Galatea 3d printer

‘Drawn’ - 3D Printed Designer Furniture Arrives Via Kickstarter - 3DPrint.com

Galatéa is much more than just a statuesque mechanical arm–she is responsible for bringing an entire furniture factory and boutique to life in vivid color and modern shape. And not only that–this amazing 3D printer represents the classic fairy tale of the technology–demonstrating everything about it that is beneficial to both innovators and consumers.

Their story could have leapt straight out of a sci-fi movie: talented industrial designers and engineers take what was nearly scrap and reinvigorate it with purpose, using it to take on an entrepreneurial challenge in a futuristic world, while imbuing the machinery with a magic and personality of its own. With the Galatéa 3D printer, Sylvain Charpiot and Samuel Javelle of France have taken something once on its way to becoming obsolete and rebuilt it into a machine that many would say represents the most forward-moving and progressive technology we know.

This 3D printer has allowed the French designers not only the obvious end reward of building innovative and utilitarian technology that many manufacturers would probably seek were it mass produced on its own, but they’ve been able to use it to their own devices as well for doing what they are good at–designing and building beautiful furniture and stylish products for the interior. This line, created by men, but produced by Galatéa, is called Drawn.

“Our main asset is Galatéa, the giant 3D printer made from a robotic arm,” states the team on their Kickstarter page. “She is the star in our team and she always manages to steal the show.”

With Galatéa, Charpiot and Javelle are able to bypass all the talking, meeting, and waiting with manufacturers who could live halfway across the globe stalling their momentum just to get to the simple prototype phase and then again moving slowly from there. The 3D printer allows them to take their own path as a manufacturer–and quickly, too–as Galatéa is able to produce large pieces in relatively little time.

“She extrudes different shades of plastic material, specially the one used to make the Lego bricks, by heating it up to 230 °C and pushing it through its nozzle,” says the team. “The resulting look is instantly recognizable.”

Each 3D printed work can be customized for the buyer, who is actually able to get involved in the design of their furniture. Digital design allows for easy and fast changes to existing ideas, and the pieces can then be 3D printed in two hours by the large-scale, multi-color Galatéa.

Last we reported, Drawn was just a few furniture pieces in to production, and the team was looking toward creating a line. Now, they’ve produced coffee tables, dining tables, living room pieces, and more. Galatéa’s creators are also ready to take her work one step farther, with a Kickstarter campaign meant to raise €15,000 (around $17,000 USD) by July 22nd. While Galatéa and her resulting productivity has gained exposure and popularity and has been seen in venues like Maker Faire last year in Paris, the team needs to get on the trade show circuit and make contacts for beginning to sell the inventory of furniture already 3D printed by the busy Galatéa 3D printer.

Those who support the Drawn Kickstarter campaign can look forward to some cool furniture at great prices. Beginning as low as €30 to €35 (around $34-$40 USD), you can pledge your support and receive some of Drawn’s modern works for the interior like a toilet paper shelf or contemporary, personalized 3D printed hangers. For a bit more as the pledges ascend, you could be the proud owner of a Drawn 3D printed bottle rack, lamp, or champagne bucket.

At the €120 level, supporters receive a Drawn ottoman. Moving upward to €160, you can look forward to receiving a chair. As you spend a bit more, the Drawn giant vase is available, and upward until you reach support levels of €600 with groupings of their 3D printing chairs available–all the way to €5,000, where you are able to have your own set of furniture custom-designed just for your home.

The Drawn Kickstarter campaign is a good way to get some great deals on one-of-a-kind modern 3D printed furniture and other pieces for the home, adding color, function and comfort.

Found in an old dismantling automobile factory, Galatéa has ironically gone from taking products to the end of the line where they no longer have use to creating fresh new designs which will grace the homes of many fashion and technologically savvy consumers.

Will you be supporting the Drawn Kickstarter campaign? Discuss in the Drawn 3D Printed Designer Furniture forum thread over at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed furniture • drawn • france • galatea 3d printer • kickstarter • robotic arm 3d printer

Please enable JavaScript to view the comments powered by Disqus.

Exclusive: Galatea the Ultra fast very large 3D Printer now available

by edi

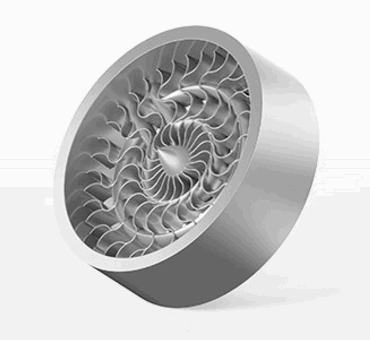

Aerospace

Drawn, the French startup founded 2 years by Sylvain Charpiot in Lyon, is unveiling today its disrupting 3D Printer, the Galatea 1. 0. After 2 years of development, Sylvain managed to come up with a 3D Printer that can seriously compete with Massivit, the Israel based startup that recently received a significant funding from Stratasys.

