Curatio 3d scanner

Curatio A Low-Cost amp; Dedicated 3D Hand Scanner

Skip to main content

The James Dyson Foundation websites use cookies. By continuing to use our websites, you accept that cookies may be stored on your device, as outlined in our privacy policy.

What it does

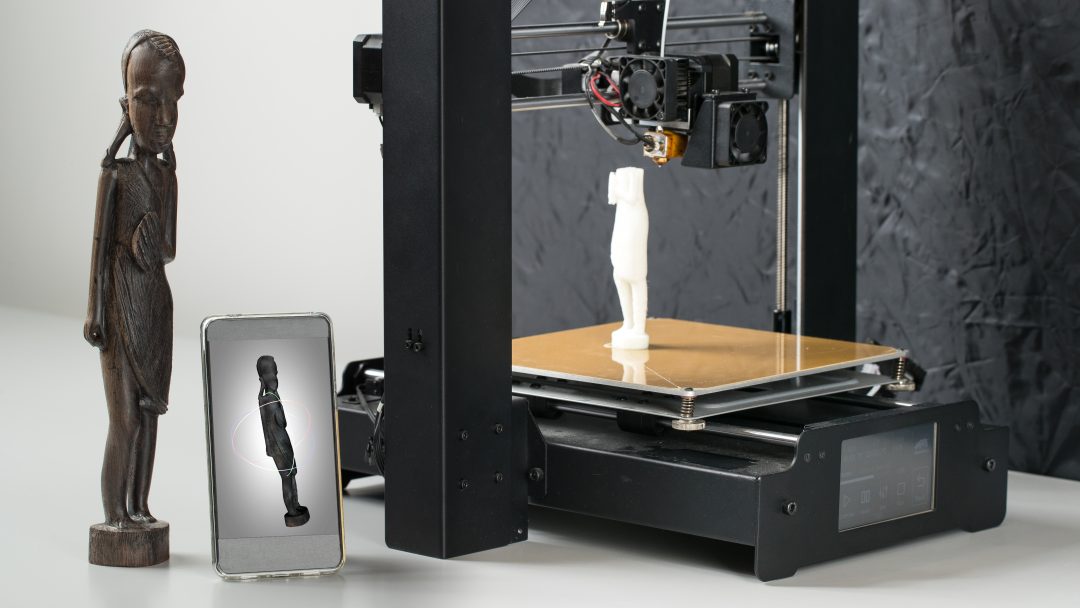

I developed the first dedicated and low-cost 3D Hand Scanner. Using Raspberry Pis, the scanner is able to create a precise surface model of the hand. It opens a new world of possibilities: think of 3D printed braces and personalized surgical instruments.

Your inspiration

3D Scanning is an emerging field in technology. From scanning ants to scanning cities, the possibilities seem endless. However, body parts are still very hard to scan due to their agile nature. A prior graduate (Pamela Loreto) designed a 3D printed brace, and during her process she experienced the frustrating process of trying to scan a hand properly.

The need for customized ergonomic products is beyond doubt. For instance, many papers have been published about the lack of ergonomics in surgical instruments. "Current instruments do not meet standard ergonomic requirements" and "are only available in one size".

How it works

Consisting of 27 bones, the hand is one of the most flexible and precisely controlled parts of the human body.

Scanning the hand 360° is very difficult due to the agile nature of the hand. Most scanners have a particular point of view; this means that the scanner has to turn around the hand, or the hand has to turn in front of the scanner. Both ways, the hand will move which results in a loss or accuracy.

