3D printing metamaterials

The future of 3D printing

Posted By Marianna Papageorgiou on Nov 8, 2017 |

Have you ever heard of metamaterials before? Did you know that when you combine design and engineering you can create new properties that you cannot find in nature? Metamaterials are pretty impressive for this: for their emerging properties. Promising as it sounds, it has already been studied by researchers at Hasso Plattner Institute in Potsdam, Germany. In this blog post, we will introduce you to the metamaterial mechanism and see how they can be 3D printed so that they perform as machines and not as passive constructions. Also, we will see some of the applications of metamaterials and we will explain how metamaterials work.

What are metamaterials?

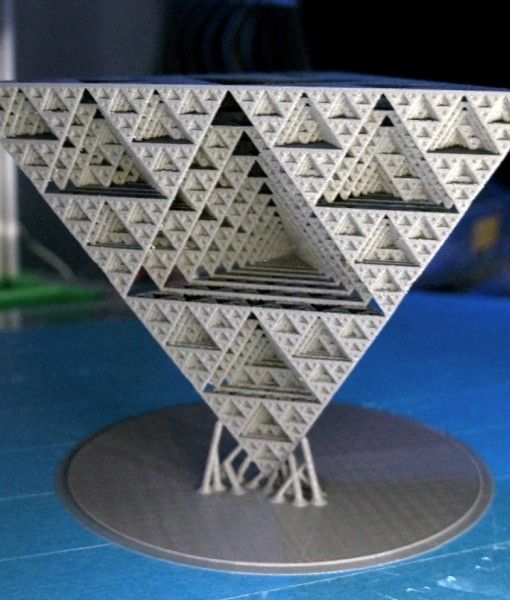

Metamaterials are materials that derive their mechanical properties from their structure and not from the material they are made of. They are named metamaterials after the Greek word “μετά”- “meta”, meaning “beyond”, because their newly designed structures go beyond the natural arrangement, to new forms of organization. Metamaterials are made from assemblies of multiple elements and they are structured in a way so as to give us the mechanical properties we want, and which we cannot find in ordinary materials. They are characterized by repeated patterns and grids, with precise shape, geometry, size, orientation and arrangement.

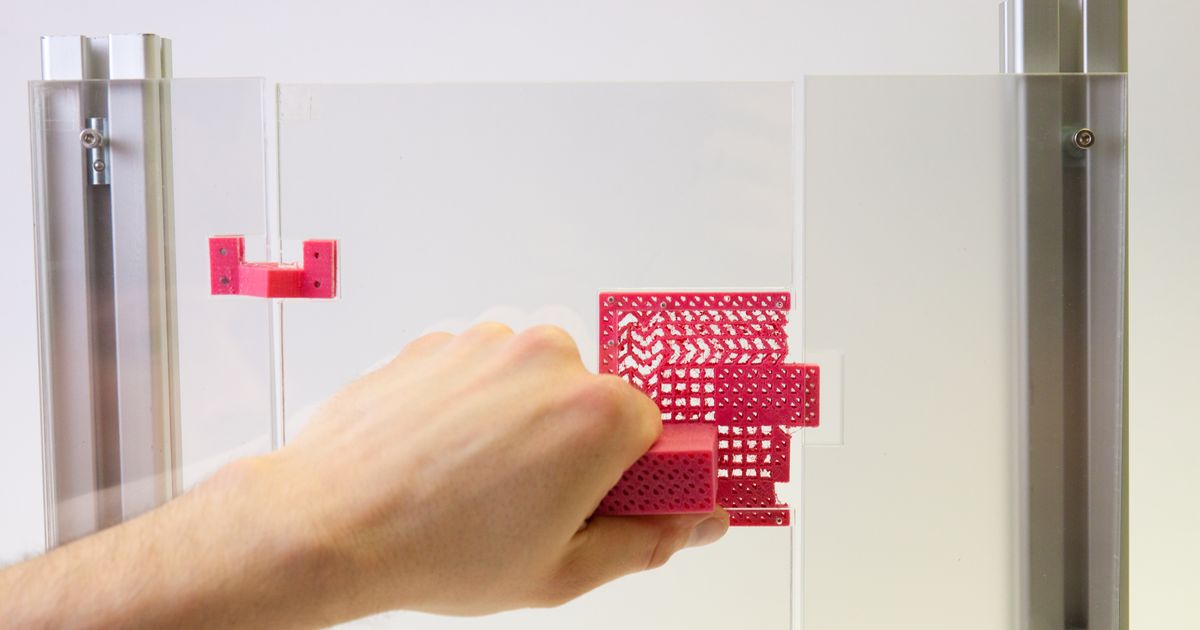

When the user applies a force to the handles, the hinge array in the center transmits this force to the brackets, and the liers close.

Are there different types of metamaterials?

Yes! When talking about 3D printing experiment with these artificial materials, we are referring to mechanical metamaterials, or elastic metamaterials. Keep in mind that other metamaterials exist, such as electromagnetic metamaterials.

