Enclosed vs open 3d printer

Enclosed Vs. Open Printers - 3D Printers - Talk Manufacturing

mobius29er

#1

I originally started this thread on which printer to buy: link.

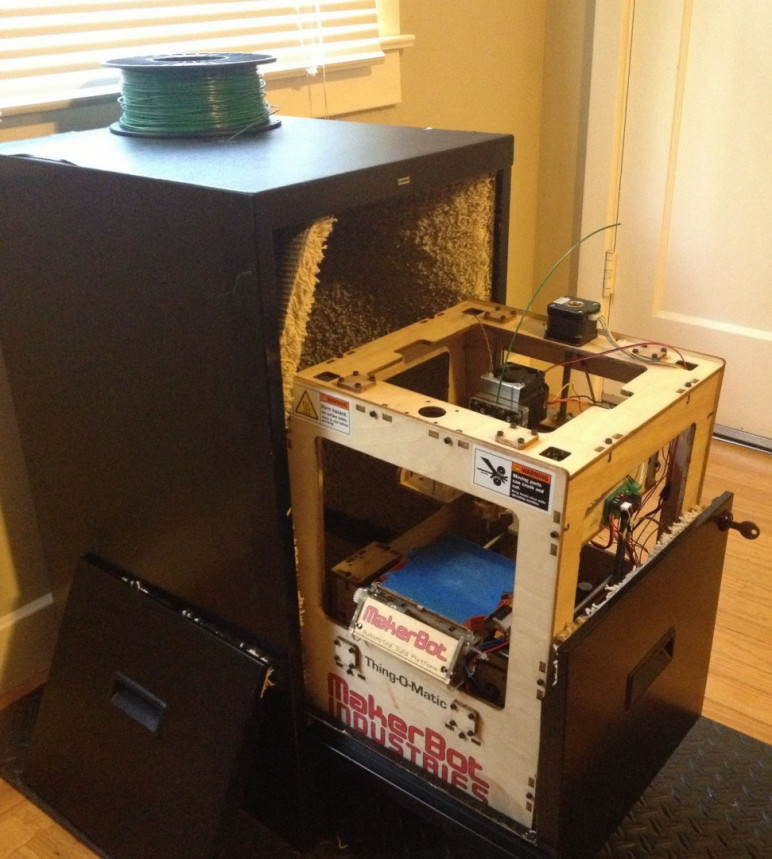

I had a lot of helpful responses. I am leaning toward the Lulzbot TAZ 5, but I was curious about the benefits/drawbacks of having an open 3D printer vs having an enclosed one (like the Ultimaker).

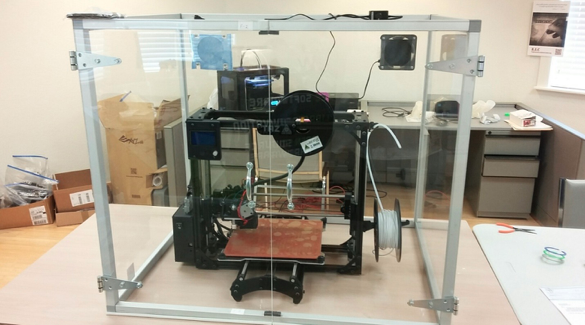

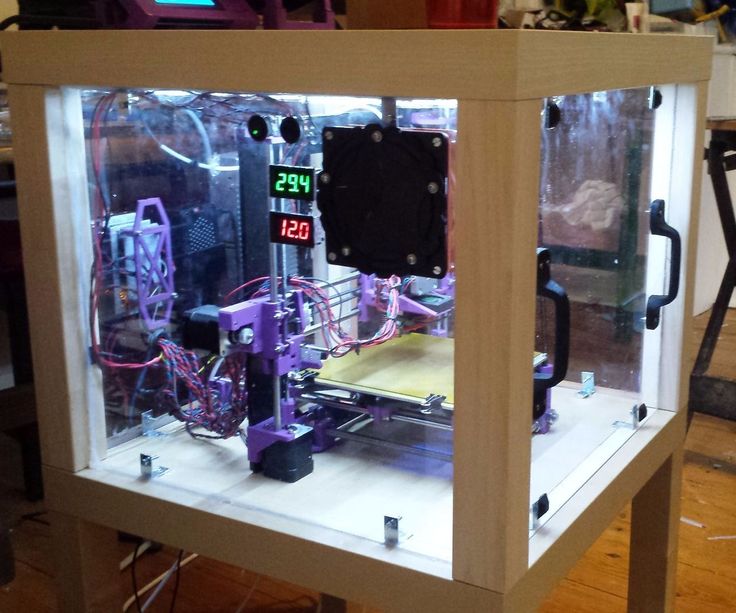

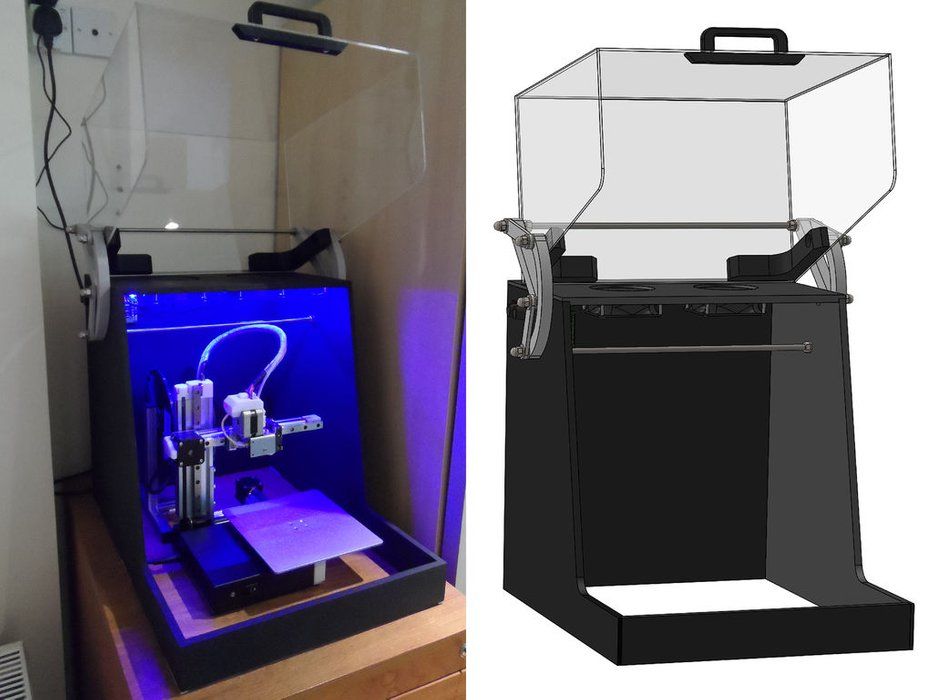

Also I am wondering if anyone knows of any Lulzbot enclosure makers or good forums on how to build a custom enclosure for an open printer.

James_McKinney

#2

I have a FlashForge creator pro, which is enclosed. As I understand it an enclosure makes printing ABS a lot easier by reducing cold drafts and helping raise the ambient temperature a little all in an effort to reduce warping.

