Cow 3d print

Cow best 3D printer files・Cults

Skip to contentCowboy Kit for action figures

€15

Cowboy V1 Head for Action figures

€12

Zebu cow gold pendant with gem diamonds 3D print model

€50

krishna with cow 3d file

€15.29

Space cowboys heads for kitbashing

€4

Maggie - Home on the Range

€1.57

Vampire Hunter Cowgirl Gunslinger

Free

Bull key ring

€0.66

Minecraft Skeleton Flexi articulated

€2.80

LegendGames Gold Mine western set

€5. 82

LegendGames Cactus Set

€3.49

Wall Street Charging Bull

€5.06

Civil War Style Revolver, Cult

€5.72

Chihiro's Journey keychain, tree, cow and UFO

Free

Bravestarr Kerium Nugget

€1.49

Bravestarr Hat

€1.86

Rubber Band 6 Shooter | V4

Free

Cuernitos devil or cow costume

Free

Cow Head Cookie Cutter

€1.09

Cowboy - Rooster Cogburn

€4.46

Cute Cow Keychain

€0.66

Demon Skull

€3

Cow Mate Mate Set

€3. 86

86

Minecraft Creeper Halloween Edition Flexi articulated

€2.80

Spike from Cowboy Bebop

€10 -20% €8

Cow

€0.97

Minecraft Warden Halloween Edition Flexi articulated print-in-place

€2.80

Cute Highlander

€3

Cute Cow Headset Holder

€2.53

Cutter Set Farm Animals 10 cm

€7.50

Cow Cutter 10 cm

€2.50

Cowboy boot

€3.04

Set of 4 Cowboy Boot Polymer Clay Cutters for Jewelry and Crafts w/ Floral Option- Imprint, Western Boho Vibes

€1. 37

37

Bull cookie cutter

€2

2D Silhouette/Stencil UFO Cow Abduction

€0.66

2D Silhouette/Stencil UFO Cow Abduction

€0.66

2D Silhouette/Stencil Cow Hills

€0.66

2D Silhouette/Stencil Farmer/Cowboy Leaning on Fence

€0.66

2D Silhouette/Stencil Farmer/Cowboy Leaning

€0.66

2D Silhouette/Stencil Farmer with Cow

€0.66

Convicted cow

Free

Ufo Cow

€4.05

Call me Trinity

€20

Woody from Pixar Toy Story

€3. 50

50

Bull box container

€2

Cow farm zenon key chain

€0.64

Bull Skull

€0.50

cowboy cookie cutter

€3.59

3d Cow Print - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 596 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Cow is not an option

"MN": What are the prospects for 3D printing in the field of cooking?

Fadin: Much has already been achieved. The biggest progress is in the confectionery art, where 3D printers work wonders: they print chocolate inscriptions, figures, cakes. The printer also helps bartenders: try to make the thinnest inscription on a cup of cappuccino with your hands. Health food is being actively printed for people who cannot consume hard food. For example, peas are crushed for them and then reprinted on a printer. The taste is the same, but the texture is not the same.

The biggest progress is in the confectionery art, where 3D printers work wonders: they print chocolate inscriptions, figures, cakes. The printer also helps bartenders: try to make the thinnest inscription on a cup of cappuccino with your hands. Health food is being actively printed for people who cannot consume hard food. For example, peas are crushed for them and then reprinted on a printer. The taste is the same, but the texture is not the same.

Sooner or later every home will have a similar printer. I think in the next decade. It remains only to buy consumables for it - a kind of "cartridges" of food pastes, from which dishes on demand will be printed.

Illustration: Alena Bocharova Moreover, the printer does not limit imagination and creativity: it is possible to print dishes of complex shapes from pastes containing both meat and vegetable food. The restaurant will move to the house. This is important because the aesthetics of serving strongly influences eating behavior. There are, of course, people who are used to eating fast food, on a newspaper and so on, but sooner or later they are overtaken by health problems.

There are, of course, people who are used to eating fast food, on a newspaper and so on, but sooner or later they are overtaken by health problems.

"MN": What's stopping you from spreading the technology now? Price?

