3D print methods

Types of 3D Printing Technology Explained

Multi Jet Fusion (MJF)

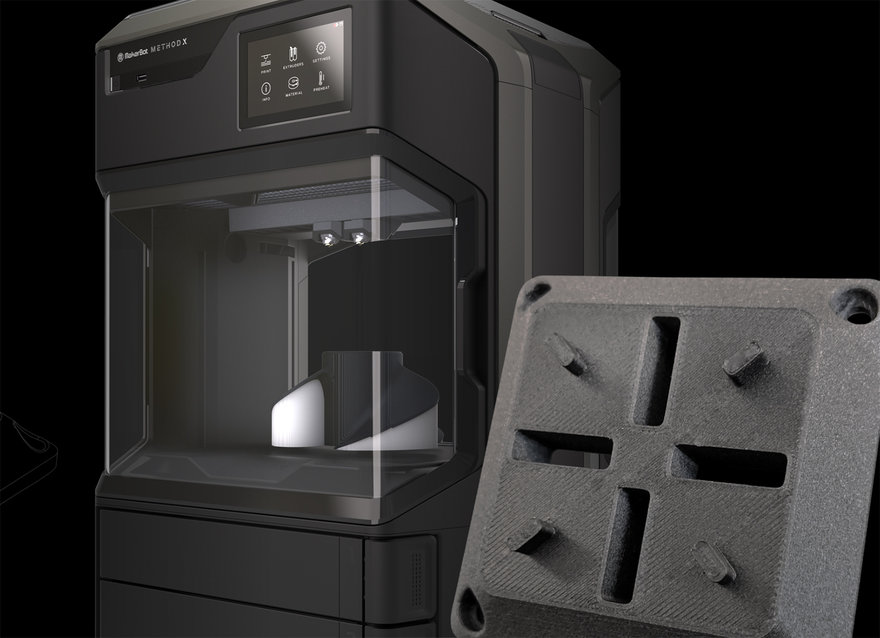

Similar to SLS, Multi Jet Fusion also builds functional parts from nylon powder. Rather than using a laser to sinter the powder, MJF uses an inkjet array to apply fusing agents to the bed of nylon powder. Then a heating element passes over the bed to fuse each layer. This results in more consistent mechanical properties compared to SLS as well as improved surface finish. Another benefit of the MJF process is the accelerated build time, which leads to lower production costs.

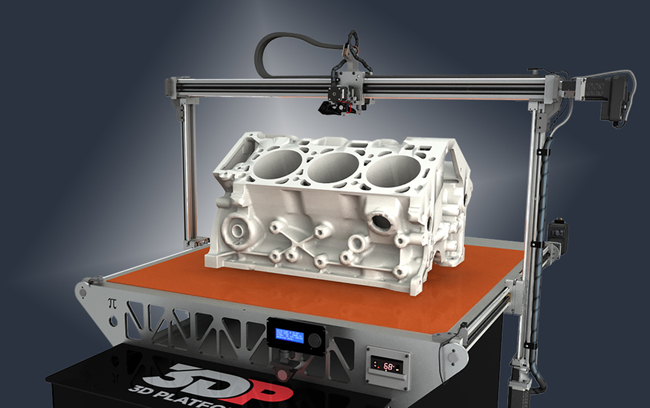

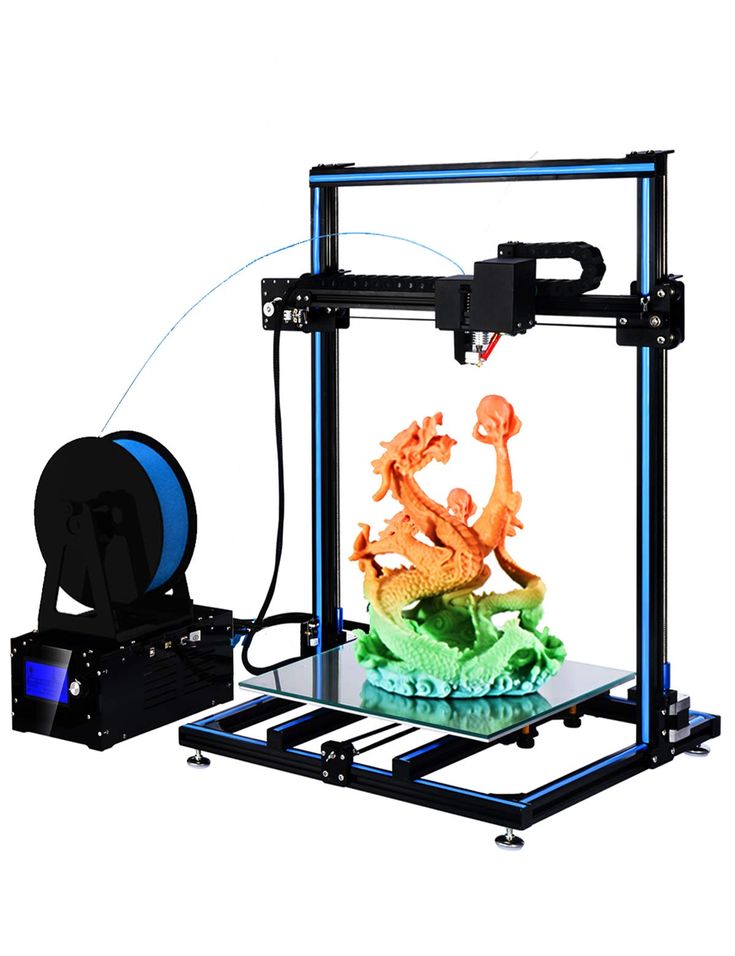

Fused Deposition Modeling (FDM)

