Folding 3d printer

The Foldie 3D Collapsible 3D Printer Looks Like It Will Fit Right In - 3DPrint.com

3D printers designed for the desktop can often be quite touchy when moved from one place to the next. Ask any maker who travels with his 3D printer regularly how much fun it is to dismantle and reassemble his machine and you’re likely to hear some foul language followed by muffled whines and grumbling. Especially when their machines are self-built or assembled from kits. And while there have been a couple decent designs for folding or collapsible printers over the last few years, they are often still large and unwieldy to move, just large and unwieldy in a slightly more compact form.

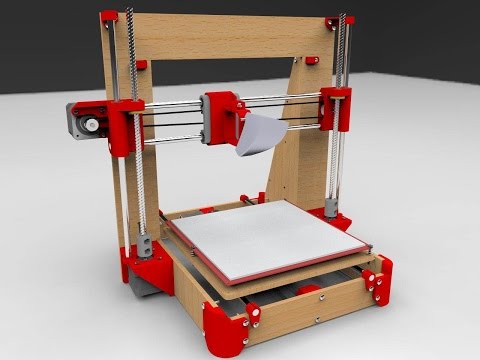

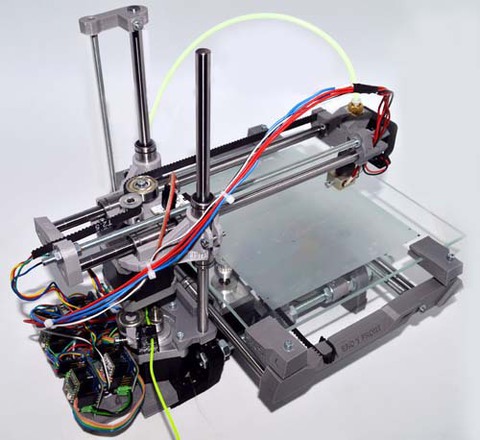

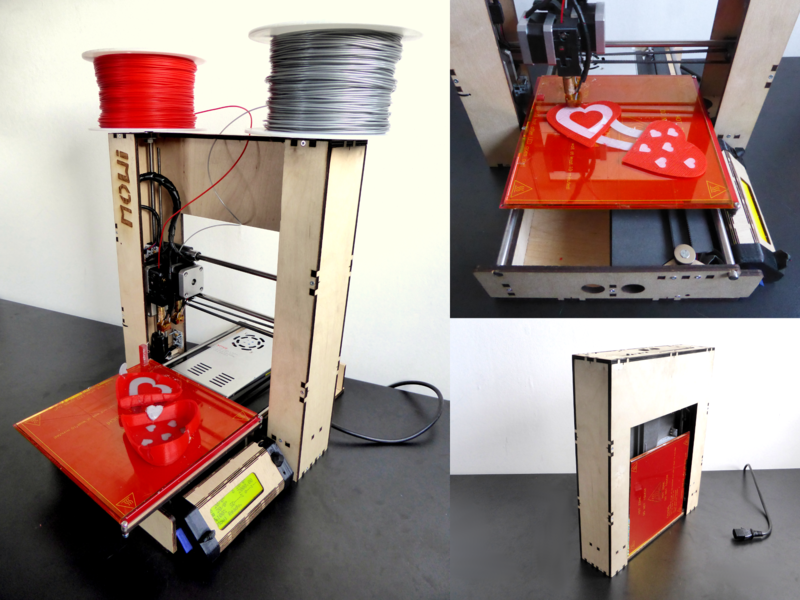

With extreme portability in mind, a Belgian 3D printer reseller and service company called 3D Printers VDB has been developing a compact and easy to move collapsible 3D printer called the Foldie 3D FFF Printer. The Foldie 3D has evolved through a few iterations in the last few months, but two things remain constant. Almost all of the parts on the printer are completely 3D printable, and it has the ability to be fully collapsed and tucked inside a standard 19 inch laptop bag. And that includes everything that it needs to run, including the printer’s power source and a spool of 3D printing filament.

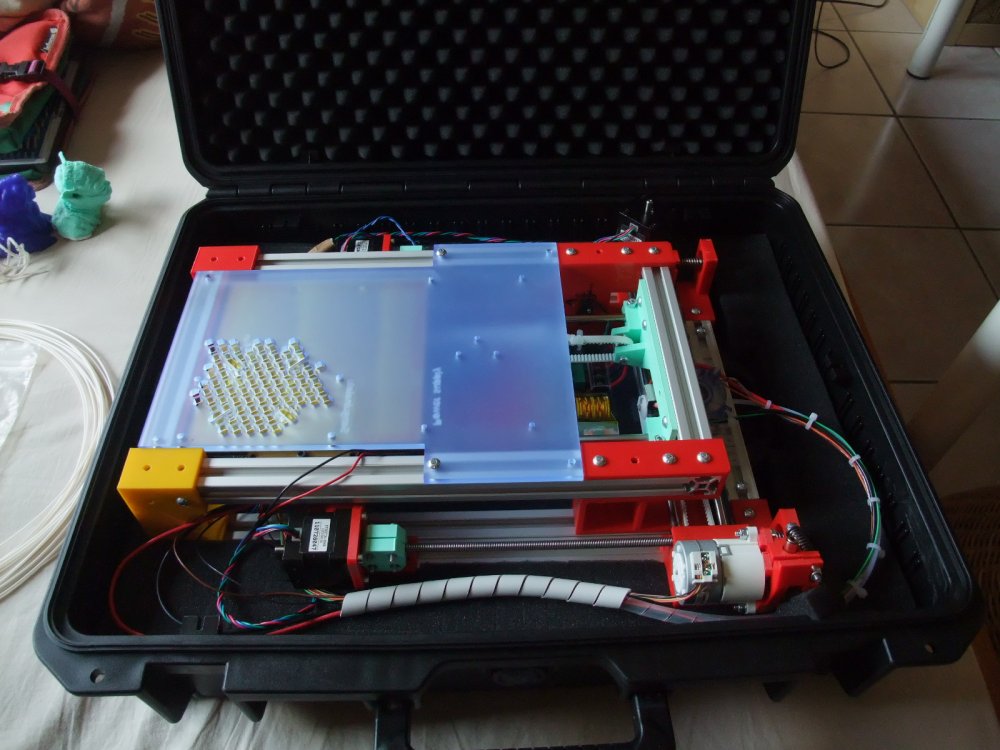

An early prototype Foldie 3D and power supply tucked into a 19 inch laptop bag.

The reason 3D Printers VDB CEO Yvan Van den Bossche decided to create the Foldie 3D was to offer younger makers, students or those new to the technology access to an affordable DIY 3D printer kit. While he hasn’t completed the retail kit yet, he estimates that anyone choosing to build their own from his files could easily do so for less than $340, and that’s provided that you don’t skimp on the few non-3D printable components. The only non-printable parts are six glider rods, a single threaded rod, the four stepper motors, the electronics and a handful of screws, bolts, washers.

