Eiger 3d printing

Eiger 3D Printing Software | Markforged

Skip to navigation

Eiger™

A leading digital manufacturing software for driving business transformation.

Try It Yourself

Produce parts on-demand and at the point of need with the first connected, secure additive manufacturing platform.

From design to part — easily and quickly

Eiger is an integrated, connected platform designed to take you from CAD to functional part quickly. The browser-based 3D printing software workflows are secure, fast, and intuitive.

Try It Yourself

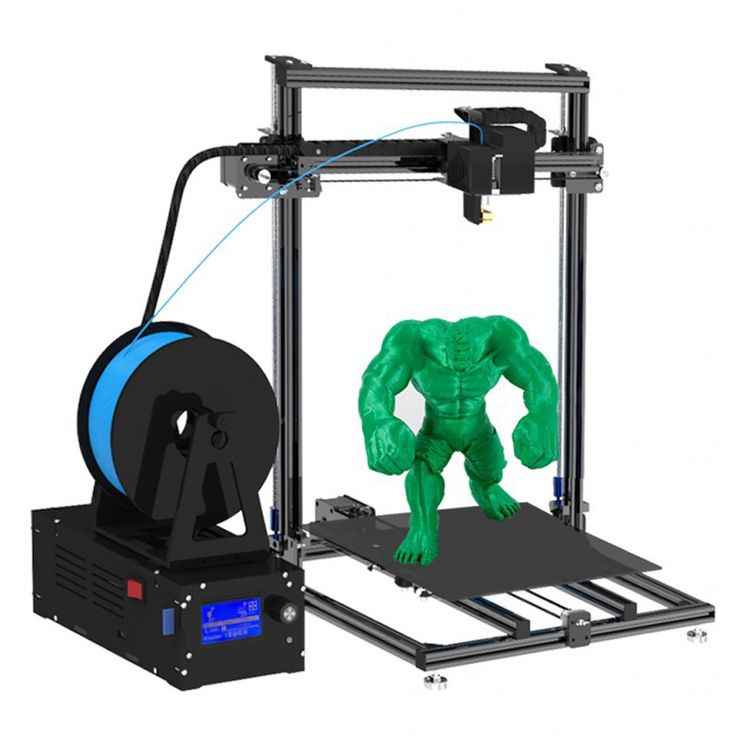

Print with fibers, composites, and metals

Eiger, our 3D printing software, enables you to slice and print composite parts reinforced with continuous fibers and metals. You can prep parts for printing with a single click, or drill deeply into part settings to optimize your final product.

Interact seamlessly with printers

Eiger software fully integrates with all Markforged 3D printers, enabling you to create builds, print parts, and monitor prints in a seamless workflow.

Customize Support Placement

Eiger makes it easy to automatically generate supports that are optimized for most parts. Using Support Overrides, you can choose where to place supports to avoid internal channels, small overhangs, or threading or to provide extra support.

Try It Yourself

Store and access parts effortlessly

A secure part library enables you to dynamically manage engineering projects of any size — complete with versioning. Eiger part files are securely stored and can be versioned, edited, and printed anywhere.

Eiger part files are securely stored and can be versioned, edited, and printed anywhere.

Try It Yourself

Manage projects with simple organizational features

Organize and bucket your parts in an intuitive, simple way with folders. Organize parts and projects alphabetically, by create date, or by edit date.

Find the right part every time

Easy-to-use filters sort parts by part name, material, or user — enabling you to quickly find the part you need when you need it.

Drive fleet wide success with real time monitoring

A single place to manage your printer fleet in real time, whether in one spot or worldwide. Benefit from automatic updates while getting analytics, usage data, and live telemetry in a single place.

Try It Yourself

Monitor devices in real time

Eiger empowers you to monitor any connected device in your organization from anywhere in the world. Get real time updates on critical project progress as it happens.

Get real time updates on critical project progress as it happens.

Customer success, built in

Eiger 3D printing software updates automatically push to your organization, unlocking new features and continuously improving printer performance. Support is fully integrated into the software experience and is directly accessible from both part and printer pages.

Eiger Core

Designed to take you and your teams from CAD to strong, functional parts quickly that can be shared and iterated.

Try Eiger

Eiger Fleet

Designed to scale your additive manufacturing operations through centralized control over printers, users, parts, and workflows.

Learn More

Offline Eiger

Designed to take you from CAD to strong, functional parts quickly when Internet access is intermittent or restricted.

Learn More

Learn about online and offline software operations in Eiger Deployment Options and Data Security

Learn the basics of 3D printing software in From Art to Part: A Step-by-Step Guide to 3D Printing

Blacksmith — Trust your parts off your print bed with in-process quality control

Markforged’s revolutionary software Blacksmith enhances part quality and provides both real time and documented part inspection, verifying that the part you printed is the right part for the job.

Learn More

Collaborative and Scalable

Share parts across teams. Kick-off and monitor prints from anywhere on a secure, connected infrastructure.

Day One Productivity

Turnkey for any skill level and feature-rich when you need it. It’s powerful — not complicated.