0. After 2 years of development, Sylvain managed to come up with a 3D Printer that can seriously compete with Massivit, the Israel based startup that recently received a significant funding from Stratasys.

Galatea specifications are impressive

Sylvain is a seasoned engineer with a real passion for innovation and local manufacturing. Following his graduation from the prestigious ENSAM school in France, Sylvain went on managing large production centers in Czech Republic and then in Southeast Asia, where he was leading a team of nearly 1,000 manual workers. During this early years in developing countries, he understood that technology could help him bring back some of the jobs that have been delocalised to low wages countries. He decided to move back to France, to learn some business skills to become an Entrepreneur. This was the time when were becoming more popular and open source. Naturally Sylvain embraced this Maker movement as he saw the power of this technology to bring manufacturing closer to its homeland. In 2012, Sylvain started working on a prototype of a large 3D Printer, the Galatea.

In 2012, Sylvain started working on a prototype of a large 3D Printer, the Galatea.

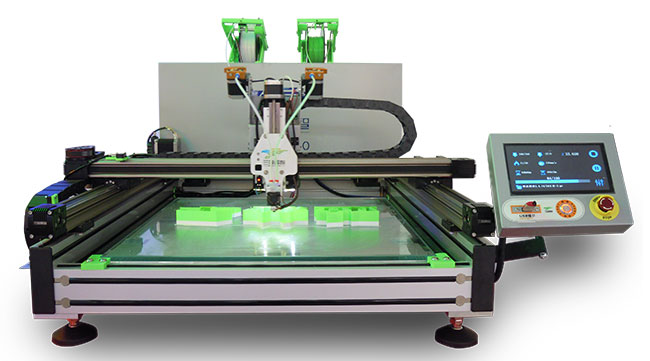

Today after 4 years of research and development, Sylvain is delighted to introduce Galatea 1.0 the 3D Printer that can print objects with size up to 2m by 1.2m by 1.5m. The Galatea is able to print at the speed of 30 cm per hour with resolution up to 1 mm. These specifications are impressive and very much comparable to what Massivit can do. As we reported in a previous article, the Massivit 3D Printer can print objects of 1.5m by 1.2m by 1.8m at a speed of 35 cm per hour with a Z resolution between 1mm and 1.5mm

Galatea: built with a respect of Nature in mind

Sylvain has been adamant about the capacity of the Galatea to print from recyclable materials. The current 1.0 version is able to print from ABS, Cellulose acetate, Polycarbonate, and some composite materials. It can also print using recycled materials. Massivit patented process is relying on a closed source Gel inducing significantly higher running costs. For large objects, the difference in the cost of material could become very significant.

For large objects, the difference in the cost of material could become very significant.

Galatea: a competitive price for a quality 3D Printer

As we reported in a previous article, the Massivit 3D Printer starts at $300K and will require the Massivit Gel to be operated. The Galatea 1.0 is being sold at a price point significantly lower. Running costs are also expected to be lower than for the Massivit. Sylvain has received strong interest from a growing number of possible buyers in a diverse range of sectors, from startup to marketing agencies and product design businesses. The machine is able to produce large furniture, decorative objects, real size statues,…

The machine comes with two software, including one specifically developed for the Galatea 1.0. The software is easy to use. The Galatea can be operated 24h a day in a production mode, as it has been recently for the manufacturing of large Lion statues for the opening of the Grand Lyon Stadium. The 3D Printed statutes are 4.2m height. It took 20 days of non-stop production.

The 3D Printed statutes are 4.2m height. It took 20 days of non-stop production.

Tags: 3dprint, 3dprinting, business

French company Drawn prints amazing furniture on its own 3D printer

Archive

When most people think about 3D printing, they envision objects that are no larger than a basketball. Yes, 3D printed items tend to be small, and in most cases this is due to two factors: 1. 3D printers have a limited working volume, so creating larger objects is difficult; 2. 3D printing is a very slow process. This is why it is extremely rare for us to hear news that someone has managed to 3D print, say, an entire table or chair.

3D Printed Chair

Today we're talking about Drawn, which is now showcasing its 3D printer and 3D printed furniture at the Maker Faire Paris. Among the main goals of the company are to launch their own line of 3D printed furniture, hold workshops for those who want to design and print furniture, and finally allow artists and designers to use the company's services and print the furniture of their dreams.