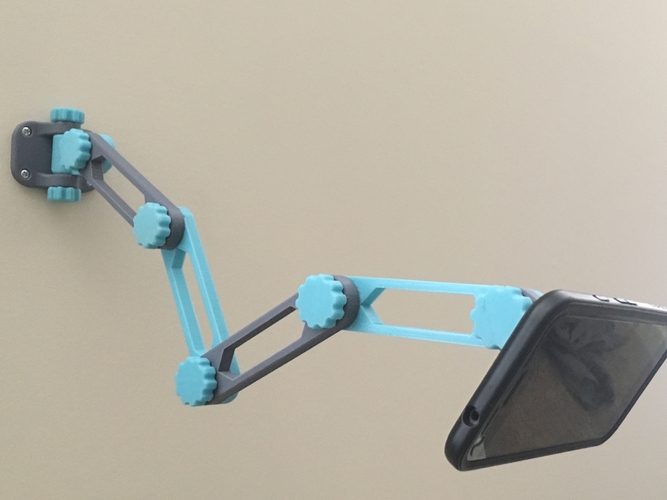

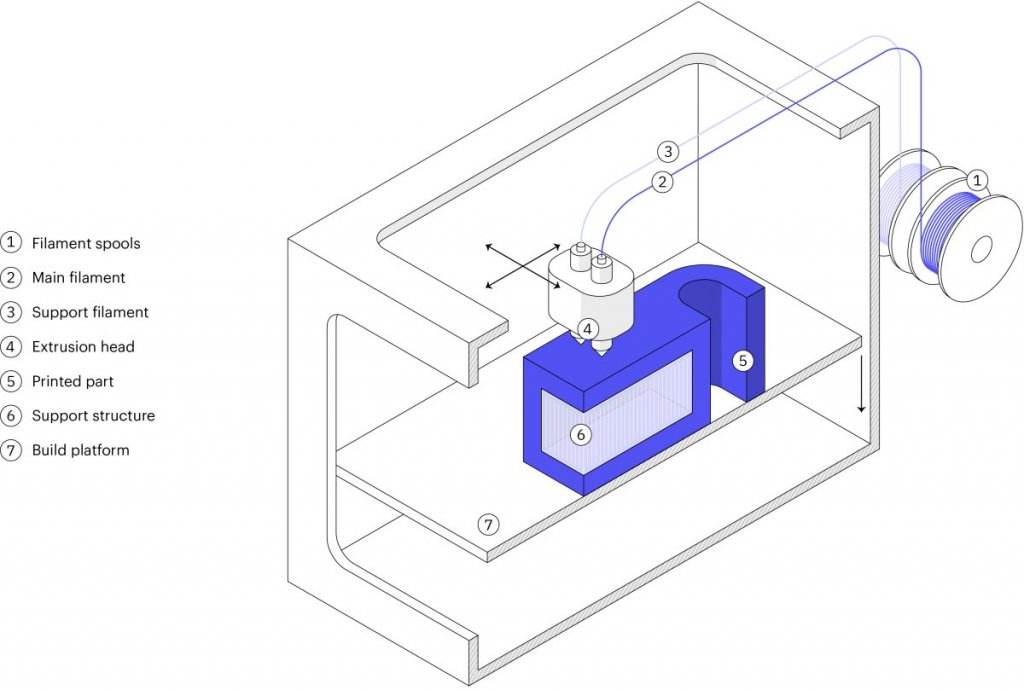

Fused deposition modeling (FDM) is a common desktop 3D printing technology for plastic parts. An FDM printer functions by extruding a plastic filament layer-by-layer onto the build platform. It’s a cost-effective and quick method for producing physical models. There are some instances when FDM can be used for functional testing but the technology is limited due to parts having relatively rough surface finishes and lacking strength.

Metal 3D Printing Processes

Direct Metal Laser Sintering (DMLS)

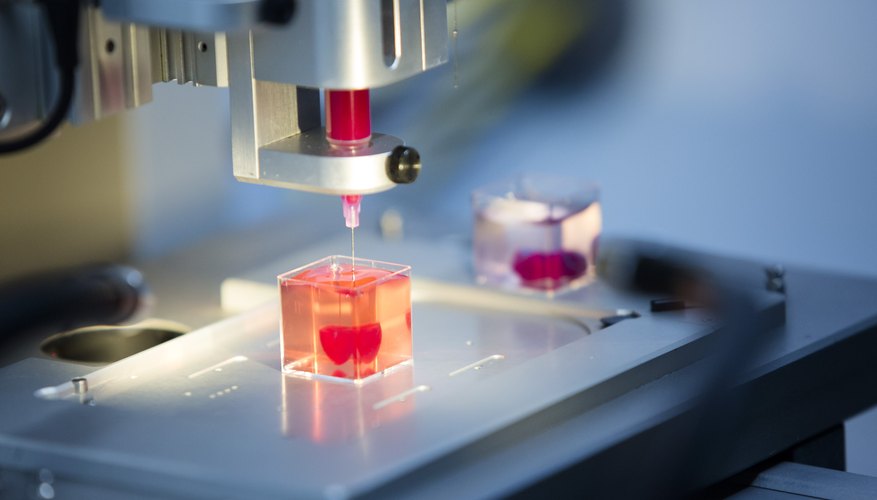

Metal 3D printing opens up new possibilities for metal part design. The process we use at Protolabs to 3D print metal parts is direct metal laser sintering (DMLS). It’s often used to reduce metal, multi-part assemblies into a single component or lightweight parts with internal channels or hollowed out features. DMLS is viable for both prototyping and production since parts are as dense as those produced with traditional metal manufacturing methods like machining or casting. Creating metal components with complex geometries also makes it suitable for medical applications where a part design must mimic an organic structure.

Electron Beam Melting (EBM)

Electron beam melting is another metal 3D printing technology that uses an electron beam that's controlled by electromagnetic coils to melt the metal powder. The printing bed is heated up and in vacuum conditions during the build. The temperature that the material is heated to is determined by the material in use.

When to Use 3D Printing

As stated earlier, there are a couple common denominators among 3D printing applications. If your part quantities are relatively low, 3D printing can be optimal—the guidance we give our 3D printing service customers is usually 1 to 50 parts. As volumes start to near the hundreds, it’s worth exploring other manufacturing processes. If your design features complex geometry that is critical to your part’s function, like an aluminum component with an internal cooling channel, 3D printing might be your only option.

Selecting the right process comes down to aligning the advantages and limitations of each technology to your application’s most important requirements. In the early stages when ideas are being thrown around and all you need is a model to share with a colleague, those stair-stepping surface finishes on your part aren’t of much concern. But once you hit the point where you need to conduct user testing, factors like cosmetics and durability start to matter. Although there is no one-size-fits-all solution, properly utilizing 3D printing technology throughout product development will reduce design risk and, ultimately, result in better products.

Although there is no one-size-fits-all solution, properly utilizing 3D printing technology throughout product development will reduce design risk and, ultimately, result in better products.

What Are the Different Types of 3D Printing?

In this article, Mr. Amit Kothari discusses different types of 3D printing and its processes.

© Labdox Private Limited

The term 3D printing encompasses several manufacturing technologies that build parts layer-by-layer. Each varies in the way they form plastic and metal parts and can differ in material selection, surface finish, durability, and manufacturing speed and cost.

