3D printed mycelium

Blast Studio 3D prints structural column from mycelium

Jennifer Hahn | Leave a comment

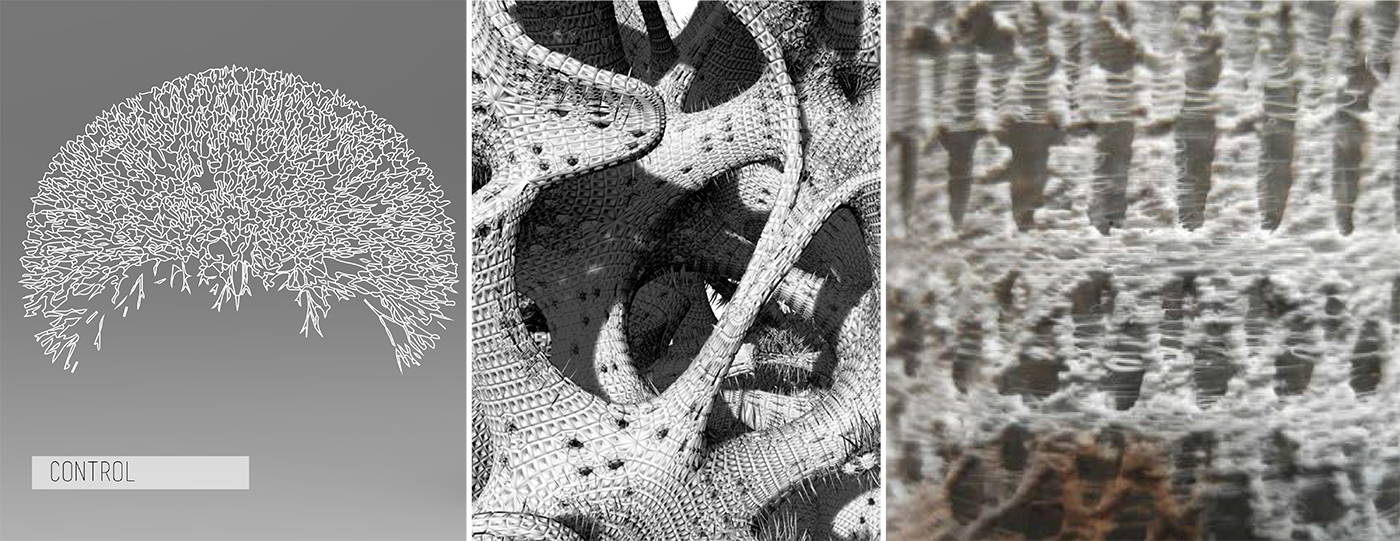

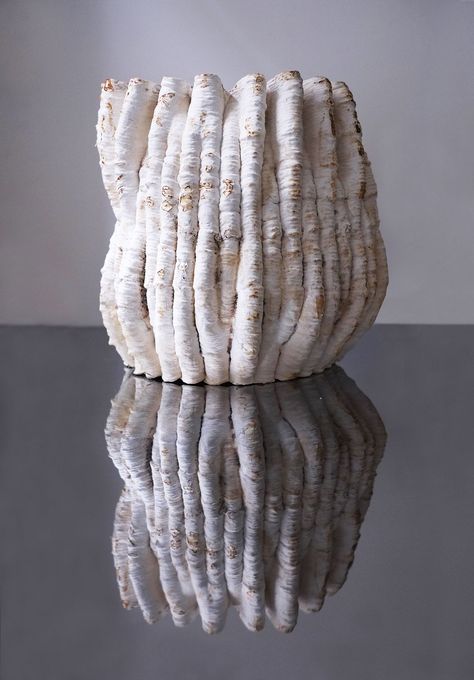

London practice Blast Studio has developed a method for 3D printing with living mycelium and used it to form a column that could be harvested for mushrooms before serving as a structural building element.

The two-metre-high Tree Column has a ridged, undulating structure reminiscent of a tree trunk.

