Icon vulcan 3d printer

Vulcan | ICON

- Vulcan

- Projects

- Updates

- Careers

- Contact

Vulcan

SpaceOlympusMars Dune Alpha

ProjectsUpdatesCareersContact

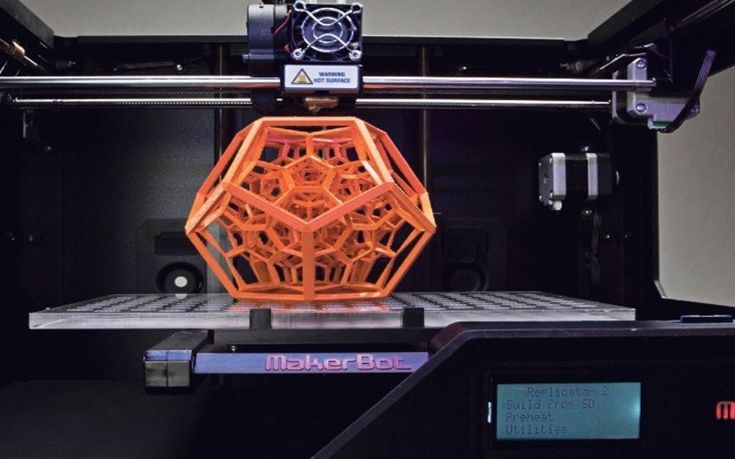

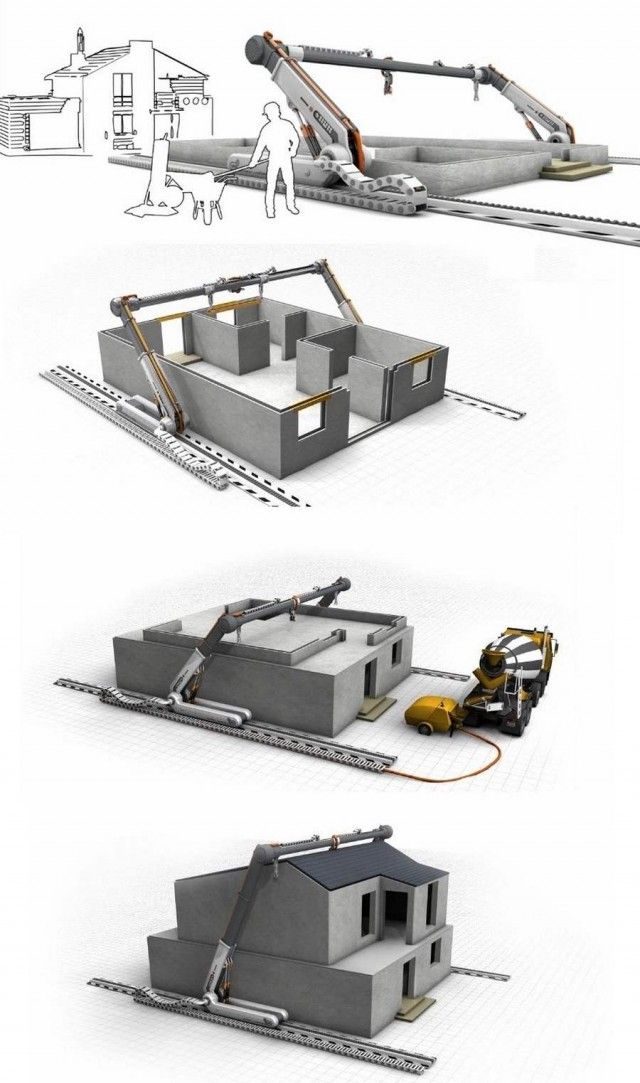

Meet ICON’s next generation Vulcan construction system.

Designed and engineered from the ground up for volume 3D printing of homes with precision and speed.

Robotic Construction

The large-scale construction 3D printer is 1.5x larger, 2x faster and capable of printing homes and structures up to 3,000 square feet. The Vulcan can produce resilient, single-story homes faster than conventional methods and with less waste and more design freedom.

| Total Width | 46.5 feet |

| Total Height | 15.5 feet |

| Weight | 9500 lbs |

| Voltage | 230/240 V single phase |

| Print Height | 10. |

| Print Width | 36.5 feet |

| Print Length | Infinite |

| Print Speed | 5-10"/sec |

| Software | BuildOS |

| Material Mixing & Pumping | Magma System |

| Required Concrete | Lavacrete |

Digitally Native

ICON's tablet-based operating system controls every aspect of print operations via an intuitive, simple, and beautiful user interface. The operating system translates floor plans into print jobs and then directs both Vulcan and Magma, using real-time data down to the millisecond, to produce the highest quality printed structures in the world. From its powerful CAD and print planning to enabling machine learning and predictive analytics for Vulcan robots, this advanced software brings construction into the 21st century.

Mix Master

Magma is the first end-to-end automated material delivery system for use in 3D-printed additive construction. The Magma system feeds Vulcan printers with ICON’s advanced material, Lavacrete. Using any of ICON's proprietary Lavacrete blends, the Magma system mixes Lavacrete, additives, and water automatically, depending on current site weather conditions, then supplies the ready-to-print Lavacrete to the Vulcan. Smart and working in perfect sync with a Vulcan printer on site, a Magma takes the guesswork out of complex, high-performance cementitious material.

