Economist 3d printing

A new type of 3D printing may bring it into the mainstream

Science & technology | Additive manufacturing

It is to the old version as the printing press is to the pen

EARLY FORMS of additive manufacturing, or 3D printing as it is popularly called, began to emerge in the 1980s. But it took more than a decade for the technology to start taking off. Initially, it was used to make prototypes. Now, intricate components are routinely 3D-printed in plastic and metal, for use in products ranging from jet engines and robots to cars.

Listen to this story.Enjoy more audio and podcasts on iOS or Android.

Your browser does not support the <audio> element.

Listen to this story

Save time by listening to our audio articles as you multitask

Sales of 3D-printing services and machines grew by more than 17% in 2021, to reach around $15bn, according to preliminary estimates for a report by Wohlers Associates, a firm that tracks the industry. However, as useful as additive manufacturing has become, it struggles to compete on cost and speed with more established ways of making things, such as injecting molten plastic into moulds or stamping out metal parts with a giant press.

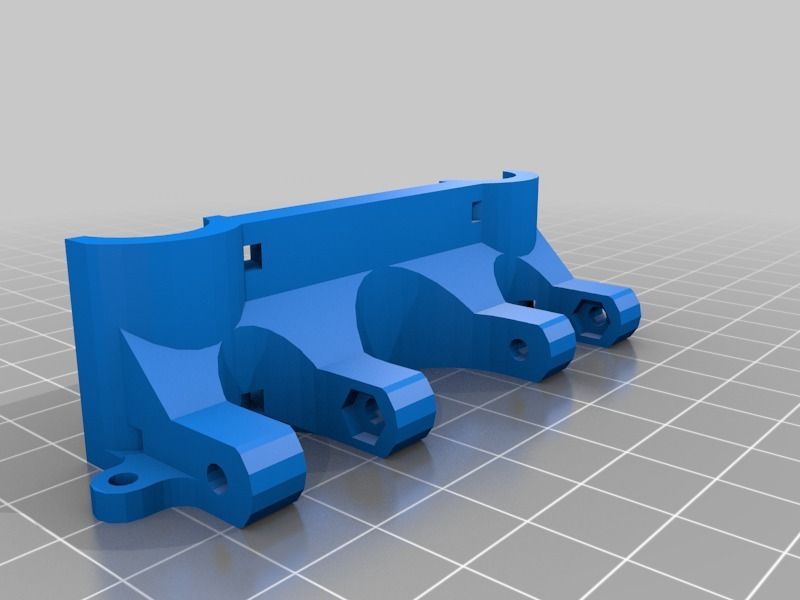

As a result, most manufacturers use 3D printers to produce low-volume, high-value parts. The extra time and expense this takes can be worth it for certain items. Making things additively produces objects layer by layer, so tricky internal structures can be incorporated more easily into a design. Shapes can also be optimised for strength and lightness, saving materials. But what if these advantages could be had at the speed and cost of conventional factory processes? A new form of additive manufacturing aims to do just that.

The origin of this process, trademarked “Area Printing”, goes back to 2009. That was when James DeMuth, having finished his master’s degree in mechanical engineering at Stanford University, started work at the National Ignition Facility, part of the American Department of Energy’s Lawrence Livermore National Laboratory (LLNL). This uses some of the world’s most powerful lasers to study nuclear fusion.

This uses some of the world’s most powerful lasers to study nuclear fusion.