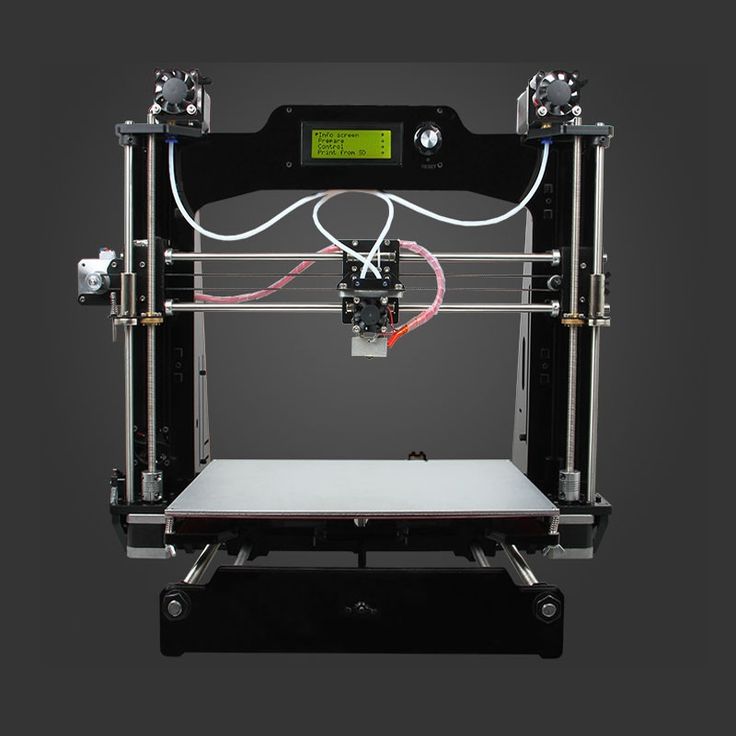

Fadin: A printer today costs about the same as a good food processor - about one and a half thousand dollars. Not so much, but not too little either. The microwave is definitely cheaper.

Another thing is that for each new food mixture it is necessary to test 3D models, without which the printer will not print a single figure.

And someone has to develop and test a new food paste with them. Someday this will be done automatically, but now it requires a significant amount of time from food technologists and chefs, as well as from engineers.

The price problem is relevant in a related field - 3D bioprinting of cultivated food, where not just food pastes are used, but animal cells grown in a bioreactor. The best minds of the planet in different countries are looking for an opportunity to grow meat, fish, seafood, so that not a single animal or marine reptile is harmed. Beefsteak, for example, has already been printed - expensive and not very tasty. And it is necessary that the cultivated chicken be comparable in price with natural chicken of the same mass in mass production.

The best minds of the planet in different countries are looking for an opportunity to grow meat, fish, seafood, so that not a single animal or marine reptile is harmed. Beefsteak, for example, has already been printed - expensive and not very tasty. And it is necessary that the cultivated chicken be comparable in price with natural chicken of the same mass in mass production.

"MN": And what's the problem?

Fadin: Cells cannot grow in the air - they need a nutrient medium. The catch is that it should not be of animal origin. Until recently, blood agar was used, which means that the principle of "no cow was harmed" is violated. Today, they are experimenting with vegetable "broth" - this is a humane solution that allows you to supply cells with everything they need. The problem is that such a "broth" is very expensive, as well as bioreactors, where such experiments are being carried out.

"MN": Why such concern for cows?

Fadin: Rather, about the human habitat. Agriculture, in particular animal husbandry, exacerbates environmental problems when scaled up. And quite seriously. In addition, there are a number of other problems. For example, growing protein will reduce the risk of allergic reactions.

It will also make the product “cleaner”: cows are often fed with antibiotics, their feed sometimes contains harmful impurities, and where this is not present, meat is very expensive. By growing the cell mass, you can not only “purify” the final product, but also add vitamins and microelements necessary for a person to it. And even personalize this process.

And finally, a live cow is simply a pity. But humanity has not yet learned to do without animal food.

In some 3-4 thousand years, this can be achieved, but we must try. In the meantime, without a total and drastic change in the diet, we are forced to look for possible ways to solve the problem without harming human health and the environment. "Meat in a test tube", grown individually for the customer, depending on his health, taste preferences and needs for trace elements and vitamins, is one of the best solutions. But so far, printing with living cells is more desirable than real.