Among the main goals of the company are to launch their own line of 3D printed furniture, hold workshops for those who want to design and print furniture, and finally allow artists and designers to use the company's services and print the furniture of their dreams.

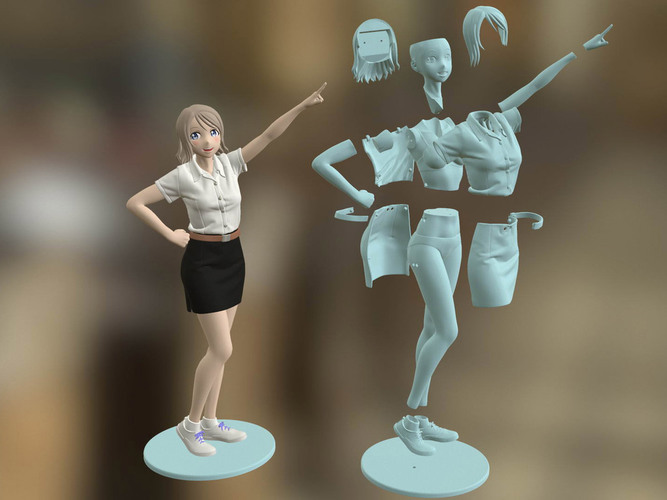

It all started in 2012 when Sylvaine Sharpiot and Samuel Javellet met at a seminar in Lyon, France. They both dreamed of making custom-made furniture. Enlisting the help of investors, they assembled a 3D printer with a robotic arm and named it Galatea (“Galatea”, the name of the statue of a beautiful woman created by the mythological Greek sculptor Pygmalion).

The Galatea 3D printer can print very large objects, although it is primarily intended for making furniture. Drawn has produced some truly amazing pieces of furniture so far, which they showcased at the Maker Faire this week.

“Soon we will release an exclusive line of furniture and will be ready to bring to life all your design projects,” the founders of the company say.“Our goal is to make furniture simple and versatile.”

It is not yet known if Drawn is going to sell its Galatea 3D printer, but if it does happen, companies will definitely line up. It is enough to look at the displayed samples of furniture to see how neatly and evenly the layers lie. Yes, the layers can be seen with the naked eye, just like any other fusing 3D printer. However, Drawn presents this as a design feature. The company does not try to hide the fact that visible lines remain after printing. Instead, she emphasizes their presence to draw extra attention to her furniture. Also, this 3D printer can print in different colors.

Article prepared for 3DToday.ru

Follow author

Follow

Don't want

1

Even more interesting articles

5

Subscribe to the author

Subscribe

Don't want

Alexander Gessler wrote a small handy program to convert 40+ 3D file formats (OBJ, S. ..

..

Read more

four

Subscribe to the author

Subscribe to the author

Don't want to

The progress of 3D printing in recent years has gained such a rapid pace that we will soon stop...

Read more

3

Subscribe to the author

Subscribe

Don't want

Recently, cloud-based 3D printing services have been developing. This concept allows the implementation of...

Read more

Archives 3d printer - NewsRobotics.ru

We present you a new device called "Galatea" - a robotic arm that resembles road construction equipment. The device was invented by engineer Sylvain Charpiot, founder of the French startup Drawn. Galatea is a large-scale 3D printer, formerly an industrial robot that worked in a car factory and now makes furniture out of 100% recyclable materials. The end product that can be obtained with the instrument is only limited by the imagination. To create simple furniture, the robot heats plastic (Drawn claims to use the same kind of plastic as Lego) to over 440 degrees Fahrenheit. At the moment, objects can reach about 200 cm in length and 120 cm in height.

The end product that can be obtained with the instrument is only limited by the imagination. To create simple furniture, the robot heats plastic (Drawn claims to use the same kind of plastic as Lego) to over 440 degrees Fahrenheit. At the moment, objects can reach about 200 cm in length and 120 cm in height.

The target audience for this device is not ordinary citizens, but designers or interior decorators or managers of restaurants, event halls or other public places. (The objects created are single-use items. Company representatives say they are recycled immediately after the event).

The instrument can be adapted to the individual preferences and requirements of users. Everything is in your hands: the shape of the object, its color, the material used and the size.

A Kickstarter campaign is currently underway to raise funds so that Sharpiot can create a mini version of the robot. So he will be able to take part in international exhibitions. There are still more than 20 days left of the campaign, and the engineer has already reached his financial goal with a figure of more than 20,000 USD. Ultimately, Sharpiot hopes to expand the business to include additional materials such as wood and linen.

Ultimately, Sharpiot hopes to expand the business to include additional materials such as wood and linen.

