Eka 3d printer price

EKA DLP 3D Printer - A Jewelry 3D Printer For Production.

EKA Series of DLP 3D Printers for Jewellery

Are you from Jewelry Industry ? If yes then you are at right place to take your Jewelry making process to the next level.EKA series of DLP 3D Printers are Made in India High Speed DLP 3D Printers which helps you achieve your Jewelry Manufacturing Goals with maximum work efficiency !!!

Why use EKA Series of DLP 3D Printers for Jewelry Making? (Watch Video)

6 Step Jewelry Making Process with EKA

[1] CAD Design

Prepare a Jewelry CAD Design with CAD Software.

[2]. STL File

Convert CAD Design into .STL file format to use with EKA Controller Software.

[3] Prepare a Program

Take .STL file into EKA Controller software and prepare a program to start a 3D Print with EKA.

[4] 3D Print with EKA

Apply program from EKA controller to EKA and start a 3D Print of CAD Design, You have CAM Piece Ready with you.

[5] CAM Finishing

Now you have CAM Piece of your CAD design, Do a proper finish with tools and use it for Silicone Mold / Direct Casting Process.

[6] Jewelry in Hand

Do High Temperature Jewelry Casting from CAM Piece, and Your CAD design is Ready as a final Jewelry.

Work Gallery

Jewelry CAM work from EKA

Check WHAT our client's have to say about EKA

We are using EKA DLP 3D printer for our Jewelry Master Piece Development, It has given an exponential boost to our Jewelry Production work, with EKA now we have more scope of manufacturing for any complex Jewelry Design which is impossible to make with conventional hand made process.

Mr. Gopi

Production Manager, Smridhdhi Jeweltech, Bangalore

I can only say that – ” WE ARE SATISFIED”. High Speed & Best Quality work of Our Complex Jewelry Design help us achieve our Jewelry Production Goal. Which was not possible without EKA. No any single reason to avoid this amazing 3D Printing technology.

No any single reason to avoid this amazing 3D Printing technology.

Mr. Nikhil

Owner, Momai Art, Mumbai

EKA is my Business Partner, I started CAM Service Business with EKA 3D Printer and it had never disappointed me. As a CAM service Provider I need an accurate & high speed 3D Printer, which I found in EKA.

Mr. Ankit

Owner, Lucent CAM, Bharuch

We started using EKA for making of Jewelry Master Piece and we found J Curve in our Jewelry Production Speed.EKA made our process very easy,effective & efficient.

Mr. Yash

Sambhav gold,Vijaywada

Very Satisfied with performance with EKA Star 3D Printer, EKA team provided a good dedicated training to our person for operating of machine, which helps us a lot to achieve our goal, Highly recommended to start using 3D printer in jewelry making process.

Mr. Samar

S M Jewellers, Chandigarh

Customer Review for EKA

Is EKA based on DLP Technology ?

Yes, EKA is based on DLP(Digital Light Process) Technology, Compare to LCD based 3D Printer, EKA is Superior in every aspect of quality and performance due to it’s advanced DLP Technology.

Is it Indian Made 3D Printer ?

Yes, EKA is Indigenous 3D Printer.

Does it required any Training to Operate EKA ?

Yes, We will Provide Full Onsite Training to our customer with Lifetime after sales support.

What type of Material EKA Support ?

EKA supports both Direct Castable & Non-Castabe Resin Material.

What is Warranty Period for EKA ?

EKA Comes with standard 24 Months of Warranty, We will cover full warranty during this 24 Months.

Can We use EKA for Production work ?

Yes, EKA is made for Production work only, High Speed CAM work is best advantage of EKA.

Surat-Based Make3D Unveils EKA Star – A DLP 3D Printer For Fast Jewellery Manufacturing

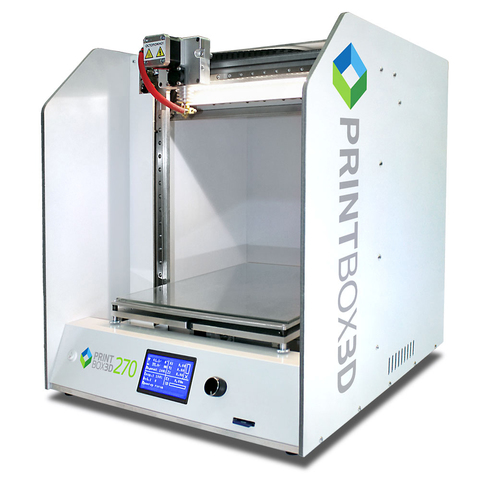

Surat-based Make3D has launched EKA Star – a new DLP 3D Printer manufactured for jewellery and dental applications. The new printer is an affordable DLP 3D printer featuring an advanced HD UV LED Project Engine for faster 3D printing.

