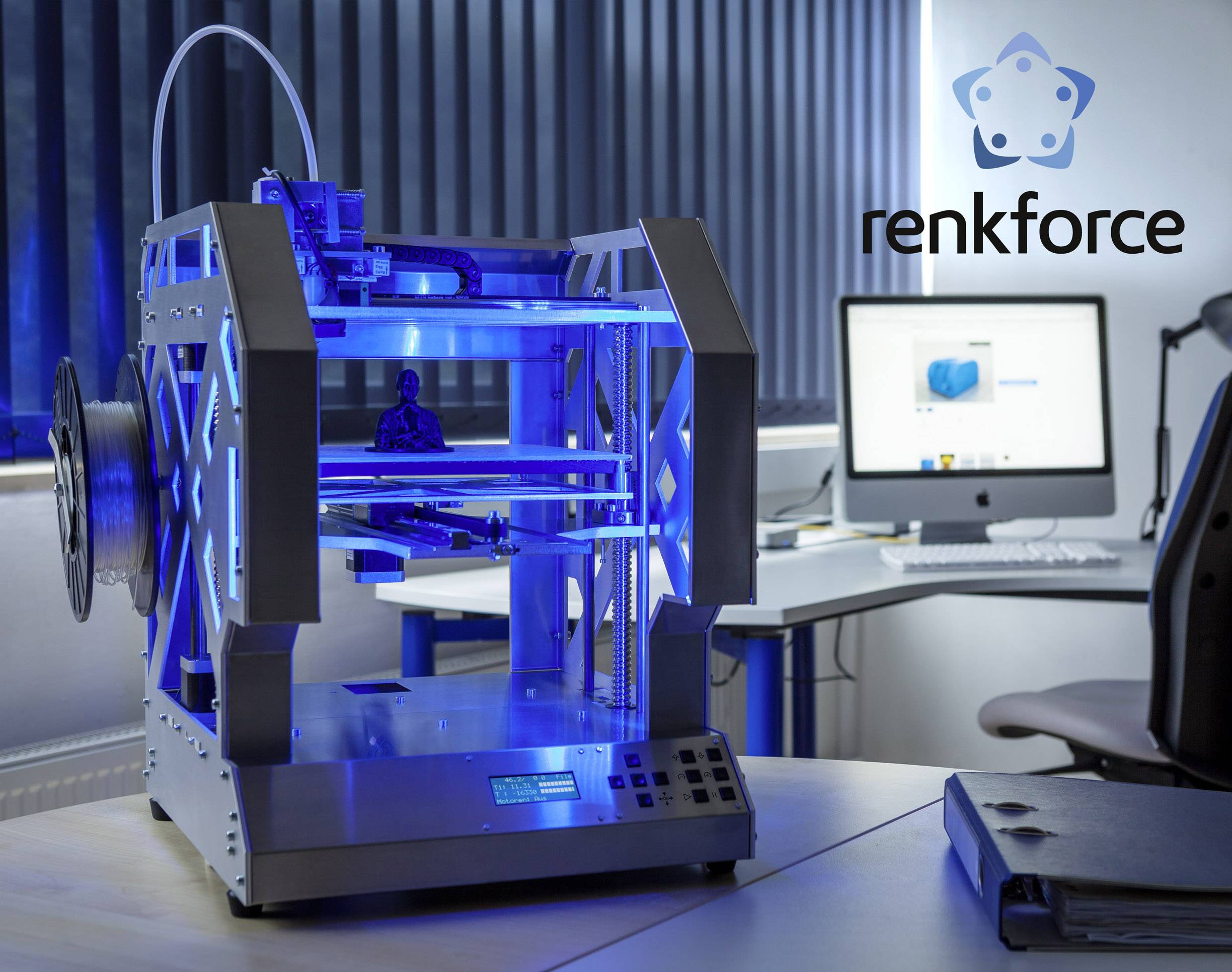

Fiverr 3d printing

Best 3D Hubs alternatives for custom 3D printing

3D hubs is probably the first name that most people consider when they think of online 3D printing services. Indeed, 3D hubs has evolved over time into a professional online manufacturing service that includes CNC Machining, 3D printing, plastic mold injection and myriad other services offered by a global network of engineers associated with 3D hubs. But 3D hubs didn’t start out with a laser-focus on pro-manufacturing services.

- In this article, we will be taking a look at some of the best alternative online 3D printing services available for custom 3D printing jobs.

