Eos m 100 3d printer price

Small Metal 3D Printer specialized for Medical Products

10_filigreeSmall laser spot for complex and delicate parts

12_laser200-watt fiber laser for consistent part quality

60_resp_peopleEspecially suitable for medical applications

The power stability of the 200-watt fiber laser ensures optimal and consistent processing. The small laser spot with excellent detail resolution is ideal for manufacturing highly complex, delicate parts.

With its small build space on a round construction platform of 100 mm in diameter, the system is primarily geared towards cost-efficient production in small quantities.

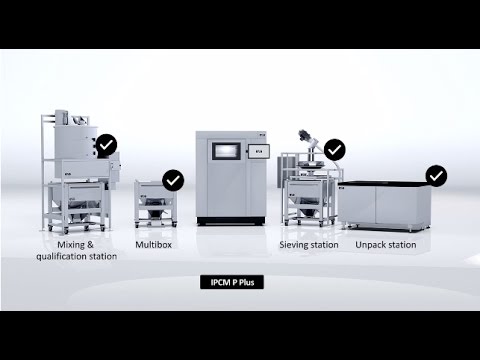

Setup and cleanup are possible in just a few minutes thanks to the modular inner structure and the powder bed container. The material is easy to switch and maintenance is quick to perform.

| Construction Volume | Ø 100 x 95 mm (Ø 3.9 x 3.7 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 200 W | |

| Precision Optics | F-theta-lens; high-speed scanner | |

| Scan Speed | up to 7.0 m/s (23 ft./sec) | |

| Focus Diameter | 40 µm (0,0016 in) | |

| Power Supply | 200 - 240 V | |

| Power Consumption | max. 1.7 kW / average 0.60 kW 1.7 kW / average 0.60 kW | |

| compressed air supply | max. 4,000 hPa, 50 l/min | |

| Machine Dimensions (W x D x H) | 800 x 950 x 2,250 mm (31 x 37 x 89 in) | |

| Recommended Installation Space | min. 1.00 x 3.00 x 2.5 m (3 x 10 x 8 ft) | |

| Weight | 580 kg | |

| Software | EOSPRINT, EOS RP Tools, Cambridge or Materialise Magics Metal Package and modules |

The EOS M 100 system is part of the portfolio of additive metal systems that we use ourselves for development. The system is characterized by ease-of-use when handling powder and exchanging powder components. It has great potential for reducing set-up times, increasing productivity and improving ergonomics and safety for machine operators.

The system is characterized by ease-of-use when handling powder and exchanging powder components. It has great potential for reducing set-up times, increasing productivity and improving ergonomics and safety for machine operators.

Michael Keane | Head of Technical Process Development | Boston Scientific

EOS M 100 Building Platform with Dental Job

EOS Application Dental Crowns

EOS Dental Crowns and Bridges

EOS Dental Building Process

01

02

03

04

53_individual_production Metal Materials for the EOS M 100

EOS CobaltChrome

Cobalt-chrome is often used in aerospace and medical applications. Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

EOS StainlessSteel 316L

Parts show a high level of corrosion resistance, toughness and ductility as well as a high resistance to acids.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

Tungsten W1

The refractive materials family of powders encompasses EOS Tungsten W1, a pure tungsten alloy, which is designed and tested for use on EOS’ metal systems.

13_automation Software

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

3D Printing in Medicine

Example Applications and References

find out more

EOS M100 3D Printer In-Depth Review

ADVERTISEMENT

6.5Expert Score

EOS M100

EOS M100 3D Printer is a highly productive metal 3D printer for the additive manufacturing of delicate metal parts & especially suitable for medical technology.

Affordability

3

Quality

6

Speed

7

Capability

7

Practicality

8

User Expectations

8

PROS

- There is a separate tab of success stories which tells about which printer was used in which industry to generate what!

- If you plan to be an EOS customer, there is a lot to gaze all over the website and learn from.

CONS

- The website is too long. And, so if you are not used to navigating in a proper fashion, you might get lost!