Based on best-in-class LED technology, the new 3D Printer has a minimum layer height of 25 microns and delivers superfine output for jewellery design.

EKA Star – a DLP 3D Printer

Above: The EKA Star DLP 3D Printer from Make3D/Image Credit: Make3D

Features of EKA Star

- Build Volume: 105x59x105 mm

- XY Resolution: 53 Micron

- Z Resolution: 10 to 50 Micron

- Print Speed: Up to 1500 layers/Hour

- LED Source: HD UV LED Projector Engine

- LED Source Life: 30000+ Hours

- LED Wavelength: 0.1 %

- UV LED Wavelength: 405 nm

- Input Files: STL & SLC

- Machine Software: Licence Software EKA Controller

- Input Files: STL & SLC

- Machine Software: Licence Software EKA Controller

The EKA star DLP 3D Printer is manufactured specifically taking into account the requirements of the Jewellery & Dental Industry. The affordability of the DLP 3D Printer makes it competitive in the market.

One of the core equipment of a DLP 3D printer is its projector and that determines the output quality of any print. Since Make3D uses a best-in-class HD projector, the quality is not a matter of concern.

Since Make3D uses a best-in-class HD projector, the quality is not a matter of concern.

[penci_related_posts taxonomies=”undefined” title=”Inline Related Posts” background=”” border=”Grey” thumbright=”yes” number=”4″ style=”grid” align=”none” displayby=”cat” orderby=”random”]

According to the company, “The HD projector engine helps in faster 3D printing that may prove highly beneficial to jewellery designers, jewellery manufacturers, dental labs, or individual entrepreneurs who want to start a business around jewellery and dental industry. Such businesses should buy this machine for high-quality 3D prints.”

This is not the first time that the company has launched a new printer. The company is already credited with the launch of various 3D printers such as Pratham, Pratham 3.0, Pratham 5.0 FDM 3D printers and EKA DLP 3D printer. Make3D also offers 3D printing services in multiple 3D printing technologies.

The products launched by Make3D cater to various industries such as the casting industry, R&D firms as well as Personal Hobbyists, Educational Institutes etc. The EKA series of 3D Printers of the company are specially made for jewellery & dental industry.

The EKA series of 3D Printers of the company are specially made for jewellery & dental industry.

The company also has a diverse base of clients and includes some esteemed clients such as IIT Varanasi, ISRO, D.Y. Patil College, SVNIT Surat and many more.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Indian Scenario page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

3D printing - to schools (technomarathon for assembling 3D printers in Yekaterinburg) / Sudo Null IT News We have been developing this very interesting and promising direction for the third year already. During this time, our residents managed to hold a lot of events, seminars and lectures aimed at popularizing the technology.

The technical education of schoolchildren can be considered an equally important area of work for hackspace. On these issues, we even have several articles on Habré (one, two, three, four). And it would be foolish of us not to try to combine these two directions. Give children printers

On these issues, we even have several articles on Habré (one, two, three, four). And it would be foolish of us not to try to combine these two directions. Give children printers , and children's printers .

What is the best way to combine 3D printing and children's technical creativity? And most importantly, where to start? Probably, you can buy a printer for school, tell the computer science teacher how to use it. is that enough? Obviously not.

This year, together with the Ural New Education Club, a friendly organization, we launched a series of events to assemble 3D printers by teachers and schoolchildren. What is it, and did we manage to assemble these same 3D printers, read below under the cut!

Techno marathon

The first event was held as part of the City of Technocreativity festival, which started in February in our city. At the suggestion of the head of the club, Irina Zakirova, this action was called "Technomarathon".

History

The idea of an event for the collective assembly of 3D printers is not new. In our country, for example, guys from the Navigator Campus hackspace are engaged in such a noble cause. They call this action "Makerton 3D Printer".

