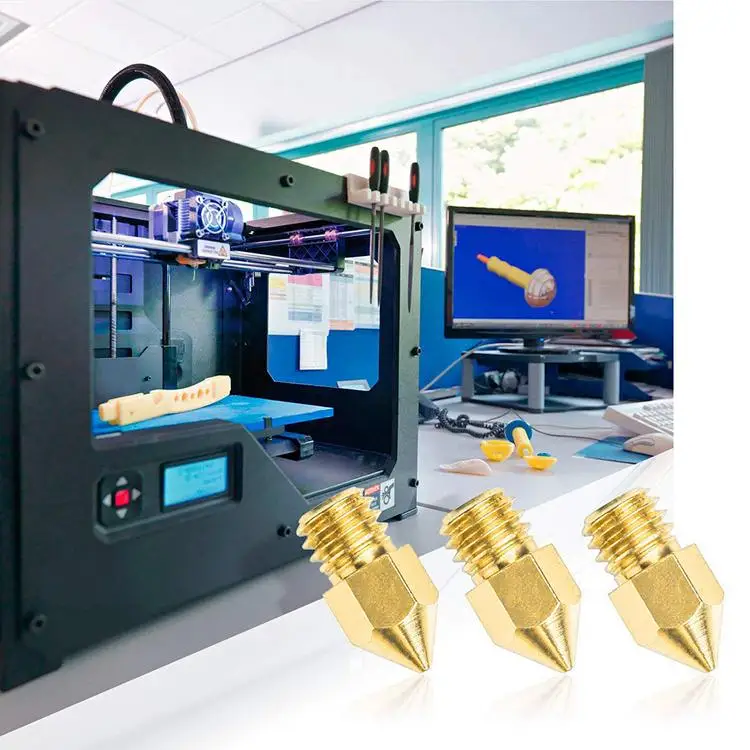

Best 3d printer nozzle brands

Ultimate 3D Printer Nozzle Comparison

I always wanted to do a 3D printer nozzle comparison to see what are the differences between nozzles and if it’s worth buying more expensive nozzles. Well, this finally happened and in the following article you will find a visual comparison between a large selection of nozzles.

Testing Apparatus

Because I want be able to test future hardware better, I purchased an Andonstar ADSM201 electronic microscope. It’s not the best electronical microscope on the marked but it does it’s job well enough to say it’s worth the money.

I regret not spending just a bit more to get the Andonstar ADSM301 which can also be used for measuring with the included software. But hey! Live and learn.

To be honest, the price difference was a bit higher at the time but anyway. I’m still happy with it.

If you know any microscope software which can be used on a PC for measuring please let me know in the comments.

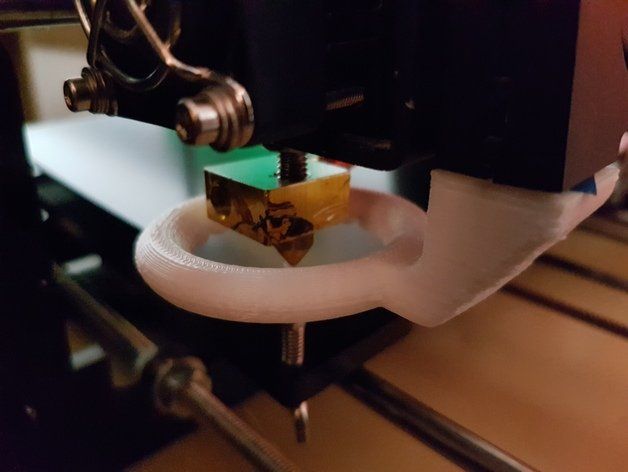

I printed a white PLA shield to be able to diffuse the light better. It’s really hard to get close to a shiny object so this helped a bunch. Each nozzle has been photographed from three sides so you can see the quality differences between them.

What’s the best 3D Printer Nozzle Upgrade?

In my experience with a boatload of different nozzles, I found out that most of the cheap nozzles, or the ones included with some printers are bad. Like, really bad. This is the reason why I always recommend people to buy a good nozzle.

You don’t need to spend a huge amount of money to get better quality. Just pick up some nozzles machined well because this can make your prints look a lot better.

People often spend money on all kind of upgrades but they cheap out when it comes to nozzles. This is a bad idea because a nozzle is important to print quality.

For example, if the nozzle hole is not cut to a precise size your printed lines can be different. This can be somewhat compensated by performing a flow calibration but it’s an extra step you need to do.

It’s also important to use different nozzles for different materials and printing situations. It’s not a good idea to print abrasive filament (ex: carbon fiber filament) with a brass nozzle because the tip will get sanded and the extrusion hole will get larger over time. This can happen even during a long print.

If you’re thinking: “No problem, I will just get a hardened steel nozzle“. Well, it’s also not the best “all-round” nozzle. The hardened nozzle will be more resistant to wear but it will have lower thermal transfer and you will need to up your temperatures with around 10C to have the correct temperature inside the nozzle.

That’s why you should pick the correct nozzle for the job, and have a few spares just in case.

Performance Comparison for 3D Printer Nozzles

I got this nice table from Trianglelab where they show the thermal conductivity, hardness, maximum printing temperature and the thermal expansion coefficient for various nozzles.

There’s also a nice applicable materials tab which will hep you understand what kind of nozzles are used for different types of materials.

This information should apply to all nozzles which use the same materials in the table.