Specialized for rapid production of delicate 3D printed metal medical parts, EOS M 100 has a 200-watt fiber laser for consistent part quality. Small ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

Landing onto EOS’s website is like seeing a piece of a ten-second video of a science fiction movie.

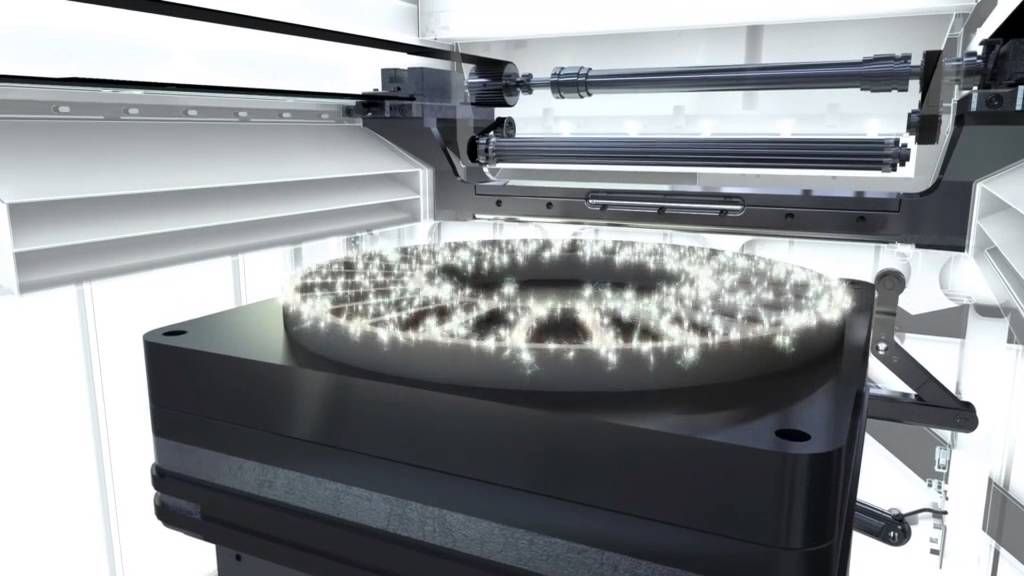

Yes! There is a video going in the background of “Shaping the Future of manufacturing 3D Printing Solutions for your production,” which starts with a dark background which, you later realize, is sand.

Suddenly in a specific part of the sand looks as if bullets are getting fired.

Like, volcano, there is a sand explosion, and all you get is not a dead body or something else, but a generation of part!

Seven tabs placed on the top right corner of the website are not all!

Six more tabs are placed beneath these seven tabs somewhere on the center screen.

The website is available not only in the English language but also in languages whose abbreviations are DE and CN.

For reaching the webpage of EOS M100 you have to navigate through the Products and Services tab’s Additive Manufacturing Metals, to EOS Metal Systems, then you will be able to notice EOS M100.

So, overall while navigating through all this should tell you two things about the manufacturer’s website:

- It is big.

- EOS M100 is not the only printer that the manufacturer, manufactures.

Under the Additive Manufacturing Metals option, you have EOS Metal Systems as well as EOS Metal Materials.

Which means the manufacturer also supplies you with the 3D printing materials.

Apart from Additive Manufacturing Metals, there is “Additive Manufacturing Plastics.”

So, overall you have a list of machines that require plastics as a 3D material and a list of machines that require metals as 3D material.

Apart from this, there are “Software Solutions,” “Service and Consulting,” and “Getting Your Parts Manufactured.”

Remember 3D printing services provider websites? EOS does that too. And now speaking about the printer EOS M100.