- We’ll also consider what makes these online 3D printing services tempting for the average user.

Disclosure: This post contain affiliate links, we may earn advertising commissions for sharing products we know and love.

1. MakeXYZ

MakeXYZ.com is a unique proposition. The website’s primary focus is to connect users with local makers. Even the search box on the homepage defaults to location search instead of material or 3D printing technology search (which you can do by the way, just use the advanced search function).

The advantages of MakeXYZ primarily lie in its focus on local sourcing. By making sure to put local manufacturers near you in the spotlight, MakeXYZ makes it certain to reduce unnecessary freight costs, as well as to allow the customer to have somewhat of a better experience by connecting with someone nearby instead of from across the globe.

2. Fiverr

Fiverr is arguably the best way to connect directly with the right maker for CAD design and even printing and shipping. Fiverr, while not a standalone 3D printing service, it is one of the most economical ways to connect with service providers who offer such services.

See, Most affordable 3D printing service – Real use case example

You will be able to find a global market of service providers that specialize in designing, optimizing and cleaning up 3D printer files. And afterwards, you can simply search for 3D printers that would print your custom job and ship the 3D print to your address all for a transparent, decided-before-ordering price. And if you cannot seem to find the right 3D printing seller by searching, simply post a Custom job request and let the sellers contact you.

And afterwards, you can simply search for 3D printers that would print your custom job and ship the 3D print to your address all for a transparent, decided-before-ordering price. And if you cannot seem to find the right 3D printing seller by searching, simply post a Custom job request and let the sellers contact you.

3. Print a thing

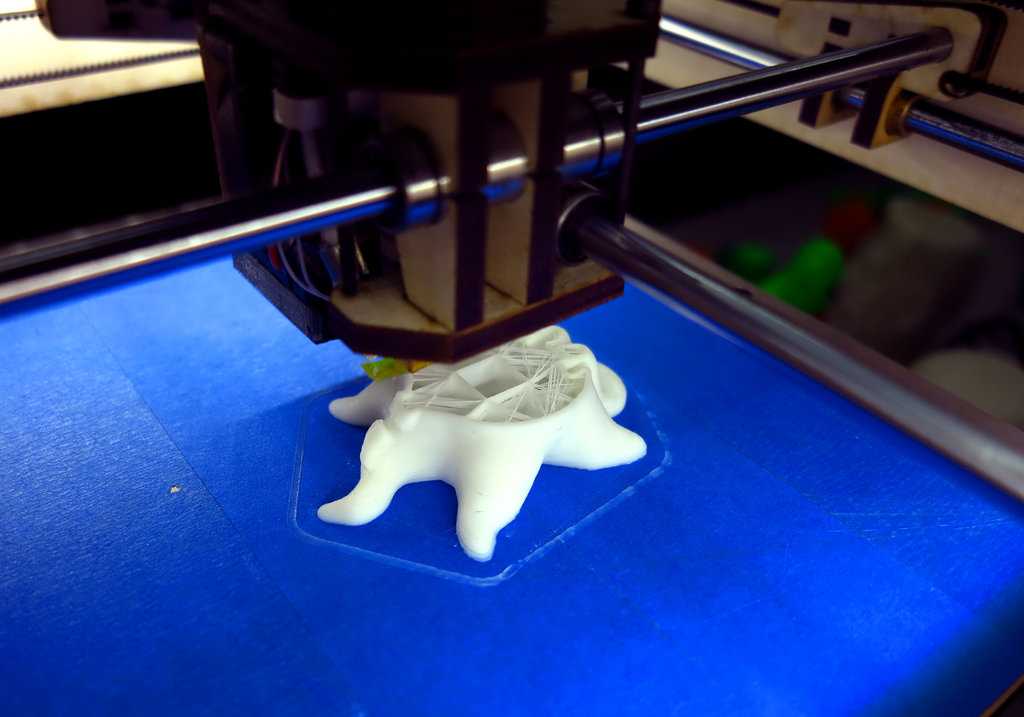

Although the service itself is still in beta, print a thing has the makings of a good marketplace that puts ease-of-use front and center. Think of it as what 3D hubs would’ve looked like, had it maintained its community roots when growing up.

