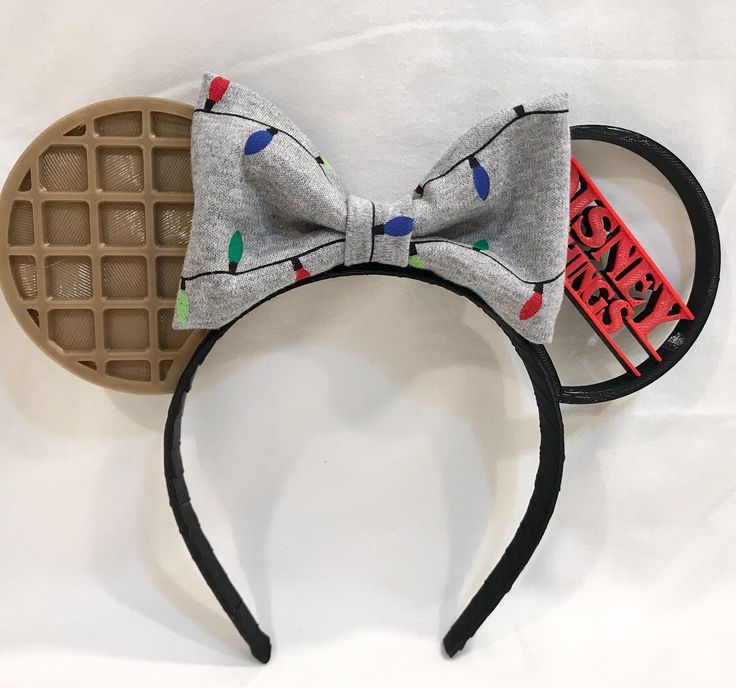

3D printed disney ears

DIY 3D Printed Interchangeable Mickey Ears

This post may contain affiliate links. If you purchase something through the link, I may receive a small commission at no extra charge to you.

8.0K shares

These 3D Printed Interchangeable Mickey Ears are fun to make with a 3D printer! They’re lightweight, cute and you can make multiple pairs for all of your favorite characters!

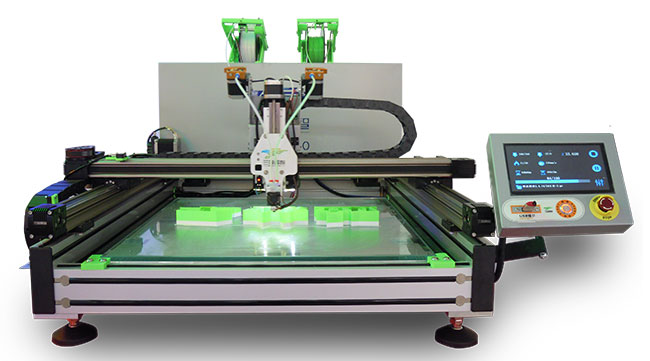

To be able to make this project, you will need a 3D printer. Chris bought one a few years ago and we’ve been experimenting with different projects and designs ever since.

These 3D printed interchangeable Mickey ears were some of the first things we tried to make and there was a lot of trial and error with them!

If you don’t have a 3D printer of your own, a lot of libraries have Maker Spaces where they have cutting machines (like a Silhouette Cameo or Cricut), 3D printers and more. Check your local library to see what they offer and what you can use!

If you are new to 3D printing there is a learning curve. Chris and I like to browse Thingiverse for ideas and test prints, it’s the best way to learn the software!

For these interchangeable Mickey ears Chris and I experimented with the size and design of them for a while until we got them right. I let Chris do the designing and then compared the shape to the Mickey Ears Disney makes and sells until I felt like they were close enough.

I also really wanted the ears to be interchangeable so we figured out a way to use magnets in the ear design to make it happen. This is probably my favorite part of the entire design, but it isn’t necessary if you don’t want to change out your ear designs during the day!

Interchangeable Mickey Ears have three different parts, the

- headband,

- 3D printed magnetic bars, and

- 3D printed Mickey Ears.

If you do not want to make your ears interchangeable, you don’t need to print out the bars and you’ll just superglue your Ear designs directly to the headband. However, I think they’re easier to store and take up less space if you can remove the ears.

However, I think they’re easier to store and take up less space if you can remove the ears.

Materials You’ll Need for These 3D Printed Mickey Ears:

You will need….

- 3D Printer

- Filament

- Headband

- Small Magnets

- Faux Suede Ribbon

- Super Glue

Commonly asked questions when making 3D Printed Interchangeable Mickey Ears:

1. How do you find the center of the headband?

I have a few other Mickey Ears that I used to help me find the center by laying my own headband on top of them and then using a fabric pen to mark where the ears sat. This was super helpful and easy!