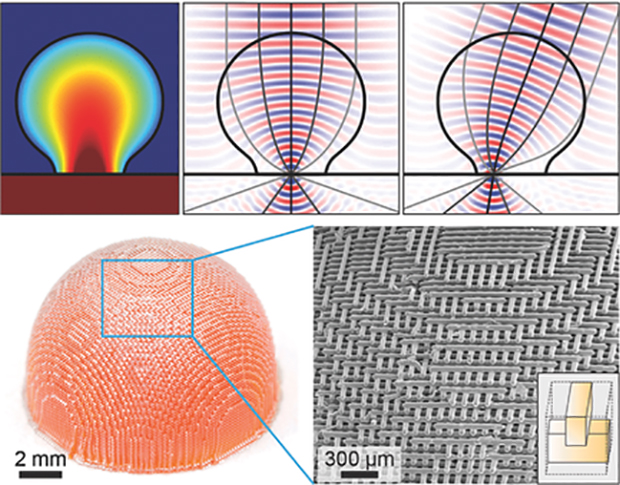

Some electromagnetic metamaterials, such as photonic metamaterials, interacts with light and have a negative refractive index. Negative refraction is when light refracts or bends outward on the material. It is one of the main differences that they have with materials such as glass lenses, that has a positive refractive index. The electric and magnetic field of these electromagnetic materials are the opposite of the behaviour of optical devices materials.

The electric and magnetic field of these electromagnetic materials are the opposite of the behaviour of optical devices materials.

Metamaterials are also known be linked to some experiments to create invisibility cloaks, thanks to this negative refractive index. Indeed, a cloaking device has been made in 2006. It was partially working, but it proves that these artificial materials are allowing to do science experiments that were typically impossible with natural materials.

Applications of metamaterials

Due to metamaterials mechanisms’ newly designed properties, they have the ability of influencing electromagnetic waves by blocking, absorbing or bending waves, to cause impact that goes beyond what is possible with conventional materials. This allows constructing applications which would never have been feasible with conventional materials. Nor many fields of engineerings will remain unaffected by the introduction of metamaterial mechanisms. Some of the fields which have already embraced them are optical filters, medical devices, electrical engineering, remote aerospace applications, sensor detection, seismic metamaterials and much more. Just to give an example, metamaterials allow for creating superlenses which permit imaging below the diffraction limit that is the minimum resolution that can be achieved by conventional glass lenses. In this blog post, we will see applications of mechanisms of metamaterial objects that perform a mechanical function, such as macroscopic movement.

Just to give an example, metamaterials allow for creating superlenses which permit imaging below the diffraction limit that is the minimum resolution that can be achieved by conventional glass lenses. In this blog post, we will see applications of mechanisms of metamaterial objects that perform a mechanical function, such as macroscopic movement.

How metamaterials work?

Metamaterials are artificial structures with mechanical properties that are defined by their usually repetitive cell patterns. Based on this concept, researchers have created objects with unusual behaviors, such as metamaterials that collapse when compressed, that shrink in two dimensions upon one and objects that mix layers of soft and hard cells in order to emulate different materials. This allows users to create objects that perform mechanical functions, as we will explain below in the article.

The key element behind the metamaterial mechanisms is a specialized type of cell, which only ability is to shear. Unlike the rigid cell, this shear cell is designed to deform in a very specific way when a force is applied: when subjected to an external force, it shears and thereby applies a force to its neighboring cells.

Unlike the rigid cell, this shear cell is designed to deform in a very specific way when a force is applied: when subjected to an external force, it shears and thereby applies a force to its neighboring cells.

When a shear cell is subject to compression forces, it complies by shearing on a circular trajectory.

The objects described below implement devices that transform input forces and movement into a desired set of output forces and movement – also known as mechanisms!

Metamaterial mechanism #1: Door latch

The following picture shows a door latch mechanism. This door latch is implemented as a metamaterial mechanism. It consists of a single block of material based on a grid of cells that together implement handle, latch and springs. When you push down the handle, it causes the central hinge array to deform, the cells shear and the latch of the door is pulled inwards which unlocks the door.

Metamaterial mechanism #2: Pantograph

This one is a pantograph. It is a single part that consists of cells of different elasticities. One edge of the pantograph is attached to the desk and the rest of is free to move. Two pencils are placed on the grid, but only one it is meant to be for the user to draw. When the user of the mechanism is drawing something with his pencil, the secondary pencil creates an identical replicate of the original drawing on a smaller scale.

It is a single part that consists of cells of different elasticities. One edge of the pantograph is attached to the desk and the rest of is free to move. Two pencils are placed on the grid, but only one it is meant to be for the user to draw. When the user of the mechanism is drawing something with his pencil, the secondary pencil creates an identical replicate of the original drawing on a smaller scale.

You may wonder, don’t these structures ever break? The answer is no, because metamaterial mechanisms operate only to the point where they still fully return to their original shape. So, material fatigue or material damage is not a problem.

We invite you to watch the video below, that illustrates even more examples of how artificial structures perform mechanical properties:

3D printing metamaterial mechanisms

Are you intrigued by the uses and the potential of metamaterial mechanisms? Don’t hesitate to create your own 3D printed metamaterial mechanism! Once you create the 3D design of the structure that fits your purpose save it in . STL format and upload it on our online 3D printing service. You can pick the 3D printing material of your choice among the many we provide you. The ideal materials for metamaterial mechanisms are the very elastic ones as they return to their original shape without deforming permanently and the materials that withstand high forces without breaking. Our PEBA 2301 fulfills the criteria of elasticity as it is a very flexible material. We also offer you flexible polyurethane that withstands repetitive stresses such as hinging mechanisms and friction fits or elastomeric polyurethane which has an excellent elastic behavior under cyclic tensile and compressive loads.

