Cube 3 3d printer release date

Cube 3D Printer Review 2022

3.5

See Price

Since the popularization of 3D printers, and give the inherent difficulty of 3D printing, there’s been demand for affordable, easy to use models that work out of the box.

3D Systems and the widely popularized Cube 3D printer strive to plug that gap. Does it live up the hype? Let’s investigate as we pull apart the secret inner workings of the most stylish printer on the market.

| Printing Area | 152x152x152mm |

| Print Tech | Plastic Jet Printing |

| Supported Filament | ABS and PLA |

| Extruders | 2 |

| Layer Thickness | 70 microns and 200 microns |

Table of ContentsShow

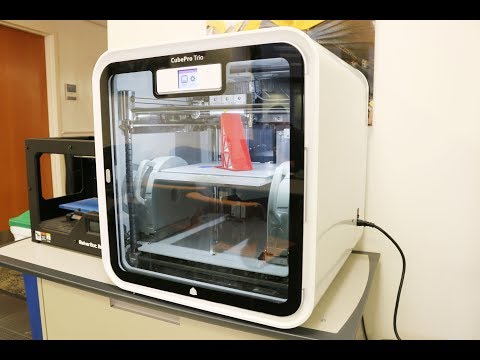

Design

3D Systems is onto its third generation of the Cube with all the enhancements this encompasses. An all-in-one cube casing houses the printer, hence the name, and is advertised primarily as a user-friendly personal desktop model. With simplicity in mind, it aims to introduce first-timers to the world of 3D printing without the oft-complicated installation of entry-level DIY models.

Straight out of the box, the Cube is a piece of engineering bliss. Aesthetically pleasing, compact, classy, and dare we say, beautiful, it resembles a product distributed by Apple, where functionality and ease of use are as much a consideration as design.

The sleek white exterior panels are miles away from the functional, bare-bones design of plenty rival models. So much so that the Cube is very much at home sitting alongside other home office devices rather than confined to a workshop. The self-contained shell means keeping track of diverse components isn’t a factor.

The print area is a modest 152x152x152mm, providing enough working space for most small scale projects, especially for beginners trying their hand at 3D printing for the first time. With both 0.2mm and 0.07mm (200 and 70 microns) print resolution layers, the Cube offers a degree of versatility, but not enough to cater for a large variety of print projects.

The print head ensures the X-axis, while the PrintPad (read build plate) manages the Y and Z axis. The PrintPad is removable for easy cleaning in hot soapy water. Every print job requires the application of Cube Glue, a weak adhesive produced by 3D Systems that assists the printed filament to solidly in place on the build plate. It takes some practice to apply the appropriate amount, and you need to wait for it to dry enough or suffer the consequences as we did.

The Cube sports dual extruders for simultaneous double color or material prints housed in out of sight purpose-built plastic casings that sit inside the vertical outer side panels. ABS and PLA are the only supported materials, and the Cube only works with 3D Systems proprietary filament Smart Cartridges that come in a selection of twenty-three colors.

These are significantly more expensive than generic filament bought from a hobbyist retailer, which was a big con for us when assessing the Cube 3D printer. These materials are of a higher quality, ostensibly, to justify the higher cost. To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

Each cartridge includes its own integrated, snap-in nozzle, which it must be said, is incredibly simple to install and, in theory, foregoes the need to battle with removing debris and build up from the extruders every time. Two cartridges come as standard with each new device.

Connectivity through a USB port mounted on the bottom of the side casing (the package includes a USB flash drive) and a WiFi connection allowing the user to trigger prints from their computer or via a flash drive, gives options.

3D Systems have even designed a dedicated Cubify mobile app for both Android and iOS (plus MacOS and Windows through the Cubify software) packed with printing ideas, blueprints, and guides. The software converts into the required file type and forwards the instructions to the printer. It cannot be used to design prints though.

It cannot be used to design prints though.

The user interface, we love. Inviting and perfectly intuitive, it’s hard to go wrong using the in-built 2.5” color touch screen LCD. Beginners should find getting around the settings and options a breeze. Indicators such as how much material is left are welcome additions for users who might not have yet developed the skills to gauge how much filament a project requires.

Printing

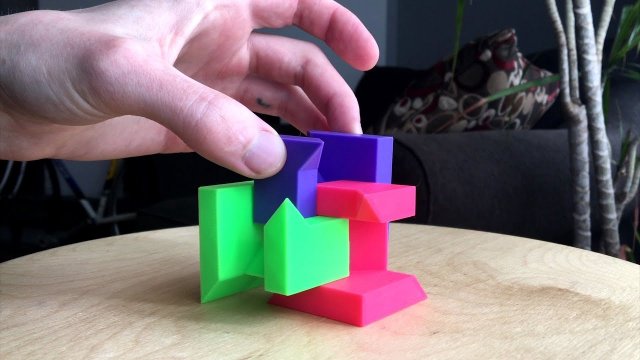

For a 3D printer touted as an out of the box solution, the printing process was hit or miss. The first few prints went well, especially for smaller prints. The results were generally error-free and full of detail with smooth contours and layers with few flaws. Ghosting was all but absent.

However, the Cube starts to struggle with larger projects that more often than not end in a bundle of filament only good for the landfill. The waste is especially hard to stomach given the exorbitant cost of the cartridges. The Cube Glue did little to fix the issue but works well for smaller prints.