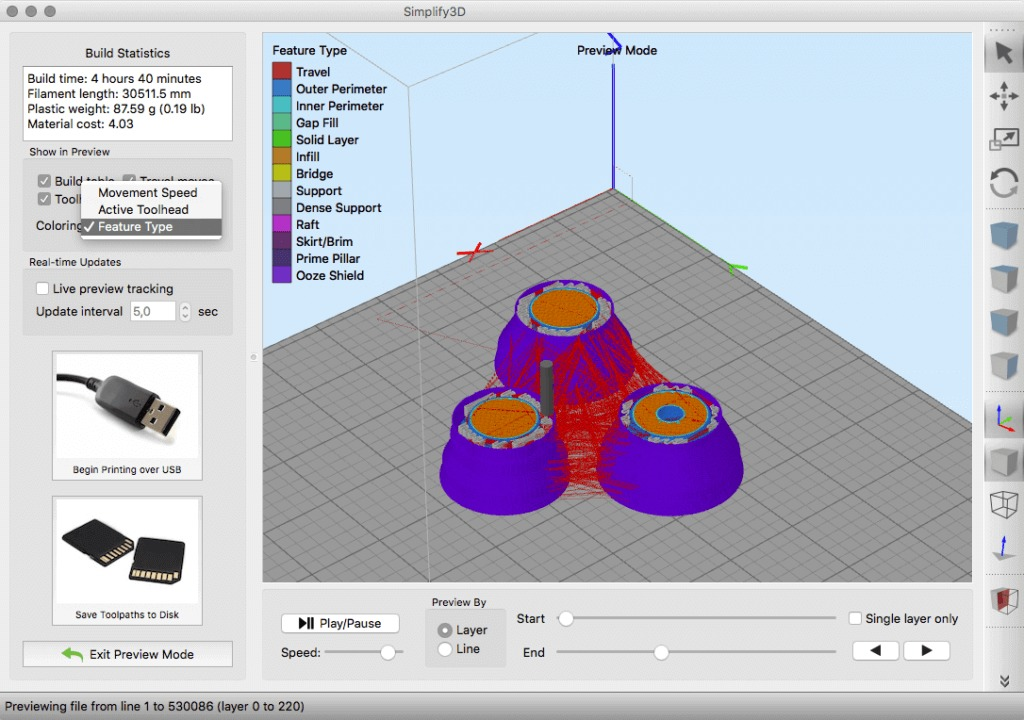

Print a thing allows a seamless web user experience, whereby you simply upload an STL file or a thingiverse URL; select the technology you want to use (right now they only offer FFF/FDM and SLA) and presto! The website spits out a checkout quotation.

Behind the scenes, Printathing.com relies on networking with 3D printers around the globe to form its “supplier network”, and based on internal algorithms, printathing then assigns your 3D print to what it considers the best maker for the job.

To the user, it all appears as if you merely order something online, and then it is sent to you in real life via the magic of 3D printing and logistics.

4. 3D Experience Make marketplace

The Make Marketplace is unique in that while it is run by Dassault Systems, a reputable name in the professional 3D design space. It still focuses on connecting customers directly with professional on-demand 3D printing and subtractive manufacturers.

As of writing, the Make Marketplace offers a selection of 119 unique service providers. The interface itself screams business instead of user-friendliness. But if you are in the market for pro-grade services but still want to have direct communication with your 3D printer, the Make marketplace may just be a good place to look.

5. Other Pro-grade on-demand manufacturing websites

Nowadays, almost all the 3D printer juggernauts run their own on-demand 3D printing websites. All these websites focus on pro-grade services, and they come with a suitably higher price per print. There is little in the way of differentiation between these services as they all tend to offer almost the entire spectrum of materials selection imaginable along with other subtractive manufacturing techniques as well.

There is little in the way of differentiation between these services as they all tend to offer almost the entire spectrum of materials selection imaginable along with other subtractive manufacturing techniques as well.

- Sculpteo

- Shapeways

- Xometry

- i.Materialise

These websites represent the club that 3D hubs is now a part of. But if that is what you are after, then we recommend trying out all of them before ordering to make sure that you are satisfied with the premium that you would pay on these services.

6. CraftCloud by All3DP

Craftcloud itself is not an online 3D printing service, instead Craft Cloud is an online price comparison tool that connects to an ever-increasing number of online 3D printing services. By its very nature, Craftcloud offers some of the biggest material and technology selections of any website.

While you do lose the ability to connect with individual makers, Craftcloud offers a streamlined user-interface to offer customers the lowest possible quotations for their needs.