Posted on Author RomanCategories Mini-robots, IndustrialTags 3d printer, galatea, scale printer, RobotLeave a comment on This manipulator makes furniture of any shape and size

3D printers have already printed residential complexes, houses, and now, one of the companies in the Netherlands is going to "print" the bridge!

A Dutch company (MX3D) has developed a robotic 3-D printer to build a steel bridge over a canal in Amsterdam!

On their website, MX3D wrote “With our robots that can draw steel structures in 3D, we will print a bridge… We are researching and developing cost-effective robots with which we can print beautiful and functional objects in almost any form!

“This bridge shows how 3D printing is finally entering the world of large-scale, functional objects and sustainable materials to achieve unprecedented freedom of form.

How will the bridge be built?

Two robots will work at the same time. Small pieces of molten metal will weld together to form long steel structures on each side, eventually joining together.

Construction will start in September 2015.

Watch the video below for more information.

Posted on Author RomanCategories CommunicationTags 3d printing, 3d printer, canal in amsterdam, bridgeLeave a comment on 3D printer will build a bridge over the canal in Amsterdam- Robotic cheerleaders from Murata, despite the fact that the company does not create robots !

- Harvard scientists are trying to convey to Us the idea why robots made of soft materials are cool!

3. This "Adept Quattro" robotic machine quickly processes fish and determines the presence of caviar:

work of people in space. The results of the project will help astronauts reduce the amount of time they spend on routine space station maintenance tasks:

- queue, simple structures are needed:

6. MQ-4C Triton drone platform made its first flight earlier this month. In the video, you can really appreciate the scale of the drone (wingspan of 130 feet), it is significantly larger than that of their predecessor Global Hawk.

MQ-4C Triton drone platform made its first flight earlier this month. In the video, you can really appreciate the scale of the drone (wingspan of 130 feet), it is significantly larger than that of their predecessor Global Hawk.

Currently, 3D printers still need a lot of improvements, and one of the most striking problems is that their printing power is limited by the size of the printer itself. The print head on a 3D printer can only move around a certain perimeter. That's why the idea of moving the printer to a wheeled platform is just incredible; this could be quite a big leap in the world of new technologies.

Designed by industrial designers from NEXT and LIFE agencies, the 3&Dbot printer can operate in almost limitless space, but the instrument still needs a flat surface to function effectively at this stage. On the way to creating a mobile 3D printer of such a model, unexpected difficulties and controversial issues arise; the most important among which is the development of a tracking system that will control the trajectory of the mechanism and ensure absolutely precise movements. This also includes the regulation of wheels that can act in all directions.

The limited print head height will not be an insurmountable problem either. Once the model gets too tall for the robot and it can no longer add layers, the robot can easily 3D print a temporary support, ride on it, and continue working.

Posted on Author RomanCategories ROBOTICS NEWSTags 3d printer, dbot, printing on wheels, printer on wheels, RobotLeave a comment on 3D printer can print anything, anywhere! 3D printers are great at making small objects. Of course, some of them can print objects comparable to a car. But all these manipulations cannot go beyond the boundaries of one room.

Of course, some of them can print objects comparable to a car. But all these manipulations cannot go beyond the boundaries of one room.

To solve this problem, a team of researchers from the Institute of Modern Architecture of Catalonia (ISAA) in Barcelona created a group of 3D printers that can create objects directly on the right place. 3D printing of the structure in one continuous process, forming layer by layer in one specific place.

The robots that participate in the process are called “Minibuilders” due to their small stature (the largest being 42 cm wide). The “Minibuilders” team has three robots that perform various functions during the construction process, working independently of each other, but in coordination with each other, in a common work. Each Minibuilder performs its role in a particular order, using instructions provided by the central computer in conjunction with its own sensors and local positioning systems.

The first robot called “Foundation” comes into action - this robot makes the foundation of the object.

The “Grip” robot follows the Foundation robot. Using his four rollers, he moves around the structure and sets up additional materials to create a wall.

The last robot under construction is the "Vacuum" robot. It is attached to the surface of the structure. Moves vertically (down to up), applying additional material, thereby providing strength to the object.

Video shows Minibuilders in action:

Posted on Author RomanCategories Communication, Helpers, IndustrialTags 3d printing, 3d printer, robotics, minibuilder robotsLeave a comment on A team of several large-scale 3D printers "Minibuilder" can create large-scale objects . This 3d printer is a small and very compact printer, its dimensions are 57x36x32 centimeters, which allows it to be placed on a standard user's desk. This little wizard can print 3D objects at home from very durable materials such as carbon fiber, fiberglass, PLA, nylon and composite materials.