ADVERTISEMENT

Features

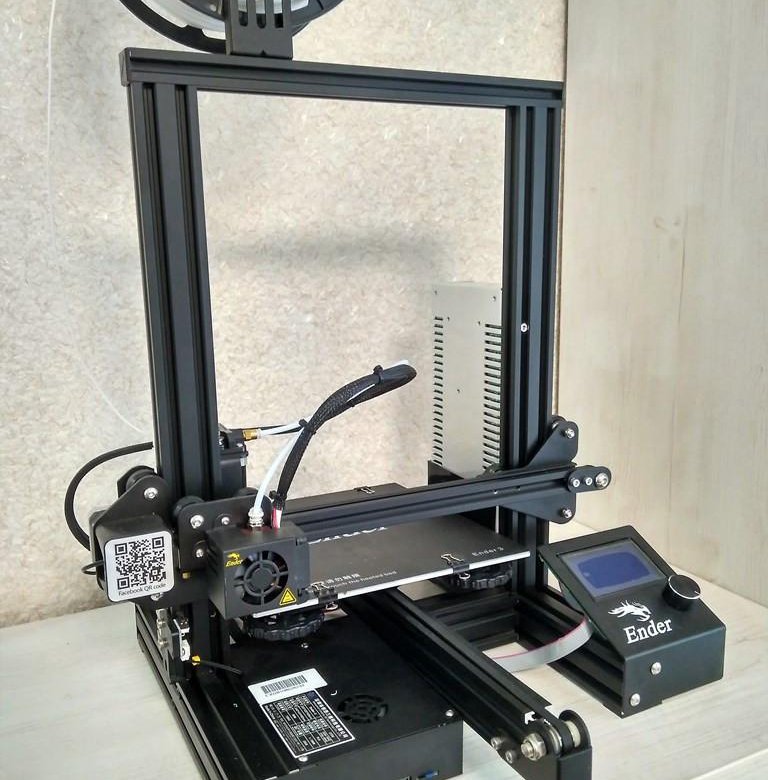

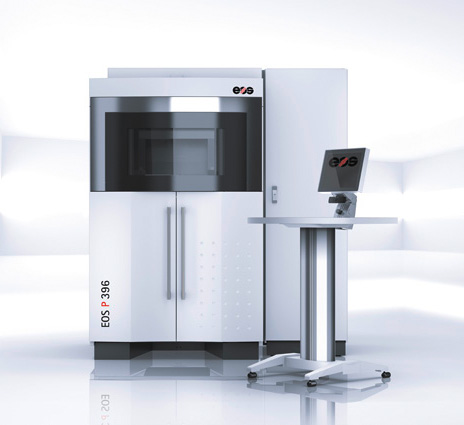

There is a decent picture of the machine, which acquires the complete center screen of the device from which you are operating on the website.

The machine at first sight, for anyone new to 3D printing, is going to look like a refrigerator.

Text just beside the machine’s photograph readout EOS M100 Rapid Production Delicate 3D Printed Metal Parts.

By now, at least one thing should be clear about this machine i.e. it 3D prints metals.

It makes us wonder why, on their websites, the website makers, keep a down arrow on webpages!

Are they really under some kind of a fear that someone would be so much in haste that he or she would, navigate to some other webpage without scrolling down and thinking that the webpage only has that much which appears on their screen at that moment of time and nothing more?

Anyways! When you scroll down, you get to encounter three features of this machine:

- Small laser spot for complex and delicate parts.

- 200- watt fiber laser for consistent part quality.

- Especially suitable for medical applications.

And because you have scrolled down completely enough, there is a lady’s face that appears and she is trying to do something with the machine.

Scrolling down even further, you notice there is a video of her showing how to keep things inside the machine and close the door, only after pressing the lever.

Moving further down you have three specifics about this machine i.e. Laser Power, Build Space and Accessories.

And then there is a lot of Technical Data which we will mention in the specifications section next.

There is a quote from Boston Scientific about EOS M 100 by some Michael Keane who is Head of Technical Process Development in which ease of use, reducing setup times, increasing productivity and improved ergonomics as well as ensuring safety for machine operators are some of the features that are mentioned about this printer.

ADVERTISEMENT

Laser Power

3D Printers that use the laser in them can be using either the Stereolithography technique of 3D printing, or Selective Laser Sintering, or Selective Laser Melting.