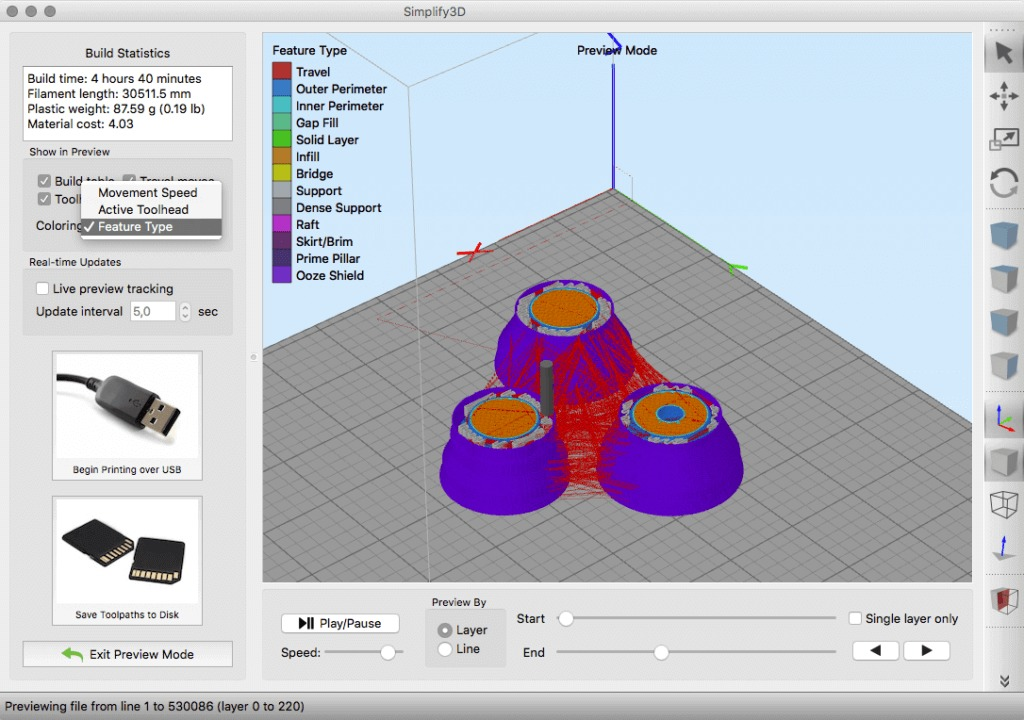

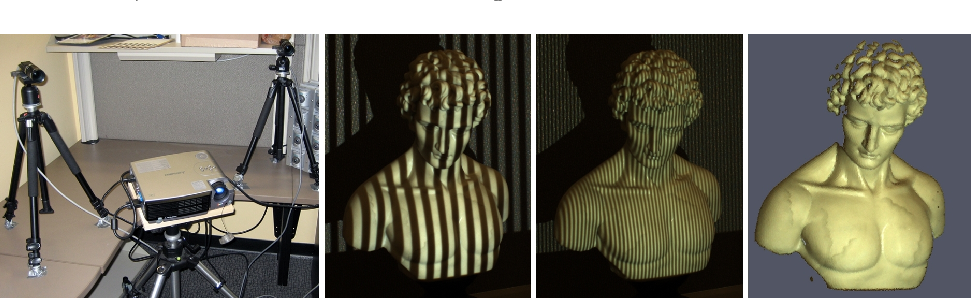

Using Raspberry Pis, laser pointers and 32 cameras, the scanner is able to create a precise surface model of the hand. By taking 32 pictures at the exact same time, and adding surface details on the hand by projection, the pictures can be used to create a surface model. The technique is called Photogrammetry, a powerful and flexible technique which is developing quickly and only requires off-the-shelf parts.

The technique is called Photogrammetry, a powerful and flexible technique which is developing quickly and only requires off-the-shelf parts.

After a thorough analysis phase, photogrammetry proved to be the best choice, because it is flexible (a large variety of components), fast (scan can be made in 1/100 s) and components are cheap.

A lot of questions had to be answered. How many pictures were necessary? Where should the cameras be positioned? What is the influence of light in the environment and projection?