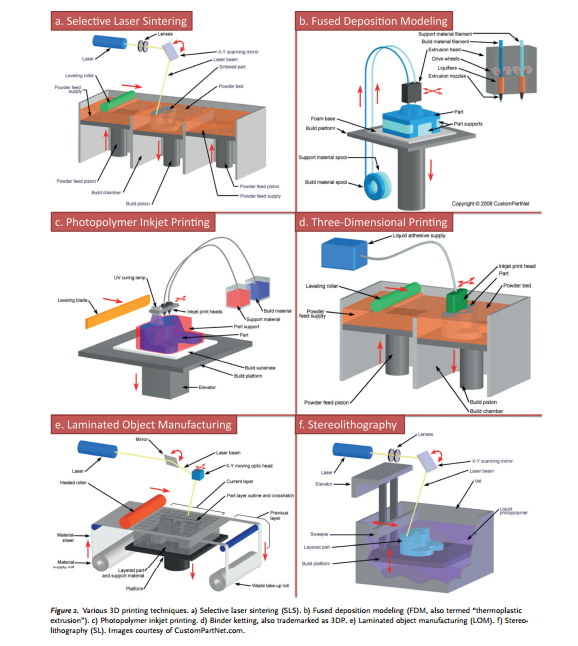

There are several types of 3D printing, which include:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Digital Light Process (DLP)

- Multi Jet Fusion (MJF)

- PolyJet

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

Types of 3D Printing and Its Processes

3D printing is becoming the future of the manufacturing era. This is because there are many different processes which are suitable for a different type of materials. A few of them are mentioned below.

This is because there are many different processes which are suitable for a different type of materials. A few of them are mentioned below.

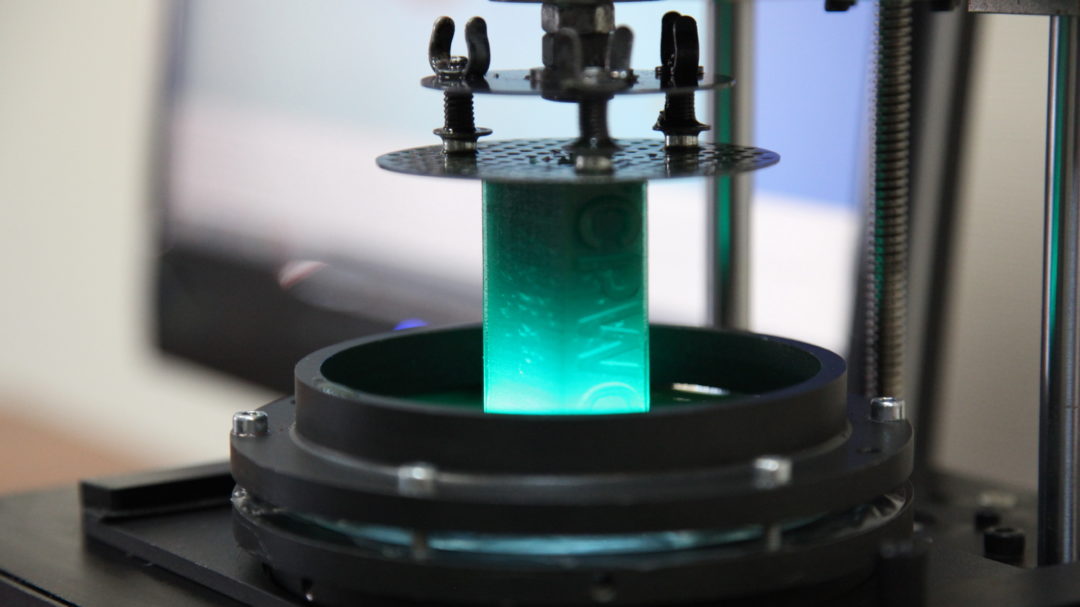

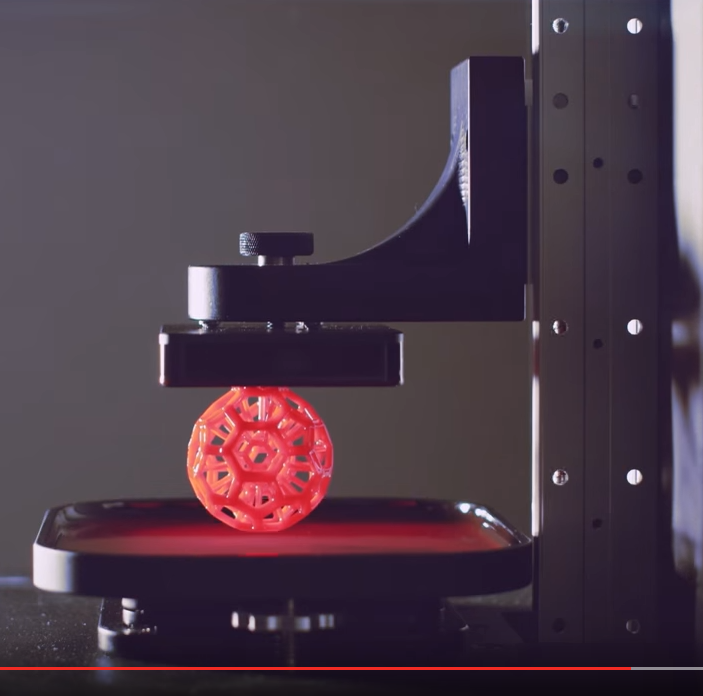

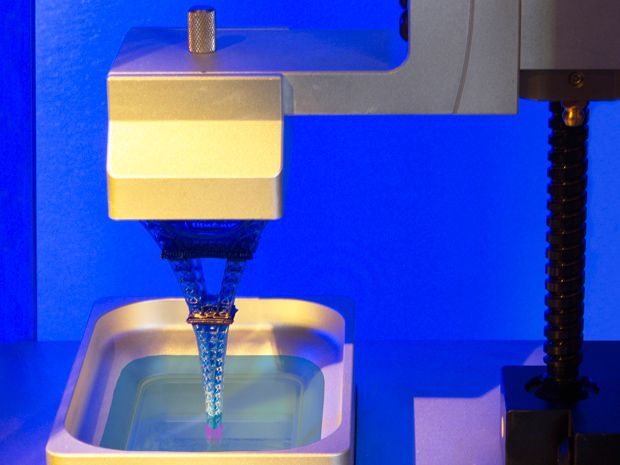

It is the world’s first 3D printing innovation introduced by Chuck Hull in 1986. It works by a 3D printing technique called Vat Polymerization where a material called a photopolymer gum specifically restored by a light source. Stereolithography (SLA) is the first modern 3D printing measure. SLA printers dominate at delivering elevated levels of detail, smooth surface completions, and tight resistances. The quality surface completions on SLA parts look decent. It’s generally utilized in the clinical business and basic applications incorporate anatomical models and microfluidics. In particular, an SLA printer utilizes mirrors, called galvanometers. One is situated on the X-pivot, the other on the Y-hub. These point to the purpose of a laser pillar across the tank of gum, specifically relieving and setting a cross-part of the item in the forming zone, developing it layer by layer.