Trianglelab

Top Quality Brass V6 Nozzle

This is one of the best budget nozzle you can buy. For around 2$ for a nozzle, it’s great. You can see that the machining is great for both the nozzle body and hole.

It’s recommended for PLA if you do a lot of detailed prints because it has a sharp tip which should help with small prints like a miniature.

The Top Quality Brass V6 Nozzle can be purchased from the following websites:

AliExpress

Top Quality Brass Volcano Nozzle

This nozzle is the same as the regular V6 nozzle but made for a Volcano heatblock. The machining is just as good and you can’t really go wrong with it. Because it’s cheap you can easily discard it if it gets messy. There’s also a low cost for regularly replacing the nozzle to make sure the nozzle hole is constant.

The Top Quality Brass Volcano Nozzle can be purchased from the following websites:

AliExpress

T-V6 Brass Nozzle

The T-V6 brass nozzle is similar to the sharp version but it has more it has a different design with more copper on the tip. This should help maintain a constant temperature of the filament right to the point where it leaves the tip. I would use this kind of nozzle if I mainly print PETG or ABS. Same quality machining we love is present with the T-V6

The T-V6 Brass Nozzle can be purchased from the following websites:

AliExpress

T-Volcano Brass Nozzle

The Volcano variant identical to the V6 version but with a longer thread for Volcano heatblocks. Unfortunately, mine had a small ding on the external part of the tip but the hole is intact. I don’t think there’s going to be any kind of issue with that considering it’s so small.

The T-Volcano Brass Nozzle can be purchased from the following websites:

AliExpress

MK8 Brass Nozzle

This MK8 brass nozzle is excellent if you want to upgrade your nozzle on a Creality machine. Excellent finish and a fair price for a well machined nozzle. It’s a bit sharper than the T-V6 but this is just for maintaining the same length as a regular MK8 nozzle. It’s a great all-round nozzle for PLA, PETG, TPU and ABS.

Excellent finish and a fair price for a well machined nozzle. It’s a bit sharper than the T-V6 but this is just for maintaining the same length as a regular MK8 nozzle. It’s a great all-round nozzle for PLA, PETG, TPU and ABS.

The MK8 Brass Nozzle can be purchased from the following websites:

AliExpress

T-V6 Plated Copper Nozzle

With the T-V6 plated copper nozzle, you will get better thermal performance which comes with copper. The filament will melt more efficiently and it’s a great choice for printing higher temperature materials.

I wouldn’t buy this if I mainly print PLA but for PETG it’s great. I have been using a plated copper nozzle and it performs well. Besides that, the plating should help with PETG because it sticks less on the nozzle tip and it’s easier to clean.

Because of the plating and the nature of the copper, the tip is not perfect like with the brass nozzles but nothing major.

The T-V6 Plated Copper Nozzle can be purchased from the following websites:

AliExpress

T-Volcano Plated Copper Nozzle

The Volcano variant of the T-V6 looks just as good and it’s made for printing faster with a high flow rate. With a copper nozzle you should be able to increase the maximum flow rate of your hotend a bit but for exact values it’s important to do a test.

With a copper nozzle you should be able to increase the maximum flow rate of your hotend a bit but for exact values it’s important to do a test.

The tip looks a bit better compared to the T-V6 and this should be an indication that plating is not the same for each nozzle. Maybe Trianglelab’s plating process could be improved.

Otherwise, it’s a great nozzle which will make PETG printing easier.

The T-Volcano Plated Copper Nozzle can be purchased from the following websites:

AliExpress

T-V6 Plated Copper Ruby Nozzle

As you can see, the copper ruby nozzle I pictured below is not new. I’ve used it for a while (around 200 hours of printing) and now it looks like this. But I thought I should share it anyway.

As you can read in my Ultimate 3D Printer Upgrade Purchase Guide I don’t recommend buying ruby nozzles because they are expensive and really delicate. Even tough the hole is intact, the side of the tip has a small chip on it. I haven’t seen a decrease in quality because of that but still it’s such a shame. I’ve learned my lesson and I will avoid ruby nozzles.

I’ve learned my lesson and I will avoid ruby nozzles.

There’s also some damage caused by my pliers used when replacing the nozzle. Because copper is softer, you can easily scuff and damage your nozzle so always use a tubular bit with a torque wrench for any copper nozzle to avoid this.

With the same amount of money you can get a dozen regular nozzles and have more print time from them.

The T-V6 Plated Copper Ruby Nozzle can be purchased from the following websites:

AliExpress

Mellow

NF-V6 Sharp Brass Nozzle

I used a half dozen NF-V6 brazz nozzles and on different printers and they worked great. The machining is consistent on all the nozzles I had. These were the nozzles I used for printing a lot of Covid masks and they worked great.

They turn a bit darker after using them for a while but the quality remains the same and I haven’t encountered any issues. I usually change them when they get nasty, but I can’t say I do it for any other reason. For ~2$ they’re the best cheap nozzles you can get.

For ~2$ they’re the best cheap nozzles you can get.

The NF-V6 Sharp Brass Nozzle can be purchased from the following websites:

AliExpress

NF-V6 Sharp Volcano Brass Nozzle

This is the Volcano sharp nozzle from Mellow and they’re just as good. I have them installed on my Artillery printers to replace the horrible stock nozzles. If you have an Artillery nozzle, this is a good replacement to get if you need a cheap alternative.

These sharp V6 volcano nozzles are also recommended when printing miniatures because of the thin tip.