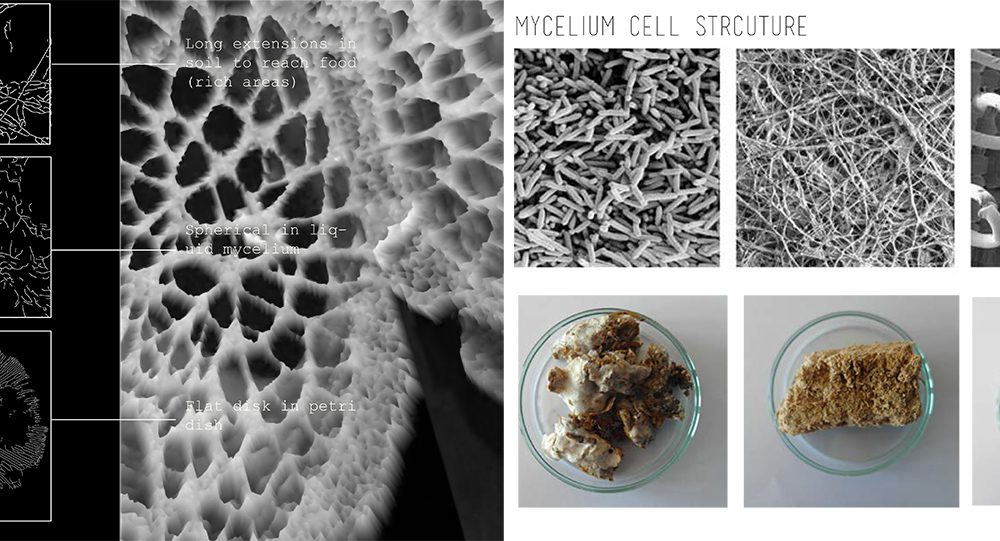

Its shape was algorithmically designed to enhance the column's structural capacity and provide optimum growing conditions for mycelium, the root system of fungi.

The Tree Column (above) is on display at London's Design Museum (top image)The column was constructed by mixing mycelium with a feedstock of waste coffee cups collected from around London and feeding it into a custom-made cold extruder, similar to the kind used for 3D printing with clay.

Once printed into shape, the mycelium consumes the pulped paper cups and grows to take over the whole column, producing mushrooms that can be picked off and eaten.

The mycelium root structure is then dried to create a load-bearing architectural element with natural insulating and fire-retardant properties.

The column is 3D printed from layers of myceliumBlast Studio is working to scale up the technology to print a pavilion and in the future, it hopes to construct entire buildings. Co-founder Paola Garnousset said this could effectively allow cities to grow architecture from their own waste while providing food for their inhabitants.

"Our vision is to start a new type of living architecture that could self-repair and be harvested to feed people," she told Dezeen.

"The idea would be to 3D print a living structure in situ, which would be inoculated with different varieties of mushrooms, some with high structural resistance and some delicious ones."

Mushrooms can grow on the surface of the structureThe Tree Column's production process starts with shredding paper coffee cups and boiling them in water to produce a sterilised paper pulp. This is then mixed with the mycelium, as well as any desired natural pigments to add colour.

This is then mixed with the mycelium, as well as any desired natural pigments to add colour.

The resulting biomass paste is pushed through an extruder and 3D-printed, layer by layer, to form 10 separate modules, which are stacked into a column measuring 2.1 metres high and fused together using more mycelium.

Its many folds and crevices were generatively designed to create a structure that could support itself during the additive manufacturing process, as well as supporting the mycelium's growth process by creating sheltered "microclimate pockets" that trap moisture along the length of the column.

The column is more than two metres tall"For the mycelium to grow well, it needs a humid environment away from airflow, like in the undergrowth where it grows naturally," Garnousset explained.

"We were inspired by the shapes of cacti that can successfully grow in the desert by capturing moisture from the wind and creating shade in their folds."

For the first three to four weeks, until the mycelium has grown to encompass the entire column, it needs to be kept inside a contained humid environment similar to a greenhouse.