SLA is a quick prototyping measure where exactness and accuracy are taken seriously. It can create objects from 3D CAD information in only a couple of hours. This is a 3D printing measure its fine subtleties and precision by changing over fluid photopolymers (a unique kind of plastic) into strong 3D items, each layer in turn. The plastic is initially warmed to transform it into a semi-fluid structure, and afterward, it solidifies on contact. The printer develops every one of these layers utilizing a bright laser, coordinated by X and Y filtering mirrors. A recoater sharp edge also gets across the surface right before the next step to guarantee each thin layer of gum spreads equitably across the article. The print cycle proceeds thusly, building 3D items from the base up. When finished, the 3D part will typically have a synthetic shower to eliminate an overabundance. It’s additionally basic practice to post-fix the article in a bright broiler. This makes the product more grounded and more steady.

SLA printing has gotten support from many assortments of ventures. A portion of these incorporate auto, clinical, aviation, diversion, and furthermore to make different customer items. Printers that are used are Vipers, ProJets, and iPros 3D printers fabricated by 3D Systems.

Specific laser sintering (SLS)SLS softens together nylon-based powders into strong plastic. Since SLS parts are produced using genuine thermoplastic material, they are tough, reasonable for utilitarian testing, and can uphold living pivots and snap-fits. In contrast with SL, parts are more grounded, yet have harsher surface completions. SLS doesn’t need help structures so the entire form stage can be used to settle various parts into a solitary form—making it appropriate for part amounts higher than other 3D printing measures. Numerous SLS parts are utilized to model plans that will one day be infusion-shaped.

It utilizes a 3D printing measure called Power Bed Fusion. A container of thermoplastic powder (Nylon 6, Nylon 11, Nylon 12) is warmed simply beneath its liquefying point. At that point, a recoating or wiper sharp edge stores a meager layer of the powder – generally 0.1 mm thick – onto the forming stage. A laser bar starts examining the surface, where it specifically ‘sinters’ the powder, which means it hardens a cross-part of the article. Likewise, with SLA, the laser is centered around an area by a couple of galvos. When the whole cross-segment is filtered, the stage drops somewhere near one thickness of layer stature and the entire cycle is rehashed until the item is completely made. Powder that isn’t sintered remaining parts set up supporting the item that has been sintered, dispensing with the requirement to support structures. Not many of the applications for SLS are the assembling of practical parts, complex ducting requiring empty plans, and low-run creation. Its qualities are in the production of utilitarian parts, which leaves behind great mechanical properties, and with complex calculations.

A container of thermoplastic powder (Nylon 6, Nylon 11, Nylon 12) is warmed simply beneath its liquefying point. At that point, a recoating or wiper sharp edge stores a meager layer of the powder – generally 0.1 mm thick – onto the forming stage. A laser bar starts examining the surface, where it specifically ‘sinters’ the powder, which means it hardens a cross-part of the article. Likewise, with SLA, the laser is centered around an area by a couple of galvos. When the whole cross-segment is filtered, the stage drops somewhere near one thickness of layer stature and the entire cycle is rehashed until the item is completely made. Powder that isn’t sintered remaining parts set up supporting the item that has been sintered, dispensing with the requirement to support structures. Not many of the applications for SLS are the assembling of practical parts, complex ducting requiring empty plans, and low-run creation. Its qualities are in the production of utilitarian parts, which leaves behind great mechanical properties, and with complex calculations. SLS is restricted by requiring longer lead times and its greater expense when contrasted and FDM/FFF.

SLS is restricted by requiring longer lead times and its greater expense when contrasted and FDM/FFF.

PolyJet is another plastic 3D printing measure, yet there’s a curve. It can create various parts with different properties, for example, tones and materials. Architects can use the innovation for prototyping elastomeric or over-molded parts.