But if you don’t have other headbands to go off of I suggest laying them on a fabric cutting mat and finding the center that way (you can also use your Silhouette mat!). Lay your ears on top of the headband until you find the desired look, mark the spot with a fabric pen, and then super glue them on. Easy peasy!

2. Does the headband slide around on your head if it’s windy?

Short answer? YES.

But if you use a certain type of fabric to wrap the headband with you can make it so that they don’t. I suggest wrapping your headband with this textured trim and then using faux suede to put on the inside of the headband. The faux suede will grip your hair and help the interchangeable Mickey Ears (mostly) stay put. That’s not to say that a strong gust of wind won’t push them a little bit…but they shouldn’t slide right off your head unless the wind is crazy strong.

I used satin ribbon for my first headband. Don’t do this. It is slippery and I had to keep pushing the headband back in place because it would slide around!

3. What type of glue do you use to keep the ears in place?

Gorilla super glue is our favorite. It doesn’t take long to dry and it is STRONG.

Hot glue did not have as good of a grip on the ears so I do not suggest using it. Stick with super glue.

4. Do you have a specific type of headband that you suggest using for the headbands?

Honestly, any type of headband will work for this. I used these headbands from Amazon and I really liked them because they were wide and did not squeeze/hurt my head after a few hours of wearing them.

I used these headbands from Amazon and I really liked them because they were wide and did not squeeze/hurt my head after a few hours of wearing them.

You could also go to Sally’s to try to find headbands that you like. Target does not have them….trust me, I looked.

5. Where can I find designs to use for my Mickey Ears?

Chris and I like to browse Thingiverse.com for Interchangeable Mickey Ears and other projects!

If you’re new to 3D printing, using other people’s designs for personal use only is a great way to get comfortable with the software and your printer. Once you get more comfortable you can start experimenting with your own designs!

FAQ’S

Does this tutorial only work with interchangeable ears or can you make a regular pair?

You do not need to make interchangeable ears if you don’t want to! I love them because they save space in my bag but it isn’t necessary to make the ears removable.

You can still follow this tutorial, just leave out the small 3D printed magnetic bar and glue the ears directly onto the headband!

What if I don’t have a 3D printer at home?

Most library’s have a Maker Station now (ours is called Makerspace) that have all sorts of machines and equipment you can use!

Ours have:

- 3D printers,

- a Silhouette Cameo and Curio

- Heat Press,

- Sewing machines and more!

Make sure you check to see if yours is open though! Ours is currently letting you print things on a 3D printer by appointment only.

Silhouette Alta vs. Prusa 3D Printer

I have never used the Silhouette Alta 3D printer so I cannot speak to the ease of printing on it. I would say that the learning curve with the software is probably similar to using the software for the Prusa 3D printer we own.

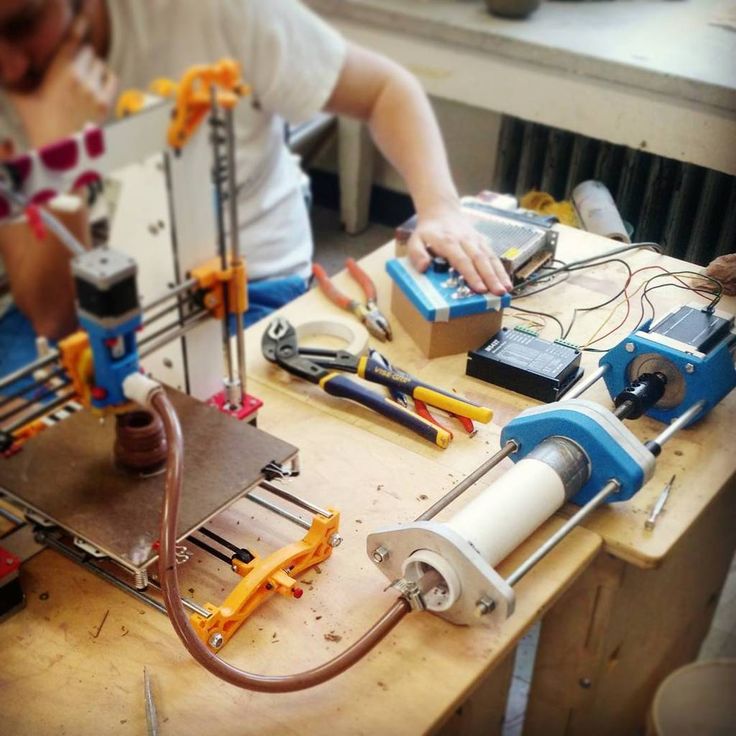

However, Chris had to build his Prusa 3D printer himself and if parts break on it he has to troubleshoot it all on his own.