So, this printer is also using one amongst them for 3D printing of metal, but which one?

Is something you need to find out yourself because it is not mentioned on their website or if it is, we might have not stumbled on that topic.

In any of these 3D printing technologies, the laser is used to cure or to solidify the layers which are on the print bed.

So, the quality of parts and functional prototypes that will be printed does depend a lot on the quality of laser that is in place.

EOS M 100 boasts of using the power stability of a 200-watt fiber laser that according to the company, ensures optimal and consistent processing.

Highly complex parts with delicacy can be 3D printed using this laser power.

Build Space

Cost-efficient production in small quantities is something that the company claims it printer does.

Although having a small build space, the printer can build on around a construction platform of 100 mm in diameter.

This is a nice hint that the company gives in terms of the build space to all those who are willing to subscribe to it are the only ones who should think of buying the printer.

ADVERTISEMENT

Accessories

The EOS M 100 is equipped with a modular structure because if which post-processing and cleaning and setting up the printer does not take as much time as it does in other printers.

So, the overall print time for producing a product decreases.

There is also a powder bed container present inside the printer, because of which, it is very easy to switch and maintain and quickly perform tasks on the printer.

Specifications

For all of you who are interested a lot in the technical data, there is also an option of downloading the fact sheet pdf about the printer.

For all those who want to stay limited with the technicality that the company believes you should be exposed to, here is the thing.

The construction volume of this printer is 100 mm * 95 mm.

The laser type used by EOS M 100 for curing the 3D printed part is Yb-fiber laser.

Now you know that the lighting that you saw in the video about which it is mentioned at the start of this article, was a laser and there was no bullet-firing happening anywhere.

Instead, the Laser was curing or solidifying the part!

The precision optics used by this printer is the F-theta lens; a high-speed scanner that scans at a speed of up to seven meters per second.

The focus diameter of this laser is 40 micrometers. The power supply needed for EOS M 100 is 200 to 240 Volts.

The maximum power consumption of this printer is 1.7 kilowatts whereas the average is 0.6 kilowatts.

The compressed air supply system has a maximum pressure of 4000hPa, 50 I/min.

The machine dimension is 800 mm * 950 mm * 2250 mm.

The minimum recommended installation space by the company is one meter * three meters * 2.5 meters. It weighs 580 kilograms.

ADVERTISEMENT

Price

You will have to “request a quote,” to get the price of this printer.

Writing “EOS M 100 price” on google would give you the price of Canon EOS M 100 so, beware and clear in your mind, whether it is the camera that you wish to buy or the 3D printer.

There is a link that leads to the All3DP website wherein information about How much does a metal 3D printer cost in 2020? is mentioned.

This did pop up in our Google search when you type down “EOS M100 3D printer price,” opening which we were able to find this 3D printer listed for $350,000.

However, it is better to ask for a quote by filling the form on the manufacturer’s website if you are genuinely interested in purchasing the printer.

First Impressions

Like we stated in the earlier part of this article, the 3D printer looks like a refrigerator to people who haven’t had much experience with looking at industrial 3D printers.

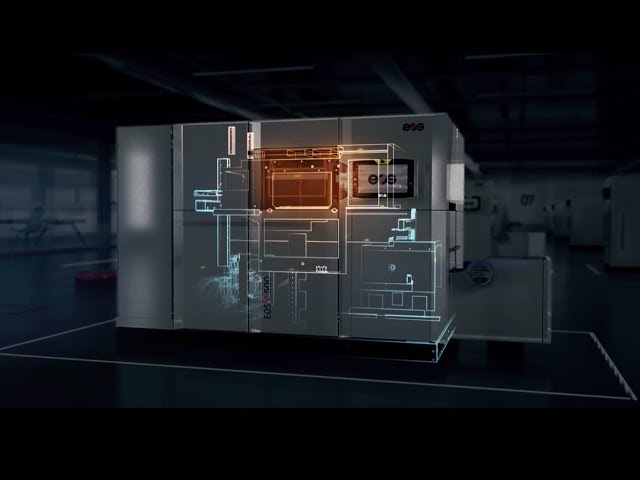

There is a video of EOS 100 that takes us through various ends of the machine and name its features.

