Gigabot 3d printing

Gigabot X Update | re:3D

Hot off the 3D printing press, it's a Gigabot X update!

It’s been about four months since we closed out a successful Kickstarter campaign for our pellet printer, Gigabot X, on April 23rd. Since we last touched base with you, our engineers have been hard at work making improvements to the design for our Kickstarter backer beta testers.

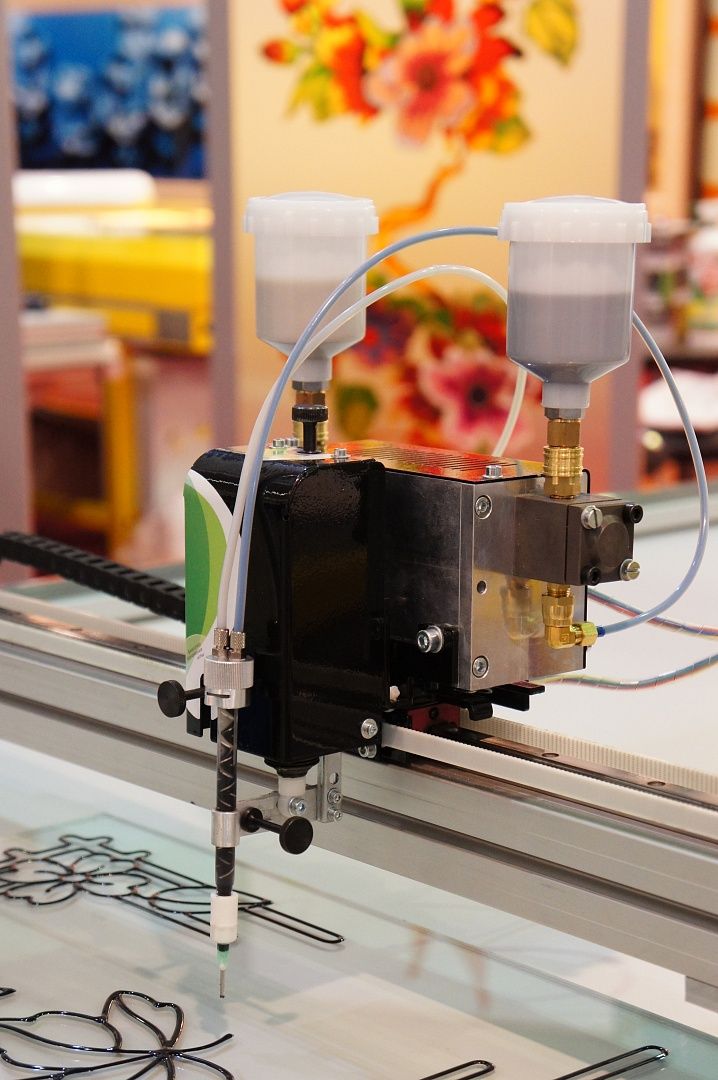

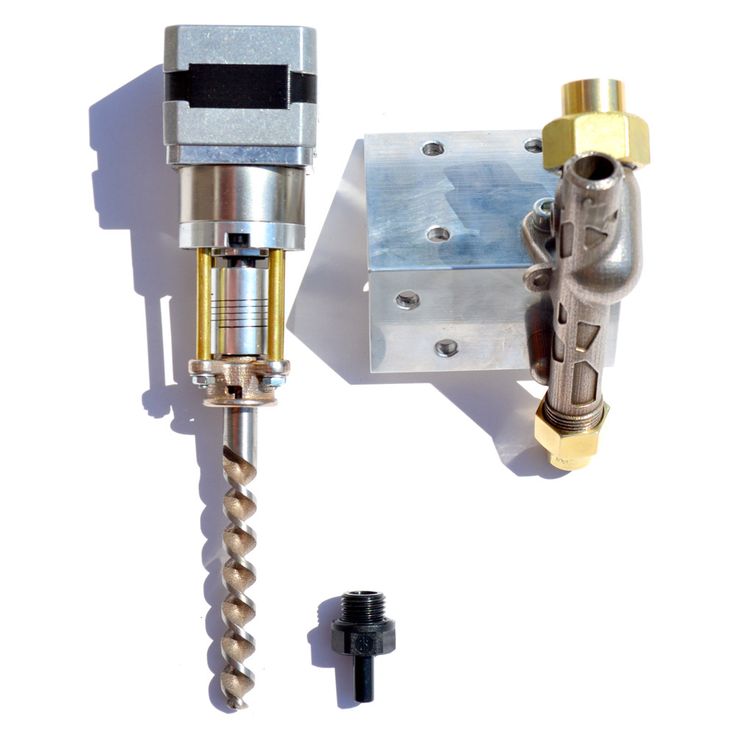

The main focus of the redesign has been the extruder, which has been completely overhauled over the last several months. There’s a new metal extruder body, improved wiring of heaters and the external motor driver, and a redesigned screw for more consistent extrusion.

Some previously 3D printed components within the extruder body were switched to metal for the purpose of durability. Originally printed for ease of testing modifications, our engineers found that some components weren’t lasting as long as they’d like to see due to the tremendous forces being generated within the