1 Like

skyjames

#3

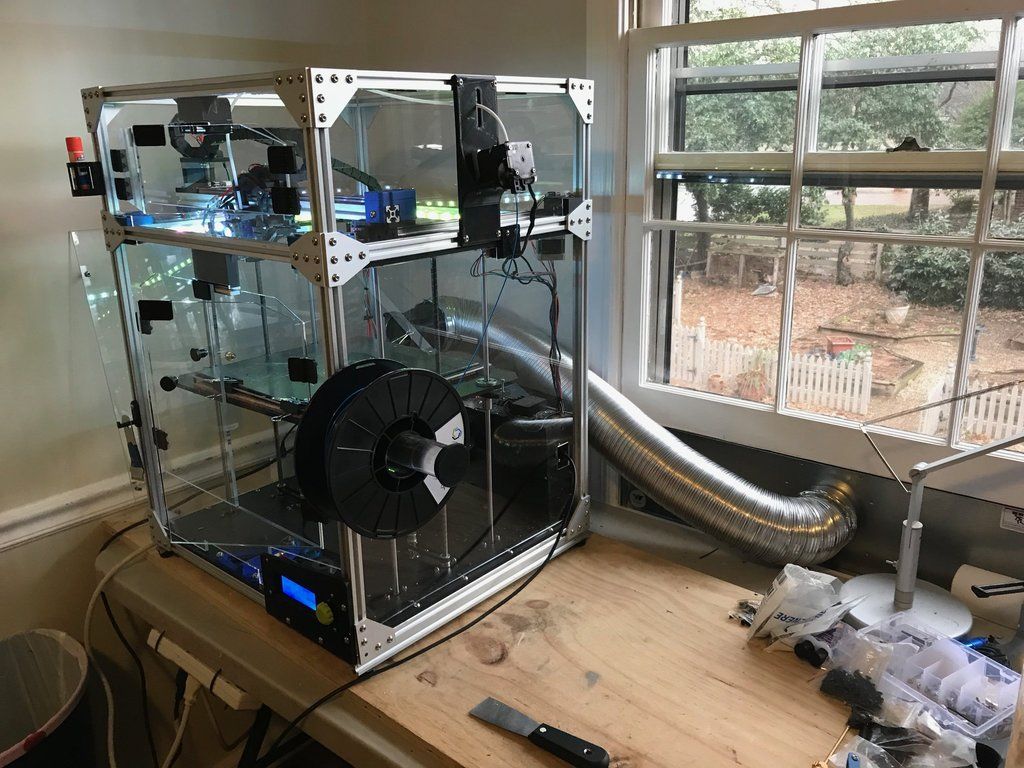

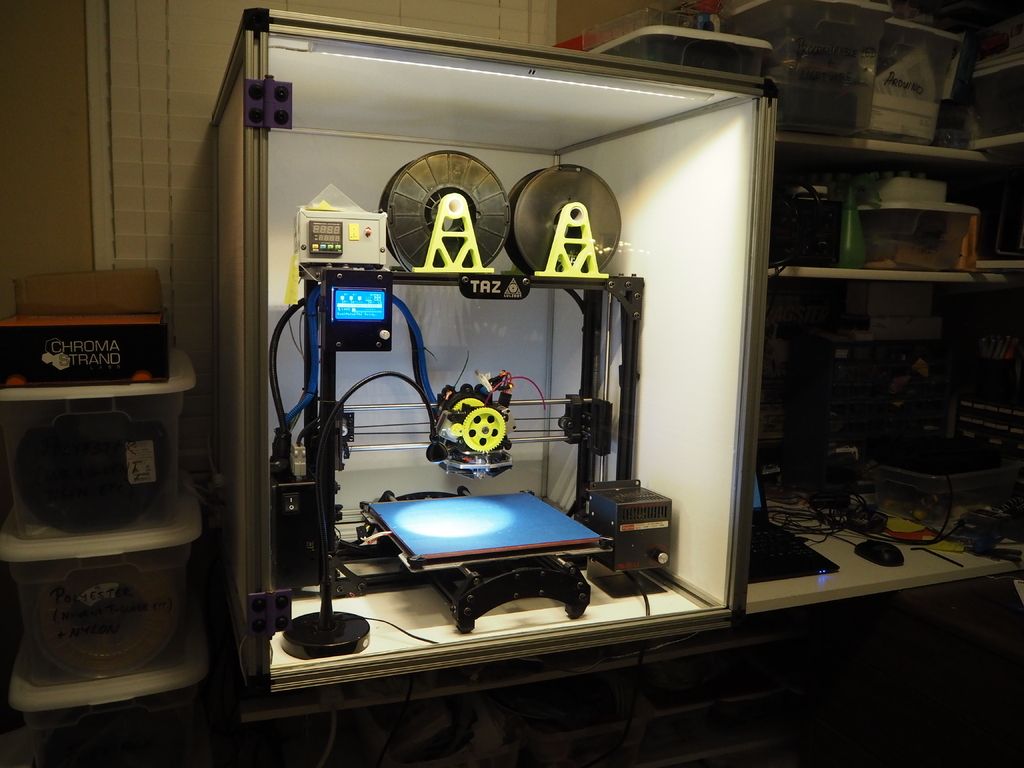

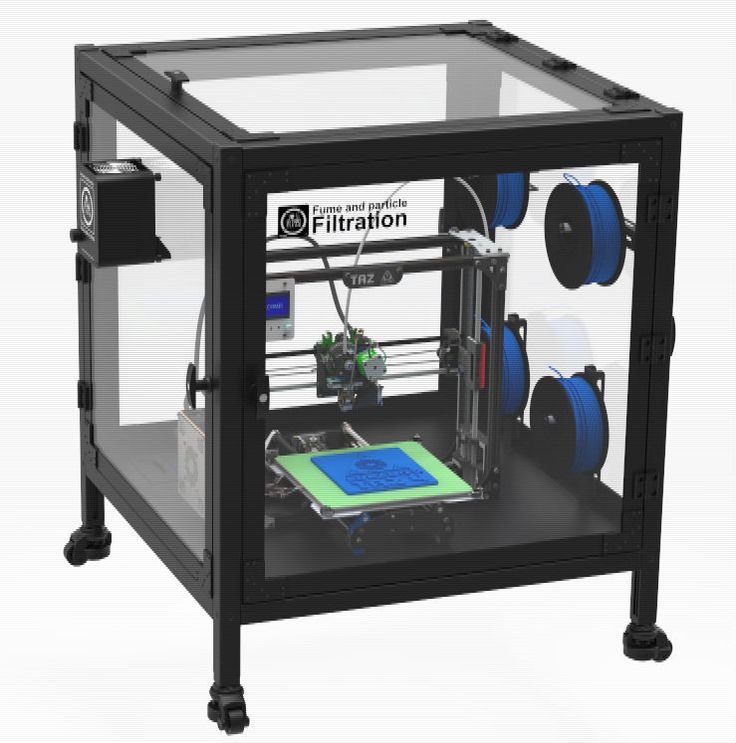

The reason to enclose a 3D printer are many: Contain any fumes, lower the noise it produces, and reduce the temperature fluctuations around the the part being printed. However the draw back of these added features is that number one it costs more and number two it adds complexity meaning more points of failure and also makes it harder to fix - i.e. instead of just reaching in and fixing or turning something you have to disassemble the enclosure first. It is hard to find a consumer level printer that has an actual enclosure that will provide a substantial benefit when it comes to keeping a steady temperature as most of them including the flash forge pro and the Ultimaker have an open top so that the filament can be fed in. Since heated air rises this means that it is constantly leaving the top. What it does do however is help prevent drafts from cooling the part and possibly warping it as in the case of ABS which can be a problem. Additionally the sides are usually just thin plexiglass which has minimal insulation value. Putting the printer in a complete enclosure (just google TAZ5 Enclosure - the majority are DIY jobs - just a box so you could easily figure one out) can work but the risk you run here is that the electronics will overheat as you are putting everything in the environment that is going to get heated (though this doesn’t seem to big of a deal or at least nobody admits it). If you go up to a professional grade 3D Printer this is one of the features they have. Basically the printer is a giant oven that is insulated as well as heated and keeps the ambient air temperature surrounding the part at a constant temperature - and you pay for that feature in spades. If simply enclosing a 3D printer made a significant difference in print quality all companies would spend the extra $100 dollars to do it.

Since heated air rises this means that it is constantly leaving the top. What it does do however is help prevent drafts from cooling the part and possibly warping it as in the case of ABS which can be a problem. Additionally the sides are usually just thin plexiglass which has minimal insulation value. Putting the printer in a complete enclosure (just google TAZ5 Enclosure - the majority are DIY jobs - just a box so you could easily figure one out) can work but the risk you run here is that the electronics will overheat as you are putting everything in the environment that is going to get heated (though this doesn’t seem to big of a deal or at least nobody admits it). If you go up to a professional grade 3D Printer this is one of the features they have. Basically the printer is a giant oven that is insulated as well as heated and keeps the ambient air temperature surrounding the part at a constant temperature - and you pay for that feature in spades. If simply enclosing a 3D printer made a significant difference in print quality all companies would spend the extra $100 dollars to do it. That being said if you plan on putting your printer directly under the air conditioning vent in your office, or next to the window that is always open even in the winter and you live in Wisconsin then an enclosure is worth considering. On the whole I would start off with whichever printer you decide on and then if you run into problems that enclosing it will fix then design the enclosure around that problem.

That being said if you plan on putting your printer directly under the air conditioning vent in your office, or next to the window that is always open even in the winter and you live in Wisconsin then an enclosure is worth considering. On the whole I would start off with whichever printer you decide on and then if you run into problems that enclosing it will fix then design the enclosure around that problem.

stopaginn

#4

I have a Taz 5 without the enclosure. The biggest issue is temperature stability. However, I do a test print before I print real high quality items and verify how the environment affects the print. My Taz is in the garage where I have, for the last week dealt with big swings in temperatures, but had great prints. The Taz is quiet and really the only plastic that smells is ABS. I don’t recommend an enclosure, my opinion.

I don’t recommend an enclosure, my opinion.

I do recommend the Taz 5 as it prints beautifully. I am using Simplify 3D software which provides every fine adjustment and control. However, I think Cura and Matter Control are very good slicers too.

sjohnson_NCSU

#5

A few comments:

1) An enclosed printer is a must when working with either a) large printed parts and b) high temperature materials like ABS and Polycarbonate to mitigate warping and to get great layer adhesion

2) Almost all of the consumer printers out there worth a lick are not enclosed. You mention the ultimaker, but its not actually enclosed. It looks enclosed, but the front and top are open so heat escapes.

3) You should look at the Fusion3 F400-S (http://www.fusion3design. com). Its in the same price range as the Ultimaker and Taz but is fully enclosed and has a much larger print area.

com). Its in the same price range as the Ultimaker and Taz but is fully enclosed and has a much larger print area.

3D Printer With Vs. Without Enclosure: The Pros & Cons

I was thinking about getting a new 3d printer and I saw that there were two different types: open and enclosed. So, I did some research into the different benefits and drawbacks of each. Then put together this helpful to explain what I found.

So, 3d printer with vs. without enclosure: what are the pros and cons? Open printers are easier to maintain. But, enclosed printers provide superior print quality. Open printers are less expensive than enclosed printers. Closed printers also require a lot of external addons that take up a lot of space.

There are a few reasons why you would get an enclosed 3d printer rather than an open one. Also, how much they differ in price is very interesting. So, keep reading and I will explain the reasons why you would get an enclosed 3d printer or open printer. As well as, pricing information differences between the two types.

As well as, pricing information differences between the two types.

Pros and Cons of an Open 3d Printer vs. an Enclosed 3d Printer

| Enclosed 3d Printer | Open 3 Printer | ||

| Pros | Cons | Pros | Cons |

| Superior print quality | Hard to clean | Easy to monitor the print | Good print quality. |

| Looks professional, impresses the wife | Hard to change parts | Easier to clean | Looks like a toy |

| Quiter | Harder to watch the print | Easier to change parts | No wind and dust protection |

| Can walk away from it |

As can be seen by the table above, an open 3d printer has a lot more advantages than drawbacks. An enclosed 3d printer on the other hand has much more cons than pros. But, the one factor that could trump all of them is the print quality.

Some manufactured products require the superior print quality that can only come from an enclosed 3d printer. More on this later.

