Journal of 3d printing in medicine

3D Printing in Medicine | About

Skip to main content

Aims and scope

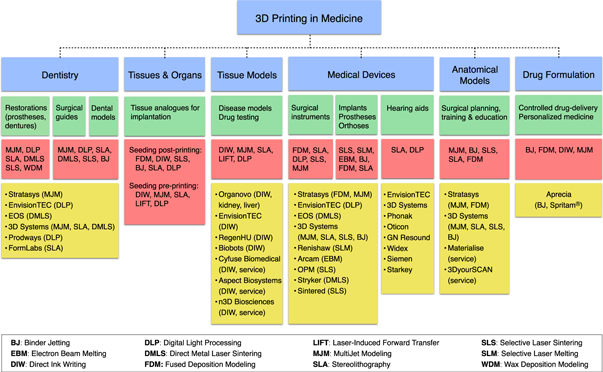

3D Printing in Medicine publishes 3D printing innovation that impact medicine. Authors can communicate and share Standard Tessellation Language (STL) and related files via the journal. In addition to publishing techniques and trials that will advance medicine with 3D printing, the journal covers "how to" papers to provide a forum for translating applied imaging science.

Benefits of publishing with BMC

High visibility

3D Printing in Medicine's open access policy allows maximum visibility of articles published in the journal as they are available to a wide, global audience.

Speed of publication

3D Printing in Medicine offers a fast publication schedule whilst maintaining rigorous peer review; all articles must be submitted online, and peer review is managed fully electronically (articles are distributed in PDF form, which is automatically generated from the submitted files). Articles will be published with their final citation after acceptance, in both fully browsable web form, and as a formatted PDF.

Flexibility

Online publication in 3D Printing in Medicine gives you the opportunity to publish large datasets, large numbers of color illustrations and moving pictures, to display data in a form that can be read directly by other software packages so as to allow readers to manipulate the data for themselves, and to create all relevant links (for example, to PubMed, to sequence and other databases, and to other articles).

Promotion and press coverage

Articles published in 3D Printing in Medicine are included in article alerts and regular email updates. Some may be highlighted on 3D Printing in Medicine’s pages and on the BMC homepage.

In addition, articles published in 3D Printing in Medicine may be promoted by press releases to the general or scientific press. These activities increase the exposure and number of accesses for articles published in 3D Printing in Medicine. A list of articles recently press-released by journals published by BMC is available here.

A list of articles recently press-released by journals published by BMC is available here.

Copyright

As an author of an article published in 3D Printing in Medicine you retain the copyright of your article and you are free to reproduce and disseminate your work (for further details, see the BMC license agreement).

For further information about the advantages of publishing in a journal from BMC, please click here.

Open access

All articles published by 3D Printing in Medicine are made freely and permanently accessible online immediately upon publication, without subscription charges or registration barriers. Further information about open access can be found here.

As authors of articles published in 3D Printing in Medicine you are the copyright holders of your article and have granted to any third party, in advance and in perpetuity, the right to use, reproduce or disseminate your article, according to the BMC license agreement.

For those of you who are US government employees or are prevented from being copyright holders for similar reasons, BMC can accommodate non-standard copyright lines. Please contact us if further information is needed.

Article-processing charges

Open access publishing is not without costs. 3D Printing in Medicine therefore levies an article-processing charge of £1290.00/$1890.00/€1590.00 for each article accepted for publication, plus VAT or local taxes where applicable.

If the corresponding author's institution participates in our open access membership program, some or all of the publication cost may be covered (more details available on the membership page). We routinely waive charges for authors from low-income countries. For other countries, article-processing charge waivers or discounts are granted on a case-by-case basis to authors with insufficient funds. Authors can request a waiver or discount during the submission process. For further details, see our article-processing charge page.

Visit Springer Nature’s open access funding & support services for information about research funders and institutions that provide funding for APCs.

Springer Nature offers agreements that enable institutions to cover open access publishing costs. Learn more about our open access agreements to check your eligibility and discover whether this journal is included.

For more information on APCs please see our Journal Pricing FAQs

Indexing services

All articles published in 3D Printing in Medicine are included in:

- WTI Frankfurt eG

- TD Net Discovery Service

- Semantic Scholar

- PubMedCentral

- ProQuest-ExLibris Summon

- ProQuest-ExLibris Primo

- OCLC WorldCat Discovery Service

- Naver

- Institute of Scientific and Technical Information of China

- Google Scholar

- Gale

- EMBASE

- EBSCO Discovery Service

- Dimensions

- DOAJ

- Chinese Academy of Sciences (CAS) - GoOA

- CNKI

The full text of all articles is deposited in digital archives around the world to guarantee long-term digital preservation. You can also access all articles published by BioMed Central on SpringerLink. We are working closely with relevant indexing services such as Web of Science (Clarivate Analytics) to ensure that articles published in 3D Printing in Medicine will be available in their databases when appropriate.

You can also access all articles published by BioMed Central on SpringerLink. We are working closely with relevant indexing services such as Web of Science (Clarivate Analytics) to ensure that articles published in 3D Printing in Medicine will be available in their databases when appropriate.

Peer-review policy

Peer-review is the system used to assess the quality of a manuscript before it is published. Independent researchers in the relevant research area assess submitted manuscripts for originality, validity and significance to help editors determine whether the manuscript should be published in their journal. You can read more about the peer-review process here.

3D Printing in Medicine operates a single-blind peer-review system, where the reviewers are aware of the names and affiliations of the authors, but the reviewer reports provided to authors are anonymous Publication of research articles by 3D Printing in Medicine is dependent primarily on their scientific validity and coherence as judged by our external expert editors and/or peer reviewers, who will also assess whether the writing is comprehensible and whether the work represents a useful contribution to the field.

Submitted manuscripts will generally be reviewed by two to three experts who will be asked to evaluate whether the manuscript is scientifically sound and coherent, whether it duplicates already published work, and whether or not the manuscript is sufficiently clear for publication. Reviewers will also be asked to indicate how interesting and significant the research is. The Editors will reach a decision based on these reports and, where necessary, they will consult with members of the Editorial Board.