The NF-V6 Sharp Volcano Brass Nozzle can be purchased from the following websites:

AliExpress

Top Quality Brass V6 Nozzle

The top quality brass V6 nozzles are similar to the Trianglelab version I covered before. Same design and quality. I wouldn’t be surprised if they are the same nozzles but sold under different stores, so choose the one which fits best for you when ordering.

With my nozzle there’s a really minor scuff on the tip which won’t impact the printing quality.

The Top Quality Brass V6 Nozzle can be purchased from the following websites:

AliExpress

Top Quality NF-V6 Volcano Nozzle

Same V6 brass nozzle but in a Volcano formfactor. Nothing new to say about it other than it’s machined really well and can be used as a good all-round nozzle for your Volcano hotend.

The Top Quality NF-V6 Volcano Nozzle can be purchased from the following websites:

AliExpress

NF-V6 Plated Copper Nozzle

The V6 plated copper from Mellow looks just like the Trianglelab version but the tip has a better plated finish. An excellent nozzle if you need to print higher temperature materials and have better prints with PETG.

The NF-V6 Plated Copper Nozzle can be purchased from the following websites:

AliExpress

NF-V6 Volcano Plated Copper Nozzle

The Volcano variant is about the same. Nothing new to add here. Just be careful not to tighten your copper nozzle too much to avoid any kind of damage. Otherwise, smooth printing for a fair price.

The NF-V6 Volcano Plated Copper Nozzle can be purchased from the following websites:

AliExpress

NF-MK8 Plated Copper Nozzle

This MK8 nozzle was bundled with my NF-Smart Copper Hotend and as you can see it’s not great. It has a small chip on the inside of the nozzle. This is not the best thing for a nozzle but during printing I could not see any scuffs on the layer. So maybe it’s fine ?

Besides that, the plating seems to have some kind of damage or oxidation. Not sure why this happened but it is what it is.

The NF-MK8 Plated Copper Nozzle can be purchased from the following websites:

AliExpress

NF-V6 Sharp A2 Hardened Steel Nozzle

I must say, I’m not a big fan of hardened steel nozzles. Firstly, because I don’t have a specific need for them (I mainly print PLA and PETG) but I had a lot of questions about them so they’re added to this comparison.

I like the machining quality and the black color but do keep in mind that Mellow Sharp A2 hardened steel nozzles don’t have a plastic repellent coating so you might get a bit more “stickiness”.

It’s also important to keep in mind that when installing one of these nozzles you should do a temperature tower calibration to see how well the nozzle can transfer the heat from your heatblock. I needed to increase the temperature with ~10C compared to a regular brass nozzle.

Please don’t buy a hardened steel nozzle if you might print some abrasive filament in the future. It’s not worth the cost and the trouble. This is a nozzle specifically made for people who print abrasive filaments more often than regular plastic.

The NF-V6 Sharp A2 Hardened Steel Nozzle can be purchased from the following websites:

AliExpress

NF-V6 Sharp A2 Volcano Hardened Steel Nozzle

As you have probably guessed, the Volcano variant of the Sharp A2 is made for faster printing where you need a longer heating zone to efficiently print at high speeds. Otherwise, it’s the same nozzle as the V6 variant.

The NF-V6 Sharp A2 Volcano Hardened Steel Nozzle can be purchased from the following websites:

AliExpress

E3D

If you haven’t lived under a rock, you’ve probably heard about E3D. They made the really popular V6 hotend and they are the reason why most of the nozzles we get now have the “standard” V6 thread. Their latest popular product is the E3D Hemera extruder which is on my Ultimate 3D Printer Upgrades list.

They made the really popular V6 hotend and they are the reason why most of the nozzles we get now have the “standard” V6 thread. Their latest popular product is the E3D Hemera extruder which is on my Ultimate 3D Printer Upgrades list.

E3D always focused on delivering high-quality printing hardware for 3D printers and this can be seen in the quality of their products.

Brass V6 Nozzle

The Brass V6 nozzle is the cheapest offering from E3D and it’s the one which comes with the V6 hotends. Machining is good and you should get good results with it when printing regular materials like PLA, PETG, TPU and ABS.

The E3D Brass V6 Nozzle can be purchased from the following websites:

E3D Online

Brass V6 – 0.15 mm Nozzle

I also got a 0.15 mm nozzle and the nozzle hole is really tiny. It’s the same material as the regular V6 and considering the size of the hole, it’s pretty impressive to see that E3D can machine something like this. Not sure if it can be successfully used for consistent prints but I will try it out and share the results.

The E3D Brass V6 0.15 mm Nozzle can be purchased from the following websites:

E3D Online

Hardened Steel V6 Nozzle

The hardened steel V6 nozzle from E3D maintains the same good machining. The nozzle coating is really dark and hard to photograph, but it’s one of the most durable nozzles in their line-up. The hardened steel nozzle is great for printing abrasive materials like carbon fiber infused filament or glow in the dark. Just remember to always do a temperature test in advance, because usually hardened nozzles need about 10C more due to their lesser thermal transfer.

The E3D Hardened Steel V6 Nozzle can be purchased from the following websites:

E3D Online

Nozzle X V6

The Nozzle X V6 is probably E3Ds flagship nozzle because it offers abrasion resistance and a coating to avoid material build up. This should make the nozzle easier to clean and printing sticky materials like PETG should be easier compared to a regular nozzle.

Machining is good and the coating has a similar color to the Vanadium nozzle from Slice Engineering.