hopper as the screw extrudes pellets. Now that the design of certain pieces is more final, we started machining certain components in metal to better deal with wear and tear.

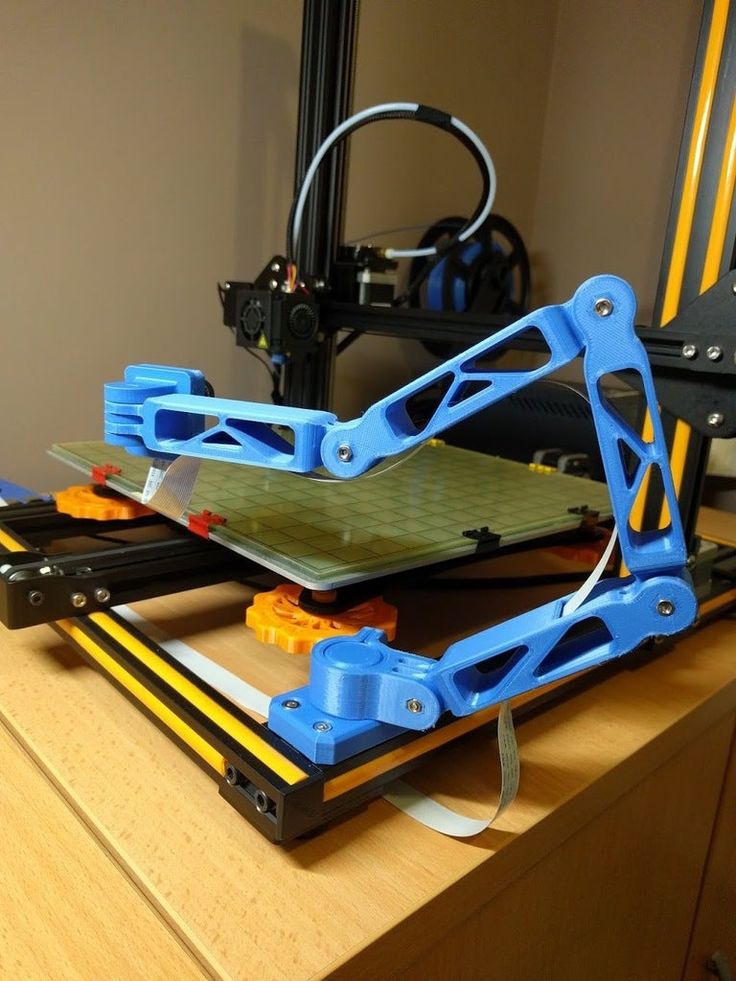

The modular, 3D printed hopper has also seen significant changes. With the previous design, our R&D team found that the amount of pellets being pushed through by the screw was much higher than they expected – and wanted. They increased the size of the hopper to slow down the rate, which also provides the dual benefit of not having to replenish the pellets as often.

The first Gigabot X prototype took a trip up to Michigan and is currently residing at Michigan Tech University, where a group of students are performing material testing research as a collaboration supported by our NSF SBIR Phase I. Some of the materials they’ve been validating include PLA, PET, polypropylene, and ABS, in both recycled and virgin forms. One of our favorites we’ve been printing with is recycled PET, better known as the common disposable water bottle.