Editorial policies

All manuscripts submitted to 3D Printing in Medicine should adhere to BMC's editorial policies.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appeals and complaints

Authors who wish to appeal a rejection or make a complaint should follow the procedure outlined in the BMC Editorial Policies.

Submit manuscript

- Editorial Board

- Manuscript editing services

- Instructions for Editors

- Sign up for article alerts and news from this journal

Annual Journal Metrics

- ISSN: 2365-6271 (electronic)

Medical Applications for 3D Printing: Recent Developments

1. A.I. Committee, ASTM International Committee F42 - Additive Manufacturing Technologies, ASTM F2792-12 Standard Terminology for Additive Manufacturing Technologies, American Society for Testing and Materials, West Conshohocken, PA, 2009.

A.I. Committee, ASTM International Committee F42 - Additive Manufacturing Technologies, ASTM F2792-12 Standard Terminology for Additive Manufacturing Technologies, American Society for Testing and Materials, West Conshohocken, PA, 2009.

2. Sidambe AT. Biocompatibility of advanced manufactured titanium implants — A review. Materials. 2014;7(12):8168–8188. [PMC free article] [PubMed] [Google Scholar]

3. Gu Q, Hao J, Lu Y, Wang L, Wallace GG, Zhou Q. Three-dimensional bio-printing. Science China. Life Sciences. 2015;58(5):411. [PubMed] [Google Scholar]

4. Shafiee A, Atala A. Printing technologies for medical applications. Trends in molecular medicine. 2016;22(3):254–265. [PubMed] [Google Scholar]

5. Elahinia MH, Hashemi M, Tabesh M, Bhaduri SB. Manufacturing and processing of NiTi implants: a review. Progress in materials science. 2012;57(5):911–946. [Google Scholar]

6. Ventola CL. Medical applications for 3D printing: current and projected uses. PT. 2014;39(10):704–711. [PMC free article] [PubMed] [Google Scholar]

[PMC free article] [PubMed] [Google Scholar]

7. Ho CMB, Ng SH, Yoon YJ. A review on 3D printed bioimplants. International Journal of Precision Engineering and Manufacturing. 2015;16(5):1035–1046. [Google Scholar]

8. Abduo J, Lyons K, Bennamoun M. Trends in computer-aided manufacturing in prosthodontics: a review of the available streams. International journal of dentistry. 2014. 2014. [PMC free article] [PubMed]

9. Fahmy MD, Jazayeri HE, Razavi M, Masri R, Tayebi L. Three Dimensional Bioprinting Materials with Potential Application in Preprosthetic Surgery. Journal of Prosthodontics. 2016. [PubMed]

10. Sheth R, Balesh ER, Zhang YS, Hirsch JA, Khademhosseini A, Oklu R. Three-dimensional printing: an enabling technology for IR. Journal of Vascular and Interventional Radiology. 2016;27(6):859–865. [PubMed] [Google Scholar]

11. Collins F. US to develop chip that tests if a drug is toxic. Reuters. 2011. Oct 6,

12. Arslan-Yildiz A, El Assal R, Chen P, Guven S, Inci F, Demirci U. Towards artificial tissue models: past, present, and future of 3D bioprinting. Biofabrication. 2016;8(1):014103. [PubMed] [Google Scholar]

Towards artificial tissue models: past, present, and future of 3D bioprinting. Biofabrication. 2016;8(1):014103. [PubMed] [Google Scholar]

13. Marro A, Bandukwala T, Mak W. Three-dimensional printing and medical imaging: a review of the methods and applications. Current problems in diagnostic radiology. 2016;45(1):2–9. [PubMed] [Google Scholar]

14. Rengier F, Mehndiratta A, von Tengg-Kobligk H, Zechmann CM, Unterhinninghofen R, Kauczor HU, Giesel FL. 3D printing based on imaging data: review of medical applications. International journal of computer assisted radiology and surgery. 2010;5(4):335–341. [PubMed] [Google Scholar]

15. Martelli N, Serrano C, van den Brink H, Pineau J, Prognon P, Borget I, El Batti S. Advantages and disadvantages of 3-dimensional printing in surgery: a systematic review. Surgery. 2016;159(6):1485–1500. [PubMed] [Google Scholar]

16. Pati F, Gantelius J, Svahn HA. 3D bioprinting of tissue/organ models. Angewandte Chemie International Edition. 2016;55(15):4650–4665. [PubMed] [Google Scholar]

2016;55(15):4650–4665. [PubMed] [Google Scholar]

17. Vodiskar J, Kütting M, Steinseifer U, Vazquez-Jimenez JF, Sonntag SJ. Using 3D physical modeling to plan surgical corrections of complex congenital heart defects. The Thoracic and cardiovascular surgeon. 2017;65(01):031–035. [PubMed] [Google Scholar]

18. Wu XB, Wang JQ, Zhao CP, Sun X, Shi Y, Zhang ZA, Li YN, Wang MY. Printed three-dimensional anatomic templates for virtual preoperative planning before reconstruction of old pelvic injuries: initial results. Chinese medical journal. 2015;128(4):477. [PMC free article] [PubMed] [Google Scholar]

19. Truscott M, Booysen G, De Beer D. Rapid prototyping and manufacturing in medical product development.. Annals of DAAAM & Proceedings; 2010. pp. 1573–1575. [Google Scholar]

20. Suaste-Gómez E, Rodríguez-Roldán G, Reyes-Cruz H, Terán-Jiménez O. Developing an ear prosthesis fabricated in polyvinylidene fluoride by a 3D printer with sensory intrinsic properties of pressure and temperature. Sensors. 2016;16(3):332. [PMC free article] [PubMed] [Google Scholar]

Sensors. 2016;16(3):332. [PMC free article] [PubMed] [Google Scholar]

21. Tan ET, Ling JM, Dinesh SK. The feasibility of producing patient-specific acrylic cranioplasty implants with a low-cost 3D printer. Journal of neurosurgery. 2016;124(5):1531–1537. [PubMed] [Google Scholar]

22. Ahlhelm M, Günther P, Scheithauer U, Schwarzer E, Günther A, Slawik T, Moritz T, Michaelis A. Innovative and novel manufacturing methods of ceramics and metal-ceramic composites for biomedical applications. Journal of the European Ceramic Society. 2016;36(12):2883–2888. [Google Scholar]