There is a filled powder supply bin that goes into the head part of the machine, as shown in the video.

The duty of which, looks from the name of this part, is to supply with powder material whenever needed.

The head part of the machine is what we term, would open up when you open the part that has a touch screen interface on the outer part of the machine.

On the left of the print, you have a mechanism that is going to recoat the metal.

After one layer is printed, it will lower, and then the second layer would be printed.

There are four button type structures that are just beneath the touch screen interface.

In the video, you are also shown how a vacuum is then used after a part is completely 3D printed.

It sucks up the remaining unprocessed part, successfully letting you fastly start another 3D printing process.

The video does not show any information about what is actually present in the tail part of this machine, so we can assume, it might have to deal with the lasers that are used for curing.

ADVERTISEMENT

Setup

Since it is an industrial 3D printer, it should come like most of the industrial 3D printers i.e. completely assembled.

All you have to do is read the manual before starting to 3D print and contact the company if you need any assistance with the 3D printer.

Printing Type/Cost

As discussed in the earlier part of the article, one of three 3D printing techniques is utilized by this 3D printer for making parts and functional prototypes.

It uses a laser for the curing of layers of parts or functional prototypes.

And one thing we can surely comment on is, the printing cost of this printer is going to be higher than other FDM 3D printers of the same grade because all of these 3D printing techniques claim to generate parts and functional prototypes with more accuracy and hence more infill, lesser layer resolution than FDM.

Print Quality

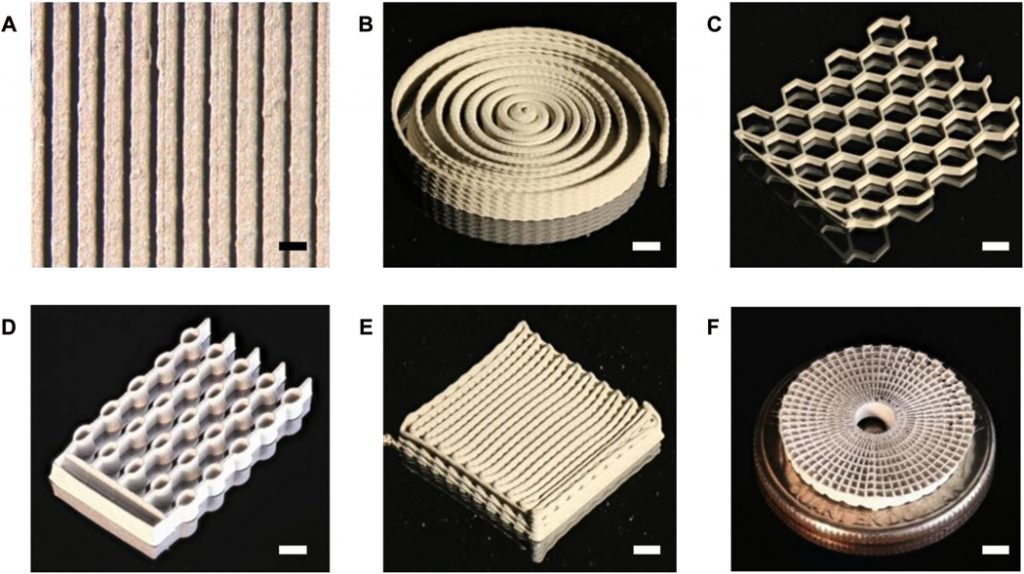

Credit: gpiprototype.comThe webpage does have some five photographs, starting with a dental job that has been printed on EOS M100, followed by Dental Crown, followed by Dental Crown and Bridges, overall the company has mentioned a little bias that their printer carries for building parts and functional prototypes used in the medical field.