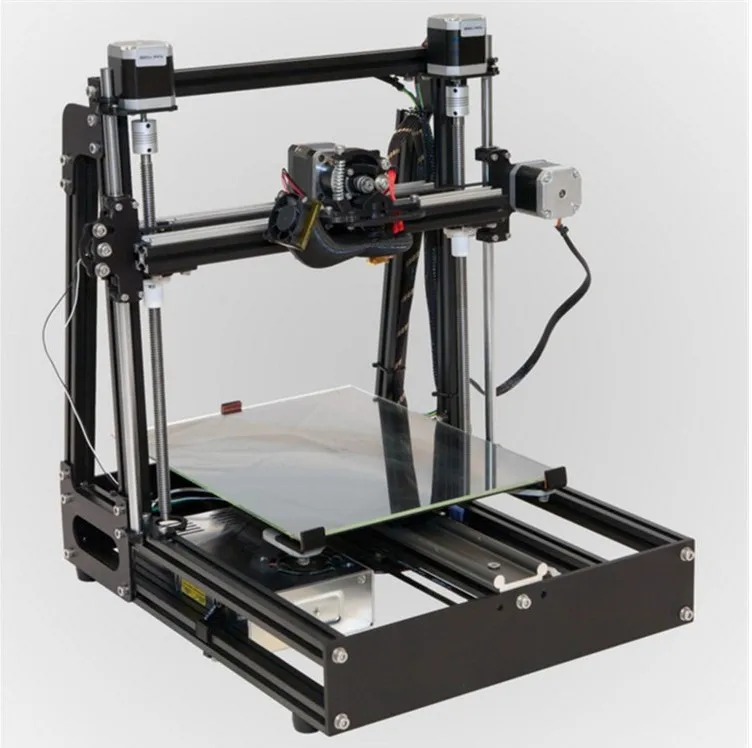

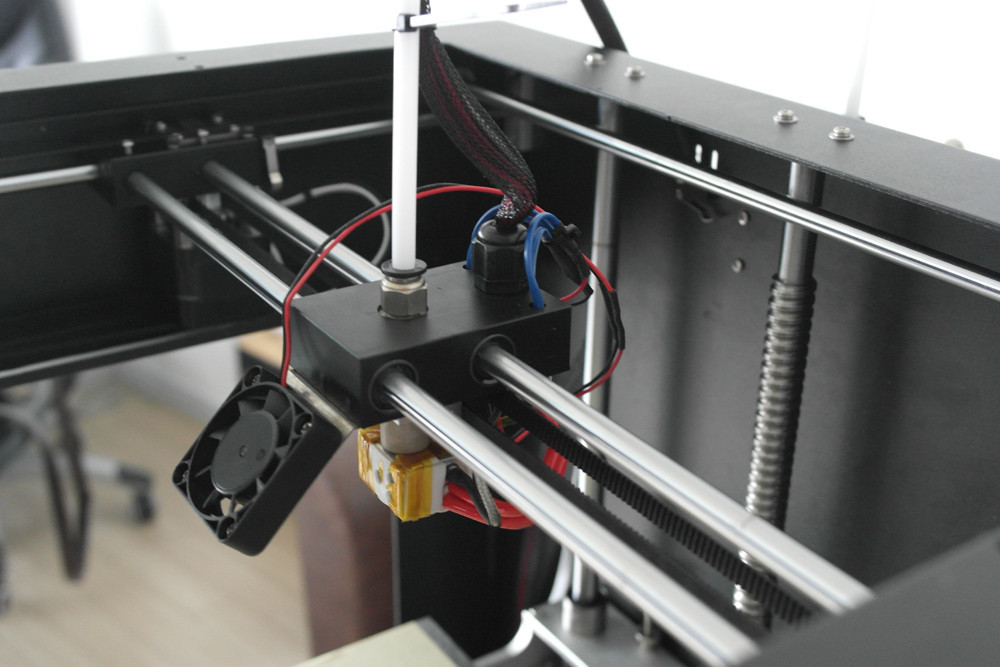

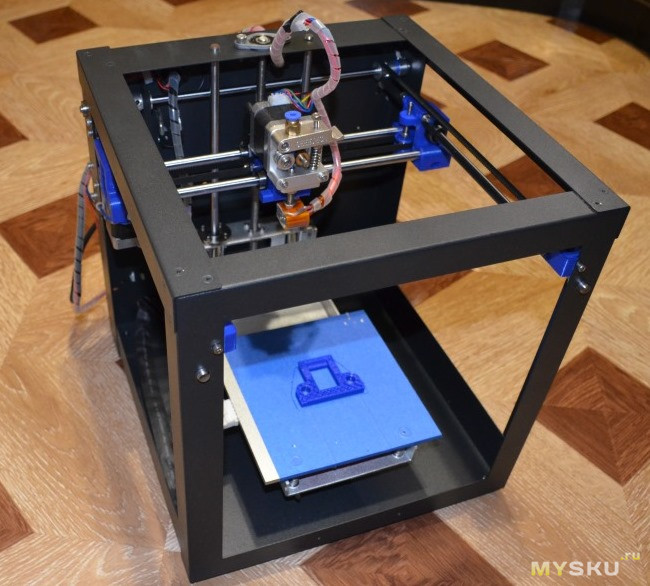

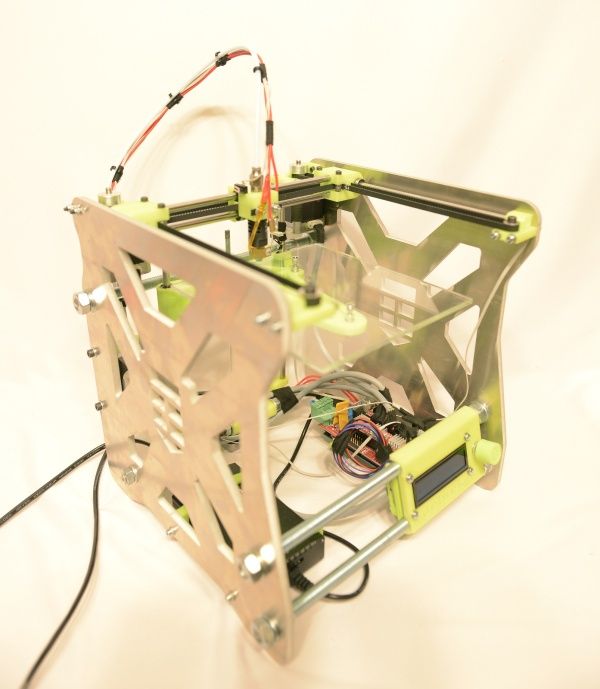

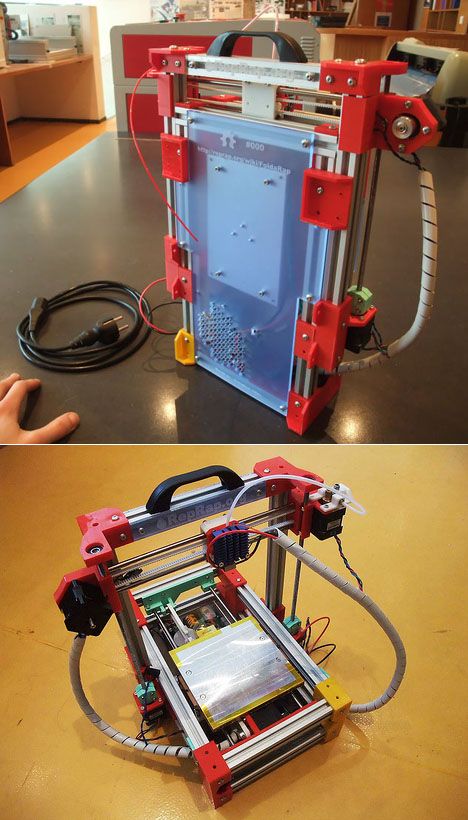

The current iteration of the Foldie 3D.