The E3D Nozzle X V6 can be purchased from the following websites:

E3D Online

Stainless Steel V6 Nozzle

The stainless steel nozzle from E3D is a “bridge” between the regular brass nozzle and the hardened steel nozzle. I call it a bridge because it offers better abrasion resistance compared to brass, but it’s not as good as the hardened steel. The thermal performance is also not as good as brass, so I can’t say this is a nozzle I see myself using too much.

I’d rather print with a brass nozzle and replace it after it wears down, instead of using the stainless steel nozzle.

The E3D Stainless Steel V6 Nozzle can be purchased from the following websites:

E3D Online

Brass Volcano Nozzle

The brass volcano nozzle is the same as the regular brass V6 but made specifically for Volcano heatblocks which allow you to print faster. My particular nozzle is a 0.6 mm nozzle, so in combination with the volcano heat block can lower your print times significantly.

The E3D Brass Volcano Nozzle can be purchased from the following websites:

E3D Online

Copper Plated Volcano Nozzle

With the copper plated volcano nozzle, E3D tries to harness the best thermal performance offered by the copper and put it into a volcano form factor. The copper plated nozzle should be the best choice when printing at high speeds with high flow and it should allow the filament to be melted faster compared to a brass nozzle.

The machining is good, plating quality is great and I don’t have any complaints for it.

The E3D Copper Plated Volcano Nozzle can be purchased from the following websites:

E3D Online

Nozzle X Volcano

Just like it’s smaller sibling, the Nozzle X volcano has the same coating which repels plastic and makes it easier to clean. Unfortunately, my sample had a small “ding” in the tip. Considering that the small defect is not inside the extrusion hole, I don’t think it will have any impact in print quality. But if you consider the price, you would expect the nozzle to be flawless.

But if you consider the price, you would expect the nozzle to be flawless.

The E3D Nozzle X Volcano can be purchased from the following websites:

E3D Online

Hardened Steel Volcano Nozzle

With the hardened steel volcano, you get the same great abrasion resistance in a volcano form factor which should be great for printing abrasive materials at a high printing speed. Good machining quality, and overall a nice finish.

The E3D Hardened Steel Volcano Nozzle can be purchased from the following websites:

E3D Online

Phaetus

V6 Hardened Steel Nozzle

The hardened steel nozzle from Phaetus is the one to use if you plan to print abrasive materials. It’s important to use this nozzle only if you mainly use abrasive materials, because the thermal transfer is not as good as brass or copper plated nozzles. As you can see, the machining quality is great, and there’s nothing to complain about it.

The Phaetus V6 Hardened Steel Nozzle can be purchased from the following websites:

AliExpress

Banggood

V6 Plated Copper Nozzle

The V6 Plated Nozzle from Phaetus is best suited for printing PETG and TPU which tends to stick to the nozzle. But it works with any type of material, increasing the thermal transfer between the block and the material. My sample had some tiny marks on the side of the tip, but I don’t think it impacts the print quality considering how small they are. The price is also similar to other plated copper nozzles out there.

But it works with any type of material, increasing the thermal transfer between the block and the material. My sample had some tiny marks on the side of the tip, but I don’t think it impacts the print quality considering how small they are. The price is also similar to other plated copper nozzles out there.

The Phaetus V6 Plated Copper Nozzle can be purchased from the following websites:

AliExpress

Banggood

V6 Brass Nozzle

This is probably the cheapest V6 Nozzle from Phaetus. For around 5$, it’s one of the best nozzles you can get if you want to keep the cost low. The machine quality is good and I can’t really complain about anything at this price point.

The Phaetus V6 Brass Nozzle can be purchased from the following websites:

AliExpress

Banggood

Artillery

Stock Volcano Brass Nozzle

This badly machined nozzle which is included with all the Artillery printers made me want to do a comparison between all the nozzles. I always said that the nozzle should be the first upgrade to do for the Sidewinder X1 and Genius. The included nozzles are just plain bad and you can see that in the images below.

The included nozzles are just plain bad and you can see that in the images below.

The hole is not cut well and you can’t expect accurate extrusion with something like that. The tip is also not smooth which can cause some uneven layers. Just replace it as soon as possible with a better nozzle and I guarantee you will get better prints.

The Stock Volcano Brass Nozzle can be purchased from the following websites:

AliExpress

No-Name

Generic Cheap V6 Brass Nozzle

This V6 brass nozzle was purchased for 20 cents just so you can see how bad some nozzles can be. Sure, you can’t expect any quality from such a cheap nozzles but this is a good example of a bad nozzle. If your nozzle looks like this, then it’s time for an upgrade.

The Generic Cheap V6 Brass Nozzle can be purchased from the following websites:

AliExpress

Generic Cheap V6 Stainless Steel Nozzle

This Stainless Steel nozzle has a really bad thermal transfer besides the bad machining. I needed to increase the temperature with a whopping +20C just to be able to print PLA. Even after I did this, the layers would not bond properly. Avoid this at all costs.

I needed to increase the temperature with a whopping +20C just to be able to print PLA. Even after I did this, the layers would not bond properly. Avoid this at all costs.

The Generic Cheap V6 Stainless Steel Nozzle can be purchased from the following websites:

AliExpress

Generic Cheap Sharp Brass Volcano Nozzle

This Volcano nozzle wins the “Worst Nozzle In This Test” trophy. I wasn’t even able to test it because the tip is clogged from machining chips. I’m also not sure if it’s made from real brass because it has a somewhat different color. Looks like it’s just painted to look like brass.