"Meat in a test tube", grown individually for the customer, depending on his health, taste preferences and needs for trace elements and vitamins, is one of the best solutions. But so far, printing with living cells is more desirable than real.

"MN": Why print if you can get a cell mass? Fried or boiled - and you're done!

Fadin: Food is not only taste and smell, but also appearance and texture. And the latter must meet expectations, otherwise, even with the right taste and smell, it will not be possible to eat it. Just imagine: jelly-like meat...

It is an art to create the taste of a product from an alternative protein. It took us a year to achieve the desired texture, taste and smell of the printed dish. The taste of fried squid is the taste of fried protein plus a marine flavor. To achieve this, we took a mass of white beans (in our opinion, it most accurately conveys the structure of a seafood) and added ordinary and pickled seaweed, water and salt to it.

Ivan BerezutskyThen they printed "squid" (the process takes 4 minutes 15 seconds) and fried. The taste, color and smell turned out to be one hundred percent squid, it is indistinguishable from the real one. Fortunately, there is something to compare with: printed and natural squid lie on the same plate, the dish is called “Squid and squid”. It is one of the most popular on the menu.

co-owner and chef of the Twins Garden restaurant

We don't just eat a bunch of cells. The steak should be with fat, blood, maybe with a vein, otherwise it's tasteless. Meat is a complex product in this regard. So growing cellular meat is only half the battle, the other is to assemble it into the desired structure, familiar to our consumption.

This is exactly what bioprinting methods are needed for, which are gradually evolving. From additive printing (layered), we move on to formative, which is more like creating a snowball. When printing with individual cells, it is more difficult to achieve the high density required for printing living tissue.

When printing with individual cells, it is more difficult to achieve the high density required for printing living tissue.

Cells are quite a social substance, they communicate with each other, and for this the distance between them must be small.

For different types of cells, it ranges from 25 to 50 microns. If the distance is greater, then the cells do not have a signaling system that would allow them to communicate, and then the team does not add up, the tissue dies.

Therefore, we first sculpt a small and fairly dense ball, which consists of several thousand cells. It already has the makings of a living tissue and, in fact, is a “brick” in bioprinting, only round. Then we carefully lay such "bricks" with the help of hydrogels, and we get a living tissue.

1. Insert the food paste capsule into the nozzle.

2. Turn on the printer.

3. Load a 3D product model from a laptop or SD card.

4. Select print options.

Select print options.

5. Start the printing process.

In order to successfully apply the format printing method, we are learning how to use magnetic and acoustic printing technologies. Their principle is as follows: under the influence of certain forces, a kind of trajectory is set for the cells, and they are compressed into the cellular structures described above. This allows not only stacking cells with a certain density, but also forming tissue many times faster than with layer-by-layer printing. Mastering this method should allow us to print much more complex organ structures. This method - magnetic assembly - we are currently using on the ISS.

Illustration: Alena BocharovaMN: Can you be more specific?

Fadin: This is our joint project with Roscosmos. Our 3D bioprinter has been working on the ISS for a couple of years now, we are trying to assemble cells into structures under weightless conditions. On Earth, gravity prevents us from achieving what we want, but in weightlessness it is not. If you think a step or two ahead, then in long-term space flights, the crews will need meat. This amount of canned food is too much weight, a cow is not an option at all. Plus, it would be nice to cook protein, preferably in a variety of ways.

On Earth, gravity prevents us from achieving what we want, but in weightlessness it is not. If you think a step or two ahead, then in long-term space flights, the crews will need meat. This amount of canned food is too much weight, a cow is not an option at all. Plus, it would be nice to cook protein, preferably in a variety of ways.

"MN": Do you also need to cook? Can't print a dish right away?

Fadin: Something that does not require heat treatment is possible. As practice shows, it is better to use this method: print - separately, frying pan - separately. It is possible to mechanize the process as much as possible: a smart stove is already able to cook independently without human intervention - it will select the temperature, time and mode itself. In addition, cooking technologies can correct some shortcomings of the previous process: in the case of a fried steak 99% of people will not catch the difference between farmed and natural meat, while tasting tartare or carpaccio, this percentage will be lower.