Michigan Tech has also done us the incredible service of creating improved Slic3r profiles for these materials. The profiles are working fantastically on the new Gigabot X in the Houston office, and we’re seeing improved quality of prints thanks to them. Backers will benefit from these profiles, which have improved the overall printing experience greatly.

Another thing our team is particularly excited about is that the MTU students were also able to 3D print with multiple sized pellets and have also been experimenting with printing directly with ground-up plastics with success. These results were then submitted to a peer-reviewed journal, and we would love to invite the community to check out the research in Materials. You can also share questions and comments with us on the Gigabot X forum by creating an account and logging in.

Testing of Gigabot X is still ongoing and small tweaks continue to be made, but things are moving along well. Over the next three to four months our team will be rounding out testing, cleaning up and finalizing the design and documentation of the machine, and getting the first bots ready for backers. Our team is really excited for the moment that we get to put this technology into the hands of our early adopters.

Our team is really excited for the moment that we get to put this technology into the hands of our early adopters.

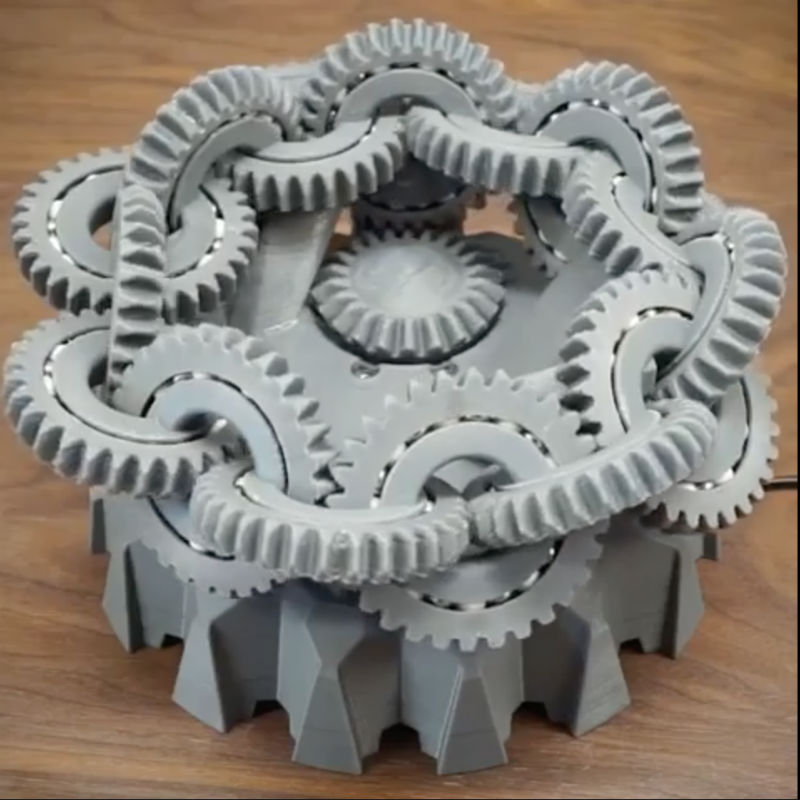

As re:3D R&D Intern Robert Oakley put it, “I’m really looking forward to seeing what people make with it… It’s really cool to see when people start figuring out how to use our printers to make cool objects that we haven’t thought of before.”

Stay tuned for an upcoming post about what Gigabot X was printing in the video above!