STL format and upload it on our online 3D printing service. You can pick the 3D printing material of your choice among the many we provide you. The ideal materials for metamaterial mechanisms are the very elastic ones as they return to their original shape without deforming permanently and the materials that withstand high forces without breaking. Our PEBA 2301 fulfills the criteria of elasticity as it is a very flexible material. We also offer you flexible polyurethane that withstands repetitive stresses such as hinging mechanisms and friction fits or elastomeric polyurethane which has an excellent elastic behavior under cyclic tensile and compressive loads.

Laser Cutting metamaterial mechanisms

You can create a metamaterial mechanism with laser cutting as well! Though, keep in mind that there are a few more constraints compared to 3D Printing. The most obvious restriction is the design freedom. For example, you cannot create lattice structures and impossible geometries such as these you can achieve with 3D printing. The functionality of a metamaterial mechanism is defined mostly by its structures and not its material. So, even if rubber foam material would be the ideal material to use for creating metamaterial mechanisms with laser cutting, you can still use other materials too. Among the list of the laser cutting materials we offer, the most adequate one would be the acrylic material.

The functionality of a metamaterial mechanism is defined mostly by its structures and not its material. So, even if rubber foam material would be the ideal material to use for creating metamaterial mechanisms with laser cutting, you can still use other materials too. Among the list of the laser cutting materials we offer, the most adequate one would be the acrylic material.

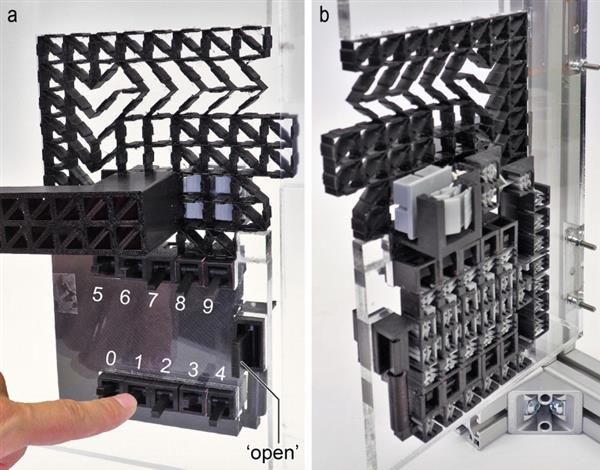

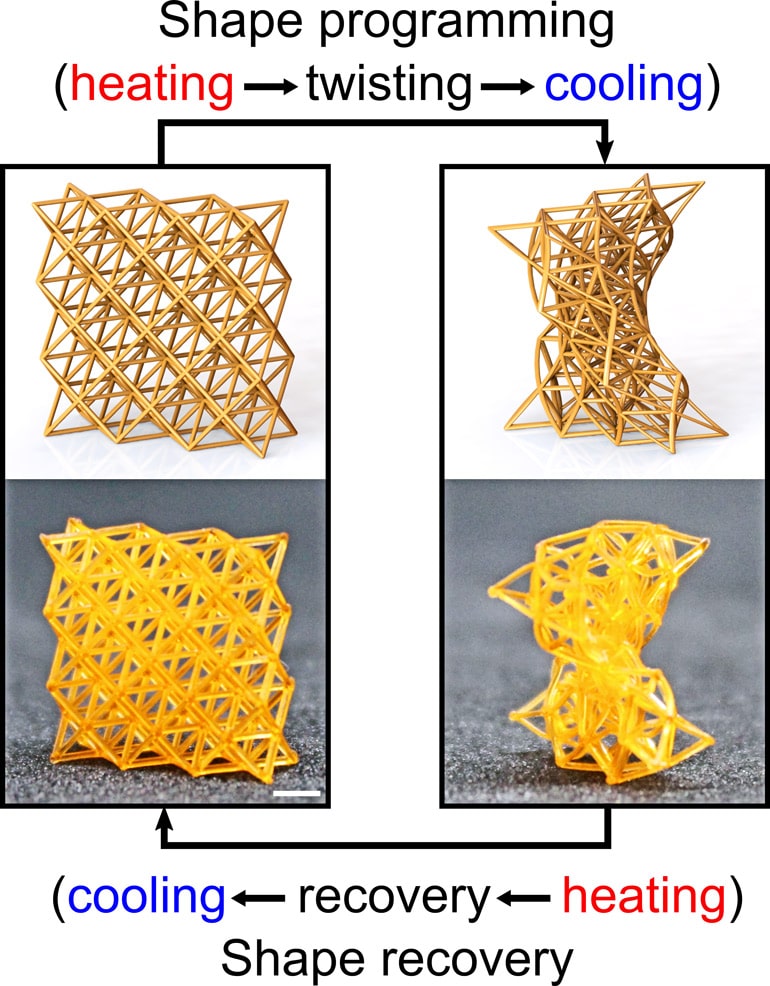

If you want to get deeper into this topic, you can read the research project about metamaterial mechanisms from the Hasso Plattner Institute. We hope this article inspired you to explore more about the potential of this arising technology! If you want to continue reading about disruptive technologies with promising applications and follow the future metamaterials researches, we invite you to read this blog post about 4D printing technology!