Mycelium is "part of the solution" to carbon-negative buildings

After that, it is dried at 80 degrees Celcius, effectively killing the organism to stop its growth and solidify the material, which Blast Studio estimates has a similar structural capacity to medium-density fibreboard (MDF).

"The column is very light and good in both compression and flexion thanks to the elasticity of the material," Garnousset said. "In small constructions such as houses and small buildings, concrete could be substituted by mycelium."

Blast Studio has also created a blue version of the columnIf a Tree Column is damaged or no longer needed, it can be recycled and reprinted to form a new architectural element.

But Blast Studio is also looking at creating a self-repairing version of the pillar by drying the mycelium just enough to stop propagation without killing the organism, which would allow it to re-grow over any cracks once exposed to water.

This is made by mixing the paper pulp and mycelium with natural indigo pigmentA Tree Column is currently on display as part of the Waste Age exhibition at London's Design Museum and will be used as the first building block for the Tree Pavilion, which the studio is hoping to construct by the end of the year to show that its technology could be applied to a larger architectural scale.

A number of other architects and designers, including Dirk Hebel and New York studio The Living, have also created experimental pavilions using mycelium instead of traditional emissions-intensive structural materials such as concrete and steel.

The column forms part of the Waste Age exhibition at the Design MuseumThis generally involves the mycelium being grown in a mould to form bricks. But Blast Studio's 3D-printing technology is able to create complex shapes without the need for formwork, which are optimised to improve the performance of the building element while reducing its weight and material use.

While these kinds of applications are still nascent, a number of companies are already working to create certified insulation and acoustic panels from mycelium, which can perform better than their plastic equivalents while sequestering carbon during their growth process.

The top photo is by Felix Speller.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

New! Dezeen In DepthSent on the last Friday of every month, Dezeen in Depth features original feature articles, interviews and opinion pieces that delve deeper into the major stories shaping architecture and design.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

3D Printing With Fungus - Artist Creates Chairs and Other Objects Out of Mushrooms - 3DPrint.com

As we have mentioned before, one of the few downsides to 3D printing is the plastic waste created by all the prints. We have seen many bioplastics come to market, as well as methods of recycling plastic bottles and old 3D prints, in order to turn them into reusable 3D printer filament. All this is great, but there is no doubt that plastics continue to pile up and damage the environment, as more and more of it is produced. Likely, similar to most of our problems, science and technology will prevail, but it may take some time.

Likely, similar to most of our problems, science and technology will prevail, but it may take some time.

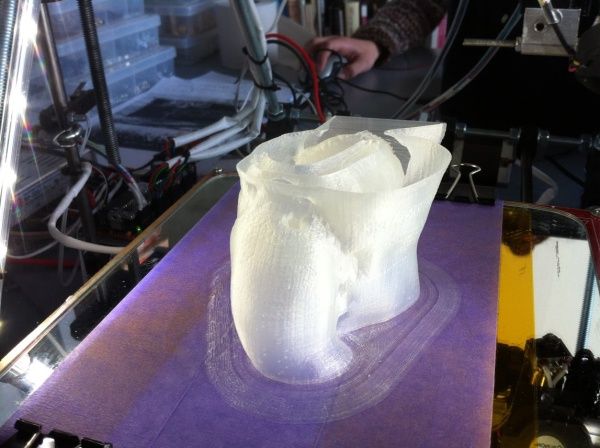

One artist from The Netherlands, Eric Klarenbeek, has gone a step further than just recycling plastics, or using bioplastic filament. He has come up with an innovative, and very artistic method of 3D printing with fungus… Yes Fungus!