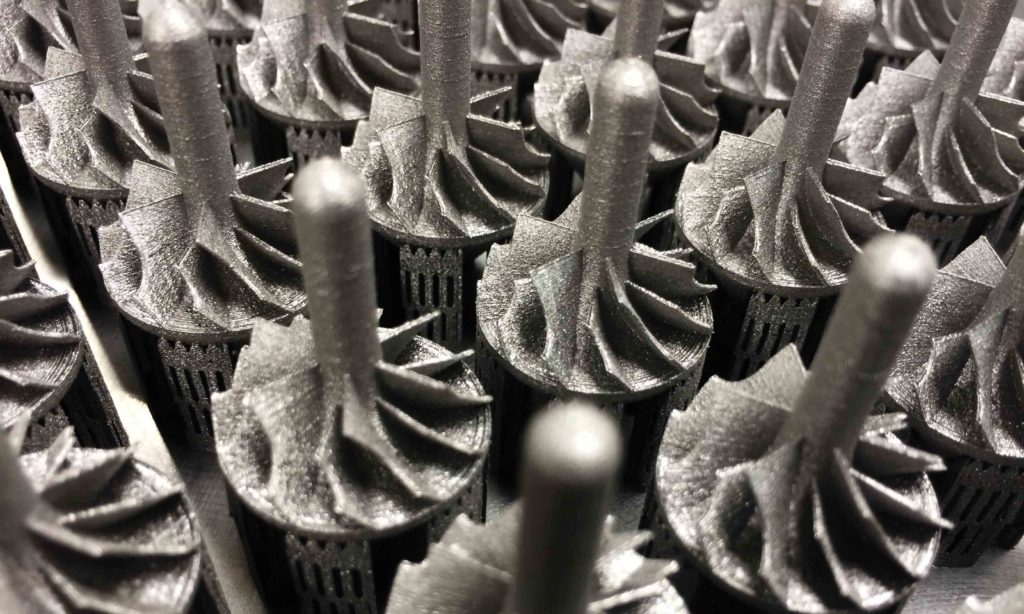

One of the challenges Mr DeMuth was given was to find a way to use a highly specialised type of steel to manufacture a 12-metre wide fusion chamber containing many complex features. He considered a form of 3D printing, called Laser Powder Bed Fusion (L-PBF), for the job. This employs a laser beam to weld together particles on a thin bed of powdered metal, to form the required shape of the object’s first layer. Then more powder is added and a second layer is welded on top of the first. And so on, until the item is complete.

The problem is that, as with most other forms of 3D printing, there is an inverse relationship between resolution, which governs the level of detail that can be printed, and the speed of the process. Hence, some large components with fine details can take days, if not months, to print. Producing the chamber looked as if it might take decades. L-PBF was clearly unfeasible for such an application.

L-PBF was clearly unfeasible for such an application.

This got Mr DeMuth and a group of colleagues thinking about how to speed things up without compromising quality. After some work, they started using a device called an optically addressed light valve, which had been developed at LLNL. This permits a pulsed infrared laser, with its beam shaped to have a square cross-section, to be patterned with a high-resolution image. Working a bit like a photographic negative, the image can block or pass light, creating millions of tiny laser spots, much like the pixels that make up a digital image.

When projected onto a bed of powder, this patterned laser light can weld a complete area in one go. Mr DeMuth likens the process to producing documents with a printing press instead of writing them out individually with a pen.

Not such a dotty idea

In 2015 Mr DeMuth co-founded Seurat Technologies, to commercialise the technology. This Massachusetts-based firm is named after Georges Seurat, a post-impressionist French artist who pioneered a painting style called pointillism that builds pictures up from dots. Several companies, including GM and Volkswagen, a pair of carmakers, Siemens Energy, a division of a large German group, and Denso, a big Japanese components firm, have partnered with Seurat to explore the use of its first prototype area-printing machine.

Several companies, including GM and Volkswagen, a pair of carmakers, Siemens Energy, a division of a large German group, and Denso, a big Japanese components firm, have partnered with Seurat to explore the use of its first prototype area-printing machine.

This prototype produces a series of small, patternable squares on the powder bed. Their size depends on the material. Aluminium requires 15mm squares. Titanium requires 13mm. Steel requires 10mm. Individually, these squares might seem small. But 40 of them can be printed adjacent to each other every second, so a large area can be covered quickly. The prototype was designed to work at this scale to keep the size of the laser and the amount of energy it consumes to a practical level.

With the equivalent of 2.4m pixels projected in each square, the machine can print parts with layers just 25 microns (millionths of a metre) thick at a rate of 3kg an hour. This is ten times faster than a typical L-PBF machine at such a fine resolution, says Mr DeMuth. Production versions of the area printer are now being built, and future generations of the machine should end up being 100 times faster.

Production versions of the area printer are now being built, and future generations of the machine should end up being 100 times faster.

All that, says Mr DeMuth, means area printing will be competitive with mass-production factory processes, such as machining, stamping and casting. As an example, he believes that by 2030 it will be possible to produce silverware (utensils that nowadays are made from stainless steel) for $25 a kilo. “That means we could actually print silverware cheaper than you could stamp them out,” he adds.

Other laser-based 3D printers are getting faster, too. L-PBF machines, for example, may be fitted with several beams—though the complexity involved could limit their number. And many non-laser ways to print things are improving as well, using all manner of materials to make items ranging from buildings to bridges to biscuits. One way or another, then, 3D printing seems at last to be ready to give traditional factories a run for their money. ■

■

To enjoy more of our mind-expanding science coverage, sign up to Simply Science, our weekly newsletter.

This article appeared in the Science & technology section of the print edition under the headline "A Gutenberg moment"

Science & technology March 19th 2022

- Russian tanks in Ukraine are sprouting cages

- War in Ukraine threatens an intriguing piece of wildlife science

- How to tweak drug-design software to create chemical weapons

- A new type of 3D printing may bring it into the mainstream

From the March 19th 2022 edition

Discover stories from this section and more in the list of contents

Explore the editionReuse this content

A gooey way to 3D print plastics

Science & technology | Additive manufacturing

Use high viscosity resins and alternate layers

The use of plastics for mass production traces its roots to the 1860s and John Wesley Hyatt, a printer from Albany, New York. Hyatt was responding to the offer of a $10,000 reward to anyone who could come up with an alternative way of making billiard balls—which were, in those days, carved out of ivory, a commodity becoming in short supply. His solution was to form them by pumping a molten synthetic plastic called celluloid into a mould.