“Since we still are in Dev fase, I can’t disclose too much, except that Foldie will stay open source, and a crowdfunding will be raised with all components sourced neatly together in a kit. The parts and firmware will be made public and free, available via Thingiverse and Instructables to ensure an even more accessible approach than GitHub for example,” said Van den Bossche.

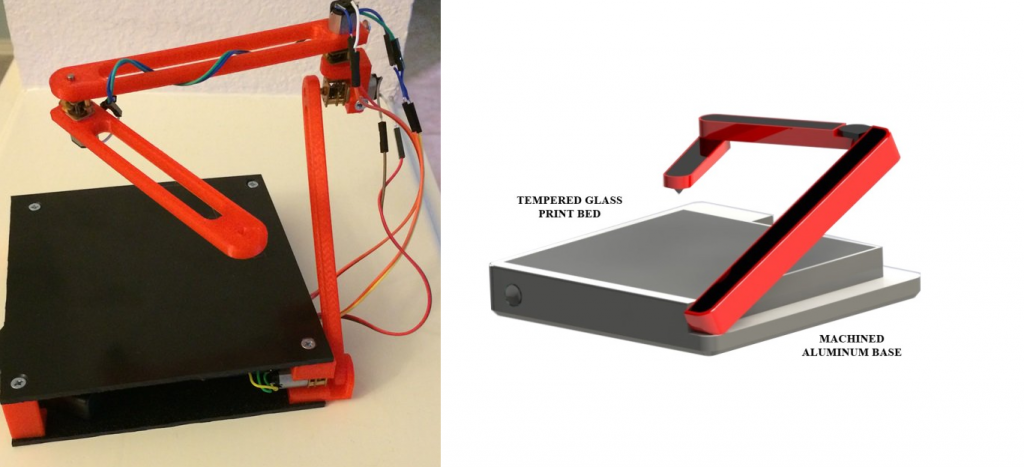

Once he’s ready to launch the retail version, Van den Bossche will be crowdfunding a kit that will include some pretty great extras. It will include a 160mm borosilicate (high heat tolerant glass) printing bed that can be optionally heated. He expects the printer to be able to print objects around 150mm high, although the exact printing envelope is still being developed. To keep costs down, the non-heated print bed option will include a universal laptop-power-plug as a power source, however if the kit is upgraded to the heated bed option a more powerful power supply will be included.

All of the required parts packed away into a laptop bag.

The Foldie 3D can be be run with an optional tablet that will come preinstalled with several open source or free software packages, including repetier host, meshmixer, SketchUp, and 3D printing essentials added to the browser, like Microsoft’s Netfabb online repair service. He expects to use a powerful tablet with 8gb ram running Windows 10 with an upgraded cost of a little over $400. The base kit price has yet to be determined, but with so few parts that are not 3D printed it is certainly going to be an affordable buy-in price.

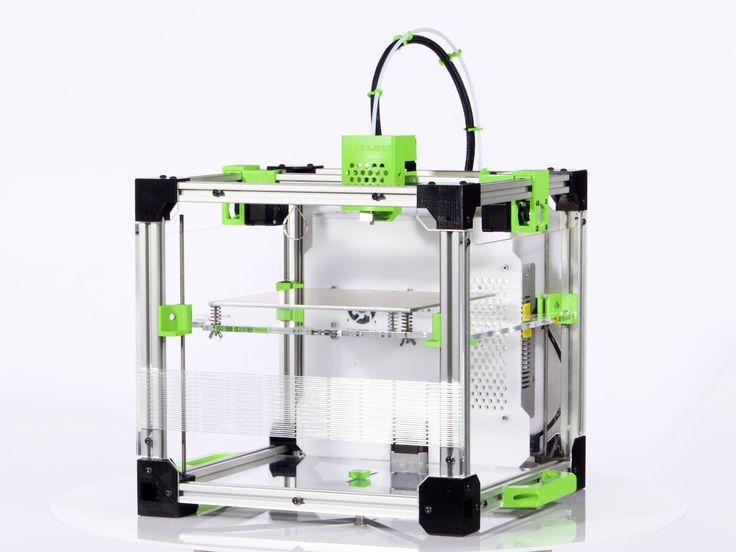

While his primary project is currently the Foldie 3D, Van den Bossche is also developing the Foldie 3D Qubic, a large-scale version of the Foldie. Before turning to 3D printing and design, Van den Bossche graduated school as a chocolatier and baker, so he plans to combine his two passions and develop what he calls the world’s first real chocolate 3D printer.

The fully assembled Foldie 3D prototype.

“Why ‘real’? Current companies claiming that title don’t print chocolate, but cocoa paste. I intend to create a printer that brings the chocolate (real and Belgian) tempered in front of the nozzle, So the end product cracks and melts in peoples mouths as our famous Belgian Chocolate should.” he explained.

Foldie 3D is printed entirely in biodegradable PLA materials, and Van den Bossche encouraged anyone printing their own to do the same. He designed the printed to be perfectly sturdy and dependable with PLA parts, so he says that there is no need to use ABS unless it is absolutely necessary. He said that he would hate to see his design made from a material that could potentially pollute the planet any further than it already is. Let us know what you think of this portable 3D printer design over on our Foldie 3D Collapsible 3D Printer forum thread at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D Printers VDB • belgium • collapsible 3D printer • compact 3d printer • crowdfunding • foldable 3d printer • Foldie 3D • thingiverse • travel 3d printer • Yvan Van den Bossche

Please enable JavaScript to view the comments powered by Disqus.

Bend Your Prints To Eliminate Supports

- by: Arya Voronova

When designing even a reasonably simple 3D-printable part, you need to account for all the supports it will require to print well. Strategic offsetting, chamfering, and filleting are firmly in our toolkits. Over time we’ve learned to dial our settings in so that, hopefully, we don’t have to fumble around with a xacto knife after the bed has cooled down. On Twitter, Chris shows off his foldable 3D print experiments (nitter) that work around the support problem by printing the part as a single piece able to fold into a block as soon as you pop it off the bed.

The main components of this trick seem to be the shape of the place where the print will fold, and the alignment of bottom layer lines perpendicular to the direction of the fold lines. [Chris] shows a cross-section of his FreeCad design, sharing the dimensions he has found to work best.