3D printed mixture of straw and mycelium fungus

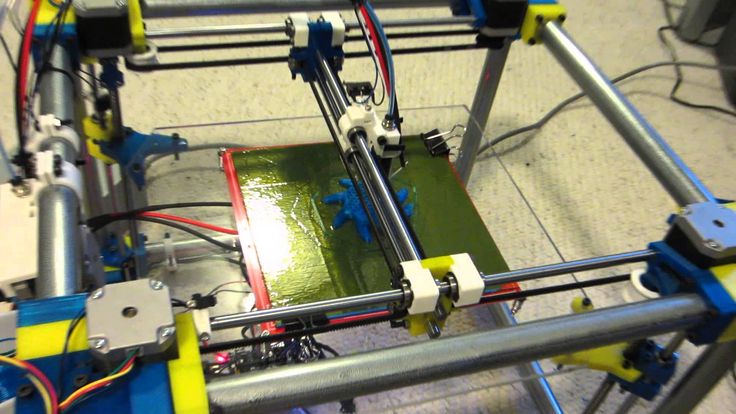

The process used by the 35-year-old artist is quite amazing. He takes ground up straw, and infuses it with Mycelium fungus. The fungus is known for taking a liking to straw, thus the reason for its use. He uses this material as sort of a filament within a large 3D printer. The printer works just like any other FDM printer, slowly extruding the straw and mycelium mixture, layer by layer, until a desired configuration is created. Unlike FDM printers, however, there is no need for heat. Instead of melting plastics, Klarenbeek relies on nature to do its work. Once an object is printed out using his mixture, he soaks it in water, and lets it sit for a couple of days. Slowly the mycelium fungus takes hold. As it grows, it replaces the water, fusing together the straw mixture. The end result is a solid structure which is extremely light in weight, kind of like that of cork.

Slowly the mycelium fungus takes hold. As it grows, it replaces the water, fusing together the straw mixture. The end result is a solid structure which is extremely light in weight, kind of like that of cork.

“We adapted the 3D-printer and invented a way to print straw injected with mycelium. By infusing this mushroom it acts as a kind of glue so that all these straw parts [come] together and as soon as you dry it you get a kind of cork material, which is all bound together,” says Klarenbeek.”

3D Printed Mycelium Chair

Klarenbeek then uses bioplastic to 3D print a very thin outer shell which mimics the shape of that of the straw mixture. He places the 3D printed mycelium infused straw into the plastic shell, and allows it to continue to grow. After a couple of days he has a very solid, structurally stable object. An example would be the chair you see in the picture above. Like you can see, as evidence that the mycelium is intertwined throughout the object,

Additional straw and mycelium prints

mushrooms tend to grow from the 3D prints.

“This chair is really a metaphor for what could be made with this technique of 3D printing a living organism and then have it grow further,” says Klarenbeek. “It could be a table, a whole interior or even a house. We could build a house with it.”

Although we may not be seeing houses made from straw and mushrooms anytime soon, the method used here is certainly one that is quite intriguing. Because the printed straw does not need to be heated while extruded, it saves significantly on energy costs. In addition, when the printed object is no longer needed, it can be composted, and broken down in someone’s garden. In fact it would make an exception fertilizer.

What do you think of Klarenbeek’s work. Could this method of 3D printing have a future? Will we be building homes out of mushrooms some day? Let us know in the 3D printed Mycelium Fungus forum thread on 3DPB.com. Check out the video below where Klarenbeek explains his work in further detail.

[Source: EricKlarenbeek. com

com

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d house print • 3d print fungus • 3d print mycelium • art • fungus printing • mycelim

Please enable JavaScript to view the comments powered by Disqus.

Mycelium dress and telescopic bag: a digital clothing collection was presented in St. Petersburg

A collection of digital clothing was presented in the Concept Group RASKROI creative space in St. Petersburg, which was developed by young designers using 3D visualization, prototyping and 3D printing. The works are presented in free access for everyone within the framework of the exhibition RASKROI FABLAB REVIEW.

The concept of the exhibition was based on the fashion industry's desire for sustainable production and a combination of digital and physical experience. 25 designers presented their works, who developed them for three months in the following areas:

1.

3D-printed jewelry and accessories SENSIBLE SEA

3D-printed jewelry and accessories SENSIBLE SEA When creating works, designers were inspired by Atlantis, the prerequisite for the death of which was the predominance of the material over the creative. All jewelry was 3D printed using pla plastic, which is made from cornmeal, a natural raw material.