One of the guests ordered our alternative protein squid because he had never tried the real one due to a severe allergy to seafood. After the tasting, he asked his daughters if what he tried really tasted like squid, and having received a positive answer, he cried with happiness. Moments like this are what we create for. Can you imagine how many people in the world deny themselves this or that product due to allergies? Our discovery made a real splash: we presented a 3D squid a year and a half ago at the international gastronomy congress Madrid Fusion, then in Oxford, and everywhere there was a lively interest. I am convinced that in 10 years people will already choose whether they eat their usual proteins or alternative ones - the main thing is that the latter should not be inferior to the usual ones in terms of taste " .

Ivan Berezutsky

co-owner and chef of the Twins Garden restaurant

"MN": Did I understand correctly that as soon as we understand how to get a cheap cell mass and a product from it with the desired texture and taste, the bright future pictured above?

Fadin: The issues of quality control and market access still need to be resolved. Today, there are few countries that are ready to allow dishes from "test-tube meat": it is not clear how to certify such a cell mass. Actually, the only one who did this is Singapore. So not only cells, but also powerful minds must mature. In this case, it will be necessary to make changes to the legislation. And then it's up to the market.

Today, there are few countries that are ready to allow dishes from "test-tube meat": it is not clear how to certify such a cell mass. Actually, the only one who did this is Singapore. So not only cells, but also powerful minds must mature. In this case, it will be necessary to make changes to the legislation. And then it's up to the market.

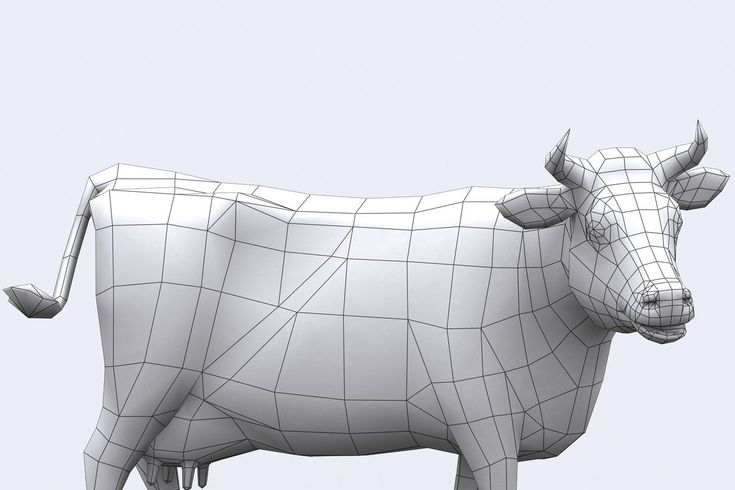

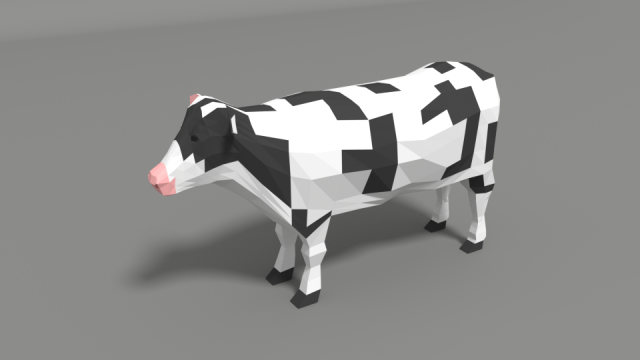

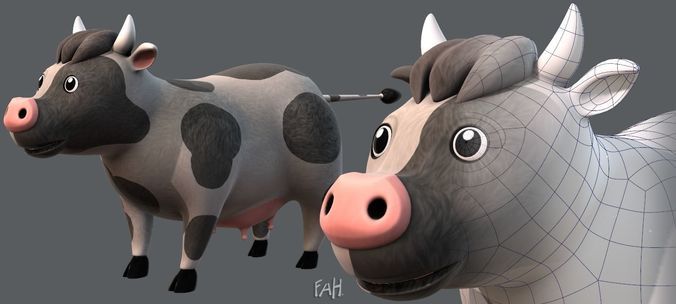

3D modeling rules for 3D printing

It is known that a prerequisite for 3D printing is the presence of a 3D model, according to which the printer will grow a three-dimensional object. But, even after simulating an object, you should not assume with absolute certainty that the job is done, and soon the printer will give you the finished product. The fact is that not all models are suitable for 3D printing. There are certain requirements for the dimensions, thicknesses and design of models - and these requirements vary depending on the material used and the printer. In addition to these individual characteristics, there are general requirements that distinguish print models from other 3D models. And now we will talk in more detail about how to prepare a model for 3D printing.