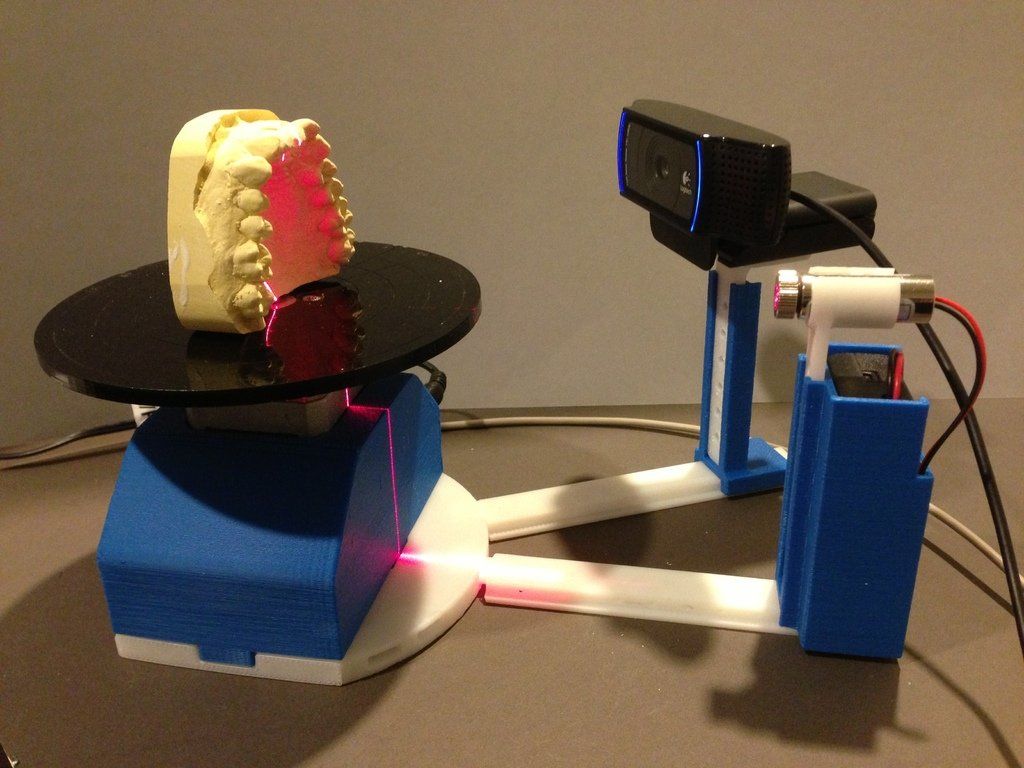

To answer these questions, I built a diorama; a flexible setup that allowed me to take a lot of pictures with one Raspberry camera of a mannequin arm. Over 100 scans were made to get insight in the influencing parameters and to design the 'perfect' camera setup.

After discovering the ideal lighting and projection circumstances, a curve could be made which showed the relation between the amount of pictures and the accuracy of the model. For a model with a maximum deviation of 1 mm, 32 pictures were necessary.

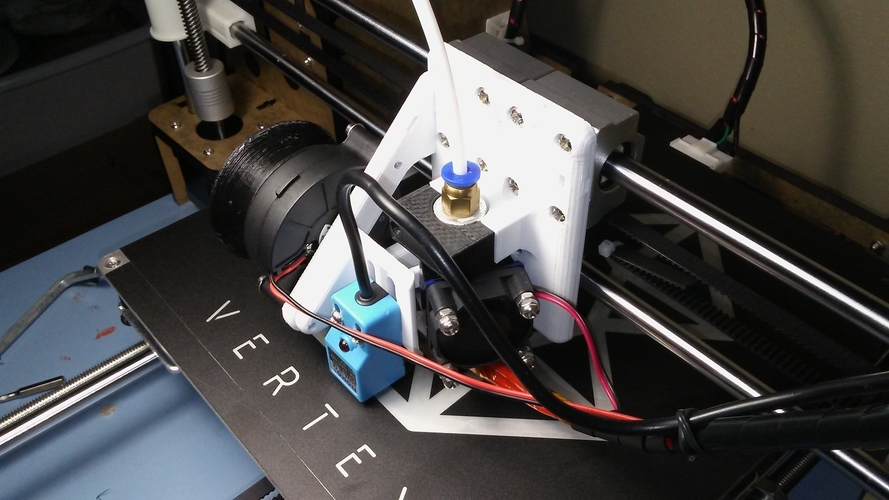

How do you design a 32-fold camera? For this project, 32 Raspberrys were the cheapest and best option. They are controlled with a Python script, which triggers the cameras at the same time. Afterwards, they will send the pictures one by one to a central hub via Wi-Fi.

After acquiring most of the important parameters, the final prototype was built en optimized countless times.

For a model with a maximum deviation of 1 mm, 32 pictures were necessary.

How do you design a 32-fold camera? For this project, 32 Raspberrys were the cheapest and best option. They are controlled with a Python script, which triggers the cameras at the same time. Afterwards, they will send the pictures one by one to a central hub via Wi-Fi.

After acquiring most of the important parameters, the final prototype was built en optimized countless times.

How it is different

Scanning the hand 360° is very difficult due to the agile nature of the hand. Most scanners have a particular point of view; this means that the scanner has to turn around the hand, or the hand has to turn in front of the scanner. Both ways, the hand will move which results in a loss or accuracy. I could find no scanner which was dedicated to the hand or suited for hand scanning under

Future plans

With the scan, a parametric model can be used to make personalized medical instruments, but much more. There is a world of possibilities to extend to: imagine customized performance sports gear (Formula 1 Steering Wheel, Bicycle Steers, Golf Clubs, Climbing Gear), e-sports (Computer Mice, Controllers) 3D printed medical solutions (Lightweight Water-resistant Braces, Low-Cost Orthotics and Prosthetics) and a very valuable data-set for everyone who designs products which require precision and work with the human hand.

There is a world of possibilities to extend to: imagine customized performance sports gear (Formula 1 Steering Wheel, Bicycle Steers, Golf Clubs, Climbing Gear), e-sports (Computer Mice, Controllers) 3D printed medical solutions (Lightweight Water-resistant Braces, Low-Cost Orthotics and Prosthetics) and a very valuable data-set for everyone who designs products which require precision and work with the human hand.

Awards

Featured on the Dutch Design Week 2015 in Eindhoven.

Created by

- Pieter Smakman

University / Institution

- TU Delft

Region

- Netherlands

Notification

A message

3ders.

org - Student designs 'Curatio' 3D hand scanner equipped with 32x Raspberry Pi cameras

org - Student designs 'Curatio' 3D hand scanner equipped with 32x Raspberry Pi camerasFeb 8, 2016 | By Benedict

Nowadays, in what could be considered a Golden Age of customization and specificity, knowing your measurements can be extremely valuable. Whether you’re a professional athlete looking for the perfect-fitting sportswear and equipment, or a patient requiring an artificial limb, the one-size-fits-all culture of past generations is surely behind us.

