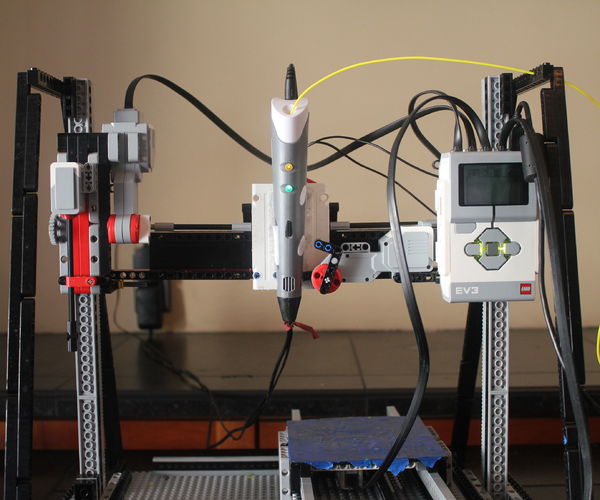

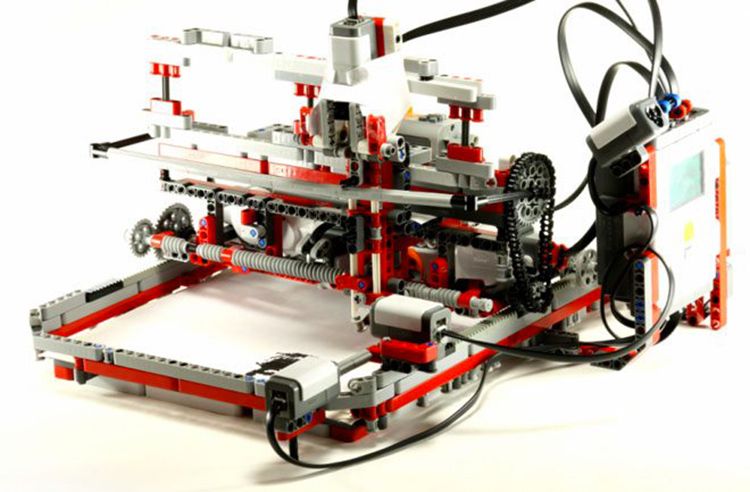

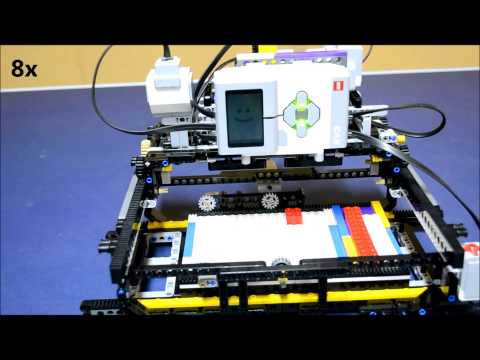

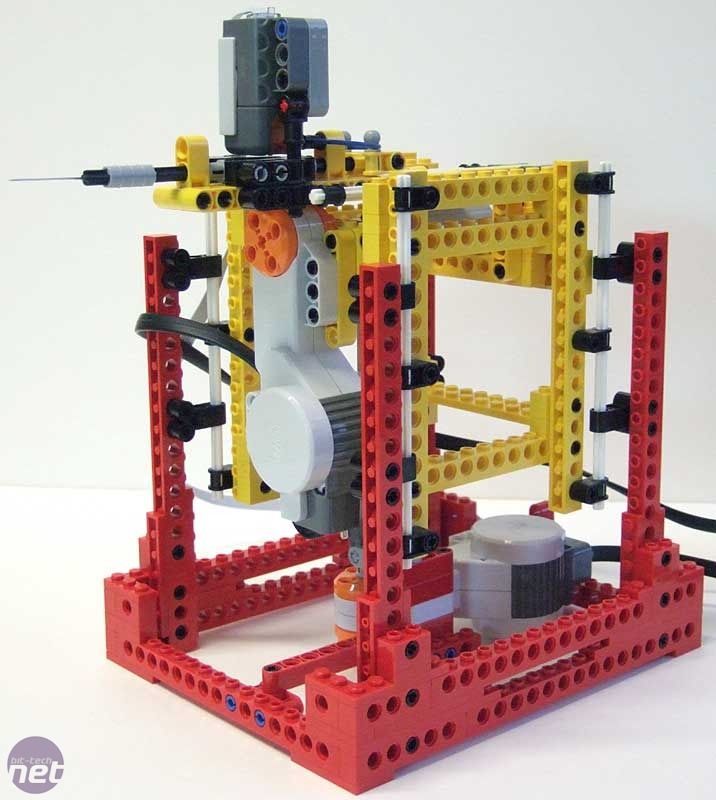

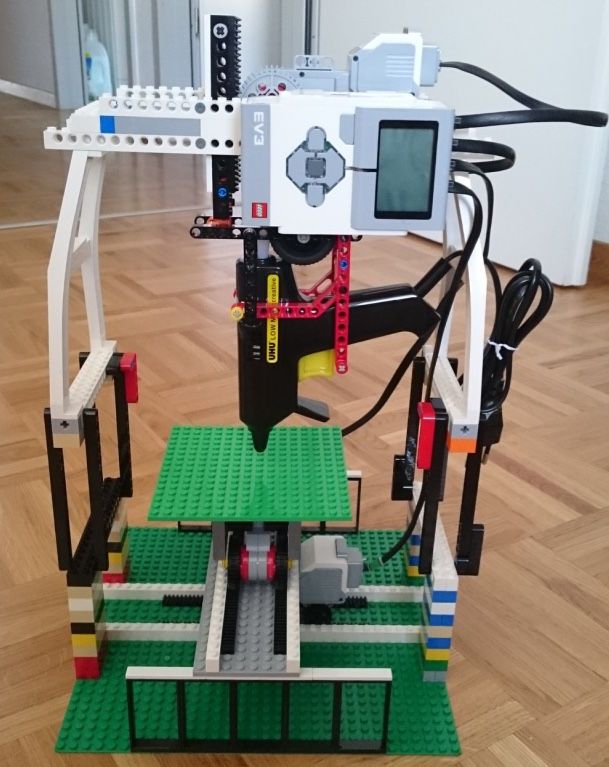

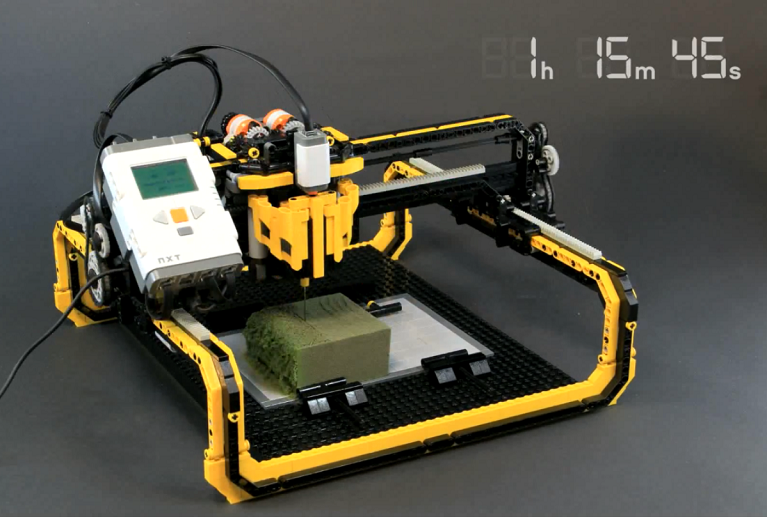

Nxt 3d printer

SLA 3D Printer & Additive Manufacturing Company

Increase Throughput. Improve Productivity. Reduce Total Cost of Ownership.

Nexa3D is a leading provider of ultrafast 3D printing solutions. Our photopolymer and thermoplastic range of industrial 3D printers offer unrivaled speed and throughput, superb surface finish, all on an open material platform. Our patented Lubricant Sublayer Photo-curing (LSPc) 3D printing process unlocks productivity gains by as much as 20x greater than those of conventional SLA or DLP processes. We offer a range of polymer solutions, spanning from a desktop resin 3D printer, industrial 3D printers, and a thermoplastic laser sintering solution for serial production.

Professional Resin 3D Printer

Resin 3D printer with 4.8L build volume, unmatched speed, and an open material platform.

Explore XiP

Industrial 3D Printer

16L build volume, intelligent build optimization, and patented LSPc technology delivering 6. 5x the speed.

Explore NXE 400Pro

Industrial 3D Printer

Fast, affordable scalable prototyping and manufacturing without sacrificing accuracy.

Explore NXE 200Pro

Photopolymer Dental 3D Printer

8.5L build volume, intelligent build optimization, and LSPc technology printing dental models in minutes.

Explore NXD 200Pro

Thermoplastic 3D Printer

Production-grade thermoplastic SLS system offering the highest throughput in its class.

Explore QLS 820

Compare 3D Printers

Customers Benefiting from Ultrafast 3D Printing

Customer Stories

As a leading provider of ultrafast 3D printing solutions, our patented Lubricant Sublayer Photo-curing (LSPc) process delivers these benefits:

Exponentially greater throughput with 6.5x greater speed

Optimized supply chain with scalable on-demand manufacturing

Superb surface finish quality with minimal post processing required

Open material platform unlocking many manufacturing use cases

Free Sample Part

“Our R&D Team is able to reduce time to obtain functional samples by as much 80%, and reduce tooling costs by as much as 90%.