Photo Credits: Hasso Plattner Institute

3D printing metamaterials

News - 14 April 2022

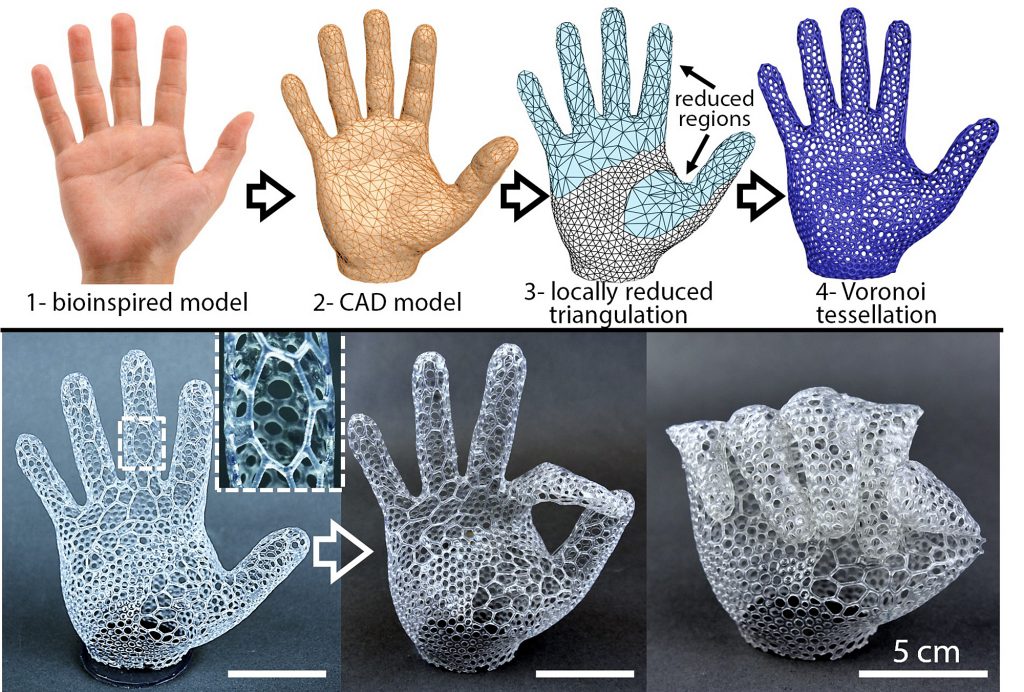

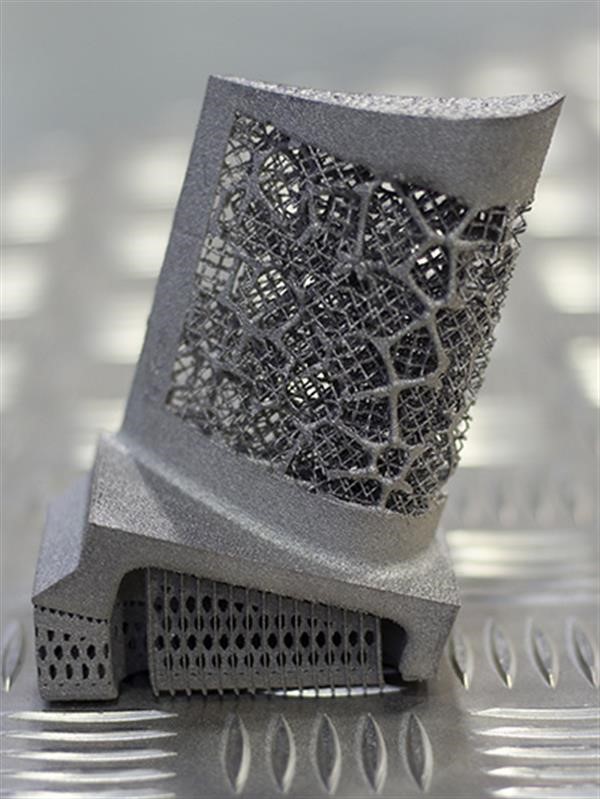

Imagine wanting to construct a personalised bike saddle, but the materials at your disposal are either too stiff for some parts of the buttocks or too soft for others… Creating a product that has different parts, each with unique requirements, often requires the use of different materials. But innovations in 3D printing are changing this by making it possible to create objects with spatial gradations in surface and volumetric properties – in other words, functionally graded materials (FGMs). These engineered metamaterials go beyond the characteristics found in naturally occurring materials. For his PhD, Tim Kuipers explored how toolpath generation and a manufacturing technique called fused filament fabrication (FFF) can be used to create more complex objects with varying material properties.