Hyatt was responding to the offer of a $10,000 reward to anyone who could come up with an alternative way of making billiard balls—which were, in those days, carved out of ivory, a commodity becoming in short supply. His solution was to form them by pumping a molten synthetic plastic called celluloid into a mould.

Listen to this story.Enjoy more audio and podcasts on iOS or Android.

Your browser does not support the <audio> element.

Listen to this story

Save time by listening to our audio articles as you multitask

Although Hyatt appears never to have received the prize, the process he invented, injection moulding, became the way in which most plastic items are made. At least they were until the emergence in the early 1980s of additive manufacturing, popularly known as 3d printing. Machines that can print things in plastic have become ever more capable, turning out objects ranging from toys to medical implants, and components for cars, drones and aircraft.

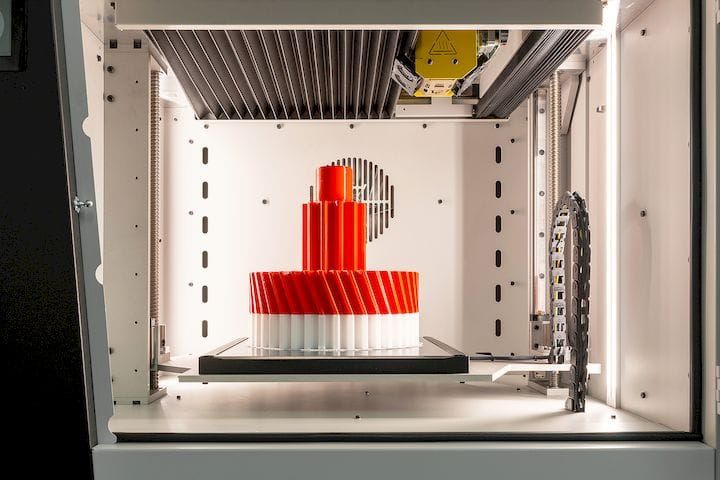

Another advance is now in the making. bcn3d Technologies, a Spanish producer of 3d printers, has developed a new form of plastic printing which it calls viscous lithography manufacturing (vlm). From an initial 500 firms said to be keen to try the idea out, bcn3d has whittled the number down to 20 large manufacturers from industries such as carmaking, electronics and engineering. These are now working on potential applications at the company’s base in Barcelona. The plan is that early next year they will install vlm machines at their factories around the world before the printers go on general sale in 2024.