Of course, this is Twitter, so other hackers are making suggestions to improve the design — like this sketch of a captive wedge likely to improve alignment. As for layer line direction alignment, [Chris] admits to winging it by rotating the part in the slicer until the layer lines are oriented just right. People have been experimenting with this for some time now, and tricks like these are always a welcome addition to our toolkits. You might be wondering – what kinds of projects are such hinges useful for?

The example Chris provides is a Eurorack rail segment — due to the kind of overhangs required, you’d be inclined to print it vertically, taking a hit to the print time and introducing structural weaknesses. With this trick, you absolutely don’t have to! You can also go way further and 3D print a single-piece foldable Raspberry Pi Zero case, available on Printables, with only two extra endcaps somewhat required to hold it together.

With this trick, you absolutely don’t have to! You can also go way further and 3D print a single-piece foldable Raspberry Pi Zero case, available on Printables, with only two extra endcaps somewhat required to hold it together.

Foldable 3D prints aren’t new, though we typically see them done with print-in-place hinges that are technically separate pieces. This trick is a radical solution to avoiding supports and any piece separation altogether. In laser cutting, we’ve known about similar techniques for a while, called a “living hinge”, but we generally haven’t extended this technique into 3D printing, save for a few manufacturing-grade techniques. Hinges like these aren’t generally meant to bend many times before they break. It’s possible to work around that, too — last time we talked about this, it was an extensive journey that combined plastic and fabric to produce incredibly small 3D printed robots!

We thank [Chaos] for sharing this with us!

07. 10.2021

10.2021

Content

-

- Advantage 3D prints for the manufacture of costume elements 9000

- Making master models

- Rating of the best cosplay printers

- FDM printers

- Photopolymer printers

- Totals

Probably everyone wanted to feel at least for a while in the shoes of their favorite hero. Or briefly be in a fantasy world. Cosplay allows, at least for a while, to plunge into a fictional world with its own laws.

Cosplay should not be confused with role-playing, because cosplay does not imply the development of the character or history of the character. It focuses on the detailed reproduction of the image of the character to the smallest detail. nine0003

Some people think that cosplay is limited only to curvy girls in skimpy outfits, but this is far from the case. The skill of some cosplayers is amazing. They manage to single-handedly create amazing things with precision and detail that many workshops cannot reproduce.

Terminator suit from Warhammer 40k

A good cosplay is not only an external correspondence to the appearance of the selected character, it is the ability to convey the character and other features of the character (for example, characteristic movements, facial expressions, etc.). At photo shoots, with the help of Photoshop, they try to add the atmosphere of the world to better convey the nuances of the character. nine0003

It is believed that the term Cosplay was coined by Japanese journalist Nobuyuki Takahashi. The word itself is a combination of the initial letters of the word costume (costume) and play (play).

Warhammer 40k universe photoshoot

The advantage of 3D printing for costume elements

Previously, a cosplay costume was literally made from improvised materials. Each, to the best of his skills, available tools and ingenuity, used various, mainly construction, materials to assemble the costume - isolon, glue gun, tourist rugs, etc. nine0003

nine0003

Now available special materials for the manufacture of parts. The most popular of them is Eva foam.

Eva

Eva is a very convenient material for making a variety of armor. The biggest advantage over other materials is thermoplasticity. When heated, eva easily bends, and after cooling, it keeps its shape. On sale you can find eva foam of various hardness and thickness.

nine0043

Making armor from eva

But there are certain nuances - for the correct cutting of eva, patterns are needed (there are special patterns or patterns for pepakura are redone). When cutting, it is necessary to take into account the location of the edges and make the cut not straight, but at an angle. Sections, after gluing, must be further processed with sandpaper. The surface of the eva is porous, so before painting it is desirable to treat the surface with latex to obtain a smooth surface. For painting and putty, it is desirable to use elastic materials, because eva still remains a little flexible. nine0003

nine0003

Pepakura

Papercraft - this is the name of patterns (reamers) for the manufacture of various elements from paper.

Not only cosplayers are addicted to papercraft, for some it is enough to glue a paper model for a collection.

Usually pepakura is used as an inexpensive and easy way to make massive armor when there is no way to get eva foam.

First, the paper model is glued together. Paper is usually chosen with a high density to minimize the risk of deformation of the model during further work. nine0003

Finished paper model

After gluing, the model must be strengthened. For this, fiberglass and epoxy resin are usually used. When impregnating a paper model, it is very important to ensure that the geometry of the model does not "lead". Usually epoxy and fiberglass are applied in several layers. Before applying a new layer, it is necessary to wait for the polymerization of the old one, usually it takes 24 hours.

The resulting model is strong, but too angular. Models in papercraft are high-poly and it is necessary to manually smooth out the angularity with putty and sandpaper. After painstakingly removing the surface of the model, it can be painted. nine0003

Left paper model, right after strengthening, processing and painting

Models made by this method are very heavy due to epoxy and putty. And the manufacture of one product takes a lot of time, but this method remains popular because of its availability and low cost. Epoxy can be found in any building market, and fiberglass is easily interchangeable with other materials.

Modeling and casting

This method is suitable when you need to quickly produce many identical parts. A master model is made (for example, from plasticine) and a mold is removed from it using special silicone, into which epoxy, special two-component plastics or polyurethanes can then be poured, depending on what characteristics you need to get in the finished product.

Two-component plastic purity print with metallic powder

To color the finished casting, you can knead the dye into liquid plastic or rub the mold with special powders.

It makes sense to make silicone molds if you need to make many identical elements, it is not advisable to remove the silicone mold for one casting. Silicone is still not cheap and not everywhere you can buy it. In addition, it is necessary to have some skills in silicone and plastic/resin casting in order to minimize the amount of air bubbles and get a quality casting. nine0003

Handy materials

And of course, masters know how to use the most unexpected things for cosplay. For example, PVC pipes are often used to make frames for fantasy weapons. Izolon for making feathers for wings, etc.

Acrylic folding knife

Using PVC pipes as a sword frame

3D printing

Using a 3D printer to make a complete costume may not always be advisable due to the high cost. But in the manufacture of elements with complex geometry, small elements or high detail, it can greatly facilitate the task and save a lot of time. A 3D printer becomes indispensable for printing engineering, moving elements. This is very convenient when a seat for all wiring and electronics is immediately included in the model and you don’t have to puzzle over where to place everything after assembly. nine0003

But in the manufacture of elements with complex geometry, small elements or high detail, it can greatly facilitate the task and save a lot of time. A 3D printer becomes indispensable for printing engineering, moving elements. This is very convenient when a seat for all wiring and electronics is immediately included in the model and you don’t have to puzzle over where to place everything after assembly. nine0003

But 3D printing also has its drawbacks. When fabricated on an FDM printer, models must be further processed to obtain a smooth surface. If you print on a photopolymer printer, then the cost of the finished product will be quite high. Large elements of the costume will have to be printed in parts and then glued together.

Cosplay 3D printer application examples

Whole costume printing

A 3D printer is becoming an indispensable tool for manufacturing geometrically complex suits or, for example, functional elements of armor. nine0003

Iron Man Armor.