The Generic Cheap Sharp Brass Volcano Nozzle can be purchased from the following websites:

AliExpress

Slice Engineering

Slice Engineering got really popular since they released their Mosquito Hotend which is one of the best hotends available right now. They don’t have the cheapest products available, but you get what you pay for.

Every piece of hardware I got from there has ridiculously good machining. That’s why I can easily recommend them if you are looking for the best quality out there.

That’s why I can easily recommend them if you are looking for the best quality out there.

Vanadium™ Nozzle

The Vanadium Nozzle is an excellent high-temperature material nozzle. It’s made from Vanadium alloy for improved abrasion resistance. This nozzle can be a good choice if you already have a Mosquito Hotend and you plan to print at high temperatures or with abrasive filaments.

Slice Engineering trusts this nozzle so much that it offers a lifetime warranty for any abrasion damage making the purchase price a bit more forgiving.

It’s coated with a plastic repellent coating which works really well and even after a few hundred hours of use, mine looks great. It’s also made 100% in USA if that’s something you care about.

As you can see, machining is excellent. This is something Slice Engineering does really well with all their products so there’s no surprise here. For some reason, even tough is made from hardened steel, I didn’t need to increase my print temperature with this nozzle but maybe it has something to do with the Mosquito.

I would have loved to see a similar nozzle but in a Volcano format because it really is a great nozzle.

The Vanadium™ Nozzle can be purchased from the following websites:

SliceEngineering – Use 3DPRINTBEGINNER code for a small discount (affiliated code)

Ollson Ruby

Olsson Ruby V6 Brass Ruby Nozzle

Another example of a broken ruby nozzle.

I got an Olsson Ruby Nozzle and after only ~20-30 hours of printing it “died”. The ruby tip got cracked and now I have an expensive paperweight. Because the tip is not made from the same material, it has lower heat transfer. Can’t say if this is good or bad, but I now keep it in my nozzle box waiting to be used at some point.

Considering the huge premium, you pay for a ruby nozzle and how easily they can be damaged, I don’t really recommend buying one.

The Olsson Ruby V6 Brass Ruby Nozzle can be purchased from the following websites:

OlssonRuby

Amazon

BIQU

Stock V6 Nozzle

This is the nozzle I got with the BIQU B1 printer. It has the same V6 compatibility but with a much bigger brass head. I think this is made for storing more heat and somehow compensate for the bad aluminum block.

It has the same V6 compatibility but with a much bigger brass head. I think this is made for storing more heat and somehow compensate for the bad aluminum block.

Anyway, it works well and the machining is better than expected. It has a small ding on the side of the tip but no issues encountered during printing.

The BIQU Stock V6 Nozzle can be purchased from the following websites:

AliExpress

Creality

Creality MK8 Nozzle

I always liked the Creality nozzles for some reason. I was able to print well will them and I wasn’t really surprised when I put one under the microscope.

The machining quality is close to the one you get from Trianglelab and Mellow so I don’t really see a reason change them for a similar brass nozzle.

Maybe only if you want to upgrade for a plated copper nozzle, but otherwise these should be fine. Anyway, if you replace them make sure you buy the same nozzle from Creality because I know there are other manufacturers which make worse nozzles and sell them with the same branding.

The Creality MK8 nozzle can be purchased from the following websites:

AliExpress

Mingda

Mingda D3 Pro Nozzle

This is the stock nozzle which comes with the Mingda D3 Pro and the quality is good. Not as good as other nozzles listed here, but overall it’s decently machined and it performed well during my time with the printer.

Raise 3D

Raise 3D E2 Brass Nozzle

This is the stock brass nozzle you are getting with the Raise E2 printer. It’s sharper than other nozzles, but it uses the same M6 thread as a regular V6. There’s also a small particularity in the point of contact of this nozzle to the heat break. There’s a small cut to better match the heat break and make sure the contact is perfect.

The overall quality seems fine, but nothing to write home about.

Raise 3D E2 Hardened Nozzle

The hardened nozzle from Raise 3D looks a bit better than the brass version, and overall, it’s much cleaner looking. I haven’t tested it yet, but I will update the article with impressions when I do.

Wrapping up

Hopefully, this article helped you see some of the differences in build quality between various nozzles. Now you should be able to make an informed decision if you want to replace your nozzle.

Check back soon because I plan to do constant updates to this article, when I get my hands on different nozzles. If you want to see a specific nozzle tested, leave me a message below and I will try to add it to the comparison.

If you are wondering what other upgrades you can do to your printer, make sure you read my Ultimate 3D Printer Upgrade Purchase Guide where I covered my favorite 3D printer upgrades.

While this article contains affiliate links, all opinions are my own. Please make your own decision before purchasing anything.

Liked it?Consider supporting 3DPrintBeginner if this content helped. You can also join Patreon for exclusive perks! |

What is the Best Nozzle for 3D Printing? Ender 3, PLA & More – 3D Printerly

Choosing the best nozzle for your 3D printer is something that people want to get perfect, but what does it mean to get the best nozzle for 3D printing?

The best nozzle for 3D printing is a 0. 4mm brass nozzle due to the balance of printing speed and print quality. Brass is great for thermal conductivity, so it transfers heat more efficiently. Smaller nozzles are great for print quality, while larger nozzles are great for speeding up prints.

4mm brass nozzle due to the balance of printing speed and print quality. Brass is great for thermal conductivity, so it transfers heat more efficiently. Smaller nozzles are great for print quality, while larger nozzles are great for speeding up prints.