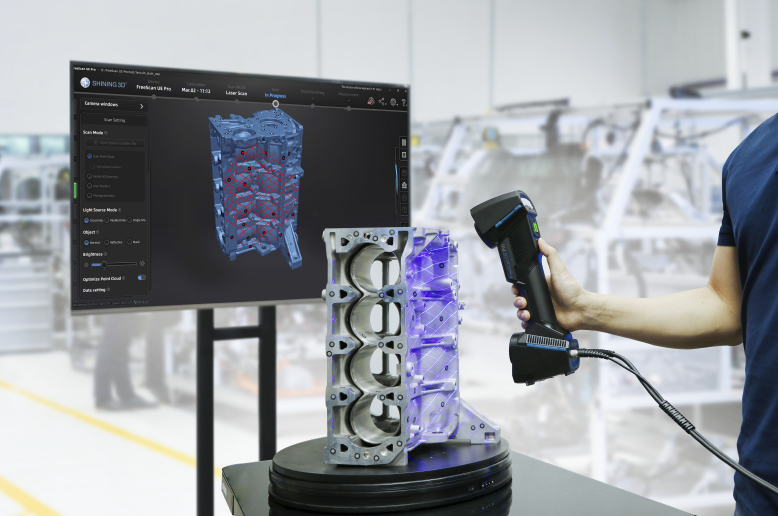

One piece of technology doing its best to assist made-to-measure services in a range of fields is the 3D scanner, which can capture 3D images of a body or body part. Unfortunately though, taking accurate 3D scans of humans and their various body parts can be tricky, since people are liable to move around, whether they want to or not, causing inaccurate data—a problem not associated with other, more stationary 3D scanning subjects.

Pieter Smakman, an Industrial Design Engineering and Integrated Product Design student at the Delft University of Technology, recognized this deficiency in 3D scanners and wanted to fix it, focusing particularly on 3D scans of the human hand—measurements of which can inform custom-made tennis rackets, steering wheels, prosthetic fingers, wrist fracture braces, and much more. The student thus set about designing Curatio: a dedicated 3D hand scanner.

The student thus set about designing Curatio: a dedicated 3D hand scanner.

“Good 3D scanners already exist, but they’re really only suitable for stationary objects,” Smakman explained. “They are not good enough for scanning the human body. If someone with their hand in the air has to stand on a rotating disc during a scan, the person can’t help but move. So a scan like this isn’t very accurate.”

Once Smakman had the idea for his project, he had to make a number of important design decisions. Via what method would his device capture the images? From what materials would he build the body of the scanner? What hardware would he use? After a thorough analysis phase, the student decided upon a photogrammetry scanner, for its flexibility, speed, and affordability.

The engineer decided he would build a “ring” of many cameras, between which a subject could place their stationary hand, with each camera firing at the exact same moment to eliminate movement problems. The designer built a PMMA frame using a laser cutter, using aluminum profiles to create two camera rings.

The designer built a PMMA frame using a laser cutter, using aluminum profiles to create two camera rings.

To obtain the perfect camera placement, Smakman used a mannequin arm and set up a single Raspberry Pi camera in a number of different positions. “They are affordable printed circuit boards the size of a packet of cigarettes with the functionality of a fully-fledged computer,” Smakman said of the Raspberry Pi, which provided the brains of Curatio.

After over 100 scans, the designer found the perfect arrangement, which would require 32 Raspberry Pi cameras. He had initially been taking 48 photos for a single scan, but realized that fewer were required: “On the computer I discarded 1 photograph from each series, through which I discovered that 32 images were sufficient for producing a good 3D scan.”

The challenge facing Smakman now was figuring out how to operate those 32 cameras in perfect unison, in order to produce a flawless 3D scan of a human hand. He tested the mini computers by having them photograph a stopwatch simultaneously. Each photograph showed the exact same time to a hundredth of a second.

Each photograph showed the exact same time to a hundredth of a second.

However, Smakman still had a problem when trying to send the images down the line to a main computer: the wireless network was overburdened. The quick-thinking student overcame this problem by incorporating a send delay into each Raspberry Pi. The code modification did the trick, and his 3D hand scanner was complete. “What I then felt... It’s truly wonderful when it all works,” the Curatio designer said. “Especially because no one has done this before.”

The prototype Curatio was able to produce hand scans with a maximum deviation of 1.5mm from the subject. Smakman envisions the 3D hand scanner being used as the starting point of a 3D printed wrist brace service called “Carpifix”. In the Carpifix business model, a patient could have their hand 3D scanned, after which medical professionals could use the 3D images to produce a custom-fit, 3D printed brace for that patient.