· Selection of materials

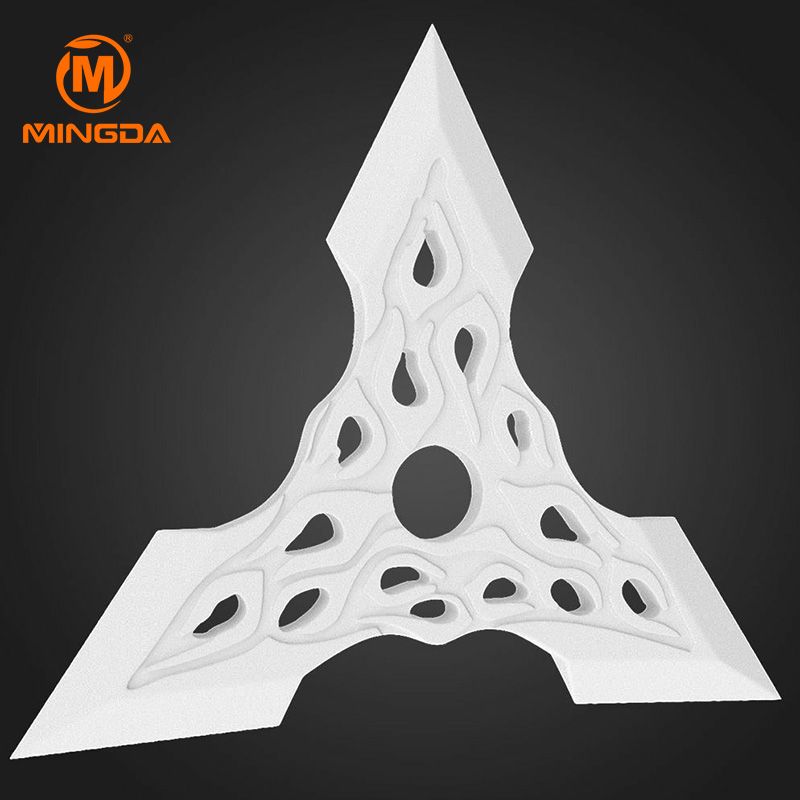

The first obvious benefit when using an online service, is the breadth of materials that you get to choose from.

Even if the service only offers FDM technology, the selection of filaments as well as the quality of filaments on-offer would generally far exceed what any enthusiast could practically use on their own.

Material choices range from normal PLA, to polycarbonate, nylon, ABS, metal and wood fill. Even powder metal 3D printing for engineering-grade functional prototypes. With the right online service, you can be sure to find the exact material that you want for your project.

· Availability of different 3D printing technologies

Almost all of these 3D hubs-like online 3D printing services get one thing right: by relying on a network of individuals and professionals, they are able to offer a vast range of different technologies to the customer.

It is also one of the few ways that average consumers can have access to higher-end 3D printing technologies like full metal 3D printing.

Choices ranging from FDM and SLA, to SLS, SLM, Metal-Jet printing and everything in between are actually quite commonplace now for on-demand 3D printing services. No matter your needs; with the right service and budget, you are sure to find exactly the right 3D printing technology.

· Professional print quality

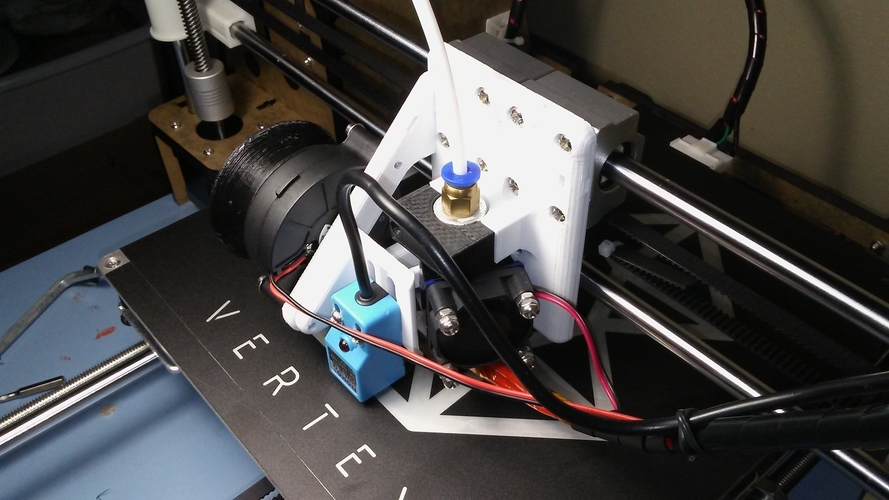

Most of us are decent at best when it comes to optimizing our 3D prints for quality of print. As a rule, enthusiasts balance printing quality with the cost of filament to be used as well as having to deal with other limiting factors such as ageing 3D printers or entry-level hardware.