The collection, in particular, presents the Qwatro telescopic bag, which combines modern 3D printing technology and traditional beading - the handles of the bag are made using the technique of volumetric tapestry weaving with cubic beads. Visitors will be able to see bracelets in the shape of sea creatures, complemented by magnets and LED lamps, as well as a women's silk organza top, which is 3D printed with a 3D pattern of shells and ammonites.

2. INCEPTION digital clothing virtual show

In developing the work in this direction, the designers relied on the process of continuous development of technologies and their vision of the clothing of the future. When developing digital clothing, 3D modeling and physical simulation of fabrics were used. As a result, the collection includes clothing-armor (plain in appearance, but at the same time multifunctional and protecting a person in conditions of possible climate deterioration), clothing using the Crasy Wool technique (creating fabric from waste from textile industries, when pressed pieces of fabric are sewn together , obtaining a canvas with a unique pattern), clothing made from mycelium (the vegetative organ of a fungus, which, after processing and drying, becomes similar in appearance to the skin and at the same time strong and flexible enough to be dyed and stitched).

When developing digital clothing, 3D modeling and physical simulation of fabrics were used. As a result, the collection includes clothing-armor (plain in appearance, but at the same time multifunctional and protecting a person in conditions of possible climate deterioration), clothing using the Crasy Wool technique (creating fabric from waste from textile industries, when pressed pieces of fabric are sewn together , obtaining a canvas with a unique pattern), clothing made from mycelium (the vegetative organ of a fungus, which, after processing and drying, becomes similar in appearance to the skin and at the same time strong and flexible enough to be dyed and stitched).

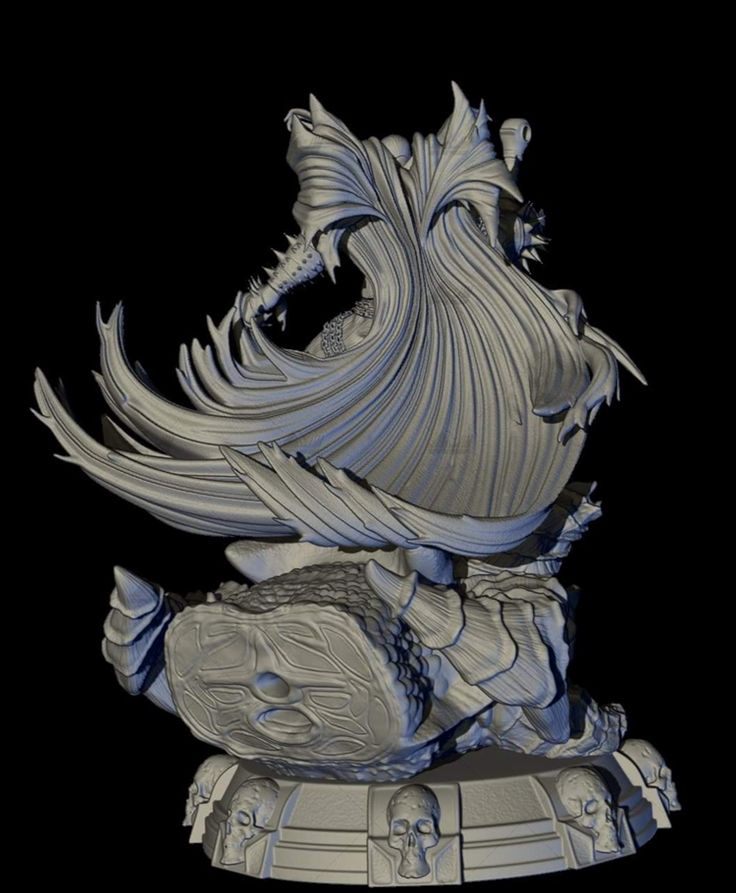

3. Digital-fashion installation OVERDRESSED

As part of this direction, designers explored 3D textures and materials in one image using 3D animation and generative graphics. The main role was played by only one dress, for which various textures and images were invented without changing the shape. Thus, the designers rethought the concept of universality and worked out complex textures that cannot be physically repeated in reality.

