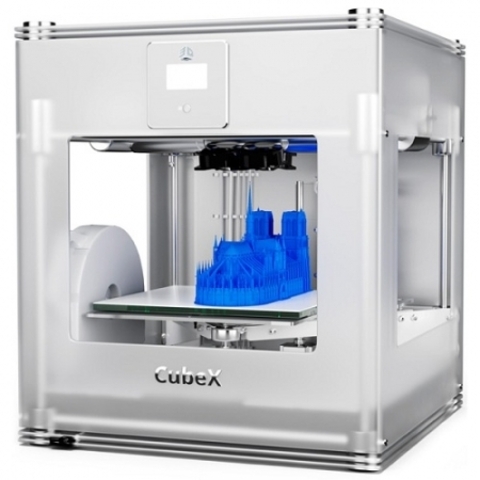

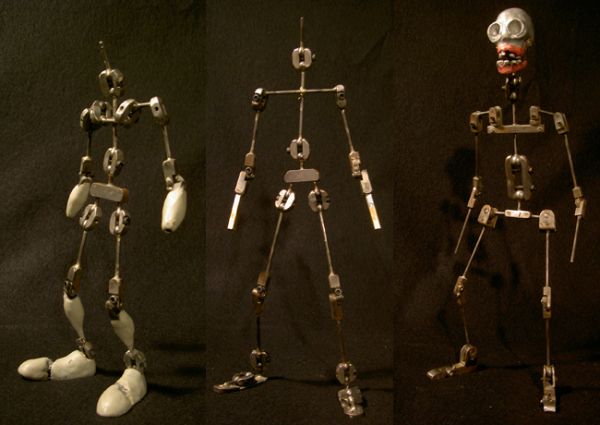

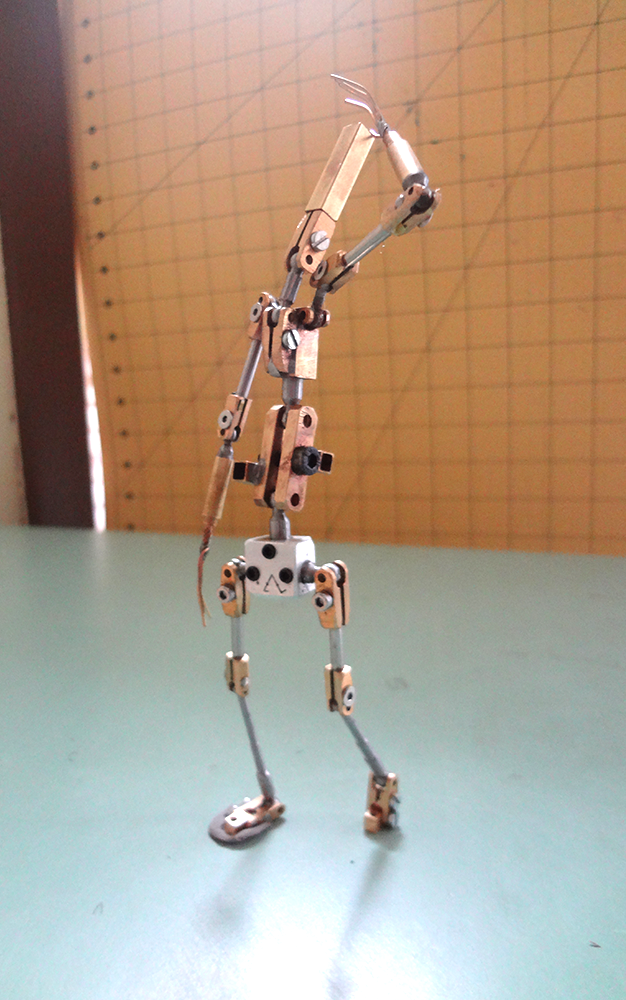

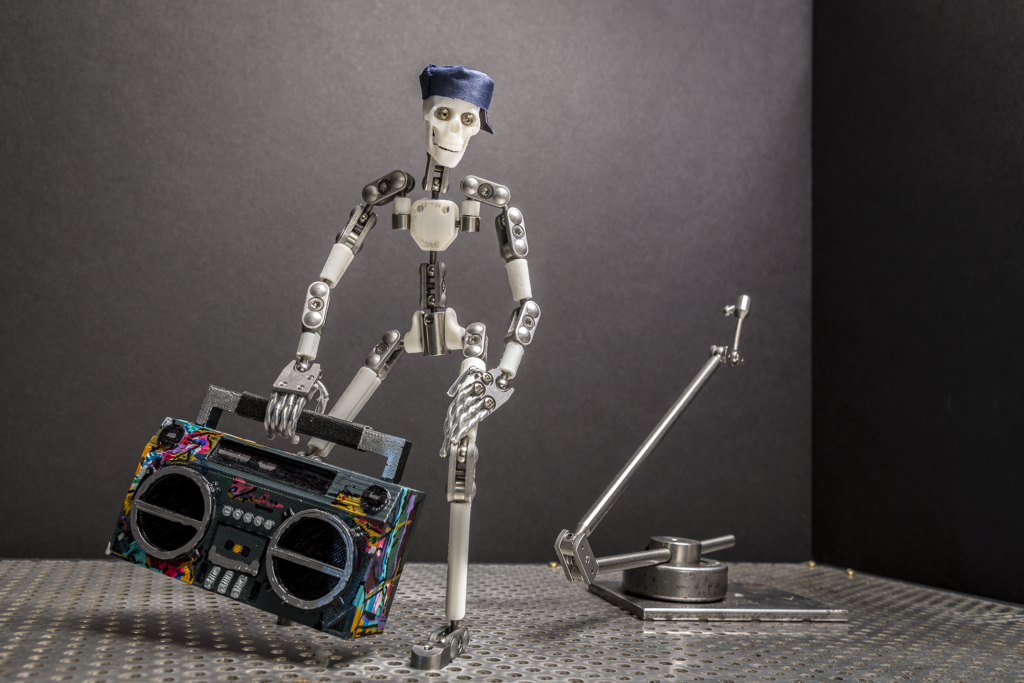

Stop motion armature 3d print

3D file Stopmotion Armature - 15cm Basic Model_V01・3D printing idea to download・Cults

Hard Surface Dragon flexi Print-in-place

€2.75

Phone charging support

€0.69

ukulele and cavaquinho holder

€0.69

Best 3D printer files of the Gadget category

Pusheen key ring

Free

ESP32 WiFi Robot

Free

Mother's day Gift Box

Free

Trigger Happy from Skylanders Swap Force

Free

Fidget toy keychain

€0.59

Mate holder - Peugeot 208

Free

Ebike Handle To Throttle Acceleration Adapter

€2. 39

RC CAR willys classic

€25

Best sellers of the category Gadget

DJI AVATA GoPro Mount

€2.50

WALL KEY HOLDER - EYE (ENTIRE COLLECTION)

€1.88

App to turn your photo into 10 types of decoration

€3.56

Writing Machine V2.0 - 2D Pen Plotter

€6.69

Tactical Repeating Bow (TRB)