The essence of the event is extremely simple. We invite several teams of participants who are invited to assemble a 3D printer on their own. For assembly, the teams are given everything they need - a kit for assembling a printer (in varying degrees of readiness), tools, instructions. It is also necessary to have competent engineers ready to help at any time. Often times, a build is like a competition. The one who assembles his printer faster than the rest gets some useful prize. For example, he gets a 3D printer for free!

We've been dreaming of this idea since we were founded, waiting for the stars to align, so to speak. And finally, half a year ago, we managed to combine our engineering knowledge with the organizational skills of Irina Zakirova, and began preparations for the 3D printer assembly technomarathon!

Why?

So, let's start with the most important question: why does a school need a 3D printer? We encounter a lot of skepticism about this, which we constantly have to break up with examples from life and world experience. So what is a printer for? Yes, at least for the quick reproduction of tutorials. Looking at the portals of foreign 3D printers, you can find many different objects that allow a child to more effectively learn a particular lesson.

So what is a printer for? Yes, at least for the quick reproduction of tutorials. Looking at the portals of foreign 3D printers, you can find many different objects that allow a child to more effectively learn a particular lesson.

A simple example is a biology lesson. What if instead of a picture of DNA, each child can print out a piece of the double helix, feel it, understand its spatial features? Even to throw at a neighbor, and then it will be more useful than contemplating a picture.

Another example is a plant cell. You can pull out the mitochondria :)

For a biology lesson, you can also print, for example, bones, organs, or whole animals. In physics: working models of mechanisms, stands for physical experiments. In mathematics: surfaces given by tricky functions, sections of figures, fractals. Etc. I think we will devote an entire article to this separately.

The same question can be asked to the house of creativity. But there the answer is even easier. A 3D printer in technical creativity is an indispensable tool for the rapid production of parts. Today, printed parts are widely used in educational robotic projects, in aircraft and ship modeling. A good example is a 3D printed quadcopter.

A 3D printer in technical creativity is an indispensable tool for the rapid production of parts. Today, printed parts are widely used in educational robotic projects, in aircraft and ship modeling. A good example is a 3D printed quadcopter.

There is an even more valuable layer of applicability of a 3D printer - this is 3D modeling. It's one thing to just print the finished model. Other: first invent an object, then design an object, and finally print it on a 3D printer. It is this case that is most interesting to us from the point of view of children's technical creativity.

At whose expense is the banquet?

But back to our techno-marathon. And the first question: who will buy printers for schools?

The first option that we have tried is to try to get some kind of specialized grant. Unfortunately, the option didn't work. This does not mean that the approach is wrong in principle, we just failed.

The second option is to ask big (and not so big) companies for money. As you know, industrial enterprises often take patronage over schools, and do their best to help these schools with the ruble. But in order to bring such an idea to the company's management, you need to have direct connections and recommendations. We started our event with a clean face, and we didn’t have any friendly enterprises. As a result, of the six teams that applied, one company (Beloyarsk NPP) paid for the 3D printer, the other bought the printer with grant money (thanks to SKB-Kontur, and hello to all IT companies). Again, the option itself works. After the first techno-marathons, we hope for a much wider support from the enterprises of the region.

As you know, industrial enterprises often take patronage over schools, and do their best to help these schools with the ruble. But in order to bring such an idea to the company's management, you need to have direct connections and recommendations. We started our event with a clean face, and we didn’t have any friendly enterprises. As a result, of the six teams that applied, one company (Beloyarsk NPP) paid for the 3D printer, the other bought the printer with grant money (thanks to SKB-Kontur, and hello to all IT companies). Again, the option itself works. After the first techno-marathons, we hope for a much wider support from the enterprises of the region.

The third option is to pay for printers from non-budgetary funds of the school or art house. As practice has shown, this is also quite a working option. Of course, provided that the 3D printer costs reasonable money. Here, in fact, the second big organizational question arises:

What kind of printer will we assemble?