23. Parthasarathy J, Starly B, Raman S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. Journal of Manufacturing Processes. 2011;13(2):160–170. [Google Scholar]

24. Wang K, Zhao Y, Chang YH, Qian Z, Zhang C, Wang B, Vannan MA, Wang MJ. Controlling the mechanical behavior of dual-material 3D printed meta-materials for patient-specific tissue-mimicking phantoms. Materials & Design. 2016;90:704–712. [Google Scholar]

Materials & Design. 2016;90:704–712. [Google Scholar]

25. Ploch CC, Mansi CS, Jayamohan J, Kuhl E. Using 3D printing to create personalized brain models for neurosurgical training and preoperative planning. World neurosurgery. 2016;90:668–674. [PubMed] [Google Scholar]

26. McMenamin PG, Quayle MR, McHenry CR, Adams JW. The production of anatomical teaching resources using three dimensional (3D) printing technology. Anatomical sciences education. 2014;7(6):479–486. [PubMed] [Google Scholar]

27. Zhao Y, Yao R, Ouyang L, Ding H, Zhang T, Zhang K, Cheng S, Sun W. Three-dimensional printing of Hela cells for cervical tumor model in vitro. Biofabrication. 2014;6(3):035001. [PubMed] [Google Scholar]

28. Snyder J, Son AR, Hamid Q, Sun W. Fabrication of microfluidic manifold by precision extrusion deposition and replica molding for cell-laden device. Journal of Manufacturing Science and Engineering. 2016;138(4):041007. [Google Scholar]

29. Lode A, Krujatz F, Brüggemeier S, Quade M, Schütz K, Knaack S, Weber J, Bley T, Gelinsky M. Green bioprinting: Fabrication of photosynthetic algae laden hydrogel scaffolds for biotechnological and medical applications. Engineering in Life Sciences. 2015;15(2):177–183. [Google Scholar]

Green bioprinting: Fabrication of photosynthetic algae laden hydrogel scaffolds for biotechnological and medical applications. Engineering in Life Sciences. 2015;15(2):177–183. [Google Scholar]

30. Duan B, Hockaday LA, Kang KH, Butcher JT. 3D bioprinting of heterogeneous aortic valve conduits with alginate/gelatin hydrogels. Journal of biomedical materials research Part A. 2013;101(5):1255–1264. [PMC free article] [PubMed] [Google Scholar]

31. Faulkner-Jones A, Fyfe C, Cornelissen DJ, Gardner J, King J, Courtney A, Shu W. Bioprinting of human pluripotent stem cells and their directed differentiation into hepatocyte-like cells for the generation of mini-livers in 3D. Biofabrication. 2015;7(4):044102. [PubMed] [Google Scholar]

32. Ollé-Vila A, Duran-Nebreda S, Conde-Pueyo N, Montañez R, Solé R. A morphospace for synthetic organs and organoids: the possible and the actual. Integrative Biology. 2016;8(4):485–503. [PubMed] [Google Scholar]

33. Goyanes A, Det-Amornrat U, Wang J, Basit AW, Gaisford S. 3D scanning and 3D printing as innovative technologies for fabricating personalized topical drug delivery systems. Journal of Controlled Release. 2016;234:41–48. [PubMed] [Google Scholar]

3D scanning and 3D printing as innovative technologies for fabricating personalized topical drug delivery systems. Journal of Controlled Release. 2016;234:41–48. [PubMed] [Google Scholar]

34. Khaled SA, Burley JC, Alexander MR, Roberts CJ. Desktop 3D printing of controlled release pharmaceutical bilayer tablets. International journal of pharmaceutics. 2014;461(1):105–111. [PubMed] [Google Scholar]

35. Goyanes A, Martinez PR, Buanz A, Basit AW, Gaisford S. Effect of geometry on drug release from 3D printed tablets. International journal of pharmaceutics. 2015;494(2):657–663. [PubMed] [Google Scholar]

review of the article of the journal Science and Technology No. 6 for 2020.

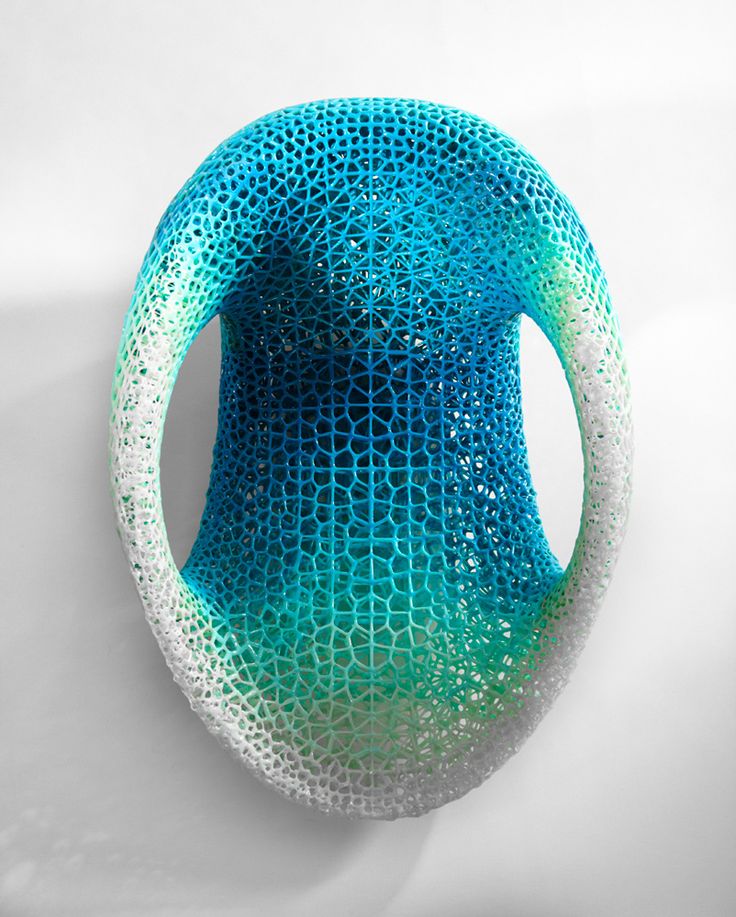

3D printing is widely included in the application of modern medicine, the use of 3D printing in medicine is expanding significantly every month, as we are told by Science and Technology magazine No. 6, 2020, which describes how 3D printing can be used to produce ears , parts of the skeleton, respiratory tract, jawbone, parts of the eye, cell cultures, stem cells, blood vessels and vascular networks, tissues and organs, new dosage forms and much more.