Enclosed 3d Printer Pros

Superior print quality

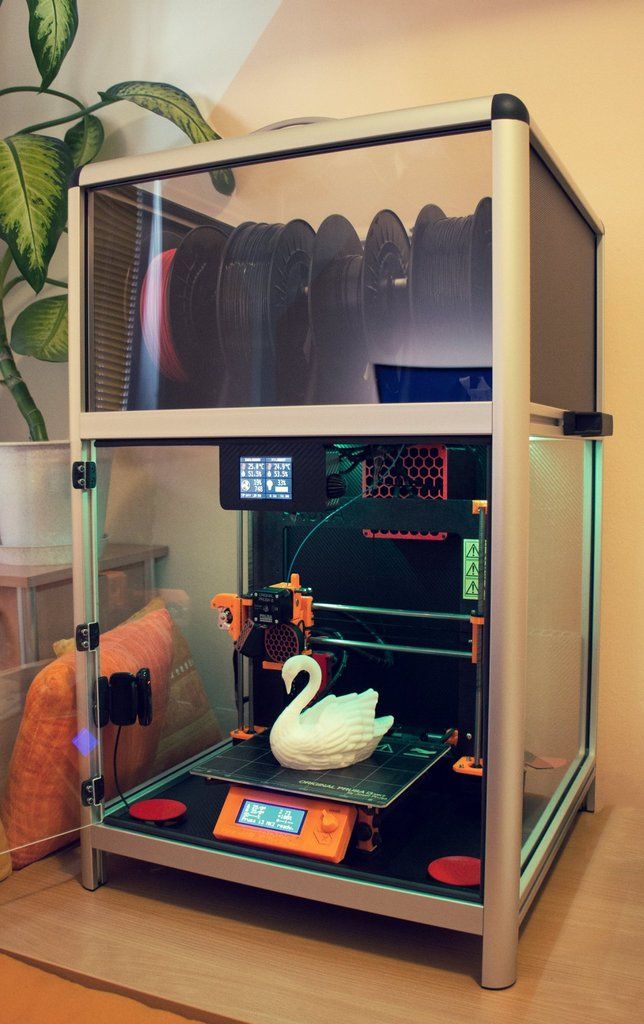

You get a superior print quality from an enclosed 3d printer. This is because the temperature is maintained at a stable temperature. When your 3d print cools unevenly it causes minor imperfections and warping. So, using an enclosure gives a more reliable and higher quality print.

On top of that, an enclosure stops dust and other particles in the air from landing on your 3d print. When particles land on your print as it is printing it leaves small indents.

When printing using PLA you won’t notice a difference between printing in an enclosed 3d printer or not. Unless it gets affected by particles. This is because PLA forms well at room temperatures, and isn’t so sensitive to temperature changes.

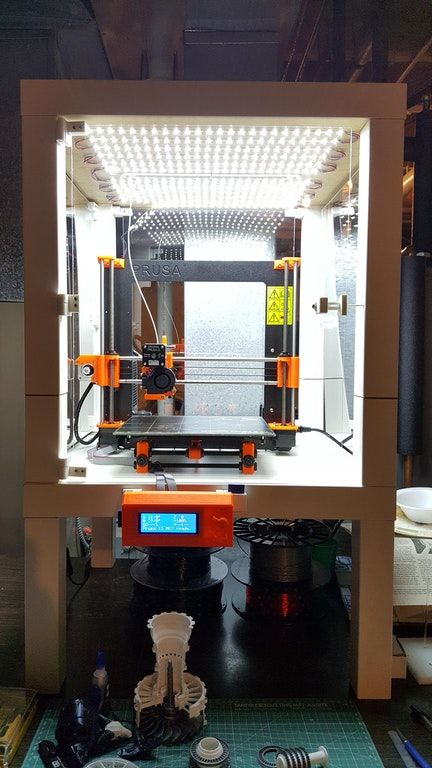

Looks professional and impresses your wife

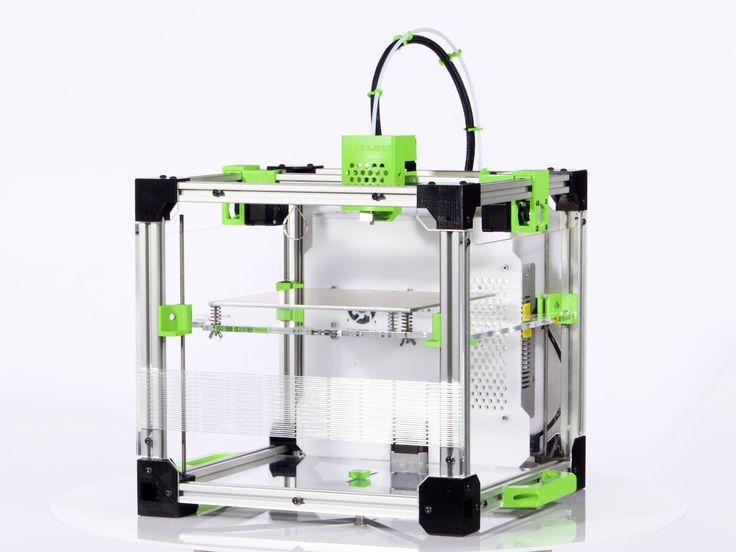

The “impresses your wife” bit is a bit of a joke. But, an enclosed 3d printer looks like a professional grade machine. Similar to what you would see in a hospital. Compare that with an open 3d printer and you can see the difference.

But, an enclosed 3d printer looks like a professional grade machine. Similar to what you would see in a hospital. Compare that with an open 3d printer and you can see the difference.

It keeps the parts inside your 3d printer safe when it is sitting on your desk, from accidentally bumping into it and breaking something.

Open 3d printers can look a bit like a toy. There’s the old adage ‘look good, feel good’. There is some truth to it. When you work on a professional looking machine you feel better about yourself and produce better quality work.

Quieter

The enclosure provides a noise barrier. So, you can’t hear the whirring and robot noises as your 3d printer works as much. Giving you more peace and quiet to explain the print. Let’s face it 3d printers are loud. Muffling any of the sound is a welcome relief.

Enclosed 3d Printer Cons

Hard to clean

The enclosed case creates many hard to reach places. Making it difficult to clean away waste plastic. Over time dust can build up, if you leave the case open.

Over time dust can build up, if you leave the case open.

You can also drop small tools into it. It’s a real nuisance when this happens. When getting a new one you should look for a model that has easy access around the machine.

You will likely want an air compressor, pipe cleaners, and other tools to keep your 3d printer clean and tidy. As always, you should consult your user manual for specific cleaning instructions.

Hard to change parts

When you need repair, work on, or upgrade something. It is a lot more work to take everything off, the shell, clips, and screws. And being able to see where screws are and there are tight angles that are hard to work with.

Harder to watch the print in action

If you’re printing a particularly delicate part and want to watch it for errors. Or, you need to line up a piece you are printing on. Both are more difficult with an enclosed 3d printer. Because the case blocks good viewing angles.

It’s a tossup between the cons and the noise factor. A 3d printer is noisy. You should look for reviews on the 3d printer you are buying to see if it is noisy. Prints that require lots of time like hours to days will drive you a bit nuts if you have to work next to them

A 3d printer is noisy. You should look for reviews on the 3d printer you are buying to see if it is noisy. Prints that require lots of time like hours to days will drive you a bit nuts if you have to work next to them

Open 3d Printer Pros

Easy to monitor the print

With an open 3d printer you can see any part of the print. So, if there are minor issues consistently coming up with your prints, you can see them. Compared with an enclosed 3d printer you won’t have as much trouble troubleshooting your prints.

It will save you more time, and be less frustrating when your prints aren’t coming out perfect.

Easier to clean

3d printer manufacturers in general recommend routine maintenance that should include:

- Keeping your printer 3d printer lubricated

- Cleaning out your filament nozzle

- Picking your extruder gear clean

- Replacing worn out build-surface area tape

- Updating your 3d printer firmware

According to Pinshape. com all of these take considerably less time with an open 3d printer. Accessing screws is way easier, and getting your hands into the right spot. Aim to get a 3d printer which comes apart easily, or is well designed. So that it is easier to maintain and clean.

com all of these take considerably less time with an open 3d printer. Accessing screws is way easier, and getting your hands into the right spot. Aim to get a 3d printer which comes apart easily, or is well designed. So that it is easier to maintain and clean.

Easier to change parts

This pro goes hand in hand with being easier to clean. Accessing parts and being able to see what you are working on with an open 3d printer is a huge advantage.

If you are the kind of person who likes to tinker then you should definitely go for an open 3d printer, as long as you are happy with how it looks.

Open 3d Printer Cons

Good print quality

Huh? Good print quality is a con. Yes, dear reader yes. Although the print quality of an open 3d printer is good. An enclosed 3d printer provides more consistent and better quality prints.

Partly because it blocks the dust and particles floating the air from landing on it. But, also because it keeps the environment around your print at an even temperature.

Sudden temperature changes from wind, or a sudden door open causes imperfections in your prints.

When a cool or warm breeze blows on your print as it is printing parts of it cool and melt at different rates. When your print is finally done it can show warping. Physicists and scientists would say it is due to a non-uniform temperature.

Looks like a toy

Entry level models and some beginner 3d printers look like a toy. If that’s not the look for you, you can upgrade to a more expensive open printer.

Alternatively, you can get an equivalent priced enclosed 3d printer. Enclosed 3d printers look more professional, and that you are serious about your 3d printing.

No wind and dust protection

The construction of an open 3d printer allows dust and wind to blow freely through the printer. With an enclosed 3d printer you don’t have this problem, because the protecting barrier blocks it.

So, you have to take steps to stop drafts, and excessive dust from getting on your prints.

Summary

Overall, it depends on your personal preference in regards to the pros and cons. The deciding factors are the noise, print quality, look, and how easy it is to clean and repair. Take into account your unique situation when deciding which one to get.

Why are some 3d printers enclosed?

Enclosing 3d printers came about to increase the print quality. In other manufacturing processes like metalwork screens are used to protect the user from sparks and heat. But, in the case of 3d printers the enclosing case keeps out unwanted wind and dust.

When the filament is squeezed from the 3d printer it is liquid and cools to become hard. When parts of the print become hard faster than others it makes the print collapse or warp.

So, an even temperature is required to print well. There’s nothing worse than a collapsed print.

When a 3d printer is enclosed it protects from dust, pet hair, and other small particles that can stick to the surface of a drying print. In doing so, the prints come out perfectly.

In doing so, the prints come out perfectly.

Do 3d printers require enclosures?

3d printers can be used with or without enclosures. It’s up to you. The main reason people use an enclosure is to reduce imperfections that result from wind and dust. When the surface temperature of a 3d print cools unevenly it leaves ripples and distorts the shape.