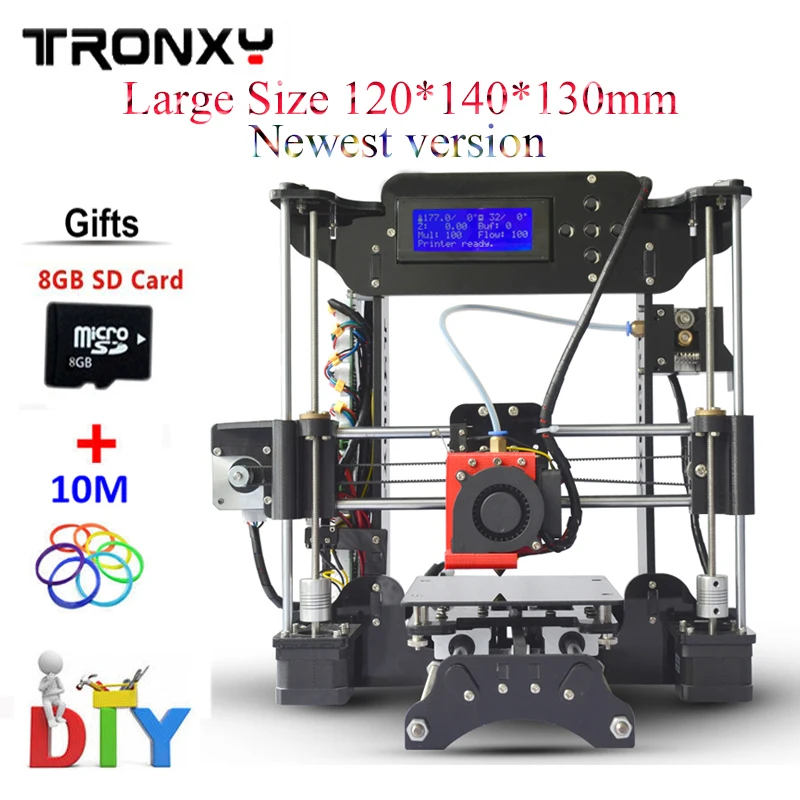

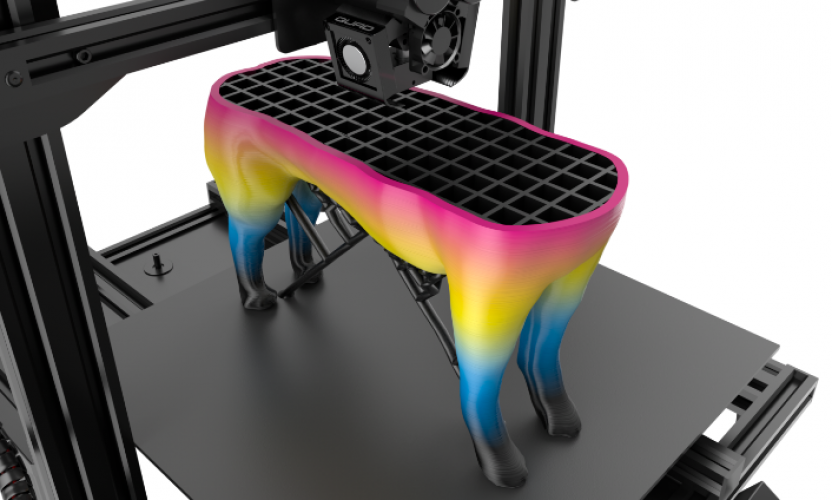

3d printers can make plastic objects in several ways. One widely used technique involves an extrusion head tracing lines of molten polymer onto a so-called build plate. Once the first layer is done, the plate moves down a tad, a second layer is added on top of the first, and so on. More recent machines project a pattern of ultraviolet (uv) light into a vat of photosensitive liquid resin to cure and solidify the layers required to create an object. A build plate then steadily pulls the object out of the vat.

More recent machines project a pattern of ultraviolet (uv) light into a vat of photosensitive liquid resin to cure and solidify the layers required to create an object. A build plate then steadily pulls the object out of the vat.

It is this second approach on which vlm is building, as it were—though the process works more like an upside-down screen printer. The machine consists of a pair of liquid-resin reservoirs, one each on either side of a build plate. Above all of these sits a transparent screen that shuttles back and forth. When one side of the screen is above a reservoir a roller coats its underside with a thin film of resin. At the same time, the adjacent side of the screen, having already been coated at the second reservoir, is positioned over the build plate.

The plate then rises to make contact with the resin film on this part of the screen. A pattern of uv light from an lcd is projected through the screen from above to cure the resin in particular areas, allowing a complete layer to be solidified in one shot. As the build plate is lowered it peels this layer away. The peeled part of the screen then slides back to its reservoir, where any unused resin is recovered to be reused, and the newly coated other side of the screen is subjected to the same process of uv curing and peeling. And so the process continues, back and forth, until the object is complete.

As the build plate is lowered it peels this layer away. The peeled part of the screen then slides back to its reservoir, where any unused resin is recovered to be reused, and the newly coated other side of the screen is subjected to the same process of uv curing and peeling. And so the process continues, back and forth, until the object is complete.

One benefit of printing in resins is that they produce finely detailed, high-quality plastic parts. A drawback is that they can be brittle. It is possible to mix additional materials into resins, to improve strength, for instance, or to add flexibility. But, a bit like adding more ingredients to a cake, this thickens the mixture, which can make the resin difficult to print. The vlm process, however, can cope with this because, as Eric Pallarés, the company’s chief technology officer, explains, it is designed from the get-go to use much thicker resins.

The two reservoirs can also be filled with different resins, allowing more complex construction. This would permit, say, a soft-touch surface to be added to a rigid switch. Strength could be achieved by mixing in filler materials made from the shredded remains of previously printed objects. Alternatively, a soluble material could be printed, to support delicate structures during construction, and these supports could then be washed away. At the moment, support structures often have to be added and removed laboriously, by hand.

This would permit, say, a soft-touch surface to be added to a rigid switch. Strength could be achieved by mixing in filler materials made from the shredded remains of previously printed objects. Alternatively, a soluble material could be printed, to support delicate structures during construction, and these supports could then be washed away. At the moment, support structures often have to be added and removed laboriously, by hand.

Ejecting injection

So far, vlm is proving roughly ten times faster at making things than most other forms of plastic printing, claims Mr Pallarés. And the size of objects which can be produced is limited only by the size of the lcd used to project the image of each layer. As with most 3d printers, including those which use different processes to print metals, vlm is capable of making complex structures that are difficult or impossible to fabricate with conventional production methods such as injection moulding.

Injection moulding is also uneconomic when it comes to producing low volumes, because the precision-engineered moulds it requires can cost several hundred thousand dollars to make. That does not matter if those moulds are being used to make huge numbers of things, but for small batches the cost is prohibitive.

Additive manufacturing, however, thrives on low volumes of production, because 3d printers run on software, which is easier and cheaper to change than physical moulds. When it comes to making millions of cheap and cheerful plastic things, Hyatt’s invention is likely to retain its edge for a while. For more bespoke items, additive manufacturing is just getting better and better. ■

Curious about the world? To enjoy our mind-expanding science coverage, sign up to Simply Science, our weekly newsletter.