But just as important in medicine is the use of 3D models for training surgeons and students, with the help of 3D printing you can create a model of any organ with any known pathology.

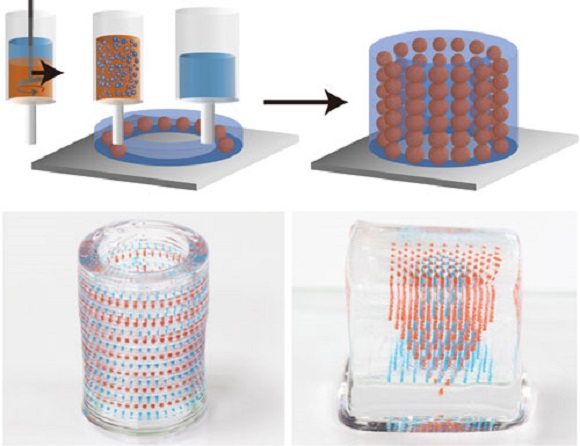

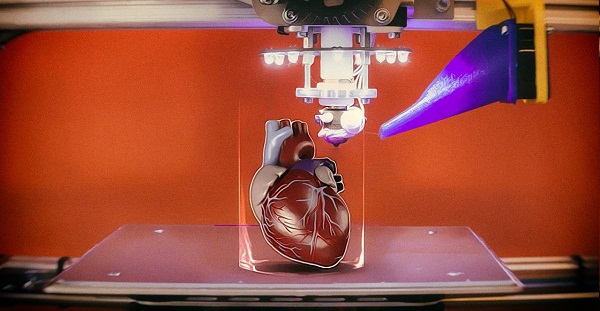

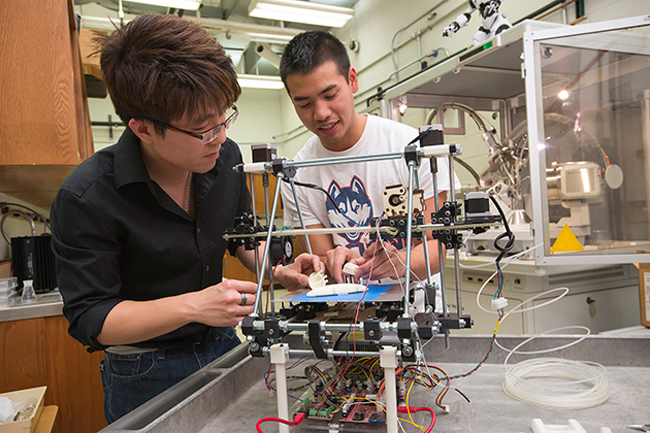

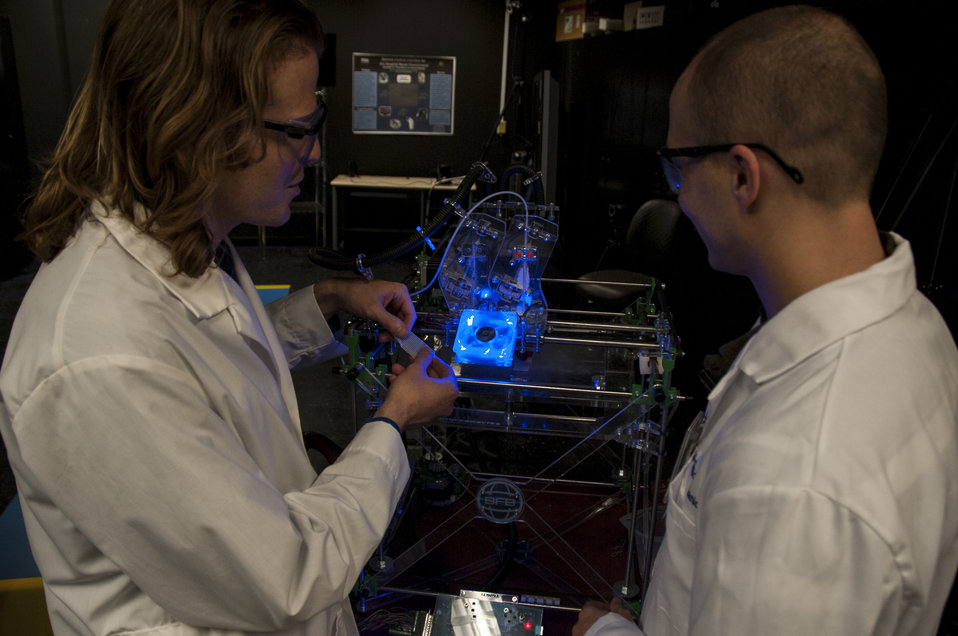

The main industry for 3D printing is undoubtedly bioprinting, one of the many types of 3D printing used in the medical field. Where bioprinters use a syringe dispenser to apply bioink (layers of living cells or a structuring base for them) when creating artificial living tissue. In addition to being used as an alternative to donor tissues, such tissue constructs or organoids can be used for medical research.

Source: press.ginkgo3d.com

3D bioprinting systems can be laser, inkjet or extrusion, inkjet bioprinting is the most common and effective. Where, with this method, several printheads are used to accommodate various types of cells (organ-specific, blood vessel cells, muscle tissues), which is the main task in the manufacture of heterocellular tissues and organs.