If you are printing and a cool breeze comes through it can make your prints fail. This is the key reason why people use enclosures.

It has added benefits of keeping it safe from pets, or children. As prints take a long time, you may have to step out of the room. So, it is nice to know that your 3d printer is enclosed.

Particles in the air also settle on the surfaces of 3d prints when they are open. This leaves little marks on your prints surface. Therefore, you do require an enclosure for your 3d printer if you are worried about a pet or person touching it, or if you have it in a drafty room.

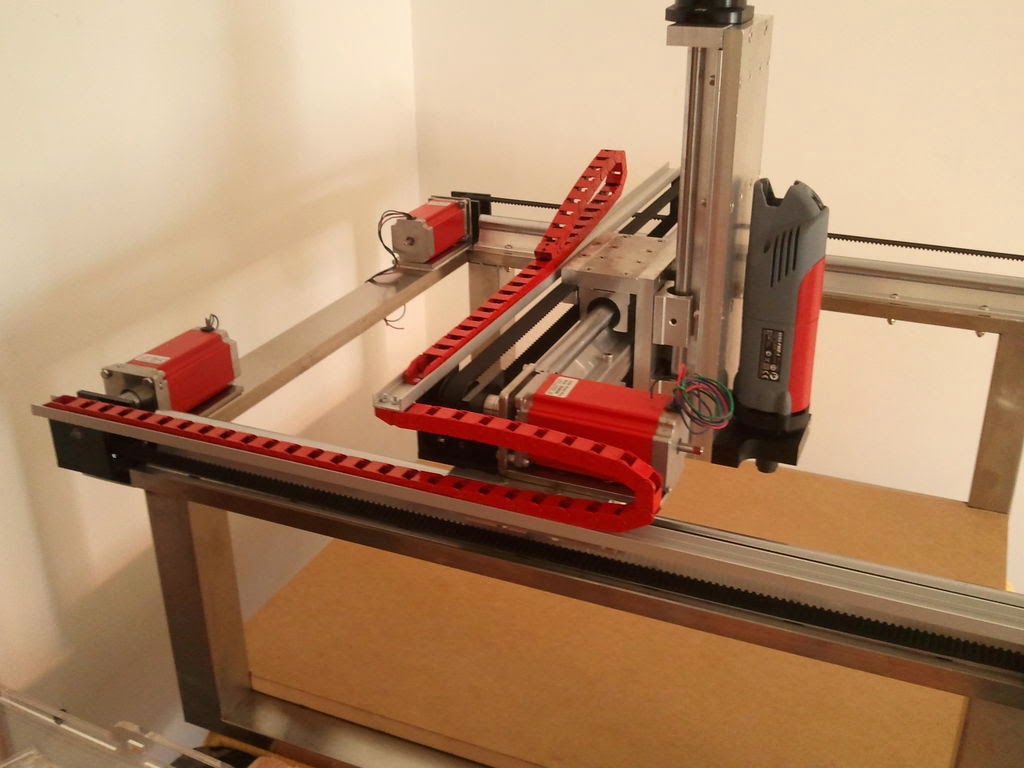

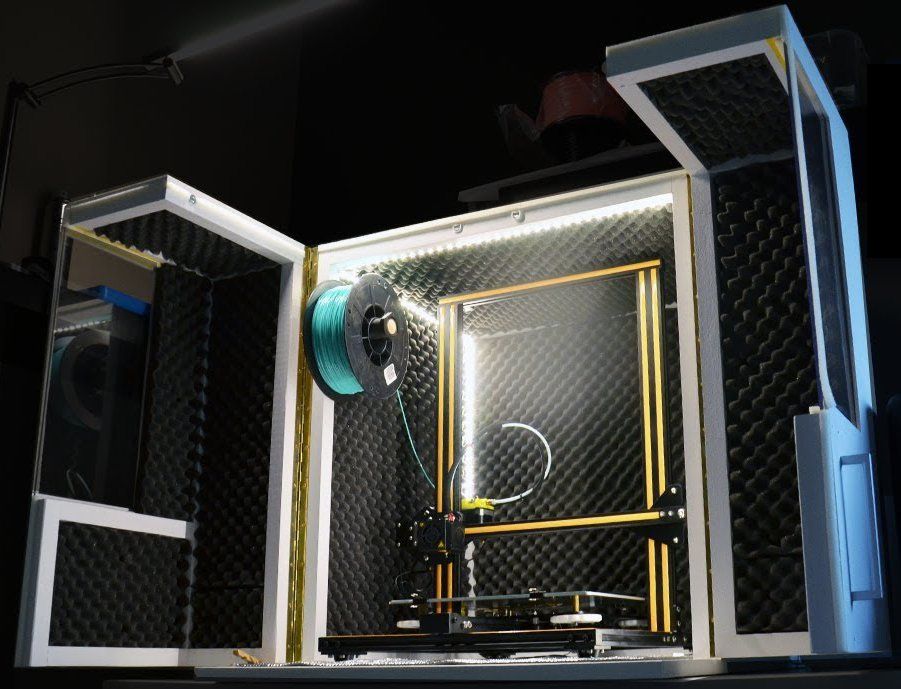

How do you build an enclosure for an open 3d printer?

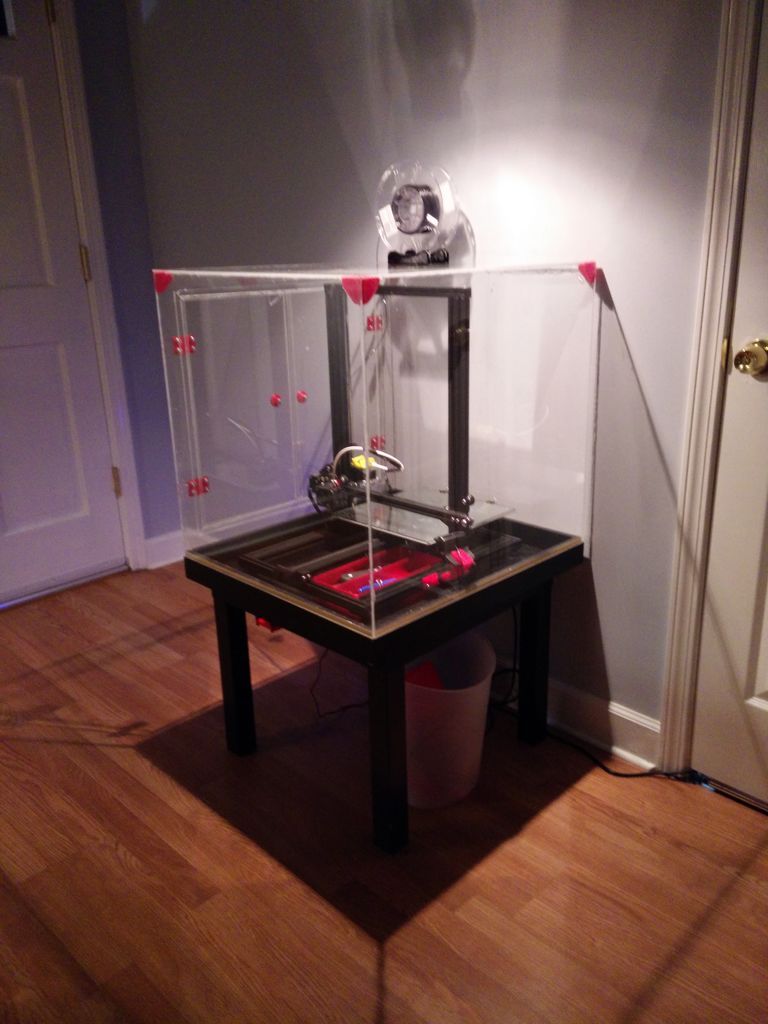

You can use a photo studio tent as a 3d printer enclosure. Although they weren’t made originally for it, they are the perfect size to fit a 3d printer.

Although they weren’t made originally for it, they are the perfect size to fit a 3d printer.

They are really inexpensive and start from about US$15. You can find a few options here.