Overall, the Cube is ideally suited to small jobs and is relatively economical with the material when it works correctly. From what we can gather, the lack of a heated plate, and the fact the software didn’t factor in the need for supports worked to the detriment of larger prints that require stability and uniform heat distribution as vertical layers build up.

The Cube is loud, to the point that it can become an annoyance by reverberating into adjacent rooms. For such a little machine, the noise is disproportionate possibly due to clanks bouncing off the casing.

Where our opinion of the Cube shifted drastically was when we encountered systematic jamming in the jet on the print head. The problem appeared to happen after only a handful of jobs using a brand new cartridge. Either the filament reacts badly to being exposed and goes brittle, or warehouse storage is conducive to the chemical properties of the plastic to harden more than necessary while sitting in the cartridge. It was hard to tell.

It was hard to tell.

Regardless, we have here a serious design flaw; feeding the filament through a tube doesn’t work well. Once a jam occurs, the nozzle does nothing but churn the plastic into a clumpy mess. If it isn’t a jam, the filament breaks inside the cartridge. There’s not much that can be done other than load in a replacement.

Speed wise, the Cube isn’t remarkable and gets the job done within acceptable limits.

Small prints can take anywhere from four to ten hours depending on the size, while bigger jobs were a bust most of the time, so we were never able to finish them to know how long the process takes.

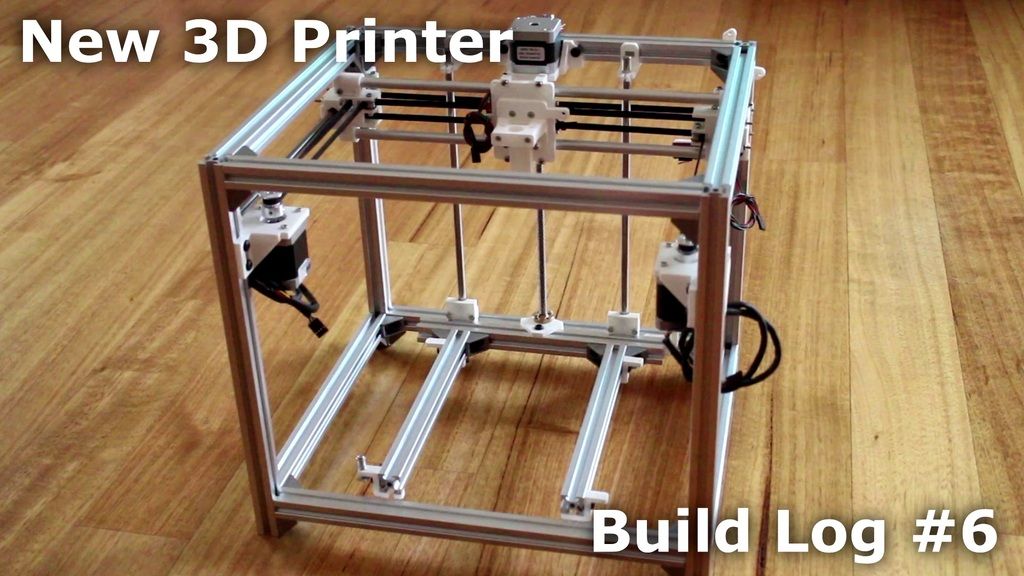

Assembly

The Cube comes pre-assembled and only requires the user to install the cartridges, a straightforward procedure. The Cube is packaged well and comes with a quick start manual, USB key, cabling, glue, spatula, plyers, power supply, and the printer itself.

The Cube self-calibrates by make sure the build plate is perfectly level and at the right distance from the print head via a set of magnets under the plate, although the device asks the user to tweak the plastic circular knobs below the plate as required. The instructions are straightforward and won’t daunt even the most unversed user.

The instructions are straightforward and won’t daunt even the most unversed user.

That aside, the Cube allows you to be up and printing within 45 minutes after unboxing the device, unheard of for printers in this price range where hours of assembly are the name of the game.

Support

3D Systems has discontinued the Cube, and the model is no longer in production, arguably due to lackluster reviews caused by the filament jamming issue.

As a consequence, the Cube is now available at a fraction of the cost of its initial retail price, around the $1000 mark. You can pick one up for around $200-$300 on Amazon, if not less. 3D Systems continues to sell cartridges for the time being, although third-party manufacturers have popped up selling them at a fraction of the cost.

Support wise, 3D Systems offers a 90-day warranty for parts and labor, but no refunds whatsoever due to discontinuing the product. Specific resellers may offer different refund policies.

3D Systems has a robust after-sales support service with a dedicated phone team that can help with the jamming issue by walking through a variety of detailed fixes. They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

Verdict

The Cube isn’t a bad printer overall and produces some quality results for smaller projects. The design is the model’s strongest asset, and it’s hard to find fault with the look, feel, and ease of use (bar the jamming issue).

At a much-reduced price, the Cube is an ideal no-nonsense first time 3D printer for those who want to experience the joys of printing without the hassle and tinkering of similarly priced DIY equivalents. The dual extruder setup is also a bargain.

The cartridges are a downside, but if you buy them from a third-party, the costs are more palatable. There’s also a DIY fix for the jamming problem, which isn’t particularly difficult to perform and is an excellent way to introduce a beginner to the modification aspect of the hobby.

The Cube isn’t ideal, but its hard to argue with for the bargain price.