Constantly Improving

Automatic software updates continually make your hardware and parts better over time. We are always adding new features and enhancing existing ones.

Security built into your workflow

Our software’s security model, world-scale infrastructure, and unique capability to innovate will help keep your organization secure and compliant.

Already a Markforged Customer?

Talk to an expert Request a demo Try the softwareLet’s get started.

Markforged Eiger Software - Manage 3D Parts and Print Builds

Toggle Nav

Menu

Account

Settings

Currency

USD - US Dollar

- CAD - Canadian Dollar

Eiger provides you with a seamless platform to import CAD data, customize part print properties, understand print specs, and send print jobs to your Markforged 3D printer.

Integrated, Cloud-Based Software to Manage Markforged 3D Printers

Eiger is a powerful digital manufacturing software designed to help you manage parts and builds on your Markforged 3D printer. It provides you with a seamless platform to import CAD data, customize your part print properties, understand print specs, and send print jobs to your machines.

KEY FEATURES AND BENEFITS

Cloud-Based Software

Manage your complete digital manufacturing workflow from Eiger. Manage part files and folders, prints, machines, and users – all from one easy location.

Print Details and Material Cost

Understand in-depth information for individual part files or multi-part builds regarding print times, material usage, and material cost.

Custom Fiber Routing

Customize internal fiber routing using the Eiger internal view by

selecting individual layers or groups of layers and assigning fiber

types and directions. Maximize mechanical performance of parts with

targeted fiber configurations.

Maximize mechanical performance of parts with

targeted fiber configurations.

Integrated Dashboard Analytics

Understand detailed information regarding performance and usage across your entire fleet. Material usage and print jobs can be tracked across both machines and users.

Automated Job Nesting

Print and nest multiple parts at the same time to increase productivity and job output.

Integrated Help Desk

Reach out for help with your tricky part files using the integrated help desk icon.

Fine-Tune Print Customization

Easily customize your prints by changing materials, layer heights,

supports, and infills across your entire fleet of Markforged printers

from one place.

HOW CAN HAWK RIDGE SYSTEMS HELP?

The Hawk Ridge 3D printing team is dedicated to your success. We supply you with everything you need to start printing with Eiger, as well as helping you to be more productive. We are here to offer suggestions on best practices with Eiger to ensure that you are getting the most out of your printers.

SERVICES

MORE THAN JUST A PROVIDER

Our team supplies you with everything you need to get Eiger up and running quickly on your Markforged machine.

TRAINING

IMPROVE PERFORMANCE THROUGH TAILORED LEARNING

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations and best practices when it’s convenient for you.

SUPPORT

TOP-RANKED SUPPPORT, COMMITTED TO YOUR SUCCESS

When your system needs a little TLC, we offer both online or on-site technical support. Our certified Technicians and Applications Engineers are available to help troubleshoot and work with you on challenging parts

Our certified Technicians and Applications Engineers are available to help troubleshoot and work with you on challenging parts

LEARN MORE

FREQUENTLY ASKED QUESTIONS

How much does Eiger cost?

Eiger is free to sign up for and use; try it today!

Can Eiger handle multiple users with access to the same machines and part files?

Yes, Eiger allows for the creation of an organization which will tie together all users, parts, and machines.

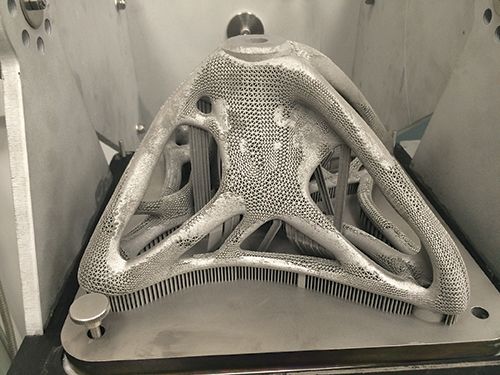

Does Eiger work for the Metal X?

Yes, Eiger works for all Markforged machines and allows for seamless transitions between printers and materials.

Does Eiger allow for customizing fiber directions and locations with the composite systems?

Eiger has an integrated “internal view” that allows for selecting

individual layers, or groups of layers for custom fiber routing

configurations.

Can I track my organization’s material usage with Eiger?

Eiger has an integrated analytics dashboard which will communicate how much material is being used across the complete organization. Data can be filtered and downloaded so you are only capturing the most relevant information.

Is there an offline version of Eiger available?

Yes. Even though the Eiger cloud is very secure, some organizations have high-security requirements that are more suitable for Offline Eiger which can be purchased on a subscription basis per machine.

Email address is required to login

Recently Viewed

No recently views items

Clear All

3D printed custom ear tips | iGo3D.ru

Formlabs Audio believes that the future of personal audio devices depends on custom-made headphones that perfectly follow the anatomical shape of the wearer. Thanks to the rapid development of gadgets and 3D printing, it has become possible for the first time to bring the category of personalized headsets to the mass market, combining smartphone-assisted scanning, automated manufacturing and affordable 3D printing in their creation.