But innovations in 3D printing are changing this by making it possible to create objects with spatial gradations in surface and volumetric properties – in other words, functionally graded materials (FGMs). These engineered metamaterials go beyond the characteristics found in naturally occurring materials. For his PhD, Tim Kuipers explored how toolpath generation and a manufacturing technique called fused filament fabrication (FFF) can be used to create more complex objects with varying material properties.

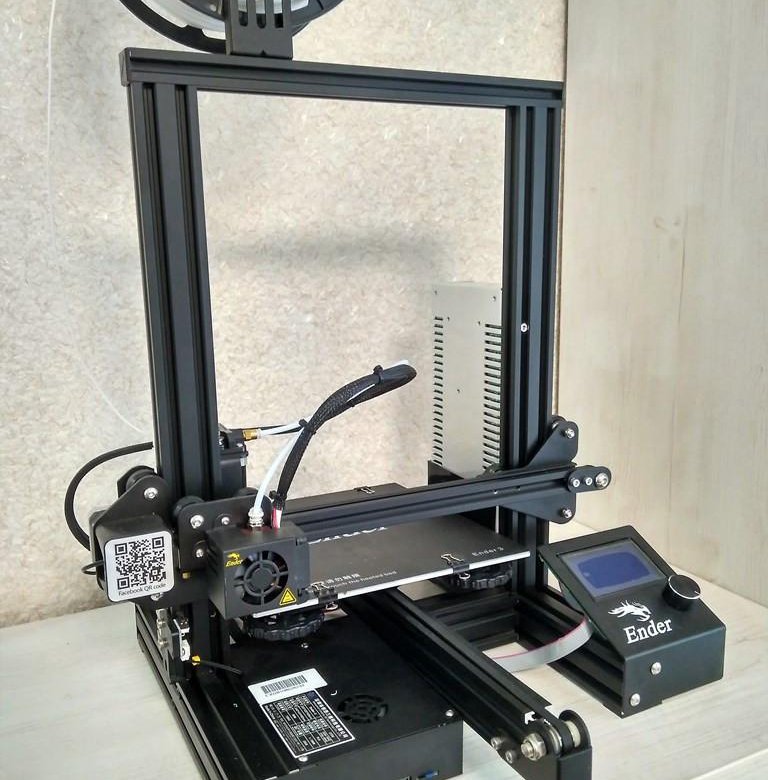

In 3D printing, the toolpath has a direct influence on the printing time, material cost, and mechanical properties of the printed object. Prior to his PhD, Kuipers spent three years as a software engineer at Ultimaker, a 3D printer manufacturer. There, he worked on algorithms for toolpath generation, also known as slicing.

A critical part of the 3D printing process, this software is responsible for converting a 3D model into specific instructions for the printer. “Normally, software just stays in a computer, but with 3D printing it becomes something real,” says Kuipers. “That’s what really drew me to 3D printing.”

“Normally, software just stays in a computer, but with 3D printing it becomes something real,” says Kuipers. “That’s what really drew me to 3D printing.”

Read Tim's thesis:

The beauty of FGMs

Manufactured functionally graded materials (FGMs) have a lot of potential. Rather than a homogeneous block of material, FGMs consist of a fine-scale geometry of one or more base materials and can have varying properties such as colour or stiffness. Manufacturing products with FGMs requires fewer components and materials because a single material component can have different properties in different regions. That means you can actually improve a product’s performance by optimising the spatial gradation of material properties throughout the product. And the potential applications for FGMs are broad, ranging from personalised footwear to medical devices to airplane wings.

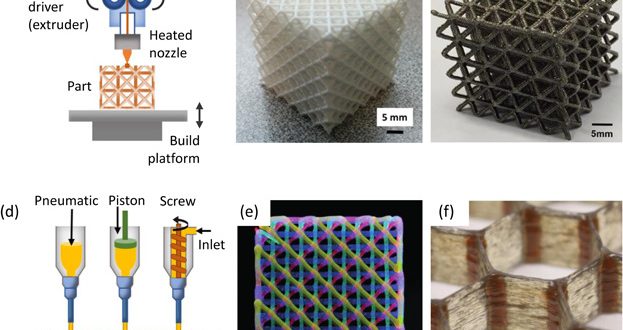

Why FFF?

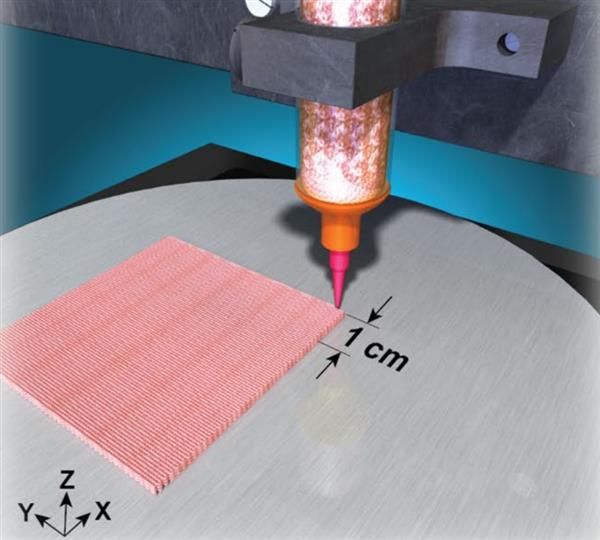

While each 3D printing method has its own advantages and constraints, fused filament fabrication (FFF) has exploded in popularity in recent decades. This is in part because it is relatively low-tech (easy to use) and less expensive than some other methods. In FFF, thermoplastic material is extruded through a heated nozzle to create objects layer by layer.