3D Systems Cube 3 review: An excellent compact printer for making small 3D objects

The 3D Systems Cube 3 is one of the most compact dual-extruder 3D printers I've seen. The machine is well-designed and capable of calibrating on its own, which means it's ready to work right out of the box. It's also very easy to use and can print objects of high detail.

It's far from perfect, however. At times during my testing period, large print jobs failed half-way through the print cycle, and the printer takes a long time between jobs to cool down. The machine also uses 3D Systems' proprietary -- and expensive -- filament cartridges.

If you're on the market for a compact 3D printer to make small objects, you'll enjoy what the Cube 3 does. And at the current price tag of $999 (which converts to around £655 and AU$1,285; actual prices in those countries aren't available at this time), it's also one of the most affordable dual-extruder machine on the market. Keep in mind, however, that the total cost of ownership will climb steadily as you replenish printing supplies.

Keep in mind, however, that the total cost of ownership will climb steadily as you replenish printing supplies.

If you don't mind something larger in physical size, I'd also recommend the single-extruder XYZPrinting Da Vinci 1.0 AiO, which is cheaper but also supports 3D scanning.

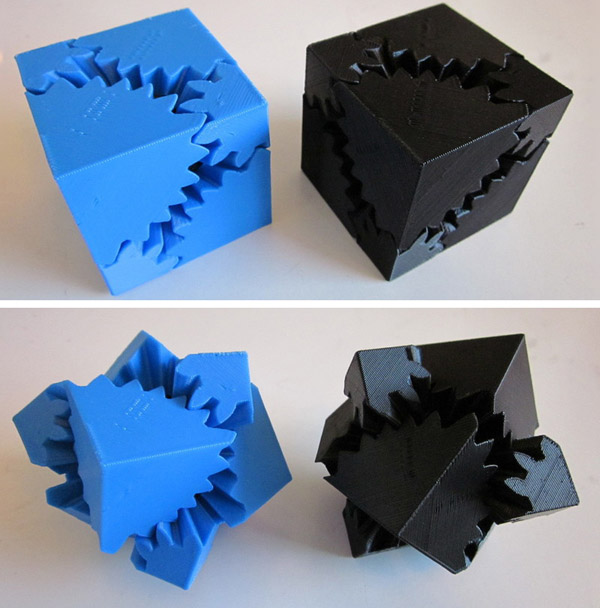

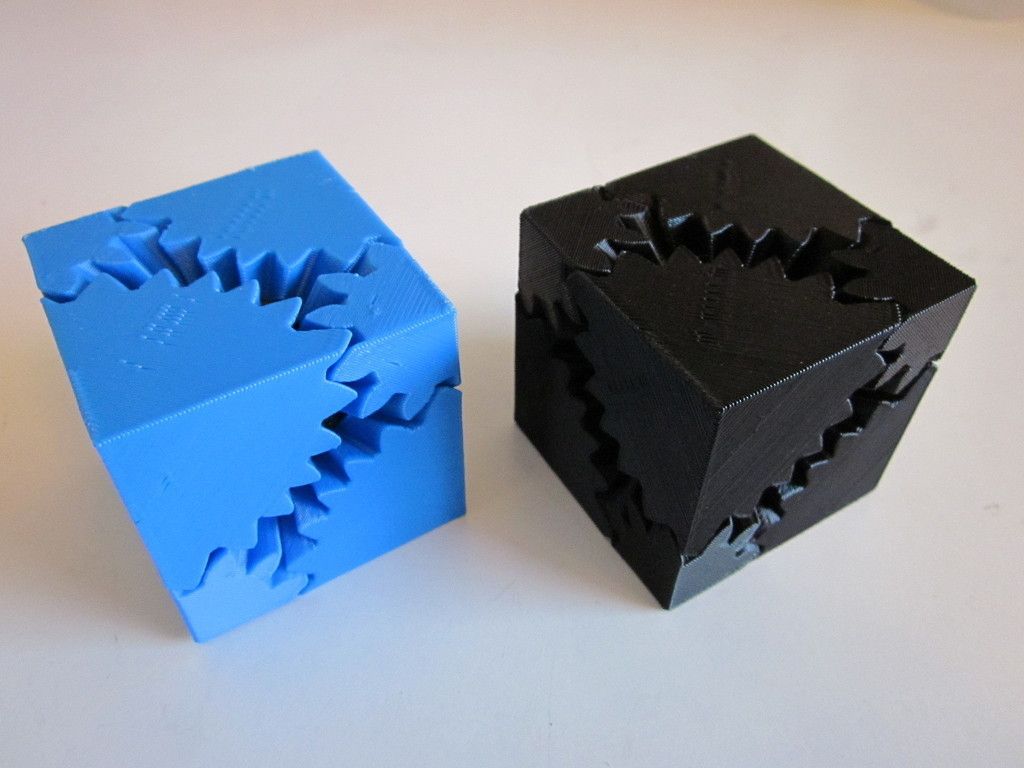

Though compact, the Cube 3 can print fairly large objects. Josh Miller/CNETExcellent design