With the NXE 400Pro, we’re able to go from CAD to scale in just 48 hours.”

Max Rodriguez,

Senior Manager of Global Packaging

View Case Study

Gain 20x Productivity

Nexa3D reduces prototyping and production cycles from hours or days to mere minutes. The combination of our larger-format build area, print speed, and post-processing automation delivers up to 20x productivity gains, making our 3D printing process comparable only to injection molding — without existing supply chain complexities, extended lead-times, and the substantial costs typically associated with tooled plastics.

Talk to an Expert

Open Material Platform

We believe in the power of an abundant material ecosystem. That’s why we continue to partner with leading material providers to deliver a comprehensive range of high-impact functional materials that are tailored to your mechanical requirements and performance needs.

Nexa3D Material Selector

Meet Our Team | Nexa3D

We are dedicated to digitizing the world’s supply chain sustainably.

Watch Video

Who We Are

We are a team of passionate additive manufacturing practitioners that are committed to digitizing the world’s supply chain sustainably.

We make the world’s fastest polymer 3D printers accessible to professionals and businesses of all sizes. Our groundbreaking technology is shattering traditional 3D printing productivity barriers and opening the aperture of additive materials.

Our printers take current additive manufacturing speeds from ‘dialup internet’ to ‘broadband’ printing and are capable of continuously printing at speeds of up to 8 liters per hour. This represents up to 20x productivity gains over all current state additive products and is comparable only to injection molding economics — existing supply chain complexities, extended lead-times and the substantial costs typically associated with tooled plastics.

Patented Technologies

We engineered from the ground up two new print engines that are designed for high speed production applications; Lubricant Sublayer Photo-curing (LSPc) for photoplastics print engine and Quantum Laser Sintering (QLS) print engine for thermoplastics.

Beyond our game-changing hardware innovations, we are coding the interplay between chemistry, process and speed at scale. Our Digital Twin Printing (DTP) software unlocks new material properties and assures process stability, higher yields and performance.

Our Material Partners

We believe the best way to propel the additive manufacturing industry forward is to work together with our material partners to innovate and develop a steady stream of high performance 3D printing materials. To democratize access to production polymers, we formed partnerships with world-class material suppliers including Henkel, BASF, and Keystone. Together we are unlocking the full potential of performance polymers that are addressing a broader range of industrial and medical prototyping and production use cases.

Together we are unlocking the full potential of performance polymers that are addressing a broader range of industrial and medical prototyping and production use cases.

Taking Action on Sustainability

We are deeply committed to sustainability. We apply circular economy principles in every phase of our design and delivery process by rigorously measuring and improving on what matters: minimizing process waste, reducing energy consumption per part and working with our customers to reduce their overall carbon footprint. We partner with ForestNation, provider of products and services to help reforest the Earth and generate sustainable livelihoods in developing countries.

Learn More

Board of Directors

Executive Leadership Team

Izhar Medalsy

Chief Technology Officer

Leadership

Dr. Kevin McAlea

Chief Operating Officer

Leadership

Nina Swienton

Chief Marketing Officer

Leadership

Michael Currie

Vice President, General Manager Desktop Business Unit

Leadership

NXT Factory's 3D Laser Sintering Printer Will Increase SLS Printing Performance Tenfold

News

NXT Factory is gearing up to revolutionize resin 3D printing.

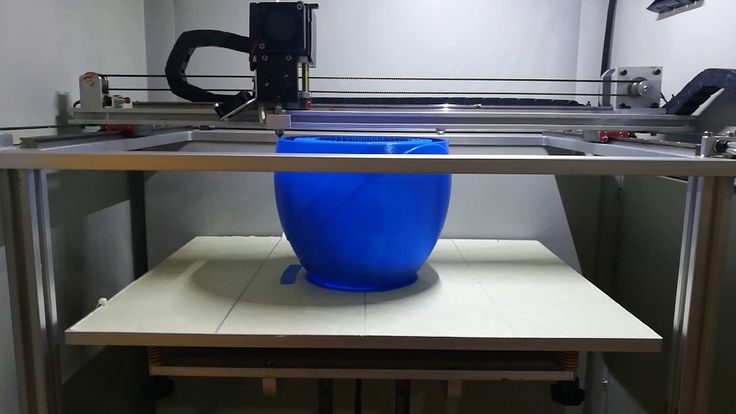

The 3D printer being developed is based on laser sintering technology, however, unlike existing SLS systems, the formation of each layer takes only about a second, and the printing speed as a whole exceeds the performance of the closest analogues by about ten times.