This is in part because it is relatively low-tech (easy to use) and less expensive than some other methods. In FFF, thermoplastic material is extruded through a heated nozzle to create objects layer by layer.

As Kuipers explained in his thesis, a 3D model is converted into toolpaths for the 3D printer, which describe the geometry of the extrusion lines the printer’s nozzle should traverse. But there are several manufacturing constraints to take into account in this process. For example, you have to consider the maximum overhang angle to prevent printing in mid-air as well as use chemically compatible materials to prevent a multi-material print job from falling apart during the manufacturing process.

Exploring different perspectives

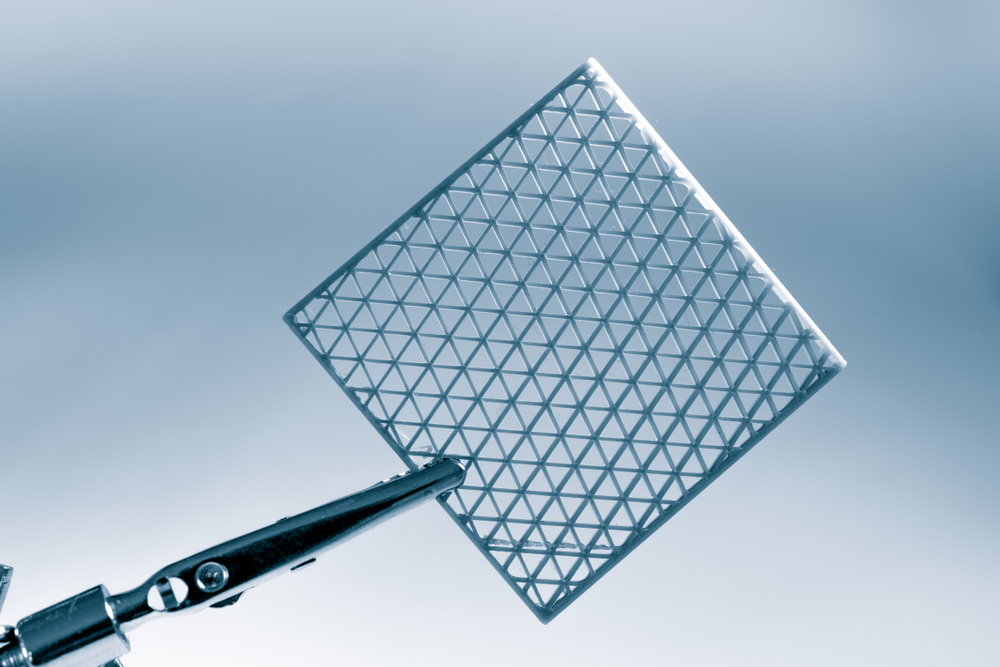

Kuipers investigated four different perspectives on how toolpaths can be used in FFF to create FGMs that addressed some of the constraints and resulted in innovative contributions. The first cycle of his research focused on properties of the product such as colour (grayscale) and surface roughness. Next, he researched how foams can be printed with flexible material which allows for varying densities and stiffness. Furthermore, he explored printing structures with chemically incompatible materials and proposed a mechanism for interlocking two materials using a repeating lattice structure at the interface between the two bodies.

The first cycle of his research focused on properties of the product such as colour (grayscale) and surface roughness. Next, he researched how foams can be printed with flexible material which allows for varying densities and stiffness. Furthermore, he explored printing structures with chemically incompatible materials and proposed a mechanism for interlocking two materials using a repeating lattice structure at the interface between the two bodies.

Finally, he worked on generating toolpaths for variable width geometry and introduced a more reliable method for printing thin geometry with a spatially graded thickness. Such structures can be used to create FGMs with a functionally graded stiffness. “I think what I’m most proud of is that this framework is now being integrated into the commercial software called Cura, which is an open-source slicer for 3D printing that is not only used by Ultimaker but by loads of printers all over the world,” he said. “There are potentially millions of people I’m reaching with this research so that’s really cool.”

“There are potentially millions of people I’m reaching with this research so that’s really cool.”

The big picture

If FFF technology can be used to manufacture FGMs, Kuipers said that designers and researchers with access to such additive manufacturing systems could design more complex products with improved performance. At the same time, using FFF technology means that FGMs can be produced at a lower cost and with a wider range of materials, unlocking a broader range of applications. In otherwords, the future looks bright for 3D printed metamaterials.

Future plans

After his PhD, Kuipers plans to take a year-long sabbatical to travel and consider what the next phase of his life will look like.