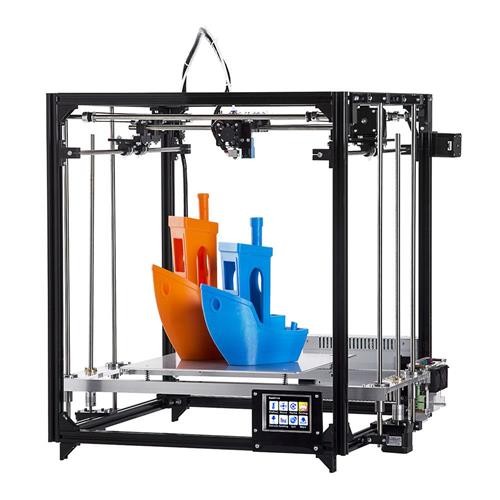

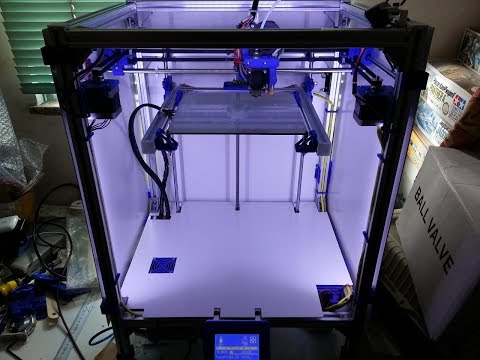

As the name suggests, the Cube 3 -- short for third-generation Cube -- looks like a cube, and a compact one, at that, measuring just 13.2 by 13.5 by 9.5 inches (33.5 by 34.3 by 24.1cm). Note that this is the shape of the printer with two filament cartridges already loaded inside the two recessed cartridge holders on its left and right sides.

To fully appreciate the design, you have to look at many other 3D printers where the filament holders protrude from the printer itself. With the Cube 3, when all parts are installed, its surface is mostly flush and smooth, giving the printer an almost perfect cube shape.

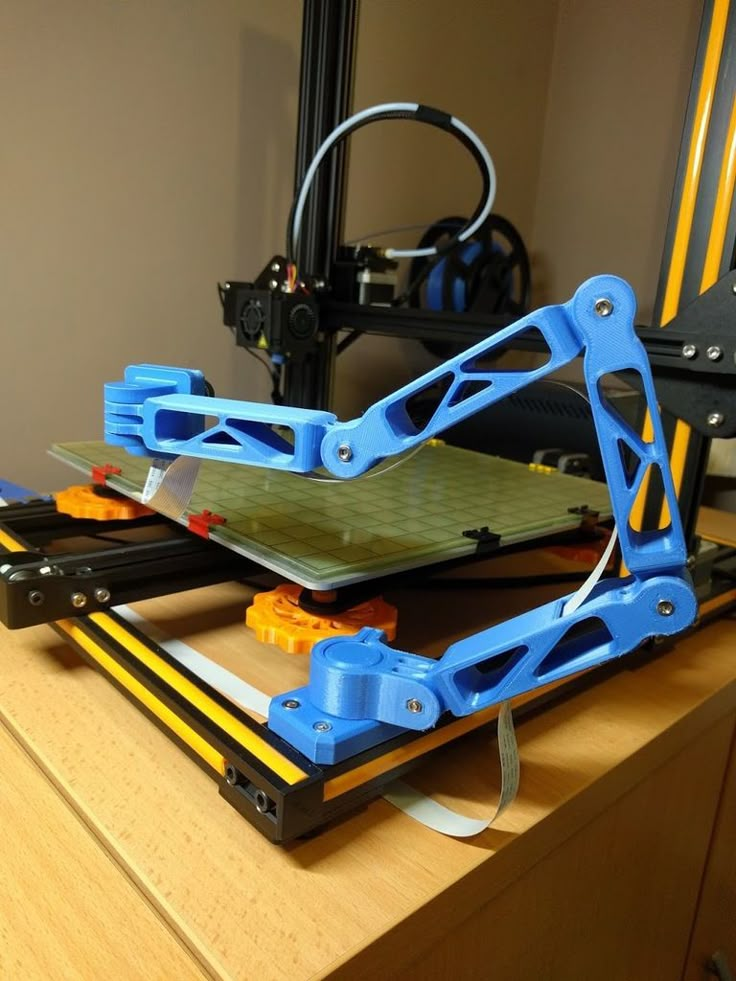

The printer doesn't have a lot of surface, however, since its front and back side are open, allowing you to view and work with the print platform easily. The Cube 3 is the first 3D printer I've worked with that employs an active print platform. During a print job, the platform moves backward and forward as well as up and down. This means the print-head on top just needs to move sideways. (In many other 3D printers, the print platform only moves up and down, requiring the print-head to move in all other directions.)

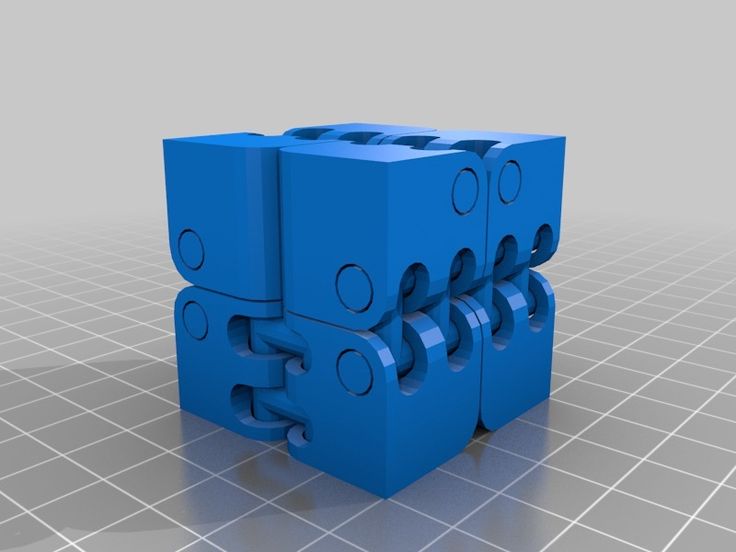

This kind of mechanism reduces the amount of space needed, allowing the printer to be compact, yet still have quite a large print platform. Indeed, despite the small physical size, the Cube 3 can print objects of up to 6 by 6 by 6 inches (15.25cm cubed). Judging from what we saw at CES 2015, the active platform is a new trend in 3D printing, with many upcoming printers sharing this design.