Re:3D’s New 3D Printers - Gigabot 4, Terabot 4, GigabotX 2 & TerabotX 2

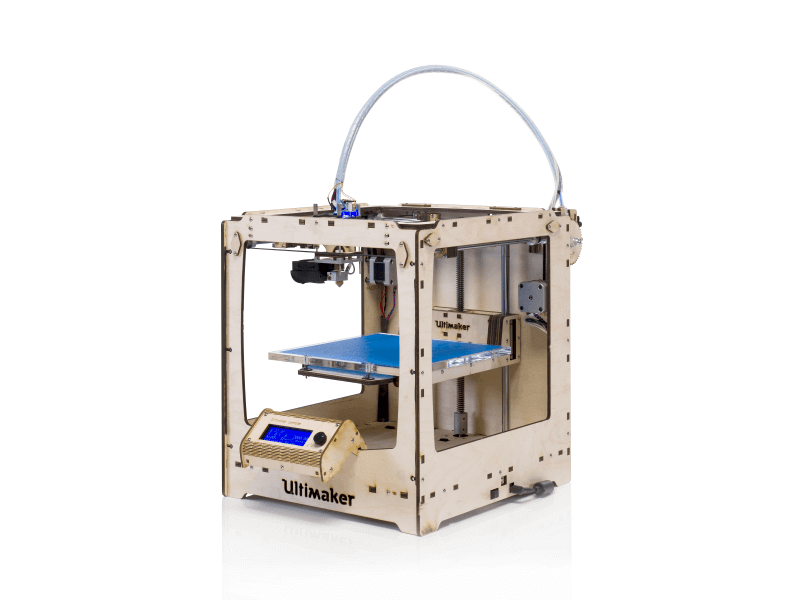

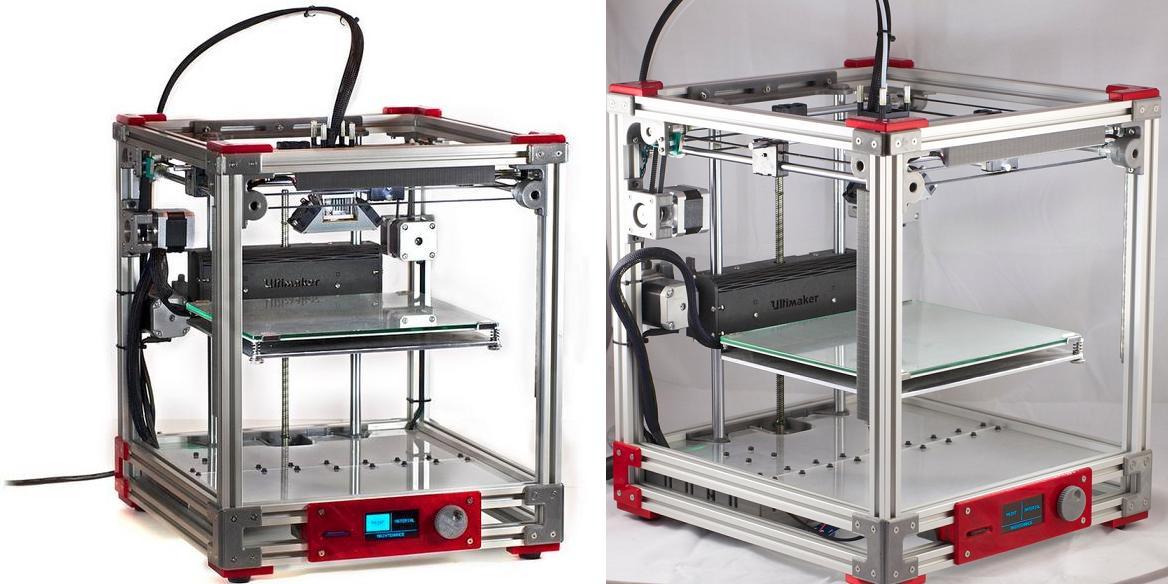

(Left to Right) Re:3D’s New 3D Printers – Gigabot 4 with enclosure, Gigabot 4 XLT, Terabot 4, Exabot, TerabotX 2, Gigabotx 2 XLT, GigabotX 2 with enclosure/Source: re:3DWith the release of Gigabot 4, Terabot 4, GigabotX 2, and TerabotX 2, re:3D, Inc. announced the inclusion of UltiMachine’s ArchiMajor 32bit control board and the transition to Klipper firmware. Re:3D’s new 3D printers will feature eight integrated stepper motor drivers, three heater outputs, five thermocouple inputs, four controllable fans, and eight endstops are included on the advanced board.