The Magma system feeds Vulcan printers with ICON’s advanced material, Lavacrete. Using any of ICON's proprietary Lavacrete blends, the Magma system mixes Lavacrete, additives, and water automatically, depending on current site weather conditions, then supplies the ready-to-print Lavacrete to the Vulcan. Smart and working in perfect sync with a Vulcan printer on site, a Magma takes the guesswork out of complex, high-performance cementitious material.

Rock Solid Science

ICON’s proprietary Lavacrete can be printed at high speeds while retaining form, enabling homes to be built faster, while keeping construction projects on schedule and on budget. Dynamically mixed based on location using real time weather conditions and print needs, Lavacrete creates homes and structures with a single building material that will last longer than traditional construction materials and methods. As a high strength concrete boasting a compressive strength of 2,000 - 3,500 psi, Lavacrete can withstand extreme weather and greatly reduce the impact of natural disasters, while providing maximum efficiency.

FAQ | ICON

Media interested in writing a story about ICON, please visit our CONTACT page. To download assets for your story, visit our electronic press kit for media only.

What is ICON?

ICON develops advanced construction technologies that advance humanity. Using proprietary 3D printing robotics, software and advanced materials, ICON is shifting the paradigm of homebuilding on Earth and beyond. Follow @ICON3DTech on Instagram, Twitter, Facebook, LinkedIn and YouTube.

Tell us about the origins of ICON and the company’s mission.

ICON is an advanced construction technologies company dedicated to revolutionizing homebuilding. Through proprietary 3D printing technology and cutting-edge materials, ICON provides sustainable solutions to a number of our world’s most pressing issues, including the pandemic of homelessness in the developing world, the difficulty of constructing off-planet space habitats, and the exorbitant cost of customized housing.

ICON’s three co-founders were independently working on large-scale 3D printing for homebuilding in 2017. Jason Ballard, co-founder the CEO spent the last decade+ of his life focused on sustainability and health in the built environment. After working on literally thousands of homes, Jason began saying to himself, "Surely there is a better way to build homes that is more affordable, less wasteful, and more energy efficient than conventional building methods." Approaches to construction hadn't changed in so long it was like people had forgotten how to even imagine a different way. That began a months-long study and research project (including prefab, insulated concrete forms, SIP panels, advanced framing, robotic bricklaying, architectural fungus, etc.) that landed Jason on 3D printing as the most promising technology to create a true revolution that checked all the boxes he cared about. He re-connected with his TreeHouse co-founder and friend Evan Loomis and the two decided to start working on it and build a prototype in a warehouse in Austin on the weekends. Meanwhile, a fresh college-grad and engineer named Alex Le Roux was working on a similar project in Houston. His prototype was actually able to print a mortar-based tiny home. Eventually, after hearing rumors of each other for months, the three entrepreneurs met and decided to start working together.

Meanwhile, a fresh college-grad and engineer named Alex Le Roux was working on a similar project in Houston. His prototype was actually able to print a mortar-based tiny home. Eventually, after hearing rumors of each other for months, the three entrepreneurs met and decided to start working together.

Fast forward to today... ICON is a for-profit advanced construction technologies company using 3D robotics, software, and advanced materials to reinvent the homebuilding industry. The first 3D printer was ready to print in early 2018 and successfully printed a permitted, 3D printed home in Austin in March 2018 alongside nonprofit partner, New Story. In March 2019, ICON unveiled its next generation 3D printer for homes, the Vulcan, and began shipping the technology for projects in the U.S. and in Mexico. To date, ICON has delivered two dozen 3D-printed homes/structures across the U.S. and Mexico, the most completed by any construction tech company.

Tell us more about ICON’s printer?

ICON unveiled its next generation “Vulcan” 3D printer for homes on March 11, 2019 and a few months later began shipping the award-winning technology to begin its very important work of delivering affordable, resilient, dignified housing around the world. To date, the Vulcan construction system has delivered two dozen 3D-printed homes / structures across Mexico and the U.S.

To date, the Vulcan construction system has delivered two dozen 3D-printed homes / structures across Mexico and the U.S.

The Vulcan is the first printer of its kind in that it has the capability of printing homes in which people actually want to live. It can be operated by anyone with basic training thanks to the improvements in automation, mechatronics and a suite of specialized software.

Has ICON received any funding?

ICON has raised $451 million in funding to date.

February 2022: ICON raised $185 million in a series B-1 round of financing led by Tiger Global.

August 2021: ICON completed a $207 million series B round of financing led by Norwest Venture Partners. ICON welcomed Jeff Crowe, Managing Partner at Norwest Venture Partners, a leading multi-stage investment firm, to its Board of Directors. From world-renowned architects to the country’s largest homebuilders, ICON’s line-up of series B investors also included 8VC, BIG-Bjarke Ingels Group, BOND, Citi, Crosstimbers, Ensemble, Fifth Wall, LENx, Moderne Ventures and Oakhouse Partners.

August 2020: ICON announced its series A round of financing led by Moderne Ventures. The company welcomed Constance Freedman, Founder and Managing Partner of Moderne Ventures and Khan Tasinga, Director at Palantir Technologies, to its Board of Directors. Notably, the international architecture firm BIG-Bjarke Ingels Group joined the series A round of investors, which also includes CAZ Investments, Citi, Crosstimbers Ventures, Ironspring Ventures, Next Coast Ventures, Oakhouse Partners, Trust Ventures, Vulcan Capital and Wavemaker Partners.