Online 3D printing services on the other hand, are run as businesses, so the makers are always paying attention to the quality of output of their machines since it directly impacts their bottom-lines. If you want even more consistency and accurate results, then you could even opt for one of the professional on-demand additive manufacturing services online.

As a rather safe generalization, you would be getting much higher quality 3D prints with online 3D printing services than you would at home.

3D hubs is a household name these days for online pro-manufacturing services. But it wasn’t always this way. Even a few years back, 3D hubs was a bustling community network that allowed 3D printing enthusiasts and makers around the world to connect with one another to satisfy their 3D printing demands.

Rewind time even just five years and there was NO alternative to 3D hubs. Not because no one else tried, but because the 3D printing community, by and large saw 3D hubs as their online home.

Changing times

But then, corporate goals at 3D hubs shifted quite dramatically over the last few years. 3D hubs went from being a marketplace that connected makers and enthusiasts around the world to a curated selection of affiliated makers at first, and then finally 3D hubs became one hub of pro-manufacturing services that we see now today.

Suffice to say, this left many a 3D printing maker as well as enthusiast with a sour taste. But thankfully, with time, many viable alternatives have emerged to 3D hubs.

The 3D printing world was left with a void when 3D hubs decided to change directions, but thankfully, with time and effort, the online custom 3D printing service business has never been more diverse nor healthier.

Tags: Custom 3D printing

Freelance Logo Design, Web Design & Graphic Design

With the world's #1 custom design marketplace

1,079,532

freelance designers

25 - 100+

designs per project

442,407

completed projects

Our design services

See all categories Hide all categories

Get inspired by beautiful design

Only the best freelance design

Here's why 100,000+ businesses have chosen DesignCrowd:

Let's get started

See why customers love DesignCrowd - 4. 9 average from 3,060 ratings

9 average from 3,060 ratings

Here's what real businesses say about DesignCrowd

-

“By using DesignCrowd we have saved at least 50% compared to our normal creative agencies. Crowdsourcing is a brilliant way to pick the creative brains of a global design team.”

Duncan Patmore Global Product & Marketing Director, HI-TEC, UKVIEW THIS CONTEST

-

“I chose DesignCrowd because I liked the idea of having designers from all over the world submit. I received over 70 designs to choose from and have been very happy with my new logo. ”

Karen Dunn Founder & CEO, Transcendent Woman, USAVIEW THIS CONTEST

-

“The speed and efficiency in receiving my designs was very impressive.

Stuart Wilson Director, Star Logic, UK Many thanks for your quick respones to my queries. Much appreciated.”

Many thanks for your quick respones to my queries. Much appreciated.”VIEW THIS CONTEST

-

“Great experience with DesignCrowd. I received 100+ designs from 40 designers. Designers offered logos based exactly on what I requested and fresh ideas as well. This is an awesome service. ”

Melissa Preston Owner, Mel Marie Photography, USAVIEW THIS CONTEST

-

“DesignCrowd changes the game for getting creative work done. You get access to an army of designers who are great at what they do.

James Allworth Harvard Business School, USA My personal opinion? Its a great service and I highly recommend it.

”

My personal opinion? Its a great service and I highly recommend it.

”VIEW THIS CONTEST

What Europe's first fully 3D printed house looks like

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Project Milestone

Europe's first fully 3D printed home welcomes its new occupants, a couple from Amsterdam

What's happening

What it means

The creation of the first fully 3D printed house in the Netherlands is just the beginning of a new phase in the industry. Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

In addition, in an era of global concern about the state of the environment, such "green" technologies help to reduce environmental damage to the environment - with 3D printing, the consumption of cement and waste of building materials is much less than with "traditional" construction.

Finally, with the help of a 3D printer, almost any design idea can be realized, which will allow you to move away from the concept of residential buildings in the form of "concrete boxes". The development of this technology makes it possible to erect buildings of such forms that are difficult and expensive to build using traditional methods.

The technology of printing houses on a 3D printer is actively developing in Russia, France, the USA and other countries. It is assumed that this will help solve the problem of providing citizens with affordable and decent housing.