The PCB and Raspberry Pi touchscreen controller are housed within a 16″ electrical enclosure and work together to control an agile software stack with web capabilities. This board not only boosts Gigabot and Terabot processing power, but it also enables better control of re:3D’s supply chain and electronics quality with a strong US manufacturing partner.

Introducting Gigabot 4 & Terabot 4/Source: re:3D“As a US based company, UltiMachine enjoys designing custom solutions to enable open-source US 3D Printer OEMs to enhance their offerings and scale.”

– Johnny Russell, CEO, UltiMachine

Re:3D’s printers will have a host of new features and additions which make the machines more reliable and produce better results.

Gigabot 4: In Gigabot 4, re:3D has made some technological improvements to increase its reliability and longevity. Many of these updates revolve around the extrusion system, which includes an all-metal extruder body, 20 Series Hot Ends for 0.8 nozzles, Terabot 4, tube style thermocouples, and heater cartridges as standard, resulting in the most robust, industrial extruder system. Gigabot 4 comes in a standard 600 mm cubed kit, with the option of adding an enclosure if desired.

Terabot 4: The enclosure is included as standard with the Terabot 4. Other structural additions, such as the side panels, help to protect the motors and electronic components.

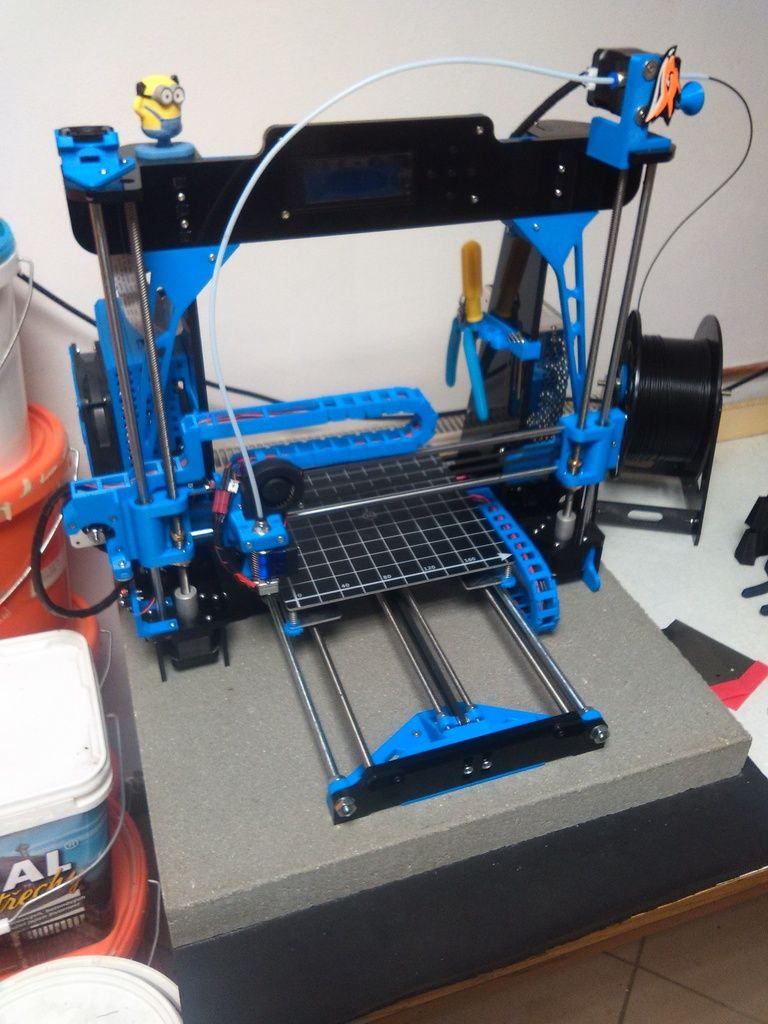

GigabotX 2: The GigabotX 2 has a precision engineered feeding and extrusion system for processing pelletized and granular thermoplastics. Material is manually fed into the 24-hour capacity hopper, which is supported by an independent hopper gantry system, allowing for a full and smooth range of motion as well as consistent feeding into the extruder.