And now we will talk in more detail about how to prepare a model for 3D printing.

First of all, you need to remember that STL files (for one-color models) and WRL (for color plaster 3D printing) are suitable for 3D printing. Almost all 3D modeling programs allow you to export models to STL, so this should not be a problem. You should also take into account that for online download on our website, files no larger than 50 MB each are accepted, as well as an extended list of formats that are automatically exported to STL: STP, STEP, OFF, OBJ, PLY and directly STL. If the file size is more than 50 MB, then you need to send the model to our email address: [email protected]. By the way, one of the easiest ways to reduce the volume of the model and the file size is to create hollow 3D models, we already wrote about how this works in our blog.

Before you start creating a model for 3D printing, it is important to understand what material you want to print the product from. Each material has its own individual characteristics for 3D modeling - maximum and minimum model dimensions, wall thicknesses, distance between moving parts, etc. You can learn more about the requirements for a particular material in the appropriate section on our website.

Each material has its own individual characteristics for 3D modeling - maximum and minimum model dimensions, wall thicknesses, distance between moving parts, etc. You can learn more about the requirements for a particular material in the appropriate section on our website.

If you use the online model upload on our website, it will automatically check for standard 3D modeling errors. Models are checked instantly, and if errors that prevent 3D printing were not found, then immediately after uploading the model will appear in your personal account in the "My Models" section. If the model did not pass the test, then you will see a notification that the file cannot be loaded, then you will need to check and refine the model again.

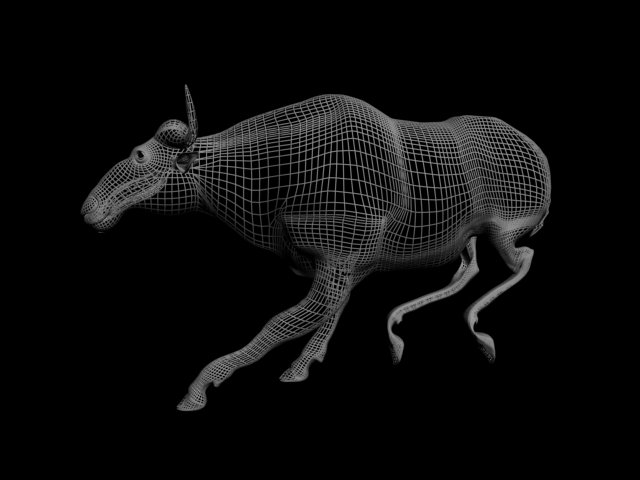

What are the most common errors encountered when modeling for 3D printing?

- Inverted normals - incorrectly oriented normals. Normals should always point outward, they define the boundaries of the object and allow the 3D printer software to understand which is the inside and which is the outside of the model.

If at least one of the normals is directed in the opposite direction and contradicts the other normal, then this causes a failure in 3D printing, since the printer cannot distinguish between the front and back sides of the object.

If at least one of the normals is directed in the opposite direction and contradicts the other normal, then this causes a failure in 3D printing, since the printer cannot distinguish between the front and back sides of the object. - Non-manifold geometry - Non-manifold 3D model is a prerequisite for 3D printing. The essence of this concept is that each edge of a 3D model must have exactly two faces.

The following errors are usually included in this concept:

o Mesh with holes - "unclosed" mesh problem. Remember the basic rule of 3D modeling: your model must be "watertight" or "airtight". If a hole is formed, it means that some edge is missing one face, therefore the model is not manifold, and therefore not suitable for 3D printing.

o Presence of internal polygons. There must be no faces inside the model, for example inside walls.

o Common ribs. An error occurs when more than two polygons are attached to the same edge.