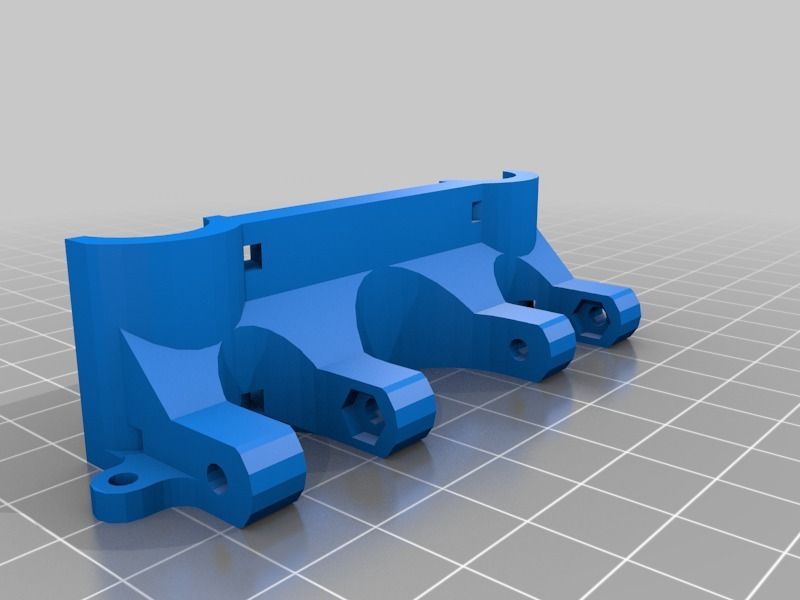

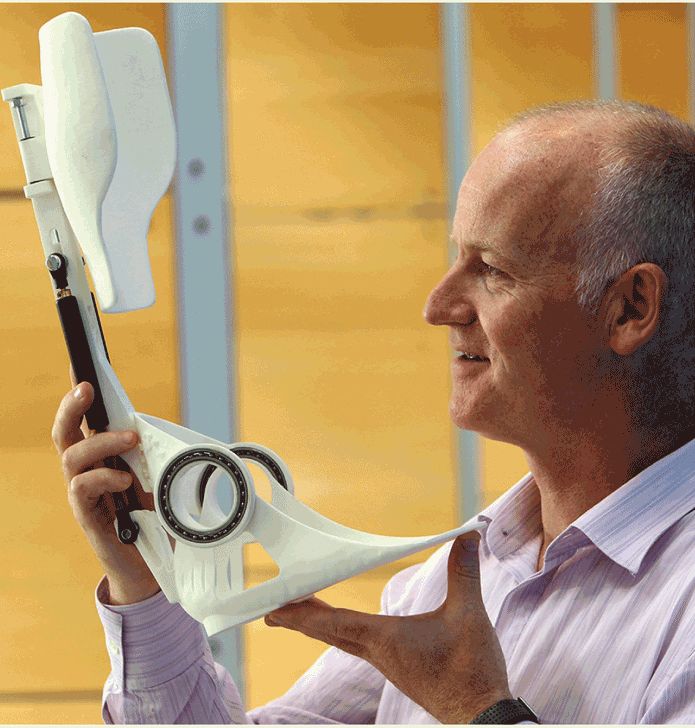

A separate branch of 3D printing in modern surgeons was assigned to the production of surgical instruments. Today's surgeons are trying to perform operations with as little trauma for the patient as possible, so they often require a personalized instrument. The use of 3D printing makes it possible to create such tools within hours.

The use of 3D printing makes it possible to create such tools within hours.

Now the doctor can create a ready-made model for convenience and efficient work.

Using 3D printing, pharmacists can analyze a patient's pharmacogenetic profile and other characteristics such as age, weight or gender to determine the optimal dose of drugs and the order in which they should be administered. If necessary, the dose may be adjusted, depending on the clinical response. With 3D printing, it is possible to produce personalized medicines in completely new formulations, such as tablets containing multiple active ingredients, either as a single mixture or as complex multi-layered tablets.

If necessary, the dose may be adjusted, depending on the clinical response. With 3D printing, it is possible to produce personalized medicines in completely new formulations, such as tablets containing multiple active ingredients, either as a single mixture or as complex multi-layered tablets.