3D System Cube 3 specs

| Extruder | Dual-extruder |

|---|---|

| Plate | Removable plate |

| Print Technology | Fused Deposition Modeling |

| Build volume | 6 x 6 x 6 inches (15. 25 x 15.25 x 15.25 cm) 25 x 15.25 x 15.25 cm) |

| Layer thickness | 70 microns; fast mode: 200 microns |

| Printer control | Color touchscreen |

| Printable materials | ABS, PLA |

| Power source | 230 V / 120 W |

| External dimensions (WHD) | 13.2 x 13.5 x 9.5 inches (33.5 x 34.3 x 24.1 cm) |

| Weight | 17 lbs (7.7 kg) |

| Inputs | Wi-Fi, USB thumbdrive |

| Operating system supported | Windows 7 or later, Mac OS 10.8 or later |

The printer has a removable print plate, which is the top part of the print platform. The fact you can remove it means you can easily clean the surface after a job, or prepare it with glue before starting one. The plate attaches to the platform via a magnet, making it very easy to work with since there are no latches or screws to deal with.

The proprietary cartridges fit the printer really well. Josh Miller/CNET

Josh Miller/CNETProprietary and expensive filament cartridges

Out of the box, the Cube 3 is mostly assembled. You just need to remove the packaging and install the two included black and green filament cartridges.

Filaments are the raw material for fused filament fabrication (FFF) 3D printing, which is the technology used in most consumer-grade 3D printers. Think of them as the equivalent of ink cartridges in inkjet printers. They come in different colors and are basically easy-to-melt, quick-congealing plastic strings that are fed through the print head's nozzle during a print job. The print head then heats up and extrudes (that's why it's called an extruder) melted plastic onto the print platform below to create the 3D object.

Since the Cube 3 is a dual-extruder printer -- that is, one with two nozzles -- it can work with two sources of filament at the same time should you want to print objects of two colors.

Filaments always comes rolled up in spools. Many printers use open spools and allows users to pick filament of their own. The 3D System, however, put the Cube 3's spools inside its proprietary plastic cartridges. And this is both good and bad for consumers.

Many printers use open spools and allows users to pick filament of their own. The 3D System, however, put the Cube 3's spools inside its proprietary plastic cartridges. And this is both good and bad for consumers.

Good because the cartridge fits snugly into the printer as mentioned above. On top of that, each cartridge comes with a sensor that enables the printer to automatically recognize the type of filament being used (PLA or ABS), how much filament is left, and what color it is. In my testing, installing and replacing the filaments on the Cube 3 was the easiest of all 3D printers I've worked with. Each of the cartridge has a print-jet, which is the head of a filament feeding tube, that fits perfectly on top of the print-head. I didn't have to deal directly with the filament strings at all.

The printer's touchscreen makes working with it a walk in the park. Josh Miller/CNETThe downside is you have to get the filament cartridges directly from 3D Systems, and they cost $49 each. You can't refill the filament in each cartridge; rather, you have to buy a new cartridge entirely. The Cube 3 also has its own type of cartridges that are not even compatible with other 3D printers from 3D Systems, such as the CubePro for the Cube first and second generations. In testing, I couldn't print a large number of objects with one cartridge. Roughly speaking, an object that takes about 10 hours to print would use up about a fifth of a cartridge. On average, you can print about a dozen iPhone 6 Plus cases per filament cartridge.

You can't refill the filament in each cartridge; rather, you have to buy a new cartridge entirely. The Cube 3 also has its own type of cartridges that are not even compatible with other 3D printers from 3D Systems, such as the CubePro for the Cube first and second generations. In testing, I couldn't print a large number of objects with one cartridge. Roughly speaking, an object that takes about 10 hours to print would use up about a fifth of a cartridge. On average, you can print about a dozen iPhone 6 Plus cases per filament cartridge.

To 3D Systems' credit, the company takes back empty cartridges for recycling and includes a return shipping label for each of them. You do have to pay the shipping cost, however.

Easy to operate, Wi-Fi printing supported

On its front, the Cube 3 has a power button and a small touchscreen for you to manage its operation. You can use this screen to control all the functions of the printer, from printing to calibration to installing and replacing the filaments. Whatever action you pick, it will walk you though it, step by step.

Whatever action you pick, it will walk you though it, step by step.

It's important to note that the Cube 3 can calibrate itself. Calibration is an important process: you make sure the print platform's entire surface is leveled and at a perfect distance from the print head's nozzle. If it's not set correctly, the printer won't produce an object that accurately reflects the 3D model, or even just pump out plastic strings. Many printers require manual calibration; the Cube 3, however, will handle that by itself. In the rare case that it needs your interaction for this process, the touchscreen will display clear instructions as to what you need to do. In my experience, the Cube 3's calibration process was only as difficult as pressing buttons on the screen a few times.