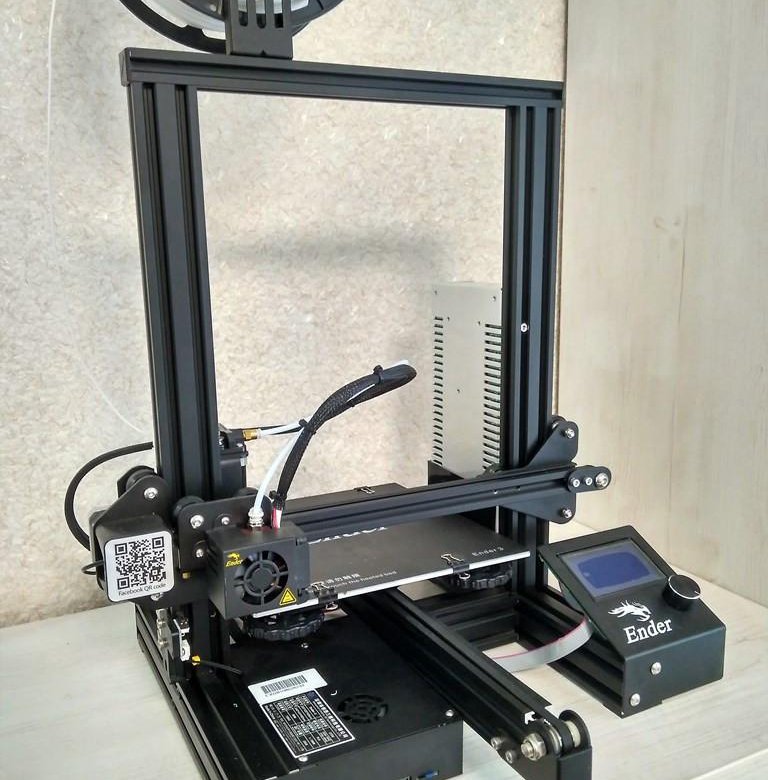

The first thing that comes to mind is the RepRap series 3D printer. These are printers that have been specifically designed to be assembled at home. There is a lot of documentation, videos on RepRap, and in our hackspace we once started with just such a simple machine. In general, the choice fell on the Prusa I3 from the Spanish company BQ. Here he is handsome, in the photo.

These are printers that have been specifically designed to be assembled at home. There is a lot of documentation, videos on RepRap, and in our hackspace we once started with just such a simple machine. In general, the choice fell on the Prusa I3 from the Spanish company BQ. Here he is handsome, in the photo.

By the way, one of those collected by our tech marathon runners.

Members

According to the generally accepted practice, teams of an arbitrary number of people take part in the event. As many teams participate as the organizers are able to withstand at a time. In our case, three teams per day was the best option. In total, six teams entered our first techno-marathon, which we divided into two groups:

February 28, 2015

- Upper Pyshma Center for Education and Vocational Guidance;

- School No64 from the city of Lesnoy;

- Polytechnic department of the Palace of Youth.

March 5, 2015

- Children's Art Center of the city of Irbit;

- School No1 GO Zarechny;

- House of children's creativity in the Oktyabrsky district of Yekaterinburg.

Everything you need

In order to assemble printers, in addition to the teams of participants, we needed:

- soldering irons - to solder nuts into the plastic parts of the printer;

- files (flat and round) - for finishing parts that fit into each other;

- screwdrivers and hex set;

- drill and drill bit set - drill poorly printed holes;

- scissors and stationery knife;

- ruler - for calibration;

- pliers - to flatten everything :)

- hammer or mallet - to drive the bearings.

And of course, all this had to be multiplied by the number of teams.

And we also need helpers, who can be students of technical universities, or just handy guys (or girls). You always have to be on the alert and help the lagging teams.

You always have to be on the alert and help the lagging teams.