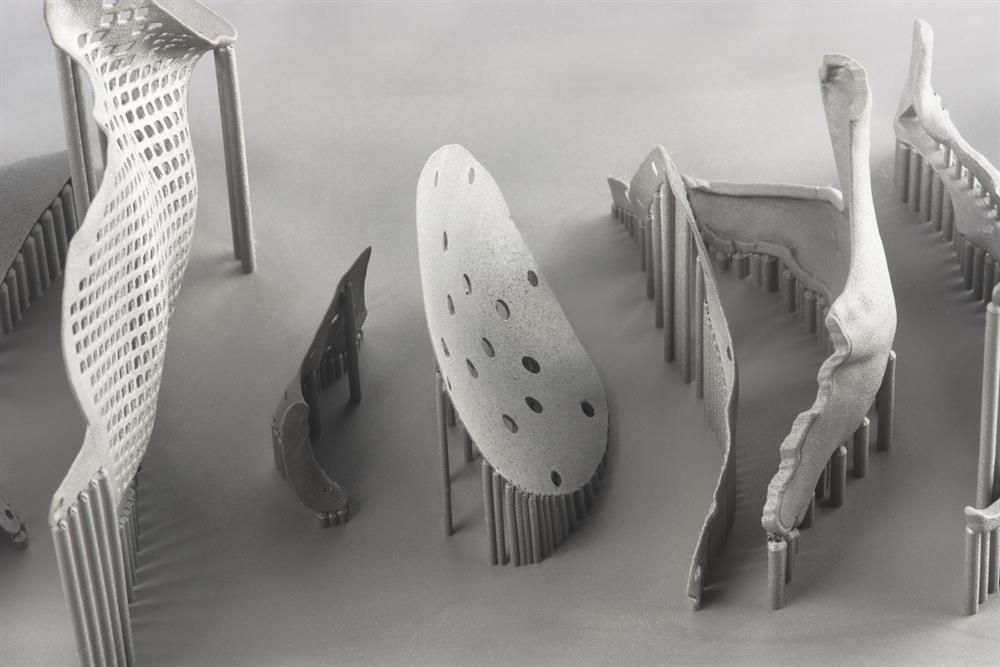

Source: eos.info

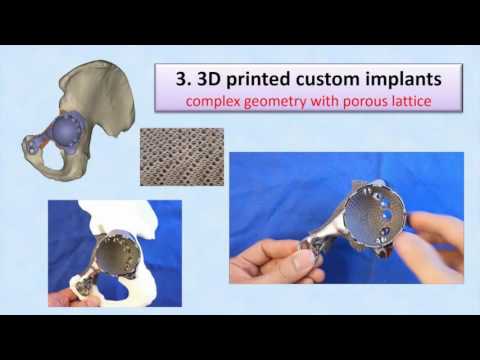

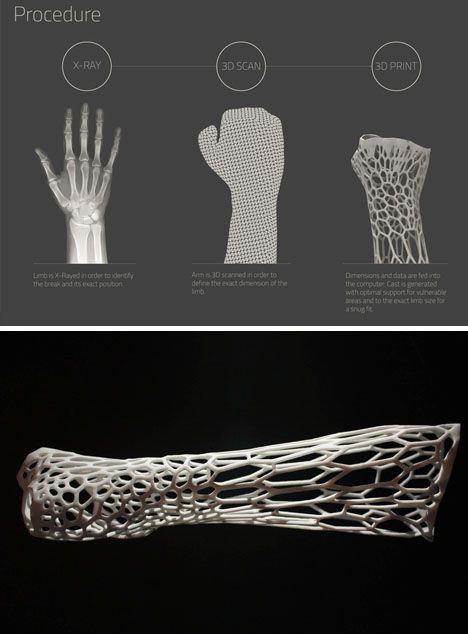

3D printing has been successfully used in medicine for the manufacture of complex custom prostheses or surgical implants. Implants and prostheses of any possible geometry can be made by converting X-ray, MRI or CT images into a 3D printable model using special software.

The rapid production of custom implants and prostheses solves a pressing problem in orthopedics, where standard implants often do not fit the patient. This is also true in neurosurgery: skulls are individually shaped, so it is difficult to standardize a cranial implant.

A real revolution in medicine occurred with the advent of 3D technologies.

Source: ithl.co.kr

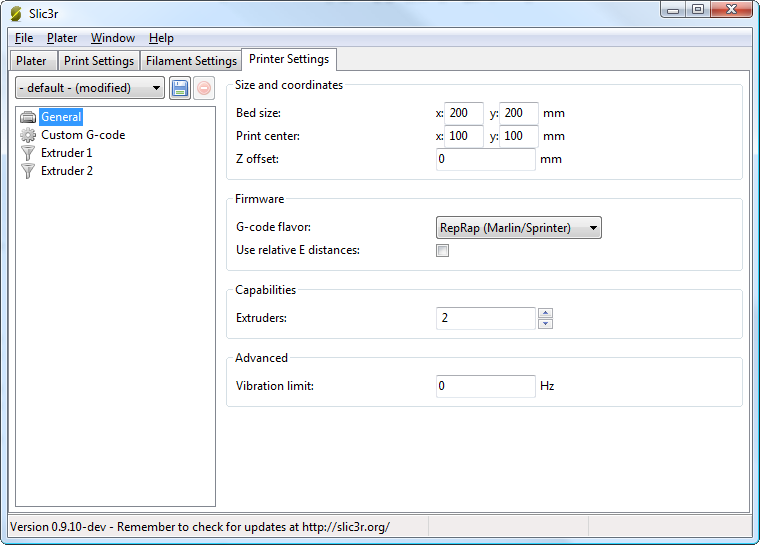

3D bioprinter with Nano master SMP-III microextrusion system, Musashi Engineering, Tokyo, Japan, with the following parameters:

print speed 130mm/min;

Until now, doctors could only rely on a 3D model on a computer screen created from CT and MRI images, and such a reconstruction is not always enough to get a complete picture of the real organ and possible complications.

Having a highly detailed, tactile model of a patient's living organ during preparation for an operation can be critical to its success. Even experienced surgeons have appreciated the potential of the new technology.

But hand-held 3D scanners used to determine the size and depth of the wound have also found their indispensable application. Based on this information, the 3D printer prints subcutaneous, dermal, and epidermal skin cells at appropriate depths to completely cover the wound, which has changed the operation and efficiency of burn center rehabilitation.

Source: intermercados.com.br

The use of additive technologies in medicine is expanding so rapidly that it is more like a revolution in healthcare. The use of 3D printing in medicine enables the individualization of medical devices, medicines and equipment, increases cost efficiency and productivity, reduces waiting times for patients and improves the availability of medical care.

Compiled by Oleinik N.A., Berestnev A.V., Farafonova O.A.

Source

3D printing applications in medicine, Additive technology applications in medicine, 3D printing, 3D models, bioprinting, 3D bioprinter with Nanomaster SMP-III microextrusion system, 3D handheld scanners, 3D -technologies

Application of modern 3D printing technologies in medicine

Author : Kalagova Anna Valerievna

Category : Medicine

Posted by in young scientist #2 (240) January 2019

Publication date : 01/13/2019 2019-01-13

Article viewed: 2643 times

Download the electronic version

Download Part 1 (pdf)

References:

Kalagova, A. V. Application of modern 3D printing technologies in medicine / A. V. Kalagova. - Text: direct // Young scientist. - 2019. - No. 2 (240). - S. 54-56. — URL: https://moluch.ru/archive/240/55584/ (date of access: 06.11.2022).

V. Application of modern 3D printing technologies in medicine / A. V. Kalagova. - Text: direct // Young scientist. - 2019. - No. 2 (240). - S. 54-56. — URL: https://moluch.ru/archive/240/55584/ (date of access: 06.11.2022).

The article describes the main directions of the use of 3D technologies in the treatment and diagnosis of various diseases, the advantages and disadvantages of these methods are indicated. The analysis of cases of their application is carried out and the corresponding conclusions are drawn.

Keywords: 3D printing, prosthetics, tumor, 3D printer, model.

Recently, modern 3D technologies have been actively used in many areas of society. Their rapid improvement allows the use of 3D printers in various fields of science and technology. Today, the unique methods of modern printing are actively used in medicine, and the list of objects that are already quite successfully created using 3D printing technology demonstrates the huge potential that 3D printing can bring to modern healthcare.

Although 3D printing technology has been around for over 30 years, it still seems to many to be nothing more than an exotic way of making 3D plastic souvenirs. But this is far from the truth.

At the moment, 3D printing is used in dentistry, transplantology, plastic surgery, traumatology, prosthetics and many other branches of medicine.