3D printed metamaterials and better sound

You are here

Home

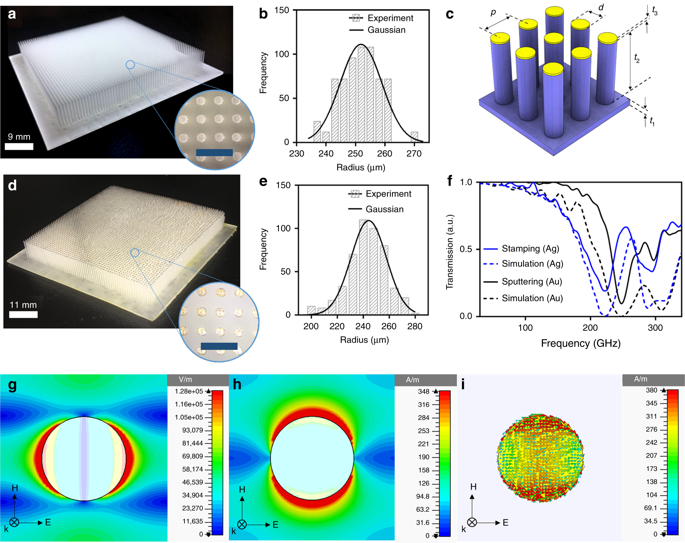

British researchers have developed a 3D printing method to manipulate sound. According to scientists, such experiments with additive manufacturing of materials can improve sound transmission in concerts and theaters.

What are acoustic metamaterials?

Researchers at the British universities of Bristol and Sussex have developed new 3D printed metamaterials that are changing the way sound is transmitted. They believe that one day their work could be used for many purposes, from improving the sound in concert halls to creating high-intensity ultrasound to fight tumors.

The idea is similar to the manipulation of light rays: whether it is directing the light to one point or scattering it throughout the room. With the help of acoustic metamaterials, researchers hope that it will be possible to either amplify or transmit sounds with the most accurate directionality.

With the help of acoustic metamaterials, researchers hope that it will be possible to either amplify or transmit sounds with the most accurate directionality.

Acoustic metamaterials are common materials (such as plastic, paper, wood, or rubber) but constructed in a special way. In other words, their internal geometry shapes the sound passing through them.

The work of scientists is focused on 3D printing of metamaterials in the cavity of bricks, more reminiscent of Lego. Such building blocks are assembled into structures for the manipulation of sound waves. For this, different methods are used. Certain frequency bands can be distributed, filtered or focused. This makes it ideal for problematic sound environments.

What will concerts and theatrical performances look like in the future?

To be fair, the concept of "acoustic lenses" has been around for fifty years. But this is the first time sound systems with "practical" sized lenses have been investigated.

In the future, acoustic metamaterials may change the way sound is transmitted in concerts and theaters. They will be able to ensure that every viewer really gets the sound they paid for. Scientists are developing sonic capabilities that can match the quality and richness of sounds with headphones.

The prototypes demonstrated by the researchers, while being simple, lower the threshold for creating new sound experiences. Devices based on acoustic metamaterials will lead to new ways of transmitting, perceiving and even sound “thinking”.

Source

Tags:

3D printed metamaterials, 3D printing method, sound manipulation, additive manufacturing, acoustic metamaterials, the concept of "acoustic lenses"

Other materials:

- Introducing ScanPod3D Orthopedic 3D Scanners

- Heineken Experience with 3D Printing

- Laser Stereolithography in Medicine

- Fabrication of XCT Parts from Domestic Stainless Steel Powder

- Preparation for materialographic analysis of 3D printed samples

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

Metamaterials. Auxetics.