October 2018: ICON announced $9 million in seed funding led by Oakhouse Partners. Jason Portnoy, Managing Partner, Oakhouse Partners, who led the seed round of funding, joined ICON's Board of Directors. Seed round investors included Cielo Property Group, D.R. Horton and Emaar among others. ICON’s round of funding accelerated the development of its printers, created a variety of home types and designs and enhanced its core technology stack to further its mission of using advanced construction technologies to advance humanity.

Is ICON a publicly traded company?

No, ICON is a privately held company.

How long was the next generation of the Vulcan 3D printer in development?

The ICON team began research and development immediately following the completion of their first prototype 3D-printed home in March 2018. The work shifted into high gear about fall 2018 following a seed round of financing.

What features does the next generation Vulcan have in comparison to its predecessor?

Tablet-based controls, advanced UI, 4x larger print area, 2.5x faster, automated material mixing, pumping, and delivery, safety features, remote monitoring, and on-board lighting for printing at night or in low-light conditions and more.

Where and when will you be 3D printing more homes?

ICON has delivered two dozen 3D-printed homes and structures to date across the U.S. and Mexico, the most completed by any construction tech company.

Numerous projects are underway to deliver social housing, disaster relief housing and mainstream housing developments in addition to the development of construction systems for further exploration of the Moon and eventually Mars.

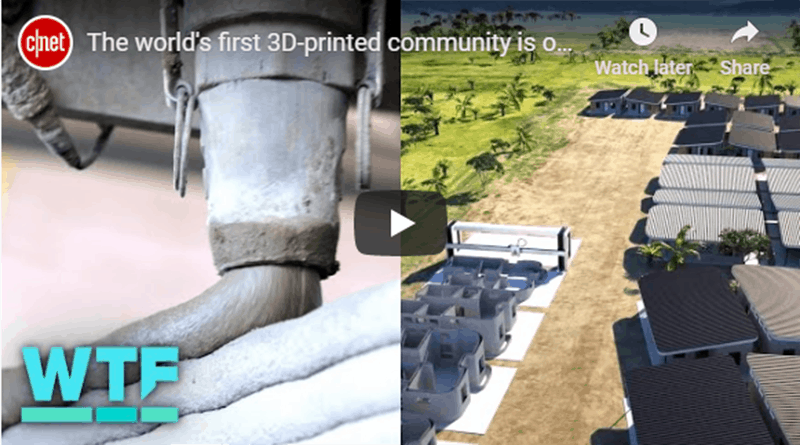

What are the challenges of 3D printing in less than ideal conditions?

The Vulcan construction system has delivered projects in seismic zones, flood-prone areas and a variety of climates. The printer that was deployed to Nacajuca, Mexico in 2019 to deliver the world's first community of 3D-printed homes for housing nonprofit, New Story, was designed to work under the constraints common in places like Haiti and rural El Salvador where power can be unpredictable, potable water is not a guarantee, and technical assistance is sparse. Building the printer to not rely on these items was crucial to bet on the reliability of the printer in the field.

When will the first humans move into a 3D printed home by ICON?

In late summer 2020, the first humans to ever live in a 3D-printed home in the U. S. moved into their 400 square-foot homes at Community First! Village in Austin, TX. Learn more.

S. moved into their 400 square-foot homes at Community First! Village in Austin, TX. Learn more.

Additionally, the world's first community of 3D-printed homes were completed in Nacajuca, Mexico for housing nonprofit, New Story. The organization is working with families on the best dates to move into their new homes, but likely will occur once the neighborhood is complete, which includes ecoblock homes as well. Learn more.

The first, permitted 3D-printed home located in Austin, TX (also known as the Chicon House) is used as an office space for the owner.

Is the first printed home by ICON a permanent structure?

Yes. In March 2018, ICON built the first, permitted 3D-printed home in the U.S. Located in Austin, TX, the 350 square foot proof-of-concept home was 3D printed on-site and is a permitted, permanent structure that has received a full Certificate of Occupancy permit by the City of Austin.

How long are the 3D printed houses expected to last that ICON has printed?

The printed homes are expected to last as long or longer than standard Concrete Masonry Unit (CMU) built homes. The homes are built to the International Building Code (IBC) structural code standard.

The homes are built to the International Building Code (IBC) structural code standard.

Are the roof, windows and other finishes done conventionally or also 3D printed on ICON's past and current projects?

To date, each of ICON's delivered projects have included conventional construction methods for the finish out of the homes including the roof, windows and other finishes. To learn more about ICON's projects, visit the Updates page.

Are there challenges meeting housing codes?

Beyond torrential downpours in Austin over the printing time period of the first, permitted 3D printed home we delivered in March 2018, the challenges included mostly structural engineering and foundation adjustments as the city had never seen a building of its kind. The home received a full certificate of occupancy.

The homes at Community First! Village in Austin, TX are built to standard building codes according to IBC, City of Austin and ADA. The team is currently working with the City of Austin on its first mainstream housing development of 3D-printed homes for developer 3Strands.