Thus, the designers rethought the concept of universality and worked out complex textures that cannot be physically repeated in reality.

“The trend for virtual looks has existed for a long time, but it was the pandemic that became the impetus for the development of the digital clothing industry. And today we are one of the first in Russian fashion retail who have the opportunity not only to experiment with digital clothing, but also, with the help of our creative platform RASKROI, to give all interested designers the opportunity to create a variety of works and even full-fledged collections. This direction seems promising to us, which can lead the industry to more conscious and environmentally friendly consumption,” commented Anastasia Nemayeva, General Director of Concept Group.

The exhibition is available at: st. Kazanskaya, 25. Anyone can visit it until April 2 inclusive. Every Tuesday at 19:00 and Thursday at 14:00 there will be mediations on the exhibition.

About the Concept Group:

The Concept Group portfolio includes Acoola (children's clothing and accessories), Concept Club (women's clothing and accessories), and Infinity Lingerie (lingerie). Concept Group's business is based on a multi-brand and multi-channel model that allows diversifying the revenue structure. A significant part of the proceeds is provided by the federal retail and franchise network with 234 stores. All products are developed in our own design studio and manufactured to the highest quality standards.

Concept Group's business is based on a multi-brand and multi-channel model that allows diversifying the revenue structure. A significant part of the proceeds is provided by the federal retail and franchise network with 234 stores. All products are developed in our own design studio and manufactured to the highest quality standards.

Information about the RASKROI space:

The RASKROI experimental space in St. Petersburg is located on Kazanskaya, 25. It was opened in 2021 for everyone who works in fashion and aspires to get into the industry. In the RASKROI space, there is an open coworking with a cafe, a design bureau and a Fablab technology workshop with a 3D scanner and 3D printers, lectures, master classes, educational and business events about fashion and technology are regularly held. The launch of RASKROI is Concept Group's move towards a more sustainable business model and a way to support the development of an innovative creative environment in St. Petersburg.

Concept Group

Tags: Additive technology 3d printingRendering

Free 3D file Mushroom growing chamber v1・3D printer model for download・Cults

Hexa Jug Watering Pot

Free

Pot for growing plants "Megalopolis"

Free

Watering pot for bulbs

Free

Hexa mug

Free

JW Planter

Free

Grail Cup

Free

Fun Funnel

Free

Chairman

Free

Best 3D Printer Files in the Gadget Category

Nuclear Bomb Lamp / Lampara de Bomba Nuclear

3. 73 €

73 €

DJI Ryze Tello Bumper Augmentation

Free

Air motor, printed fully assembled, ready to use

3.09 €

Pen and ink bottle (work pen)

1.90 €

M Second - Robot Car

4.87 €

Coke Lid! Jar lid

Free

Pen Holder: The Lord of the Rings - The Fellowship of the Ring

2.90 €

Storage box with sliding door

0.50 €

Bestsellers in the Gadget category

Survival pistol with arrows

6.29 €

GIFT BOX WITH A FLEXIBLE DUCK HEART FOR VALENTINE'S DAY

2,80 €

FoldaBox - print in place

1. 37 €

37 €

Gear Box Seal on site

€3.50 -25% 2.62 €

Renewed bone finger

6.32 €

Long range cable

0.50 €

FLEXI GIRAFFE

0.93 €

Case set for Samsung Galaxy s23 ultra (3 in 1)

2.31 €

JEEP WRANGLER PEN HOLDER - 3-IN-1

1,85 €

Car air vent phone holder PRINT-IN-PLACE

2,50 €

Switchable Business Card Application

€3.50

Automatic thread loader.

Never run out of filament again while printing!

Never run out of filament again while printing! 9.36 €

Dock Flame Switch

2.99 €

Cubone joystick holder

3,50 €

Owl - wall key holder

1.90 €

Bambu AMS Color 2 tier rack (for 2 AMS units 1 top 1 bottom)

2.26 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining activities and creating future developments is very simple. Here are 4 solutions available to everyone:

-

AD: Disable AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

Learn more