So, the parts and functional prototypes are printed with dimensional accuracy required by parts and functional prototypes to be in that field.

ADVERTISEMENT

Software

EOS 3D Print2 is the name of the software that EOS recommends to be used with this 3D printer.

Customer Service

A tab called Customer Center is present on the website, which when you click on you get to know that there is something called Digital Support called EOS Customer Portal is something offered by the company as a solution to all its customer’s problems.

Parameters Influencing Buying Decision

A quick recap of what we have been talking about in this article.

3D Printer Cost: Needed to be asked to the company.

3D Print Quality: Commendable.

3D Print Speed: Not so good, not so bad.

3D Printer Capability: There are three metals listed on the company’s website from which the 3D printer is able to 3D print parts and functional prototypes.

3D Printer Practicality: Can be used for the production of medical industry related parts with ease.

3D Printer User Expectations: It is an industrial-grade printer, hence meant for that class of individuals.

The Verdict

EOS’s website has too much taken from in terms of learning about 3D printing, about their printers, printing material, and even specify if you wish to print from their printers, without buying them!

So, even if you do not wish to plan to buy the machine, it would have something interesting for you to check out if you are just a 3D printing lover.

Canon EOS M100 Specifications - Canon UK

Canon EOS M100 Specifications - Canon UKA compact, easy-to-handle, connected mirrorless camera with superb image quality for those who can't get enough of smartphone photos.

See new model

- Overview

- Specifications

- Reviews

- Support

- You might also be interested in...

Tell your story wherever you are.

Watch video

High quality without the hassle.

Amazing results.

Amazing results. Tell your story with beautiful photos and cinema-quality video Stylish and compact, the EOS M100 mirrorless camera makes it easy to capture and share every moment with simple touchscreen controls, Bluetooth and Wi-Fi connectivity.

Watch the full list of technical characteristics

180 °

Turning screen

24.2

megapixels

Bluetooth®

Connection

Quality without efforts

Impressed by your photos: automatic surveillance modes, usual sensory sensory sensory sensory sensory sensor and a 24.2 MP CMOS sensor, ISO sensitivity range up to 25600, help you effortlessly achieve the perfect quality of photos and Full HD videos.

Compact for spontaneous shooting

Stylish, compact and handy, the EOS M100 has all the features of a DSLR, but much smaller and lighter. Create impressive images - The powerful DIGIC 7 processor guarantees stunning shots, with fast-start continuous shooting up to 6.![]() 1fps so you never miss a fast-paced scene.

1fps so you never miss a fast-paced scene.

Easy connection

Easily connect to mobile devices using Bluetooth®*, Wi-Fi and the Canon Camera Connect app. Enjoy simple and convenient operation thanks to the tilting touch screen, which is convenient for taking selfies.

Unique design

Give your camera a unique look with a wide range of accessories. Choose from three noble classic body colors, then give your camera a unique look by adding an Eh41-FJ case in any shade.

Canon aims to achieve net zero CO2 emissions from its operations by 2050

We will achieve this by reducing product lifecycle CO2 emissions by an average of 3% per year. By following this plan, emissions will be reduced by 50% by 2030 compared to 2008. We understand that this initiative must be in line with the rate of decline stipulated in the Paris Agreement.

We will continue to look at the targets from a long-term perspective to evaluate our contribution to a carbon-neutral society.:quality(80)/images.vogel.de/vogelonline/bdb/410900/410995/original.jpg)

Learn more

Canon Photo Companion App

The perfect partner for any photo story maker, the Photo Companion app gives you access to curated content and expert advice to help you bring stories to life.

Learn more

Recommended lenses

* For using EF 50mm f/1.8 STM, EF 70-300mm f/4-5.6 IS II USM, EF-S 10-18mm f/4.5-5.6 IS STM lenses with EOS camera M100 requires the fixing adapter EF-EOS M.