This article appeared in the Science & technology section of the print edition under the headline "Gooey goings on"

Science & technology September 3rd 2022

- Mines are the neglected workhorses of naval strategy

- A gooey way to 3D print plastics

- The genes of a jellyfish show how to live forever

- Mouse “embryoids” can now be grown from stem cells

From the September 3rd 2022 edition

Discover stories from this section and more in the list of contents

Explore the editionReuse this content

HOW THE ECONOMYIST BECAME A 3D PRINTING INNOVATOR: THE SUCCESS STORY OF NIKOLAY DURNIKIN

In Sirius, young talents find mentors, become part of a professional team, implement real projects and take their first confident steps in the profession. One of the brightest examples is Nikolai Durnikin, the winner of the All-Russian Olympiad for schoolchildren, a recipient of a grant from the President, and a participant in many Sirius events. Today he is a driver of one of the projects and an employee of the Center for Prototyping and Additive Technologies. About how a young economist from St. Petersburg became an innovative 3D printing engineer to create new spatial art objects, print park sculptures and even residential buildings, read in our success story of Nikolai Durnikin.

One of the brightest examples is Nikolai Durnikin, the winner of the All-Russian Olympiad for schoolchildren, a recipient of a grant from the President, and a participant in many Sirius events. Today he is a driver of one of the projects and an employee of the Center for Prototyping and Additive Technologies. About how a young economist from St. Petersburg became an innovative 3D printing engineer to create new spatial art objects, print park sculptures and even residential buildings, read in our success story of Nikolai Durnikin.

Hackathon person

Nikolai has been a very enthusiastic person since childhood. He read a lot and was interested in science - he tried to learn as much as possible in order to change the world in the future and make people's lives better.

In the 11th grade, Nikolai won the All-Russian Olympiad for schoolchildren in economics and became the recipient of a Presidential grant for students who showed outstanding abilities. After graduating from the Physics and Mathematics Lyceum in Chelyabinsk, the young man successfully entered the Graduate School of Management at St. Petersburg State University. And although his main specialization - state and municipal administration - was not related to engineering, Nikolai was very passionate about IT and tried to realize himself in various projects. He is a real hackathon man - he has passed more than 50 competitions.

After graduating from the Physics and Mathematics Lyceum in Chelyabinsk, the young man successfully entered the Graduate School of Management at St. Petersburg State University. And although his main specialization - state and municipal administration - was not related to engineering, Nikolai was very passionate about IT and tried to realize himself in various projects. He is a real hackathon man - he has passed more than 50 competitions.

“It was in my second and third years. Now my health does not allow me to participate in hackathons,” Nikolay jokes. - After all, during the competition you work without sleep and rest for several days or even a week. Good places are occupied by those who sleep less and work hard. This is hell. But for me, it was a cool school to practice combat programming skills. Before, I was fond of only the Olympics, but it is divorced from life. And here you need to do something real in a very short time.

Nikolai met like-minded people at the competitions. He created long-term teams to work on interesting IT projects together. The young man joined the society of coders, worked on social problems. For example, he and his friends created a road safety map. According to Nikolai, his liberal arts education gave him a lot of free time, which he devoted to improving his technical skills. Therefore, his thesis was related to both IT and public administration, and was devoted to the digital transformation of public administration in Russia.

He created long-term teams to work on interesting IT projects together. The young man joined the society of coders, worked on social problems. For example, he and his friends created a road safety map. According to Nikolai, his liberal arts education gave him a lot of free time, which he devoted to improving his technical skills. Therefore, his thesis was related to both IT and public administration, and was devoted to the digital transformation of public administration in Russia.

Veteran of Sirius

Nikolay's path in Sirius began from the moment he became the recipient of the Presidential Grant for students who showed outstanding abilities in the field of science, culture or sports. The Talent and Success Foundation is the operator of the program and is engaged not only in searching, but also in supporting and accompanying grantees.

“It was too late for me to go to school programs, but it turned out that there are many interesting projects and activities for students at Sirius,” says Nikolai. - The first time I came to Sochi was in my second year at the All-Russian Conference "The Way to Success". It was an opportunity for the grantees to get acquainted with the work of the Talent and Success Foundation and even suggest their own improvements. I then tried to promote the idea that information security programs were needed and that this direction should be strengthened here (Right now, Sirius University, together with Rostelecom, is creating a cyber training ground for training young specialists in the field of information security - ed.). I remember that even then I was struck by the scale of the Science Park, the equipment of laboratories and workshops. How great it was to realize that the legacy of the Olympics was given to young people for educational activities, filled with life, science, and creativity.”

- The first time I came to Sochi was in my second year at the All-Russian Conference "The Way to Success". It was an opportunity for the grantees to get acquainted with the work of the Talent and Success Foundation and even suggest their own improvements. I then tried to promote the idea that information security programs were needed and that this direction should be strengthened here (Right now, Sirius University, together with Rostelecom, is creating a cyber training ground for training young specialists in the field of information security - ed.). I remember that even then I was struck by the scale of the Science Park, the equipment of laboratories and workshops. How great it was to realize that the legacy of the Olympics was given to young people for educational activities, filled with life, science, and creativity.”

Six months later, Nikolai applied for a summer internship at the Sirius circuit engineering laboratory. The young man was not at all embarrassed that he was studying in the humanities, and he did not lose. During the practice, the young man was really interested in prototyping and additive technologies.

During the practice, the young man was really interested in prototyping and additive technologies.