Using the screen, you can also connect the printer to a Wi-Fi network. Once that's done, you can initiate a print job from any computer connected to the same Wi-Fi network. 3D Systems says that it will soon release mobile apps for Android and iOS for printing directly from a mobile device. Alternatively, the printer has a USB port that you can connect a thumbdrive to. If the thumbdrive contains standard 3D Model files, you can then print them using the touchscreen. A 2GB thumbdrive is included with the Cube 3, but you can use any drive of your own.

Alternatively, the printer has a USB port that you can connect a thumbdrive to. If the thumbdrive contains standard 3D Model files, you can then print them using the touchscreen. A 2GB thumbdrive is included with the Cube 3, but you can use any drive of your own.

Activation needed

You definitely need an Internet connection to use the Cube 3, at least initially.

The first time you turn the machine on, it asks you to activate it with 3D Systems. This process involves going to the activate page, creating an account, and typing in the machine's serial number. It will then provide you with an activation code, which you must enter into the printer via the touchscreen. Once that's accomplished, you can start using the machine.

After that you can download and install the Cubify printing software if you want to print directly from a computer that's connected to the same Wi-Fi network. The software will send the 3D model file to the printer, which can take up to 10 minutes, depending on the size and complexity of the object. After that, the printer will print the object on its own without the need for the computer.

The software will send the 3D model file to the printer, which can take up to 10 minutes, depending on the size and complexity of the object. After that, the printer will print the object on its own without the need for the computer.

Note that if you choose to print from a computer, the printer will not retain the 3D model on its internal storage so you can print the same thing again. For this reason, it's a better idea to use the software to export the model to a thumbdrive, then print from the printer's USB port. This way you can make as many prints of the same model without having to use the software or the computer again for that item.

The software offers standard customization, including scaling, layer thickness, filling patterns, the level of filling (hollow or solid), and so on. You can also use the software to connect to your account and get more 3D models from the Cubify community. Like all other printing software, Cubify also works with 3D models downloaded from other sources, such as Thingivers.

The Cube 3 supports standard 3D model files, which means you can also use other 3D printing software to export the models to a thumbdrive before printing them out via the printer's USB port.

Performance

On the whole, the Cube 3 worked well in my testing. It also was quite fast for a 3D printer, taking just 10 minutes or less to print a standard iPhone 6 case. It took longer to print a two-color object, but that's not surprising. And even then, I had no problem printing objects that took a few hours to finish.

Here's a large object that failed halfway through. Josh Miller/CNETWith larger objects that took 10 hours or more, however, it was a different story. More than once in my trials (though definitely not always), the object printed halfway just fine, but then failed completely. Then, I'd get a plastic string as if the printer hadn't been properly calibrated. Beyond being time-consuming, those failures wasted a lot of filament. And even more puzzling, the same job would be successful when I started over even though I hadn't recalibrated.

I've experienced such inconsistency before with other printers, and so far haven't haven't found a good reason why. That said, it's a good idea to check on the printing process once in a while when printing a large object.

My only other complaint about the Cube 3's performance is that it always needs to cool down its print head before you can resume printing again. Since printing a 3D object requires the print head to be heated to melt the filament, the cool-down phase is not only a waste of time, but also a waste of energy if you want to make multiple prints in a row.

Other than that, the printer is very well built, with an excellent mechanism. All of its parts are well put together with sharp and precise movements. The Cube 3 is a bit noisier while operating than other 3D printers I've reviewed. It isn't deafening, but it's still loud enough to be distracting if you use it in a quiet room.

Conclusion

There's much to like about the Cube 3, especially its design, its printing mechanism and ease of use. In fact it would make the best 3D printer I've worked with if there was no issue with the large objects randomly failing in mid-job.

In fact it would make the best 3D printer I've worked with if there was no issue with the large objects randomly failing in mid-job.

And while I don't like the cost of the proprietary filament cartridges, I really enjoy how they make using the printer a much better experience, comparable to using an inkjet printer. 3D Systems has put a lot of good ideas into the Cube 3 and most of them are successfully realized.

All things considered, the printer has enough to justify its $999 price, which is one of the lowest for a dual-extruder printer. For this price, and at the current stage of consumer-grade 3D printing, the Cube 3 is almost as good as it gets.