What I do like about the Prusa is that you can buy a part to print up to 5 different colors so you can have a multi-colored design. It’s probably my favorite feature.

But, the Silhouette Alta comes out of the box ready to go so it is a great option if you don’t like a lot of set-up!

Materials

- Headband

- Elastic Ribbon

- Faux Suede Ribbon

- Hot Glue

- Magnets

- Super glue

Tools

- 3D Printer

- Filament

Instructions

- Place magnets in magnetic bars and ears.

Before you glue them in make sure that you have the magnets turned the right way so the ears and magnetic bars stick together.

Before you glue them in make sure that you have the magnets turned the right way so the ears and magnetic bars stick together. - Use super glue to attach the magnetic bars to your headband. (see post on how to find the center of your headband to get the correct placement for your ears)

- Tightly wrap your headband with the elastic ribbon. Use hot glue to attach the ends of the ribbon to the headband.

- Cut a piece of the faux suede ribbon and super glue it to the inside of your headband (this will help it stay on your head).

- Make a bow using this no-sew tutorial.

- Attach it to your headband in between the ears with super glue.

Recommended Products

As an Amazon Associate and member of other affiliate programs, I earn from qualifying purchases.

-

Original Prusa i3 MK3S kit

-

PLA 3D Printer Filament

-

Headbands, 1 Inch Wide

8. 0K shares

0K shares

3d Printed Ears - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

For the first time, a 3D-printed ear was transplanted into a patient For a 20-year-old patient with a deformity of the right ear, a special ear implant was made from her own cells.

Patient before and 30 days after surgery / Microtia-Congenital Ear Institute

Patient before and 30 days after surgery / Microtia-Congenital Ear Institute According to independent medical experts who evaluated the technology's first clinical trial, this transplant was a breakthrough in tissue engineering.

A patient from Mexico was born with microtia, a rare birth defect that deforms the pinna or outer part of the ear.

The 3D printing manufacturing process typically involves a computer-controlled printer applying material in thin layers to create the exact shape of an object. The new ear implant from 3DBio Therapeutics combines several patented technologies, starting with a method to turn a small sample of a patient's cells into billions of cells. The company's 3D printer uses collagen-based "bio-ink", which is safe for the body and ensures the sterility of all materials.

A surgeon removed 0.5 g of cartilage from a woman's deformed ear. Chondrocytes, the cells responsible for cartilage formation, were then isolated from a tissue sample and grown in a proprietary suspension of nutrients. Live cells were mixed with bioink. Collagen was injected through a syringe into a specialized 3D bioprinter, which squeezed the material out of the nozzle in an even, thin stream, moving in a circle, creating a small oblong shape that was a mirror image of the patient's healthy ear. The entire printing process took less than 10 minutes.

Live cells were mixed with bioink. Collagen was injected through a syringe into a specialized 3D bioprinter, which squeezed the material out of the nozzle in an even, thin stream, moving in a circle, creating a small oblong shape that was a mirror image of the patient's healthy ear. The entire printing process took less than 10 minutes.

The printed ear shape was then placed in a protective biodegradable shell and placed in the refrigerator overnight. The next day, it was implanted under the patient's skin just above the jawbone. As the skin tightened around the implant, the shape of the ear appeared.

3DBio Therapeutics notes that their implant is more cosmetic. According to them, after transplantation, the ear will independently regenerate cartilage tissue, acquiring the appearance of a natural organ.

The company's specialists estimate the probability of implant rejection as low, since the cells for printing the organ were taken from the patient's own tissues.

The transplant was performed by Dr. Arturo Bonilla, pediatric reconstructive surgeon from San Antonio. “If everything goes according to plan, this technology will be revolutionary,” he said.

In total, 11 people are currently participating in clinical trials for the transplantation of such implants. The company's executives said that with more research, the technology could be used to fabricate other implants, including intervertebral discs, noses, knee menisci, and laparectomy reconstructive tissues. Perhaps in the future, much more complex vital organs, such as the liver or kidneys, could be produced using 3D printing.

Meanwhile, United Therapeutics Corp. experimenting with 3D printing to produce lungs for transplantation. And scientists at the Israel Institute of Technology reported in September that they had 3D printed a network of blood vessels needed to supply blood to implanted tissues.

Printing organs: how ears, skin and noses are made with a 3D printer

- Natalka Pisnya

- BBC Russian Service, USA

Subscribe to our ”Context” newsletter: it will help you understand the events.