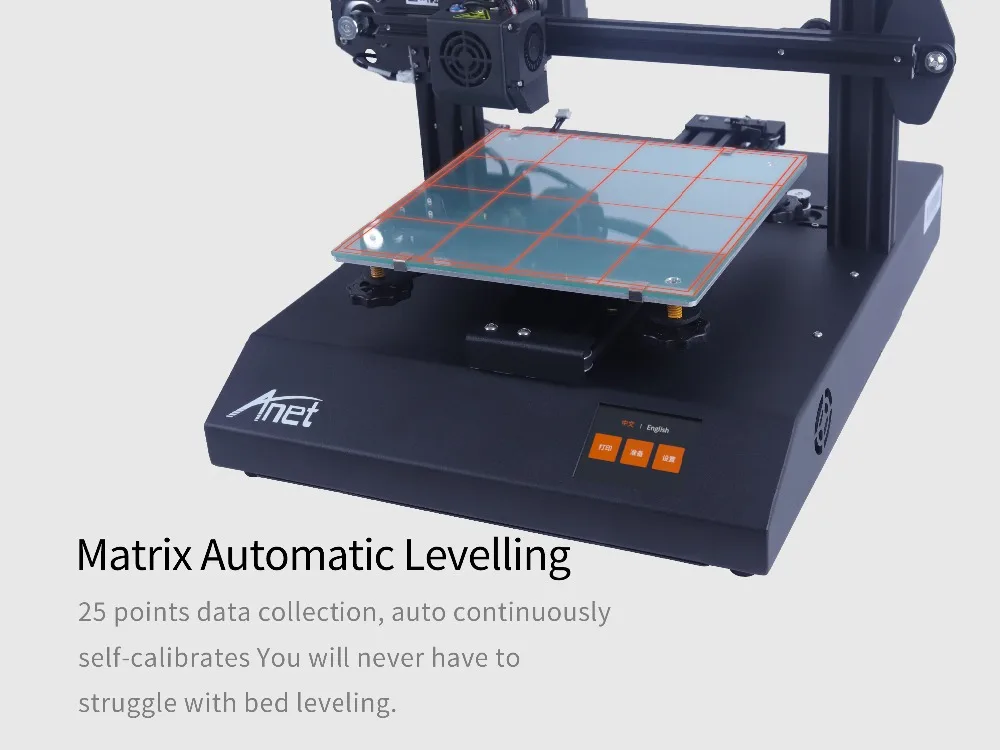

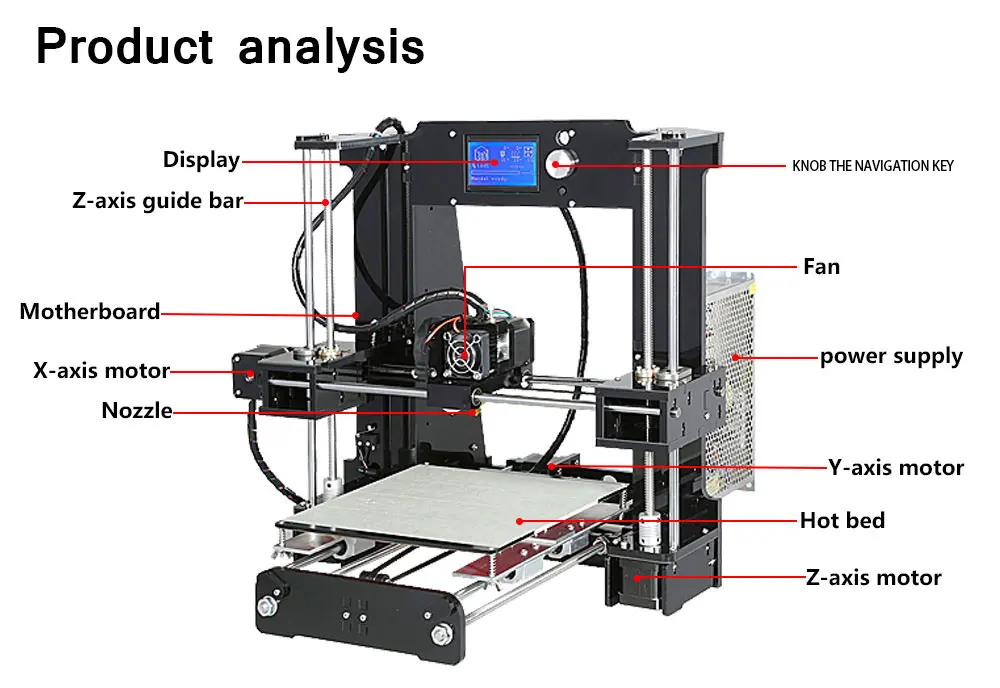

Fused Deposition Modeling (FDM) aka Fused Filament Fabrication (FFF)An FDM printer works by expelling a plastic fiber layer-by-layer onto the forming stage. It’s a savvy and fast strategy for delivering actual models. There are a few occasions when FDM can be utilized for practical testing however the innovation is restricted because of parts having generally harsh surface completes and lacking strength. It is a 3D printing innovation that utilizes a cycle called Material Extrusion. Material Extrusion gadgets are accessible and reasonable of all. They work by a cycle where a spool of a fiber of strong thermoplastic material (PLA, ABS, PET) is stacked into the 3D printer. It is then pushed by an engine through a warmed spout, where it liquefies. The printer’s expulsion head at that point moves along explicit directions, keeping the 3D printing material on a form stage where the printer fiber cools and cements, shaping a strong item. When the layer is finished, the printer sets out another layer, until the item is complete. Basic applications for FDM incorporate electrical lodgings, structure and fit testings, jigs and fixtures, and investment casting patterns. The best part about FDM is that it offers the best surface completion in addition to full tone alongside the reality there are different materials accessible for its utilization.

It is then pushed by an engine through a warmed spout, where it liquefies. The printer’s expulsion head at that point moves along explicit directions, keeping the 3D printing material on a form stage where the printer fiber cools and cements, shaping a strong item. When the layer is finished, the printer sets out another layer, until the item is complete. Basic applications for FDM incorporate electrical lodgings, structure and fit testings, jigs and fixtures, and investment casting patterns. The best part about FDM is that it offers the best surface completion in addition to full tone alongside the reality there are different materials accessible for its utilization.

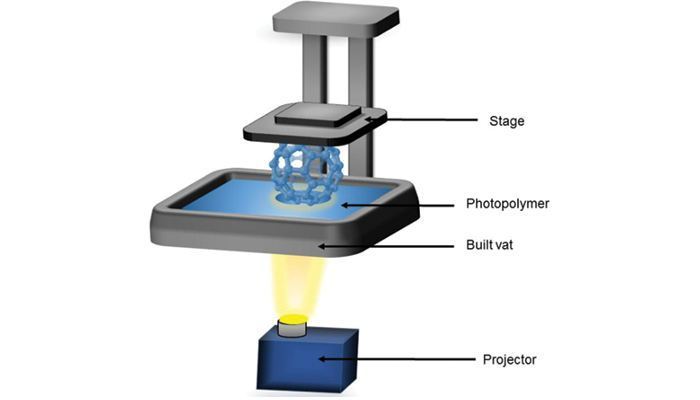

DLP has quicker print times than SLA in light of the fact that each layer is uncovered at the same time, rather than following the cross-part of a zone with the purpose of a laser. Regular applications for SLA and DLP are infusion shape type polymer models, adornments, dental applications, and amplifiers. They have fine element subtleties and smooth surface completion. They are restricted by being weak, in this way unsatisfactory for use as mechanical parts.

They have fine element subtleties and smooth surface completion. They are restricted by being weak, in this way unsatisfactory for use as mechanical parts.

Multi Jet Fusion assembles utilitarian parts from nylon powder. As opposed to utilizing a laser to sinter the powder, MJF utilizes an inkjet cluster to apply melding specialists to the bed of nylon powder. At that point, a warming component disregards the bed to combine each layer. This outcome in more predictable mechanical properties contrasted with SLS just as improved surface completion. Another advantage of the MJF cycle is the quickened fabricate time, which prompts lower creation costs. MJ differs from other types of 3D printing technologies that deposit, sinter, or cure build material with point-wise deposition. Instead, the print head jets hundreds of droplets of photopolymer and cures/solidifies them using UV light. Once a layer is deposited and cured, the build platform lowers by one layer thickness, and the process is repeated until the 3D object is built. Another difference from 3D printing technologies is instead of using a single point to follow a path that outlines the cross-sectional layer, MJ machines deposit build material in a fast, line-wise manner. Articles made with MJ need help during printing and are printed all the while during the form cycle with a dissolvable material that is taken out in post-handling. MJ is one of the solitary sorts of 3D printing innovation that can make objects produced using numerous materials and with full tone. The advantage to this is MJ printers can fabricate multiple objects in a single line without affecting build speed. As long as the models are arranged correctly with optimal spacing, MJ can produce parts faster than other types of 3D printers. Hence, there are multiple processes for multiple projects, selecting the best suitable process is of utmost importance

Another difference from 3D printing technologies is instead of using a single point to follow a path that outlines the cross-sectional layer, MJ machines deposit build material in a fast, line-wise manner. Articles made with MJ need help during printing and are printed all the while during the form cycle with a dissolvable material that is taken out in post-handling. MJ is one of the solitary sorts of 3D printing innovation that can make objects produced using numerous materials and with full tone. The advantage to this is MJ printers can fabricate multiple objects in a single line without affecting build speed. As long as the models are arranged correctly with optimal spacing, MJ can produce parts faster than other types of 3D printers. Hence, there are multiple processes for multiple projects, selecting the best suitable process is of utmost importance

© Labdox Private Limited

Technologies and methods of 3D printing - ANRO technology

The active introduction of 3D technologies contributed to the creation of progressive 3D printers with a rich set of options. 's high-performance 3 D-printing technologies have produced original designs for marketing, catering, industry and landscaping.