Smakman’s creation was first showcased at Dutch Design Week 2015 in Eindhoven, Netherlands.

Posted in 3D Scanning

Maybe you also like:

- 3D scanned people star in music video for N. Lannon’s ‘Another Love’

- MIT develops 3D scanners cheaper and 1,000x better than current technology

- Kinect now easy 3D printing tool with release of 3D Scan app for Windows 8.1 and 10

- 3DMakery opens up Africa's first 3D scanning booth with an exciting launch

- Occipital acquires Lynx to make portable 3D scanning even more precise

- CultLab3D’s 3D scanning conveyor belt allows high-speed digitization of historic artifacts

- South Korean researchers develop user-friendly, handheld 3D scanner and $18 scanner tool for smartphone

- VR3D launches Vietnam's first virtual museum with 3D scans of ancient relics

- La Bayadère ballet featuring 5 foot tall elephant made with 3D scanning

- Eora 3D Scanner turns smartphone into a 3D scanner, now available on Kickstarter for $229

Bill Rodriguez wrote at 7/21/2016 3:34:06 PM:

This is very interesting! Do you have you code posted on github?

Kamrenae wrote at 2/14/2016 10:38:38 PM:

I'm looking to start an after school program for makerspace, but need to know where to begin?!?! Any help on this would be fabulous!! Thanks!!

5 directions of 3d scanning at Smithsonian Institution

Pelevin N. 0 Comments 3d scanning, Archeology, Smithsonian Institution

0 Comments 3d scanning, Archeology, Smithsonian Institution

What happens when the "American attic" unleashes 3d scanning?

A miniature head model of President Abraham Lincoln, a five-million-year-old whale skeleton, and even busts of long-deceased Institute workers will soon be on the shelves of the Smithsonian Institution in Washington.

The Smithsonian is called "the American attic" because everything you need and don't need is stored there.

But the arrival of 3D scanners and printers, which took over the Smithsonian's 3D Digitization Lab in Land Rover, Maryland, did come as a surprise.

One of the scanners is the size of a toaster and is positioned on a tripod. The rotating mirror occupies a U-shaped notch located in the upper part. So the machine can reflect a laser beam that scans a room or cave. Another scanner resembles a robot arm attached to a support. Both scanners look as if a special effects film studio or a NASA lab would be a better place for them.![]()

However, these scanners have become a key component in Smithsonian research: they have been used to better understand the past. Scientists use 3D scans and 3D prints to study the world's most fragile artifacts, both artistic and paleontological, that are over a million years old, without having to touch the exhibits.

Over the past four years, a pair of Smithsonian workers have scanned many objects from 19national museums and galleries, as well as the National Zoo and archaeological sites around the world.

Vince Rossi and Adam Metallo, dubbed "Laser Cowboys", have scanned everything from contemporary art pieces to rare finds from Chilean dig sites over the course of their career. They both made their living making props for theatrical productions before starting to produce models of artifacts for exhibitions at the Smithsonian Museum. Rossi joined the Smithsonian in 2004 and Metallo in 2009

In their museum activities, the creation of a model of an ancient relic meant the work of making a plaster cast of it or sculpting it from clay.

After many curators began to protest against immersion of ancient objects in plaster, Rossi and Metallo wrote a request to the Smithsonian for a 3D scanner and printer.

“Our priority was to create the best show models,” says Rossi. But after receiving a grant six years ago, he found the technology was in high demand and could allow researchers to study objects without having to touch them.

“Usually 3d devices are non-contact,” says Metallo. They work by measuring the speed of a laser beam bouncing off various parts of the exhibit, which does not involve any use of a tape measure or calipers.

This has become music to the ears of many curators and scientists.

“The ability to scan an object in 3D allows us not only to bring it back to the real world through 3D printing, but also to study its properties,” said Rossi. “The rational use of these tools is to work with the received data, and not just make models on a 3d printer.”

Since the Laser Cowboys secured a place at the Smithsonian Lab about four years ago, a wide variety of object types have passed through their instruments.

Here are 5 of the most incredible and intriguing objects from their list:

1. Cosmic Buddha Sculpture Decoded

This amazing figure has kept its secrets hidden for over 1300 years. Almost 6 feet tall, the reincarnation of the Chinese Buddhist vision of heaven and hell, the Buddha sculpture towers over its pedestal in the Smithsonian Frier and Sackler Gallery in Washington DC, headless and armsless.

However, while museum visitors are looking at the navel of the sculpture - the belly of the seated Buddha is at eye level - it is difficult for scientists to study it.

“In order to study in detail the inscriptions carved on the sculpture, scientists would have to go to the gallery hall, taking a ladder with them and, climbing it, look over the shoulders of the Buddha,” says Metallo.

