of its manufacture.