Emily Yarid has been modeling, building and refining Iron Man armor since 2013. She initially took it up out of boredom, deciding to upgrade the costume she had.

In the Tony Stark suit, the reactor glows, the helmet automatically closes and opens. On the back there are functional "wings" that open and close.

One of Emily's ready-made costumes

The girl uses a 3D printer to make armor elements. After printing, she processes and paints the details herself.

Printed Armor

Tony Stark Mask

HALO

A user with the nickname mosquitobandito collects full-fledged armor from the HALO universe. nine0003

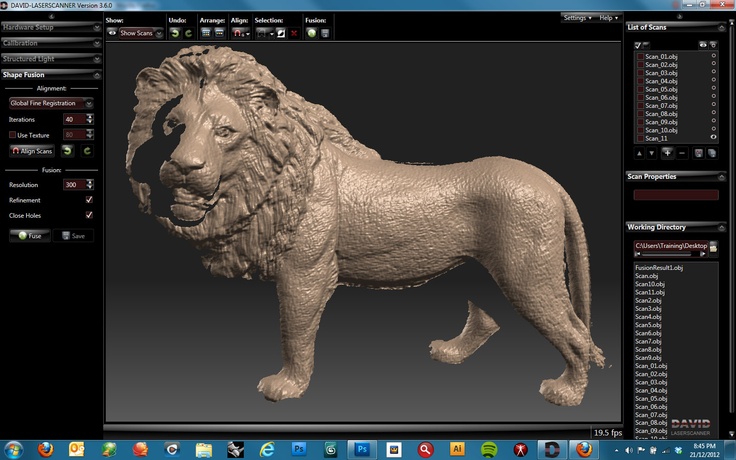

Armor 3D model

Armor is almost entirely 3D printed. There are a lot of issues that need to be addressed when modeling to keep the armor as mobile as it is in the game.

Shoe cover

Pre-assembly of the upper part of the armor before gluing and processing. nine0047

The armor part is pre-cut into several parts and printed in parts on an FDM printer. After printing, be sure to check how the parts fit together, as the plastic may shrink unevenly.

Treated and painted hand protection

Costume print

Making a full-fledged costume using 3D printing is not always justified. Simple shapes are much faster and cheaper to make from other materials such as eva. nine0003

But complex details such as helmets, weapons, armor elements are much more accurate if they are made using 3D printing.

Steam Punk Star Wars Helmet

Hand making all the patterns would take much longer, and it is important to make all the patterns symmetrical. This is a very painstaking work that requires a lot of patience, perseverance and experience. nine0003

nine0003

Iron Man Steampunk Helmet

Composite weapon

Some elements seem quite simple to manufacture, but it can be very difficult, even with a template, to make symmetrical and smooth bends.

Wolverine Collectible Helmet

Master model making

Sometimes the material with the desired properties is found only among foundry resins and plastics. But to remove the form, you still need a master model.

Epoxy sword casting

It was necessary to make a transparent sword. Epoxy resin is well suited for manufacturing. The master model (except for the rose) was printed on a 3D printer.

Prepared master model nine0003

The sword was printed in half - it is much easier to get a high-quality casting without bubbles. The halves of the sword are still the same and can be glued together. After printing, the surface of the master model was brought to perfect smoothness and primed.

After printing, the surface of the master model was brought to perfect smoothness and primed.

Formwork is being prepared from improvised materials for pouring silicone molds

Preparation of the master model for filling with silicone

A slightly tinted epoxy resin is poured into the resulting mold to give an icy blue tint. After casting, 2 halves can be glued together with the same epoxy. nine0003

The result is a stunning sword, as if carved from ice. Such an effect would be difficult to achieve using other materials.

Finished casting

Finished Epoxy Sword

Rating of the best cosplay printers

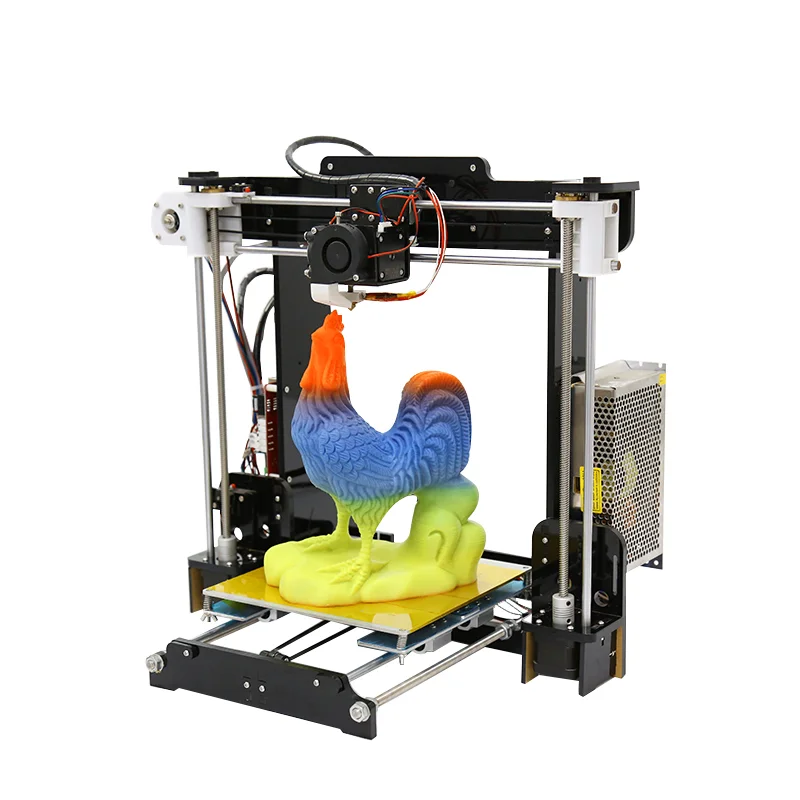

FDM printers

FDM technology for making cosplay has its pros and cons. nine0003

Pros:

-

Large build area. Some printer models can print an entire full-size helmet.

-

Inexpensive consumables.

The cost of a plastic thread (filament) is still much cheaper than consumables for other technologies.

The cost of a plastic thread (filament) is still much cheaper than consumables for other technologies. -

A wide selection of different materials. You can find a filament for any task - from engineering to decorative. nine0003

Minuses:

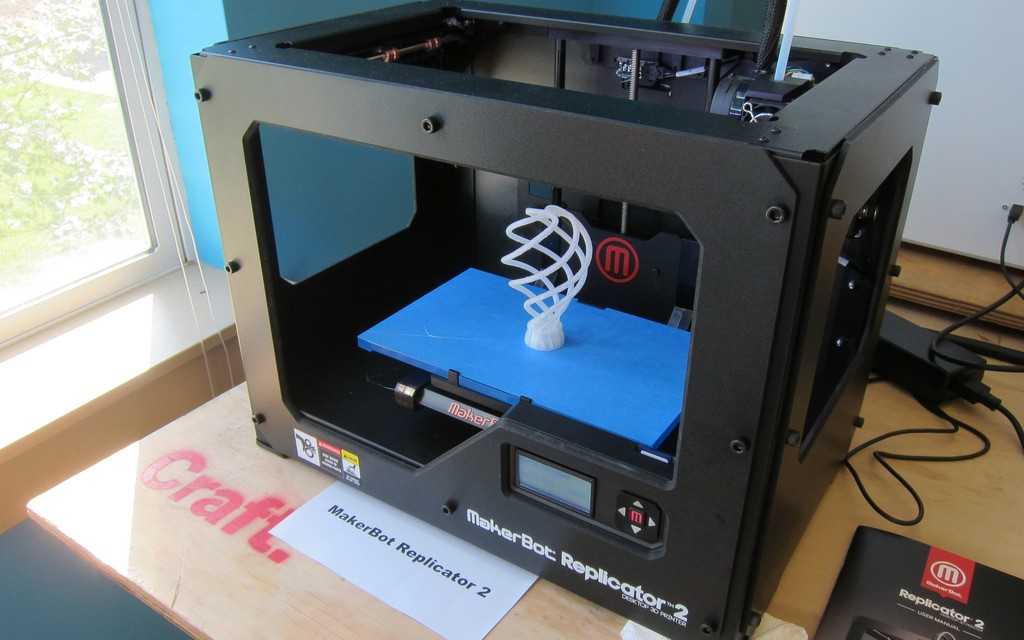

Creality3D Ender 6 (build kit)

Creality3D Ender 6

Specifications:

Print technology: FDM/FFF

Working area size: 250x250x400 mm

Number of extruders: 1

Closed Camera: Yes

Heated table: Yes nine0003

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Inexpensive printer for a beginner who knows how to handle tools. Supplied as an assembly kit. A large build area will allow you to print large parts in their entirety, and the version with a closed body can print with any, even engineering, plastics.

FlyingBear Ghost 5 3D printer (assembly kit)

nine0043

Flying Bear Ghost 5

Specifications:

Print technology: FDM/FFF

Working area size: 255x210x200 mm

Number of extruders: 1

Closed chamber: No (but there is an option to purchase)

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

A very popular device due to its affordable price. It is sold as a kit kit (for self-assembly), but thanks to the detailed instructions and a huge number of video guides, assembly should not be a problem.

It is sold as a kit kit (for self-assembly), but thanks to the detailed instructions and a huge number of video guides, assembly should not be a problem.

The huge fan base of FlyingBear Ghost 5 makes it easy to find ready-made upgrades and add-ons for the printer. This device is perfect for those who like to experiment and learn something new.

Wanhao Duplicator 6 Plus

Specifications:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: 260 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

Wanhao Duplicator 6 Plus is a reliable workhorse for those who do not want to delve into all the nuances of a 3D printer. Available in 2 versions - with a closed case and not. It is better to immediately purchase a printer with a closed housing so that there are no problems with printing engineering plastics such as ABS, Nylon, etc.

Raise3D Pro2

Raise3D Pro2

Specifications: nine0003

Print technology: FDM/FFF

Working area size: 305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others nine0003

This is already a serious device with a large print area and 2 extruders for printing complex models. Raise3D Pro2 can be a great help in a small workshop for making decorations and cosplay.

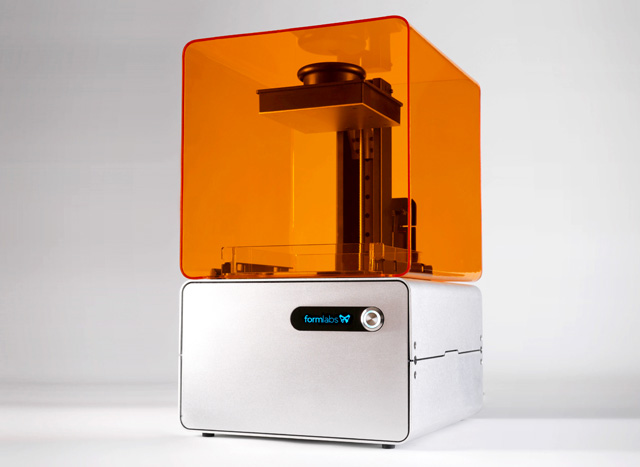

Photopolymer printers

Photopolymer printing is not yet so common for making large items due to expensive consumables, but Western cosplayers have already appreciated the advantages of photopolymer printers for printing small items. nine0003

nine0003

Pros:

-

The ideal surface of the finished model.

-

Amazing detail that is impossible to get on FDM printers.

-

Large selection of resins. You can get an optically transparent model.

Minuses:

Anycubic Photon Mono

nine0043

Anycubic Photon Mono

Specifications:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0.051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

Affordable photopolymer machine with a small print area. Suitable for making small items. nine0003

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Specifications:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

The Phrozen Sonic Mighty 4K is a professional 3D printer with a large print area and a 4k monochrome sensor. This allows you to quickly receive finished products with amazing accuracy. nine0003

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Specifications:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0.01-0.3mm

A professional 3D printer with a huge (by the standards of photopolymer printers) printable area. Perfectly fit into the workshop for the manufacture of various props. nine0003

Totals

Making cosplay requires a creative approach and solving various problems. After all, it is not at all easy to transfer into reality what is implemented in a film or game using computer graphics.

3D printing, due to its flexibility and versatility, can speed up and simplify the production of various costume elements. A 3D printer can help you get better quality stuff, even for beginners.

A 3D printer can help you get better quality stuff, even for beginners.

For workshops, a 3D printer can become an indispensable assistant in the manufacture of complex, movable costumes with movable elements. A big plus can be the ability to make an almost exact copy of any costume or its element at any time. nine0003

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | nine0554 Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

#Application

Expert in additive technologies and 3D printing with over 5 years of experience.

Share

all materials

Top 20 3D Printable Toy Models

Why 3D print toys? What toys can be 3D printed? 1. Mini monster truck 2. Surprise eggs 3. Gliders with elastic band 4. Folding sword 5. Micro catapult 6. Spinning top 7. Moving animals 8. Spirograph 9. Transformers 10. Toy tool set 11. Castle 12. Lego bricks 13 Ballista 14. Edible toys 15. Anti-stress keychain 16. Chunky Trucks set 17. Sword rattles 18. Vikings Squigglepeeps 19. Math Spinner 20. Jumping Turtles Results