's high-performance 3 D-printing technologies have produced original designs for marketing, catering, industry and landscaping.

3D printing is a procedure for designing three-dimensional compositions of a given geometric shape. The process of obtaining the original model is based on the phased construction of the object with clear applied layers, clearly demonstrating the edges of the product.

Innovative 3D printing methods are in high demand in the construction industry, architecture, education, medicine, bioengineering and many other fields. Unlike traditional methods of obtaining parts - milling, turning, they allow you to achieve high accuracy, the greatest savings in materials and time.

Features of 3D printing

Designed models are reproduced using special computer graphics programs , which are designed specifically for this purpose. Building one model can take from a couple of hours to two or more days, depending on the specifics of the project. The desktop device allows designers and design professionals to turn original prototypes into reality.

The desktop device allows designers and design professionals to turn original prototypes into reality.

The advantage of modern technology is the efficiency and cost-effectiveness of modeling objects, for example, in the manufacture of products in production. 3D printers are indispensable for creating unique products in preschool educational institutions, building more complex samples in schools and specialized institutions. Modern technologies make it much easier to work with 3D models, so this technology becomes accessible to children. 3D modeling allows you to create objects of unique geometric shapes of varying degrees of complexity.

Basic 3D printing

- Fused deposition prototyping (FDM). An accessible modeling method, which consists in the layer-by-layer application of a hot thread from a fusible working product (wax, metal, plastic). Most often used for rapid prototyping of various models, for example, mass production of jewelry, souvenirs and toys;

- Selective Laser Sintering (SLS).

One of the famous prototyping methods. The product is formed from a powder product (ceramics, metal-plastic) by melting under the influence of a laser. The advantage of SLS is that you don't have to use a special structure to support floating elements;

One of the famous prototyping methods. The product is formed from a powder product (ceramics, metal-plastic) by melting under the influence of a laser. The advantage of SLS is that you don't have to use a special structure to support floating elements; - Laser stereolithography (SLA). The most famous modeling method using a special liquid polymer that hardens under the influence of mercury radiation. The advantages include high print resolution, the least amount of waste and ease of finishing the product;

- Electron Beam Melting (EBM). Advanced adaptive manufacturing method using special electron beams. Widely used in the production of various titanium products. Unlike models produced by SLS, blanks are solid and highly durable;

- Production of models using lamination (LOM). Progressive way of forming various models using layer-by-layer gluing. The resulting objects can be upgraded by machining.

The advantage of this technology is the availability of the main consumable material - paper;

The advantage of this technology is the availability of the main consumable material - paper; - Multi-jet simulation (MJM). A popular type of printing based on multi-jet modeling of a photopolymer product. It is used in various industries. The advantages include the possibility of multi-color printing and the interaction of materials of different properties and characteristics.

Other 3D modeling technologies are common in adaptive and industrial manufacturing. All of them have their own characteristics and nuances. However, the simplest and most popular 3 D-printing method for is Fused Deposition Modeling (FDM).

3 reasons to choose FDM technology

- Simplicity. Printing technology is accessible even to small children. Therefore, it can be used both in schools and offices, and in preschool institutions;

- Originality. FDM technology allows you to design objects with unusual geometry and cavities, which is beyond the power of other types of modeling;

- Variety.

When working with FDM technology, a wide variety of plastics can be used, which makes it possible to obtain a fairly wide range of models with different physical and chemical properties. 3D objects can be durable, flexible, luminous, soluble in water, and with many other properties.

When working with FDM technology, a wide variety of plastics can be used, which makes it possible to obtain a fairly wide range of models with different physical and chemical properties. 3D objects can be durable, flexible, luminous, soluble in water, and with many other properties.

FDM technology uses time-tested thermoplastics that are used in traditional manufacturing of various products.

Advantages of modern 3D printing technology from ANRO-technology

- High speed. Modern technologies provide short terms of product prototype development;

- Minimum material consumption. Progressive 3D printers allow you to produce objects with the lowest waste rates;

- Robust internal structure. Innovative devices help to design large objects with minimal weight;

- Environmentally friendly. The materials used in prototyping are completely safe and do not pose any harm to the user.

Additional advantages of creating a 3D object include durable and convenient storage of materials that does not require special conditions.

3D technology is the future of prototyping, because thanks to them today the most non-standard design projects are being implemented both in everyday life and in the industrial sphere.

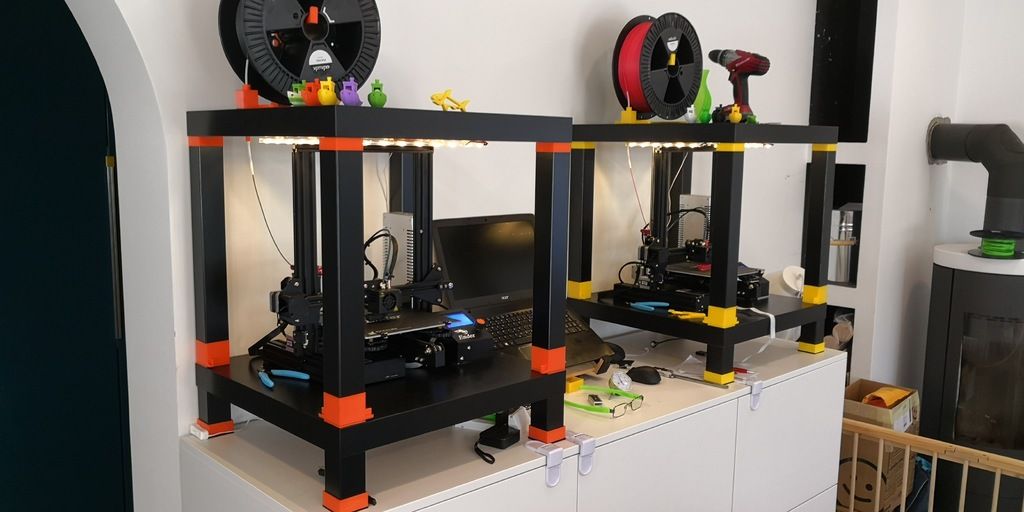

Our company is engaged in the development and supply of 3D printers based on FDM technology. Our 3D printers with specialized software are suitable for children from 6 years old. Small 3D prints can fit at home and delight children and adults with the opportunity to print their own 3D models of objects and toys.