Assembly

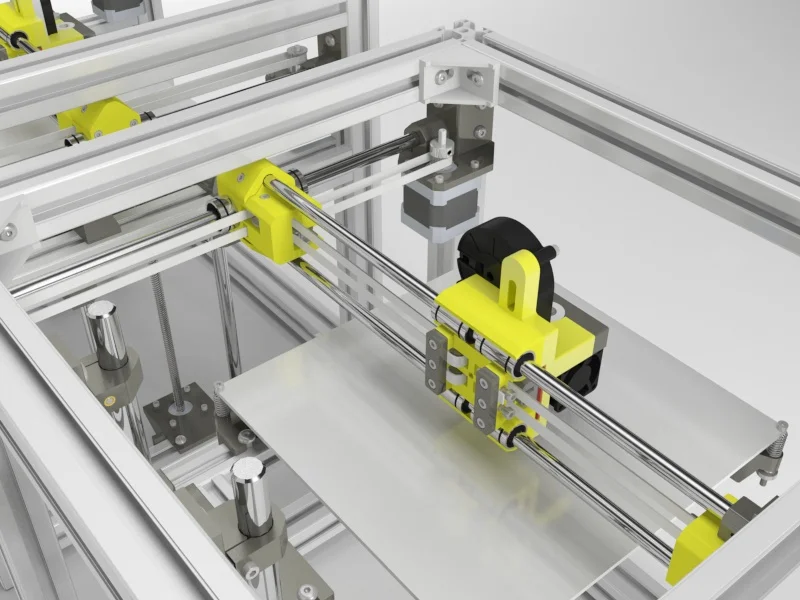

The assembly of 3D printers was carried out according to a clear (Russian-language) step-by-step instruction provided by the manufacturer. In general, it must be admitted that the Prusa I3 Hephestos printer from BQ was ideal for the tech marathon. Yes, there were awkward moments with breaking parts and ill-fitting grooves, but it is extremely difficult to find Russian-language analogues for such money.

So let's unpack the boxes with the parts. Everything is packaged very conveniently and presentably.

We intensively put together all the body parts. At this stage, by the way, several times there were problems with the layout. The fact is that the frame of the printer is almost symmetrical, and you can easily confuse which side to put it on. Of course, it has a large "Prusa I3" written on it, but the participants, immersed in the assembly, often did not pay attention to it. As a result, some printers had to be rebuilt at a pace (not completely, of course).

As a result, some printers had to be rebuilt at a pace (not completely, of course).

Electronics

The most important part. If you mess up something, you can easily burn the 3D printer controller or some sensors. Fortunately, in the native instructions there are color schemes, following which it is difficult to confuse anything.

Calibration

The printer is already ready. All axes work as expected, moving in the right direction. The penultimate stage before printing comes - calibration. In fact, we need to adjust the working surface and the vertical axis limit switch so that the nozzle is at a distance of 0.3-0.5 mm at all points in the field.

Duration

Now about time. Initially, we allocated 5 hours for everything about everything. This was supposed to include an introductory lecture for 30-40 minutes, lunch, and the assembly itself. Oh, how wrong we were! The first event ended in the evening, at about 8 o'clock!

Oh, how wrong we were! The first event ended in the evening, at about 8 o'clock!

The second tech marathon took about the same time. From this we can conclude that, on average, assembling a printer takes about 8 hours (if you mess around and mess around a little less).

Final

And here are our satisfied participants with their 3D printers!

Team of the Polytechnic Department of the Youth Palace of Youth of Caterinburg

Team of the Center for Education and Professional Orientation of the Verkhnyaya Pyshma

Team of the NO64 school from

The Center for Children's Creativity of the city of Irbiti

9000Team House of Children creativity of the Oktyabrsky district of Yekaterinburg.

Team of School No1 GO Zarechny

What are 3D printers working on after the technomarathon?

We ourselves, as the organizer, are terribly interested in the further fate of the assembled 3D printers. The very first feedback came from Leonid Gushchin, a teacher at the Robotodrom of the Palace of Youth:

The very first feedback came from Leonid Gushchin, a teacher at the Robotodrom of the Palace of Youth:

So, 3D printing technologies have come to our circle!

The 3D printer is calibrated and printed the first model: a small robot figure. In honor of the fact that this model is the first, she even received the name Erem. Well, meet our plastic friend!

Of course, the robot figure was not limited:

On Wednesday we played around with robot models))

And today we have already printed mounts for servos:

And one more thing:

Well, a 3D printer is really an extremely useful thing! And of course, you understand his work much better when he assembled it himself.

So once again, thanks to the organizers and experts for the techno-marathon!

Acknowledgments

- Thanks to Irina Zakirova, the main organizer of the event: “When you organize and hold an event, the results of which are so satisfied with the participants, you feel joy and pride in the quality of the work done.

We did it!"