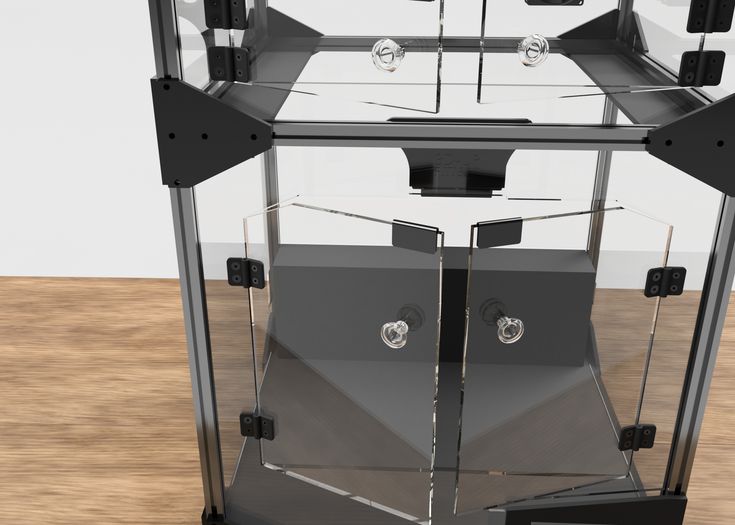

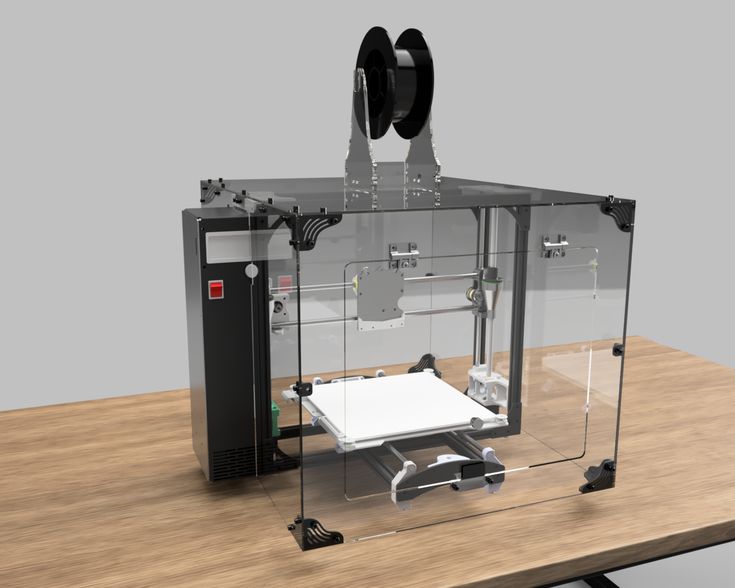

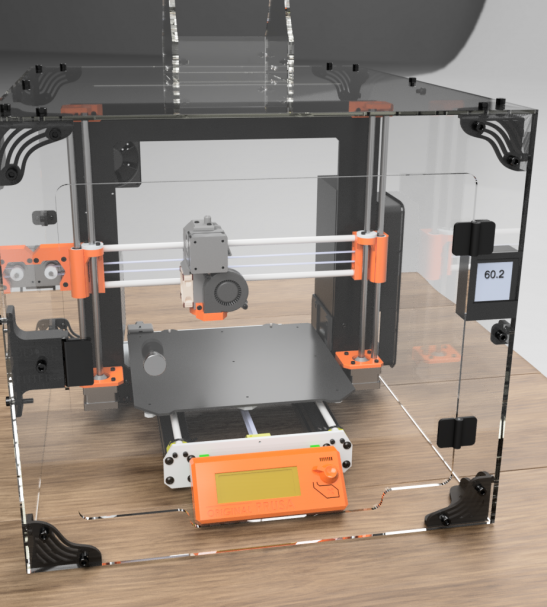

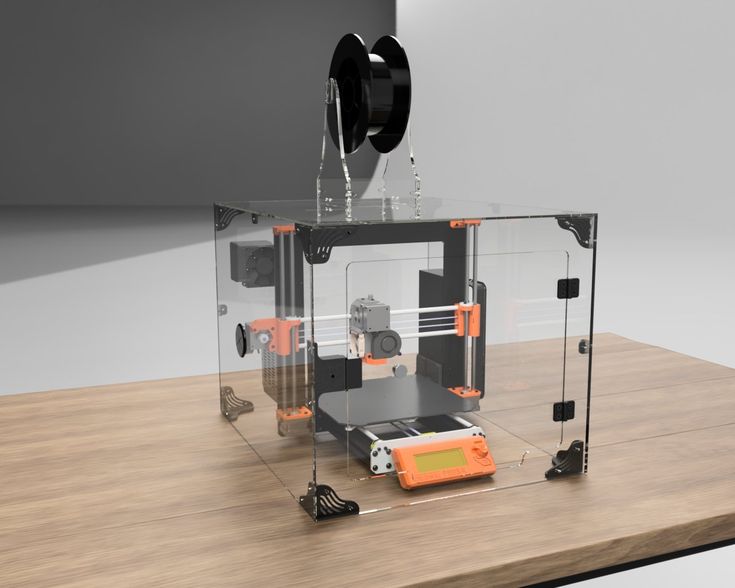

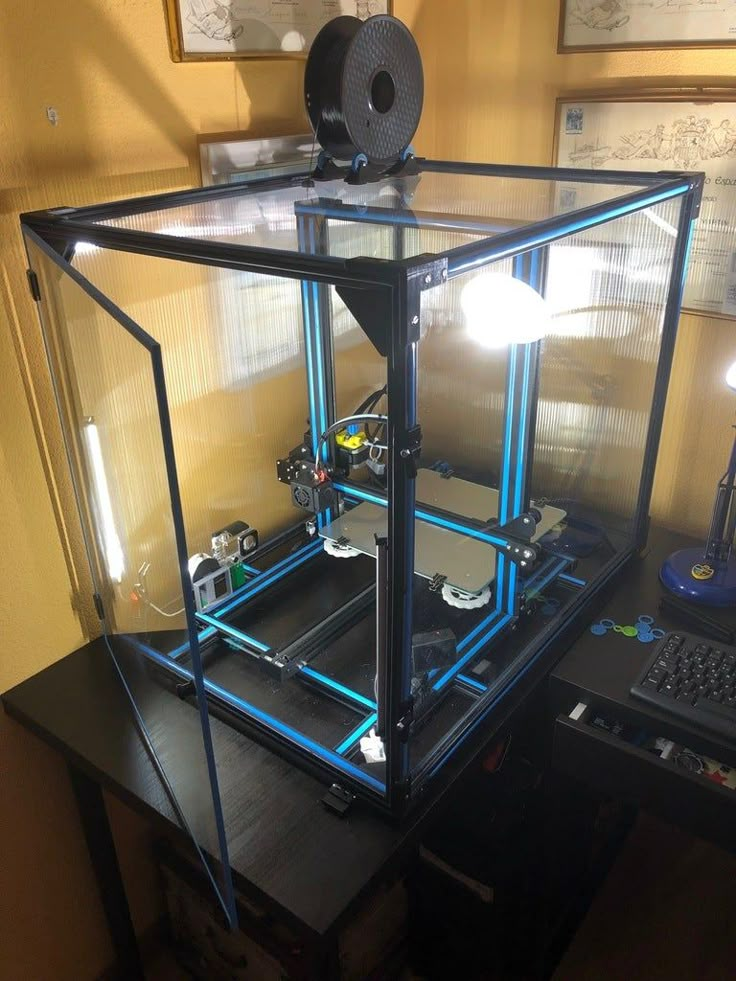

Other methods involve using perspex and plastic parts to construct a see through cabinet.

Here is a video with some cool ideas for how to make one that is easy access, and lets you see your prints easily.

Is it safe to have a 3d printer in your room?

In general, it doesn’t matter what room you put your 3d printer in, as long as it has a good environment for printing. The factors you want to look out for when choosing a room for your 3d printer are the temperature, humidity, sunlight, and windflow.

Temperature

You want to aim for an even temperature. The temperature that your 3d printer should run out varies by brand and model of 3d printer. Most are about room temperature.

So, watch out for rooms that are difficult to warm in winter. Otherwise, when you want to print in the winter you will have to turn on the AC, or heat the room for a long time. Which may or may not be practical for you.

Alternatively, you can use a small radiant heater. But, I would avoid the fan times as they may blow your print and change its shape.

An open 3d printer is easier to use during cold temperatures than an enclosed 3d printer. Because you can’t use a radiant heater to warm the surrounding area.

Humidity

An overly humid room is unsuitable for 3d printing. Most 3d printing manufacturers recommend humidity below 10-15%. In winter humidity can get upwards of 50%+.

A dehumidifier is a solid option to get the humidity down to the required levels. One that I recommend is the [affiliate link] because [product benefits].

You should definitely check it out, if you need to lower the humidity of your room for 3d printing. You can monitor the humidity levels in your room by using a humidity reader.

When the room is too humid the 3d print doesn’t dry fast enough. It is due to some complicated thermal physics.

But, because it doesn’t dry fast enough the print starts to buckle under its own weight. Giving you a print fail.

Sunlight

Sunlight is hot and dries out your prints. You don’t want to print in direct sunlight especially the very hot midday sun. Early morning and late evening sun is OK. When the sun shines on your prints, it dries unevenly. It then is more brittle.

So, if your room has heaps of sun then consider closing the curtains. If you need to print for a long time, you may want to consider moving your 3d printer to another room.

Windflow

Some rooms are drafty. You want to limit wind blowing around your 3d print. According to thermodynamics observations when wind blows on a hot surface it carries away the heat. It cools it more quickly.

It cools it more quickly.

With 3d prints you want it dry and harden evenly. When a breeze comes through it changes the temperature making it either hotter or colder. Either way it causes your prints to fail, and should be avoided.

There are a range of things to dry to lessen drafts in your room. According to Simplemost.com, they are:

- Using weather-stripping

- Install new sweeps

- Use foam tape

- Apply rigid foam insulation and foil stripping

- Apply window film

- Hang insulated curtains

- Use a door snake

- Re-caulk your windows and doors

Look to eliminate drafts using the above methods to get the best quality prints. Or choose a less drafty rim to 3d print from.

Is it safe to run a 3d printer overnight?

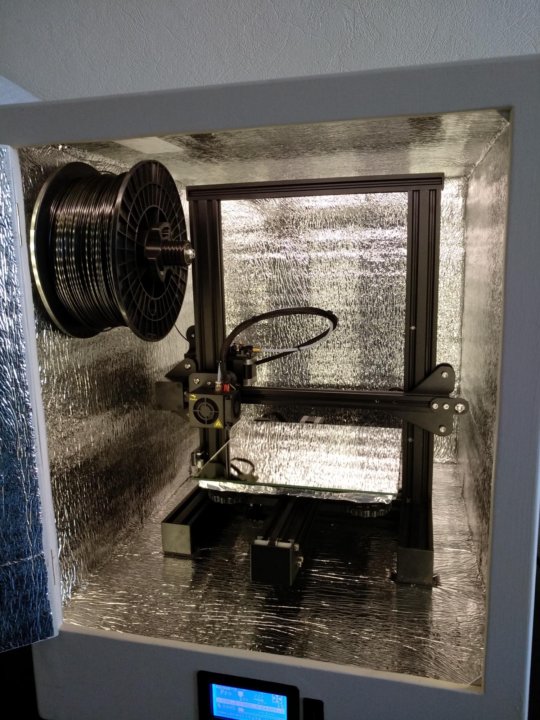

It is generally unsafe to run a 3d printer while not supervising it. With that being said, depending where your 3d printer is located it can make sense to run it overnight. For example, if it is in your garage. 3d printers are really noisy.

3d printers are really noisy.

So, unless you have an enclosed 3d printer or have it at the other end of the house it will be too loud to sleep through. You might get used to the noise after a while though, and it depends how heavy a sleeper you are.

If you have an open 3d printer your cat or dog can injure itself if it starts to play with it. Because it moves around erratically. So, make sure it is enclosed. You can even build a makeshift cover if you are the hands on type.

Take a look at the specific manual for your 3d printer to see what they recommend. The worst thing that could happen is the gun fails and empties the filament tank. Any other issue is very rare, and is similar to asking can I leave a fridge on overnight.