Can you print two-story buildings?

The current technology is focused on single-story structures. We look forward to future advancements and delivering multi-story projects.

How long was ICON working on 3D printing before printing the first home in Austin, TX?

The team was tinkering for 2-3 years before forming the company, and then was actively in stealth mode for about a year creating the Vulcan construction system, which was unveiled during SXSW in March 2018. The next generation of the Vulcan construction system was unveiled in March 2019 and began printing homes summer 2019.

When was the first prototype home created and how long did it take?

In March 2018, the first permitted, 3D printed house was created in ~47 hours of total printing time spread across several days. The 350 square-foot home is located in Austin, TX. The home served as a proof-of-concept and was created in partnership with the housing non-profit, New Story. New Story and ICON broke ground on the first 3D printed community in the world in late summer 2019 in Tabasco, Mexico.

New Story and ICON broke ground on the first 3D printed community in the world in late summer 2019 in Tabasco, Mexico.

Is the Vulcan printer for sale?

We’re glad you’re interested in the future of homebuilding and considering a 3D-printed home. We are working hard to make more printers as fast as we can. We are working with strategic partners to deliver specific projects and continuing to further the advancements of the technology stack. We will keep everyone posted as there is new information to share.

When can we purchase 3D printed homes by ICON?

In March 2020, developer 3Strands, announced America's first 3D-printed homes for sale marking it the first multi-home mainstream housing development project leveraging ICON's proprietary 3D printing technology to construct the two to four bedrooms homes.

In the future, we hope to see ICON’s technology stack of robotics, software and advanced material in the hands of many developers, architects, builders and organizations. At this time, we are working with a handful of strategic partners to deliver big projects both domestically and internationally and continuing to iterate on the technology.

At this time, we are working with a handful of strategic partners to deliver big projects both domestically and internationally and continuing to iterate on the technology.

How long does it take to 3D print a home using ICON’s technology?

Currently we have printed homes ranging from 400-500 square feet using the Vulcan 3D printer for homes, with each home taking around 24 hours spread across several days to complete the full wall system. We have printed three homes at a time, simultaneously, in Austin, TX and two at a time, simultaneously, in Mexico, which further increases the speed in which we can deliver homes.

What controls the Vulcan printer? How many people are needed to 3D print a house?

The ICON team communicates with the printer via an ICON developed app for mobile devices such as a tablet or smartphone.

Past and current projects require around 3-4 people for an average print job including 1-2 on the printer system and 1-2 on the Magma system.

What is the process from start to finish of 3D printing a home?