Updated on 07/30/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

Chinese scientists have grown and transplanted auricles to five children at once - RT in Russian

February 1, 2018, 00:02

Anastasia Ksenofontova

Scientists from China have grown new ears for five children born with microtia - insufficient development or complete absence of the auricle. Each of the organs was obtained from the patients' own cells. Specialists achieved the necessary shape using 3D printing technology. About a unique experiment - in the material RT.

Tissue Engineering

According to statistics, one in five thousand children is born with microtia - a deformity of the auricle. As a rule, in this case, instead of an ear, the baby has either a small bump or a lobe. External defect in most cases is accompanied by poor hearing. Previously, microtia was eliminated with the help of reconstructive plastic surgery: the ear was formed from artificial materials or from the cartilaginous part of the patient's rib and attached to the head.

But in the near future, most likely, such operations will be carried out using new technology. Chinese scientists have conducted a successful experiment to reproduce hearing organs from patients' own cells. To do this, the main cells of cartilage tissue, chondrocytes, were isolated from the ears affected by microtia. Then they filled a special biodegradable frame and cultivated for three months. To give the new cartilage the desired shape, the specialists used CT scans and 3D-printed models of healthy ears of patients.

- 3D printed bladder and ear skeletons

- © wakehealth.edu

“3D printing is just a way of making cells. The main achievement is that a number of cells were brought to such a state that they could form tissue. In this case, progenitor cells must be applied, which will then turn into tissue. But these cells must first be isolated. Advances in stem cells (undifferentiated cells that can divide and form into different types of cells under the influence of certain biological stimuli) mainly play a role here. - RT ), ”explained in an interview with RT a researcher at the Research Institute of Physical and Chemical Biology. A.N. Belozersky Moscow State University Alexei Nesterenko.

In total, five children with congenital unilateral microtia aged 6 to 9 years old took part in the experiment: four girls and one boy. After the new organ was fully formed, the doctors performed a reconstruction of the auricle for the children.

“We have been able to successfully design, fabricate and regenerate auricles for our patients. Nevertheless, much more effort is needed to ensure that such an experiment becomes not a single one, but is regularly carried out in hospitals, ”the researchers say.

Each patient was followed for at least two years. Scientists noted that in three children, the new ears did not differ in shape and size from healthy ones. In the other two patients, six months later, only slight distortions were noticed.

Related

From head transplants to space tourism: the most anticipated scientific events of 2018

In 2018, doctors plan to transplant a head to a living person, and astronomers promise to grow potatoes on the Moon, dive into the Sun and...

“Tissue engineers have been trying for over two decades to create perfectly shaped cartilage for pinna reconstruction in microtia patients. This work demonstrates that tissue engineering methods for the restoration of ears and other cartilage tissues will soon become a reality, ”said Lawrence Bonassar, professor of biomedical engineering at Cornell University.

This work demonstrates that tissue engineering methods for the restoration of ears and other cartilage tissues will soon become a reality, ”said Lawrence Bonassar, professor of biomedical engineering at Cornell University.

“The concept is not new”

The approach that scientists have successfully put into practice is based on one of the earliest experiments in the field of creating artificial human organs. At 19In 1997, experts grew cartilage in the shape of a human ear using calf chondrocytes and then implanted it under the skin on the back of a mouse. The rodent looked intimidating, but the new organ took root, and the experiment itself laid the foundation for the creation of artificial cartilage in the shape of a human ear.

According to Nesterenko, similar progress has been made in human skin grafting. The skin material was taken from the patient, which was then grown in a special medium, after which it was transplanted back. According to the expert, protocols for the creation of organs may appear in the coming years, which will be confirmed at the highest level and then introduced into clinical practice.

- Six-year-old girl gets first ear grown from her own cells

- © Cao et al/EBioMedicine

“The concept is not new. However, Chinese scientists for the first time managed to conduct similar experiments on five patients. In addition, specialists observed the children for the next two years, and during this time the ears settled down, ”said Tessa Hadlock, head of facial plastic and reconstructive surgery at the Ear and Eye Hospital in Massachusetts.

Despite the breakthrough in the use of artificially grown human cartilage, the scientists' approach has several limitations.

“When you take cells from someone's body and then culture them, you need to apply stimulant compounds to make them divide. The danger lies in the fact that cells can begin to divide uncontrollably, ”Hedlock emphasized.

Another limitation is that the scientists used chondrocytes from ears affected by microtia.