“First of all, I was told that I just have to do my projects here. This surprised me very much,” the young engineer admits. - I imagined that during the internship you are given a specific task, you complete it and that's it, you are free. And here is the task: come up with some improvement in the laboratory. The approach surprised me. This is such a mandatory freedom that disciplines you. I realized that everything is in my hands, and I can really bring my projects to life.

In addition to his own ideas, Nikolai helped the laboratory work with schoolchildren at the Big Challenges forum: he supported young engineers, explained them, distributed tools, accompanied their projects, and realized that he definitely wanted to come back here again. He jokingly refers to himself as a Sirius veteran. In total, Nikolai spent more than 7 months here during his 4 years of study at the university. I came to educational modules, forums, conferences, sometimes in two directions at once, in order to have time to attend as many interesting lectures as possible at a time, to get acquainted with experts.

I came to educational modules, forums, conferences, sometimes in two directions at once, in order to have time to attend as many interesting lectures as possible at a time, to get acquainted with experts.

“I used to come to Sirius to be nourished by knowledge, communication, this unique energy,” says the young man. – There are many talented young people here, an incredible concentration of famous teachers, famous scientists. And when I graduated from university, I realized that I definitely want to come back here.”

Print a house on a 3D printer

Sirius has an employment program for such enthusiastic graduates. All recipients of a grant from the President of Russia can participate in it. This year, 543 graduates of the grant program received diplomas of graduation from the university.

Nikolay was invited to work at the Sirius Center for Prototyping and Additive Technologies. He became one of the inspirers and a key member of the project team to develop 3D printing technology for spatial frame structures from plastic waste. An ordinary 3D printer prints in a horizontal projection, the Center has figured out how to teach the printer to print in different planes.

An ordinary 3D printer prints in a horizontal projection, the Center has figured out how to teach the printer to print in different planes.

Now Nikolai is successfully testing his developments, creating three-dimensional figures much faster than with standard 3D printing. Several institutes abroad are working in this direction, but Nikolai is sure that he has a chance to overtake foreign colleagues and, together with his scientific team, be the first to create a working model of a new 3D printer.

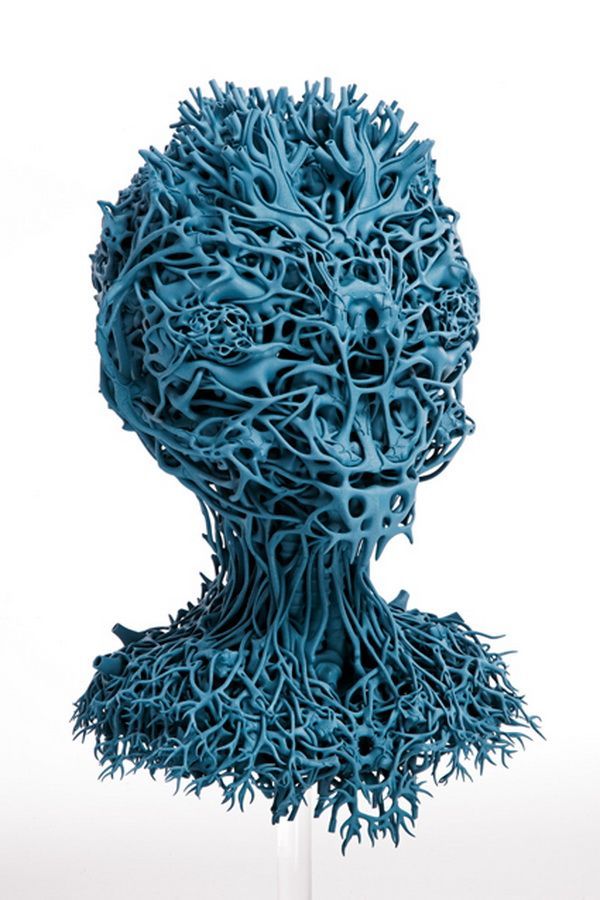

Technology can have many applications. For example, using such a printer, you can build entire orbital stations. The authors of the project plan to create voluminous park sculptures and art objects in the near future to decorate the territory of the Sirius urban district with them. They will be printed from recycled plastic, which is collected on the territory of the Center. In the future, this technology can be used in construction, printing entire houses.

“Then I can improve people's lives, build cheap, comfortable and durable housing. It is very important that all people live well enough so that they have time and opportunities to be creative,” Nikolay says.

It is very important that all people live well enough so that they have time and opportunities to be creative,” Nikolay says.

A young engineer is now devoting all his time to creating software for a new printer. The laboratory is very pleased with him, because he is an incredibly enthusiastic specialist.

“The entire infrastructure of Sirius, all the sites that are supported by the Talent and Success Foundation are a special space where people can not only work, but a place where many people want to come to be creative and realize their projects. And here they have these opportunities, - says the project, head of the Center for Prototyping and Additive Technologies Oleg Vartanov. “Nicholas came here for this very reason. He sees prospects and an opportunity to implement those projects that are unlikely to be so easily implemented somewhere other than Sirius. As long as we have the Center we can do good things.”