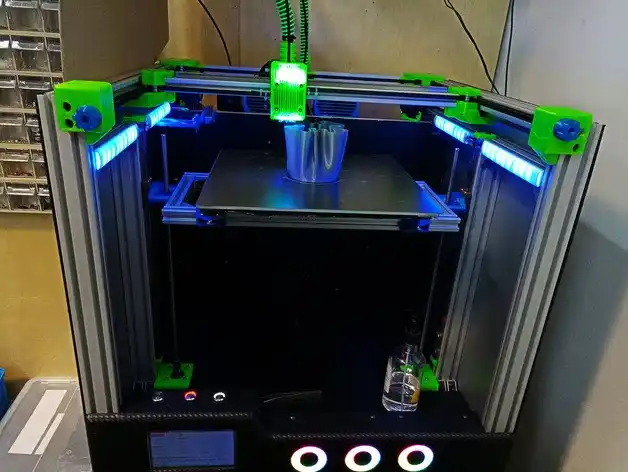

3D printer 3D Systems CubeX Trio

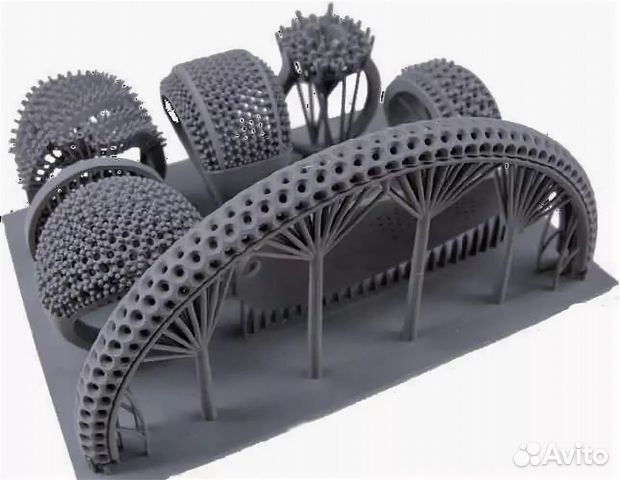

The new flagship from Cubify has not "home", but rather "office" dimensions. Huge platform - in this part the printer surpasses any other currently available. The Trio model can print high-quality and large parts with a size of 27x27x24 cm (basketball).

Mono, Duo, Trio - one, two or three extruders

With different colors of filament, you can print three-color compositions (for example, a simple globe). Three separate color cartridges supply filament to three printing extruders (and this is also the maximum of what is on the market). Resolution - from 0.100 to 0.250 mm, three degrees are available: high resolution (and low speed), standard and reduced. It takes 20 minutes to print the same basketball or globe at top speed.) Cubify printers do not lead in terms of speed, but we recall that at this level of quality we are already talking about semi-professional 3D printing.

Three separate color cartridges supply filament to three printing extruders (and this is also the maximum of what is on the market). Resolution - from 0.100 to 0.250 mm, three degrees are available: high resolution (and low speed), standard and reduced. It takes 20 minutes to print the same basketball or globe at top speed.) Cubify printers do not lead in terms of speed, but we recall that at this level of quality we are already talking about semi-professional 3D printing.

Cubify CubeX Trio Printer Design

When it comes to design and layout, the CubeX printers are impeccable (especially for the “bigger is better” proponents). The maximum print area (among the available custom ones), is especially impressive in the Trio version. Hence the weight of 36 kg. Such a device can no longer be called portable; rather, it is a stationary 3D printer for large offices and design laboratories.

Externally, the device corresponds to the name: it is a cube. It is framed by a rigid plastic construction that is open on four sides, so you can work with the printer from either side. This implies an unpleasant need to monitor safety in the presence of, for example, children, but the protective frame is quite functional in this area (there are more open and therefore unsafe models on the market). The plastic is of good quality for reliable thermal insulation. Filament cartridges are also hidden inside, the filament itself can be either PLA or ABS type, and the vast majority of other 3D printers can only work with one type of plastic.

This implies an unpleasant need to monitor safety in the presence of, for example, children, but the protective frame is quite functional in this area (there are more open and therefore unsafe models on the market). The plastic is of good quality for reliable thermal insulation. Filament cartridges are also hidden inside, the filament itself can be either PLA or ABS type, and the vast majority of other 3D printers can only work with one type of plastic.

The printer received the Emerging Technology Award at CES 2013

A bright "feature" of 3D Systems - as already mentioned, printing in several colors at the same time, only 18 colors are available. During the six months the model has been on the market, the manufacturer has added three more colors, including, according to numerous requests, dark glossy shades. One filled cartridge will cost $ 100, even if it is a standard white or black filament. And this is also a leading indicator on the market, unfortunately, not a positive one. It is also unpleasant that the printer only accepts branded cartridges, and since there are no third-party suppliers now, you will have to fork out.

It is also unpleasant that the printer only accepts branded cartridges, and since there are no third-party suppliers now, you will have to fork out.

Printing with Cubify CubeX Trio

Both Cubify printers use a cartridge-based filament delivery system (MoistureLock type), similar to the touch screen, and unlike the previous Cube model, can print directly via USB connection.

Most of the negative feedback about CubeX is not about print quality or design, but about the separately purchased cartridges and their prices.

CubeX Trio target audience are “prosumers”, visual art professionals and educators

Three-step filament density setting available

Cubify CubeX Trio printer connection

A 3D printer in terms of the sum of its parameters, it is supposed to have everything on board up to Wi-Fi. For management, a good touchscreen with intuitive menus is provided, in which a home (or office) Wi-Fi network is connected. The printer is capable of remembering entered passwords. Thus, this 3D printer is the only one (if you do not take into account the usual, not “double” and “triple” Cubes from the same manufacturer) via Wi-Fi accepts layouts. Worth a look anyway.

The printer is capable of remembering entered passwords. Thus, this 3D printer is the only one (if you do not take into account the usual, not “double” and “triple” Cubes from the same manufacturer) via Wi-Fi accepts layouts. Worth a look anyway.

Producer Support and Attitude

Everyone who has experienced the atmosphere in high growth areas knows that this is important. So far, 3D printers are far from TVs in terms of prevalence, and questions, errors, and claims against the manufacturer are inevitable. Now the company is available 16 hours a day, but only for residents of the States, a three-month warranty is given. The blog, as expected, is regularly filled with useful information and PR, including promising technologies.

Total

Objectively, in the spring of 2013 this is the best printer. The best in the tight-fitting group of quality consumer/prosumer 3D printers. Touchscreen, Wi-Fi, a huge platform and three-color printing (unfortunately, not RGB yet :).