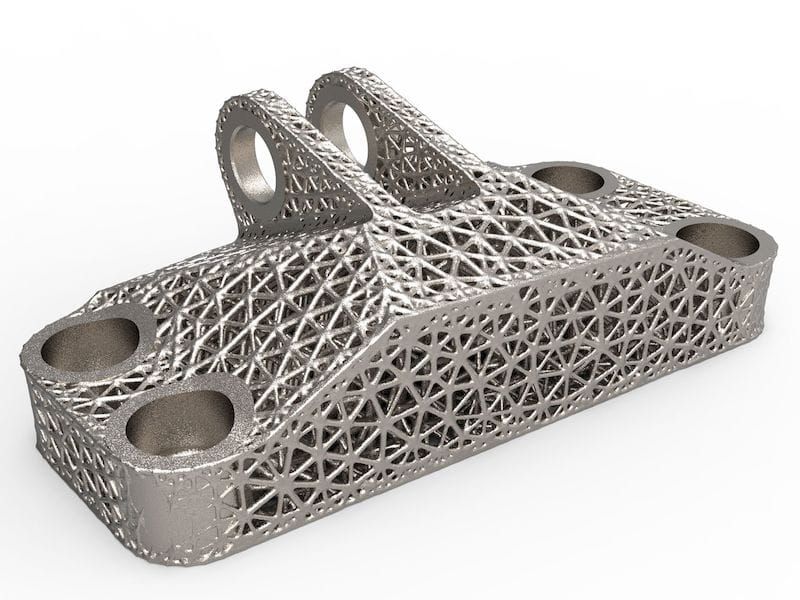

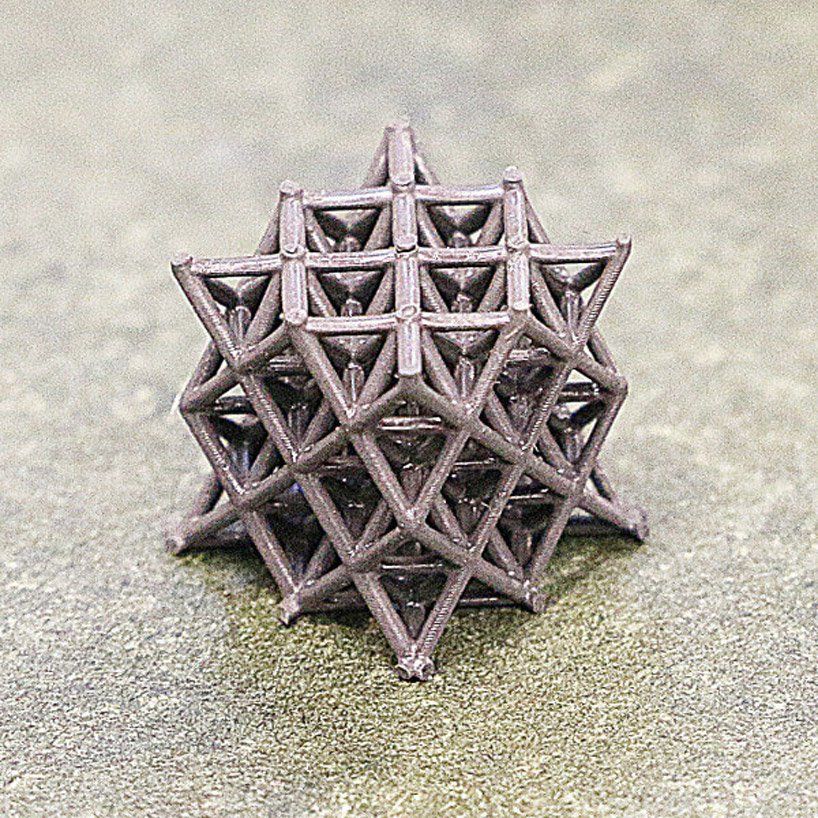

A promising area for the use of 3D printers is the creation of metamaterials. Metamaterials are materials whose properties are determined to a greater extent by an artificially created structure and to a lesser extent by the chemical composition or structure of molecules.

Before the advent of additive technologies, it was almost impossible to create such materials. Today the situation has changed a lot. Now a large number of scientific studies on metamaterials are carried out in the field of acoustics and electromagnetism. But this article is not about them. I will talk about one of the types of mechanical metamaterials - auxetics. Such materials have a negative Poisson's ratio.

The first artificially created auxetic can be considered the material obtained by Roderic Lakes (Roderic Lakes)[1] in 1987 year. It was a foamed polymer, which was then deformed at elevated temperature. As a result, such a "sponge" had a negative Poisson's ratio.

As a result, such a "sponge" had a negative Poisson's ratio.

It is worth noting that auxetics are also found among ordinary natural materials. For example, cristobalite[2] is a mineral found in volcanic rocks. Presumably, the material from which our bones are made is also an auxetic [3].

For those who are not familiar with Poisson's ratio or have forgotten what it means, I'll explain using an example picture.

Take a plate with dimensions a by b and stretch it in the directions shown by the arrows. In the stretched state, the dimensions of the plate will change, let's denote the new dimensions as a' and b'. Poisson's ratio shows how much the size b will change if we stretch the plate along the size a. In this case, for ordinary materials, with an increase in the size a, the size b will decrease. For example, for most metals, the value of Poisson's ratio is approximately 0.3. This means that if we increase the size a of our plate by 10 mm, then the size b will decrease by 0. 3 * 10 mm = 3 mm.

3 * 10 mm = 3 mm.

As I said earlier, auxetics are materials with a negative Poisson's ratio. I will show this in the following picture:

Due to the negative Poisson's ratio, when the auxetic plate is stretched along dimension a, dimension b also increases. Personally, I was very impressed when I first met these materials. I immediately wanted to find schemes and try to print on a 3D printer. I found several scientific articles on auxetics and chose the most interesting, in my opinion, schemes.

The first scheme is the most common. The general view of the elementary fragment and the structure are shown in the picture.

At the first stage, I made a model of an elementary fragment, but with some modifications to check whether the printer can print all the elements, since in the model the minimum wall thicknesses are equal to the nozzle diameter (0.4 mm).

Printed. I printed all models with FLEX material.

The model was successfully printed and bent as it should and where it should be. Let's move on to printing a fragment of the material.

Let's move on to printing a fragment of the material.

The photo shows that the walls are not connected at the edges, it turned out that I made a mistake with the dimensions. According to the model, in these places the wall is 0.29 mm, and during slicing, this area was simply ignored. I did not notice this, but even so, the central cells still remained operational and, when compressed, the material shows exactly the properties that we expect.

This auxetic circuit proved to be very unstable. When compressed, the middle cells strive to move to the side.

At the end of the article there is a link to a video showing all printed circuits.

The following schemes are interesting in that the properties of the auxetic in them are not as obvious as in the first. The circuit in the picture is called chiral.

It should be noted that there are quite a lot of chiral auxetics. Here are some examples.

Making a model, printing.

It turned out even more interesting than with the first scheme.