Among the many areas of 3D printing in medicine, the most developed ones can be distinguished:

- Skull replacement;

- Joint prosthetics;

- Dentistry and maxillofacial surgery;

- Printing of medical equipment;

- Assistance in surgery.

1. Skull Replacement . In 2014, Dutch scientists and doctors at the University Medical Center Utrecht (UMC) performed an operation to replace the upper part of the skull with a custom-printed plastic implant. The patient was 22 years old, she suffered from a rare disease associated with softening of the bones of the skull, which greatly increased intracranial pressure. The girl suffered from severe headaches, gradually lost her sight, and began to lose coordination of movements. The unique operation was performed under the guidance of the famous surgeon Bon Verweij and lasted 23 hours.

The girl suffered from severe headaches, gradually lost her sight, and began to lose coordination of movements. The unique operation was performed under the guidance of the famous surgeon Bon Verweij and lasted 23 hours.

Three months after the operation, all the patient's symptoms leveled out: headaches ceased to disturb, vision was restored, and the appearance did not leave traces of surgical intervention [1].

Shortly thereafter, a similar operation was performed in China, where a man with a damaged skull received a 3D-printed titanium replacement.

To date, such operations have become relatively frequent, and the technology itself is being improved and is rapidly developing.

One of these was held by the head of the Regional Vascular Center from Nalchik (Russia, KBR) Zaur Kozhaev. After the accident, the patient's skull had a defect 15 cm in diameter. Employees of the scientific laboratory of the Kabardino-Balkarian State University modeled the patient's skull, and the model obtained from the 3D printer made it possible to select an exact copy of the desired implant.:quality(80)/images.vogel.de/vogelonline/bdb/1605100/1605167/original.jpg) The model was sent to the forge, where a titanium prosthesis was made exactly according to it.

The model was sent to the forge, where a titanium prosthesis was made exactly according to it.

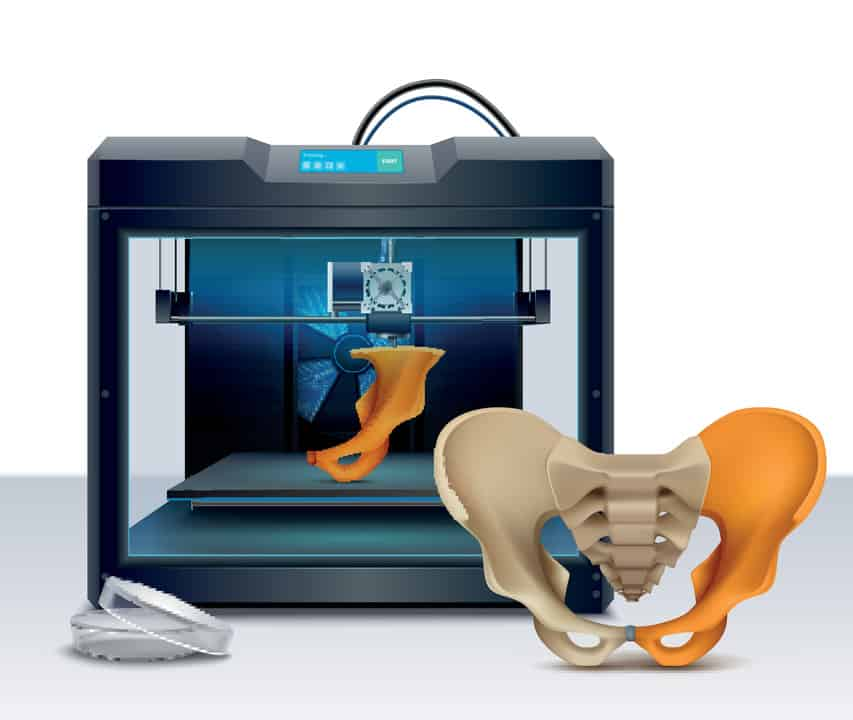

2. Joint prosthetics. One of the priority areas of 3D printing in medicine is the production of individual joint prostheses (most often the hip, knee and shoulder), made on the basis of computed tomography data. Modeling of the joint and the future prosthesis is carried out in a special computer program that allows you to get the exact shape of the product, taking into account the individual anatomical features of the patient. This allows you to create not standard titanium implants, but bone models, the structure of which is as close as possible to real ones.

The 3D printing process begins with a CT scan of the patient's damaged joint. Further, the results obtained are converted into a three-dimensional computer model, which is sent for printing. A 3D printer grows an exact copy of the joint, according to which a titanium prosthesis is created.

A 3D printed implant has a number of advantages over conventional prostheses. Usually, a standardized prosthesis is selected for prosthetics of the joint, after which the bone is turned to fit it. In the case of 3D printing, CT results are taken as the basis and a joint is created that most naturally fits the patient. In addition, standard prostheses are destroyed 10–20 years after implantation, losing their functional ability.

The first such operation was performed at the beginning of 2014 in the United States by employees of the Conformis clinic, where the patient was implanted with a 3D-printed knee joint. The patient notes that now he walks normally and even goes in for sports, without stopping every quarter and without feeling a foreign body in the body [2].

3. Dentistry and maxillofacial surgery. Dentistry owes 3D technology to individual crowns, caps (an alternative to braces) and dental prostheses; it has become easier, faster and cheaper to create casts of teeth and jaws.

4. Printing of medical equipment. 3D printing is being used to produce some surgical instruments, including forceps, hemostatic forceps, hand scalpels and staples. The iLab group is also using 3D printing to create umbilical cord clamps for hospitals in Haiti. The main advantage of such tools is their low cost, which is 10 times less than a high-quality stainless steel equivalent.

5. Help at surgical operation. In the spring of 2015, Chinese surgeons at the XiangYa Urological Hospital of Central South University managed to remove a kidney tumor from a 60-year-old woman. Thanks to a preliminary study of a 3D printed tumor model, they not only successfully removed the tumor, but also saved the kidney itself. This is simply an unprecedented case among operations of this kind.

Like some other Chinese doctors, Dr. Qi Ling chose 3D printing technology to plan ahead for the operation.