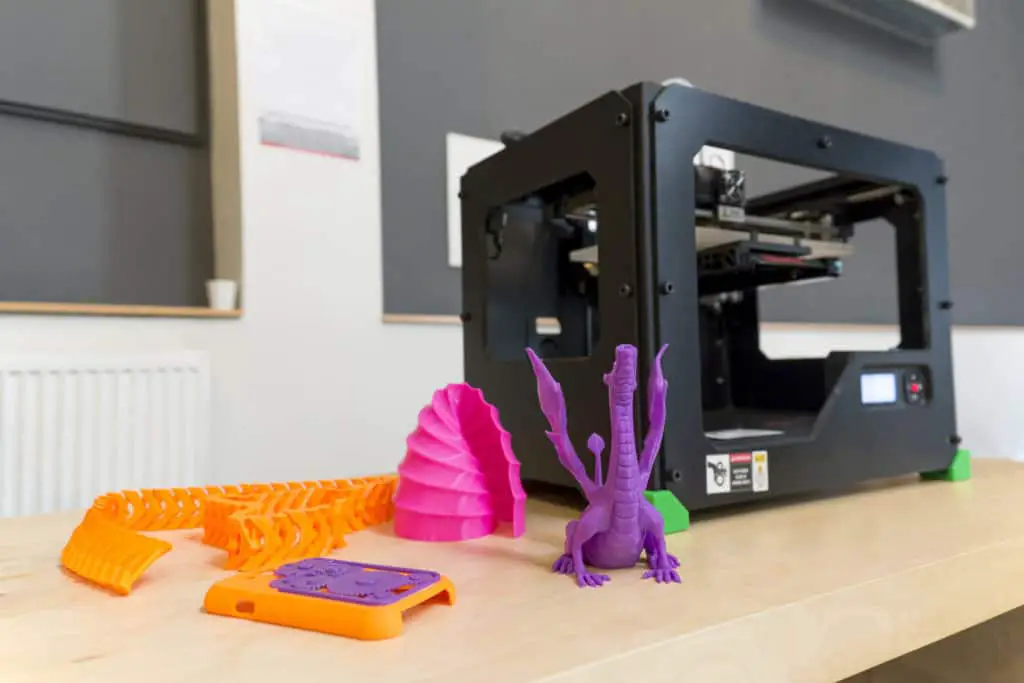

Today, 3D printing is developing and spreading very rapidly, gaining more and more popularity. And no wonder, because 3D printing is an invaluable tool for prototyping designs, creating mockups, fabricating parts, and more. At the same time, it is no longer difficult to buy a 3D printer at an affordable price even for home use. However, a 3D printer is not only a tool, it is also a kind of toy. A toy capable of creating other toys! Using a 3D printer to make toys gives you control over the material, color, size and other components, so the models you create with 3D printing will be unique! nine0003

But what if you don't have your 3D printer and you need to print a toy or some part of it? It doesn't matter, in this case our 3D printing studio will help you! You only need to place an order by uploading the file of the desired finished model, after which our specialists will contact you to calculate the cost and resolve other possible issues.

Why 3D print toys?

This is probably the first question that comes to mind, and it is not surprising, because often 3D printing can cost you more than the cost of such a toy in the store. But there are also a number of advantages of 3D printing, as well as cases when it would be more profitable and appropriate to turn to creating models on a 3D printer. nine0003

- As already mentioned, a toy printed on a 3D printer can be absolutely unique due to the ability to set exactly the shapes, sizes and colors that you and your child want.

- Some toys can be difficult to find in the store, and their cost may exceed the cost of their printed copy.

- Sometimes you only need to replace one or a few broken or missing parts of a toy, such as a building toy. In this case, it will be much more profitable and more expedient to use a 3d printer than to buy a whole set for a high price. nine0010

- An important factor is, of course, the impressions of the 3d printing process itself, which will captivate both a child and an adult.

And the positive emotions of your child from the toy you created will be the best reward!

And the positive emotions of your child from the toy you created will be the best reward! - And for those who are just getting acquainted with their printer and 3d printing in general, the process of creating toys will be an excellent, exciting simulator to improve their skills and gain experience.

Which toys can be 3D printed? nine0062

In the context of constant development and increase in the possibilities of 3D printing technology, you can create almost any toy on a 3D printer, but the result largely depends on the capabilities of your device, your abilities, as well as the time, resources and effort that you are willing to devote to this process. Therefore, more or less simple projects are most often created on a 3D printer. But the relative ease of manufacture does not mean boring finished products! Below we will give you a list of 20 interesting 3D printed toys that are not particularly difficult to create. Among these crafts you will find toys for children of all ages, including the smallest: mechanical products, motion figures, building blocks and even rattles! For each toy from the list, we leave a link to the finished model so that you can try them yourself. So let's get to know them better! nine0003

So let's get to know them better! nine0003

1. Mini monster truck

Two monster trucks. Source: Thingiverse

Not everyone can afford a monster truck, but if you have a 3D printer, you can print yourself a mini copy of it... which is almost as cool. Thanks to the all-printed suspension and removable discs that attach easily and without the aid of glue to the body, this truck is perfect straight from the printed surface.

You can even choose from a variety of body styles and wheels. And for a two-tone tire, stop printing the wheel at 19.8 mm and replace the filament.

Model files for download can be found here.

2. Surprise eggs

Surprise! Source: Twitter

Bigger is not always better. And often the most interesting thing is just a small size, and these 3D printed eggs with a surprise are an example of this.

These tiny cars with moving wheels and other accessories are amazing! Plus, you have plenty to choose from, as you can print surprise eggs with just about anything inside, be it a fire engine or even a fighter plane! nine0003

No support required for these models. We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

3. Elastic Gliders

Get ready to take off! Source: Thingiverse

With 3D printed gliders you will be able to “pull” even more fun out of ordinary rubber band ! Just 3 simple steps, and your glider will take off: hook it with an elastic band, pull it towards you and release it.

With this model on Thingiverse, you and your friends can take to the skies a whole fleet of these rubber gliders!

100% infill and a layer height of 0.1 mm are recommended for greater aircraft strength and longer life for thin wings. nine0003

4. Folding sword

Telescopic pirate sword. Source: Thingiverse

This toy may not be best given to a child when there are breakable items nearby. But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

This Telescopic Pirate Sword is designed for printing at low speed using a 0.4mm nozzle. Also, successful printing requires a printer with a good retract and precise settings for Coast (turning off extrusion at the end of the layer print) and Wipe (“wiping” the nozzle at the end of the layer). nine0003

5. Micro Catapult

Hit all your enemies (or at least your classmates). Source: Thingiverse

This little catapult is a great toy for kids and bored office workers alike. She can throw small crumpled pieces of paper and any other small things that will fit in her. Selected ammunition can fly about 2 meters, which is enough to hit unsuspecting victims at another table! nine0003

This model is an all-printed prefabricated assembly that does not require any supports or special adjustments. A minimum filling and layer height of 0.25 mm is sufficient.

A minimum filling and layer height of 0.25 mm is sufficient.

Despite the fact that many catapults are made from PLA plastic, the author of the design still insists that this model is not for PLA, but for ABS plastic. We can also recommend PETG filament for this printing, which has the best qualities of PLA and ABS.

6. Top

The oldest toy for the whole family. Source: Thingiverse

As far as we know, the spinning top is one of the oldest toys in the world. In ancient times, tops were made from almost any material: from stone and wood to fruits and nuts. And now additive technologies allow you to make your own spinning top using a 3D printer! All you have to do is print this model, glue the pieces together and have fun with this simple yet fun toy!

Offered 0.2 mm layer height and 20% infill.

7. Moveable animals

Cute articulated octopuses. Source: Thingiverse

Making flexible prints with a 3D printer has become completely affordable and common practice thanks to special filaments such as TPU. But what if we said that you don't have to use flexible plastics to create flex parts?

But what if we said that you don't have to use flexible plastics to create flex parts?