“Previous attempts to determine the meaning of these inscriptions have been unsuccessful,” said Keith Wilson, curator of the ancient Chinese art section at Frier-Sackler, two galleries devoted to Asian art. Researchers had to work from photographs or ink prints of carvings.

Researchers had to work from photographs or ink prints of carvings.

Looking closer at the carving after scanning it, Wilson realized that it was possible to improve the carving site with a computer and get a clearer picture.

So, last year he got Metallo and Rossi to work on the sculpture.

Using a handheld 3d scanner, Metallo and Rossi were able to digitally model the sculpture and carvings for Wilson. The Laser Cowboys then improved their scans using a photographic technique called photogrammetry (a technique in photography that uses successive images to obtain measurable dimensions). This technique helped them reproduce the depressions where the sculpture's head and arms should have been.

Digital scans have already helped Wilson more accurately determine the age of the sculpture. “I re-dated it 550-557. AD,” said the curator. Previous estimates attributed the sculpture to 581-618. AD

Metallo says the next step will be to rotate and align the digital model, "like turning a globe into a map. "

"

2. Prehistoric Whale Remains Preservation

Smithsonian paleontologist Nicholas Pyenson was in Chile's Atacama Desert excavating for penguin and dolphin remains several years ago when a colleague unexpectedly told him of a nearby site littered with fossilized whale remains. about 5 million years old.

“There were dozens and dozens of whale skeletons,” Pienson recalls of a 2011 trip. It's not every day that scientists stumble upon a whale burial site, and Pienson said his mind went blank at that point.

But the valuable find was endangered. The road services were busy expanding the Pan-American Highway, which ran side by side with the find site.

Thus, the researchers had only one month to document the 35 whale skeletons found. Also, the remains had to be moved to make way for the highway under construction.

Documenting the remains while they are still in the ground can tell scientists a lot about where the animals died, how the sediments buried their bodies, how the bones were preserved and how they fit together.

“Typically, researchers start by drawing a grid meter by meter over the skeletons, sketching the approximate locations of the fossils on paper, and then recreating the location of the find, which can reveal important scientific information,” Rossi said.

But the time limit meant that detailing each skeleton by hand was not possible. So Pienson turned to the Smithsonian 3D Digitization Group.

Two weeks later, thanks to an investment from the Smithsonian and the National Geographic Society, Rossi and Metallo sank into the sand, scanning the skeletons of a fossilized whale.

“It was an incredible effort, we worked 22 hours a day,” Pienson recalls. “We were able to capture a digital image of the place that was detailed enough to allow us to answer our questions.”

So the researchers were able to study digital scans of the area to find out how the bones fit together and how they ended up in the area.

Upon examination, scientists found that the bones were brought to that area by a fast-flowing river that flows into the lake.

While researchers are still examining scans and physical specimens at the nearby Chilean Museum, they are already planning to make a full-size model of the whale to be displayed at the Smithsonian's National Museum of Natural History later this year.

3. Reconstruction of the "Hall of Extinct Monsters"

We wrote about this scan earlier.

31,000 square meter space at the Washington National Museum of Natural History. m., which presents various types of dinosaurs, is better known as the "Hall of Extinct Monsters". The hall is scheduled to be renovated next year. And this reconstruction will be the most grandiose in the history of the museum.

The hall holds 27 dinosaurs, including Stegosaurus, Triceratops, and Diplodocus. Some of the dinosaurs on display, notably Stegosaurus Stenops, are especially valuable to researchers because they were the first of their kind and gave scientific names to all the others.

Scientists have used fossils to describe entire varieties of the dinosaur genus, with which individuals have subsequently been compared.

“Scanning allows us to examine in detail those specimens that still remain in the exhibition hall,” Matthew Carrano, curator of the museum's dinosaur section, wrote in an email. The scans will also help researchers and Smithsonian staff improve the mountings of exhibits.

It is hoped that designers will be able to use digital models when placing exhibits. Using 3D scanning, scientists will be able to digitally inspect the skeleton and position it in various locations in the new hall to decide where to place it.

After the April connection of Rossi and Metallo, more than 80% of the hall and its petrified inhabitants were digitized, despite some difficulties.

4. Support for Contemporary Art

Two works of contemporary art at Washington's Hirshhorny Museum and Sculpture Garden have attracted the attention of laser cowboys.

If you were to ask how many people it would take to change an electric light bulb behind a modern art masterpiece called "Lunar Landscape", the answer would be two "laser cowboys".

This exhibit is a three-by-two-foot (0.9 m by 0.6 m) wall-mounted installation made from a material called magnesite. The thin magnesite frames are perforated and covered with colored acetate gels so that the light from the same light bulbs on the back of the structure streams through it.

This is one of the largest lunar structures, created by the creator from America Isamu Noguchi (Isamu Noguchi), who spent seven months in a prison camp in Arizona during World War II. Gwynne Ryan, a conservative sculptor from the Hirshhorn, calls this piece of art "the prize object of our collection."