Print material enters the extruder via the gravity fed feed throat or the optional active feeding system, or crammer, which includes a motorised auger that pushes material into the extruder at a user-controlled feed rate.

“Installing the UltiMachine ArchiMajor 32bit PCB was a critical evolution in the Gigabot & Gigabot X portfolio. Not only does the board offer increased performance, it has been critical in our transition to Klipper firmware, a front mounted touchscreen, and WIFI connectivity while providing the customer with increased capability for open source modifications. Our relationship with UltiMachine has been critical in ensuring supply chain resiliency.”

– Samantha Snabes, Co-founder and Catalyst, re:3D

To learn more about all the new features in the Gigabot 4, Terabot 4, GigabotX 2 and TerabotX 2 3D printers, visit the official website.

About re:3D: re:3D, Inc. is a group of visionaries dedicated to lowering the cost and scale barriers to industrial 3D printing. re:3D provides 3D printing contract services, consulting, design, and education services in addition to creating products for customers in over 50 countries.

re:3D provides 3D printing contract services, consulting, design, and education services in addition to creating products for customers in over 50 countries.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

Nexa3D NXD 200 3D printer

With a build volume of 8.5L, a printable area of 275x155x200mm, intelligent optimization, and revolutionary patented LSPc technology, the NXD 200 3D printer is the ideal machine for the dental industry.

Characteristic description

The NXD 200 is equipped with a full featured set of tools including auto orientation, support generation, mesh recovery and detail editing options. Proprietary LSPc (Lubricant Sublayer Photo-curing) stereolithographic 3D printing technology and optimal platform filling guarantee the accuracy of prints, the uniformity of their structure and the repeatability of models from one edge to the other.

The printer has more than double the footprint capacity of currently available machines, allowing for much larger parts, high productivity and ultimately cost savings.

NXD 200 from Nexa3D is a turnkey solution for dentists. The design of the device consists of modules and easily replaceable elements, which, with constant modernization of technologies, eliminates equipment obsolescence.

The unique xCure post-processing system unleashes the potential of the printer consistently and quickly. Proven post-processing workflows provide the optimum balance of temperature, UV wavelength and material-specific cure time to ensure perfect cure. These efficient cycles guarantee consistent mechanical properties and predictable product throughput. The end result is less post-processing, faster time-to-market, better 3D printer throughput, and of course, a quality part.

The patented Everlast membrane increases the life of the liquid-liquid separation surface on Nexa3D membranes exponentially. As the name suggests, the product is more durable, resilient and extends the period of trouble-free operation of the printer by 25 times. Everlast membrane provides less downtime for element replacement and long continuous cycles in complex batch production operations. The development demonstrates stable optical transmission, so even the thousandth part will be identical to the first. Everlast membranes have a stronger but more resilient surface that allows you to print objects from difficult technical materials. The membrane is fully compatible with Nexa3D hardware workflows and settings, including dynamic monitoring of its condition as predicted by the applied feedback.

As the name suggests, the product is more durable, resilient and extends the period of trouble-free operation of the printer by 25 times. Everlast membrane provides less downtime for element replacement and long continuous cycles in complex batch production operations. The development demonstrates stable optical transmission, so even the thousandth part will be identical to the first. Everlast membranes have a stronger but more resilient surface that allows you to print objects from difficult technical materials. The membrane is fully compatible with Nexa3D hardware workflows and settings, including dynamic monitoring of its condition as predicted by the applied feedback.

Intelligent software

Nexa3D's proprietary NexaX v1 software integrates hardware and materials into a powerful, user-friendly system, delivering a new level of intuitive operation and affordable maintenance. Materialize MagicsPrint software is responsible for the optimal placement of models and automatic placement of supports.

The programs are compatible with the Windows 10 operating system and provide for remote printer management: sending for printing, compiling job statistics. Supported input file formats are .stl and .3mf.

Used polymers

Nexa3D has developed a wide range of impact-resistant functional consumables for the NXD 200 3D printer tailored to increased productivity, making them ideal for serious production and same-day prototyping.