Compatible accessories

Technical characteristics

24.2 "Image sensor CMOS

APS-C CMOS 24.2 MP

Digic 7

Powerful DIGIC

DIGIC

002 Dual Pixel CMOS AF

High speed photography, smooth movie recording

6.1 fps

Continuous shooting at 6.1 fps.

Full HD 60P

Smooth and realistic video

7.5 cm LCD touch screen

High-resolution swivel LCD touch screen

Wi-Fi/NFC

Wirelessly connect, share and copy files 9003 9002 Bluetooth

Permanent connection

See full specification sheet

Capture a story

Tell your story with a wide range of interchangeable lenses. And if your muse knows no limits, there's a full range of Canon EF and EF-S lenses that can be mounted with the mount adapter.

And if your muse knows no limits, there's a full range of Canon EF and EF-S lenses that can be mounted with the mount adapter.

VIEW

Canon EOS M100

Ratings & Reviews

You might also be interested in...

*Equipped with Bluetooth® low energy technology. The Bluetooth® word mark and logos are registered trademarks of the Bluetooth® SIG, Inc. and are used by Canon Inc. on the basis of a license. All other trademarks and trade names are those of their respective owners.

orStainless steels for 3D printing

In our work we use both domestic stainless alloys and foreign ones offered by equipment manufacturers.

Ph2 Stainless Steel for 3D Printing

Ph2 is a stainless steel alloy used on EOS equipment and has good corrosion resistance and excellent mechanical properties. This type of steel is widely used in a variety of medical, industrial products that require high hardness, strength and corrosion resistance. Parts made from this material can be machined, welded, polished or coated.

Parts made from this material can be machined, welded, polished or coated.

3d printers working with this alloy:

- EOS M 290, part dimensions 250*250*325 mm

- EOS M 400, part dimensions 400*400*400 mm

|

| Synthesis | After H900 heat treatment | |

| Tensile strength (s B ), MPa | XY | 1150±50 | 1450±100 (min 1310) |

| Z | 1050±50 | 1450±100 (min 1310) | |

| Yield strength (s 0.2 ), MPa | XY | 1050±50 | 1300±100 (min 1170) |

| Z | 1000±50 | 1300±100 (min 1170) | |

| Elongation at break δ, % | XY | 16±4 | 12±2 |

| Z | 17±4 | 12±2 | |

| Hardness HRC | 30-35 | min 40 | |

Heat treatment H900 - carried out at 482°C, holding time 1-4 hours.

316L stainless steel for 3D printing

316L - This material is used on SLM Solutions equipment. Thanks to molybdenum, steel of this grade is particularly resistant to corrosion, high temperatures and aggressive environments. It is used in the production of equipment for the chemical industry, as well as for the production of products used in aggressive environments, such as, for example, sea water of cold seas. It is non-magnetic and well weldable.

3d printers working with this alloy:

- SLM 280HL, part dimensions 280*280*350 mm

| Mechanical properties | |

| Tensile strength (s B ), MPa | 625±30 |

| Yield strength (s 0.2 ), MPa | 525±30 |

| Impact work, J | 75±4 |

| Hardness HV | 237±4 |

Stainless steel 07X18H12M2 for 3D printing

07X18H12M2 Thanks to molybdenum, steel of this grade is particularly resistant to corrosion, high temperatures and aggressive environments. It is used in the production of equipment for the chemical industry, as well as for the production of products used in aggressive environments, such as, for example, sea water of cold seas. It is non-magnetic and well weldable.

It is used in the production of equipment for the chemical industry, as well as for the production of products used in aggressive environments, such as, for example, sea water of cold seas. It is non-magnetic and well weldable.

3d printers working with this alloy:

- SLM 280HL, dimensions of parts 280*280*350 mm

| Mechanical properties | |

| Tensile strength (s B ), MPa | 660±20 |

| Yield strength (s 0.2 ), MPa | 420±5 |

| Elongation at break δ, % | 33±4 |

| Relative contraction, % | 39±3 |

Stainless steel 12X18H10T for 3D printing

12X18H10T - domestic stainless steel alloy.

build size

build size