There are more details that you’ll want to know when it comes to choosing the best nozzle for 3D printing, so stick around to find out more on this topic.

What is the Best Nozzle Size/Diameter for 3D Printing?

Generally speaking, we have 5 different nozzles sizes that you’ll find in the 3D printing industry:

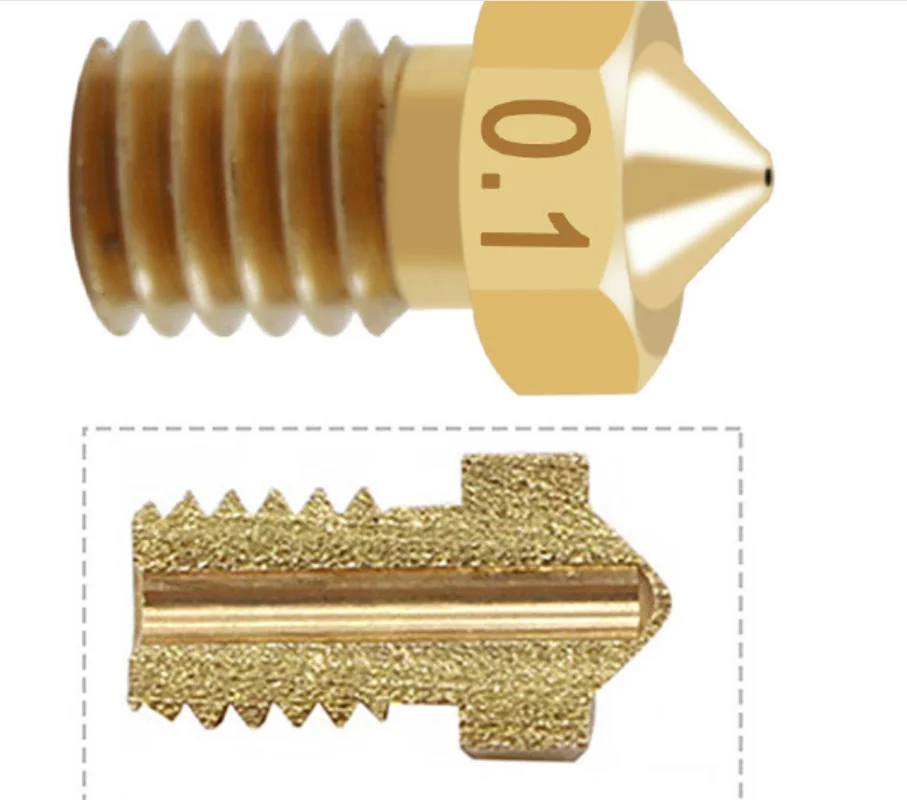

- 0.1mm

- 0.2mm

- 0.4mm

- 0.6mm

- 0.8mm

- 1.0mm

There are sizes in between there like 0.25mm and whatnot, but you don’t see those very often so let’s talk about the more popular ones.

With each nozzle size, there are distinct advantages and disadvantages to gain. These really do depend on what your goals and projects are with the objects you are printing.

For example, when it came to responding to the pandemic with mask accessories, clips and other things, speed was of the essence. People designed their objects with speed in mind, and this meant using nozzles of a larger size.

Although you may think people would go straight with a 1.0mm nozzle, they also had to balance the quality of the objects since we want them to follow certain standards and procedures for safety.

Some of the most popular designs called for nozzles that used nozzles with 0.4-0.8mm diameters. This meant you could produce some sturdy, good quality models, still with good timing.

When it comes to printing that miniature or the full bust of a character or famous figure, you’ll ideally want to use a nozzle diameter on the lower end, like a 0. 1-0.4mm nozzle.

1-0.4mm nozzle.

Generally speaking, you want a small nozzle diameter when details and overall quality is important, and printing time isn’t of the essence.

You want a larger nozzle when speed is the most important factor, and you don’t require a high level of quality in your prints.

There are other factors such as durability, strength, and gaps in the print, but these can be addressed in other ways.

Supports are a lot easier to remove when you use a smaller nozzle diameter since it creates thinner lines of extruded filament, but this also leads to lower strength in your prints for the most part.

Are 3D Printer Nozzles Universal or Interchangeable

3D printer nozzles are not universal or interchangeable because there are different thread sizes that will fit one 3D printer, but not on another. The most popular thread is the M6 thread, which you’ll see in Creality 3D printers, Prusa, Anet and others. You can use the E3D V6 since it is an M6 thread, but not M7.

I wrote an article about the differences on MK6 Vs MK8 Vs MK10 Vs E3D V6 – Differences & Compatibility which goes into some nice depth regarding this topic.

You can use many 3D printer nozzles with different printers as long as they have the same threading, tending to either be an M6 or M7 threading.

MK6, MK8, and E3D V6 nozzles all have M6 threading, so these are interchangeable, but M7 threading goes with MK10 nozzles which are separate.

Best Nozzle for PLA, ABS, PETG, TPU & Carbon Fiber Filament

Best Nozzle for PLA Filament

For PLA, most people stick with a 0.4mm brass nozzle for the best thermal conductivity, as well as a balance for speed and quality. You can still reduce your layer height right down to around 0.1mm which produces amazing quality 3D prints

Best Nozzle for ABS Filament

A 0.4mm brass nozzle works amazing for ABS since it heats up adequately, and can handle the low-abrasiveness of the material.