Every time the workers needed to change a light bulb in an installation, they had to lean on something, which is not desirable for a valuable piece of art.

So Metallo and Rossi scanned the masterpiece last year and created a cardboard support for this work. The interconnected parts of this support fit together like a jigsaw puzzle. In this case, the work of art is always on top. As a result, this support can accompany the installation everywhere, even if it ever goes to storage. “Restorers don't have to worry so much anymore,” says Ryan.

As a result, this support can accompany the installation everywhere, even if it ever goes to storage. “Restorers don't have to worry so much anymore,” says Ryan.

The second object from Hirshhorn that Rossi and Metallo scanned is a wax sculpture called “From Hand to Mouth”, which museum workers were afraid to exhibit in other museums because of its fragility.

So in 2009, just before the exhibit traveled to Venice, the Smithsonian Museum scanned the sculpture. Thus, the museum staff received a digital computer version of the work.

In 2013, Hirschhorn asked the sampling lab to rescan the sculpture to see if the travel had damaged it.

“The good news is that there were very slight differences between the two scanned models,” Metallo said.

it showed that the sculpture did not change its shape much, ”Rine said.

5. A case of mysterious death 140 years ago

Robert Kennicott, naturalist of the Smithsonian Institution, explored the banks of the Yukon River in May 1866, where he died suddenly. He was buried at his estate, The Grove, in Glenview, Illinois.

He was buried at his estate, The Grove, in Glenview, Illinois.

A 30-year-old man was rumored to have committed suicide by ingesting strychnine, one of a number of toxins he was using to preserve specimens at the time. But the actual cause of death remained a mystery for a century.

In 2001 Kenicott's descendants and Smithsonian staff commissioned the Natural History Museum's forensic anthropologists to investigate a mysterious death.

Researchers exhumed Kenicott's body and, after a thorough analysis, announced in 2010 that heart failure (Q-T syndrome) was the likely cause of death. This syndrome has caused the death of some athletes during the game.

While Kenicott's remains were being held by forensic anthropologists, Rossi and Metallo joined in the research: they scanned the naturalist's skull and 3D printed it for face and bust reconstruction.

“The researchers placed tissue markers on the 3d model to recreate Kenicott's skin,” Rossi said.

The bust was exhibited at the National Museum of Natural History before going to the family estate in Illinois.

Intraoral dental scanning in Moscow

Intraoral Dental Scan

Medit i500 3D Scanner

Scan Benefits

Our advantages

Prices for services

Our specialists

Intraoral Dental Scan

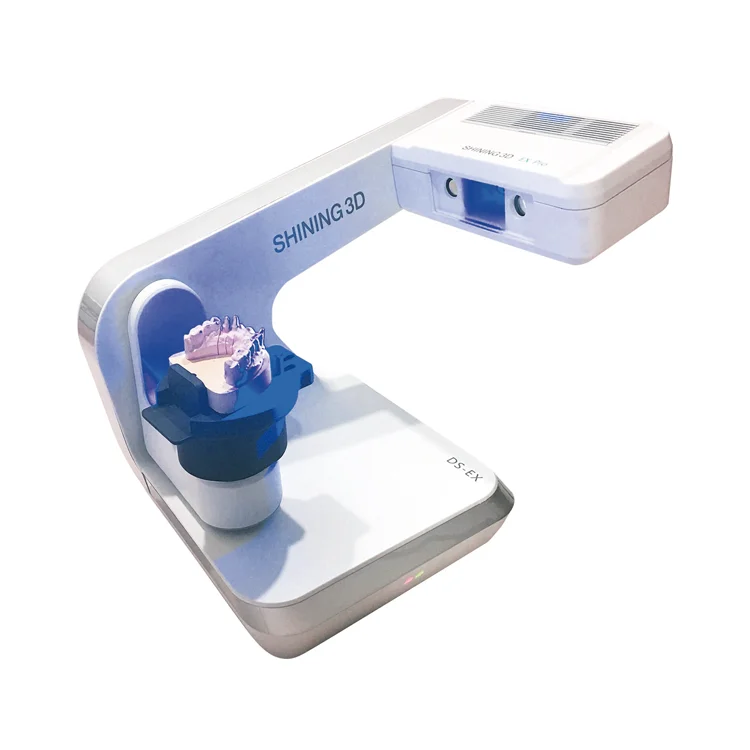

Technologies in the dental industry are evolving rapidly. New devices, materials and techniques are constantly emerging. So an alternative to physical casts of the jaw was intraoral scanning of the teeth.

A high-precision intraoral scanner is used to acquire models during the intraoral scan. Thanks to the use of the device, the treatment time is significantly reduced. In the Gorstomcenter clinic in Moscow, you can make intraoral medels before orthodontic and orthopedic treatment.