Photo copyright, Masela family archive

Photo caption,Luc Masela with his parents one month after the artificial bladder transplant. year 2001.

Now 27, Luc Masela is an athlete with a degree in economics, works for a large exhibition company, travels a lot and recently met, in his words, "the most beautiful girl in the world." Both she and most of his current friends were extremely surprised when they learned that 17 years ago he survived a dozen and a half operations.

Luke was born with spina bifida - and although he was able to walk, his bladder was severely damaged. By the age of 10, he almost did not leave hospitals: due to improper functioning of the bladder, fluid began to return to the boy's kidneys, doctors diagnosed an irreversible pathology of the organ.

You need JavaScript enabled or a different browser to view this content

Video caption,"3D printed" organs are here

Doctors offered the family two solutions: lifelong dialysis or the creation of a new bladder from a segment of the intestine. This would guarantee Luke several years of medically supervised life and a high risk of developing cancer.

This would guarantee Luke several years of medically supervised life and a high risk of developing cancer.

The urologist in charge of the boy suggested that Masela's family take part in an experimental program to grow a new bladder from his own cells. Then, in 2001, it sounded like science fiction: only nine people took part in the program itself before Luke. Despite this, his family agreed.

"The essence of the operation was reduced to two stages: first, a piece of bladder tissue was taken from me, and over the next two months, cells were grown in the laboratory in order to grow a new healthy bladder from them," says Luke.

Photo copyright, Masela family archive

Photo caption,Luc Masela, 17 years after his artificial bladder transplant

Next came the transplant, which he said took 16 hours. “I opened my eyes and saw a cut across my entire stomach, tubes of all possible sizes were sticking out of me, except for them - four IVs and a bottle feeding machine,” he recalls. “I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month.

“I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month.

The operation was performed by Dr. Anthony Atala, Pediatric Regenerative Surgeon. In two months, out of a hundred patient cells, scientists created one and a half billion. Further, an engineering structure was created on a collagen frame: the bladder was “sculpted” like a two-layer pie, the core of which dissolved over time, and it started working like a normal organ, taking root thanks to Luke’s own cells.

- An animal capable of regrowing its head

- The birth of a chimera: why do scientists need a human-animal hybrid?

- Swedish company 3D prints body parts

Luke and Dr. Atala haven't seen each other for 10 years after being discharged from the hospital. Once a dying child became the champion of the school wrestling team and went to college.

The professor took charge of the Wake Forest Institute of Regenerative Medicine in North Carolina in those 10 years, but he never forgot about Luke: his bladder was one of the most challenging and most successful projects in his early practice.

By 2018, Atala won the Christopher Columbus Prize for "work on a discovery that will have a significant impact on society"; The Times and Scientific American magazines at various times named him "Physician of the Year", he was also recognized as "one of the 50 scientists on the planet who in the next 10 years will change the way we live and work."

How to print a new face

Skip the Podcast and continue reading.

Podcast

What was that?

We quickly, simply and clearly explain what happened, why it's important and what's next.

episodes

The End of the Story Podcast

In the mid-2000s, Atala's team turned their attention to an ordinary household 3D printer and wrote special software for it, later specialized machines were created for the laboratory. Now the laboratory "grows" up to 30 different types of cells and organs, as well as cartilage and bones.

One of the team's latest achievements is ears and noses grown outside the human body.

The main customer and sponsor of Atala's developments is the US Department of Defense, and many of the patients are military victims of military operations.

It works like this: first, a CT scan of the ear or nose is done. One of Atala's assistants, Joshua Corpus, jokes that at this stage, people often ask to "improve" the shape of the nose if they thought theirs was too wide or hooked, and the ears if they were too wide.

After that, a special computer code is written, and the printing of the base of the organs begins.

For this, a bioresorbable polymer, polycaprolactam, is used. At the same time flexible and durable, in the human body it disintegrates within four years.

After printing, the layers of polycaprolactam resemble lace; after transplantation, after a few years, their place will be taken by the person's own cartilage tissues.

Polycaprolactam is then saturated with a gel created from the patient's cells, cooled to -18 degrees Celsius - so the cells, according to scientists, are not damaged, they are "alive and happy."

Image caption,Printing a test kidney sample on a bioprinter

In order for the polymer and gel structure to take shape and become something more durable, ultraviolet light is used in the laboratory - it does not damage cells.

The future implant is printed for 4-5 hours, then it is finally formed and inserted under the epidermis.