Best Nozzle for PETG Filament

PETG prints similarly to PLA and ABS, so it also prints best with a 0. 4mm brass nozzle. When it comes to 3D printing with items that come into contact with food, you’ll want to opt-in for a stainless steel nozzle, along with food-safe PETG.

4mm brass nozzle. When it comes to 3D printing with items that come into contact with food, you’ll want to opt-in for a stainless steel nozzle, along with food-safe PETG.

Not all PETG is made the same, so make sure it has some good certification behind it.

Best Nozzle for TPU Filament

Generally speaking, the larger the nozzle size or diameter, the easier TPU will be to 3D print. The main factor that determines success with printing TPU though is the extruder, and how tightly it feed filament through the system.

A brass 0.4mm nozzle will do just fine for TPU filament.

The shorter the distance that the flexible filament has to travel, the better, which is why Direct Drive extruders are seen as the ideal setups for TPU.

Best Nozzle for Carbon Fiber Filament

You want to use a wide enough nozzle diameter to ensure your nozzle doesn’t get clogged, because carbon fiber is a more abrasive material.

On top of this, you ideally want to use a hardened steel nozzle since it can withstand the same abrasiveness compared to a brass nozzle. Many people who 3D print Carbon Fiber filament will use a 0.6-0.8mm hardened or stainless steel nozzle for idea results.

Many people who 3D print Carbon Fiber filament will use a 0.6-0.8mm hardened or stainless steel nozzle for idea results.

The Creality Hardened Tungsten Steel MK8 Nozzle Set from Amazon, which comes with 5 nozzles (0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm).

Best Nozzle for Ender 3, Prusa, Anet – Replacement/Upgrade

Whether you are looking at your Ender 3 Pro, Ender 3 V2, Anet, or Prusa 3D printer, you might be wondering which nozzle is the best.

Brass nozzles are the best overall nozzles for 3D printers because they transfer heat so well compared to stainless steel, hardened steel, tungsten or even copper plated nozzles out there.

The difference is where you get the nozzle from in terms of the brand, since not all nozzles are made equal.

From doing some research, a great set of nozzles you’ll be happy with is the LUTER 24-Piece MK8 Extruder Nozzle Set from Amazon, perfect for Ender and Prusa I3 3D printers.

You get a set of:

- x2 0.

2mm

2mm - x2 0.3mm

- x12 0.4mm

- x2 0.5mm

- x2 0.6mm

- x2 0.8mm

- x2 1.0mm

- A plastic storage box for your nozzles

Nozzles for 3D printers - types, differences. Nozzle type

Nozzle is an integral part of any 3D printer, and there are many varieties of this part. Brass products are considered standard nozzles. This type is suitable for printing with conventional types of plastics, but for those that include an abrasive, such as NylonX, is not suitable. Printing with these materials requires higher performance nozzles made from stronger materials. There are also copper nozzles, Clean Tip nozzles - such nozzles are distinguished by the fact that the thread does not stick to them, and they remain clean.

3D printing allows you to replace nozzles. This allows you to achieve different results and use different materials for printing.

3D printer nozzle: what is it?

The 3D printer nozzle is a special nozzle located in the extruder heater block. It is screwed into place by means of a thread. There is a small chamber inside the nozzle where molten plastic accumulates and is squeezed out through the hole. Moreover, the key parameters of the nozzle will be: the material from which the nozzle is made and the diameter of the hole.

It is screwed into place by means of a thread. There is a small chamber inside the nozzle where molten plastic accumulates and is squeezed out through the hole. Moreover, the key parameters of the nozzle will be: the material from which the nozzle is made and the diameter of the hole.

Nozzle material

A standard desktop 3D printer is equipped with a 0.4mm brass nozzle. This is the best option for printing with ABS and PLA plastics. However, such nozzles are not at all suitable for printing with luminescent PLA, carbon fiber and metal enriched filaments. The fact is that plastics, which include solid particles, destroy the nozzle. The internal dimensions of the nozzle are distorted, and this affects the uniformity of the extruded material, which will inevitably affect the quality of 3D printing. For this reason, there are nozzles that are made from harder materials. Consider further the types of nozzles that can be found on the market.

Brass 3D Printer Nozzle

Brass Nozzle is the most popular option used in most desktop 3D printers. Of all the materials used to make nozzles, this one is the softest. But brass nozzles are easy to process, cheap and affordable. Therefore, they are easy and simple to replace.

Of all the materials used to make nozzles, this one is the softest. But brass nozzles are easy to process, cheap and affordable. Therefore, they are easy and simple to replace.

Main characteristics of brass nozzles:

- corrosion resistance;

- high thermal conductivity;

- relative softness;

- abrasion.

Application: Ideal for printing with "soft" plastics - standard ABS, PLA, PETG, and other plastic filaments that do not contain carbon fiber and metal additives.

Stainless steel or hardened steel nozzle

Steel nozzles are also used for 3D printing. They provide long-term printing with materials that contain solid particles, such as metal, carbon fiber. At the same time, such nozzles are not prone to abrasion and destruction, like softer brass nozzles. That is, you can print for a long time without reducing productivity.

But steel nozzles are not without drawbacks: lower thermal conductivity compared to brass nozzles. This can change the flow, especially when using large nozzles.

This can change the flow, especially when using large nozzles.

Main characteristics of steel nozzles:

- corrosion resistance;

- low thermal conductivity;

- relatively large weight;

- abrasion resistance.

Application: 3D printing with additives (carbon fiber, metal, glass, etc.)