Portfolio includes:

- KeySplint Soft biocompatible photopolymer;

- fast curing KeyModel Ultra for precise orthodontic prototyping;

- KeyGuide for surgical models;

- KeyTray for impression trays.

The NXD200 is the fastest 3D printer for dental labs and large scale industrial applications. Due to the high precision printing with a layer thickness of 75 microns and the isotropic properties of the printed objects, the finished models are characterized by impeccable surface quality and dimensional accuracy.

Features

| Country | US |

| Type | Professional |

| Manufacturer | Nexa3D |

| Applications | Medicine |

| Communication interface | Gigabit Ethernet RJ-45 & WiFi |

| Construction area | 275x155x200 mm. |

| Layer thickness | from 75 µm |

| Media | Photopolymer |

| Print technology | LSPc |

| Operating system | Windows 10 |

| Dimensions | 710x710x1675 mm; 160 kg |

3D Printing & Additive Manufacturing

At every step in the 3D printing and additive manufacturing process, temperature control and regulation is critical to ensure high quality parts. Optris offers a complete family of infrared temperature sensors and three shortwave infrared cameras optimized for temperature measurement on metal objects. For temperature monitoring in additive manufacturing, shortwave infrared cameras are becoming increasingly popular because they can easily monitor the temperature of the entire weld puddle and monitor temperature data at the hottest spot without the need to clearly aim at a specific point sensor. Optris IR cameras are now being used in many areas of additive manufacturing as an essential tool to improve productivity and product quality.

For temperature monitoring in additive manufacturing, shortwave infrared cameras are becoming increasingly popular because they can easily monitor the temperature of the entire weld puddle and monitor temperature data at the hottest spot without the need to clearly aim at a specific point sensor. Optris IR cameras are now being used in many areas of additive manufacturing as an essential tool to improve productivity and product quality.

Laser metal deposition is an additive manufacturing process that uses a laser beam to form a pool of molten metal on a metal substrate. The metal powder is continuously fed into the melt pool through a nozzle. The temperature sensor must be able to withstand the high energy density of the laser or its reflection. The process mainly uses a 1064 nm solid state laser or, in some cases, a CO2 laser (10.6 µm). The distribution of heat behind the beam is an indication of good or poor welding quality. Therefore, thermal imagers such as the PI 08M provide the most information about the process compared to a single point pyrometer indicating the temperature of only one heat spot.

Recommended devices:

Thermal imagers optris PI 08M, optris PI 05M or optris PI 1M

. The body of the designed 3D part is created by selectively melting and resolidifying metal powders in each layer. The building plate is lowered slightly and a new layer of powder is deposited.

To reduce the energy required to reach the required melting temperature of the powder, the layer is usually heated in advance. To obtain a high-quality object with a homogeneous metal structure, it is necessary and important to evenly distribute heat. An Optris thermal IR scanner such as the PI 640i can measure the bed temperature and this is important information for a machine in good or bad condition. In addition, individual regions of laser melting can be measured with a short wavelength camera such as the PI 08M.

Recommended devices:

Lazer power: Optris Pi 05M or Optris Pi 08m

Powder: Pi / XI / Pyrometer LT

9000

WINE-DIA additive production is a combination of two processes: Gas metal. welding and additive surfacing. The metal wire is melted using an electric arc and applied layer by layer until the desired three-dimensional shape is obtained. The heat of the previous layer can affect the shape of the next one. Temperature control during the welding process and information on heat distribution provide feedback on the quality of the welding process.

welding and additive surfacing. The metal wire is melted using an electric arc and applied layer by layer until the desired three-dimensional shape is obtained. The heat of the previous layer can affect the shape of the next one. Temperature control during the welding process and information on heat distribution provide feedback on the quality of the welding process.

Recommended devices:

Thermal imager optris PI 08M or optris PI 05M

Fused filament fabrication is a form of additive manufacturing in which filaments are fused together to form a solid part. It is an extrusion process in which an object is created by layering molten material, often using carbon fiber composites. The building plate is lifted slightly and a new layer of filament is applied. One of the challenges for a quality 3D printed product is heat distribution across the base. Uneven temperature distribution can lead to undesirable shrinkage effects, especially for large objects.