We did it!" - Thanks to Alexey Samoilov, Head of Witbox Maker School (Witbox Russia)

- Thanks to the Ural Polytechnic College for the excellent venue for the techno-marathon and help in organizing this event.

- Thanks to our experts: Oleg Evsegneev and Pavel Tomshin for their professional work. On March 5, volunteer guys — students and technical specialists — Fedor Zyablitsev, Ilya Bannikov and Igor Vormanov helped the teams a lot in the assembly. Thank you very much!

- Thanks to all the participants who, despite being tired and stressed, made it to the end!

In the news

The 3D Printer Assembly Technomarathon even got into the local issue of Vesti-Ural:

What's next?

In the near future, we plan to develop a small master class on modeling and 3D printing, which we will offer to all participants of the technomarthon, or just happy owners of 3D printers. The masterclass will take place on a separate day and will approximately take about 8 hours, including lunch and coffee breaks. The main goal of such an event is to make sure that upon returning to the educational institution, a large queue for printing forms at the printer.

The masterclass will take place on a separate day and will approximately take about 8 hours, including lunch and coffee breaks. The main goal of such an event is to make sure that upon returning to the educational institution, a large queue for printing forms at the printer.

Application for participation

Well, the most immediate plan is to recruit a new group for the techno-marathon! For convenience, we have created a small questionnaire for participant .

Write if you are from Yekaterinburg or the Region. But also check in if you are from other regions of Russia, and for you:

– schools,

– House of creativity,

– robotics club

- or another club - where children study,

It would be interesting to build a 3D printer. And if you do not have enough funds to participate, we will try to help, find sponsors.

For sponsors

In turn, for sponsors, if you want to support the development of 3D printing in schools in Yekaterinburg / region, or in your city - check in this form: questionnaire for patrons .

All registered participants will be contacted by the organizer Irina Zakirova and will discuss all organizational issues.

3D Printer Parts in Yekaterinburg

Catalog

3D Printer Parts Extruder Upgrade Replacement Aluminum Alloy Block 1.75mm Filament for CREALITY Ender3 CR-10 3D Printer Parts

471

724

In the store

Spare parts for 3D printers Titan Extruder NEMA 17 Step engine 42x42x23 mm 17HS4023 for Ultimaker Prusa I3 Kossel

in the store

PRIENTERS for 3D PRESA /MK3

Shop

3D Printer Parts Moon Lamp Light Board 16 Colors Remote Control Light

Shop

3D Printer Parts 4pcs Alignment Spring 10 25mm Reprap 3D Printer Accessories imported for Ender 3 Anet A8 Hot Bed

Shop

Printer Extruder Feed Drive Kit for Ender-3 3D Printer Spare Parts Upgrade 1. 75mm Filament Extruder Feed Drive Kit

75mm Filament Extruder Feed Drive Kit

Shop

Trianglelab 3D Printer Parts PT100 Temperature Sensor for V6 High Temperature Printer HOTEND 2017 PT100 Free Shipping

768

835

Shop

Ender3/Ender5/CR10V2/CR-10S 3D Printer Parts

734

1360

Shop

MKS TMC2209 3D Printer Parts V2.0 Stepper Motor Driver Support UART Mode for Gen L V2.0 /Robin E3D/SKR 1.3/1.4 6packs

1238

1875

in the store

3D printing accessories for WF-7610 Printing head WF-7620/7621/3620/3640/7111 Printing head 3D spare printer

8294

12760 9000 Extruder Parts Upgrade Replacement Aluminum Alloy Block 1.75mm Filament for CREALITY Ender3 CR-10 3D Printer Parts

468

720

In the store

3D printer assembly, extruder sets, a spare head of the extruder with a set of fan nozzles for the Crealy CR-10 V2, parts for the repair of the spare parts

9000 33744686

in the store

in the store in the store in the store3D Printer Upgrade Filament Extruder Feed Drive Kit for Ender-3 3D Printer Spare Parts

4319

6645

Shop

Reprap Prusa i3 9 3D Printer Parts0003

in the store

Spare parts for a 3D printer, aluminum alloy, Ender-3 printer

9000 5121023

In store

Spare parts for the 3D printer Ender 3 CR-8 extruder

9000 7511390

Shop

3D Printer Spare Parts 1.