€10

2-STROKE CYLINDER/PISTON WALL HANGER

€0.92

Jack the fidget Zombie - Halloween

€2.29

App to create dual text illusion

€3.56

DJI Avata Bumper

€3. 50

50

JEEP WRANGLER PEN HOLDER - 3-IN-1

€1.85

App to create keychains

€3.56

App to create switchable business cards

€3.56

Owl - Wall Key Holder

€1.85

ELEPHANT PIGGY BANK - NO PAINTING REQUIRED

€3

Mechanical Spinning Top Dice Box

€3.87

Perritos fantasma / Spooky dogs

€3.30

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

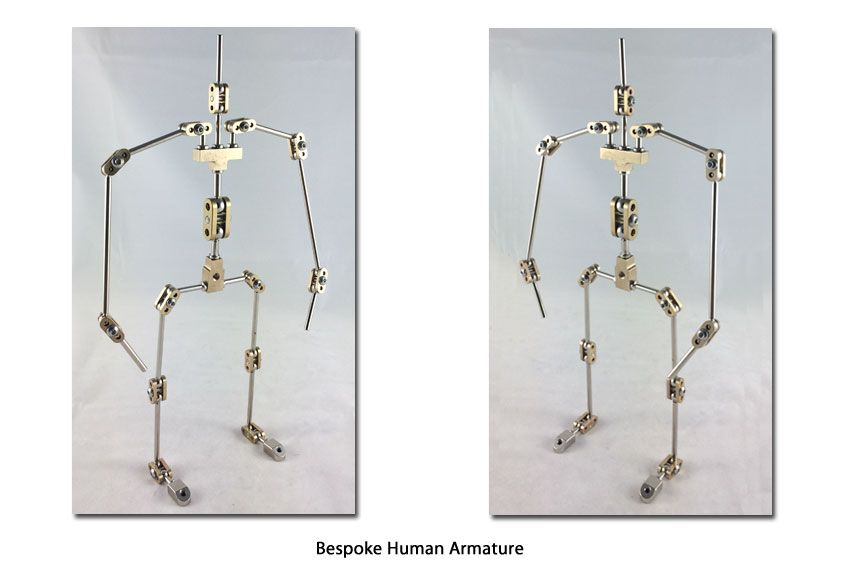

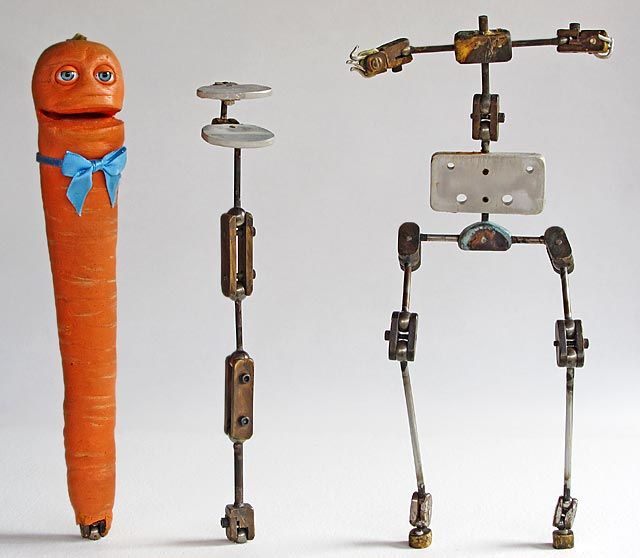

Stop motion animation armatures, 3D Modelling, Design and Printing

Elegoo Mars 3 Enclosure

£179.99

(Not yet rated)

Elegoo Saturn & Saturn S Enclosure

£189. 99

99

(1)

Elegoo Saturn 2 Enclosure

£199.99

(Not yet rated)

Mini PTC Heater UK Plug

£24. 99

99

(Not yet rated)

Mini PTC Heater US Plug

£24.99

(Not yet rated)

Modus V3 Pro Built Stop Motion Animation Armature

£249. 99

99

(Not yet rated)

Resin Storage Bottle - 1000ml

£2.99

(Not yet rated)

Resin Storage Bottle - 500ml

£1. 99

99

(Not yet rated)

Temperature Controller

£19.99

(Not yet rated)

Precision Winder Rig V3

£149. 99

99

(2)

Animation Stage - Large

£79.99

(Not yet rated)

Animation Stage - Small

£59. 99

99

(Not yet rated)

Big Rig V2

£49.99

(1)

Rig Pad

£5. 99

99

(Not yet rated)

6mm Stainless Steel Ball Stem

£2.45

(Not yet rated)

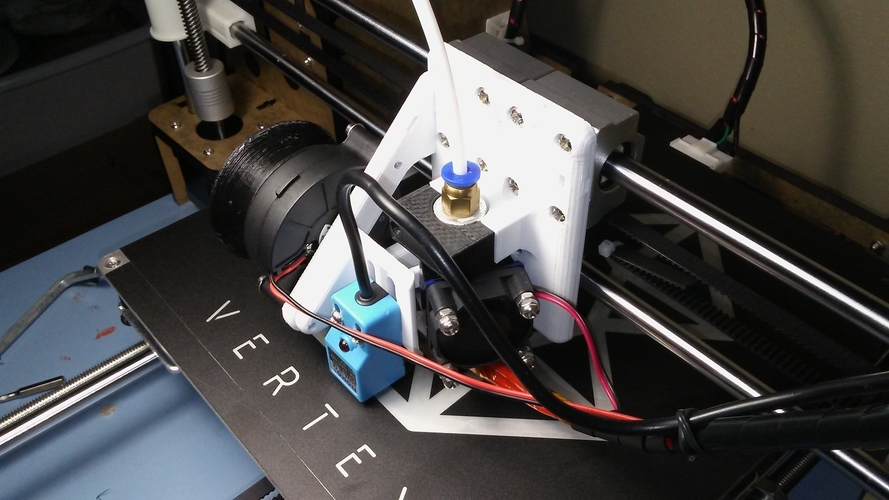

Reinforcement with fiberglass mesh in 3d printing.

Impact resistant piece.

Impact resistant piece. brtv

Loading

06/19/2022

4252

Technician

Kingroon KP3S 3.0

Hello Friend! Today we are talking about the reinforcement of printed parts. I plan to reinforce the part during printing with a fiberglass paint mesh.