Using excellent hinges that are printed in one piece with the entire model, you can create movable flexing toys even from plastics such as PLA, ABS and PETG, without any additional settings and adjustments. nine0003

The standard specifies a layer height of 0.2 mm and an infill of at least 15%.

The most popular of the models:

- Octopus

- T-Rex

- Lizard

8. Spirograph

Convenient case for creativity at any time. Source: Thingiverse

Everyone knows the children's toy spirograph, which allows you to easily draw masterpieces with repeating geometric patterns. But this model has gone a little further and is a whole case containing a platform for drawing and a compartment for storing gears and paper. It fits easily into your pocket, backpack and bag, so you can take it with you and paint whenever you want! nine0003

The case has several levels. The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

A layer height of 0.2 mm and an infill of 20% or more is recommended. As a loop, a regular straightened 1.75 mm filament thread is used. nine0003

9. Transformers

Toys from the planet Cybertron. Source: Thingiverse

Transformers are a hugely popular children's toy to this day, so these Optimus Prime and Megatron are sure to please your kids.

This printed Optimus Prime transforms from a classic Optimus truck into a fully functional standing robot. And it's amazing, considering that you immediately get a ready-to-use all-printed model right from the printing platform, which does not even require supports! nine0003

But, of course, every Optimus needs an opponent to fight. Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

10. Set of toy tools

The first tools for little craftsmen. Source: Thingiverse

The Toy Tool Set is a great way to introduce kids to basic tools, their appearance, purpose, and how they work. Print your child's first hammer, screwdriver and pliers and he'll feel like a real craftsman! nine0003

The hammer is modeled to fit two pieces together with a screw, but some users simply glue them together, which is just as pretty. You can also use a hammer to assemble pliers: just lay the two pieces on a flat surface with the screw down and tap lightly a couple of times.

Model can be found here.

11. Castle

Build your own medieval world! Source: Thingiverse

This medieval castle playset is meticulously designed for 3D printing. Walls and towers are easily attached to each other with a simple connection. You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set. nine0003

You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set. nine0003

All parts are small enough to be printed comfortably even on 3D printers with a small printable area: 140x140x140mm. For such purposes, the Flashforge Creator Pro 2 3D printer is perfect, equipped with two independent extruders and has excellent printing accuracy. This printer will cope with the study of small details, and two extruders will help you print several parts at once or one part in two colors!

12. Lego bricks

Your favorite constructor is now more accessible! Source: Pinterest

LEGO is one of the most popular toys for children. At the same time, the cubes of this designer are made of ordinary ABS plastic. So, having your own 3D printer, you can print the missing/lost Lego bricks yourself or even some of your author's design of the details of this amazing designer! At the same time, you can use not only ABS, but also other 3D plastics: PLA and PETG are also great.

Thingiverse has a lot of Lego models, and we'll take a look at one of them. It's customizable model of several different LEGO and LEGO DUPLO pieces. These bricks are not completely identical to real Lego, but they are compatible in every way.

13. Ballista

Fire! Source: Thingiverse

Introducing a fully printed ballista model, ready to use right out of the box. One has only to set the string and load the projectile, and this ballista will impress you with its simplicity and good range of the arrow. As a bowstring, you can use several layers of thread or ordinary stationery gum. nine0003

Recommended to print in PLA or PETG with 90% coverage and 0.2mm layer height.

14. Edible toys

The Open Toys project turns ordinary vegetables into toys. Source: Thingiverse

The project was originally envisioned as a way to turn commonly discarded residual materials such as wood and cork into toys: helicopters, planes, cars and so on. But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys. nine0003

But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys. nine0003

15. Anti-stress keychain

Entertaining keychain. Source: Thingiverse

Add some flair to your keychain with this cool little toy. She will entertain you wherever you are!

This model is not the easiest, but try it and you will definitely succeed! Important print quality settings are "Outer Walls Before Inner Walls" and being extra careful with temperature. It is printed with supports and requires a certain, sometimes lengthy, post-processing. Remove not only supports, but also make sure that the surface of the part is smooth, otherwise it will cling and stutter. A scalpel or a 1 mm drill will do. Periodically rotate the gears to see where it still sticks, which is especially true when using PLA. nine0003

16. Chunky Trucks set

Two models from the fun and cute Chunky Trucks set. Source: Thingiverse

Source: Thingiverse

The adorable Chunky Trucks collection includes various unique models of small trucks, fun builders and even a movable barrier. The cars are specially designed so that even the smallest children can play with them. Unlike builders, who are not recommended to be printed for toddlers so that they do not try to put them in their mouths, but which will greatly amuse older children. nine0003

All models can be printed without supports. And for long truck life, at least 25% infill and three-wall use are recommended.

17. Rattleswords

Arm your warrior! Source: Thingiverse

Rattles are an integral part of all babies. But what if we move away from banal and boring designs and build a rattle in the form of a sword for your little warrior? This fun design will not only amuse your baby, but also you, as this rattle will be a lot of fun to print! nine0003

All corners of the model are rounded for safety. There are also two versions of the tip. Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Print two sets of peas first. Then, while printing the sword, throw them inside the blade. This will ensure that the peas stay inside the rattle forever. After printing all the elements, simply fasten them with superglue. nine0003

As with any printed toy, parental guidance is required. Be sure to throw away the toy if it breaks.

18. Viking Squigglepeeps

Three Viking Squigglepeeps set sail. Source: Thingiverse

Squigglepeeps is another kid-safe toy, this time with absolutely no glue required. These fun chubby Vikings and their boat are too big to choke on, making them suitable for kids of all ages. They look funny even in one color, but they will be even more beautiful if you paint them with child-safe paints! The model also absolutely does not require supports. nine0003

nine0003

19. Math Spinner

A great way to have fun learning math! Source: 3Dtoday

This math spinner is the perfect companion for learning math. Moreover, it is suitable for all ages, because it is never too late to brush up on your arithmetic knowledge! You can print this finished model or modify it for yourself by removing or adding rings. This advanced design contains all the signs of addition, subtraction, multiplication, division, equality and inequality, as well as a pointer to the string to be solved! On the central insert there are special grooves for fixing. For this version, you will need to print 2 caps and 8 rings of numbers, the rest of the details are printed in a single copy. nine0003

Recommended coverage 25% and layer height 0.2 mm.

20. Jumping turtles

The variety of these turtles is amazing! Source: Thingiverse

Last but not least, jumping turtles! Agree, even the name sounds fun! And a variety of shell designs will give each turtle its own uniqueness. This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell. nine0003

This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell. nine0003

The model is assembled with printed H-clamps and does not require glue. All parts are printed without supports. Also note that using the raft (rafts) and brim (margins) options can have a negative effect on the results if you don't then take the time to sand and clean the edges at the base.

If you have problems with head slip, you can try to print 1 of the 3 narrower shaft head files that the author has specially uploaded for this case. nine0003

Results

We hope you liked this selection of 3D printing toys and you will definitely choose one for yourself, because 3D printing of toys is not only fun and interesting, it is also a new experience and knowledge for both you and and for the child. But we have considered only some entertaining options from the many existing ones.