What is intraoral scanning

Intraoral scanning is a procedure for obtaining a complete 3D digital model. As a result, the doctor receives more information that can be easily sent electronically to the right laboratory. This is especially important before major interventions such as implantation and prosthetics.

As a result, the doctor receives more information that can be easily sent electronically to the right laboratory. This is especially important before major interventions such as implantation and prosthetics.

An obsolete alternative to intraoral scanning is taking an impression with silicone mass or plaster. The very procedure for taking impressions was previously unpleasant for the patient, not always accurate and rather lengthy due to the need to send the impressions to the laboratory for the manufacture of orthopedic structures.

An intraoral dental scan must be performed before the following procedures:

- Correction of the bite with aligners or braces.

- Installation of crowns and inlays.

- Making veneers.

- Prosthetics.

- Implantation.

Make an appointment and find out the price in Moscow

Medit i500 dental scanner

General Yermolov, we use a high-tech i500 scanner from Medit (Korea). It is easy to use, the doctor does not have to undergo additional training to work with the equipment, and the results are as accurate as possible.

It is easy to use, the doctor does not have to undergo additional training to work with the equipment, and the results are as accurate as possible.

Characteristics of the Medit-500 optical scanner:

- Scanning the area from 1-2 teeth.

- 3D image of one, both jaws and even part of the face.

- Accurate visualization of the back teeth.

- Volumetric image of soft tissues.

- Continuous acquisition of the scanned area while moving.

- Smart algorithm, image correction, restoration of the process if it was interrupted, automatic removal of unnecessary details: fingers caught in the camera, etc.

- Color scanning with two cameras.

- Anti-fogging with air currents.

- Light weight less than 300 g.

The scanner head is light and compact, which is convenient for the patient and the doctor. Due to the small size of the sensor, the procedure is well tolerated by patients with a pronounced gag reflex, incl. children. Scanning takes a little time, so the doctor can pay more attention to the patient, and if necessary, rescan certain areas.

children. Scanning takes a little time, so the doctor can pay more attention to the patient, and if necessary, rescan certain areas.

In our center you will receive high-quality, safe treatment using the best medical technologies, which will make the process faster, more accurate and more convenient. Book an appointment online or by phone now.

Benefits of intraoral scanning:

- Hygienic procedure: no cross contamination. During the examination, interchangeable nozzles are used. After each patient, the tips are washed and sterilized in an autoclave.

- Convenience, safety and comfort for the patient. Not every patient comfortably tolerates the procedure for taking impressions. Possible allergies, gag reflex, especially in children. Scanning is allowed for the elderly and pregnant.

- High accuracy of results with minimal error. When making and scanning silicone and plaster impressions, the error can reach up to 90-100 microns, and when using a 3D scanner - no more than 10-15 microns.

- High image detail, which simplifies the planning of restoration and restoration of teeth.

- Quick research and save time. It takes 10 minutes to scan one jaw. Crowns, veneers and other customized dental restorations can be made immediately, while impressions and models take several hours to make.

- Speed of processing and correction of results. All scan data is immediately sent to the PC. If there are unscanned gaps, the doctor can immediately correct the result. If the casts are made with errors, the work will have to be done again.

- Fast data exchange: a dental technician, laboratory assistant, doctor can access the results at a convenient time anywhere in the world.

Digital impressions successfully replace classical impressions. Thanks to computer modeling, it is possible to make structures from any materials: ceramics, cermets, zirconium dioxide, porcelain.

You should trust us with your health

Highly qualified employees

Modern materials and technologies

Stress-free treatment

Safe and effective pain relief

Dental instrument disinfection

Dental service guarantee

Intraoral scanning prices

We invite you to undergo an intraoral scan at the Gorstomcenter in Moscow, not far from the metro station Pobedy Park. The price list contains current prices for 3D studies.

The price list contains current prices for 3D studies.

Full price of dental services

Our specialists

-

Nevrotova Irina Yurievna

Dentist-therapist, periodontist, chief physician.

-

Sizikova Polina Nikolaevna

Dentist-therapist, pediatric dentist, periodontist.

-

Lysenko Andrey Anatolyevich

Dentist-surgeon, implantologist.

-

Tretyakova Alla Igorevna

Dentist-therapist, pediatric dentist.

-

Timoshenko Olga Andreevna

Dentist-therapist, pediatric dentist.

-

Sevan Susanna Mukhammedovna

Dentist.

-

Pesenko Ekaterina Valerievna

Orthodontist.

-

Tregubova Elizaveta Alexandrovna

Dentist-therapist, periodontist.

-

Dybov Andrey Mikhailovich

Candidate of Medical Sciences. Dentist-orthopedist, orthodontist.

-

Denisova Ekaterina Aleksandrovna

Dentist-orthopedist, orthodontist.

Learn more