Does a 3d printer use a lot of electricity?

On average using a 3d printer consistently costs about USD$2 per month on the high end with most people paying about USD$0.50 per month to power their 3d printer.

This is very low, so therefore 3d printers use hardly any electricity.

Can a 3d printer catch on fire?

3d printers can catch fire. But, not more so than any other appliance. 3d printers heat filament using a heating tray. As it heats up if anything is close to it, it could catch fire. The radiant heat, however, is not nearly hot enough to catch a lite.

The risk of fire is the same whether you are using a 3d printer or a different appliance, and you should take the same precautionary measures. 3d printers do not make it more or less likely for a fire to start.

Is it safe to 3d print indoors?

It is generally safe to 3d print indoors. You do want to take some precautionary measures when using your 3d printer however. These include:

Nano-particles

These are ultra-fine particles that are 1/10,000 a mm in diameter, according to Wikipedia. They are too small to be seen by the human eye. But, they can be inhaled, and ingested accidentally. This causes issues with the respiratory system and bodily functions. So, you should ensure that you have good ventilation and wear a respirator mask.

Chemical vapors

When heating the filament some toxic vapors can get released. The most commonly used printing materials are Polylactic Acid (PLA), and Acrylonitrile Butadiene Styrene (ABS). You should look into the specific safety precautions for the filament you are using.

This information can be found in a manual that comes with your filament, or online on their website.

Does 3d printing smell?

When the goo (filament) gets heated it gives off a strong chemical smell. It is a good idea to print in a well ventilated room.

How long can a 3d printer run?

Some 3d prints can run up to one week. This is for very slow or large prints. Most people prefer not to do such long prints because then it has to print through the night. There is something a bit unnerving about leaving a 3d printing running overnight.

Though, there is no risk of anything bad happening, you feel more comfortable if you can watch it, and turn it off if something goes wrong.

When people print over many days they will stop during this time anyway to change the filament reel, or to start a new printing section.

So, most people don’t run their 3d printers for prolonged periods, and you can just pause it overnight depending on your specific printer, and it’s software.

Do you need an enclosure for ABS?

ABS filament does not need an enclosure to create professional looking 3d prints. In general when printing with ABS you want to:

Pay close attention to the first layer

Ensuring the platform is properly calibrated can minimize lift off, and warping. You calibrate them using your 3d printer in most cases. There are a range of materials you can use to print on.

The best is glass. We did a full discussion on the different building surfaces on our article about whether to use glass or Buildtak. You should definitely give it a read. You can do so by clicking here to go to the article.

Always turn the heated build platform on

Printing with ABS filament requires a temperature of about 80 to 110°F (26. 6 to 43.3°C) for the building platform. This helps with adhesion of the first layer to the build surface.

6 to 43.3°C) for the building platform. This helps with adhesion of the first layer to the build surface.

If you are running into issues double check the recommended temperature for your exact filament. Some people experiment with using an ordinary glue stick. Like those used to make a scrapbook.

It is a good idea to double check all the settings before testing out using glue or tape on the build surface.

Look out for stringing

Stringing is where the filament leaves strings like when you pull apart cheese pizza. This is an indication that the filament is too hot. You will want to see what is causing your filament to get too hot. You may need to lower the temperature of your build plate, or open a window.

In Conclusion

The pros of using an enclosed 3d printer is that it gives you a more stable temperature, stops particles from getting on your print, keeps pets and curious hands off it, and stops a lot of the noise.

The cons of using an enclosed 3d printer is that it is difficult to clean, repair, or upgrade, and it’s hard to watch the print as it is printing. The advantages of an open 3d printer is that you can see what is going on when it is printing. It is also easy to clean, repair, and upgrade. The disadvantages are that it doesn’t provide the most stable temperature, it looks a bit like a toy, and it allows particles to get onto your prints.

The advantages of an open 3d printer is that you can see what is going on when it is printing. It is also easy to clean, repair, and upgrade. The disadvantages are that it doesn’t provide the most stable temperature, it looks a bit like a toy, and it allows particles to get onto your prints.

8 Best Enclosed 3D Printers of 2022 (All Price Ranges)

Enclosed 3D Printers prevent cold air from entering the print, causing warping or other problems. For basic materials like PLA, 3D printer cases don't matter much, but for more complex materials like ABS and Nylon, they will save you time and time again.

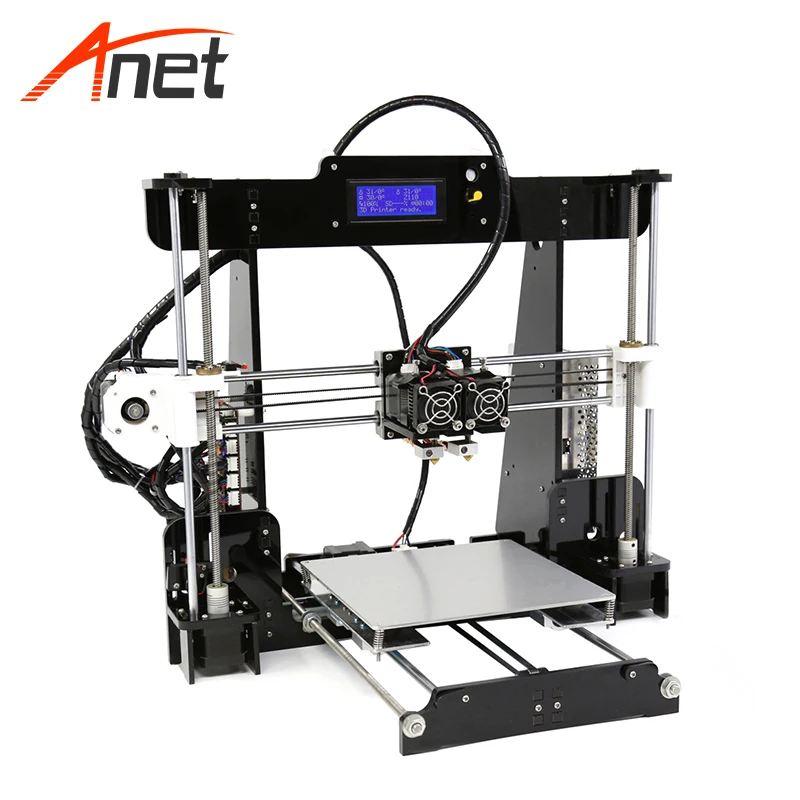

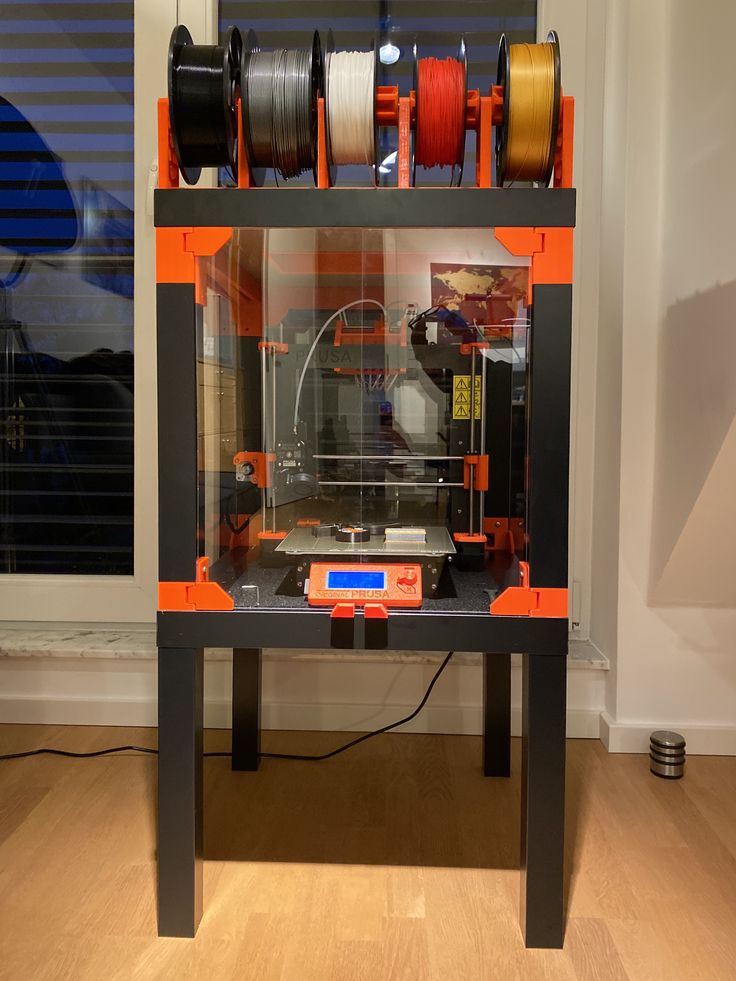

Most cheap 3D printers are open 3D printers - they don't have a frame or casing (sometimes you can buy them separately) and print outdoors. Almost all 3D printer kits like the Ender 3 and CR-10 are open source 3D printers.

However, this can cause problems. ABS, a widely used material for 3D printers, warps if it is not cooled slowly. In addition, closed 3D printers allow you to keep hot and dangerous parts of the 3D printer away from your hands and others. This is especially important for kids, which is why indoor 3D printers are some of the best 3D printers for kids.

This is especially important for kids, which is why indoor 3D printers are some of the best 3D printers for kids.

Contents

- Best Closed 3D Printers Under $1,000

- Flashforge Adventurer 3 Lite - cheapest indoor 3D printer

- Monoprice Voxel - budget indoor 3D printer

- QIDI Tech X-Pro - great 3D printer with 0 case

- Flashforge Creator Pro 2 - best inexpensive IDEX printer

- BIBO 2

- Best Enclosed 3D Printers for Consumers

- Dremel 3D45

- Raise3D E2

- Best High End 3D Printers with Housings

- Raise3D Pro2

- Ultimaker S5 (with housing kit)

- Buyer's Guide - What to look for

- Benefits of Enclosed 3D Printers

- Frequently Asked Questions

Best Enclosed 3D Printers Under $1,000

Flashforge Adventurer 3 - Cheapest indoor 3D printer

- Price: about $339

- Assembly volume: 150 x 150 x 150 mm

Flashforge Adventurer 3 Lite is a compact and quiet, fully enclosed beginner printer that provides friction-free printing. Printer setup is minimal other than a well-managed five-point calibration process, making it the best choice for beginners or students looking to start printing without the hassle.