Ruby nozzle

Anders Olsson developed the Olders Ruby nozzle. This is a brass nozzle equipped with a tip made of aluminum oxide, that is, an artificial ruby. This nozzle was originally created for 3D printing by the third heaviest material in the world. The nozzle was the result of an experiment conducted at Uppsala University in Sweden.

Initially standard nozzles made of steel and brass after printing 1kg of plastic wear out and are no longer usable. However, the nozzles have a number of disadvantages. Olson Ruby nozzles combine the high thermal conductivity of brass with the abrasion resistance of ruby. Of course, there are experts who say that the ruby tip has a low thermal conductivity, which negatively affects the printing result, but there is no evidence for this. At least for now.

Of course, there are experts who say that the ruby tip has a low thermal conductivity, which negatively affects the printing result, but there is no evidence for this. At least for now.

The main characteristics of Olsson Ruby nozzles are:

- corrosion resistance;

- low thermal conductivity;

- abrasion resistance.

Application: Can be used for highly abrasive threads.

Tungsten Carbide Nozzles

Dyze Design Tungsten Carbide Nozzles are something of a newcomer to the market as they only started production at the end of 2018. Tungsten carbide is hard, wear resistant. It is used for drilling, cutting ceramics and metals. Such nozzles also have disadvantages, but it is too early to talk about them.

Main characteristics of tungsten carbide nozzles:

- abrasion resistance, very high;

- hardness;

- high thermal conductivity;

- corrosion resistance.

Application: This is a universal nozzle that can be added to your nozzle set, and the nozzle is also suitable for printing with highly abrasive filaments.

Nozzle sizes for 3D printer

Nozzles are characterized by the hole diameter. This characteristic will affect the degree of print detail. In this case, the influence will be exerted not only on the width of the lines, but also on the height of the layer.

Beginners are advised to use a nozzle with a diameter of 0.15mm. Compared to a standard 0.4mm nozzle, this nozzle allows you to get a higher resolution in the OX and OY axes. Thanks to thin lines, sharper corners can be obtained, but this will only be possible in that case. If your 3D printer is well set up and serviced regularly.

The choice of nozzle diameter should be determined by the layer height you require. It is necessary to choose a nozzle so that the size of the layer during printing is 25-50% of the nozzle size.

If the device is calibrated correctly, optimum adhesion can be achieved between coats. For example, a standard 0.4mm nozzle allows you to print layers of 0.1-0.2mm. If you want to successfully print ultra-thin layers that are less than 0.05mm high, we recommend using the 0.2mm nozzle.

For example, a standard 0.4mm nozzle allows you to print layers of 0.1-0.2mm. If you want to successfully print ultra-thin layers that are less than 0.05mm high, we recommend using the 0.2mm nozzle.

Small nozzles have one significant drawback. They are more prone to clogging and therefore need to be cleaned regularly. In addition, smaller nozzles significantly increase print time as the print head requires more passes to coat. the larger the nozzle, the less time it will take to print, and the time will be reduced exponentially. For example, a 0.8mm wall will take half as long to print as a 0.4mm wall. Also, large extrusion lines have greater adhesion, and therefore the finished prints have greater strength. If you are not printing fine details, then you are better off using large nozzles, which will allow you to print faster.

Smaller nozzles are more commonly used for hobby, precision models with fine details, such as jewelry.

And in order to have your own opinion on this matter, it is best to experiment!

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

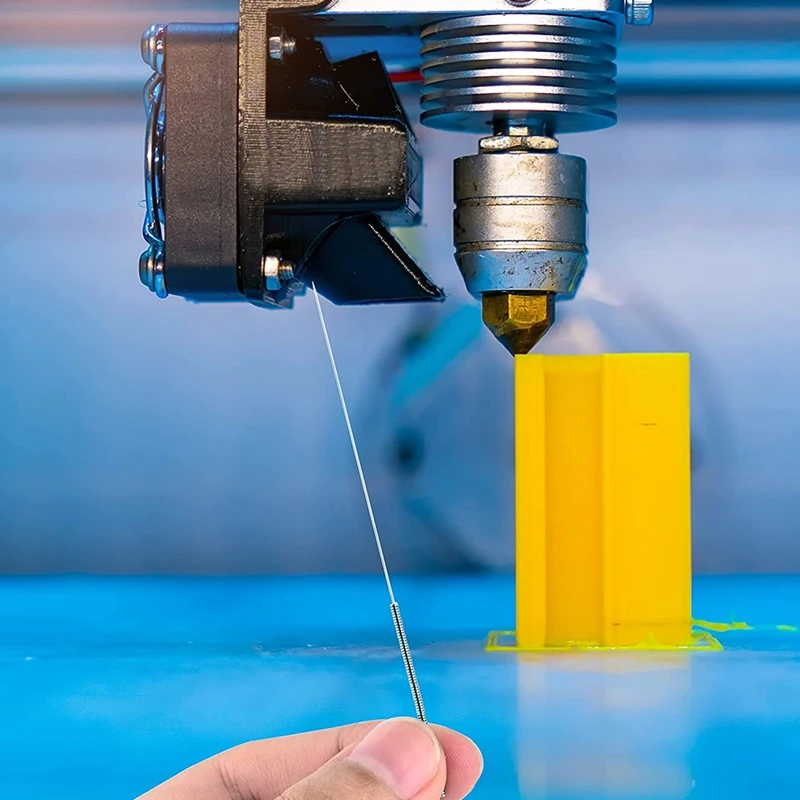

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.