CT scans of the kidney, tumor and adjacent areas were used to make an exact copy of the patient's kidney.:quality(80)/images.vogel.de/vogelonline/bdb/1612700/1612740/original.jpg) They have been carefully processed in 3D modeling software and prepared for printing. When the models were printed, the doctors were able to map out the exact locations of the future incisions and also discussed other details of the operation.

They have been carefully processed in 3D modeling software and prepared for printing. When the models were printed, the doctors were able to map out the exact locations of the future incisions and also discussed other details of the operation.

On May 11, Dr. Qi Ling and his assistants performed an operation and successfully removed the tumor without affecting the kidney itself. Thanks to the use of a 3D printed copy, they managed to reduce blood loss to 50 ml, and the operation time to 90 minutes.

“On the example of 3D printing technology, you begin to understand that it is really better to see once. We were able to study the tumor from all sides in advance, determine the location of the arteries and adjacent tissues. This allowed us to choose the most correct option for the operation,” said Dr. Ki Ling.

Pins:

- The article outlined only a small part of the application of the possibilities of 3D printing in medicine; every day this technology is being improved by scientists from different parts of the world and the possibilities of its application in medicine are only growing, capturing new areas.

- 3D printing greatly simplifies the technique of performing a surgical intervention and allows you to clearly plan its course.

- In the future, it is necessary to carry out work to improve the existing technical base, develop and implement the Federal Program for the Development of 3D Technologies.

Literature:

- http://evercare.ru/3d-printing-review.

- https://econet.ru/articles/37749-iskusstvennye-sustavy-napechatayut-na-3d-printere.

- Operative surgery: manual / under the general editorship of prof. I. Littmann. — 3rd edition in Russian. - Publishing house of the Hungarian Academy of Sciences "Akademiai Kiad6", Budapest, 1985.

Basic terms (automatically generated) : 3D printing, UMC, skull replacement, medicine, medical equipment, surgery, tumor, joint replacement, kidney itself, titanium prosthesis, surgery, patient's skull.

Keywords

model, tumor, 3D printing, 3D printer, prosthetics3D printing, prosthetics, tumor, 3D printer, model

Similar articles

Analysis of early and long-term results of various methods.

..

.. Cranioplasty (Greek kranion skull + plastike sculpture, plastic) is a general concept of neurosurgical operations performed to restore the integrity of the skull after decompressive operations , depressed fractures, gunshot wounds, and also...

Depressed bone fractures

of the skull and their correction in childrenThe article presents some aspects of the tactics of management and strategy surgical intervention for depressed skull fractures in children. Adequately performed for depressed skull fractures surgical treatment made it possible to prevent a number of...

Rationale for the use of dental implantation in the complex...

This review discusses the positive aspects of using dental implantation to improve the quality of life of patients in the treatment of partial and complete edentulism. The advantages of dental implantation over traditional methods of treatment are shown. Based on...

The advantages of dental implantation over traditional methods of treatment are shown. Based on...

Applications of decompression trepanation method

skull ...Surgical intervention in DS includes resection of the frontotemporal-parietal region skull with a diameter of at least 12 cm with durotomy and

Surgical intervention was performed in 3 ways, VCT skull with removal of the lesion and elimination of dislocation...

Optimization of the aesthetic result in

prosthetics on... Fixed dentures on implants are made to meet the patient's high requirements for aesthetics and phonetics, negative attitude to removable dentures prostheses , increased gag reflex and poor conditions of fixation and stabilization of removable dental structures. ..

..

Swimming as a means of rehabilitation after endoprosthetics...

Endoprosthetics of the shoulder joint in patients with lesions of the musculoskeletal system are the most common clinical

Bibliographic description: Tarabrina IV Swimming as a means of rehabilitation after shoulder arthroplasty joint u...

Application of 3D technologies in cardiac myocardial bioprinting

Modeling of skull parts based on the results of computed tomography and the constructed 3D model (2015).

The use of 3D technologies in medicine , including cardiac surgery, can greatly simplify the performance of professional duties by medical workers.

Voice restoration after laryngectomy.

This Operation is a modified surgical Method

Prosthetics is carried out both during of the operation to remove the larynx and ditsis were made from biologically inerticons . ..

..

Features of treatment of

patients with habitual dislocation of the shoulder...After operations on the shoulder joint — transposition of the tendon of the long head of the biceps brachii.

In this regard, all therapeutic measures in the first hours after operation should be aimed at eliminating the consequences associated with the injury caused by oneself ...

Similar articles

Analysis of early and long-term results of various methods...

Cranioplasty (Greek kranion skull + plastike sculpting, plastic) is a general concept of neurosurgical operations performed to restore the integrity of the skull after decompressive operations , depressed fractures, gunshot wounds, as well as...

Depressed bone fractures

of the skull and their correction in children The article presents some aspects of the management and strategy of surgical interventions for depressed fractures of bones of the skull in children. Adequately performed for depressed skull fractures surgical treatment made it possible to prevent a number of...

Adequately performed for depressed skull fractures surgical treatment made it possible to prevent a number of...

Rationale for the use of dental implantation in the complex...

This review discusses the positive aspects of using dental implantation to improve the quality of life of patients in the treatment of partial and complete edentulism. The advantages of dental implantation over traditional methods of treatment are shown. Based on...

Applications of decompression trepanation method

skull ...Surgical Intervention in DS includes resection of the front-and-dark area Skull with a diameter of at least 12 cm with fuel thunder and

SUMPLE Intervention were carried out in 3 ways, CCC with the removal of the uniformity and linem . ..

..

Optimization of the aesthetic result at

prosthetics on...Fixed dentures on implants are made with high requirements of the patient to aesthetics and phonetics, a negative attitude to removable dentures , increased gag reflex and poor conditions for fixation and stabilization of removable dental structures...

Swimming as a means of rehabilitation after endoprosthetics...

Shoulder arthroplasty joints in persons with lesions of the musculoskeletal system are the most common clinical

Bibliographic description: Tarabrina I.V. Application of 3D technologies in cardiac myocardial bioprinting

Modeling of skull parts based on the results of computed tomography and the constructed 3D model (2015).

The use of 3D technologies in medicine , including cardiac surgery, can greatly simplify the performance of professional duties for medical workers.

Learn more