Printer setup is minimal other than a well-managed five-point calibration process, making it the best choice for beginners or students looking to start printing without the hassle.

It is almost identical to the Adventurer 3, except for the built-in camera and thread runout sensor. These minor features do not detract from the simple typing experience.

In addition to a sleek, closed design, the Flashforge Adventurer 3 Lite has everything you need to handle tough materials like ABS: a flexible heated bed with a maximum temperature of 100°C and a maximum nozzle temperature of 240°C. With these features, you can also work with more exotic heat-sensitive materials such as metal, wood, and more.

It also has a wide range of connectivity options, including Wi-Fi and remote print monitoring thanks to FlashForge's 3D Cloud Print technology. The build volume of 150 x 150 x 150mm results in a narrow printable area, which is one of the few gripes I had when evaluating the Flashforge Adventurer 3 Lite. You won't have much luck printing bulky and tall parts, but this is easy to fix by printing in batches.

You won't have much luck printing bulky and tall parts, but this is easy to fix by printing in batches.

It is also worth noting that the filament compartment located on the side of the printer, although practical, is not intended for all types and brands of filament. You may need an external holder if your chosen third party filament is not suitable.

Key points:

- Closed chamber

- Rugged, beginner-friendly printer

- Wi-Fi connectivity

- Materials: PLA, ABS, Heavy Duty PLA, PLA Color Change, Metal Filled, Wood and High Speed PLA

Monoprice Voxel - Budget Enclosed 3D Printer

- Price: $449

- Assembly volume: 150 x 150 x 150 mm

The cheapest indoor 3D printer we recommend, the Monoprice Voxel is one of the best 3D printers for beginners. It's very easy to set up (within 10 minutes!), easy to operate with a touch screen, can print over WiFi, and comes with 8GB of onboard storage for 3D printer files. It comes with several 3D models in files, as well as some materials to get you started, so you can go from unboxing to printing in minutes.

It comes with several 3D models in files, as well as some materials to get you started, so you can go from unboxing to printing in minutes.

If you're new to 3D printing and aren't too tech-savvy, the assisted leveling system reduces the experience to a simple click. It also comes fully assembled, so you won't need any DIY skills, which is surprising considering most printers in this price range are 3D printing kits. It can also connect to Polar Cloud, allowing you to manage and control your printer remotely, and even do so for multiple printers at the same time.

Key Points:

- Cheap Indoor 3D Printer

- Beginner Friendly

- WiFi Printing and Touch Screen on an Inexpensive Device

- Materials: ABS, PLA, PETG, Flexibles

QIDI Tech X-Pro is a great 3D printer with a $500 case

- Price: $500

- Assembly volume: 230 x 150 x 150 mm

One of last year's most popular low-cost 3D printers, the Qidi Tech X-Pro offers reliability, precision, dual extrusion and an efficient closed area print, all for $500.

The layer thickness starts from 0.05 mm, the printer can print at speeds from 30 to 150 mm/s - although at such high speeds the print quality deteriorates noticeably. The printer is Mac and Windows compatible and can print over WiFi, USB or Ethernet.

Flexible, removable plate allows for easy removal of prints with minimal damage, and comes with Qidi Tech's own QidiPrint 3D Slicer. Overall, this is one of the best indoor 3D printers under $500.

Highlights:

- Large 4.5" touchscreen for ergonomic printing

- Flexible assembly plate

- WiFi printing and dual extrusion for $500

- Materials: ABS, PLA and PETG

Flashforge Creator Pro 2 - Best value IDEX printer

- Build volume: 200 x 148 x 150mm

A well-equipped update to the classic Creator Pro, the Flashforge Creator Pro 2 offers all the benefits of a case with features you don't expect to see in the $600-$700 range. We see it as an ideal second printer for manufacturers who have already completed their initial training on a budget FDM kit and are now looking for something more versatile and feature rich.

We see it as an ideal second printer for manufacturers who have already completed their initial training on a budget FDM kit and are now looking for something more versatile and feature rich.

While the Flashforge Creator Pro 2 has a solid, well-made enclosed print chamber suitable for both ABS and PLA thanks to its removable acrylic top cover, it's the independent dual extruder system that sets it apart from other best enclosed 3D printers.

The IDEX system is almost unheard of at this price point, giving manufacturers the flexibility to work with specular prints, duplicate prints, dissolvable support structures, and even print multiple materials or colors at the same time. It is suitable for complex prints with vertical overhangs or is the perfect tool to help the teacher to release as many student-designed prints as quickly as possible.

These two centerpieces aside, Flashforge Creator Pro 2 completes the offering with a touch interface, 200 x 148 x 150mm volume and compatibility with PLA, Pearl PLA, ABS, ABS Pro, PVA and HIPS materials.

It's worth noting that Flashforge made the wrong choice by tying the Creator Pro 2 to its own FlashPrint slicer. It does its job well enough, but doesn't have the versatility of an open source software suite like Cura. This isn't necessarily the deciding factor, especially for those new to 3D printing or educators who want simple software and pre-loaded settings specifically tuned to work with the Creator Pro 2 right from the start.

Highlights:

- Inexpensive independent system with two extruders

- Fully enclosed print chamber

- Materials: PLA, Pearl PLA, ABS, ABS Pro, PVA and HIPS

BIBO 2

- Price: $679

- Assembly volume: 216 x 187 x 160 mm

The Bibo 2 printer, with character and affordable for hobbyists, offers 50 micron accuracy, dual extrusion and WiFi printing, all for less than $1,000.

Although this closed 3D printer is not an IDEX printer, it still offers copy printing modes for printing two identical objects at the same time. It features an easy-to-use touch screen - which isn't a given in this price range - and has a low-filament detection feature to avoid spoiling prints.

It features an easy-to-use touch screen - which isn't a given in this price range - and has a low-filament detection feature to avoid spoiling prints.

In addition to the ABS and Nylon efficient 3D printing 3D printer body, Bibo is built in a stable and durable aluminum frame, minimizing unwanted vibrations that can slightly affect print performance and quality. Overall, this is a great indoor 3D printer for the price, and it can also come with a laser engraver kit.

Highlights:

- WiFi printing, dual extrusion and touchscreen, all for just over $500.

- Minimum layer height 50 microns

- Claims it can print polycarbonate but also says max temperature is 270C

- Materials: PLA, ABS, HIPS, flexible filaments, PETG, nylon, PC, carbon fiber

- Best Indoor 3D Printers for Consumers

Best Indoor 3D Printers for Consumers

Dremel 3D45

- Price: $1,599

- Assembly volume: 254 x 152 x 170 mm

Accurate, versatile and ideal for teaching 3D printing in schools, the Dremel 3D45 builds on nearly a century of Dremel manufacturing experience. Accuracy down to 50 microns, WiFi, USB or Ethernet cable connectivity, Mac and Windows compatibility, and iPad compatibility make the Dremel Digilab 3D45 the perfect addition to any school or business prototyping environment.

Accuracy down to 50 microns, WiFi, USB or Ethernet cable connectivity, Mac and Windows compatibility, and iPad compatibility make the Dremel Digilab 3D45 the perfect addition to any school or business prototyping environment.

The heated plate allows you to print on nylon and Eco-ABS, while the built-in HD camera provides convenient remote control of the print progress, which is easily done using cloud-based 3D printing software.

If you have any problems, the Dremel Customer Service in the USA is here to help you. Overall, this is a solid and accurate indoor 3D printer that offers good volume and results for the price.

Highlights:

- Powerful automatic leveling system

- Highly rated customer support

- Universal

- Materials: PLA, PETG, Eco-ABS, Nylon

- Price: $3,499

- Assembly volume: 330 x 240 x 240 mm

Raise3D Large Enclosed 3D Printer adds to IDEX's already impressive range of dual extruder 3D printers. The extruders of IDEX 3D printers can move independently of each other, which greatly increases the speed and efficiency of printing, especially when printing multiple identical or identical parts.

The extruders of IDEX 3D printers can move independently of each other, which greatly increases the speed and efficiency of printing, especially when printing multiple identical or identical parts.

Raise3D E2

The E2 printer has two basic modes:

Mirror mode: 3D printing simultaneously prints inverted mirror versions of your model, such as the sole of a shoe for the left and right foot.

Duplicating mode: uses both extruders synchronously, printing two identical objects at the same time and doubling the printing efficiency.

The E2 3D printer case keeps heat inside and everything else outside. If the door is opened during printing, the process is immediately suspended so that no one is burned or injured by the extruder or the heated layer. The E2 is also equipped with an efficient air filtration system that removes melted plastic particles and odors, as well as filament end sensors and power-off recovery functions.

Highlights:

- Build volume is reduced to 295 x 240 x 240mm when using the dual extruder

- Useful "Mirror" and "Duplicate" modes

- Built-in security measures

- Materials: PLA, ABS, HIPS, PC, TPU and TPE, PETG, nylon, PP, ASA, PVA, glass-filled filaments, metal-filled, carbon-fiber and wood-filled.

- Price: $3,999 / $5,999

Build Volume: 305 x 305 x 300 (605) mm

Top of the line 3D printers in the upper price range with housings

Raise3D Pro2

A true workhorse full body 3D printer, the Raise3D Pro2 series offers incredible precision, material compatibility, great workflow and many other key features.

The standard Pro2 already has a very large build area, while the Pro2 Plus extends the z-axis range to parts up to 605mm high. The extruders can reach temperatures of 300C for even the toughest materials such as PC, and the dual extruders enable efficient printing with support for soluble materials as well as multi-color 3D printing.

With a minimum layer height of 0.01mm, Pro2 3D printers can print incredibly sharp and finely detailed details. Swap out the nozzle for a smaller nozzle and focus on the small details to get a fantastic finish. The built-in camera makes it easy to control prints, while the 7-inch touch screen provides data and an easy-to-use overall workflow.