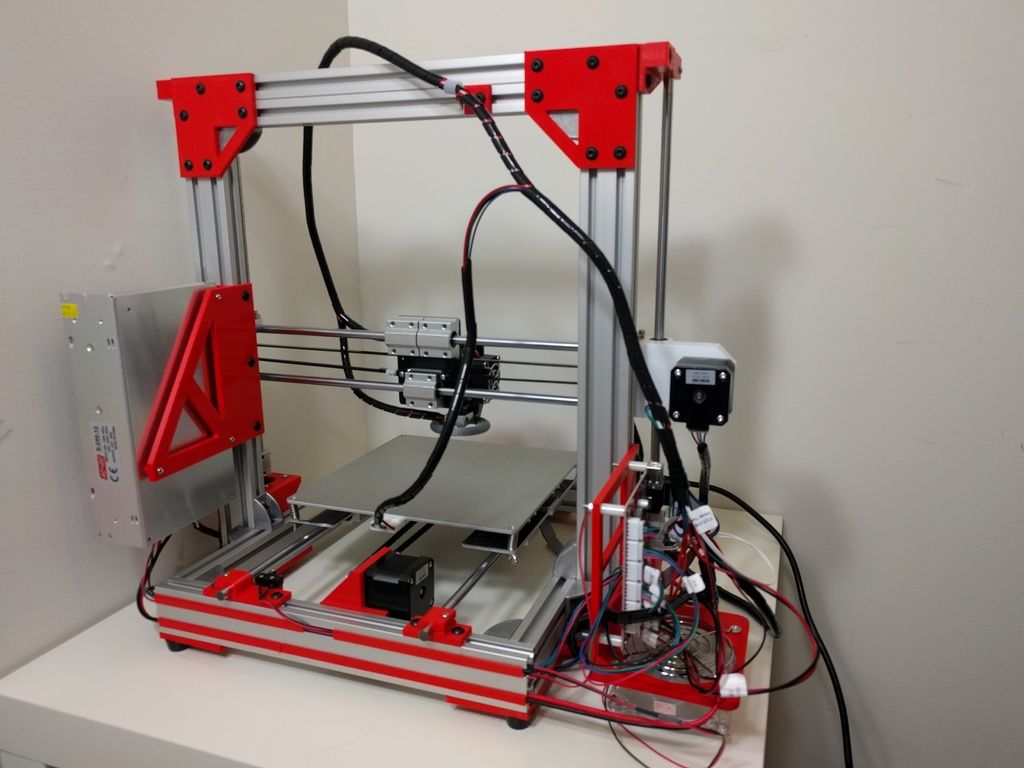

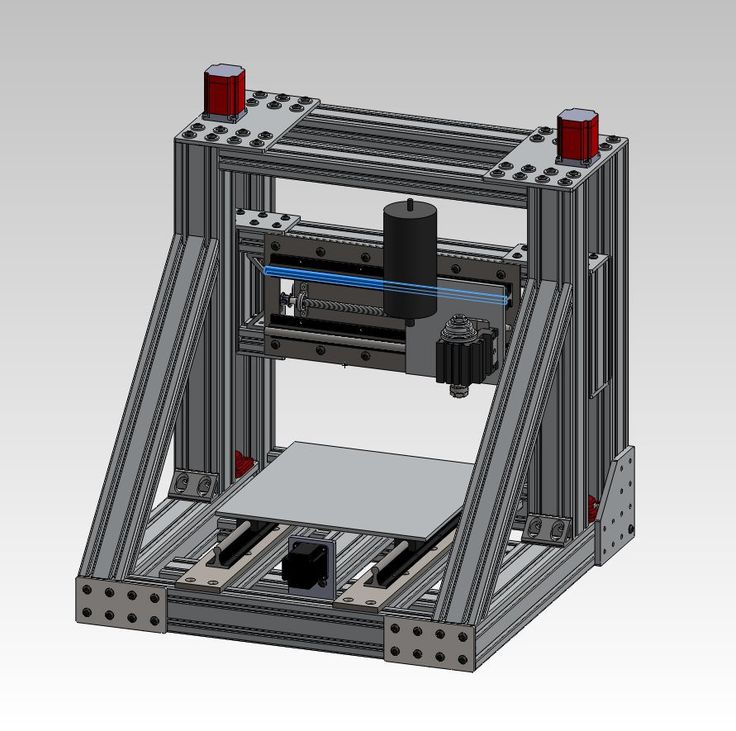

Once the foundation has been poured and cured, the ICON team affixes two rails to the edge of the foundation. The Vulcan, a mobile, gantry-style 3D printer, arrives and rolls off the truck and onto the slab. The team completes a few software checks, gets the material ready via the Magma material delivery system and then begins to extrude layer by layer to deliver the full wall system of the home. The printer is operated with an ICON developed app for mobile devices such as a tablet or smartphone.

There are others who are working on 3D printing homes. What are the particular strengths of ICON?

ICON's proven 3D printing technology provides safer, more resilient homes that are designed to withstand fire, flood, wind, and other natural disasters better than conventionally built homes and that can be built in a matter of weeks.

Our technology works reliably enough for us to begin taking on numerous customers and projects across social housing, disaster relief housing and mainstream housing developments, in addition to developing construction systems to create infrastructure and habitats on the Moon and eventually Mars with NASA.

We have a conviction about the advantages of “site printing” a house as opposed to printing in a warehouse or printing pieces for assembly later.

We believe the gantry-style architecture of the printer is the fastest, most reliable, and easiest to control approach to 3D printing one and two story buildings.

Our proprietary, advanced material “Lavacrete” has been able to pass every structural test we have put it through so far. This means our homes will be safe for people to live in and resilient to the varieties of conditions where we may deploy this technology.

We have people living in 3D-printed homes by ICON since summer 2020.

What material is used in your 3D-printed homes and structures?

We developed a proprietary formula that is unique for our current and future printing projects that we’ve dubbed “Lavacrete.” Lavacrete is a combination of Portland cement, fillers, and supplementary cementitious materials (SCM’s) along with “advanced additives” intended to help it survive extreme weather.

Why is 3D printing the most appropriate technology for addressing affordability and building performance in construction?

Conventional construction is slow, fragmented, wasteful, and has poor thermal properties which increase energy use, increase operating costs, and decrease comfort. Also, conventional materials like drywall and particle board are some of the least resilient materials ever invented. By contrast, 3D printing offers the following:

Speed

Decrease in manual labor

Concrete is a well understood, affordable, resilient material

Concrete has a high thermal mass (comfort & energy efficiency)

3D printing produces a continuous, unbroken thermal envelope (comfort & energy efficiency)

Replaces multiple systems of the home in one technology (foundation, structure, insulation, interior & exterior sheathing, moisture barrier, finished surfaces, etc.)

Near zero waste

Tremendous design freedom (curves and slopes are no more challenging or expensive than straight, plumb lines).

What category of 3D printing are you using? Is this under ICON IP? Or is this a material innovation?

The Vulcan is a gantry-style printer on rails. We have several patents pending in hardware, software, process, and materials.

What distinguishes this printer from other 3D printers?

The ease of operation, the commitment to site-printing, it’s size and speed, the level and sophistication of the automations, and the safety features.

What are the technical specs of the Vulcan?

Total Height: 11.5 feet

Print Height: 8.5 feet

Total Width: 33 feet

Print Width: 28 feet

Length: effectively infinite

Weight: 3800 lbs

Operating Horizontal Speed: 5-7 linear inches per second

Nominal Power: 16 kW

Peak Power: 35kW

Voltage: 230/240 V single phase

Water Requirements: 2 GPM

Software: Tablet-based controls

Size of operating crew: 3-4 people

Printing Material Mixing & Pumping: ICON Magma System

Standard print bead: 1" tall, 2" wide

Required Concrete: ICON Lavacrete (proprietary mixture)

What accolades has ICON received?