However, the cost of the most complete Trio package is $4000. You can compromise: a $2,500 Duo option with a good kit plus $100 per consumable, and you get semi-professional 3D printing.

Pro

Currently the best in the sum of all parameters

Printing with red, white and blue film at the same time (Trio model)

18 colors available two or three cartridges (Duo, Trio)

Cartridge price = $100

Additional extruder price (Duo, Trio) = $500

Need to convert layout files to a separate *.cubex format

| Features | |

| Trade-in | Yes |

| 10% promotion for plastic | Yes |

| Wireless connection | No |

| Weight (without packaging) | 38 kg |

| Warranty | 90 days |

| Filament diameter (printer) | 1. 75 mm 75 mm |

| Connection interface | USB |

| Number of extruders (print heads) | 3 |

| Operating systems | Windows XP, Windows 7 |

| Software | Included. Converts 3D models into layers ready for printing (G-code). |

| Manufacturer | 3D Systems |

| Construction area size | 185 x 265 x 240 mm |

| Dimensions (without packaging) | 515 × 515 × 598 mm |

| Country of origin | USA |

| Print Technology | PJP |

| Plastic type | PLA (PLA), ABS (ABS) |

| Power supply | 100 - 240 |

-->

Rating

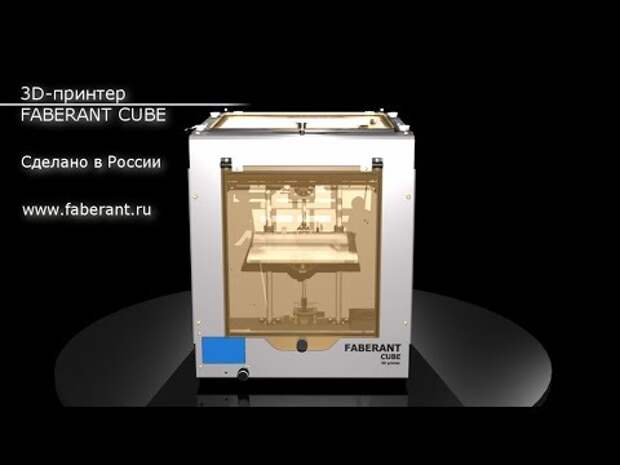

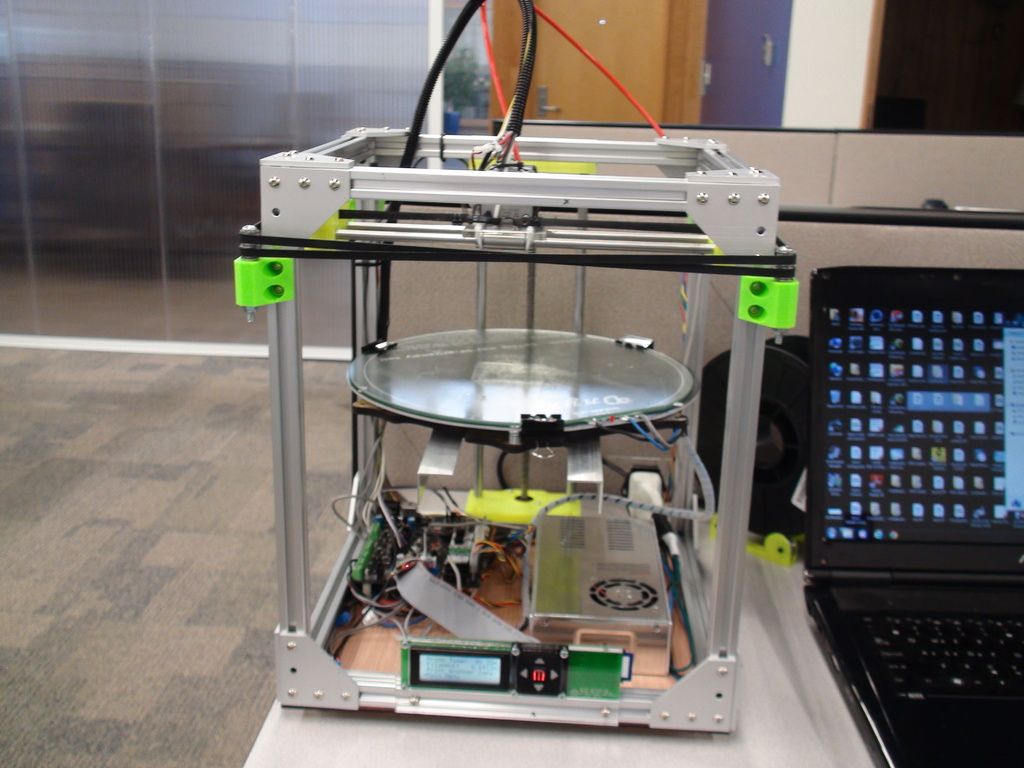

Faberant Cube 3D printer.

Short review." in the Innovations blog

Short review." in the Innovations blog 41

Innovations

The Faberant Cube 3D printer made in Russia has a closed cubic body for comfortable printing with plastics with shrinkage, an innovative motion system for printing with high precision - FCoreXY and a high-temperature all-metal Direct-extruder with a gearbox with a maximum printing temperature of 340 ° C, allowing you to print on all types of plastics. The printer has a semi-automatic table calibration, the working field of which is 200*200*245 mm (X|Y|Z) with heating up to 170 °C. 95