Highlights:

- Dual extruder build volume: 280 x 305 x 300 mm

- A complete printer: accurate, reliable, closed, versatile.

- Materials: PLA, ABS, HIPS, PC, TPU, nylon, ASA, PETG, PVA, glass, carbon fiber, wood.

Ultimaker S5 (with housing kit)

- Price: $5,995

- Assembly volume: 330 x 240 x 300 mm

The Ultimaker S5 is capable of printing industrial grade parts with layer resolution down to 20 microns. An enclosed 3D printer that becomes even more efficient and safer with the S5 Pro kit, the S5 delivers reliable and repeatable dual extrusion with amazing precision, even with abrasive filaments such as glass and carbon fiber.

Although Ultimaker manufactures its own filaments, the S5 is open and can be used with any 2.85mm filament. It prints over WiFi as well as other methods and can be monitored remotely using the built-in camera.

When you purchase the S5 Pro Bundle, you get access to 24/7 automated material handling, air filtration and heat control for 6 filaments, as well as an Air Manager that further encloses the 3D printer.

Highlights:

- Excellent accuracy and print quality

- Reliable and efficient in many materials

- Pro Bundle makes it even more efficient indoor 3D printer

- Materials: PLA, CPE, NYLON, ABS, glass, carbon fiber, PC, PVA, PP, TPU

Ultimaker s5 with optional pro kit including housing, air filter and filament storage

Buyer's guide - what to look for

Fully or partially enclosed chamber

Partially enclosed chamber printers are a bit of an oddity because they don't provide ideal printing conditions with either of the two main filament types, ABS and PLA. However, they provide an extra layer of security, which is useful for educational institutions or those with children. We recommend a fully enclosed chamber if you plan to print with ABS, and an open chamber if you choose PLA as your media. If you are going to print with ABS and PLA, choose an enclosed printer with removable covers.

However, they provide an extra layer of security, which is useful for educational institutions or those with children. We recommend a fully enclosed chamber if you plan to print with ABS, and an open chamber if you choose PLA as your media. If you are going to print with ABS and PLA, choose an enclosed printer with removable covers.

Stock Volume

Build Volume is the printable area available to you on a closed printer. In other words, it is a measure of the size and type of prints you can make. If you are planning on making large prints or multiple copies, we recommend high volume printers such as the Ultimaker S5.

Material Compatibility

By design, the enclosed 3D printer is designed to be compatible with a wider range of media types due to the ability to maintain higher temperatures around prints and keep cold air out. ABS is the most common type of material for sealed chambers, but you will also find printers that can work with nylon, PC, and other heat-sensitive materials. PLA can also be used if the printer covers are removable as this material requires cooler ambient temperatures for best results.

PLA can also be used if the printer covers are removable as this material requires cooler ambient temperatures for best results.

Heated bed

Given that the purpose of the closed chamber is to provide a stable thermal environment for printing with more complex materials such as ABS, a heated bed is a must. It helps provide an additional source of heat directly below the print, which promotes layer adhesion and slows down the cooling rate, thus avoiding unwanted defects such as warping and curling.

Connectivity

Connectivity determines how you interact with the printer, whether it's sending cut prints or fine-tuning settings. An SD card reader is more or less standard, as is USB in many cases, but for ease of use, there's nothing better than a Wi-Fi connection and thus cloud printing and monitoring.

Layer Resolution

Layer Resolution indicates the smallest layer height that can be printed. Choose a printer with a lower layer resolution for parts with more detail, such as 20 microns on the Ultimaker S5. On a closed FDM printer, 100 micron layer resolution is relatively standard and allows for a wide range of detail.

Choose a printer with a lower layer resolution for parts with more detail, such as 20 microns on the Ultimaker S5. On a closed FDM printer, 100 micron layer resolution is relatively standard and allows for a wide range of detail.

Filters

If you're buying a sealed chamber, your plan is most likely to include ABS printing. ABS not only has an unpleasant odor, but also emits potentially harmful fumes. A printer equipped with filters, carbon or HEPA, helps to extract the most toxic elements from the fumes. In addition, we also recommend working with ABS in a well-ventilated area.

Touch Screen

For convenience, we recommend an enclosed touch screen 3D printer. After all, we're all used to scrolling and swiping on our phones, so it makes sense to want the same functionality and familiar interface when working with a 3D printer. Most modern printers come with a touch screen as standard.

Price

Closed printers tend to increase in price as you pay for additional production and design. But thanks to the ever-increasing popularity of the budget category, enclosed camera printers are more affordable than ever before. You can easily buy a reliable indoor 3D printer for less than $400. Naturally, if you have the budget, new professional-grade printers that cost thousands of dollars also hit store shelves every year.

But thanks to the ever-increasing popularity of the budget category, enclosed camera printers are more affordable than ever before. You can easily buy a reliable indoor 3D printer for less than $400. Naturally, if you have the budget, new professional-grade printers that cost thousands of dollars also hit store shelves every year.

Benefits of Enclosed 3D Printers

Better ABS and Nylon 3D Printing

Housings can cool parts more slowly and maintain a more stable and higher temperature in the working chamber. This reduces buckling and splitting during the printing process.

Much safer

3D printer housings keep hot parts such as the nozzle and heated bed away from children if you have a family at home or if 3D printing is done in schools.

Quieter

The closed area keeps noise out, making them ideal quiet 3D printers. The enclosures keep out the buzz and hum of the printing process, which is a real boon if you're typing at home or in confined spaces with poor acoustics that can amplify noise levels.

Stronger and more durable

Enclosed 3D printers typically feature a sturdy four-walled cubic design that keeps vibrations and other factors from degrading print quality.

Noise Reduction

Enclosures help reduce noise by reducing hum and hum during printing, which is a real boon if you're printing at home or in confined spaces with poor acoustics that can amplify noise levels.

Drawbacks of Enclosed 3D Printers

More Expensive - 3D printers with enclosures are more expensive than open FDM printers. The logic here is obvious: manufacturers are forced to spend more money on raw materials and the assembly process, which invariably reflects on consumers.

Difficulty in maintenance and troubleshooting - Due to the enclosed design, maintenance of an enclosed 3D printer is much more difficult. Cleaning, replacing, troubleshooting or upgrading parts is much more of a hassle than an open design 3D printer.

FAQ

What is the 3D printer case for?

Enclosures help improve print performance by keeping hot air in and cold air/draughts out. For heat sensitive materials such as ABS, a stable higher temperature environment is critical for proper layer adhesion and reduced chance of warping, curling and other problems. Likewise, the shroud helps prevent dust and dirt from getting on printer parts and the print itself; this is essential for successful printing as contamination can affect adhesion and print quality.

Are closed 3D printers safer? Why?

Yes. The housing shields hot and moving parts from prying fingers and hands, reducing the chance of injury compared to open design printers where all parts are exposed and easily accessible. Whether you live with children or work in an educational setting with younger students, an enclosed 3D printer will give you peace of mind. In addition, filters, often installed in enclosed printers, remove toxic elements from the fumes.

How to maintain a closed 3D printer?

Maintaining a closed 3D printer is identical to maintaining an open design printer: regular cleaning of the bed and nozzle, updating the firmware, regularly inspecting parts for wear, leveling/calibrating the bed at regular intervals.

Are closed 3D printers better?

If you want to print on ABS, yes. The housing provides the correct, stable ambient temperature for ABS to thrive. On the other hand, if you are planning to print to PLA, an open design printer would be the best option. PLA needs plenty of cold air and ventilation to thrive.

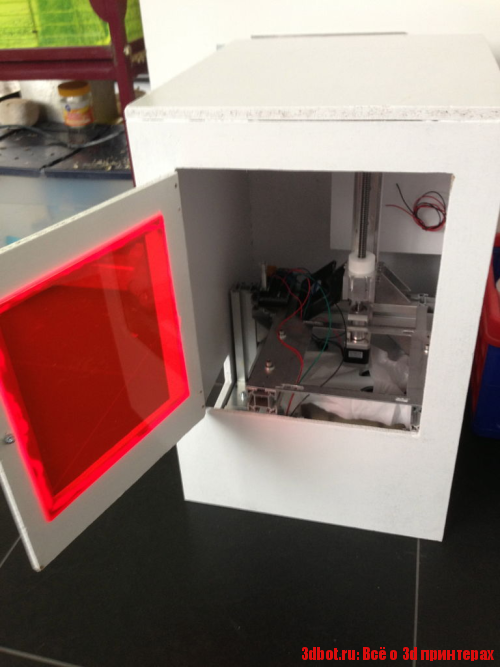

Wanhao GR2 3D printer (in a closed case) in Moscow

Out of stock

Add to compare

Item added to compare Go

10% discount on materials Free shipping within Russia

68 900 ₽

75 900 ₽

-9%

Exchange of old equipment for a new one with a surcharge. Detailed information is available on the page or from our managers.

Detailed information is available on the page or from our managers.

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When you buy a 3D printer from us,

, you get a 10% discount on all consumables.

The new 3D printer model from Wanhao - Gadoso Revolution 2 is an updated version of the famous Duplicator 6 Plus. The GR2 has completely redesigned the electronics, in accordance with user requests. Now the 3D printer has a powerful motherboard and a Touch Screen display. Implemented the ability to remotely manage the printer and monitor printing.

The GR2 has completely redesigned the electronics, in accordance with user requests. Now the 3D printer has a powerful motherboard and a Touch Screen display. Implemented the ability to remotely manage the printer and monitor printing.

Like the D6 Plus, the GR2 3D Printer comes in a closed or open case, saving you money if a closed camera isn't necessary. The large construction area, ideally suited for solving various problems, also remained the same.

Main advantages of Wanhao GR2 3D printer:

- The main upgrade is a new motherboard with an A33 Quad Core processor.

- New color Touch Screen display with full access to all printer settings.

- Print bed calibration visual assistant.

- Ability to connect via Wi-Fi, USB, Ethernet and SD card.

- Remote control and monitoring of printing through a mobile application.

- Built-in 2K webcam.

- Time-lapse recording function.

Learn more