Source

Tags:

3D PRINTING, NIKOLAY DURNIKIN, Sirius, Center for Prototyping and Additive Technologies, grant of the President, 3D printer, 3D printing technologies

Institute for Financial Business Development — 3D printing and protection

Three-dimensional (3D) printing is called by many researchers one of the main features of the "world of the near future" - the technology that is available now and promises to soon become so widespread that in some 10-15 years it will simply turn the life of every person . In addition to the domestic use of 3D printing, there are many other promising industries in which this technology is already being used: energy, medicine and dentistry, restaurants, fashion, logistics, pharmacology, mechanical engineering, aircraft manufacturing, etc.

In addition to the domestic use of 3D printing, there are many other promising industries in which this technology is already being used: energy, medicine and dentistry, restaurants, fashion, logistics, pharmacology, mechanical engineering, aircraft manufacturing, etc.

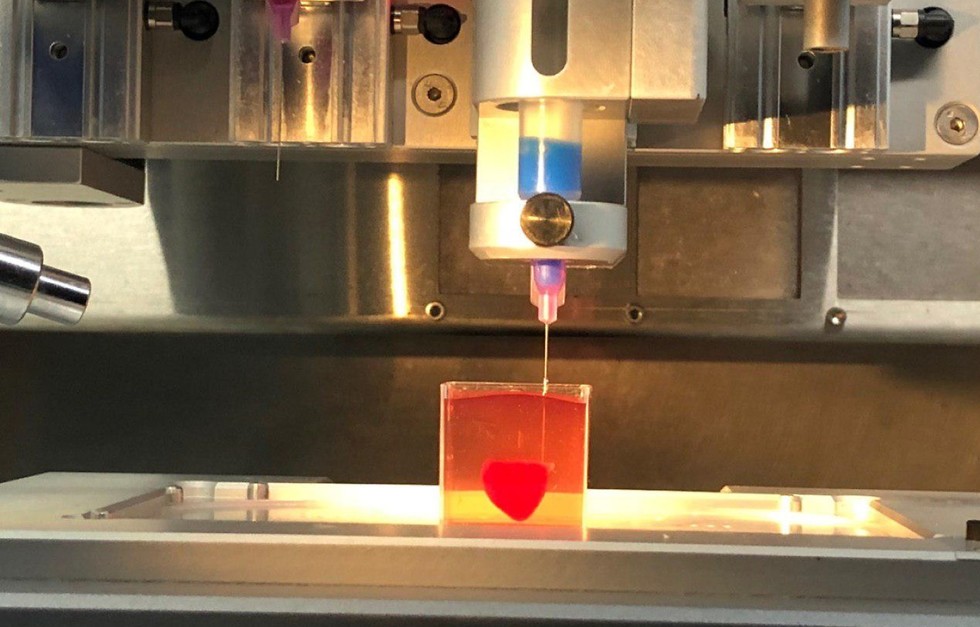

3D printing is actively used in the creation of architectural and medical models, body parts, prototypes, presentation models, components and souvenirs. 3D printers are actively used in the construction of industrial facilities and residential buildings in the USA, China, Southeast Asia and are no longer "experimental".

According to a 2015 study by the consulting firm Gartner, 3D printer shipments will grow by an average of 121.3% through 2019, and the 3D printer market will surpass $14.6 billion. Today, in many countries of the world there are laws regulating 3D printing not only in the context of civil law, but also in all spheres of life, including even criminal law. For example, in one of the states of Australia, the maximum prison term for possession of a digital model that allows you to print a firearm is 14 years. At the same time, this law really applies, and there is a precedent for arrest for 3D printing of replica pistols (in accordance with the laws of the state of New South Wales, criminal liability is provided not only for the manufacture of firearms, but also for possession of drawings according to which it can be made, including their digital models).

At the same time, this law really applies, and there is a precedent for arrest for 3D printing of replica pistols (in accordance with the laws of the state of New South Wales, criminal liability is provided not only for the manufacture of firearms, but also for possession of drawings according to which it can be made, including their digital models).

The British magazine The Economist in 2012 devoted its article "The third industrial revolution" to the introduction of 3D printing into the daily activities of companies and individuals, pointing out possible global changes in processes and attitudes towards production. The expected consequences of the spread of 3D printing can be so significant that they will lead to a shift in the economic balance in the international arena. One of the most influential strategic theorists of our time, Richard d'Aveny, notes the changing role of China and other countries that are sources of cheap labor as a possible consequence of the spread of 3D printing technology, as a result of the emergence of new opportunities for the mechanization of manual labor.

However, new technology poses a threat to intellectual property. Let's see.

On the one hand, 3D printing, or more generally, any technology that makes it relatively easy, bypassing traditional industrial technologies, to reproduce (copy!) an object with specified characteristics and configuration provides humanity with previously inaccessible opportunities to make a qualitative leap, making it easier to purchase and the use of material resources and reducing capital costs. On the other hand, 3D printing technology and other methods create easier conditions for infringement of exclusive rights due to the fact that, coupled with the speed of information dissemination, they reduce the costs of disseminating and reproducing the results of intellectual activity to almost zero.