TIME Magazine's 'Best Inventions of 2018' and TIME100 Next list featuring Jason Ballard, co-founder and CEO

Forbes '30 Under 30' featuring Alex Le Roux, co-founder and CTO

Fast Company ‘World’s Most Innovative Companies' for 2019, 2020, and 2021

Red Dot Design Award 2021

Fast Company 'World Changing Ideas' General Excellence 2020

Fast Company ‘Innovation By Design’ 2019, 2020, 2021

Popular Science 'Best of What's New/Best Innovations of 2018'

MIT's 'Innovators Under 35' featuring Alex Le Roux

Edison Awards finalist for 2019

SXSW Pitch Award - Social Good category 2018

What work is ICON doing for off-world construction?

Since its founding, ICON has been thinking about off-world construction and its natural progression around the ways additive construction and 3D printing can create a better future for humanity.

In October 2020, ICON announced it had been awarded a government Small Business Innovation Research (SBIR) contract including funding from NASA to begin research and development of a space-based construction system that could support future exploration of the Moon. ICON will also dedicated a division of the company to focus on space.

In fall 2020, ICON delivered the world’s first 3D-printed rocket pad designed by students from around the country. NASA and the student team conducted static fire with a rocket motor on the first 3D printed rocket launch pad outside of Austin, TX in March 2021.

Recently, ICON competed 3D printing the first simulated Mars surface habitat for NASA designed by renowned architecture firm BIG-Bjarke Ingels Group. Located at Johnson Space Center in Houston, Texas, Mars Dune Alpha will aid in long-duration science missions.

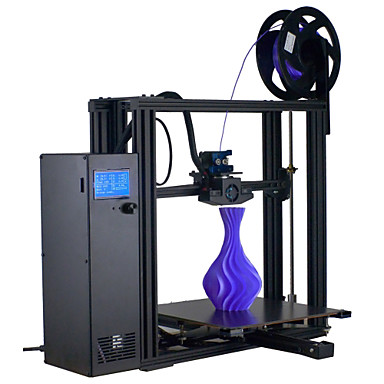

E3D Volcano - enhanced plastic heating for high print speeds

Reviews

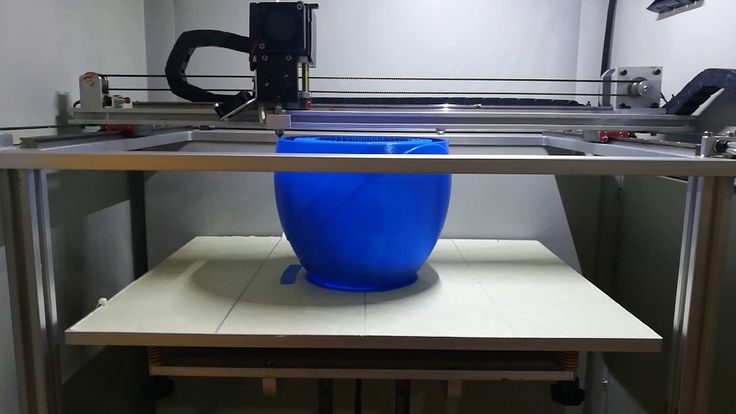

Sometimes you need to print a large part, but it stops the print time calculated by the slicer.

I do not have a separate room for a 3D printer, and the time is limited from 11 am to 11 pm, but I usually cannot print more than 8 hours a day. As a result, it turns out that I can only use a very small volume to print a part from the total volume incorporated in the design of my 3D printer.

I do not have a separate room for a 3D printer, and the time is limited from 11 am to 11 pm, but I usually cannot print more than 8 hours a day. As a result, it turns out that I can only use a very small volume to print a part from the total volume incorporated in the design of my 3D printer. I use original hot ends from E3D and can freely change nozzles from 0.25 mm to 0.8 mm. I printed with the entire range of nozzles.

- The 0.25mm nozzle is very finicky.

- The 0.3 mm nozzle is great for printing small details with PLA plastic.

- 0.4 - 0.6 mm nozzles are optimal for everyday printing.

- The 0.8 mm nozzle is already interesting for high-performance printing, but the plastic does not have time to warm up and the filament becomes thinner and cracks appear in high-speed sections. You have to limit the speed and thickness of the layer.

Examples of printing with a 0.8 mm nozzle:

Slits are already visible here:

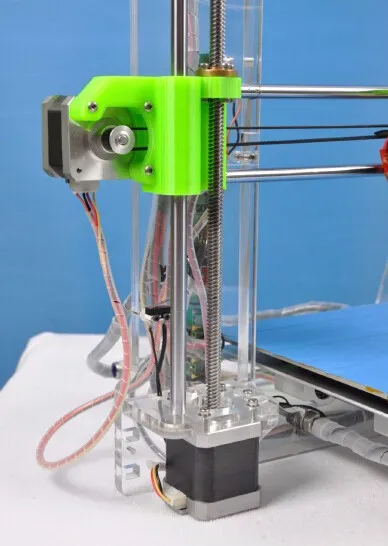

At the time I started thinking about it, E3D announced Volcano - an enlarged heating block on the hot end with a set of large-caliber nozzles for high-speed plastic consumption. At the same time, I was already preparing to materialize the design of the bar extruder.

At the same time, I was already preparing to materialize the design of the bar extruder.