Thanks to the rapid development of gadgets and 3D printing, it has become possible for the first time to bring the category of personalized headsets to the mass market, combining smartphone-assisted scanning, automated manufacturing and affordable 3D printing in their creation.

In this article, we'll show you how easy it is to create custom earbuds using Bose in-ear headphones using the Formlabs Form 3.

Preparing the file

Custom headphones provide a unique musical experience by isolating unwanted noise while maintaining comfort in everyday use.

The secure fit prevents the earbuds from falling out of the ear for added comfort.

The traditional pinna impression has been replaced by a mobile ear scan that users can perform with their own smartphones. An Australian company, Startup Hearables 3D, is developing a Hearables3D smartphone app that scans in less than one minute. Artificial intelligence technology refines the information received, improving the quality of the scanned data and recreating parts of the auricle that were not captured by the smartphone.

The finished file is then sent to the cloud, where a machine learning system, using statistical modeling techniques, turns the scanned shape of the auricle into a concrete model in a few seconds, ready for 3D printing on the Formlabs printer.

From Computer Aided Design (CAD) to 3D Printing

The CAD software market has expanded dramatically over the past few decades, providing users with a wide range of software options, each with its own advantages and disadvantages, modeling approaches and applications . We propose to consider in more detail the software available on the market. Information about the available alternatives will allow you to decide on a workspace that will become a reliable assistant in solving your tasks.

The file can also be directly imported from a smartphone into an CAD software. At this stage, you can make sure that the finished model of the earbud matches the shape of the auricle.

In a classic hearing prosthesis process, this step would be performed by a qualified sculptor. However, the rapid development of ear scanning technologies and computer-aided design programs has allowed individual users and small companies to develop such products themselves. What's more, many CAD programs already offer fully automated process steps.

However, the rapid development of ear scanning technologies and computer-aided design programs has allowed individual users and small companies to develop such products themselves. What's more, many CAD programs already offer fully automated process steps.

After validation, the file enters Formlabs PreForm, where it is prepared for printing on a Form 3B 3D printer.

Form 3B The is an advanced desktop 3D printer designed specifically for medical and healthcare applications. An accurate and reliable ecosystem leaves no room for blind work, making the production process fast and easy. Thanks to the benefits of the Form 3B printer, which uses low tear-off force stereolithography technology, the surface of the finished product is incredibly smooth immediately after printing. With a print platform that is more than three times the size of comparable 3D printers (14.5 x 14.5 x 18.5 cm) and significantly lower cost than comparable 3D printers, Formlabs devices claim a triple benefit: quality, performance and value .

Formlabs' affordable self-printing technologies make it easier than ever to create custom audio devices for patients and customers. Formlabs is building a next-generation digital audio workflow for the audio industry that can be applied from healthcare facilities that need same-day treatment to labs that scale their business to print up to 100 models per printer per day.

Varnishing

Post-Processing

Post-printing requires further processing of finished elements in Form Wash and Form Cure. This will remove excess polymer from the product and fix the properties of the material. For safe use of a product made of Flexible 80A Resin, a lacquer coating must be applied to the finished object.

This is the final step in post-processing. The video demonstrates the use of LP / W varnish from Egger. The use of varnishes from Dreve and Detax is also popular. Make sure that the lacquer you use meets safety and biocompatibility requirements.

The insert is now ready for use. As a result, the complex process was completed in just a few hours.

As a result, the complex process was completed in just a few hours.

Specifically for digital audio manufacturing, Formlabs developed BioMed Clear Resin, a transparent and biocompatible material with high impact resistance, ideal for earmoulds, shells and in-ear headphones.

Formlabs is committed to making the digital manufacturing of hearing aids, noise protection and consumer audio products affordable.

“With BioMed Clear Resin and Form 3B, we can get biocompatible, durable hearing aids with highly detailed surfaces right from the printing platform. With the availability and performance of the Form 3B printer and BioMed Clear Resin, we were able to rapidly scale our own digital production.” — Paul Thorp, Lab Director, Universal dB

EGGER HOME Comfort Flooring

Information

- Posted by Basis

twenty Jul

It's all about the atmosphere

This is a favorite of those who like to walk barefoot and enjoy the silence. The secret behind the special properties of our EGGER HOME Comfort flooring lies in the six-letter word: cork. If you're looking for a typical cork surface, you won't find it. Because we have integrated this valuable material into the structure of our flooring.

The secret behind the special properties of our EGGER HOME Comfort flooring lies in the six-letter word: cork. If you're looking for a typical cork surface, you won't find it. Because we have integrated this valuable material into the structure of our flooring.

Contemporary decors create a modern look while maintaining exceptional sound and heat insulation properties.

The ideal playground for your home

EGGER HOME Comfort flooring is highly valued not only for its soundproofing properties, but also for its ecological properties. Wood and cork from PEFC-certified forests are the main materials used for the production of flooring. EGGER flooring is free from PVC and toxic dyes!

You can walk barefoot at any time of the year – even in winter. Thermally insulating air cells in the cork layer retain heat and create a unique cozy feeling.

Low maintenance and hard wearing

This type of flooring is easy to clean.