[/mk_custom_list]

VIEW 3D PRINTERS

3D printing technologies

Today, there are many technologies for creating real objects from 3D models. The most common and affordable technology is plastic printing (FDM technology).

In our article, we give a classification of printing technologies and describe each of them.

At present, 3D printing technologies are divided into 4 main categories:

1. Extrusion - extrusion of molten material;

2. Photopolymerization - curing of the polymer by UV or laser radiation.

3. Printing by sintering and melting of materials

4. Lamination - gluing material layers with subsequent cutting;

In addition, there are other technologies that do not fall into the above categories, we will talk about them at the end of this article.

- 1. Material extrusion

1.1. Simulation Fused Deposition Modeling (Fused Deposition Modeling, FDM)

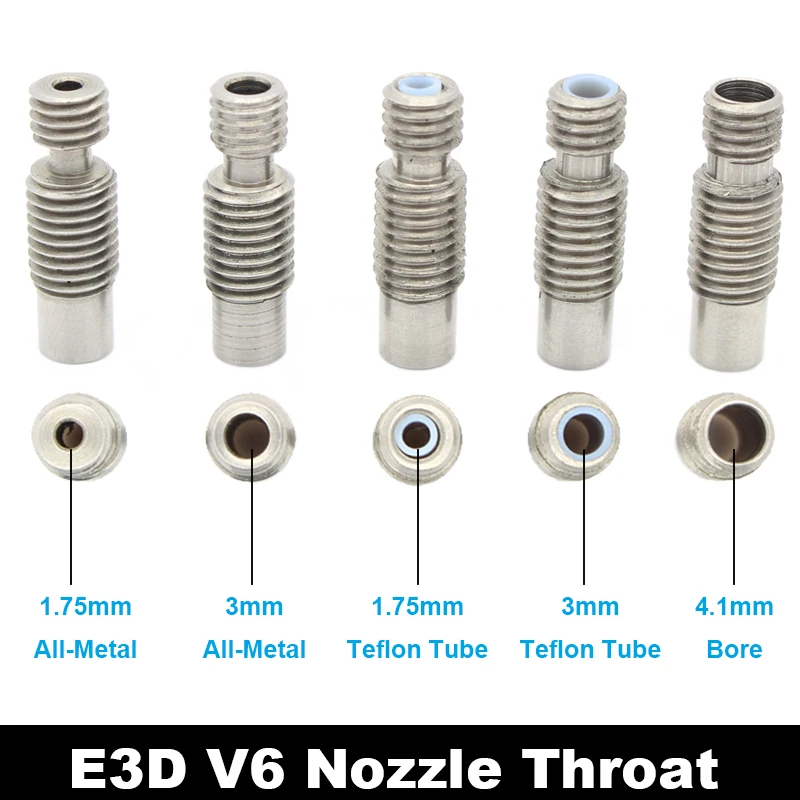

Plastic or metal filaments are unwound from a roll (cartridge) and fed into the print head (extruder). The extruder heats the filaments to a liquid state and extrudes the material through the nozzle, moving in the horizontal and vertical directions, layer by layer, forming an object.

Benefits of FDM 3D Printing

- • speed and ease of manufacturing models

- • availability;

- • safety, environmental friendliness and non-toxicity of most materials;

- • building accuracy;

- • ease of use and maintenance;

- • durability of parts;

- • easy disposal.

Media : Thermoplastics (PLA, ABS, PVA, HIPS, etc.), fusible metals and alloys, edible materials (chocolate, etc.)

1.2. Spray modeling with subsequent layer milling (Drop On Demand Jet, DODJet)

The print head simultaneously sprays both types of consumables. Then a special milling head cools the sprayed layer and mechanically processes it. DODJet technology allows you to build high-precision models with an absolutely smooth surface. Since the spraying of the working layer occurs due to a mechanically moving head, the speed of manufacturing a prototype largely depends on the complexity of the printed model.

Printing material : Casting wax

- 2. Photopolymerization

2.1. Laser stereolithography ( Laser Stereolithography, SLA)

The technology involves the use of a special photopolymer - photosensitive resin as a model material. The basis in this process is an ultraviolet laser, which sequentially transfers the cross sections of the model onto the surface of a container with photosensitive resin. The photopolymer hardens only in the place where the laser beam has passed. Then a new layer of resin is applied to the hardened layer, and a new contour is drawn with a laser. The process is repeated until the model is built. Stereolithography is the most popular rapid prototyping technology for high-precision models. It covers almost all branches of material production from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of surfaces depends on the construction step. Modern machines provide a construction step of 0.025 - 0.15 mm.

SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of surfaces depends on the construction step. Modern machines provide a construction step of 0.025 - 0.15 mm.

SLA-technology gives the best result when making master models for the subsequent production of silicone molds and casting polymer resins in them, and is also used for growing jewelry master models.

Media : Photopolymer resin

2.2. Digital Light Processing (Digital Light Processing, DLP)

Media : Liquid Resin

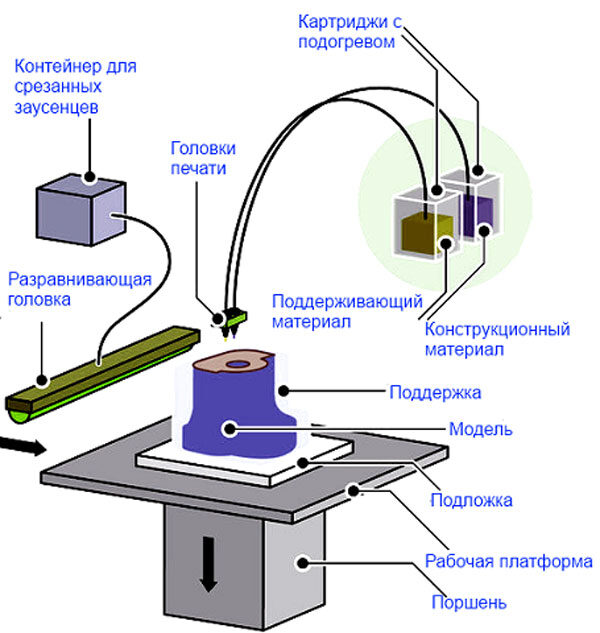

2.3. Technology MJM (Multi-Jet-Modeling)

MJM - 3D printing technology is based on a layer-by-layer section of a CAD file into horizontal layers, which are sequentially sent to a 3D printer. Each layer is formed by a print head, which, through groups of nozzles, releases either molten (temperature about 80 C) photopolymer or molten wax onto a horizontal moving platform. The photopolymer or wax is melted in the material supply system before entering the print head. If 3D printing is performed from a photopolymer, then after each layer is printed, the platform on which the layer is grown slides behind the print head under an ultraviolet lamp. A flash of an ultraviolet lamp causes the reaction of the photopolymer, due to which the material hardens. After that, the platform slides back under the print head and the layer formation cycle is repeated. The print head forms a new layer. Features of MJM technology is the ability to reproduce 3D models with high accuracy. The 3D printing process uses a support material: wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the part with support is placed in an oven with a temperature of ~60 C.