And on January 18, I paid for the purchase of Volcano . I had to wait a very long time and at some point I wrote to them that I had been waiting too long. E3D immediately agreed with me and sent the long-awaited set again. Picked up the parcel as much as 9April.

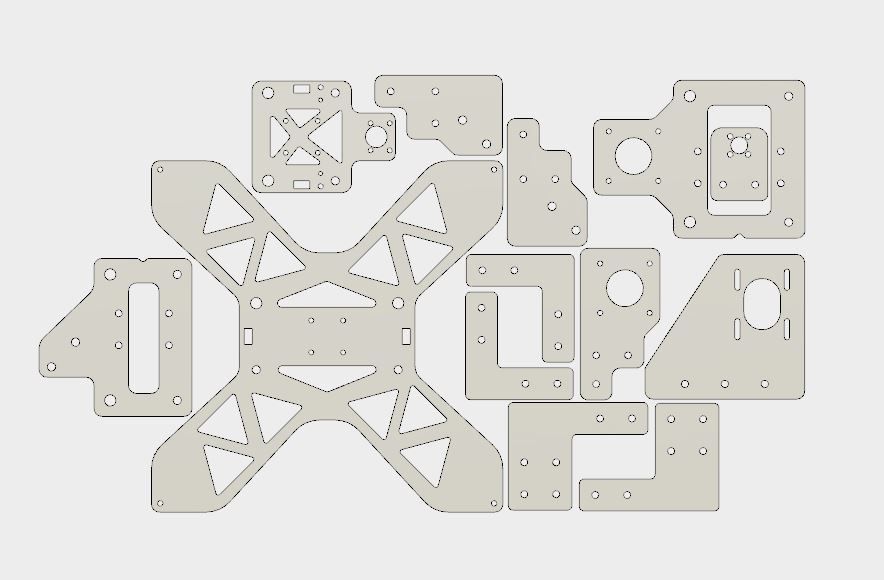

Blueprint

Unpacking a parcel from England. Standard E3D box.

Invariably there are sweets in the set.

Nozzles 0.6 mm, 0.8 mm, 1 mm and 1.2 mm.

Photo with thermal barrier tube in different positions

Screwed to a spare hotend v6

The heating cartridge turned out to be indecent length. I had to scrape the bottom of the barrel.

One Chinese guy turned out to be shorter, and he chose him

Comparison of dimensions of aluminum blocks Volcano and E3D-v6

I bet on Mendel90 with hotend v5. Due to the peculiarities of the installation of the heating cartridge, I had to remove the extruder from the carriage and unscrew the hot end.

Due to the peculiarities of the installation of the heating cartridge, I had to remove the extruder from the carriage and unscrew the hot end.

Complete. The thermistor did not change and did not fasten with a screw.

Printing with a 0.8 nozzle is coarse but fast.

Comparison of print times with 0.4mm and 0.8mm nozzles at comparable settings.

Nozzle 0.4 mm.

Nozzle 0.8 mm.

Cons:

- You need to watch the bridges. Because of the thick layer, a creepy hedgehog is obtained.

- On thick nozzles, the seal of the joint of the outer layer of the part (seam) is very rough.

- Impossible to quickly change heating blocks v6 (v5) and Volcano if the ceramic heater is soldered (for me).

Practical experience is still small and it is too early to draw conclusions , but one thing is clear - for each part you can choose the optimal nozzle and thereby reduce machine hours for manufacturing the part, which leads to a reduction in the 3D printer fleet and an increase in the amount of joy from 3D printing :)

High-speed printing is in demand by everyone who needs to print large parts without small elements, for example, cosplayers for printing helmets and armor.

Volcano can also be purchased from the Chinese on Aliexpress or in Russia from MZTO.

Draft, corrected and supplemented versions of my posts can be read in LiveJournal.

Good luck and speed printing! :)