Skin can also be grown: children affected by fires were the first to take part in the early trials of Atala - after the "printing" of the skin, scientists observed the patients for several more years. The new skin did not crack, did not burst, and grew with the children.

The new skin did not crack, did not burst, and grew with the children.

The most difficult job, according to the scientist, is facial wounds: it's not enough just to stretch the skin, you need to accurately calculate the geometry, align swelling, bone structure, and understand how a person will look after that.

In addition to the skin and ears, Atala can "print" the bones of the jaws, grow blood vessels and cells of some organs - the liver, kidneys, lungs.

This technology is especially appreciated by oncologists: on the basis of patient cells, it is possible to recreate the body's response to various types of chemotherapy and observe the reaction to a particular type of treatment in the laboratory, and not on a living person.

But the liver, kidneys, lungs and heart are still being tested. Atala says he raised them in miniature, but creating organs from various tissues to real size requires a lot of additional research.

But, according to him, cells were grown in the laboratory and a vagina was created for a girl who was born several years ago with a congenital deformity of the genital organs - several years have passed since the transplant.

Image caption,Bioprinted polycaprolactam ear implant base

Atala smiles and adds that his team is also working on a working penis. This research has been going on for several years, and the most troublesome for scientists is the complex structure of tissues and the specific sensitivity of the organ itself.

Among others, Igor Vasyutin, a Russian post-graduate student of the First Moscow State Medical University (MSMU) named after Sechenov, is working on this under laboratory conditions. He is a cell biologist, Atala's right hand.

Vasyutin has been in the USA for about a year - he came on an exchange. He is ready to talk about the behavior of stem cells for hours, but becomes less verbose when it comes to Russian science.

Vasyutin's alma mater has not reached mass regeneration of human organs and is still training on animals: local scientists "printed" a mouse thyroid gland on a 3D printer.

They are also involved in the study of human organs. According to the head of the Institute of Regenerative Medicine at MSMU Denis Butnar, several years ago the Institute recreated a special engineering design of the buccal mucosa. She functioned perfectly for the first six months, but subsequently had to undergo a second operation.

Image caption,Test specimen of an ear implant under ultraviolet light

In Russia, however, over the past few years, the Italian surgeon-transplantologist Paolo Macchiarini has been practicing, the man who was the first in history to perform a synthetic organ transplant operation - a plastic tube that replaced the patient trachea.

- Paolo Macchiarini: the rise and fall of the famous surgeon

However, seven of his nine patients died, and the breathing tubes implanted in the remaining two subsequently had to be replaced with donor ones.

Several criminal cases were brought against him, including on charges of pressure on patients and fraud, and the leading doctors of the world called Macchiarini's operations "ethical Chernobyl".

Will printed organs replace donors?

At the zenith of his career, Macchiarini argued that a new perspective is opening up for humanity: you can "print" any human organ on a printer, create an engineering structure from it, enriched with the patient's stem cells, and get the perfect prosthesis.

Be that as it may, complex human organs - the liver, kidneys, heart, lungs - have not yet been able to grow any regenerative surgeon.

Bioprinting of the so-called simple organs, however, is already available in the US, Sweden, Spain and Israel - at the level of clinical trials and special programs.

The US government is actively investing in such programs - in addition to Wake Forest, cooperating with the Pentagon, the Massachusetts Institute of Technology also receives significant amounts to recreate the work of the liver, heart and lungs.

Skin application test on a burnt wound

According to Professor Jorge Raquela, a gastroenterologist at the Mayo Clinic Research Center, "Bioprinting is one of the most exciting branches of modern medicine, it has huge potential, and the turning point of the most important discoveries is already close."

Meanwhile, Pete Basillier, head of R&D at analytics firm Gartner, insists technology is advancing much faster than understanding the implications of 3D printing.

Such developments, according to Basilière, even created with the best of intentions, give rise to a set of questions: what will happen when "improved" organs are created, the basis of which will not only be human cells - will they have "superpowers"? Will a regulatory body be created to monitor their production? Who will check the quality of these organs?

More than 150,000 Americans are on the waiting list for organ transplants every year, according to a report from the US National Library of Medicine. Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone.

Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone.

- A 3D printer helped a cyclist who lost his jaw

- Genetically modified pigs - human organ donors?

- The world's first child with both hands transplanted plays baseball

Most Americans are potential donors: upon obtaining a driver's license, they voluntarily answer the question of whether they agree to donate their organs in the event of a car accident or other dangerous incident . In case of consent, a small "heart" and the word "donor" appear in the corner of the document.

Professor Atala's driver's license is like that - despite all his achievements and faith in the "publishing organs", he is ready to share his with those around him.