The 3D printer being developed is based on laser sintering technology, however, unlike existing SLS systems, the formation of each layer takes only about a second, and the printing speed as a whole exceeds the performance of the closest analogues by about ten times. NXT Factory is a fairly young company, founded with the investment and organizational support of Avi Reichental, who ran the industry's leading company 3D Systems for twelve years and left his post in October 2015. Avi was not going to leave the additive technologies market, but instead took the chair of the board of NXT Factory, investing in the startup funds from his venture capital and technology company XponentialWorks.

NXT Factory is developing a new 3D printing technology that promises to significantly improve the performance of laser sintering 3D printers. The most obvious parallel will be a comparison of popular 3D printing techniques with photopolymers - laser and projection / mask stereolithography. While laser (SLA) 3D printers sequentially draw each layer point by point using a deflected laser beam, DLP and LCD printers illuminate the entire layers, forming an image using digital projectors or LED arrays with LCD masks. The main advantage of the second option is increased performance.

While laser (SLA) 3D printers sequentially draw each layer point by point using a deflected laser beam, DLP and LCD printers illuminate the entire layers, forming an image using digital projectors or LED arrays with LCD masks. The main advantage of the second option is increased performance.

SLS 3D printers also use laser systems: one or more deflected beams sinter layers of polymer powder, but the process takes a lot of time, similar to laser stereolithographic 3D printers. But what if you sinter each layer entirely and at once? This problem should be solved by the proprietary technology QLS (“Quantum Laser Sintering” or “Quantum Laser Sintering”). The idea is to split the generated laser beam into several million micro-beams that form a raster image on the surface of the powder.

The current prototype is designed to work with polymer materials (nylon, polyurethane, etc.) and uses a 3 kW laser. The resolution on the Z axis is estimated at 50-200 microns, and on the X / Y - 75 microns. The size of the construction area reaches 300x400x400 mm. The market launch date has not yet been announced, but the official presentation of the technology will take place at the Formnext industry exhibition in Frankfurt am Main, which opened today. At the exhibition, the company hopes to attract additional investment to complete development work and establish mass production. How it works, see the video:

The size of the construction area reaches 300x400x400 mm. The market launch date has not yet been announced, but the official presentation of the technology will take place at the Formnext industry exhibition in Frankfurt am Main, which opened today. At the exhibition, the company hopes to attract additional investment to complete development work and establish mass production. How it works, see the video:

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow author

Follow

Don't want

6

Article comments

More interesting articles

9

Follow author

Subscribe

Don't want

Monochrome LCDs with increased sharpness, light transmission, durability. ..

..

Read more

5

Subscribe to the author

Subscribe

Don't want

The World Nuclear Association (WNA) has published a report on the application of advanced manufacturing technologies...

Read more

56

Follow author

Follow

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

Nexa3D acquires laser sintering company NXT Factory

#SIU_news 08/25/2020

Nexa3D, maker of ultra-fast SLA 3D printers, announced its upcoming expansion and acquisition of NXT Factory, which specializes in quantum dot laser sintering (QLS™). Thanks to a successful business operation, the brand plans to add a number of powdered thermoplastic materials to its product line, products from which are in demand in the medical field, aerospace and engineering industries, and the industrial segment.

Strategic deal

Nexa3D's most frequently bought product is the fastest industrial 3D printer NXE400. Now, companies considered revolutionaries in the additive sector have come together in a bid to overcome performance barriers to offer the consumer innovative products, including high-speed photoplastic and thermoplastic technologies, plus a wider range of materials.

Nexa3D believes that the acquisition of NXT will optimize traditional production, reduce product costs, and establish a flexible supply chain. Combining popular techniques will double the available sales market, diversify revenue streams, and stimulate profit growth.

Stereolithography (SLA) and selective laser sintering (SLS) are the cornerstones of additive plastics manufacturing, so the tandem of enterprises is designed to stimulate technological breakthrough. The combination of two complementary high-speed technologies increases the company's competitive advantage over traditional manufacturing.

Considering the popularity that the resin 3D printing industry has received from the worldwide response to distribution of COVID-19 , combining the efforts of brands will provide an opportunity to unleash the potential of existing products, demonstrate the unique ability of additional capacity, quickly switch to large-scale serial production of the necessary personal protective equipment.

Benefits at scale

Nexa3D builds ultra-fast industrial 3D printers for stereolithography and makes high-performance resins affordable for professionals and businesses of all sizes. The activity is based on a patented photo-curing methodology and a unique structured light matrix capable of providing maximum speed and efficiency. NXT Factory creates ultra-fast selective laser sintering systems that produce thermoplastics for mass production. Proprietary printers are equipped with patented quantum laser sintering technology, which ensures the creation of functional and durable parts for the aerospace and automotive industries, the manufacture of durable goods, and the cultivation of prototypes with high quality and injection molding scale.