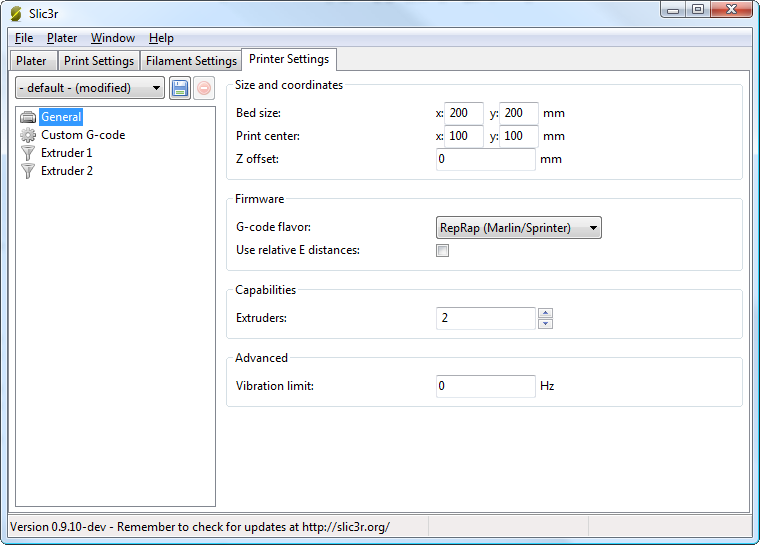

This threat of infringement exposes all the main institutions of intellectual property rights: copyright, patent law, and means of individualization (trademarks). In this regard, jurisprudence must be ready for transformations in the general economic state and be able to ensure a balance of interests and rights of each of the participants in civil circulation in the new realities. First of all, when resolving issues of legal regulation of 3D printing, it is necessary to understand the essence of the new phenomenon, from a legal point of view. 3D printing is a technology that allows you to create a three-dimensional material object according to an image that is stored digitally in a computer file, by layer-by-layer application of consumables (plastics and polymers, cement mortar, metals, etc.). The first step in 3D printing is the creation of an electronic model of an object, its electronic image. The most common format of electronic models is the so-called CAD-files (Computer Aided Design), in the Russian-language literature the abbreviation CAD (Computer Aided Design) is used. CAD design and computer modeling have been known since the mid-1970s.

In this regard, jurisprudence must be ready for transformations in the general economic state and be able to ensure a balance of interests and rights of each of the participants in civil circulation in the new realities. First of all, when resolving issues of legal regulation of 3D printing, it is necessary to understand the essence of the new phenomenon, from a legal point of view. 3D printing is a technology that allows you to create a three-dimensional material object according to an image that is stored digitally in a computer file, by layer-by-layer application of consumables (plastics and polymers, cement mortar, metals, etc.). The first step in 3D printing is the creation of an electronic model of an object, its electronic image. The most common format of electronic models is the so-called CAD-files (Computer Aided Design), in the Russian-language literature the abbreviation CAD (Computer Aided Design) is used. CAD design and computer modeling have been known since the mid-1970s. XX century.

XX century.

In 1990, the design of the Boeing 777 began. This aircraft is 100% computer designed, without a single paper drawing. The assembly process was also simulated on the computer, which made it possible to optimize and reduce production costs. Therefore, computer simulation in itself did not become a breakthrough factor, although it greatly simplified the solution of engineering problems and gave rise to new risks associated with unauthorized copying and distribution of files - physically copy the electronic drawing and broadcast easier than a paper set (a set of documentation, for example, for one jet engine can consist of millions of sheets and occupy a volume of 20-30 cubic meters), but for electronic media, technical security measures and authentication marks are used. This problem has been taken to a new level by the emergence of 3D scanning technologies, which allow recreating a 3D model from the finished product, which opens up opportunities for their subsequent reproduction (a new way of reverse-engineering (reengineering)). The 3D model is used by a computer program that calculates the algorithm and executes the CAD file, controlling the actuators that layer by layer or create a given 3D object.

The 3D model is used by a computer program that calculates the algorithm and executes the CAD file, controlling the actuators that layer by layer or create a given 3D object.

Modern models are complemented by machine vision tools that control the execution process in automatic mode to completely eliminate the need for human intervention. Also, the CAD file can be loaded into the memory of the controlled computer of the processing robotic machine. Thus, the following objects are involved in the process of 3d printing, with which certain intellectual property rights may be associated: • special software • 3D model (CAD file) • 3d printer • 3D object (an object resulting from a three-dimensional printing) From the point of view of intellectual property rights, a computer program and a 3D printer are not of any particular interest, due to the fact that they are not fundamentally new elements: all researchers unanimously believe that a program that uses a CAD file is no different from any other computer program and should be protected as a literary work, and a 3D printer, if it contains unique elements and technical solutions, should be protected by appropriate intellectual property legal mechanisms.