Subscribe to the author

Subscribe

Don't want to

28

More interesting articles

Argond

Loading

24.10.2022

1874

26

Subscribe to the author

Subscribe

Don't want

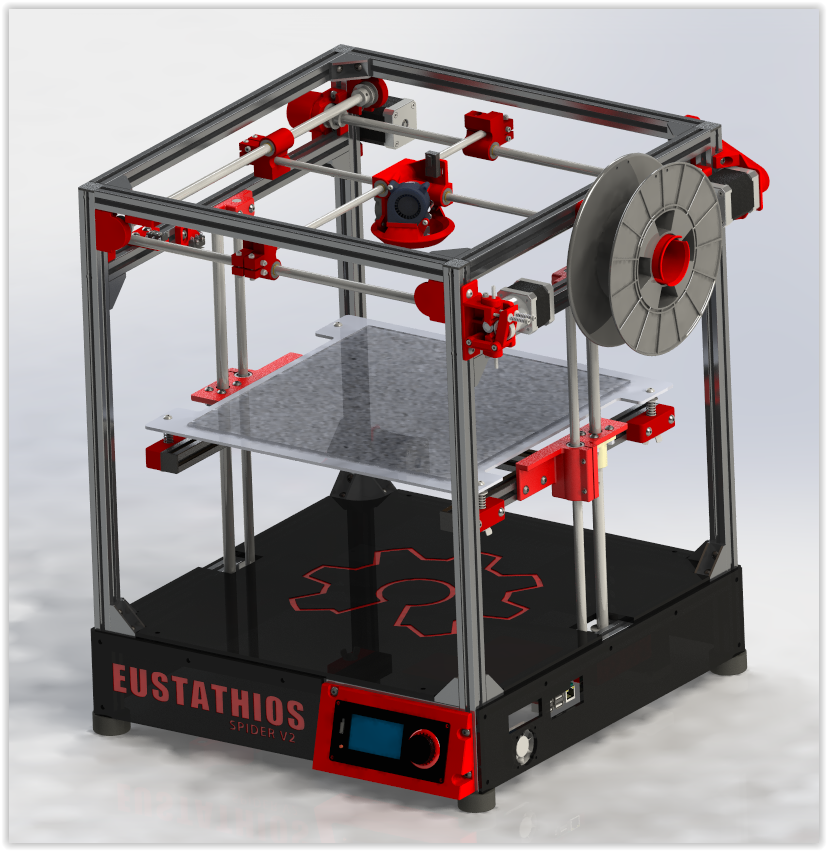

I present a review of a self-made FDM printer of my own design, similar to one of the classic ...

Read more

2

Follow author

Subscribe

Don't want

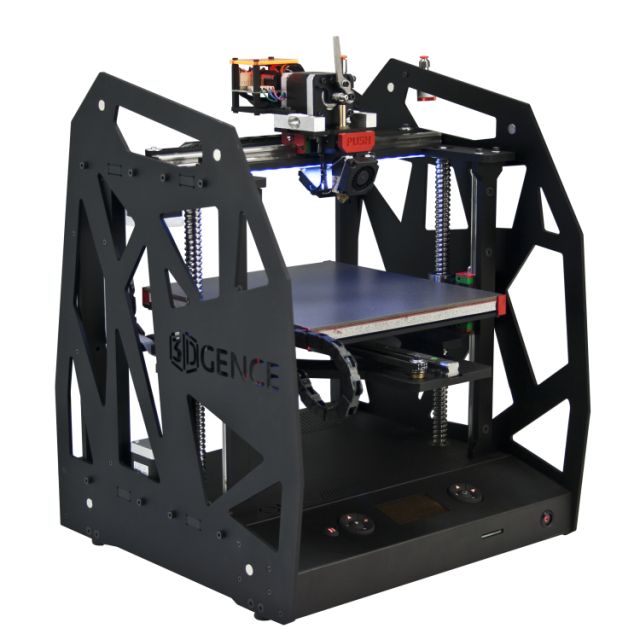

Dreambot 3D printers are reliable high performance devices for professional use. ...

...

Read more

114

Subscribe to the author

Subscribe

Don't want to

The review is a continuation of the story about the practical use of laser engraving at home ...

Read more

Icon has released a construction 3D printer Vulcan II

News

Subscribe author

Subscribe

Don't want

7

Texas-based Icon announces that it has completed development work on its second-generation Vulcan II 3D construction printer and intends to start open ordering next month.

The Austin-based startup is best known for its collaboration with New Story, a non-profit organization that promotes the idea of building low-income low-income homes, including in developing countries. The guys are going to solve the housing problem at the global level, of course, with the help of additive technologies.

Last spring, the partners presented to the public, or rather investors, a small 3D-printed house with all amenities, supposedly costing only four thousand dollars. The investors nodded approvingly and poured $9 million into the innovative venture, inspiring Texas engineers to develop a commercial version of their additive plant.

Icon's 3D printers follow the concept of Contour Crafting by Prof. Beroch Khoshnevis: movable gantry structures mounted on rails or wheels, giving a theoretically unlimited build length. The width of the working area of Vulcan II reaches ten meters, and in height - two and a half. The extruder produces layers two and a half centimeters thick and five centimeters wide at a speed of 125 to 175 mm/s. Thanks to a set of sensors and special algorithms, the system is able to adjust operating parameters such as paving speed in real time.

As befits a "volcano", the 3D printer spews "lava" - a special mixture of Lavacrete based on Portland cement. The recipe is kept secret, but the developers claim that the compressive strength reaches 6000 psi, and thus exceeds that of commercially available building materials. Upon completion of 3D printing, it is planned to finish the walls with drywall from the inside and siding from the outside.

The recipe is kept secret, but the developers claim that the compressive strength reaches 6000 psi, and thus exceeds that of commercially available building materials. Upon completion of 3D printing, it is planned to finish the walls with drywall from the inside and siding from the outside.

The maximum power consumption of the equipment reaches 35 kW with a nominal power of around 16 kW. The equipment complies with the IP66 standard (protection against dust and moisture), and even has a built-in LED backlight for working at night. Control is carried out from the tablet, while a team of four to six people is enough to operate the entire system, including a 3D printer and Magma mixing equipment.

So far, the company is working on securing pre-orders, but from next month it promises to start accepting applications from everyone with deliveries starting next year. Additional information is available on Icon's official website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow the author

Subscribe

Don't want

7

More interesting articles

9

Subscribe to the author

Subscribe

Don't want

In the village of Aisha, Zelenodolsk district of Tatarstan, work is underway to build thirty-four houses with the use of...

Read more

5

Subscribe to the author

Subscribe

Don't want to

The World Nuclear Association (WNA) published a report on the application of advanced manufacturing technologies.