I originally planned to experiment with PET tape, but the PLA spool caught my eye. I will print with this material.

Test disc size 10x20mm., 80% filling, missing 20%, I think, can be easily replaced with fiberglass mesh. I will put the reinforcement through a millimeter through a pause in the printer.

It worked! I didn't even expect it to work. Trimming cylindrical parts was not so easy.

It's time to test your strength. The test disc turned out to be much stronger than the one I printed without the grid. Not bad, showed such a method of printing. Imagine, and if there would be PET with nylon to print.

Imagine, and if there would be PET with nylon to print.

Now I will print a small plate 50x60mm. and 5mm thick. You can find such a fiberglass mesh for painting works of any size in hardware stores, starting from 5cm. in width and ending with 100cm. This material has an adhesive surface, but I played it safe and secured the material in a more secure way.

In this test, I laid the mesh tighter every three print passes. Filling 80%.

Reinforced piece withstood stronger impacts.

I think it's not bad either. We are throwing ideas where else such a reinforced type of printing can be applied?

Do not get sick, God bless you. See you.

experiment fittings

Subscribe to the author

Subscribe

Don't want

48

Article comments

More interesting articles

thirty

Subscribe to the author

Subscribe

Don't want to

During one of the attacks of perfectionism, I decided once and for all to get rid of the problem of fi. ..

..

Read more

chak198

Loading

25.10.2022

1116

6

Follow the author

Subscribe

Don't want

Good day, dear colleagues! Today we will make the correct connection of LARGE (or not very...

Read more

xedos

Loading

04/25/2016

334332

207

Subscribe to the author

Subscribe

Don't want

Good afternoon Dear readers!

GCODE: Buns from PavlushkaAfter writing the previous...

Read more

| ADMATEC is proud to introduce the world's first 3D printing process monitoring system for ceramics and metals. The Surveillance System improves control of the modular metal and ceramic 3D printer through layer tracking, foil movement, and time-lapse video recording of the print. The patented Admaflex raw material feed system has enabled the successful development and rapid implementation of a process monitoring system, because with Admaflex film you can see exactly what is happening during the printing process and record it layer by layer. For example, if 180 products are printed on the build platform and only one failure is detected, the monitoring system will detect this and continue with the remaining 179parts for a successful completion. We remind you that under a more traditional approach, such as VAT, this would mean that the entire series goes into marriage. "Our customers can now track every step of the print process with additional log files that provide proof of the print process, especially for the biomedical and aerospace industries." - Jako Saurwalt, COO Admatec. To date, since the commercial launch of the Admaflex 130 in 2016, a large number of 3D printers have been installed and launched around the world. This has provided very valuable customer feedback, which constantly pushes Admatec to further develop. One of the results of this development was the launch of this observation-based process monitoring system. | Jako Saurvalt, COO of Admatec, states: “We are constantly working to improve not only new hardware and materials, but also functionality and performance. Through software updates that aim to improve the machines of our existing customer base, we are simultaneously improving the efficiency of the technology as a whole.” “We are witnessing a gradual change in ceramic 3D printing, from being used primarily as a research and development tool, to the actual production method, especially for investment casting and aesthetic applications,” says Nadia Yaakubi, business developer at Admatec. That's why Admatec are becoming more and more famous - thanks to their "custom approach". Customers can select the desired parameters by selecting the 3D printer that best suits the function for the task at hand, whether it is for R&D or manufacturing. From customizable build platform size up to 160(x) x 100(y) x 400(z)mm and projector pixel size to determine the desired print quality, up to speeds up to 300 layers per hour, providing the complement to print metals on the same 3D printer. The control system will be added to these options for the current Admaflex 130, but the new generation of printers will have this feature de facto, as the benefits are clear. 3D printing with ceramics and metals using Admaflex technology will continue to revolutionize the design and simplification of the production of complex and expensive parts that require high detail and the use of high-performance materials. With huge potential to reduce costs and increase flexibility to increase production. |

The launch of this new feature offers complete documentation and traceability of the manufacturing process. The complex has been specially designed for demanding industries that require high performance and full traceability of the production process, such as the aerospace sector, the biomedical industry and the aesthetic sector.

The launch of this new feature offers complete documentation and traceability of the manufacturing process. The complex has been specially designed for demanding industries that require high performance and full traceability of the production process, such as the aerospace sector, the biomedical industry and the aesthetic sector.