Each layer is formed by a print head, which, through groups of nozzles, releases either molten (temperature about 80 C) photopolymer or molten wax onto a horizontal moving platform. The photopolymer or wax is melted in the material supply system before entering the print head. If 3D printing is performed from a photopolymer, then after each layer is printed, the platform on which the layer is grown slides behind the print head under an ultraviolet lamp. A flash of an ultraviolet lamp causes the reaction of the photopolymer, due to which the material hardens. After that, the platform slides back under the print head and the layer formation cycle is repeated. The print head forms a new layer. Features of MJM technology is the ability to reproduce 3D models with high accuracy. The 3D printing process uses a support material: wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the part with support is placed in an oven with a temperature of ~60 C. If 3D printing is made from wax, then the support is removed using a special solution.

If 3D printing is made from wax, then the support is removed using a special solution.

It is also important that dyes can be added to the glue, and, therefore, it is possible to obtain not only a three-dimensional model, but also a multi-colored one.

Media : Photopolymer resin, acrylic resin, casting wax

2.4. Polyjet technology (PolyJet, PJET)

PolyJet 3D printing is similar to document inkjet printing, but instead of inkjet on paper, PolyJet 3D printers emit jets of liquid photopolymer that forms layers on the build tray and is instantly fixed by ultraviolet radiation . Thin layers are laid down sequentially and form an accurate three-dimensional model or prototype. Models are ready for use immediately upon removal from the 3D printer, no additional fixation is required. In addition to the selected build material, the 3D printer also jets a gel-like support material designed to support protrusions and complex geometries. It is easy to remove by hand or with water.

It is easy to remove by hand or with water.

PolyJet 3D printing technology has many advantages for rapid prototyping, producing stunningly fine details and smooth surfaces quickly and accurately. The technology uses a wide range of materials, including rigid opaque materials in hundreds of vibrant colors, transparent and colored translucent tones, flexible elastic materials, and specialized photopolymers for 3D printing in the dental, medical, and consumer goods industries.

Media : Photopolymer resin

- Selective Laser Sintering (SLS)

In this technology, models are created from powder materials due to the sintering effect using laser beam energy. Unlike the SLA process, in this case the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part.

Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. In the SLA and MJM processes, when building overhanging elements of a part, special supports are used to protect freshly built thin layers of the model from collapse. In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass of powder. After building, the model is extracted from the powder array and cleaned.

Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. In the SLA and MJM processes, when building overhanging elements of a part, special supports are used to protect freshly built thin layers of the model from collapse. In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass of powder. After building, the model is extracted from the powder array and cleaned. The leading manufacturers of SLS machines are Concept Laser (Germany), 3D Systems (USA) and EOS GmbH (Germany).

Media : Thermoplastic, metal powder, ceramic powder, glass powder

3.2. Direct Metal Selective Laser Melting (Direct Metal Selective Laser Melting, SLM)

Thin layers of quality metal powder are evenly distributed using a special coating mechanism, the platform on which the powder is located can be lowered vertically.

The entire process takes place inside a chamber that maintains tight control of atmospheric inert gases such as argon, nitrogen and oxygen below 500 ppm. Each layer is then formed by selectively exposing the powder surface to lasers using two high-frequency X- and Y-axis scanners. The process is repeated layer by layer until the part is complete.

The entire process takes place inside a chamber that maintains tight control of atmospheric inert gases such as argon, nitrogen and oxygen below 500 ppm. Each layer is then formed by selectively exposing the powder surface to lasers using two high-frequency X- and Y-axis scanners. The process is repeated layer by layer until the part is complete. Media : Virtually any metal alloy in granular/grit/powder form

3.3. E electron beam melting (Electron Beam Melting, EBM)

The technology is the manufacture of parts by melting a metal powder applied layer by layer with a powerful electron beam in vacuum. Unlike some methods of metal sintering, parts are obtained without voids, very durable.

The technology makes it possible to produce parts of any geometric shape with the parameters of the material used. The EBM machine reads data from a 3D model, usually located in a CAD file, and builds it up layer by layer.

These layers are fused together using a computer controlled electron beam. In this way he builds whole parts. The process takes place in a vacuum, which makes it suitable for making parts from materials that are highly susceptible to oxygen, such as titanium.

These layers are fused together using a computer controlled electron beam. In this way he builds whole parts. The process takes place in a vacuum, which makes it suitable for making parts from materials that are highly susceptible to oxygen, such as titanium. An important advantage is that the powder is a pure end material without any fillers. So you do not need to subject the printed part to additional heat treatment.

EBM operates at temperatures typically between 700 and 1000°C. Parts are ready almost immediately after cooling.

Titanium alloys, as noted above, are easily processed by this technology, making it a suitable choice for the medical implant market.

Print material : Titanium alloys

3.4. Selective Heat sintering (Selective Heat Sintering)

In order to be able to heat flow, special ultraviolet lamps are used in this technology.

One of the main advantages is that for a given wavelength of infrared radiation, it is possible to select 2 types of material: one will transmit heat, and the other will reflect. Also, one of the main properties of IR radiation is the ability to choose a wavelength at which a particular material will absorb or reflect all radiation.

One of the main advantages is that for a given wavelength of infrared radiation, it is possible to select 2 types of material: one will transmit heat, and the other will reflect. Also, one of the main properties of IR radiation is the ability to choose a wavelength at which a particular material will absorb or reflect all radiation. It is interesting to note that one 100 micron (0.1mm) thick layer is printed in just 1-2 seconds. This technology is a real breakthrough in high-speed printing. It is important to emphasize that the model is formed from powder, and all unused powder can be reused.

This technology allows you to make models of the most complex geometric shapes, and also allows you to print several parts at the same time.

Media : Thermoplastic powder

3.5. Powder bed and inkjet head 3d printing, Plaster-based 3D printing, 3DP

), which is introduced into the powder.

Learn more